Best color filament for 3d printing

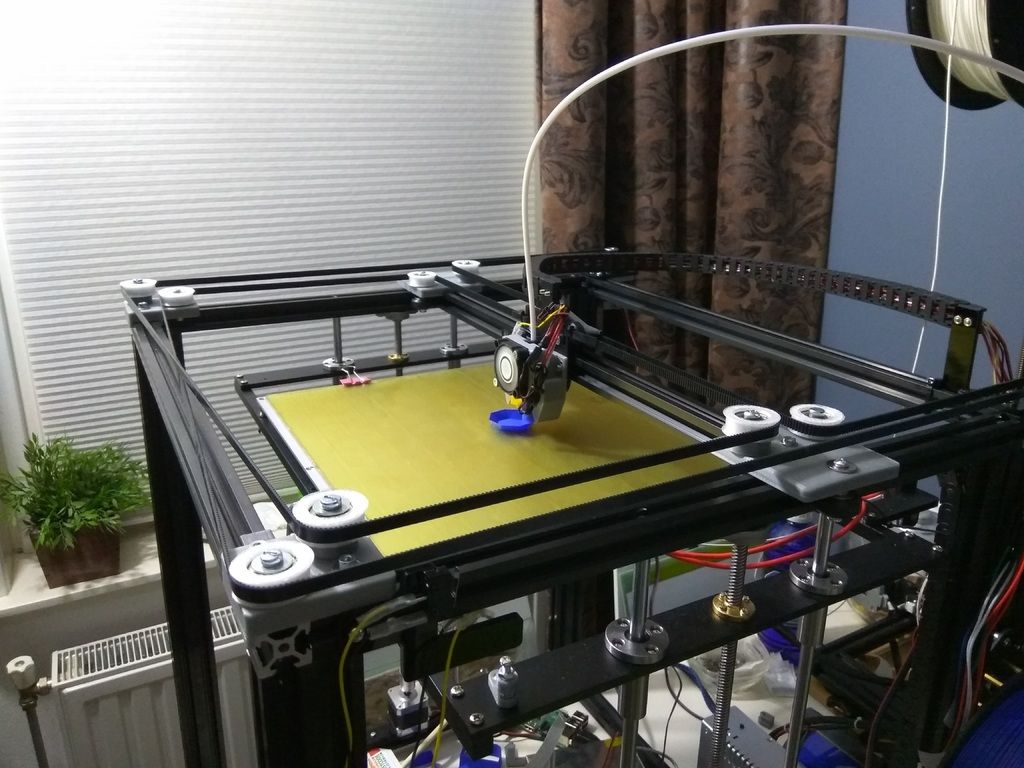

Best 3D Printing Filament Colors

So you’re just getting into 3D printing but want to make sure you have everything you need to get started. What are the best 3D printing filament colors?

The best filament colors for 3D printing that you should have in your arsenal include white, grey, blue, red, green, purple, rainbow, heat-changing, and even glow-in-the-dark. Conversely, some of the worst filament colors for 3D printing that you should avoid are neon colors, black, and yellow.

If you’re in the market for some new 3D printing filaments, then you’ve likely seen the wide breadth of choices available to you. It seems like filament makers have figured out how to make just about any color under the sun. In this article, we’ll go over some of the best filament colors out there for making the perfect 3D prints every time. You’ll also learn about three of the worst 3D printing filament colors that you should consider avoiding.

Since you’re here reading this article, we know that you really just want to know what the best 3D printing filament colors are. And to ensure we’re giving the most accurate information that we can, we’ve combined our own experience and knowledge with the opinions of others in the field and research through discussion forums. We’re confident that the filament colors seen below are truly the best ones you should get your hands on to start printing!

What Are The Best 3D Printing Filament Colors?

While listing the best 3D printing filament colors might be a bit subjective, since everyone has their own color preferences, we’re going to do our best! Based on the input from a number of 3D printing enthusiasts, we’ve come up with the following list of the six best filament colors on the market. So without further ado, let’s just straight into it.

Normal 3D Printing Filament Colors

White

Picture of a White Printer FilamentWhite is a fan favorite among just about everyone who’s serious about 3D printing. Its simple manufacturing process that doesn't require any additional pigmentation makes it compositionally strong compared to many other colors — especially those at the very bottom of this list.

To make it even better, white is also the easiest color to paint. Since it’s white, you don’t have to worry about needing to cover up another color underneath whatever you’re trying to paint. And since many enthusiasts like to paint their prints to make them perfect, white is the best base color to go with.

Grey

Picture of a Grey Printer FilamentGrey is a great filament color for 3D printing for many of the same reasons as white. It’s easy to manufacture, doesn’t have any of the brittleness or fading issues that the colors at the end of this article have, and it’s also incredibly easy to cover and paint.

Many people that regularly 3D print will default to either grey or white as their normal color to 3D print with. Grey has a bit of a range of colors as well, but for most people, a lighter grey is typically used more commonly. The lighter it is, the easier it is to paint over. But if you want something a bit darker, an average grey-colored filament will provide a great looking print!

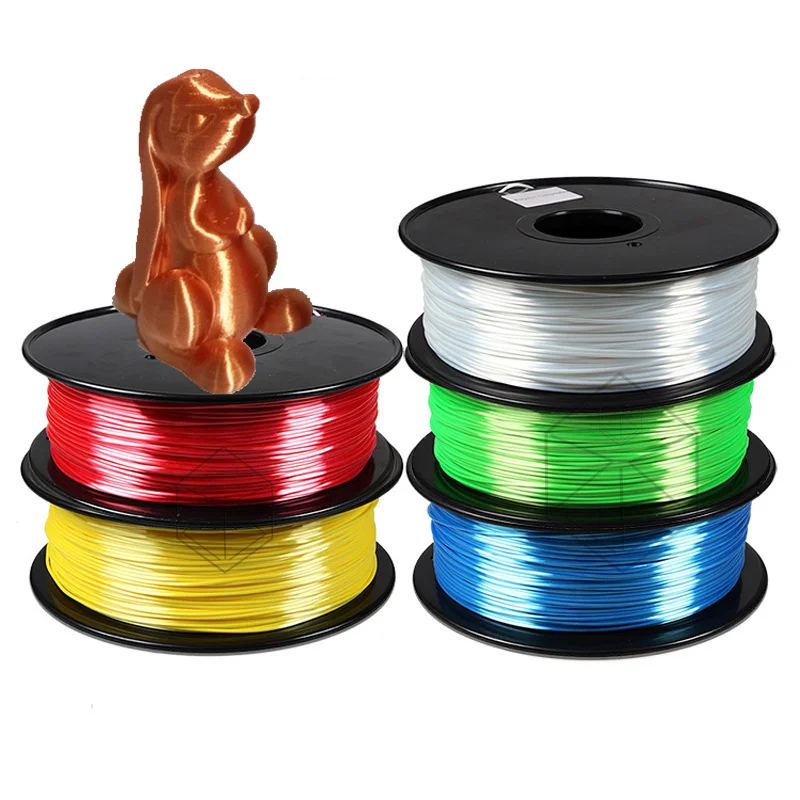

Standard Colors (Blue, red, green, purple, orange)

Picture of Standard Color Printer FilamentsFor those of you who don’t really want to use grey or white and then paint the print whatever color you like or anyone who just wants to add some color to their 3D model collection, then many “standard” colors are some of the best to use. When we say standard colors we’re referring largely to the primary and tertiary colors that make up everything else.

When we say standard colors we’re referring largely to the primary and tertiary colors that make up everything else.

Of those colors, the best ones to use for 3D printing are blue, red, green, orange, and purple. You might have noticed one exclusion, and a primary color at that — yellow. As you’ll read about later, yellow fades more than any of these other colors. But feel free to use these five colors to make some eye-popping prints!

Unique 3D Printing Filament Colors

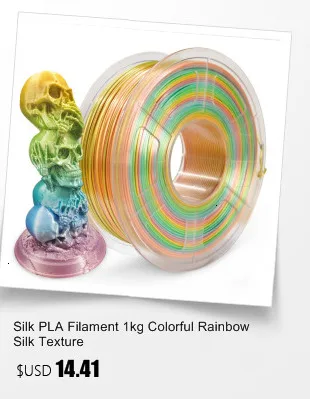

Silk Rainbow Multicolor

Picture of a Silk Rainbow Multicolor Printer FilamentWhile the above colors are great for the vast majority of 3D prints and enthusiasts, sometimes you want to change things up a bit. And one of the best ways to do that is with a rainbow multicolor filament. Our personal recommendation is to go with one of the “silk” ones that give the final print a shiny, smooth finish.

While you can get rainbow filament that looks like a normal rainbow, there are so many variations out there to choose from that you can have hundreds of rainbow prints and still not have tried them all! Keep in mind, with rainbow filaments it’s better to use them on bigger prints so that there’s enough room for multiple colors to show up.

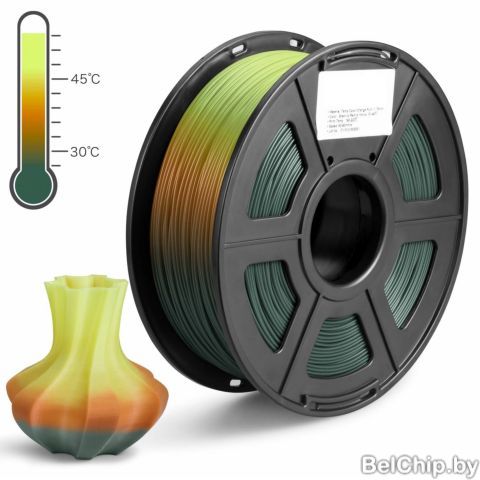

Thermochromic (Heat-Changing) Filament

Picture of a Thermochromic (Heat-Changing) FilamentAs 3D printing becomes more advanced, one of the most intriguing new technologies in filament coloration is using thermochromic filaments. That sounds like a fancy word, but it’s just the more technical way of saying that the color of the filament changes based on heat.

While the colors involved in thermochromic 3D printing filament can be all sorts of various combinations, our favorite is the Zi-Rui Thermochromic PLA Filament. Depending on the temperature, the print will change from yellow, to orange, to black. So if you move it around the room, you could get different color variations. How cool is that?

Glow In The Dark Filament

Picture of a Glow In The Dark FilamentLast but not least, we have another fan-favorite: glow in the dark 3D printing filaments. While this one might be a bit controversial since some of the cheap brands don’t offer a very high-quality filament, it’s so popular that we just couldn’t leave it off our list.

After all, think back to being a kid. Weren’t things that glowed in the dark just the coolest things ever? We all still have a bit of a kid inside us, and glow in the dark is still pretty cool! With this type of filament, you can print yourself an entire glow in the dark cache of little models and figurines. Just make sure you get a high-quality filament, such as HATCHBOX, for example!

Which 3D Printing Filament Colors Should You Avoid?

Now that you know about some of the best filament colors for 3D printing, you should probably get an idea of what some of the worst ones are. For one reason or another — which we’ll explain for each one — the next few colors you see listed here are ones that you might want to avoid using in your 3D printing.

Neon Colors

While this isn’t exactly a specific color or anything, it is widely discussed in the 3D printing world that neon colors in general are one of the main filament types or colors to steer clear of. While they can certainly create some of the most eye-popping prints that you’ll ever see, they come with a slew of potential issues.

Depending on the brand, quality, color, and more, neon colored 3D printing filaments can be a headache to use. Some of them don’t bond well and begin to fall apart. Others come out looking almost transparent, revealing the support structures inside and not looking the way you’d want it to. Overall, you’ll likely be happier with the colors mentioned above!

Black

We know, we know. Black is one of the best looking colors on quite a few things that you might be 3D printing. And the truth is, with a high-quality brand you might actually have no issues whatsoever using black filament. But for many brands and many users, black filament tends to lead to excessive brittleness and easier cracking. Why is this?

The issue of a black coloration leading to brittleness actually isn’t something that only comes up with 3D printing. It’s an issue in the entire textile industry. This is because oftentimes, black goods are the result of an over-dye, i.e. something that was meant to be a different color didn't match what it was supposed to look like. It then goes to a pile of black to be re-dyed.

It then goes to a pile of black to be re-dyed.

It is this multifaceted dying process that leads to the black filament (and other materials) being more brittle than its other-colored counterparts.

Yellow

Unlike the black filament above, yellow isn’t something to be avoided because of it being too brittle. No, instead you might want to consider avoiding using yellow filament just because of its coloration over time. Yellow pigment can be made from a lot of different sources, and its brilliance makes it a popular choice for 3D printing enthusiasts.

But the issue with yellow pigment is that it tends to react to UV light (think sunlight) more than other colors, and not in a good way. Yellow begins to break down and decay faster under UV light than other colors, which leads to the color fading much more quickly.

Best Filament Colors for 3D Printing – Unique Options – 3D Printerly

There are different color filaments in the market today. In this article, I am going to cover some of the best filament colours for 3D printing, their characteristics, share tips on how to print with them, and some amazing prints that can be achieved using them.

MatterHackers’ Quantum Filament is a modern twist to color changing filament, providing a unique blend of two colors front to back, as well as on the sides of the spool. It creates a very cool shimmering effect on 3D models when moved around, and it comes in several color combinations.

These are setting very fast due to their popularity, so I’d get your orders in as soon as possible. If you want to create visually striking 3D models, you’ll want to get yourself some spools of MatterHackers Quantum filament.

Check out the color combinations it comes in:

- White-Green

- Silver-Purple

- Silver-Gold

- Pink-Purple

- Pink-Yellow

- Purple-Gold

- Blue-Green

- Blue-Yellow

- Blue-Raspberry

- Green-Raspberry

- Silver-Raspberry

- Raspberry-Gold

You can get this filament in 1.75mm or 2.85mm diameters, having a dimensional accuracy of +/- 0.02mm which is top of the line.

There are no other filaments currently on the market that can produce this same effect on 3D models.

In order to test the best color alignment on your 3D printed objects, you can 3D print a Quantum Alignment Tower. It’s really helpful to ensure that your colors are printed in the way you want it to be.

To get a good print with Quantum PLA, a hotend temperature of 210-215°C and a bed temperature of around 50°C are required for proper bed adhesion. Users with a layer lock powder coated PEI have found that 65°C is the most ideal bed temperature for this filament.

Check out the video below to see an example of this dichromatic 3D printing filament in action.

Matterhackers Quantum PLA has seriously blown me away! from ender3

This is a high-quality silk PLA filament that contains changing silk glossy smooth silver color and shiny galaxy blue colors, it is sold at a price of around $35 on Amazon. It has a rating of 4.4/5.0 as reviewed by over 300 customers on Amazon at the time of writing.

This filament is considered good for larger prints, and prints at a dimensional accuracy of +/- 0. 02mm.

02mm.

To get a good print with AMOLEN Shiny Silk PLA, a hotend temperature of 190-220°C and a bed temperature of around 50°C are recommended.

It is a good practice to pass the filament through the fixed hole to avoid tangles after using this filament. This spool comes packaged in a vacuum bag to keep it dry and maintain the filament for a much smoother and good print.

Users are happy with the good print quality of shiny silk filament as 3D prints come out strong and smooth, having a good bed adhesion and no jams.

However, users have had difficulties with nozzle clogs which can be caused from the filament absorbing moisture in the environment, also known as being hygroscopic. This can easily be avoided by storing the filament in a vacuum bag.

This Wand Holder with Empty Plaque was printed using shiny red and silk gold multicolor AMOLEN PLA filament, it has two files to download and try out.

Rainbow multicolor filaments are a really popular design in the 3D printing world. They deliver a shiny and silky smooth appearance in a range of colors, which have a nice blend between them. It’s PLA-based so it prints easily and at low temperatures.

They deliver a shiny and silky smooth appearance in a range of colors, which have a nice blend between them. It’s PLA-based so it prints easily and at low temperatures.

This specific rainbow filament is known to be fast-changing so you should be able to use its effects without really large 3D prints.

There are other filament colors in the Amazon listing, but overall, it has a global rating of 4.5, rated by over 300 users at the time of writing.

The printing experience is good for users, as it has been reported to have a smooth extrusion and a stable printing performance. Users are particularly happy with the spectacular shiny rainbow colors of items printed when using this filament.

Since the filament is hygroscopic, it comes with a sealed vacuum bag to keep it dry and maintain its printing quality.

A few users noted that some filament spools are tangled, needing to unspool the tangled part and re-wind it, though this isn’t a common occurrence and may have been from bad quality control in the past.

Some users also had trouble with bed adhesion, but increasing the bed temperature and printing temperature should help a lot. A printing temperature of 205-215°C and bed temperature of 60-65°C works for most people.

Check out this 3D printed model using AMOLEN PLA Rainbow Filament.

Well this rainbow filament (AMOLEN PLA) came out much better than expected! from 3Dprinting

Temperature Color Changing Filament is a unique filament with a PLA base material that can change its color with temperature changes. There are a few brands out there that create these types of filaments.

They have color combinations such as pine green to brown to yellow, purple to red, blue to white, blueish green to yellow green and more.

It’s compatible with your standard FDM 3D printer and has a filament diameter of 1.75mm.

One user who said they’ve never worked with color changing filament mentioned how it prints smooth and easy with no clogs or warping. They got great results from the first print, and enjoyed how the model changed color just being in their hands while peeling away supports.

They got great results from the first print, and enjoyed how the model changed color just being in their hands while peeling away supports.

You can splash some warm water on your 3D prints to show the effects nicely.

A cool idea by one user was to 3D print a phone case, so when you remove your hand from the case, it shows a hand print, as well as hot spots on your phone. You can reset the color changing ability by putting the 3D model in your fridge for a few minutes.

Check out the examples below of color changing filaments in action.

Finally found a practical use for the temperature color change filament I got for Christmas from ender3

Here’s an electronic case showing off the color changes.

Just got a roll of temperature color change filament and its great for electronics cases! from 3Dprinting

This Glow in the Dark PLA filament is a great color for users to 3D print, having a very unique property. This specific listing on Amazon contains 20% glow powders that glow in the dark after it absorbs light energy.

This specific listing on Amazon contains 20% glow powders that glow in the dark after it absorbs light energy.

It works best when exposed to strong sunlight or UV light for about 30 minutes, but make sure not to expose it for too long since it can reduce the glowing effect. They recommend going with the green color since it has the best luminous effects.

These filaments are known to be quite abrasive, so you’ll want to use a hardened steel nozzle rather than brass if you plan to 3D print a larger model.

Another thing to keep in mind is how glow in the dark filament is not as strong as normal PLA, so keep a good angle going to the extruder without a sharp bend. It has a filament tolerance of +/-0.03mm which is pretty average.

You can bring life to many 3D models such as a 3D printed wallet, phone case, or sculptures.

One user decided to 3D print some alien flying saucers that glow in the dark. It shines brightly for around 2 minutes, then returns to a softer glow for around 30 minutes.

Some people did have issues with getting the filament to adhere to the print bed, but you should be able to fix this by raising the printing temperature and bed temperature, along with using an adhesive on the bed and a Raft.

Marble is another great color that I’ve used many times to 3D print statues and busts. It has a great aesthetic property that brings models to life, along with strong physical properties. It’s usually based on PLA with additives.

It has a filament tolerance of +/- 0.03mm so you shouldn’t get any clogs or jams while you are 3D printing. Many people love ERYONE filament, and are thoroughly impressed by the printing quality and quality control.

The filament comes neatly wound and is pretty consistent according to one user. It comes in a vacuum sealed packaging with a pack of desiccant to ensure the filament doesn’t absorb moisture from the environment.

It comes in a vacuum sealed packaging with a pack of desiccant to ensure the filament doesn’t absorb moisture from the environment.

One user who tested the ideal temperature for this marble filament found that a printing temperature of 205°C and bed temperature of 60°C worked great.

To get a good adhesion to the print, make sure your bed is level and look towards using a separate adhesive like a glue stick or hairspray.

Check out the Marble PLA 3D prints below to see how great it looks.

Marble PLA is amazing from 3Dprinting

The details in this one looks really good.

First test print with marble PLA. Blown away by the results! from 3Dprinting

Lastly, we have Diamond PLA, a lovely filament blend that incorporates a glittery effect, especially under a light. I’ve used this PLA before and it provides a really unique and special 3D model that stands out from the rest.

ZIRO are probably one of the best manufacturers that produce this Diamond PLA, so I’d definitely check them out.

It’s sold at pretty competitive price as well, being around $25 for a 1KG spool. They have over 400 reviews which are mostly positive, with an overall rating of 4.5/5.0 at time of writing.

Here are some of the colors they sell:

- Diamond Blue

- Diamond Black

- Diamond Purple

- Diamond Green

- Diamond Silver

- Twinkle Black

- Twinkling Transparent

- Twinkling Bright Red

- Diamond Red

- Twinkling Blue

To get a good print with this filament, a hotend temperature ranging 190-220 C is needed. Users have suffered less under extrusion with about 220°C and using a heated bed of 50-60°C makes the print to get a good bed adhesion.

I’d recommend 3D printing a temperature tower to see what temperature works best for your particular set up and filament. Print your first layer slow at around 20mm/s so you can get good first layer adhesion, then use a normal printing speed between 30-90mm/s.

I usually stick to around 50 or 60mm/s.

Some users had issues related to the filament absorbing moisture, storing the filament in the vacuum-sealed bag helps to maintain the filaments by keeping them dry.

Users like the textured surface that this filament produces as it allows the embedded flakes to shine better.

Best 3D Printing Filaments (Professional)

3D printing is increasingly being used in commercial and manufacturing applications. Industrial printing requires special filaments. They are characterized by increased structural support. We offer a list of the 9 most popular professional consumables:

#1. Professional 3D Printing Filament: Carbon Fiber

Carbon fiber is often added to PLA, ABS, PETG to improve stiffness. Such connections are excellent for use in aggressive environments. The only negative is that the use of these consumables contributes to the rapid wear of the extruder (especially if it is made of soft metal).

#2. Professional 3D Printing Filament: PC-ABS

ABS Polycarbonate Alloy is a rigid thermoplastic that combines the strength and heat resistance of polycarbonate with the flexibility of ABS. The material is characterized by hygroscopicity, therefore it causes certain difficulties when working with it. Another disadvantage is that the thread must be printed at a high temperature (at least 260°C). Since PC-ABS tends to warp, a high temperature of the printed layer (at least 100°C) is needed.

The material is characterized by hygroscopicity, therefore it causes certain difficulties when working with it. Another disadvantage is that the thread must be printed at a high temperature (at least 260°C). Since PC-ABS tends to warp, a high temperature of the printed layer (at least 100°C) is needed.

#3. Professional 3D Printing Filament: HIPS

High performance polystyrene is a copolymer that combines the hardness of polystyrene with the elasticity of rubber. Combined with ABS in a dual extrusion printer, HIPS is an excellent support material. Easy to sand, glue or paint. Doesn't mix well with other threads (except ABS) as they can be damaged by limonene.

#4. Professional 3D printing filaments: PVA

Polyvinyl alcohol is water soluble, so it does an excellent job as a support material. Unlike the previous consumable, it is compatible not only with ABS, but also with PLA and nylon.

#5. Professional 3D Printing Filament: ASA

An alternative to ABS designed to be more weather resistant. Acrylonitrile styrene acrylate is not affected by chemicals, high temperatures. This is a durable and tough consumable that is easy to use in additive printing.

Acrylonitrile styrene acrylate is not affected by chemicals, high temperatures. This is a durable and tough consumable that is easy to use in additive printing.

#6. Professional 3D Printing Filament: PP

Polypropylene is a strong, flexible, lightweight, chemical resistant and food safe material. True, the thread has a number of disadvantages, including poor adhesion and difficulty in deformation.

#7. Professional 3D printing filaments: Acetal (POM)

Polyoxymethylene (POM) also known as acetal. Differs in durability, rigidity, wear resistance and, the most important, low coefficient of friction.

#8. Professional filaments for 3D printing: PMMA

Polymethyl methacrylate is a rigid, impact-resistant, transparent material. It cannot boast of flexibility and ease of printing.

#9. Professional 3D Printing Filament: FPE

Flexible polyester is a flexible and soft material that boasts good adhesion, moderately high heat and chemical resistance.

Source: Ink-Market.ru.

The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important?

90% of 3D printers use 1.75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

-

Does not shrink. This makes it easy to build prefabricated or huge models without changing dimensions.

-

There are no specific requirements for a 3D printer. Any working 3D printer will do. PLA doesn't need a heated table or a closed case.

-

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

Cons:

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade.

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance. For example, more durable, with improved layer adhesion.

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area.

Pros:

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing. ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

-

It is currently the most inexpensive type of plastic for 3D printing.

-

Large selection of colors and shades.

Cons:

-

High shrinkage.

Because of this, it can be problematic to manufacture overall products.

Because of this, it can be problematic to manufacture overall products. -

Printing requires a heated bed and a closed chamber. Without this, the ABS may peel off the table or crack in layers.

-

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

RU model in ABS

ABS+ differs from conventional ABS in improved strength characteristics (elasticity, rigidity, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon.

For example for ABS or Nylon.

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products.

-

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

Cons:

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products.

-

Small palette of colors.

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot).

Using HIPS as a Soluble Support

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds.

PVA is very hygroscopic and dissolves in plain water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros:

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good impact resistance.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models.

SBS is a low toxicity plastic. It can be used to print food contact models.

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

-

slight shrinkage

-

Transparency. After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

-

Easily processed mechanically or chemically.

-

Allowed contact with food.

Cons:

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes.

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient.

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

-

High strength and wear resistance.

-

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing.

Perfectly polished and drilled.

Perfectly polished and drilled.

Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

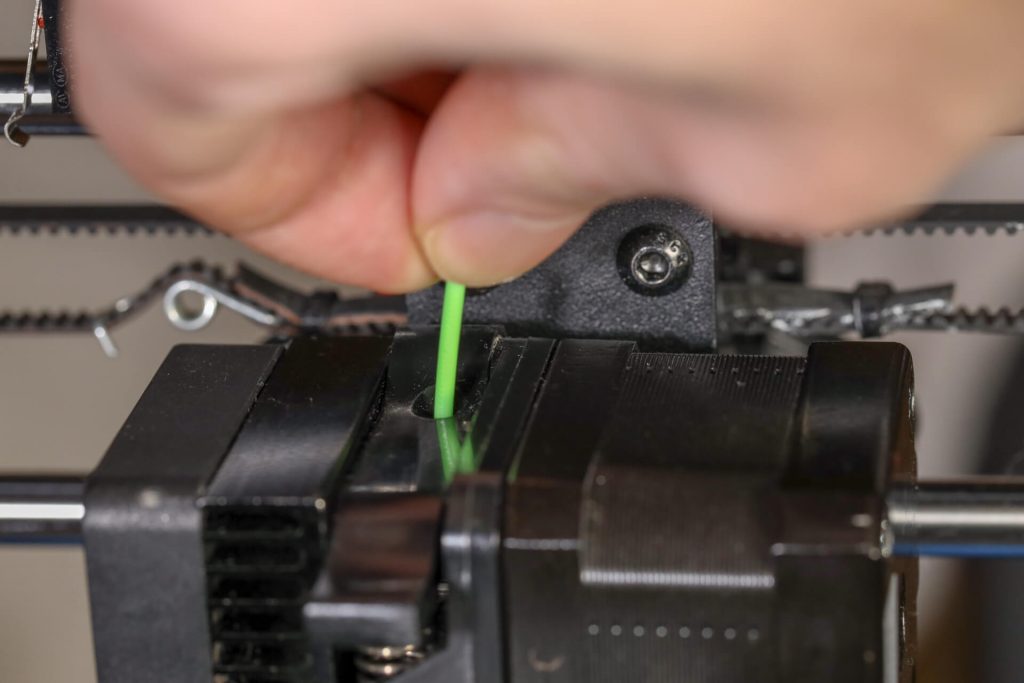

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm.

Pros:

Cons:

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

Trainers with flexible soles

Wheel for RC model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required.

Pros:

Cons:

-

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle.

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc.

Functional Carbon Fiber Composite Prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal.

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags.