Best assembled 3d printer

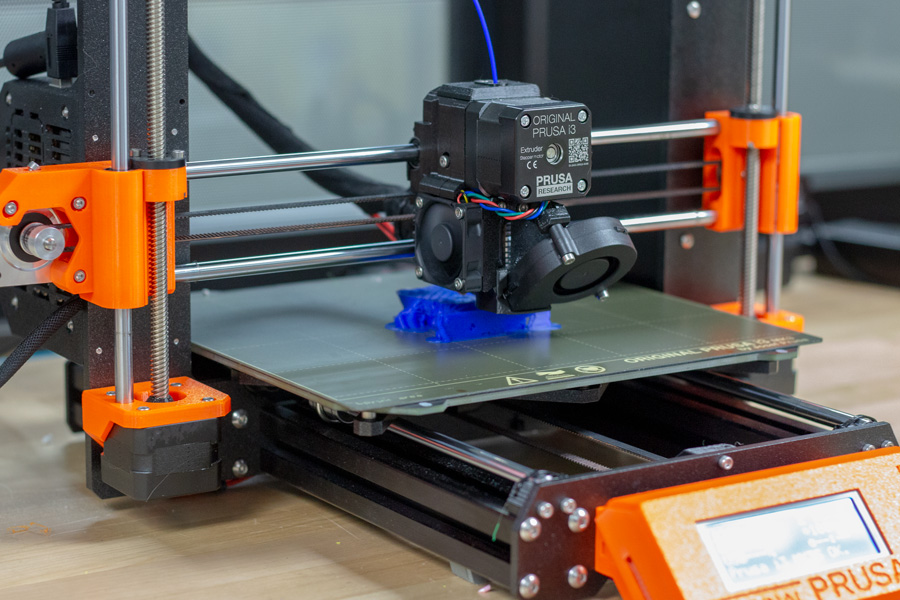

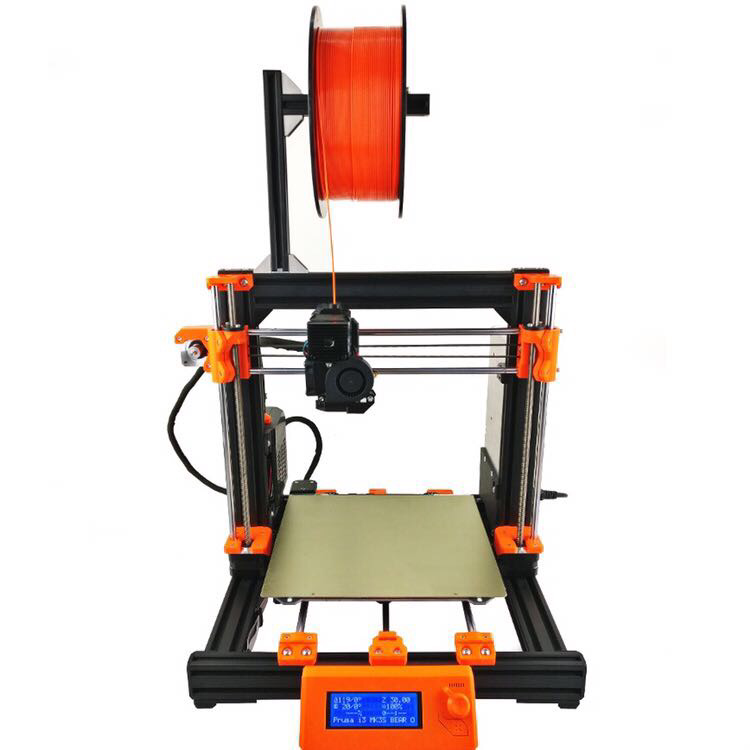

Prusa MK3S+ 3D Printer Review: The Heavyweight Champ Continues to Dominate

Tom's Hardware Verdict

The Prusa MK3S+ continues to hold its own in a market saturated with low-cost competitors.

Pros

- +

+ PrusaSlicer provides best-in-class model slicing

- +

+ Flexible build platform sets the standard

- +

+ Automatic bed leveling

- +

+ Stealth Mode enables a nearly silent printing experience

Why you can trust Tom's Hardware Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

There are few 3D printers with as many industry accolades as the Prusa i3 MK3S+, and after spending some time with this printer, it’s easy to see why it’s one of the best 3D printers currently on the market. With a price tag of $999 for an assembled machine or $750 for a DIY kit, the price point of the MK3S+ is towards the high end for an open format consumer 3D printer, but the features of this machine and the ecosystem created by Prusa (they make their own hardware, software, filament, and more) have made the MK3S+ a formidable machine for anyone interested in taking their 3D printing game to the next level.

The features of the MK3S+ (silent stepper drivers, power-panic, etc.), noteworthy when originally launched, have largely become standard on lower-cost machines and may not seem particularly impressive on a spec sheet. However, clever software implementation and well-written documentation have created a machine that provides a best-in-class printing experience. For instance, the auto-leveling SuperPINDA probe of the MK3S+ maps the build platform for surface distortions, but the printer firmware is capable of storing multiple Z-offsets so you can switch build platforms without having to recalibrate every time.

The MK3S+ is a visually distinct machine; and the Prusa team has kept their black and orange color scheme for their smaller printer, the Prusa Mini+. The bright orange printed parts on the MK3S+ have created instant brand-recognition for the Prusa line of printers, and Prusa has doubled down on this by reinforcing their branding across their machine. In fact, you can find the word ‘Prusa’ printed, engraved, or etched into the MK3S+ in 25 places, 29 if you’re using a spool of their Prusa Polymers Prusament PLA material.

Specifications

Swipe to scroll horizontally

| Machine Footprint | 16.5 x 16.5 x 15 inches (42.0cm x 42.0cm x 38.0cm) |

| Build Volume | 9.84 x 8.3 x 8.3 inches (250mm x 210mm x 210mm) |

| Material | 1.75mm PLA, ABS, ASA, PETG |

| Extruder Type | Direct Drive |

| Nozzle | .4mm |

| Build Platform | Magnetic Heatbed with removable PEI spring steel sheets |

| Power Supply | 240 Watts |

| Connectivity | USB, SD Card |

| Interface | 3.4-inch Mono LCD and click wheel |

| Filament Run-Out Sensor | Yes |

Included with Prusa MK3S+

The fully assembled Prusa MK3S+ ships with all of the accessories required to make your first print, and also includes enough spare parts to replace almost every fastener on the machine. The fully assembled MK3S+ also includes a bag of Haribo Goldbears, a signature addition from the Prusa team.

The fully assembled MK3S+ also includes a bag of Haribo Goldbears, a signature addition from the Prusa team.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Prusa MK3S+ includes a full spool of silver PLA material, screwdriver, a metal part scraper, a glue stick (for adhesion), an isopropyl alcohol wipe, lubricant for the linear rails, power and USB cables, a sheet of stickers, a printed handbook, and a diagnostic printout that confirms the functionality of the mechanical and electrical systems.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The usefulness of the handbook is hard to overstate. When you’re starting out with your first 3D printer, it can be difficult to pinpoint the cause of problems such as loss-of-extrusion, poor layer adhesion, or a clogged extruder. The included handbook is full of detailed photographs, troubleshooting workflows, and solutions to common problems. This is an invaluable resource for beginners, amateurs, and experts alike, and it’s clear to me that Prusa has set the standard for technical documentation.

Setting up the Prusa MK3S+

(Image credit: Tom's Hardware)The Prusa MK3S+ ships with a completed print attached to the build platform. This print features a serpentine line with 90 degree angles, curves, and a solid block in the center with the Prusa logo facing upwards. This print serves to confirm that the printer is functional and has been properly assembled and calibrated. I was able to easily remove the print from the build platform by bending the steel sheet and carefully removing it.

(Image credit: Tom's Hardware)After powering on, the printer automatically runs through an initial setup process. This process involves calibrating the Z axis by running it all the way to the top of the printer, running the mesh bed leveling process to set the Z offsets, and loading the filament. This entire process only took me a few minutes, and the high level of automation involved means that the only thing I needed to do was insert the filament into the extruder after it had heated up.

You might be surprised to find that the Prusa MK3S+ is based on the RepRap i3 (third iteration) frame, originally released in September of 2012. Despite this nearly decade-old release date, the MK3S+ is full of modern advancements and enough innovative features to still be a top contender in the prosumer 3D printer market.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The bright orange color makes the 3D printed parts on the MK3S+ easy to spot. The brackets mounted to the printer are printed in-house by Prusa using their own Prusament PETG filament. These brackets are robust and sturdy, and the uniform appearance between the printed parts give the printer a professional appearance. This version of the MK3S+ shipped with orange printed brackets, but the printer is also available in an all-black variant. A large selling point of the MK3S+ is the open-source nature of the machine, which means the printed parts are all available to download if you want to download, modify, or print them out yourself.

The monochrome LCD interface and click-wheel on the MK3S+ is one of the few less-than-impressive features on this machine; it feels dated and the UI navigation can be a little clunky. This stands in contrast with printers like the Anycubic Vyper, a sub-$400 machine that features a bright and responsive color touchscreen that shows detailed print statistics during printing. This monochrome display was industry standard when the original 8-bit i3-style of printers was introduced, but it feels outdated when compared to recent printers with color touchscreens.

(Image credit: Tom's Hardware)The MK3S+ uses a filament spool holder that mounts directly to the frame of the printer. The T-shaped holder is able to hold two spools simultaneously, which is ideal if you plan on swapping between multiple colors to produce a multicolor 3D print. The direct-drive extruder on the MK3S+ feeds filament straight down into the hot end, so mounting the filament directly above the extruder gives the filament a straight path between the spool and the extruder.

At the heart of the MK3S+ is the 8-bit Einsy RAMBo board, housed in a 3D printed enclosure mounted to the frame of the machine. This board is equipped with Trinamic 2130 silent stepper drivers, user-replaceable fuses, and the cable management is clean and professional.

The features made possible by this board (power-panic, live-Z adjust, silent steppers) were all major leaps when originally introduced, but many of these features have made their way down to less expensive FDM 3D printers like the Elegoo Neptune 2. The interface feels sorely in need of an update, and the addition of a color touchscreen and a 32-bit board (such as the one equipped on the Prusa Mini+) would refresh this platform.

(Image credit: Tom's Hardware)The attention to detail on the Prusa MK3S+ is clear, and a perfect example of this is the wire management across the machine. Current-carrying wires are attached to the extruder module with zip ties that act as a strain-relief to prevent the wires from fatiguing and separating. The wires from the power supply are tucked neatly under the frame of the machine, out of sight and reach from users to prevent accidentally unplugging them during printing.

The wires from the power supply are tucked neatly under the frame of the machine, out of sight and reach from users to prevent accidentally unplugging them during printing.

What Makes the Prusa MK3S+ Different?

It can be hard to understand why the Prusa MK3S+ costs so much more than a printer like the Creality Ender 3 Pro, which seems to have similar specs on paper. To understand why this machine is so much more expensive, we need to take a closer look at the individual components of the MK3S+.

(Image credit: Tom's Hardware)Critical to the success of the MK3S+ is its custom-made Delta 240 Watt power supply, mounted to the frame of the machine. This unit supplies 24V power to the bed with a max current of 10 Amps, which provides fast and reliable heating for printing high temperature materials like PETG and ASA. Less expensive machines typically use lower wattage power supplies, such as the 150W power supply used by the Flashforge Adventurer 3 Lite, which take longer to heat and can have difficulty maintaining a higher temperature.

The 24V heated bed is able to reliably hit 100C, which is more than enough to allow high temperature materials like PETG and ASA to adhere to the build platform without delaminating. The magnetic build platform is firmly held in place without any clips or latches and can easily be removed once it cools to room temperature. PETG in particular is easy to remove from the textured surface of the textured spring steel sheet, and the MK3S+ build platform is best-in-class for high-temperature adhesion.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The MK3S+ is equipped with a genuine E3D hot end, and it has the holographic sticker to prove it (seriously). E3D manufactures every component in the hot end from the nozzle to the heatbreak which means you are very unlikely to run into the type of manufacturing defects that occasionally pop up on less expensive printers (incorrectly drilled nozzles, degraded PTFE tube liner, etc. ) In addition, this nozzle is rated for a max temperature of 300C (572F), which is easily hot enough to extrude most common thermoplastics and even some higher-temperature engineering-grade materials like Nylon and Polycarbonate.

) In addition, this nozzle is rated for a max temperature of 300C (572F), which is easily hot enough to extrude most common thermoplastics and even some higher-temperature engineering-grade materials like Nylon and Polycarbonate.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The printed parts on the MK3S+ are a perfect example of a company applying its in-depth knowledge of a subject to its product. The printed brackets found on the MK3S+ have been printed in PETG, and the outward-facing textured surface shows the level of quality you can expect from using a textured sheet.

In addition, I appreciate that Prusa has applied DFAM (Design for Additive Manufacturing) principles to these parts. These DFAM principles include concepts like printing hexagons instead of circles for relief holes, which print without requiring support material, and printing brackets perpendicular to their intended load to create mechanically tough parts.

(Image credit: Tom's Hardware)The Prusa MK3S+ comes equipped with a SuperPINDA probe which is used for hands-free leveling of the build platform. The SuperPINDA (which stands for Super Prusa INDuction Autoleveling sensor) operates by detecting the proximity of the probe to the build platform and storing that information in firmware. The MK3S+ isn’t the first printer to use a probe for bed leveling, but the software implementation in PrusaSlicer means that after the printer has been set up, you can print without spending much time thinking about calibration.

The SuperPINDA (which stands for Super Prusa INDuction Autoleveling sensor) operates by detecting the proximity of the probe to the build platform and storing that information in firmware. The MK3S+ isn’t the first printer to use a probe for bed leveling, but the software implementation in PrusaSlicer means that after the printer has been set up, you can print without spending much time thinking about calibration.

Compared to the manual bed leveling process of a printer like the Creality Ender 3 Pro, the MK3S+ is faster, easier to use, and requires less trial and error. PrusaSlicer includes a “G80” command in the start G-code (the instructions the printer reads when making a part), and this command performs a ‘Mesh Bed Leveling’ which probes the bed in a 3x3 grid to create a mesh surface that is used for calibration. This mesh surface causes the Z-axis motors to undulate over uneven areas while the print head remains perpendicular in the X/Y axis. During my testing, I didn’t need to run a single non-print calibration on the printer after the initial mesh bed leveling.

During my testing, I didn’t need to run a single non-print calibration on the printer after the initial mesh bed leveling.

Build Platforms on Prusa MK3S+

(Image credit: Tom's Hardware)Removing a printed part from the build platform of a 3D printer can be a challenging experience if the printer isn’t calibrated correctly. The Prusa MK3S+ attempts to solve this problem by using a removable build platform that is held in place magnetically and can be flexed to remove parts after the platform has cooled. I’ve tried many different types of build surfaces, and the smooth PEI sheet used by Prusa is by far one of the easiest to print on, remove parts from, and clean.

(Image credit: Tom's Hardware)Prusa also offers a textured steel build platform for the MK3S+ that has a gritty surface which can give printed parts a more uniform appearance. In fact, the signature textured look of the printed parts on the MK3S+ come from this build platform.

Parts printed on a smooth build platform will have a smooth bottom surface, which looks visually distinct from the striations on the sides of the part. By using a textured sheet, I was able to make prints that have a textured appearance on the bottom as well as the sides. This sheet is ideal for printing with PETG; the high print temperature of the material requires a textured surface to stick to, but also needs a surface that it can easily detach from.

By using a textured sheet, I was able to make prints that have a textured appearance on the bottom as well as the sides. This sheet is ideal for printing with PETG; the high print temperature of the material requires a textured surface to stick to, but also needs a surface that it can easily detach from.

Printing on the Prusa MK3S+

(Image credit: Tom's Hardware)The sample prints on the included SD card with the Prusa MK3S+ are a refreshing change from the sample parts that are typically included with low-cost 3D printers. The MK3S+ includes 16 pre-sliced parts that have been prepared for PLA with the total print time included in the file name. The sample prints vary in time from 23 minutes (a simple block with the word PRUSA on it) to almost 14 hours (a castle printed at .1mm layer height), and have all been prepared using sensible settings for the machine and highlight various features (variable layer height, multicolor printing, and fine .1mm layer resolution).

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)One of my favorite sample parts is the planetary gear bearing that prints in a single print. I printed this model using the Prusament Jet Black PLA material, and after removing it from the build platform I was able to easily spin the gear freely. This part really highlights the ability of the MK3S+ to produce parts with functional strength and purpose in addition to parts designed with aesthetics in mind.

(Image credit: Tom's Hardware)Another stand-out sample print included with the MK3S+ is the dragon model titled Adalinda the Singing Serpent by Loubie3D. This model takes a little longer to print (about 8 hours), but the final print is another favorite of mine. Because this model was sliced by Prusa for the MK3S+ printer, the sample print comes out with a high level of detail and no unexpected settings that can cause problems (too many exterior shells, no retraction, etc. ) like the sample prints included with other FDM 3D printers.

) like the sample prints included with other FDM 3D printers.

Printing with PrusaSlicer on the Prusa MK3S+

(Image credit: Prusa)Prusa has developed its own in-house slicer for the Prusa MK3S+, called PrusaSlicer. PrusaSlicer is a fork of the confusing-to-pronounce Slic3r app, which is also a free and open-source app. Prusa has invested a considerable amount of time and effort in PrusaSlicer, and this has translated into one of the most powerful 3D printing slicer apps available for desktop 3D printers on the market.

(Image credit: Prusa)The current version of PrusaSlicer (2.3.3) includes profiles for printers by Prusa, Creality, Lulzbot, and more, and also includes a library of material profiles. In addition to these profiles, PrusaSlicer also includes multiple print setting profiles, which range from ultra-high detail at 0.05mm layer height to a draft mode which offers .3mm layers fast print speed at the expense of reduced quality.

Slicing Models in PrusaSlicer for the Prusa MK3S+

(Image credit: Prusa)PrusaSlicer is a feature-rich program with a simplified interface that is accessible to beginners, experts, and everyone in between. I’ve spent a lot of time in the PrusaSlicer settings, and I appreciate how much work Prusa has put into making almost every parameter of the printing process addressable without creating an overwhelming interface.

The settings are broken down into three primary categories: Print Settings, Filament Settings, and Printer Settings. Print Settings generally focuses on the speed / quality of the print, Filament Settings is used to determine temperature and extrusion parameters, and Printer Settings is used for global parameters and determining start / stop instructions.

(Image credit: Prusa)The primary interface offers three settings: Simple, Advanced, and Expert. Simple offers a stripped-down experience with only a few parameters able to be adjusted, while Advanced and Expert allow you to adjust the print on a more granular level.

PrusaSlicer Quality Settings for the Prusa MK3S+ / PLA

(Image credit: Prusa)Swipe to scroll horizontally

| Material | Prusa Basic PLA, Silver |

| Layer Height | 0.20 mm |

| Infill Percentage | 15%, Gyroid |

| Print Speed | 45mm/second |

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 1 Hour, 34 Minutes |

There are few prints that are better at testing out a printer than the 3DBenchy, so I used the included spool of silver Prusa PLA to print this model out using the default . 2mm Quality PrusaSlicer settings. I was impressed with the overall quality of the Benchy, and even with a highly-reflective material like a silver PLA which can highlight defects from uneven layers, the layers looked even and consistent throughout.

2mm Quality PrusaSlicer settings. I was impressed with the overall quality of the Benchy, and even with a highly-reflective material like a silver PLA which can highlight defects from uneven layers, the layers looked even and consistent throughout.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Benchy boat model is designed to highlight various features of a printer (such as the ability to print steep overhangs, small features, etc.), and a quick examination of the model shows that the MK3S+ performed very well and didn’t have any of the common defects typically seen on this model.

PrusaSlicer Spiral Vase Settings for the Prusa MK3S+ / PLA

(Image credit: Prusa)Swipe to scroll horizontally

| Material | Prusament PLA, Galaxy Purple |

| Layer Height | 0.20mm |

| Infill Percentage | 0% |

| Print Speed | 60mm/second |

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 3 Hours, 9 Minutes |

Slicing a model using the ‘Spiral Vase’ mode in PrusaSlicer will automatically create a model that is composed of a single continuously rising helical contour, which allows models to be printed a fraction of the time it would normally take to print using multiple layers. This mode is ideal for printing objects like vases or enclosures that only require a single contour as opposed to multiple contours and an infill structure. I printed the Curved Honeycomb Vase by eggnot to highlight this printing mode.

This mode is ideal for printing objects like vases or enclosures that only require a single contour as opposed to multiple contours and an infill structure. I printed the Curved Honeycomb Vase by eggnot to highlight this printing mode.

The Prusament Galaxy Purple is a favorite color of mine due to the glitter additive in the filament. This additive creates layer lines that are evenly blended and have a textured appearance. Combining this material with the Spiral Vase mode produces parts that look almost conventionally manufactured, with layer lines that are difficult to see. This model printed in just over 3 hours in Spiral Vase mode, as opposed to over 13 hours if it had been printed using conventional settings.

PrusaSlicer Speed Settings for the Prusa MK3S+ / PETG

(Image credit: Prusa)Swipe to scroll horizontally

| Material | Prusament PETG, Chalky Blue |

| Layer Height | 0. 2mm 2mm |

| Infill Percentage | 15%, Grid |

| Print Speed | 60mm/second |

| Extruder Temperature | 250 degrees Celsius (482 degrees Fahrenheit) |

| Heated Bed Temp | 90 degrees Celsius (194 degrees Fahrenheit) |

| Print Time | 4 Hours, 5 Minutes |

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)PETG is a material that offers increased mechanical toughness, heat resistance, and flexibility when compared with parts printed with PLA. Prusa has taken advantage of these material properties by printing many of the components on the MK3S+ with PETG, which creates a rigid part that is able to withstand mechanical stress. PETG is also notoriously difficult to print with due to the high level of stringing that can occur when printing multiple parts simultaneously, but I didn’t have any issues when printing with the Prusament PETG material on the MK3S+.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)I used the default settings in PrusaSlicer to print the clamp model provided by Prusa that was designed specifically for PETG. This model features a functional thread, a flexible ball-and-socket joint, and can be tensioned without snapping the body of the clamp. The part printed in multiple pieces without stringing, and I was able to easily assemble it and verify functionality without damaging the clamp. If printed in a more brittle material (like PLA), I would expect the clamp to crack at a transition point on the body, but the PETG was able to hold tension without deforming or breaking.

PrusaSlicer 3MF Import for the Prusa MK3S+ / PLA

(Image credit: Prusa)Swipe to scroll horizontally

| Material | Prusa Basic PLA, Silver |

| Layer Height | 0. 20mm 20mm |

| Infill Percentage | 15%, Grid |

| Print Speed | 60mm/second |

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 2 Hours, 17 Minutes |

PrusaPrinters (the online file repository created and maintained by Prusa) offers the unique ability to share 3D printable files that have been pre-sliced and prepared for the MK3S+ with detailed print statistics available from the site. A perfect example of this is the Bag Clip by Andrei; a cam-driven bag clip that highlights the type of design freedom offered by a 3D printer.

This model has been uploaded as a .3MF file that contains all of the information required to print, such as slicer settings, nozzle and bed temperature, and custom support structures (visibile in the screenshot above. ) 3MF is an increasingly popular alternative to the STL file, which doesn’t contain much information aside from the raw geometry of a model.

) 3MF is an increasingly popular alternative to the STL file, which doesn’t contain much information aside from the raw geometry of a model.

This part printed flawlessly on the first try, and the provided .3MF (or .gcode) allows a user to send this file to anyone else with the same printer and material and feel confident that the part will be indistinguishable in appearance and performance. I’ve always thought of a 3D printer as the replicator from the Michael Crichton novel Timeline, which is able to produce identical objects at various locations by converting them into digital information. However, the success of a part is frequently beholden to the settings selected by a user for fabrication, so the ability to share the fabrication plans is one step closer to being able to send a physical product as a form of digital data.

(Image credit: Tom's Hardware)At a price-point of $999 for an assembled printer (or $749 for a kit), the Prusa MK3S+ is a machine that doesn’t compromise on user experience and is absolutely one of the best 3D printers currently on the market. The MK3S+ has a professional and neat appearance, but the 8-bit monochrome LCD user interface might be a challenge for some users to get past, given the steep price. Interface aside, the prosumer features of the MK3S+ make it a stand-out machine for anyone who is looking for a reliable machine to produce functional parts without worrying about spending a lot of time tinkering.

The MK3S+ has a professional and neat appearance, but the 8-bit monochrome LCD user interface might be a challenge for some users to get past, given the steep price. Interface aside, the prosumer features of the MK3S+ make it a stand-out machine for anyone who is looking for a reliable machine to produce functional parts without worrying about spending a lot of time tinkering.

If you are looking for a less expensive machine outside of the Prusa ecosystem, the Elegoo Neptune 2 (currently on Amazon for $180) offers similar printing size and features (with the notable exception of automatic bed leveling) at a fraction of the price but without the same level of robust support and documentation provided by the MK3S+ or any of the name-brand components like the E3D hotend. If you want the Prusa experience but are looking to spend a little less money, the Prusa Mini+ (available from Prusa for $399 assembled, $349 for a kit) is an excellent place to start.

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

Creality Ender 3 S1 Pro Review: All the Bells and Whistles

Tom's Hardware Verdict

Creality took its most popular budget 3D printer and decked it out with all the upgrades, saving you time, and even a little money.

Pros

- +

Quality prints

- +

Easy assembly

- +

Auto bed leveling

- +

Direct drive

- +

Touch Screen

Why you can trust Tom's Hardware Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Today's best Creality Ender 3 S1 Pro deals

$424

View

$499

$469

View

Reduced Price

$499

View

Show More Deals

The Creality Ender 3 S1 Pro is quite a mouthful, but it’s also quite a printer. Shortly after announcing the deluxe Ender 3 S1, Creality inexplicably added even more features to their trusty workhorse and dubbed it the “pro” version.

Shortly after announcing the deluxe Ender 3 S1, Creality inexplicably added even more features to their trusty workhorse and dubbed it the “pro” version.

None of these new features will make you throw your S1 in the garbage, but they are enticing if you’re stepping up from an Ender 3 Pro or V2 model. Ready to compete with the best 3D printers on the market, the Ender 3 S1 Pro comes with Creality’s first all metal hotend, a PEI flex plate, a touch screen, an improved spool holder and a built-in light kit.

That’s on top of core improvements already introduced in the S1 version, such as a direct drive, dual Z axis, auto bed leveling, and a slot for a full sized SD card.

Retailing at $479 on Creality’s website , this printer is a far cry from its budget minded roots. It’s still $360 cheaper Prusa MK3S+ kit, but nearly twice the price of basic Ender 3s still on the market. Those bargain basement Enders are still popular because they are so easily upgraded. Nearly everything that comes on an Ender 3 S1 Pro can be added to a classic Ender 3, if you’re willing to spend at least $350 in parts and add them to the old printer yourself (which is a hassle and costs more if you don’t already own an Ender 3).

Nearly everything that comes on an Ender 3 S1 Pro can be added to a classic Ender 3, if you’re willing to spend at least $350 in parts and add them to the old printer yourself (which is a hassle and costs more if you don’t already own an Ender 3).

- Creality Ender 3 S1 Pro (Black) at Walmart for $469

Specifications: Ender 3 S1 Pro

Swipe to scroll horizontally

| Machine Footprint | 6490 x 455 x 625 mm (19.2 x 18 x 24.5 inches) |

| Build Volume | 220 x 220 x 270 mm (8.5 x 8.5 x 10.5 inches) |

| Material | PLA/PETG/TPU/ABS |

| Extruder Type | Direct Drive |

| Nozzle | .4mm (Interchangeable) |

| Filament Runout Sensor | Yes |

| Bed Leveling | CR Touch |

| Connectivity | SD card, Type-C USB |

| Interface | Color Touch Screen |

Creality Ender 3 S1 Pro: Included in the box

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with everything you need to get your printer set up. You get tools to build and maintain the printer, side cutters, a metal scraper, a nozzle cleaner, a spare nozzle, an extra Z limit switch, and a full sized SD card with a USB adapter. There’s also a small sample of white PLA to print your first model.

You get tools to build and maintain the printer, side cutters, a metal scraper, a nozzle cleaner, a spare nozzle, an extra Z limit switch, and a full sized SD card with a USB adapter. There’s also a small sample of white PLA to print your first model.

The SD card has two short videos, one on assembling the printer, and another on how to level it. You also get a PDF copy of the manual, a copy of Creality Slicer 4.8.0 and models in both pre-sliced .gcode and .stl format.

(Image credit: Tom's Hardware)The Ender 3 S1 Pro is quite a bit flashier than the old Ender 3s, but only slightly different from the previous S1.

The Ender 3 S1 Pro has a modern look, with an all-in-one design, smooth metal frame and flat cables. It has Creality’s newest direct drive, the all metal Sprite, which not only improves performance, but does away with the need for a Bowden tube.

The direct drive is an all metal, dual gear unit that works beautifully. It’s a little industrial looking compared to the rest of the machine, but the lack of plastic housing serves to cut down on weight. It’s a titanium heat break allows it to heat up to a toasty 300 degrees. This allows us to print more materials, but more important, cuts down on nasty clogs from burnt PTFE tubes.

It’s a titanium heat break allows it to heat up to a toasty 300 degrees. This allows us to print more materials, but more important, cuts down on nasty clogs from burnt PTFE tubes.

The Creality Sprite extruder is shipped unmounted and attaches with a few easy to reach screws. It’s meant to be simple to remove, so you can swap it with a laser kit , purchased separately. We’ll be reviewing the laser at a later date.

(Image credit: Tom's Hardware)I’m still not loving the awkward front-mounted parts cooling fan, which makes it hard to watch your first layer go down. The machine also comes with a run out sensor mounted near the spool holder and power loss recovery.

Like the S1, the Ender 3 S1 Pro has a CR Touch for auto bed leveling, but kept the bed’s flexible springs and knobs. Should the CR Touch fail completely, or you just hate easy bed leveling, Creality included a Z limit switch you could add to convert it back to manual.

A final intriguing addition is a dual Z axis upgrade, something normally reserved for larger printers. The two lead screws are kept in sync with a belt for added security. The extra Z axis ensures smoother prints by giving the X gantry more support.

The two lead screws are kept in sync with a belt for added security. The extra Z axis ensures smoother prints by giving the X gantry more support.

I was most excited to see my favorite upgrade – a PEI coated steel flex plate. The PC coated plate on the S1 was both too sticky and too floppy, and damaged a few vase mode prints.

(Image credit: Tom's Hardware)If you’ve used any Creality machine in the past, the new touch screen will throw you for a loop. The layout is completely different from all the old versions with a complex text menu that, honestly, doesn’t make a lot of sense in places. For example, the automatic preheat buttons are hidden under “manual” and bed leveling is stashed under settings.

(Image credit: Tom's Hardware)Assembling the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Creality Ender 3 S1 Pro is mostly pre-assembled and comes together with a handful of neatly labeled bolts and screws. Creality learned from the S1 and made the paper manual much larger. If you find video easier to follow, you can watch a good assembly video on the included SD card.

If you find video easier to follow, you can watch a good assembly video on the included SD card.

I installed the gantry first. It fits into slots on the base unit and is held in place with 2 screws and 2 bolts on each side. Then I fitted the hotend assembly onto the X gantry with four screws. The control screen bolts to the side with 3 screws and the spool holder snaps into place on the top.

Wiring is very simple as everything is already attached to the frame and only needs to be plugged in.

Last, flip the power supply switch to match your main household electric, which is 115V in the U.S. Creality placed a giant sticker to make sure you don’t overlook the hidden switch.

(Image credit: Tom's Hardware)Leveling the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with a CR Touch installed, Creality’s version of the popular BL Touch. It physically taps the build surface with a metal probe and works with both metal or glass surfaces.

To level the printer for the first time, select Level from the settings menu. Click Start and the printer will immediately go into its leveling routine without preheating and tap 16 points around the bed.

(Image credit: Tom's Hardware)Now go back to the previous menu and click “Auto Level” to set the Z offset by sliding a piece of paper under the nozzle. Move the Z offset up or down until the nozzle just scrapes the paper. The printer I tested did not need to adjust the Z, it was perfect the first time.

If the CR Touch is unable to level the bed, you will need to do a manual level. Directions for this are in the manual.

Loading Filament on the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Creality Ender 3 S1 Pro is the first Ender to include a filament loading routine in the control panel. This is located under Ready → In/Out. Click the nozzle icon, enter a number of millimeters you’d like to advance. 20 is a good place to start. If the nozzle is not hot, the Ender 3 S1 Pro will automatically warm up to 200 degrees, then advance the filament.

If the nozzle is not hot, the Ender 3 S1 Pro will automatically warm up to 200 degrees, then advance the filament.

To unload material, just reverse the process.

Preparing Files / Software for Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with a copy of Creality Slicer 4.8.0, which is simply an older version of Cura with Creality branding and every printer its ever made pre-loaded. PrusaSlicer is another popular alternative that’s also free and some consider easier to use.

The latest version of Cura (5.0) doesn’t have a profile for the Ender 3 S1 Pro, but you can use the profile for the Ender 3 Pro and adjust the build height to 270. PrusaSlicer has a profile for the Ender 3 S1, which has the same build size.

Printing on the Creality Ender 3 S1 Pro

The Creality Ender 3 S1 Pro printed wonderfully right out of the box. My first print was a pre-sliced Cat from the SD card – which was also the test print supplied with the S1. I turned out exactly the same, including the same little stray bit of filament on the mouth. This is printed using the sample filament.

I turned out exactly the same, including the same little stray bit of filament on the mouth. This is printed using the sample filament.

I like to test bed adhesion with a print in place model, like a flexi toy. This dolphin from Flexi Factory fit the bill and printed very cleanly. I did a manual color swap just to use up some final scraps of PLA. This is printed in Inland Turquoise PLA and Matterhackers Pro Series Blue PLA. This took 3 hours and 55 minutes at a .2mm layer height and 60mms speed.

Model by Flexi Factory (Image credit: Tom's Hardware)I wanted to test TPU in an interesting way, so I ran this really cool coaster set from Trilobyte3D. It won a contest on Printables.com for, you guessed it, coasters! This is a three part print, with the leaves printed in TPU laying flat, then the stem and pot printing separately without supports. The leaves are made from Matterhackers Translucent Green TPU and come off the stem to place under your drink. The stem is Emerald City Green Silk from Polyalchemy Elixir and the pot is Protopasta Recycled PLA in Still Colorful 11. Everything was printed individually at a standard .2mm layer height, and the whole project took 19 hours and 45 minutes of printing time.

The stem is Emerald City Green Silk from Polyalchemy Elixir and the pot is Protopasta Recycled PLA in Still Colorful 11. Everything was printed individually at a standard .2mm layer height, and the whole project took 19 hours and 45 minutes of printing time.

I’ve been looking for practical prints, and found it with this credit card cutlery model from jq910. I used Keene Village Edge Glow Glass PETG. It’s only a nine layers thick, but still quite sturdy. This printed in 36 minutes with a .2mm layer height and 60 mms speed.

Model by jq910 (Image credit: Tom's Hardware)To see just how big I can print with an Ender 3 S1 Pro, I took this Twisted Cloud Vase by PressPrint and expanded it 200% until it filled the bed. Then I ran it in Blue/Purple Evyone Matte Dual-Color PLA . It’s a vase mode print, so it only took 7 hours and 36 minutes at a .2mm layer height and 60 mms speed.

Model by PressPrint (Image credit: Tom's Hardware)The Ender 3 S1 Pro is a fantastic printer and a refreshing change of pace from its bare-bones beginnings. It’s easy to assemble and the CR Touch leveling system worked perfectly without a need to make any adjustments. The new PEI coated flex plate is great and all the little upgrades from light kit to all metal hotend make this printer feel like a complete consumer grade product. This isn’t a science project to stick out in the shed, it’s a real piece of hardware to sit proudly on your desk.

It’s easy to assemble and the CR Touch leveling system worked perfectly without a need to make any adjustments. The new PEI coated flex plate is great and all the little upgrades from light kit to all metal hotend make this printer feel like a complete consumer grade product. This isn’t a science project to stick out in the shed, it’s a real piece of hardware to sit proudly on your desk.

Retailing at $479, the S1 Pro has everything you need in a 3D printer, and more features than a lot of the competition. However, if you want the deluxe Ender experience and don’t need an all metal hotend, you can save a few bucks by getting the Ender 3 S1. Another feature packed printer we like is the Anycubic Kobra, priced at $319, it’s an Editor’s Choice and our pick for Best Printer for Beginners.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing.

Best Miniature 3D Printer

| Best Value | |||||||

|---|---|---|---|---|---|---|---|

| Original Prusa i3 MK3 | |||||||

4. 5/ 5.0 5/ 5.0 | |||||||

| Resolution: 50 microns | |||||||

| Connection: USB, SD card | |||||||

| Has an automatic bed leveling system. | |||||||

| Best Choice |

|---|

| Anycubic Photon |

| 4.6/5.0 |

| Resolution : 25 microns |

| Connectivity: USB |

| Relatively easy to use and maintain. |

Contents

- Introduction to 3D Printers for Miniatures

- Miniature 3D Printer Comparison Chart

- 1. Best Choice: Anycubic Photon

- 2. Best Budget: Monoprice Maker Select v2

- 3. Best Price: Original Prusa i3 MK3

- 4. Wanhao Du5plicator 7 v1.

- 5. FlashForge Creator Pro

- High Quality Miniatures 3D Printers

Introduction to Miniatures 3D Printers

When it comes to 3D printing miniatures, you should have reasonable expectations in several areas including quality and cost. It's more than just loading material into a machine and waiting for perfect-image miniatures to come out of the build platform.

It's more than just loading material into a machine and waiting for perfect-image miniatures to come out of the build platform.

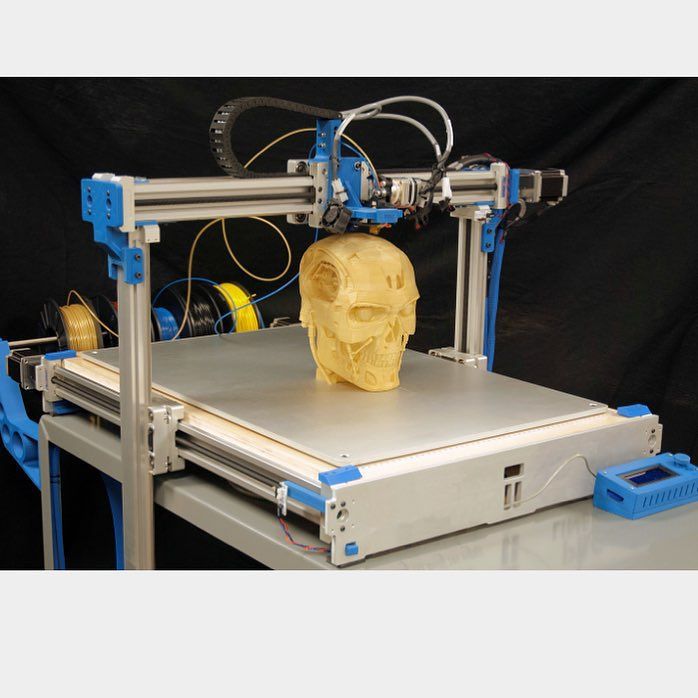

There are two types of machines you can use for miniature printing: FDM. or FFF (filament based) 3D printers and SLA (resin based) 3D printers. Both have a number of advantages and disadvantages that must be taken into account..

The FDM 3D printer uses a hot end extruder to melt the filament and apply it to the build platform, creating a 3D model one layer at a time. . It is easy to use, has a larger maximum build volume, and lower running costs than an SLA 3D printer. Also, the post-print process isn't as messy as it is on a resin 3D printer, though small models can be tricky to handle. On the other hand, a filament 3D printer is a few notches below a resin 3D printer when it comes to resolution and overall print quality, so don't expect your homemade miniatures to be on the same level as store-bought miniatures.

Some FDM 3D printers are very capable of high resolution printing like the Ultimaker 3 and Original Prusa i3 MK3, but in general an FDM 3D printer with many upgrades will still be below the SLA of a 3D printer in the same price range. The good news is that the FDM 3D printer is great for landscapes, houses, castles, and other large miniatures due to its wider print area. The dual extruder machine is also great for more complex objects with protrusions that require a significant amount of support materials.

The good news is that the FDM 3D printer is great for landscapes, houses, castles, and other large miniatures due to its wider print area. The dual extruder machine is also great for more complex objects with protrusions that require a significant amount of support materials.

SLA 3D printer, on the other hand, uses a process in which a liquid photopolymer resin is placed in a vat and exposed to a light source such as a laser or digital light processing (DLP), which causes it to solidify and form a solid object with one layer for a while. This process is more dangerous than the FDM process and requires protective equipment.

In terms of pros and cons, a resin 3D printer is the opposite of a filament 3D printer. It is more difficult to use and maintain, has a limited printable area, and is more expensive to run. It also costs more, although there are some good options on the market for under $1,000 now. On the other hand, a resin 3D printer works with outstanding precision and precision, producing extremely high-resolution miniatures that are almost store-bought. Also, it doesn't take much effort to get the best results with a resin 3D printer, unlike a filament 3D printer.

Also, it doesn't take much effort to get the best results with a resin 3D printer, unlike a filament 3D printer.

So what's best for miniatures? Well, it depends on your preferences. If resolution or print quality is more important to you, get an SLA 3D printer. If print size and running costs are more important to you, choose an FDM 3D printer. A filament-based 3D printer is also more ideal for those who want to print more than just miniatures..

miniature 3D printer comparison chart

| Make and Model | Rating | Approval | Assembly volume | Thread diameter | Material type | ||

|---|---|---|---|---|---|---|---|

| Anycubic Photon | 4.6 | 25 micron | 4.5" x 2.6" x 6.1" | NA | Resin | 14.6 lbs | USB |

| Monoprice Maker Select v2 | 4. 1 1 | 100 micron | 7.9 x 7.9 x 7.1 in. | 1.75 mm | ABS, PLA, TPU and others | 20 pounds | USB, SD card |

| Original Prusa i3 MK3 | 4.5 | 50 micron | 9.8 x 8.3 x 8.3 in. | 1.75 mm | ABS, PLA, PETG and others | 14 pounds | USB, SD card |

| Wanhao Duplicator 7 v1.5 | 4.4 | 35 micron | 4.7" x 2.7" x 7.9" | NA | Resin | 26.5 lbs | USB |

| FlashForge Creator Pro | 4.1 | 100 micron | 8.9 x 5.8 x 5.9 in. | 1.75 mm | ABS, PLA, PVA and others | 32.7 lbs | USB, SD card |

1. Best choice: Anycubic Photon

Editor's Rating: 4.6/5

The Anycubic Photon is a resin based 3D printer capable of printing miniatures with stunning quality. It is more detailed than the Wanhao Duplicator 7 v1.5 which is also in the same price range. It has a maximum layer resolution of 25 microns, which is the highest of any product shown here.

It is more detailed than the Wanhao Duplicator 7 v1.5 which is also in the same price range. It has a maximum layer resolution of 25 microns, which is the highest of any product shown here.

Although the Photon is often referred to as a DLP SLA 3D printer, the Photon is actually an LCD SLA 3D printer with a UV LED light source. It prints the object from top to bottom, which is the opposite of the bottom to top process on an FDM 3D printer. But even though the Photon is not a true SLA machine, it can still create extremely detailed and smooth miniatures, including complex ones.

The Photon comes pre-assembled and is easy to install out of the box. It has a well-designed bezel with a touch screen that allows you to preview the object you are about to print. It comes with a handy slicer and has a simple layer leveling process.

If you want to create intricate and extremely detailed miniatures, pick up Photon and don't look back. This is the best 3D printer for the job. Aside from the running costs and the usual post-press and finishing issues that resin 3D printers face, the Photon's only downside is its limited build volume.

Aside from the running costs and the usual post-press and finishing issues that resin 3D printers face, the Photon's only downside is its limited build volume.

| Specifications |

|---|

| Resolution: 25 micron |

| Volume: 4.5 x 2.6 x 6.1 in. |

| Thread: NA |

| Type: resin |

| Weight: 14.6 lbs |

| Connection: USB |

| Pro |

|---|

| Extremely detailed print quality |

| Fully assembled |

| Relatively easy to use and maintain |

| Easy initial setup |

| Intuitive touch screen interface |

| Offline printing |

| Cons |

|---|

| Fine print |

| Expensive material |

2.

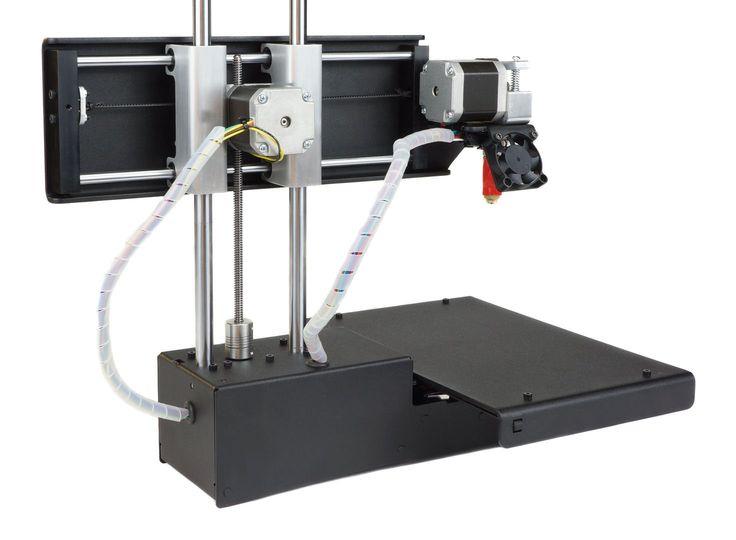

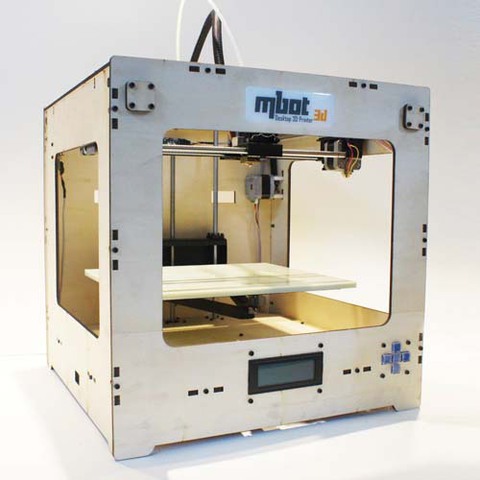

Best Budget: Monoprice Maker Select v2

Best Budget: Monoprice Maker Select v2 Editor's Rating: 4.1/5

If you can't afford to spend more than $400, the first thing you should look at is Monoprice, known for its budget 3D printers . The company offers the Maker Select v2, Select Mini v2, and Mini Delta, all of which are under $400, with the latter two selling for $200 or less. Of the three, Maker Select v2 offers the most value.

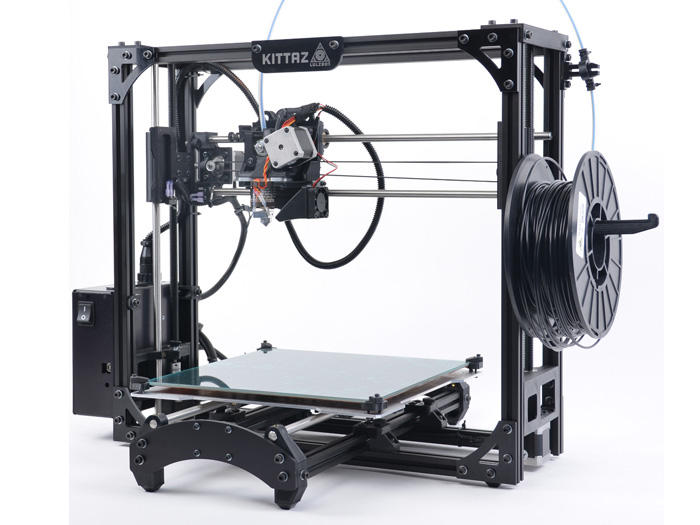

FDM Maker Select v2 open 3D printer based on Prusa i3 design. It has a solid aluminum frame and a separate control box. It features a heated print bed, has an open material system, and has a medium build volume. For connectivity, it can connect via USB and print offline via SD card.

Maker Select v2 offers an easy initial setup right out of the box. This is a partially assembled 3D printer, which means you don't have to build it from scratch like you would with a DIY kit. Just fasten the frames in place and you're done. Monoprice includes sample 3D models and free filament in the box, allowing you to start printing as soon as the initial set up is clear.

While the initial setup is simple, Maker Select v2 is far from optimized in its default form. Some upgrades are needed from the get-go, both for security and performance, and at the top of the list is the MOSFET mod. The good news is that Maker Select v2 has a large community, so you can easily get a short list of required device updates.

When it comes to print quality, Maker Select v2 is your best bet. not bad for a filament-based 3D printer. It handles large miniatures well, but struggles with small 28mm miniatures. Boosting it with a fair amount of upgrades is a good way to improve the results. But even after that, don't expect too much from it when it comes to printing small and detailed board game miniatures.

All in all, the Maker Select v2 is a solid budget miniature 3D printer. . Once set up, it's easy to use, comes with a large community, and has a heated print platform that allows you to print with ABS.

| Specifications |

|---|

| Resolution: 100 micron |

Volume: 7. 9 x 7.9 x 7.1 in. 9 x 7.9 x 7.1 in. |

| Filament: 1.75 mm |

| Type: ABS, PLA, TPU and others |

| Weight: 20 lb |

| Connection: USB, SD card |

| Profi |

|---|

| Easy to set up |

| Large Community |

| Lots of after sales support |

| Decent print quality |

| Good p bead size |

| Heavy duty frame with heated bed |

| Cons |

|---|

| Small miniature fight |

| Box mods required |

| Manual bed leveling process |

3. Best price: original Prusa i3 MK3

Look at Prusa

Editor's rating: 4. 5/5

5/5

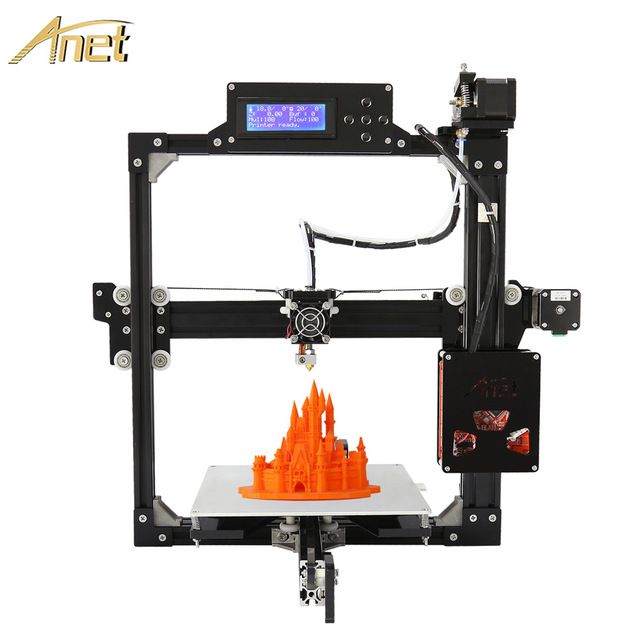

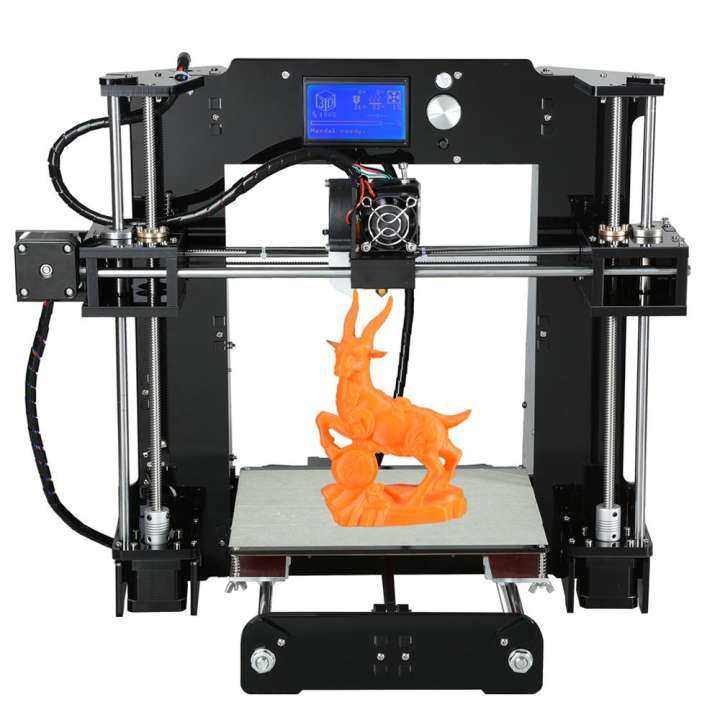

When it comes to user experience, the Original Prusa i3 MK3 is the best on this list. It is a smart FDM 3D printer equipped with user-friendly features, the most notable of which is the automatic bed leveling technology, which is a godsend for beginners.

An easy-to-assemble MK3 kit sells for about $750, while a fully assembled and factory tested MK3 kit costs about $1,000. It ships from the Czech Republic and takes a while, so don't expect it to arrive at your doorstep just a few days after your order has been processed. However, it's worth the wait given the overall quality of the product.

MK3 is an open source 3D printer with open structure. This is a medium-sized machine designed for both professionals and amateurs. It has a rigid frame with a spool holder on top and a built-in LCD controller as well as a removable heated magnetic bed. It has a more stable frame than its predecessor and boasts a new motherboard that keeps noise low and detects misaligned layers.

In addition to auto leveling system and magnetic print bed, MK3 has filament sensor and panic function and can detect extruder jam. In case of extruder jam, the machine will pause printing and move the print head away from the 3D model. All these handy features make 3D printing easy for everyone, especially beginners. The

MK3 is the best high resolution 3D printer you can get for $1,000 or less. With the right settings and the right nozzle size, it can print exceptionally detailed and clean miniatures. It prints large models with ease and has a decent print speed even at high resolutions. While not on the same level as the Anycubic Photon, the MK3 is far ahead of the Monoprice Maker Select v2 in terms of print quality. It's also a more versatile machine, able to print in a variety of materials right out of the box.

In terms of overall cost, the MK3 is a step above the Photon, mainly because you can also use it for other things outside of miniature printing, thanks to the versatility of the material and build volume. If you're looking for a reliable, high-resolution 3D printer that gets the job done and is loaded with user-friendly features, look no further than the MK3. If the price is too high for you, the Original Prusa i3 MK2S is also a great choice. The MK2S has the same print quality and reliability, but with fewer convenience features.

If you're looking for a reliable, high-resolution 3D printer that gets the job done and is loaded with user-friendly features, look no further than the MK3. If the price is too high for you, the Original Prusa i3 MK2S is also a great choice. The MK2S has the same print quality and reliability, but with fewer convenience features.

| Specifications |

|---|

| Solution: 50 micron |

| Volume: 9.8 x 8.3 x 8.3 in. |

| Thread: 1.75 mm |

| Type: ABS, PLA , PETG and others |

| Weight: 14 lbs |

| Connection: USB, SD card |

| Pro |

|---|

| Excellent print quality |

| Automatic Bed Leveling System |

| Removable magnetic build platform |

| Thread sensor |

| Power panic |

| Low noise |

| Large Community |

| Cons |

|---|

| Filament sensor has problems with translucent materials |

| Without housing |

4.

Wanhao Duplicator 7 v1.5

Wanhao Duplicator 7 v1.5 Editor Rating: 4.4/5

Wanhao is one of the most popular 3D printer brands. offering a wide range of products, most of which are based on fibers. The Chinese brand entered the SLA market with the Duplicator 7, a desktop 3D printer designed for those who prefer layer resolution.

Duplicator 7 is similar to Anycubic Photon, our top pick, also from a Chinese company. This is an SLA 3D printer with LCD screen and LED UV light source. The most noticeable difference between the two models is that the Duplicator 7 offers a larger print size. In addition, the Duplicator 7 also has a slightly lower resolution (35 microns) compared to the Photon (25 microns). But when it comes to overall print quality, the Duplicator 7 is still better than the FDM 3D printer.

Version 1.5 of the Duplicator 7 has a number of improvements, including an improved cooling system. , extra vents for better airflow, improved platform and more stable frame. The power button has also been moved to the back of the device.

The power button has also been moved to the back of the device.

If you like Photon but want more build volume, Duplicator 7 is for you. This is a robust miniature 3D printer that will amaze you with its ability to print extremely detailed 3D models. It's relatively easy to use, has a large community, and includes a resin sample so you can start printing as soon as you set it up.

| Specifications |

|---|

| Resolution: 35 micron |

| Volume: 4.7 x 2.7 x 7.9 in. |

| Filament: NA |

| Type: resin |

| Weight: 26.5 lbs |

| Connection: USB |

| Profi |

|---|

| Extremely detailed print quality |

| Large user base |

| Heavy duty frame |

| Low price for SLA |

| Open material l system |

| Larger print size than Anycubic Photon |

| Cons |

|---|

| Expensive material |

| limited assembly volume |

| Unreliable customer support |

5.

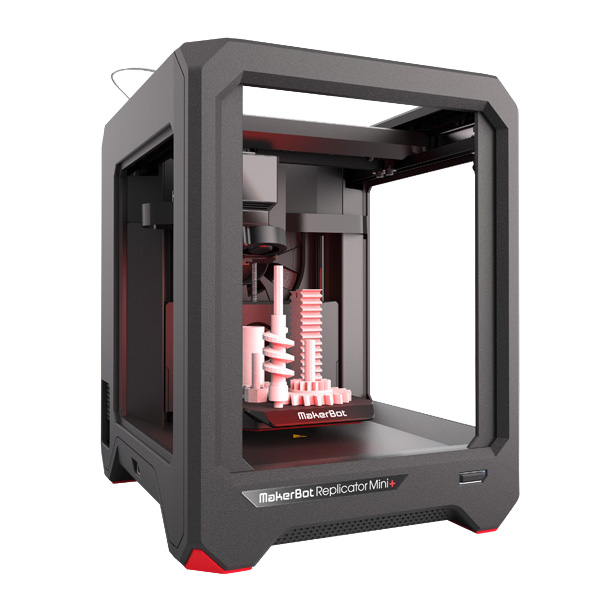

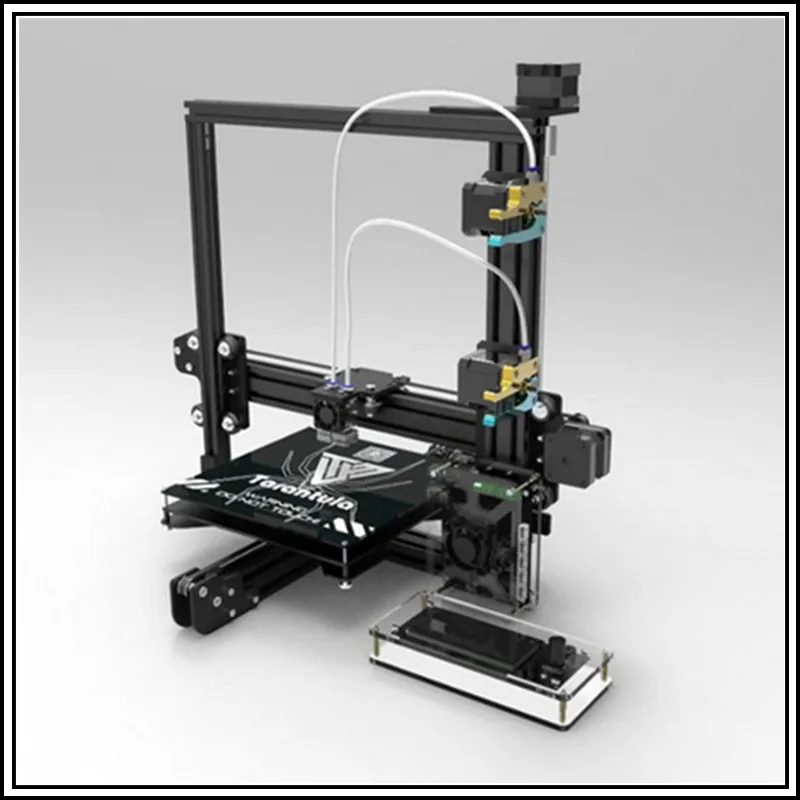

FlashForge Creator Pro

FlashForge Creator Pro Editor's Rating: 4.1/5

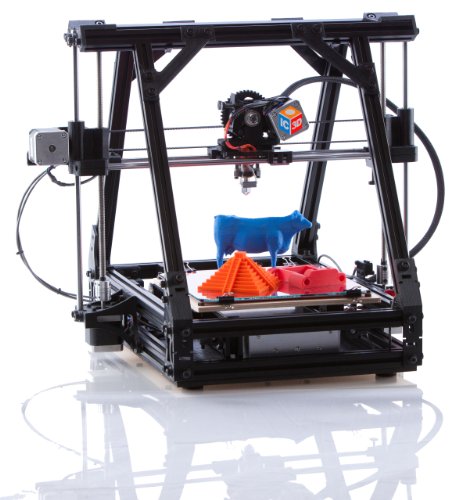

As a dual extruder 3D printer, FlashForge Creator Pro is the most different among the FDM 3D printers included in this guide. It adds new ways to print with fibers, including the ability to print in two colors without having to pause printing to change media.

The Creator Pro is an enclosed 3D printer with a solid metal frame making it stronger and more stable than most open frame 3D printers. It has a heated print bed, a pair of rear-mounted external spool holders, and an LCD controller for offline printing via SD card. The acrylic covers are removable for easy machine maintenance.

Because the Creator Pro comes pre-assembled, initial setup is an easy process, even though the instruction manual isn't the most helpful. It's ready and prints in just a couple of hours, but don't expect to see stellar results with stock settings. Creator Pro requires significant effort to reach its true potential. It is recommended to pair it with Simplify3D to make everything much smoother.

It is recommended to pair it with Simplify3D to make everything much smoother.

Once set up, Creator Pro becomes an absolute workhorse that can print non-stop for days with minimal maintenance. and with a low failure rate. It has good print quality for a filament based 3D printer and can print with both PLA and ABS without any issues. The real highlight here is its ability to print with water-soluble auxiliaries, which allows it to handle more complex miniatures with lots of protruding detail, such as a humanoid model in a complex pose.

Creator Pro can also print on a variety of materials, including more complex materials such as TPU. A full body helps maintain a more stable temperature in the print area, which is critical for certain materials. In addition, Creator Pro can use filament from other manufacturers, although you may need to create your own external spool holders as the standard ones are designed for FlashForge spools.

Overall, the Creator Pro is just as reliable as the Original Prusa i3 MK3, but not on the same level when it comes to print quality. The list of convenient features is also not as long as Monoprice Maker Select v2. On the other hand, it has a dual extruder setup and a closed frame, both of which have their own advantages.

The list of convenient features is also not as long as Monoprice Maker Select v2. On the other hand, it has a dual extruder setup and a closed frame, both of which have their own advantages.

| Specifications |

|---|

| Resolution: 100 micron |

| Volume: 8.9 x 5.8 x 5.9 in. |

| Thread: 1.75 mm |

| Type : ABS, PLA, PVA and others |

| Weight: 32.7 lbs |

| Connection: USB, SD card |

| Pros |

|---|

| Closed metal frame |

| Twin extruder setting |

| Good print quality |

| Large Community |

| Excellent after-sales support |

| Third party threads can be used |

| Cons |

|---|

| FlashForge Limited Software |

| Manual bed leveling |

| Instruction manual needs improvement |

High quality miniature 3D printers

Increasing the budget to over $1,000 opens the door to more products, from popular workhorse 3D printers to 3D printers built specifically for professional use. Here are some of the best products you can check out if you can afford to shell out more than a hefty sum for a miniature 3D printer:

Here are some of the best products you can check out if you can afford to shell out more than a hefty sum for a miniature 3D printer:

FDM: High With high print resolution and outstanding reliability, you can choose between the Ultimaker 2+, which retails for around $2,500, or the newer Ultimaker 3, which retails for around $3,500. The former has one extruder and SD card connectivity, while the latter has two extruders and Wi-Fi and USB connectivity. In terms of print quality, both machines are on par.

SLA: If you can afford to spend $3000-$4000, this is the best non-industrial resin. The Formlabs Form 2 3D printer is currently on the market. It is relatively easy to use and maintain and, as expected from a resin based 3D printer, produces exceptional 3D models. On the other hand, the Peopoly Moai, which sells in a kit for around $1,300, is one of the most affordable SLA 3D printers on the market. Although the Moai is not as easy to use as the Form 2, the Moai is also a reliable device that delivers outstanding results.

Contents

- Introduction to Miniature 3D Printers

- Miniature 3D Printer Comparison Chart

- 1. Best Choice: Anycubic Photon

- 2. Best Budget: Monoprice Maker Select v2

- 3. Best price: Original Prusa i3 MK3

- 4. Wanhao Duplicator 7 v1.5

- 5. FlashForge Creator Pro

- High quality miniature 3D printers

Attention! Never leave 3D printers unattended. They can pose a fire safety hazard.

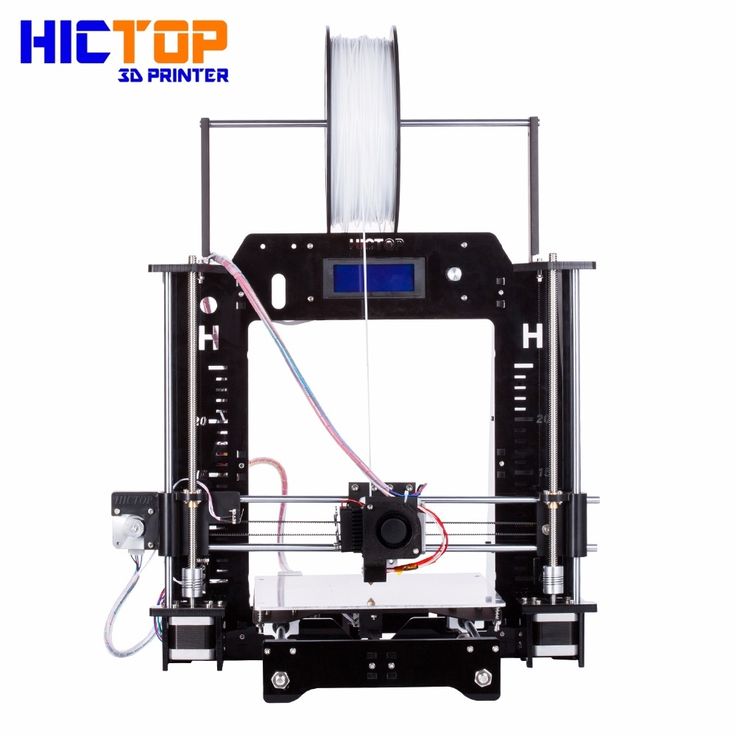

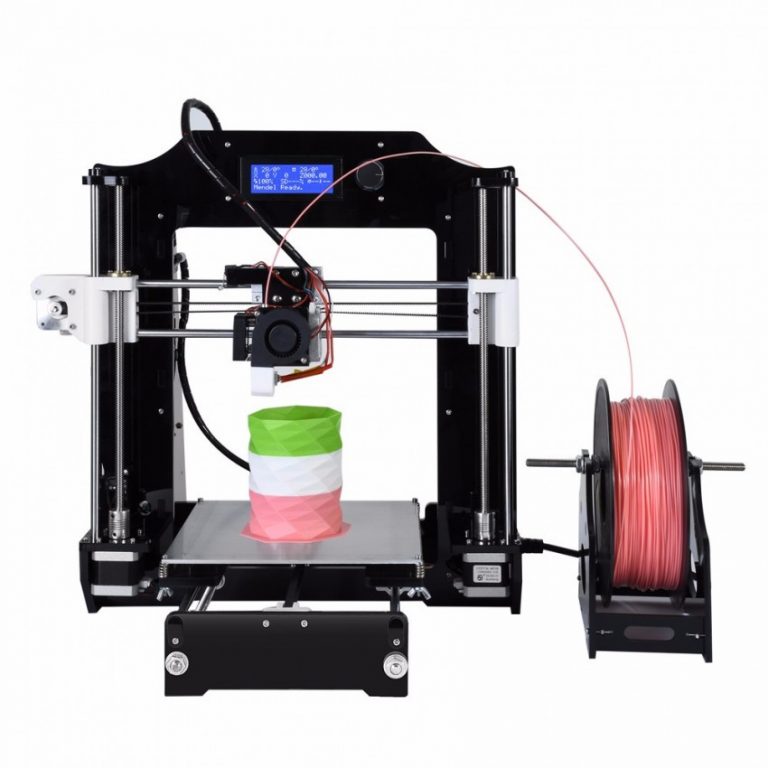

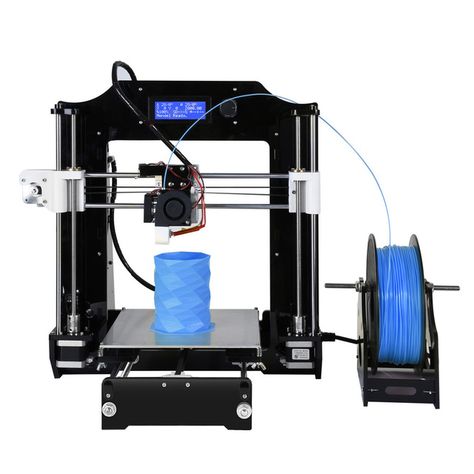

Best 3D printers for $99–$199

Reviews

The best 3D printers for beginners and for a quick start in 3D printing. Gearbest offers some great budget 3D printer options.

Attention! Special offers for 3dtoday portal appeared in the Gearbest store - Best 3D printers for $99–$199 and more.

Link to the promotion page.

Europe's most popular mini printer, the Easythreed NANO Mini, participates in this promotion.

This is a small orange cube available for a modest $99.

This is the fastest and cheapest start in 3D printing today.

Configured in a special Easythreed slicer application, printing is done offline from a microSD card.

The current price is the lowest. You get an assembled and configured desktop printer that will serve as a great start in 3D printing, as well as be safe and convenient for a child / schoolchild / student.

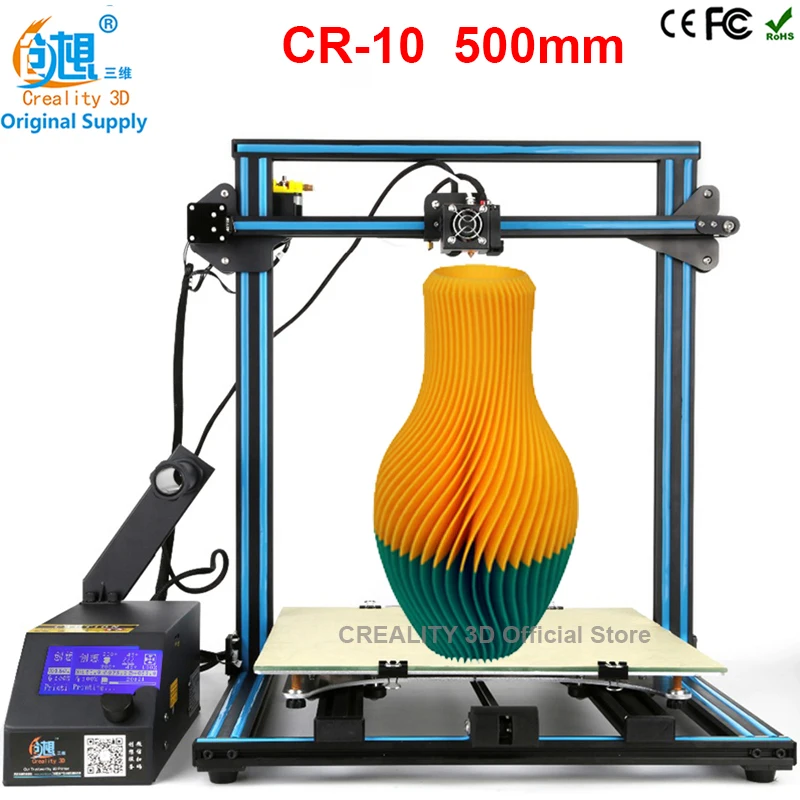

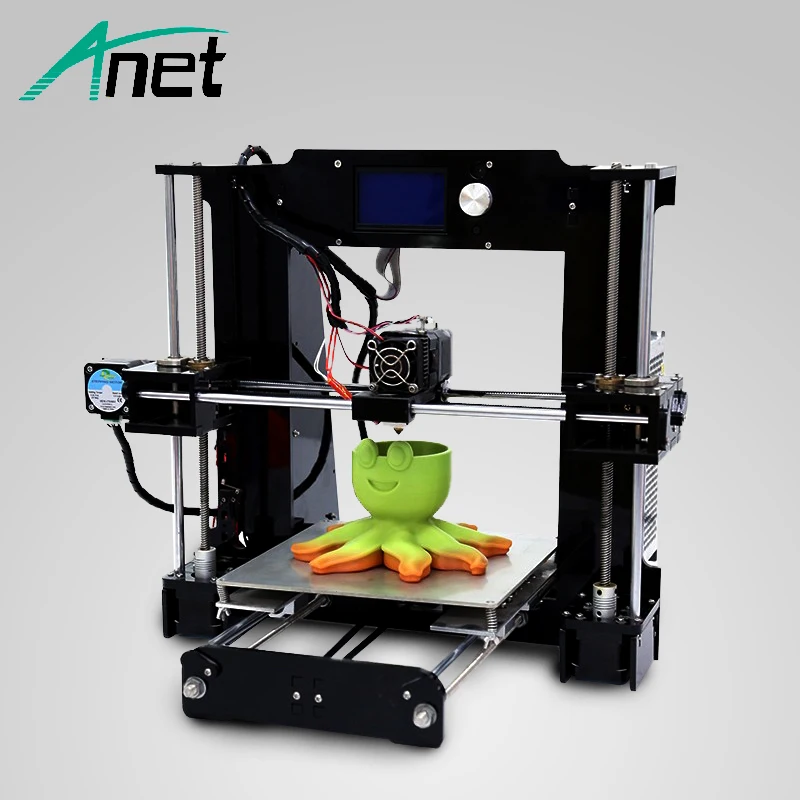

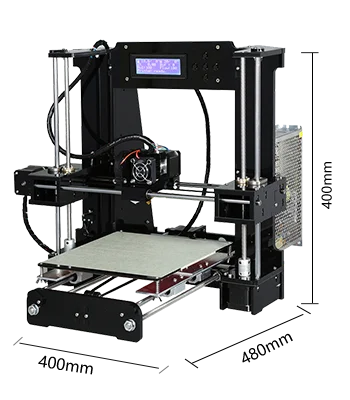

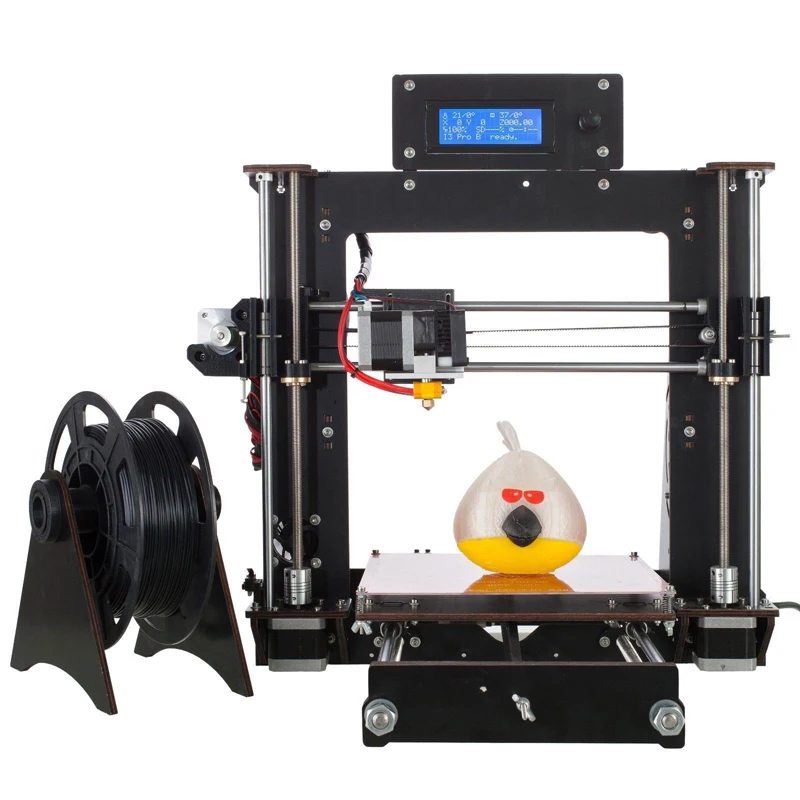

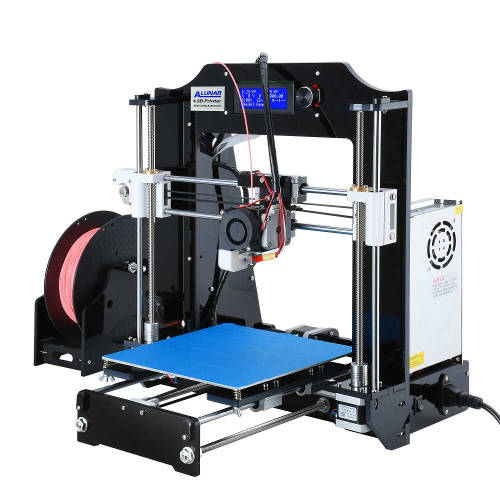

For example, on the promotion page you can find a lot of the updated JGAURORA Magic - a decent profile layout (FDM) all-metal printer for a modest $209.

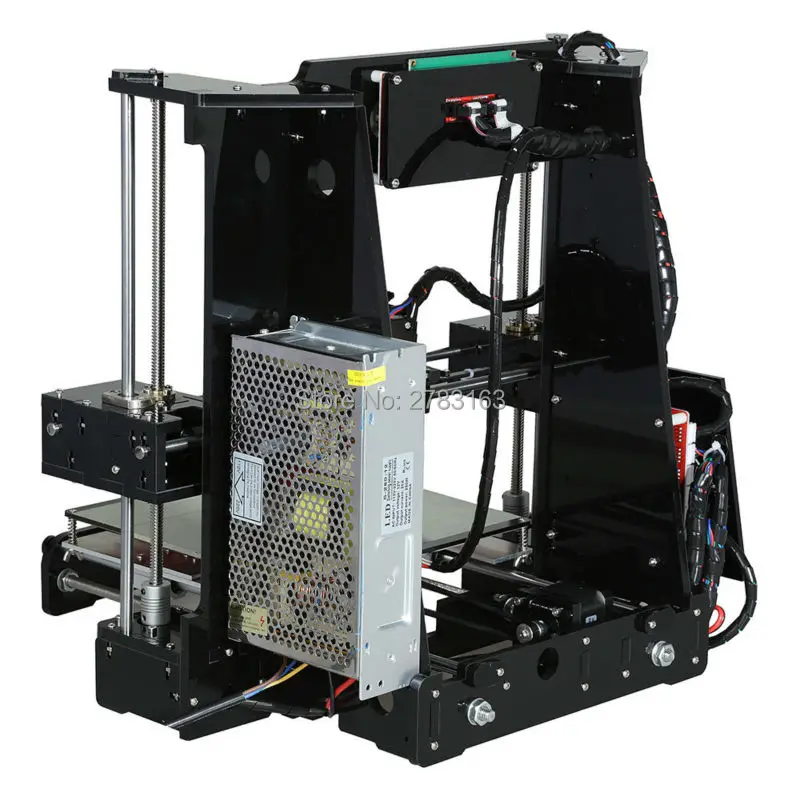

Has a full metal frame and carriages, electronics hidden in the housing, powerful (up to 110°C) print table, adhesion sticker, print pause and filament sensor. The printer is already pre-assembled and configured.

Print area 220x220x250 mm, nozzle 0.4 mm.

2018 Best Seller - Great 3D Printer Creality3D Ender-3 Has everything the previous one plus a little more! Print area 220x220x250 mm. The printer is thought out to the smallest detail, many 'sores' of such models have already been eliminated. The aluminum frame provides the maximum rigidity during the work.

The printer is thought out to the smallest detail, many 'sores' of such models have already been eliminated. The aluminum frame provides the maximum rigidity during the work.

Excellent 3D printer with a large touch screen Alfawise U30

Print area 220x220x250 mm. The printer is pre-assembled, the final assembly takes a few minutes. Everything is set up for the first print. Included is a 2.8 'touch screen with the ability to set a print pause.

3D printer with two extruders Geeetech A10M Mix-color 3D Printer - everything you need is included. The printer is pre-assembled and set up for the first print. Print field size: 220 x 220 x 260mm.

To close this post: what 3D printer doesn't think of a milling machine?

I would like to draw your attention to the Alfawize C10 CNC3018 CNC Router - an affordable desktop CNC machine for cutting, engraving, drilling and so on.

Standard cutters (collet chuck), software free. The working field is 30x18 cm. There is a choice of configurations without a laser module, and with a 2500mW module. The mount is universal.

Alfawize C10 CNC3018 Promotion Page All listed printers are beginner-friendly. These models can be the first step for those who want to try. You can figure it out without any problems, even without having a base behind you. Printers are inexpensive and suitable for schoolchildren or students. In any case, this is an opportunity for you to open a window into the world of 3D printing.

Subscribe to the author

Subscribe

Don't want

7

More interesting articles

pl32

Loading

11/07/2022

2308

23

Subscribe to the author

Subscribe

Don't want

Good afternoon, colleagues!

I present to your attention a review of my new friend - 3D with .