3D printing consumer

The Future of Consumer 3D Printing – Mosaic Manufacturing

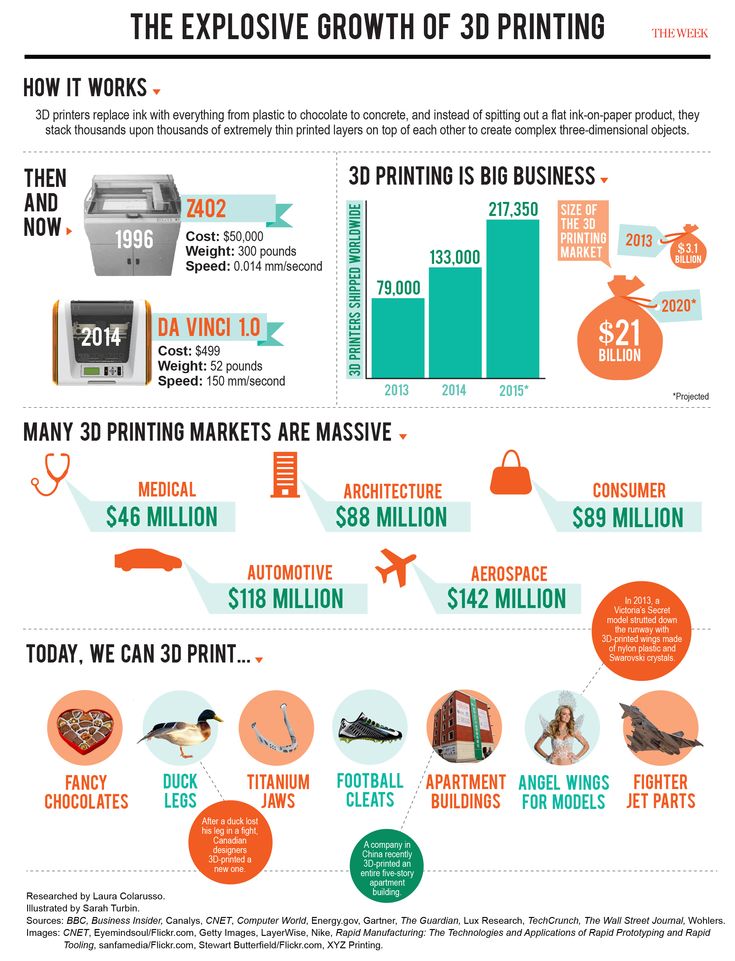

Five years ago, the media heralded 3D printing as the next industrial revolution: consumers would soon have the ability to make anything they wanted in their living rooms (supposedly). 3D printers were supposed to show up in supermarkets. The United States Postal Service was going to use them to begin delivering products (and maybe finally make money).

What ever happened to Martha + MakerBot?

MakerBot had a mission to bring the 3D printer into every home. Their team grew from 50 to over 500 in two years' time. Stratasys’s stock price went from <$10 to nearly $140/share. 3D Systems acquired over 50 companies, and 3D printing was set to take the world by storm.

This graph is awfully similar to that of the '90s dot-com bubble.

It actually depicts Stratasys's stock price.

But this reality never materialized.

Why did this shift never come to be, and what will consumer 3D printing look like when it really begins to impact our lives?

We seek to answer these questions every day, and we discuss them in the remainder of this post.

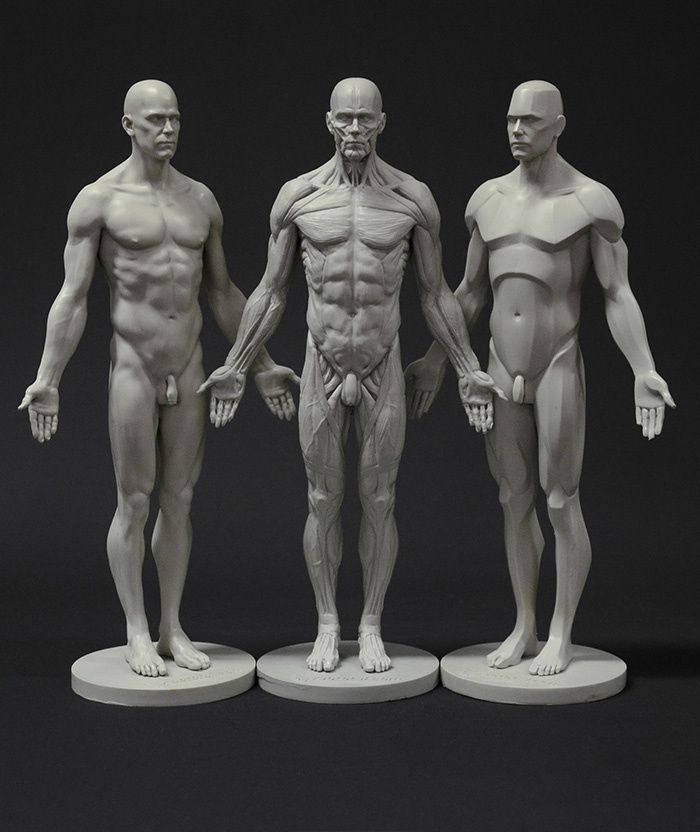

Fall from grace

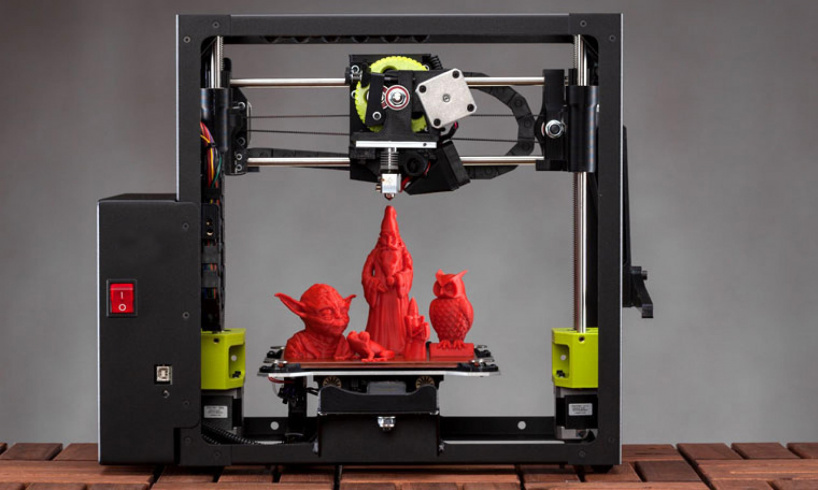

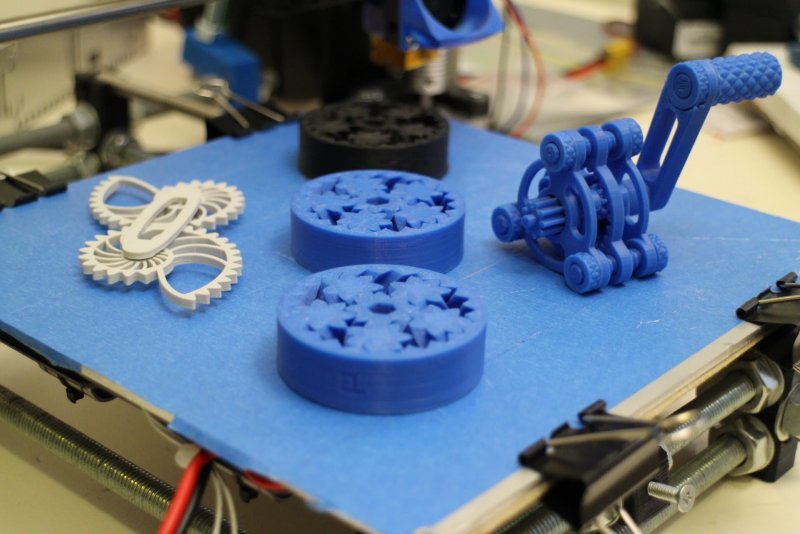

We posit that consumer 3D printing’s fall from grace accelerated as people came to realize that the industry's current printers' actual capabilities were not as miraculous as everyone thought. When people started to understand that they were limited to printing plastic Yoda heads and knobs for their dishwashers—not food, clothing, and cars—the bubble burst.

We're bullish on the future of consumer 3D printing, but we believe there still exist misconceptions about how consumers will interact with 3D printing technologies that should be discussed.

Chiefly, the misconception is around the phrase “consumer 3D printing. ” Typically, the connotation here that the consumer is the one who owns and operates the 3D printer. For this to happen, the printer must be easy to use, affordable, accessible, and safe—all things that describe today’s “consumer 3D printers”: your MakerBots, your Dremels, and your Ultimakers.

” Typically, the connotation here that the consumer is the one who owns and operates the 3D printer. For this to happen, the printer must be easy to use, affordable, accessible, and safe—all things that describe today’s “consumer 3D printers”: your MakerBots, your Dremels, and your Ultimakers.

But, like we saw over the past 5 years, these machines in their current forms do not provide sufficient value to the majority of everyday consumers to warrant their ~$1,500+ purchase prices.

We believe a shift will occur in how people think everyday consumers will interact with 3D printing. The important part about consumer 3D printing isn’t who owns or operates the machine—it’s about who gains value from it.

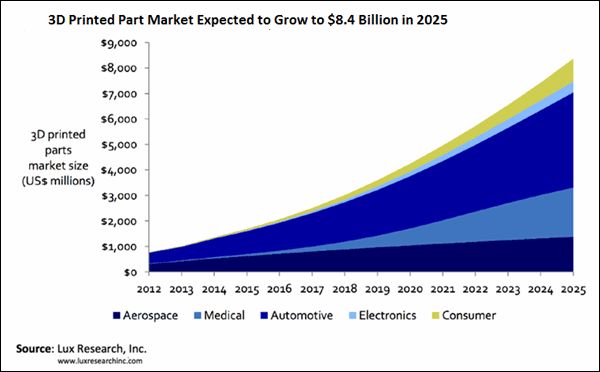

3D printing has the potential to offer substantial value through its ability to offer personalized products to consumers, and to make several parts of today’s manufacturing processes more efficient.

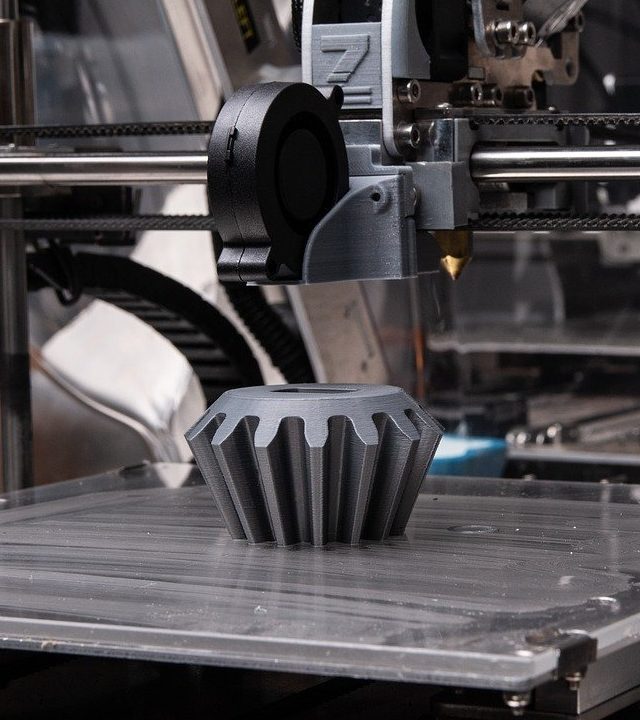

When consumer 3D printing is not constrained by the idea of fitting in someone's home, its potential increases by orders of magnitude. The cost of a printer can increase, its complexity can increase, and it can be implemented next to a more traditional manufacturing line, allowing a wider variety of products to be produced. These aspects could never happen if the consumer was responsible for operating the machine, but if you take that constraint away, you remove a significant number of limitations around the potential of 3D printing technologies, while still keeping its benefits.

The cost of a printer can increase, its complexity can increase, and it can be implemented next to a more traditional manufacturing line, allowing a wider variety of products to be produced. These aspects could never happen if the consumer was responsible for operating the machine, but if you take that constraint away, you remove a significant number of limitations around the potential of 3D printing technologies, while still keeping its benefits.

Consider what would be required to bring a 3D printer that can produce shoes, clothes, and cars to everyone's homes (or to penetration rates that rival those of microwaves and fridges). It seems eons away. Now, imagine the Amazons and Alibabas of the world that seek to deliver products to the developed world. These behemoths could house consumer-centric 3D printers in localized facilities that could provide personalized, on-demand production.

This hub-based, distributed manufacturing system will be the mid-point between where we are today, and “3D printers” one day being in people’s homes.

Not only was consumer 3D printing overhyped when its biggest players reached local peaks 3-5 years ago, its decline was further exacerbated by peoples' expectations of its growth (i.e., one in every home).

In spite of all this, consumer 3D printing continues to grow—and they may very well end up in everyone’s homes one day. But, before that happens, consumers all over the world will gain value from 3D printing through the use of 3D printers located in different types of production centers. These printers will serve as tools to augment current manufacturing workflows alongside other traditional manufacturing technologies and offer the best of both worlds: personalized products from 3D printing, and the wide range of objects offered from other traditional manufacturing methods.

So—what does this world look like, and what exactly are these products?

We’re always keeping our eyes on emerging companies using 3D printing and digital manufacturing to create new types of personalized products. Over the next few weeks, we’ll highlighting some of the spaces we’re most excited about that you should keep your eyes on.

Over the next few weeks, we’ll highlighting some of the spaces we’re most excited about that you should keep your eyes on.

- Mosaic

3D Printing in the Consumer Goods Industry

Join industry leaders by investing in additive

Increase agility with a modern manufacturing solution

In an industry where every dollar counts, investing in additive manufacturing can do more than almost anything else to move your bottom line. 3D printers provide a cost-effective, rapid way to fabricate functional parts at the point of need. They generate value wherever you deploy them — whether it’s slashing R&D spend on prototypes, helping you tool up without requiring skilled machinist time, or easily mitigating costly downtime. Building an additive-centric culture in your organization will make you more responsive, agile, and enable you to scale revenue without scaling spend.

Iterate Better

Prove out new concepts with production-grade parts at a fraction of the cost of traditionally machined parts, empowering engineers and designers to make products that better meet customer requirements. Deload your in house machining capabilities from non revenue generating parts, or eliminate your reliance on external suppliers.

Produce Better

Augment production resources with robust tools and fixtures at the click of a button, with no skilled labor or machine supervision required. Access a comprehensive library of high-performance composites and alloys with unprecedented design freedom to produce the best-performing products to date. Drastically cut your tooling spend and labor outlay while producing higher-performing tools.

Service Better

Turn maintenance into a competitive advantage by providing customers with unparalleled expediency and quality with distributed manufacturing. Mitigate costly downtime with rapid response manufacturing.

Mitigate costly downtime with rapid response manufacturing.

Talk to an Expert

Digital Forge for consumer packaged goods

Caldwell Manufacturing is a global window and door hardware manufacturer, founded in 1888. The team needed a new way to fabricate parts for R&D purposes, but found they could do so much more with the Markforged platform. Find out how Caldwell Manufacturing and over 100+ of the world’s top manufacturers are able to stay current with the Markforged platform.

“

It really changes your mindset about how we design, the way we test, the way we validate.It changes the way we put products into production. It’s changed everything.”

– Eric Mertz, CEO, Caldwell Manufacturing

Why invest in Markforged 3D printers?

- Continuous Fiber Reinforcement offers the most cost-effective way to fabricate aluminum-strength parts

- The Markforged Metal X System enables you to quickly and safely fabricate real metal parts in house

- Markforged 3D printers are managed, controlled, and monitored through a single intuitive cloud platform

- Highly accurate and reliable machines ensure you get the right part out every time

High-value consumer packaged goods applications

- Precise end-of-arm-tooling

- Ergonomic assembly fixtures

- Conformal workholding

- Line tooling — brackets, sensor mounts, and cable management

- Functional prototypes

Featured content

Customer Success Stories

Saint-Gobain

Saint-Gobain improved the overall workflow of production activities after putting their Markforged X7 to use.

Application Spotlights Customer Success Stories

Arrow Global

The Mark Two helps Arow Global expand their heavy duty prototyping process with inexpensive, strong 3D printed parts.

Consumer Packaged Goods FAQ

Which organizations in the consumer packaged goods (CPG) industry use Markforged 3D printers?

A wide range of companies in the CPG sector use Markforged 3D printers in their manufacturing operations. These include companies like Nike and Adidas (footwear), Gillette (shaving razors and personal care products), Kohler (faucets and bathroom products), and Steelcase (office, hospital, classroom furniture).

How can 3D printing be used for consumer goods manufacturing?

Manufacturers in the consumer goods sector use 3D printing for everything from prototyping, building strong tooling and fixtures, and low-volume production. This can mean:

3D printing spare parts at the point of need, which facilitates increased uptime for production lines.

3D printing end-use grippers and robotic arm components for automated production lines. Manufacturers can also print unique parts that allow customized machines to fulfill particular tasks, like this can twister.

Production of consumer goods that require customization or specialized geometries, such as custom insoles or production parts such as high-end sound system exteriors.

Rapid prototyping to improve and perfect product designs.

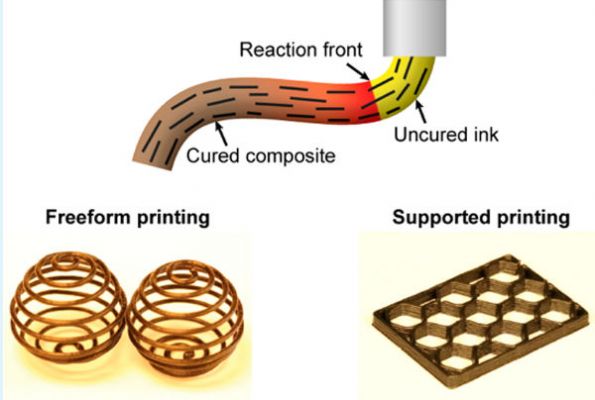

What types of printers are used for consumer packaged goods?

For CPG manufacturers, different 3D printer types can be used to solve different manufacturing challenges.

Desktop 3D printers are often used for low-volume production and rapid prototyping on one simple platform. Industrial composite 3D printers can tackle a wider variety of manufacturing challenges with higher throughput and faster speeds, the ability to print larger parts, expanded material capabilities, and oftentimes features such as artificial intelligence (AI)-powered part inspection. Metal 3D printers can bring these benefits to applications that require metal’s distinct properties.

What are the benefits of using 3D printing for CPG manufacturers?

In CPG manufacturing, additive manufacturing creates numerous benefits. It’s a much faster, cheaper, and easier way to 1.) build fixtures and tooling, 2.) arrive at a final product design, and 3.) fabricate custom, or other low-volume production parts without a need for tooling.

Low-volume production parts are much more simple and economical to build, without requiring tooling to be built first like injection molding. It allows complex geometries that are exceedingly difficult, if not impossible to achieve otherwise.

It allows complex geometries that are exceedingly difficult, if not impossible to achieve otherwise.

As expensive parts that come with long lead times can be replaced for much faster and cheaper, prototyping and production can be accelerated without the risk of being held up by supply chain delays, and availability of spare parts means far less unplanned downtime. By 3D printing parts that have historically been machined, manufacturers can not only cut down costs and improve product designs— but also have more uptime and valuable machinist bandwidth.

What consumer products are made using 3D printing?

Aside from tooling, consumer goods manufacturers use 3D printing to fabricate products such as computer hardware, mascara brushes, custom shoe insoles, and audio equipment components. 3D printed production parts can also be found in snowboard bindings, bike frames, and furniture.

What can be manufactured with a 3D printer?

Continuous fiber reinforced (CFR) composite parts as strong as aluminum can easily be printed to replace parts on production lines, act as functional prototypes, or serve as a product exterior. For parts that must be made out of metal, accessible, user-friendly metal 3D printing makes it more simple than ever to procure metal parts fast.

For parts that must be made out of metal, accessible, user-friendly metal 3D printing makes it more simple than ever to procure metal parts fast.

What materials can consumer goods manufacturers 3D print?

These parts can be printed in materials such as continuous fiber-reinforced (CFR) composites, plastics such as Onyx, Nylon, and PLA, rubber-like materials like TPU, as well as many widely-used industrial metals.

Applications that demand strength and stiffness are often printed with continuous fiber-reinforced composites, such as Onyx reinforced with carbon fiber. TPU is ideal for applications that demand rubber-like properties. Reinforced ULTEM™ 9085 Filament can be used for applications that require very high strength, heat tolerance, and chemical resistance.

For parts that require metal for aesthetic or material properties, widely used industrial metals such as tool steels, stainless steels, pure copper and Inconel are available. While PLA is ideal for many prototypes, strong composites are often used for functional prototypes testing performance.

While PLA is ideal for many prototypes, strong composites are often used for functional prototypes testing performance.

Is 3D printing good for manufacturing?

3D printing allows CPG organizations to solve many manufacturing challenges in a much easier, more economical, and simple way than through traditional manufacturing methods. Through providing the ability to produce a wide range of parts in-house, 3D printing also gives manufacturers a buffer against supply chain disruptions. For many manufacturers, the benefits of 3D printing at the point of need allows production to accommodate projects on much tighter timelines.

Can 3D printing software integrate with factory systems?

3D printing software, through application programming interfaces (APIs), can integrate with core factory systems, such as Enterprise Resource Planning (ERP) systems and Manufacturing Execution Systems (MES).

For example, these integrations can automatically 1.) trigger part replenishment based on demand, 2.) create new records for parts printed, and 3.) provide detailed quality inspection and reporting for 3D printed parts.

Learn More

Talk to a member of our team to learn more about how Saint-Gobain and other consumer packaged goods manufacturers are improving their manufacturing operations with Markforged.

Talk to an expert

3D printing: the battle for the consumer market

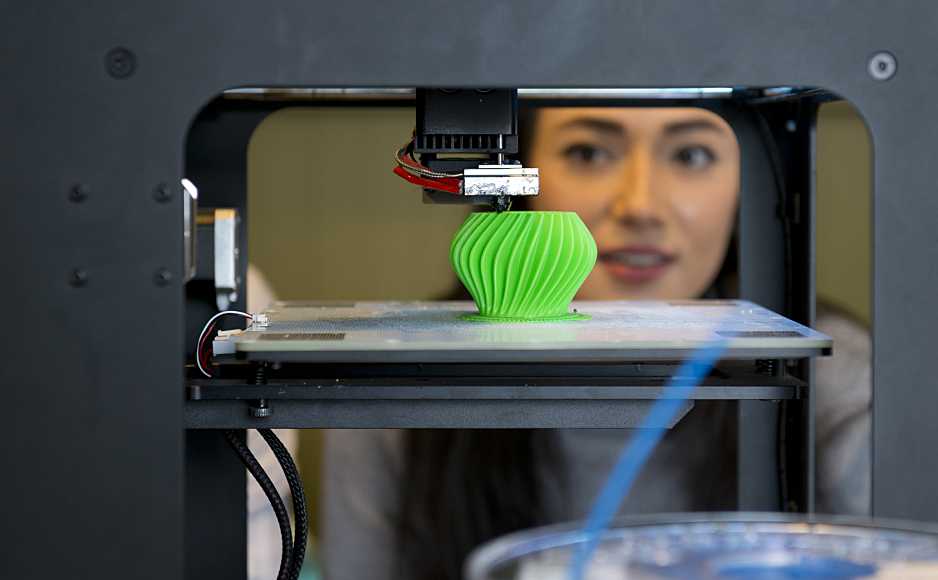

In fact, this is hardly a scene from the distant future. All the necessary technologies already exist today, and companies working in the 3D printing industry expect to bring this picture to life in the near future.

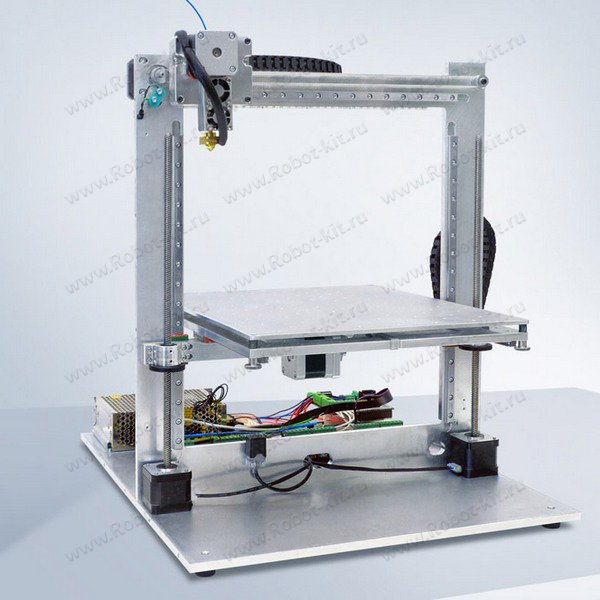

Today, the main obstacle to the widespread adoption of such technologies is perhaps the unpreparedness of consumers to live in the world of 3D printing. One factor may be the cost of 3D printers, but new models are released almost every day, and the prices of less advanced devices are constantly decreasing. As a result, it can be expected that a fused deposition modeling 3D printer designed for home use will soon be available for $19.9. However, price is not the only factor. The consumer must also have good reasons to start using these technologies. It is likely that several 3D printer manufacturers will be able to provide such a reason, which has nothing to do with technical characteristics and scientific breakthroughs.

As a result, it can be expected that a fused deposition modeling 3D printer designed for home use will soon be available for $19.9. However, price is not the only factor. The consumer must also have good reasons to start using these technologies. It is likely that several 3D printer manufacturers will be able to provide such a reason, which has nothing to do with technical characteristics and scientific breakthroughs.

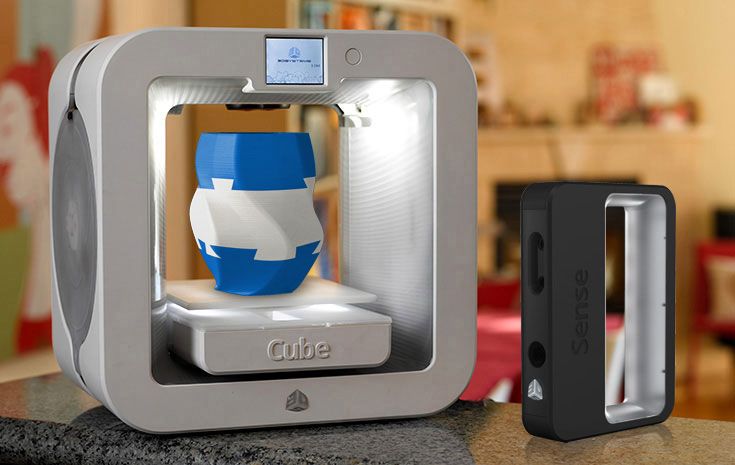

Just a few months ago, M3D, one of the many 3D printing companies that started with Kickstarter fundraising, began shipping one of the first truly consumer Micro 3D printers. The cost of the device was only $349, and it has every chance of becoming one of the first models that will really be successful in the home appliance market. This FDM 3D printer weighs less than a kilogram and has a spool of material hidden under a self-adjusting print bed. The device is not completely enclosed in the case (probably this aspect will be improved in the future), but it looks very neat and attractive. Such a 3D printer will fit perfectly next to a toaster or microwave.

Such a 3D printer will fit perfectly next to a toaster or microwave.

The printer is a cube with an edge of 18.5 cm and is available in 5 different colors. This marketing ploy is reminiscent of the first Mac computers. Apple has made working on the computer "fun", including allowing users to choose the color of the device. In addition, Apple has made sure that all wires, keyboard, mouse and other details match the style of the computer itself. The company made it so that consumers simply wanted to buy such a device for their home. It looks like the M3D is using the same tactic with the Micro 3D printer.

Another 3D printer company, Sprintray, has also introduced a device that looks attractive. A model called MoonRay works on DLP technology, does not take up much space and does not need to be assembled. Like the device from M3D, the MoonRay 3D printer was funded through a Kickstarter campaign. Deliveries of the device will begin during the summer. This 3D printer was also shown at the 3D Print Show in New York and attracted great interest from visitors.

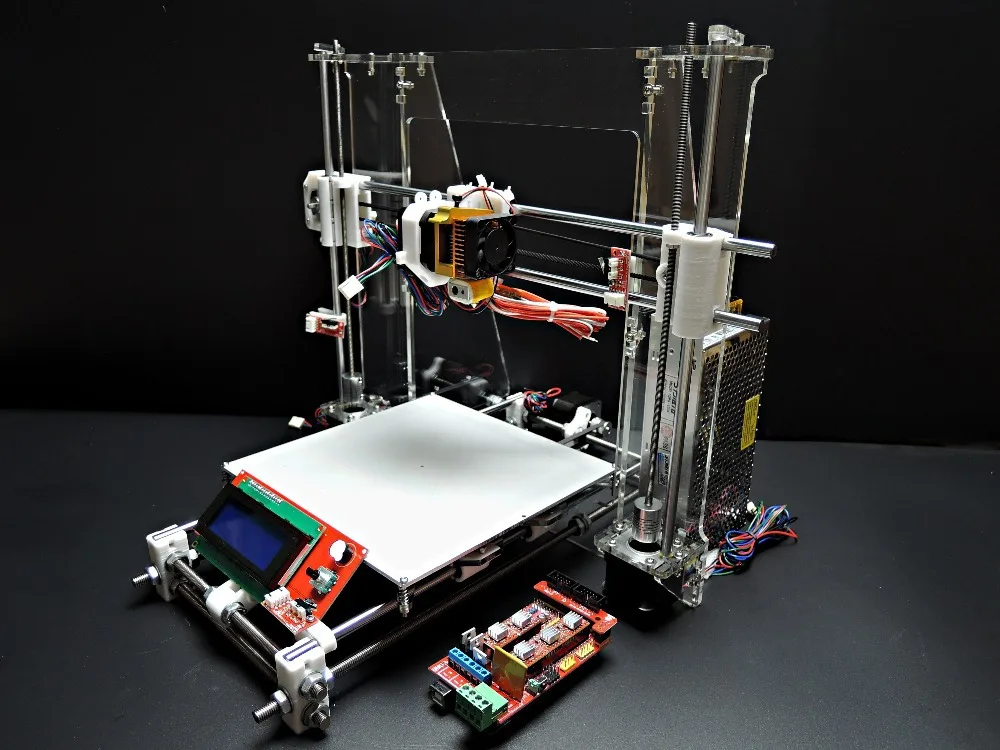

The first generations of 3D printers, of course, can hardly be called works of art. They were constructed with open straps, wires, and metal rods, and were made of plywood or crude metal frames. It is unlikely that anyone would want to put such a device next to the coffee machine. It should be noted that the new models look more and more neat and attractive, but most devices still have a predominantly "industrial" look. But the 3D market is developing very rapidly, so in a couple of years we will not be surprised to see a stylish, compact, home 3D printer at friends at home.

Why mass-produced 3D printing hasn't become a trend yet

Photo: asharkyu / Shutterstock, Chris McGrath / Getty Images

The production of goods with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

When the problem of shortage of personal protective equipment (PPE) for doctors became acute, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Adapters for masks - example of a customized product (made to order. - RBC Trends ), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization Challenges

Nike and Adidas have been experimenting with 3D printing for sneakers since 2012. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020, these opportunities remained unrealized. In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay for customized sneakers many times more expensive when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

Where personification has taken root

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Economics of innovation Living hand: who creates bionic prostheses in Russia

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production.”

Denis Alekseev, Head of R&D and Production at JSC ROBBO (educational robotics, Skolkovo resident), is sure that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

The cost of individual products may be higher, but this increase must be of value to the customer.

Main disadvantages of 3D printing:

-

low production rate;

-

often low quality products;

-

high cost of the product when trying to mass production.

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

The main question is: who will buy it?

Entrepreneurs who will find the answer to the question: who will buy them will be able to develop the production of personalized goods? Businesses that already operate in a particular market and feel the needs of their audience can feel the demand.