Best 3d printer extruders

5 Best 3D Printer Extruders

RECENT STORIES

Introducing a New Tool to Help Power Green Procurement

December 15, 2022

5 min read

“Shark Tank” Winning Food Tech Company Pivots and Scales with Xometry’s Prototyping and Injection Molding Services

December 13, 2022

9 min read

Video: The Injection Molding Process, From Start to Finish

December 1, 2022

1 min read

Fused deposition modeling (FDM) is a method of 3D printing that uses extruders. In FDM 3D printing, an extruder feeds, melts, and deposits a thermoplastic filament in a prescribed path to build parts layer-by-layer. 3D printer extruders differ based on the placement of the “cold end” and “hot end.” The cold end is the portion of the extruder where the filament is fed into the system. The hot end is where the filament is melted and then extruded by the nozzle. In some printers, the cold and hot ends are near (direct extruder) while in other printers, the ends can be far separated (Bowden extruder).

There are many different types and brands of 3D printer extruders on the market, including the E3D Hemera, the E3D Titan, and the Bondtech BMG. With so many choices, it can be overwhelming to determine which one is best for your project. When purchasing a 3D printer extruder, consider whether print speed or print accuracy is more important for your application. The placement of the cold and hot ends will have a large impact on those two parameters. This article will review the five best 3D printer extruders on the market today.

1. E3D Hemera (Best Direct Extruder)

The E3D Hemera features a dual-drive, hardened stainless steel drive train. This provides a tremendous boost in grip strength (up to 10 kg of force) on 1.75 mm diameter filaments. This leads to a more constrained filament path since the filament has less of a tendency to bend or buckle while being fed into the hot end of the extruder. Additionally, this enables the printing of highly-flexible filaments. The Hemera costs about $124-140 and has a total weight of 388 g as a direct system (the cold and hot-ends are assembled adjacently) and 327 g as a Bowden system (cold and hot-ends are assembled separately).

2. BIQU h3

The BIQU h3 is a direct extruder that uses 1.75 mm diameter filaments, has a weight of 211 g, and has a gear ratio of 7:1. Extruder can exert up to 7.5 kg of extrusion force, depending on the filament material which enables better print accuracy. It costs $70-$100. Because the BIQU h3 sits right above the print head, the overall print head system is heavier than some of the other extruders and hence, print speeds will be slower.

3. Bondtech BMG (Lightest Extruder)

The Bondtech BMG extruder uses 1.75 mm diameter filaments and has a gear ratio of 3:1. Its gear ratio enables it to feed filaments faster and hence, print parts faster compared to the BIQU h3. Additionally, it has an astounding light weight of only 75 g. It can be used either as a direct or Bowden extruder with a suitable adaptor. Coming in at $80-$100, the Bondtech BMG’s dual drive allows for uninterrupted filament feeding. While Bondtech BMG excels at being able to print parts fast due to its lightweight, its dual drive also enables great print accuracy.

4. Micro Swiss Direct Drive Extruder

The Micro Swiss Direct Drive Extruder is a direct-drive extruder. These types of extruders are different from direct extruders in that a toothed gear to feed filaments is directly mounted onto the driveshaft of a stepper motor. What constitutes a direct extruder typically relates to the placement of the cold and hot ends. This particular extruder costs about $100 and uses 1.75 mm diameter filaments. It requires no modifications to existing 3D-printer systems and can simply be plugged in to be used. Being both a direct and a direct drive, Micro Swiss exerts great grip force on filaments - enabling both fast and accurate prints.

5. E3D Titan (Best Geared Extruder)

The E3D Titan is a geared extruder with a 3:1 gear ratio. Geared extruders use a transmission ratio that reduces the rotational speed of the gears that feed the filament. This results in a steady and more powerful flow of print material as opposed to direct-drive extruders like the Micro Swiss that allow fast material flow but can’t control the consistency of the flow. The Titan can be used with 1.75 mm or 2.85 mm diameter filaments. At about $35-54, this is one of the cheapest and most effective extruders on the market today.

The Titan can be used with 1.75 mm or 2.85 mm diameter filaments. At about $35-54, this is one of the cheapest and most effective extruders on the market today.

What is 3D Printer Extruder?

A 3D printer extruder is the assembly of parts that feeds and processes filaments for printing. A 3D printer extruder has two main sections: the hot end and the cold end. The cold end of the extruder is where filaments are fed from a spool into the system. A sufficient amount of force must be exerted by the extruder’s gears onto the filament to ensure rigidity in the filament during printing. The hot end of the extruder is where the filaments are melted. In passing from the cold end into the hot end, the filament is fed through a “heat break” (a tube that allows filaments to flow freely into the nozzle) and is encapsulated by the “heat block” where it first encounters heightened temperatures. As the filament passes through the heat break and melts, it is finally extruded out of the nozzle to build parts.

For more information, see our 3D printing guide.

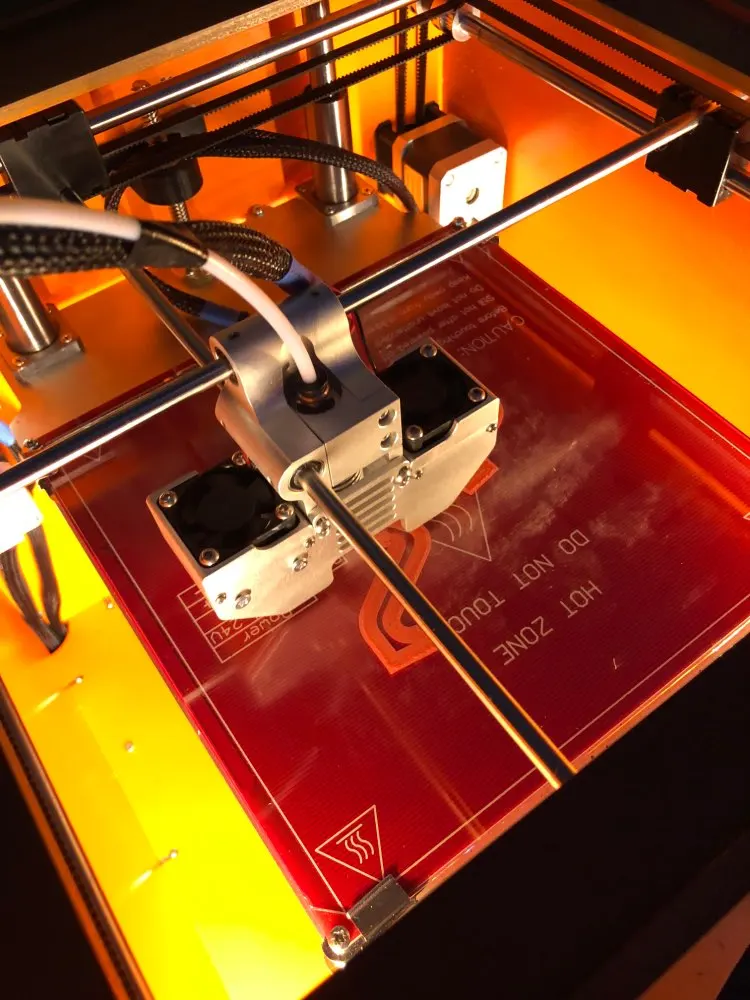

Where is the Extruder on a 3D Printer?

The location of the extruder on a 3D printer depends on the type of extruder: direct or Bowden. In direct extruders, the cold and hot ends are immediately adjacent to each other, and the cold end is mounted on top of the hot end. The cold and hot ends are located directly on top of the print head. In Bowden extruders, there is a noticeable distance between the cold and hot ends. The type of extruder has a large impact on the print accuracy and print speed of a job. Direct extruders are generally more accurate, but slower at printing while Bowden extruders are faster at printing but less accurate.

For more information, see our guide on 3D Printer Parts.

How to Select the Best 3D Printer Extruder

Below is a list of steps you can take to select the best 3D printer extruder for your project:

- Consider whether print speed or print accuracy is more important for your project.

- Determine what type of material will be used for your parts (some extruders are only compatible with certain materials and certain sizes of filaments).

- Consider the size of your part and pick an appropriate extruder (Bowden extruders are better for smaller parts).

- Determine your budget for a 3D printer extruder (direct extruders are typically more expensive).

- Choose a 3D printer extruder that is both easy to use and compatible with your 3D printer.

What are the Types of 3D Printer Extruder?

Table 1 below shows an overview of the two types of 3D printer extruders:

Table 1: Two Types of 3D Printer Extruders

| Extruder Type | Description | Feature |

|---|---|---|

Extruder Type Direct Extruder | Description Hot and cold ends are assembled together and mounted onto the print head. | Feature

|

Extruder Type Bowden Extruder | Description Separate hot and cold ends are connected by a PTFE tube through which the filament is fed. | Feature

|

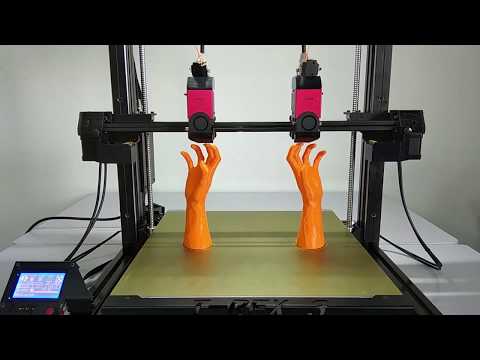

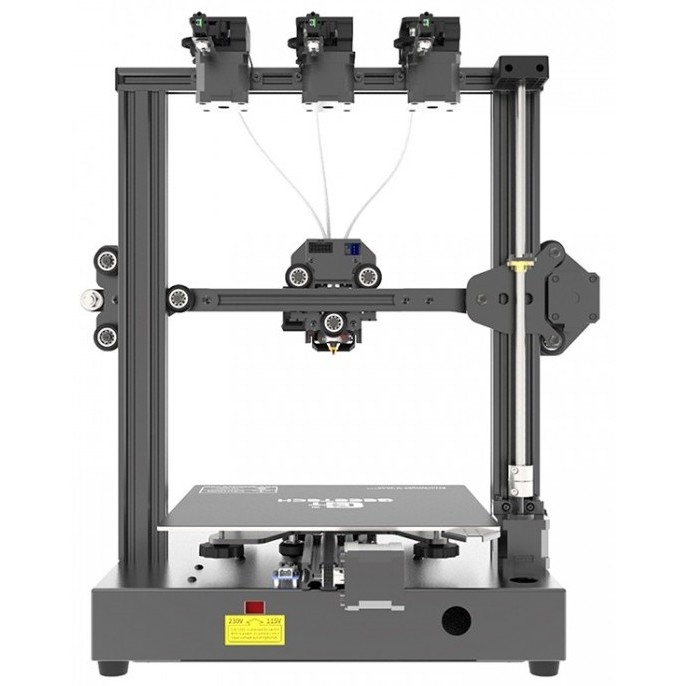

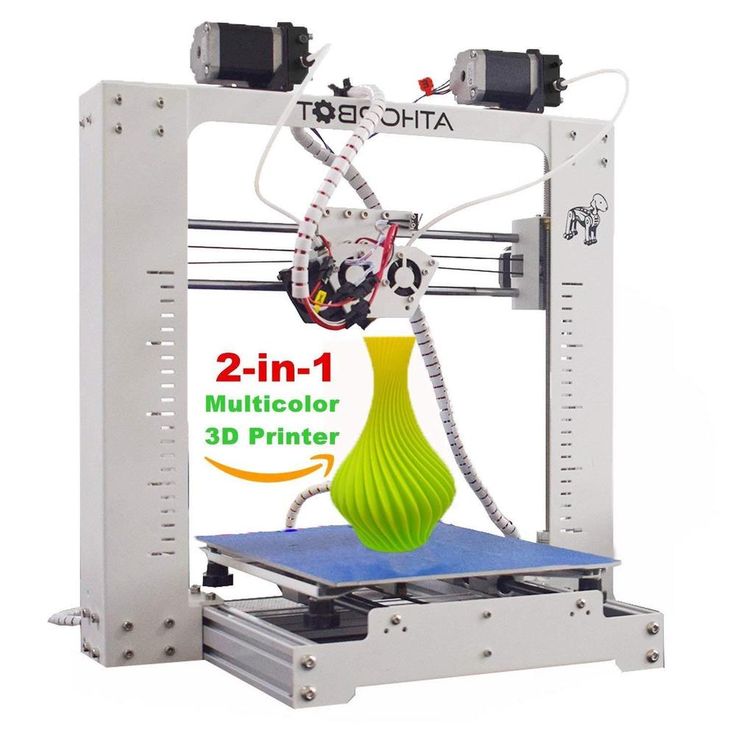

How Many Extruders Can a 3D Printer Have?

While most 3D printers only have a single extruder, there are several dual-extruder and even triple-extruder 3D printers on the market. Additional extruders enable both quicker print times and printing in multiple colors. Multiple extruders (dual, triple, or more) allow automatic switching between filaments. Depending on the system, these multiple extruders can even mix filaments together to create unique colors.

What is the Lifespan of a 3D Printer Extruder?

The lifespan of a 3D printer extruder depends on the filament material used, the frequency of usage, and the quality of the nozzle. Generally, 3D printer extruders can last anywhere between 3-6 months. To ensure maximum life, refer to the extruder’s user manual for proper cleaning and maintenance instructions.

Generally, 3D printer extruders can last anywhere between 3-6 months. To ensure maximum life, refer to the extruder’s user manual for proper cleaning and maintenance instructions.

What is the Difference Between Direct and Bowden Extruders?

The difference between direct and Bowden extruders is the placement of the cold and hot ends of the system. In direct extruders, the cold and hot ends are right next to each other. This minimizes the distance between the pinch point of the filament (where it meets the gears of the extruder) and the heated components of the hot end. The short distance reduces the tendency of a filament to bend or buckle as a result of forces experienced during feeding. However, it results in slower print speeds. Bowden extruders, on the other hand, have the cold and hot ends separated. Without a heavy assembly on the print head, 3D printers with Bowden extruders can print much faster than direct extruder printers but will require fine-tuning to minimize the potential movement of the filament.

Summary

This article presented the five best 3D printer extruders, explained what they are, and discussed each of their features to consider when purchasing. To learn more about 3D printer extruders, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Please refer to our terms and conditions for more information.

Team Xometry

This article was written by various Xometry contributors. Xometry is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding, urethane casting, and more.

The 5 Best 3D Printer Extruders in 2022 – Clever Creations

3D printer extruders nowadays are as diverse as the printers themselves. You can find them in various shapes and sizes, with many extruders being specific only to particular 3D printers. A high-quality extruder will deliver consistent and predictable results that will help you get the best-looking 3D prints.

Direct and Bowden extruders are the two major types you can find in hobbyist FDM 3D printers. Each type has its benefits and is best suited for different situations.

In this article, we will explore these differences and go over top extruders that you can build or upgrade your 3D printer with. Read on to find out which is the best 3D printer extruder for your 3D printing workflow.

| 3D Printer Extruder | Extrusion System | Gear Ratio | Filament Size(s) | Price (~) | Best Offer |

|---|---|---|---|---|---|

| E3D Hemera | Direct / Bowden | 3.32:1 | 1.75 mm | $118 | E3D |

| Bondtech BMG | Direct / Bowden | 3:1 | 1.75 mm | $89 | Amazon |

| E3D Titan | Direct / Bowden | 3:1 | 1.75 mm / 2.85 mm | $60 | E3D |

| Micro Swiss Direct Drive Extruder | Direct | 1:1 | 1.75 mm | $100 | Amazon |

| BIQU h3 | Direct | 7:1 | 1.75 mm | $90 | BIQU |

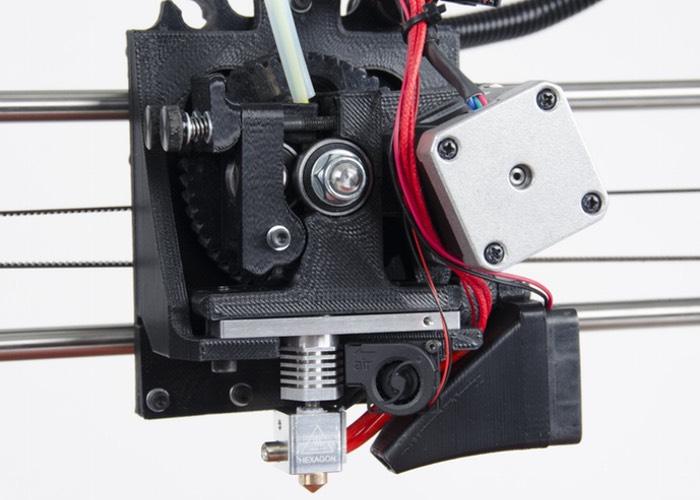

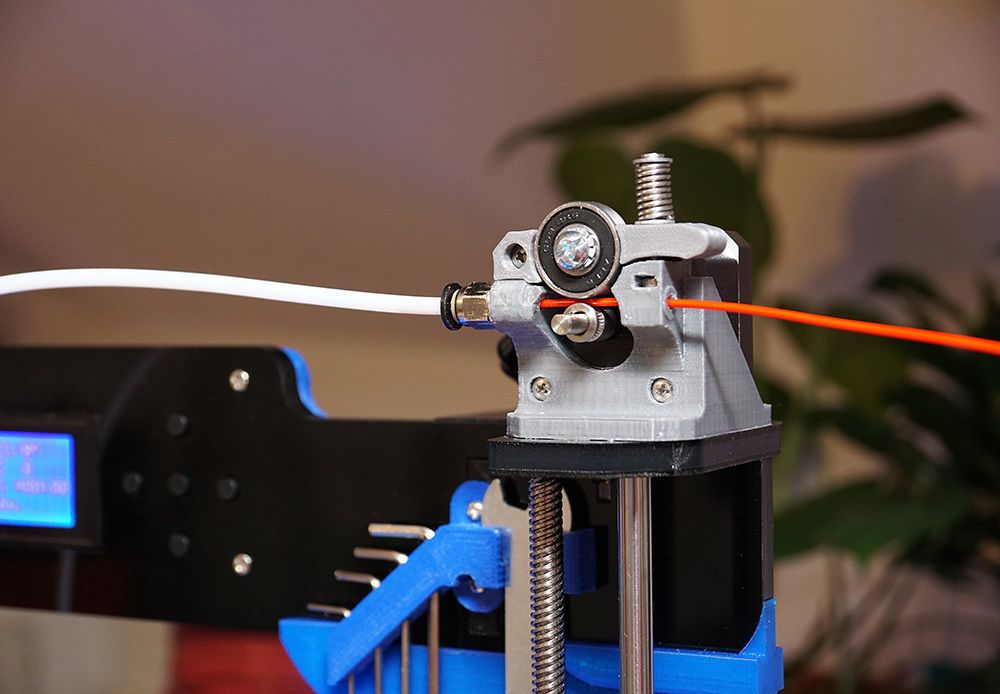

Image: Jona via Wikipedia, CC BY-SA 4.0

A 3D printer extruder is the part of an FDM 3D printer that melts and pushes out plastic filament to create the three-dimensional object. The extruder consists of various grouped parts.

The extruder consists of various grouped parts.

The first group of components is called the cold end.

The cold end consists of a mechanism designed to pull your filament from one end and push it out of another while firmly grasping it. The majority of the 3D printer extruders utilize a system of gears and a pulley combined with a spring-loaded arm to accomplish this function.

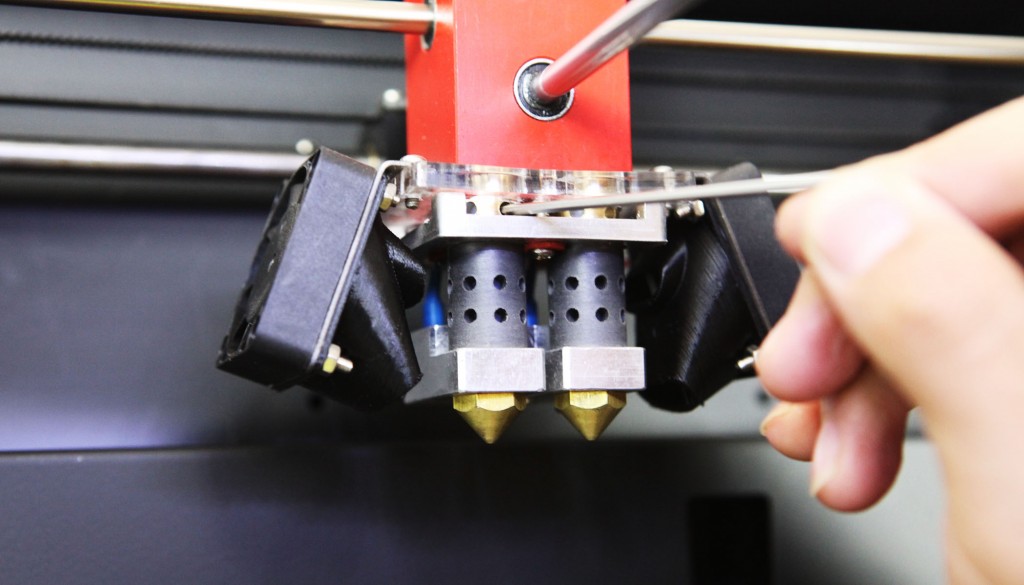

The second group is the hot end. It consists of various components, like the heat break, heater block, and nozzle.

The 3D printer filament is pushed through the heat break by the cold end until it reaches the heater block. The 3D printer filament is then melted by the heat produced by the heater and pushed out through a nozzle where it solidifies to create your 3D printed object.

The best 3D printer extruders will let you reliably 3D print at high speeds with various materials without affecting the print quality.

3D Printer Extruder TypesDirect Extruder

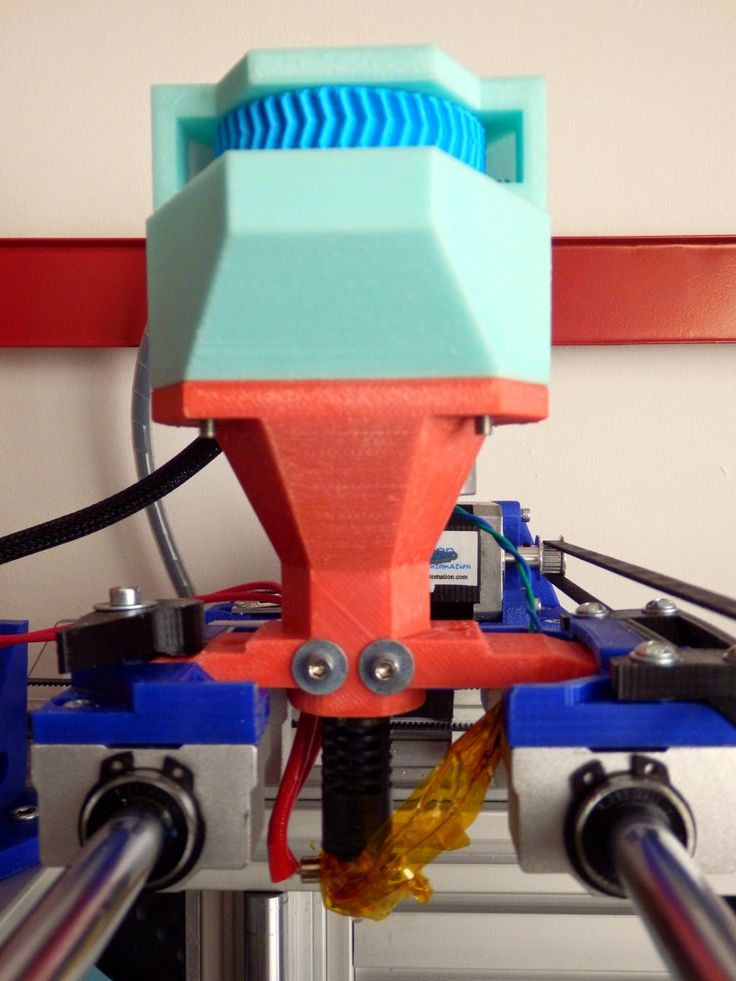

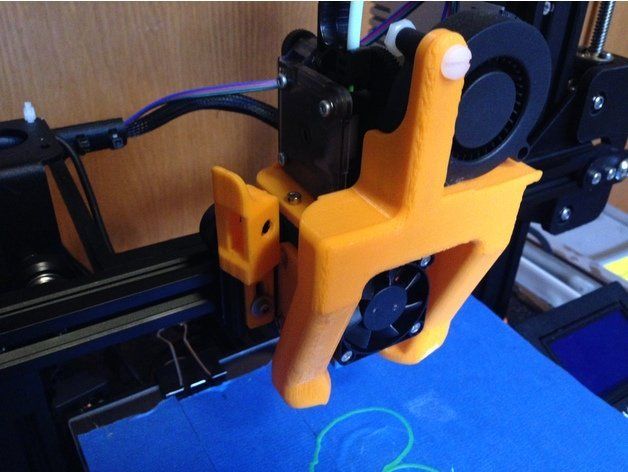

Image: Prusa3D

You can easily recognize a direct extruder system by looking at the 3D printer extruder. In a direct extruder setup, the extruder motor sits right on the top of the hot end and moves along with it. It allows for a short filament path, resulting in better retraction properties and better print quality.

In a direct extruder setup, the extruder motor sits right on the top of the hot end and moves along with it. It allows for a short filament path, resulting in better retraction properties and better print quality.

Direct extruders are known to be compatible with flexible filaments, which are filaments that Bowden extruders (see the next section) have trouble with.

However, this kind of setup leads to a bulky hot end design. It increases the overall mass of the print head and forces you to print at lower speeds. And because the 3D printer extruder sits on top of the cold end of your printer head, it reduces the overall Z-height of your printer.

Pros:

- Good retraction control

- Consistent and predictable extrusion

- Wide material compatibility

Cons:

- Heavy print head, low print speeds

- Reduces maximum print height

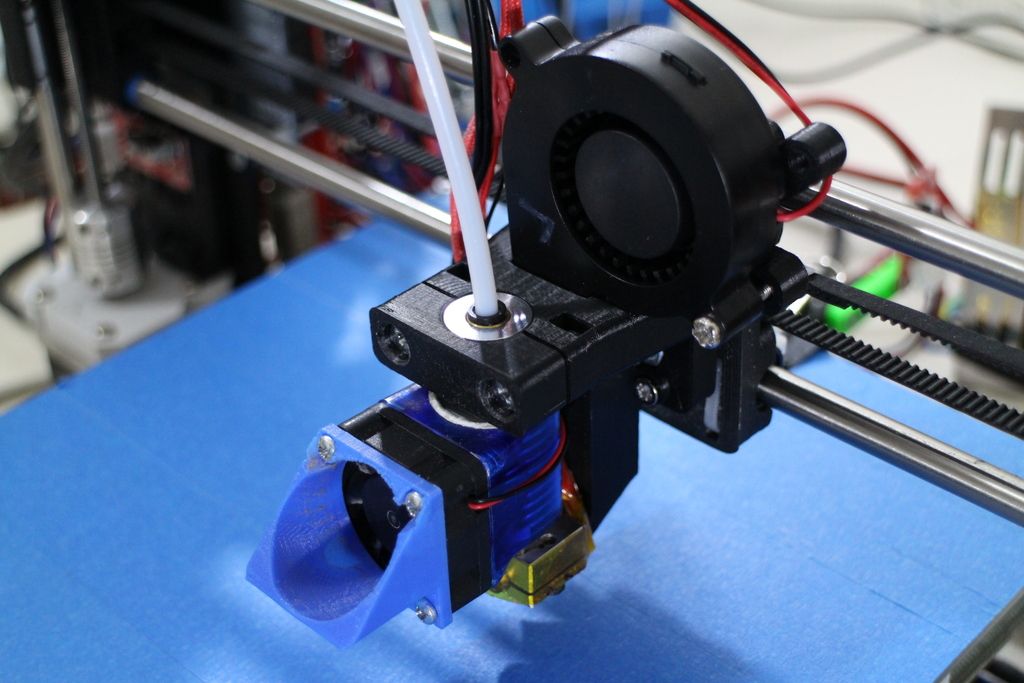

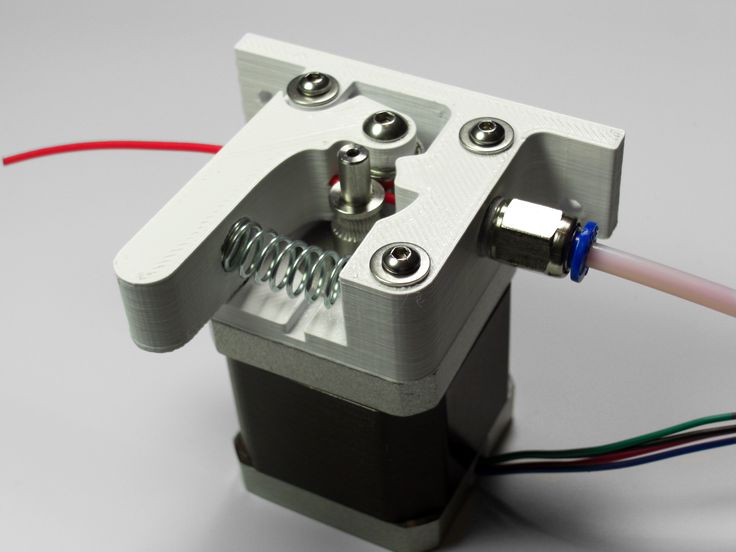

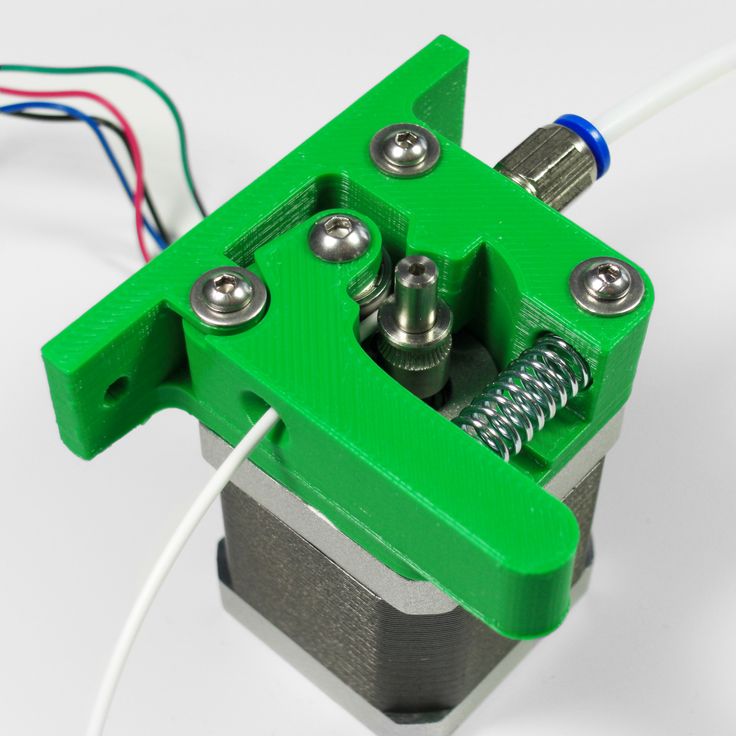

Image: jaybro187 via Reddit

Bowden extruders have their cold end mounted onto the 3D printer’s frame instead of above the hot end. The filament is then fed through a PTFE tube from the cold to the hot end.

The filament is then fed through a PTFE tube from the cold to the hot end.

This setup allows for a light print head and 3D printing at higher speeds without encountering print issues like ghosting and ringing

The lightweight design of a Bowden setup is best suited for a Delta 3D printer or dual extrusion 3D printer due to their unique construction and movement. However, you can find Bowden extruders in many budget 3D printers, as they allow for a simple print head design and increased print height.

One of their main downsides is that 3D printers with a Bowden extruder have a longer distance for the filament to travel. This can cause issues with retraction and lead to more stringing.

Pros:

- Lightweight and compact design

- Allows for fast print speeds

- Easy to access and fix issues

Cons:

- Needs fine-tuning of retraction settings

- Difficult to print with flexible materials

- Requires high power stepper motor

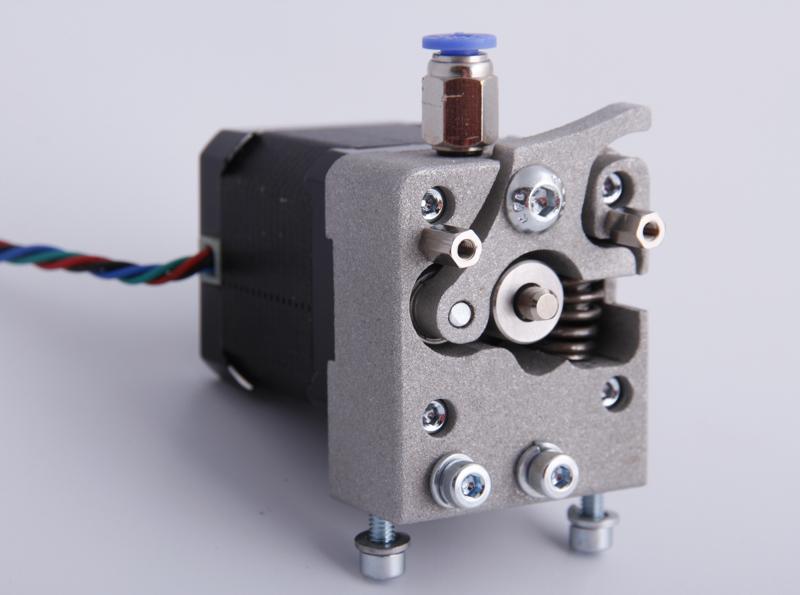

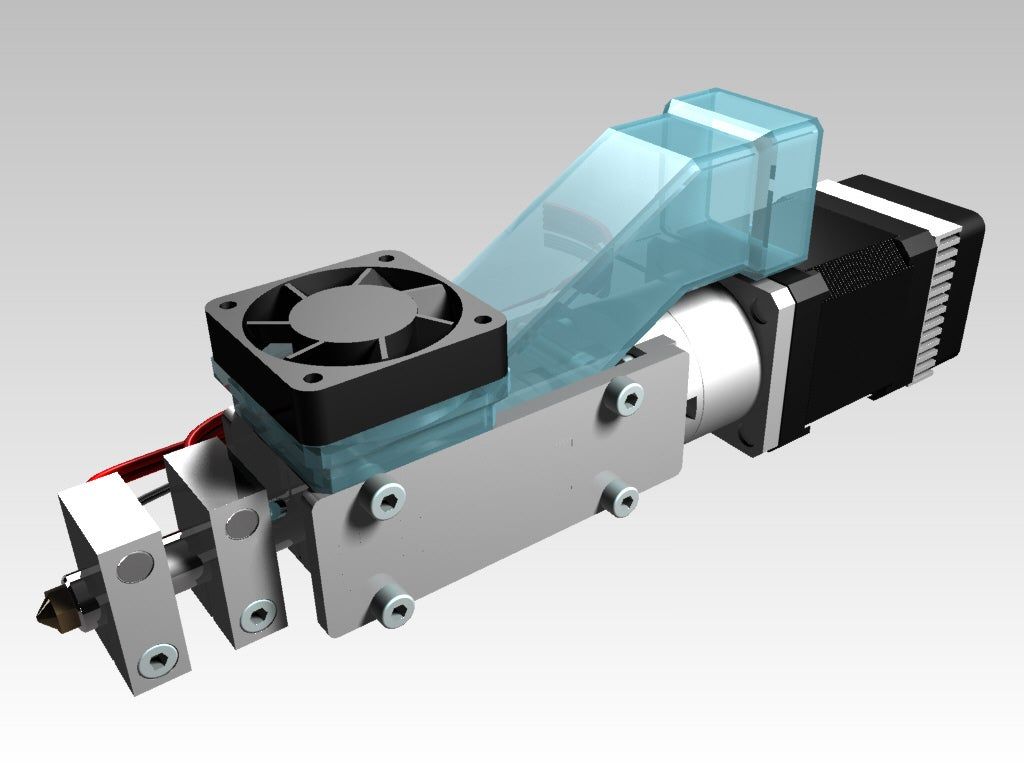

Image: E3D

Typical budget 3D printer extruders utilize a direct drive system. In a direct drive system, the filament drive gear is directly attached to the stepper motor shaft without gearing. This setup allows for a cheap and straightforward design.

In a direct drive system, the filament drive gear is directly attached to the stepper motor shaft without gearing. This setup allows for a cheap and straightforward design.

One downside, however, is that the extruder requires a high-powered stepper motor. On non-Bowden extruders, this means a lot of extra weight that has to be moved around. Not ideal.

This is where geared extruders come into play. A geared extruder uses a gear mechanism to increase torque. This gives the 3D printer extruder a better grip over the filaments, resulting in a more controlled filament flow.

Because the gear system increases torque, a smaller stepper motor can be used. This results in a more lightweight and compact setup that is ideal for direct extruders.

Pros:

- Produces high torque

- Compact size

- Suitable for both Bowden and direct extrusion setups

Cons:

- Can be expensive

- Complicated internal mechanism

Because of their similar terminology, direct and direct drive extruders sometimes get mixed up. Here are some tips to tell them apart:

Here are some tips to tell them apart:

- A direct drive extruder has its drive gear mounted directly to the stepper motor shaft. It is the opposite of a geared extruder.

- A direct extruder has its cold end mounted directly above the hot end. It is the opposite of a Bowden extruder.

If a 3D printer extruder has its drive gear mounted to the stepper motor shaft and the cold end is installed directly above the hot end, it is both a direct and a direct drive extruder.

The Best 3D Printer Extruders in 2022

E3D Hemera

Best Direct Extruder

Check Price

AmazonE3DMatterHackers

The E3D Hemera is one of the most powerful extruders available on the market today. It uses a dual drive gear system that gives you almost 100 N of pushing force on the filament, allowing for high-extrusion rates without stripping the filament.

The high pushing force makes the Hemera a great 3D printer extruder for large 3D printers that require high flow rates. It comes with a T-slot mounting system that lets you easily design and mount the extruder on virtually any 3D printer. Moreover, it is compatible with the whole system of E3D hot ends and nozzles.

It comes with a T-slot mounting system that lets you easily design and mount the extruder on virtually any 3D printer. Moreover, it is compatible with the whole system of E3D hot ends and nozzles.

The E3D Hemera is available in both direct and Bowden extruder setups, making it difficult to find a 3D printer that it does not work with.

Regardless of whether you already use the E3D eco-system, the E3D Hemera 3D printer extruder is great if you are looking for a reliable and high-performance cold end.

Standout Features

- Over 100N of pushing force

- Optimized airflow circulation

- Wide printer compatibility

Technical Details | |

|---|---|

| Extrusion type | Direct and Bowden |

| Filament diameter | 1.75 mm |

| Gear ratio | 3.32:1 |

| Weight | 388 grams (Direct) 327 grams (Bowden) |

What We Like

- Excellent for printing flexible filaments

- Easy mounting system

- High flow rate

Could Be Better

- Bulky design

- Requires fine-tuning

Find E3D Hemera at

AmazonE3DMatterHackers

Bondtech BMG

Lightest Extruder

Check Price

AmazonMatterHackers

The Bondtech BMG extruder is a geared 3D printer extruder with a gearing ratio of 3:1. It is designed to be compact while still offering you excellent grip on the filament. The extruder weighs only 75 gms (0.16 lbs), making it one of the lightest extruders available.

It is designed to be compact while still offering you excellent grip on the filament. The extruder weighs only 75 gms (0.16 lbs), making it one of the lightest extruders available.

It has an adjustable tensioner system that lets you fine-tune the tension of the drive gears on the filament. It gives you complete control over the filament feed and is compatible with multiple materials. Its quick-release mechanism, too, is designed for fast material swaps bringing down your printer operation times.

The extruder comes with an SLS printed housing that guarantees strength and precision. Its most notable drawback is its lack of compatibility with 2.85 mm filaments, but considering that 1.75mm filament is the standard nowadays, that won’t be a problem for most users.

If you’re looking for a compact, lightweight solution for your delta or other high-speed printer, the Bondtech BMG is probably the best 3D printer extruder for you.

Standout Features

- Lightweight and compact design

- High gripping force

- SLS 3D printed extruder housing

Technical Details | |

|---|---|

| Extrusion type | Direct and Bowden |

| Filament diameter | 1. 75 mm 75 mm |

| Gear ratio | 3:1 |

| Weight (without stepper) | 75 grams |

What We Like

- Easily adaptable to any 3D printer

- Adjustable tensioner screw

- Suitable for printing abrasive filaments

Could Be Better

- Does not include Bowden adapter

Find Bondtech BMG at

AmazonMatterHackers

E3D Titan

Best Geared Extruder

Check Price

AmazonE3DMatterHackers

The E3D Titan is another compact geared extruder designed for fast printing speeds. It comes with a translucent case design that gives it a unique look and its durable materials make it a highly reliable extruder.

The Titan extruder comes with a 3:1 gear ratio, similar to the Bondtech extruder. One big difference is that the Titan is also compatible with 2.85 mm filaments, which makes it a truly versatile 3D printer extruder. Another difference is that the gears on the E3D Titan have a self-cleaning tooth profile, so you don’t have to worry about any ground-up filament getting stuck.

Another difference is that the gears on the E3D Titan have a self-cleaning tooth profile, so you don’t have to worry about any ground-up filament getting stuck.

You can expect high print quality at low layer heights and minimized issues during extensive retraction cycles. The Titan extruder is compatible with many RepRap 3D printers and is known for its simplicity and high-quality extrusion.

It is an excellent alternative to the Bondtech extruder, albeit a bit heavier. If you can stand the extra weight, the E3D Titan will give you excellent results at a comparatively lower price.

Standout Features

- Self-cleaning hobbed gear teeth

- Small form factor

- Lightweight construction

Technical Details | |

|---|---|

| Extrusion type | Direct and Bowden |

| Filament diameter | 1.75 mm and 2.85 mm |

| Gear ratio | 3:1 |

| Weight (without stepper) | 125 grams |

What We Like

- Easy filament changes

- Compatible with virtually any 3D printer

- Great for printing at low layer heights

Could Be Better

- Comes without mounting bracket

- Comes without Bowden adapter

Find E3D Titan at

AmazonE3DMatterHackers

Micro Swiss Direct Drive Extruder

Best Extruder for Ender 3

Check Price

AmazonMatterHackers

The Ender 3 is one of the most popular and widely used 3D printers. However, it comes with a Bowden extrusion setup that limits its material compatibility. The Micro Swiss extruder solves this by giving you a plug-n-play direct extruder system for the Ender 3.

However, it comes with a Bowden extrusion setup that limits its material compatibility. The Micro Swiss extruder solves this by giving you a plug-n-play direct extruder system for the Ender 3.

The Micro Swiss extruder setup comes with an all-metal hot end, brass nozzle and a bracket that lets you easily install the extruder on your Ender 3. It has a lightweight aluminum body, and CNC machined gears to allow precise and predictable extrusion. The spring-loaded tensioner arm lets you adjust the filament grip and enables you to load the filament quickly.

You get a detailed guide that helps you throughout the installation process, ensuring you get everything right. However, you’ll need to do some tweaking to get the best print results with this setup.

Overall, the Micro Swiss extruder is an excellent Ender 3 upgrade that lets you print with different filaments and helps you get an improved print quality.

Standout Features

- Plug-and-play design

- Adjustable filament grip

- Hardened tool steel gears

Technical Details | |

|---|---|

| Extrusion type | Direct |

| Filament diameter | 1. 75 mm 75 mm |

| Gear ratio | 1:1 |

| Weight | N/A |

What We Like

- Easy mounting system

- Dual drive train for better grip

- Constrained filament path

Could Be Better

- Bulky design

- Limited printer compatibility

Find Micro Swiss Direct Drive Extruder at

AmazonMatterHackers

BIQU h3

Check Price

AmazonBIQU

The BIQU h3 is a dual gear extruder system with a high-temperature hot end. It has a 7:1 gear ratio on the extruder, offering you a superior grip on the filament with a relatively small stepper motor.

You get stainless steel gears precisely machined to reduce filament jams and prevent hot end clogging issues. The extruder body includes a streamlined heat dissipation structure that directs the heat away from the nozzle, easily letting you print for extended hours at high temperatures.

It is designed to be fitted on most hobbyist 3D printers like the Creality, Anycubic, and Geetech machines. The BIQU h3 is a well-built hot end, and at a price of less than $100, it offers excellent value by giving you high-temperature printing capabilities with a direct extruder setup. It is ideal for users who want a good quality extruder-hot end set up at a budget price.

Standout Features

- Dual gear extrusion

- Optimized heat dissipation system

- High gear ratio

Technical Details | |

|---|---|

| Extrusion type | Direct |

| Filament diameter | 1.75 mm |

| Gear ratio | 7:1 |

| Weight | 211 grams |

What We Like

- Low cost

- Compatible with various budget 3D printers

Could Be Better

- Short cable wire length

- Not an all-metal design

Find BIQU h3 at

AmazonBIQU

What to look for when buying a 3D printer extruder?Direct or BowdenAs discussed earlier, both Bowden and direct extruder setups have their pros and cons. Direct extruders work with more materials and offer better extrusion quality. However, they do come with the extra mass on the print head and reduce maximum print times.

Direct extruders work with more materials and offer better extrusion quality. However, they do come with the extra mass on the print head and reduce maximum print times.

Alternatively, a Bowden setup results in a lightweight print head by fixing the cold end to the 3D printer’s frame. It allows for high-speed 3D printing without the mass of a direct extruder. Bowden extruders also increase maximum print volume.

The downsides of Bowden extruders are that it is hard to get good extrusion results with flexible materials, and you need a larger motor to overcome the increased friction in the filament path.

Because the path from the cold end to the hot end is longer, the filament has to travel a greater distance before it is finally melted and extruded. This often results in poorer 3D print quality.

If you have a Delta printer or want to 3D print at high speeds on a CoreXY 3D printer, a Bowden extruder system is ideal. An independent dual-extrusion system (IDEX) on dual extruder 3D printers also benefits from a Bowden setup’s lightweight and compact form factor.

On the other hand, if you regularly print with flexible materials and need a more reliable and consistent 3D printer extruder setup, direct-drive extruders will give you a consistent print quality. However, you will need to limit your print speeds, to avoid ghosting and ringing issues in your prints.

TorqueThe force required to drive your filament through the 3D printer’s hot end is referred to as torque. The amount of torque an extruder can produce is determined by its gearing and the size of its stepper motor.

Geared 3D printer extruders have a higher gear ratio, which results in more torque. A 3D printer extruder with a 3:1 gear ratio will produce 3 times more torque than an extruder with a 1:1 gear ratio (assuming the same stepper motor and drive gear).

If an extruder doesn’t have enough torque, the filament will slip, and you’ll see artifacts in your 3D prints.

A typical NEMA 17 stepper motor coupled with an ungeared extruder will give you a maximum of 8. 4N of torque. It is sufficient for basic 3D printing at 30-60 mm/s printing speeds.

4N of torque. It is sufficient for basic 3D printing at 30-60 mm/s printing speeds.

But you need to remember that a higher gear ratio comes at the cost of a lower maximum RPM of the extruder motor. In the case of extruders like the BIQU h3, the 7:1 gear ratio will give you a lot of pushing force, but with a lower maximum print speed.

In the end, it is all about balance. If you need a small extruder for your direct extrusion 3D printer, the Bondtech BMG and E3D Titan will help you get a better balance between print speeds and torque with their 3:1 gearing ratio.

Filament diameterTwo standard filament diameters are used in 3D printing: 1.75 mm and 2.85 mm (3 mm). While 3D printer manufacturers have started to standardize on 1.75 mm filament, there are 3D printers that still work with the 2.85 mm diameter.

When choosing the best 3D printer extruder for your needs, you need to make sure that the 3D printer extruder you’re buying is compatible with the filament diameter you want to use. Some extruders can work with both diameters, while others are only designed for a specific one.

Some extruders can work with both diameters, while others are only designed for a specific one.

In this roundup, the E3D Titan extruder is the only one compatible with both the filament diameters.

WeightThe weight of an extruder plays a crucial role in the 3D printer’s mechanics. It influences both the design and the maximum printing speed of the 3D printer.

A lightweight extruder will have less inertia and let you print at higher speeds, even in a direct extruder setup. A heavy 3D printer extruder will limit your printing speeds unless you are willing to sacrifice the quality of your printed models.

The Bondtech and the E3D Titan are some of the most lightweight extruders suited for both Bowden and direct extrusion systems. These will let you print at high speeds and deliver consistent print quality with minimal issues during the printing process.

Frequently Asked Questions

How many extruders can a 3D printer have?

There’s no one-size-fits-all answer to this question, as the number of extruders a 3D printer can have depends on the specific model and make of the printer.

However, most 3D printers on the market today generally have either one or two extruders. In the case of two extruders, the machine is called a dual extruder 3D printer.

Some high-end commercial printers may have more extruders (four or more), but for the average home user, most 3D printers will have either one or two.

The benefits of having more extruders include the ability to print with multiple colors or materials and to print faster. However, more extruders also mean that the printer is more expensive and difficult to maintain. Ultimately, it is up to the user to decide whether they need a printer with multiple extruders or not.

How much does a 3D printer extruder cost?

Prices for 3D printer extruders vary depending on the type and quality of the extruder. Generally, extruders range in price from around $50 to $200.

Some of the more expensive extruders are made with better materials and offer more precise control over the printing process, while cheaper extruders may be less reliable or produce lower-quality prints.

How long does a 3D printer extruder last?

You are unlikely to have to replace any extruder components with regular use, aside from the nozzle. You can expect to swap out the nozzle every 6 to 12 months for the best results, but more frequently if you often 3D print abrasive filaments.

Where is the extruder on a 3D printer?

On direct drive extruders, the extruder is mounted on top of the 3D printer hot end. On a Bowden extruder, it is often mounted on the frame of the machine to reduce the moving mass.

Is a direct extruder on a 3D printer better than a Bowden extruder?

Yes, a direct extruder is generally better than a Bowden extruder, especially for flexible filaments. A direct extruder is attached directly to the motor, whereas a Bowden extruder uses a drive shaft to push the filament through a tube to the hot end.

The main advantage of a direct extruder is that it has less resistance than a Bowden extruder, which means that it can push filament through faster and with more force. This is important because flexible filaments are prone to tangling and jamming, so it’s critical that the printer can push them through quickly and without any resistance.

This is important because flexible filaments are prone to tangling and jamming, so it’s critical that the printer can push them through quickly and without any resistance.

Even for non-flexible filaments, a direct drive extruder gives better results than a Bowden extruder. Assuming it has been properly calibrated.

Are all 3D printer extruders interchangeable?

3D printer extruders are typically not interchangeable, but an extruder upgrade is often possible with some modification. This does require a degree of skill and knowledge to complete successfully. Without proper skills and understanding, it is possible to cause serious damage to your 3D printer.

Can you convert a 3mm extruder to a 1.75 mm extruder?

Technically, it is possible to convert a 3mm extruder to a 1.75 mm extruder. However, it is not a simple process and will require some engineering skills. You will likely need to modify the hot end and the cold end feed mechanism in order to make them compatible with 1. 75mm filament.

75mm filament.

Additionally, you may need to adjust the printer’s firmware in order to get proper calibration and functionality with the new extruder. Overall, it is a complicated process that is unlikely to be worth it compared to simply swapping out the extruder and hot end with 1.75mm variants.

Conclusion

A high-quality 3D printer extruder can mean the difference between a good print and an excellent 3D print. If you are building a 3D printer or want to do an extruder upgrade, It is important to consider the different extrusion systems. Then choose the one that offers you the best print quality without sacrificing print speeds.

Considering all the criteria, the E3D Titan extruder is the overall best 3D printer extruder on the list. It is compatible with various 3D printers, has excellent material compatibility, and is well-known to deliver consistent and reliable print quality.

However, it is an old design and lacks some of the advanced features of the newer extruders. This is where the E3D Hemera and the Bondtech BMG extruder come out as great alternatives to the Titan. The E3D Hemera is one of the most powerful extruders with a unique and practical design. In contrast, the Bondtech extruder gives you the advantages of a lightweight 3D printer extruder setup.

This is where the E3D Hemera and the Bondtech BMG extruder come out as great alternatives to the Titan. The E3D Hemera is one of the most powerful extruders with a unique and practical design. In contrast, the Bondtech extruder gives you the advantages of a lightweight 3D printer extruder setup.

Let us know your thoughts on the list and if you’ve used any of these extruders. If there’s anything else you’d like to see in the article, feel free to comment below.

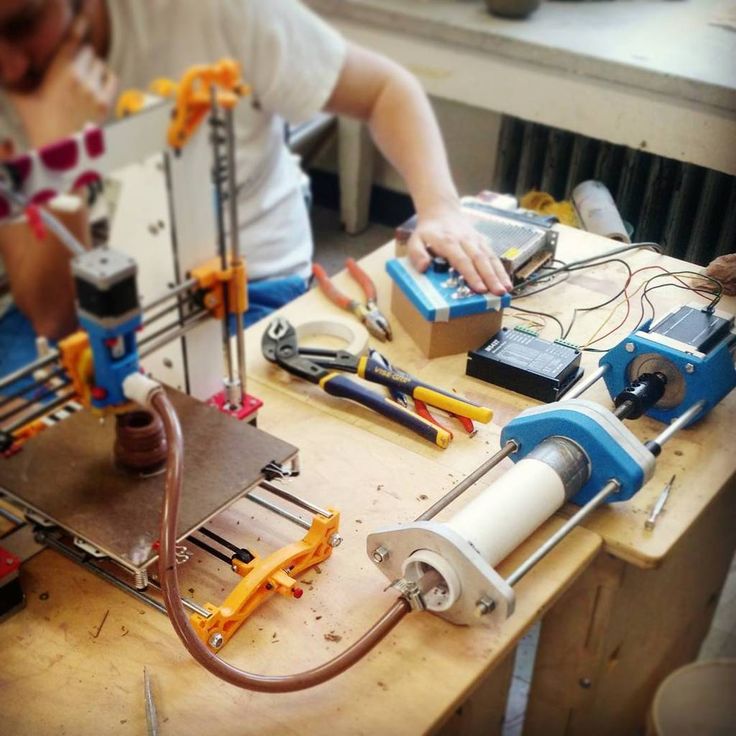

Top 5 extruders for 3D printer Anet A8

TheAnet A8 is a very popular 3D printer due to its affordability and wide customization options. This is certainly an interesting project that you can assemble yourself or buy as a set. Thanks to its affordable price and clear design, Anet A8 has long been the "people's 3D printer" and a great option to get acquainted with the intricacies of 3D printing.

Due to the extensive modification options, 3D printing results on the Anet A8 can vary greatly. And some modifications simply turn this model into an analogue of expensive 3D printers in terms of 3D printing quality. There are a lot of modifications on the Internet, and in this article we will touch on the modifications of one node - the extruder. Believe me, there are a lot of modifications to the Anet A8 extruder and they are worth discussing.

And some modifications simply turn this model into an analogue of expensive 3D printers in terms of 3D printing quality. There are a lot of modifications on the Internet, and in this article we will touch on the modifications of one node - the extruder. Believe me, there are a lot of modifications to the Anet A8 extruder and they are worth discussing.

For example, the original design of this 3D printer does not include a duct fan to help direct air from the Anet A8 extruder fan to the nozzle. And air is needed to cool the extruded plastic and keep the 3D printer in proper working order. But there is also good news - Thingiverse already has a lot of mods for blowing. Here's a great one from a user named Arjjck.

One of the simplest mods is adding an extruder button to make it easier to use the 3D printer. This 3D printed button is definitely better than the standard extruder screw, which is almost impossible to press with your fingers. Such a simple 3D printed Anet A8 extruder button will save you the pain of changing 3D printing material.

Extruder replacement is one of the Anet A8 upgrades that can greatly improve 3D print quality, so let's take a look at the interesting options.

E3D Titan extruder

The E3D Titan extruder is ideal for those who want to print using different materials, not just PLA plastic. The lightweight E3D Titan reduces clogging and features specially machined teeth that are curved to grab fibers at right angles. The teeth improve the grip of the thread and increase the accuracy of its feeding.

This extruder has been manufactured to increase torque, reduce clogging and 3D print at higher resolutions. It is designed for use with the E3D v6 hotend, allowing you to print at higher temperatures, and the 3:1 gear ratio ensures more precise movement.

According to the manufacturer, this ratio gives the E3D Titan extruder the best performance in terms of accuracy and speed. Obviously lower gear ratios run too slow while higher gear ratios run too fast. Thus, the manufacturer concluded that a ratio of 3:1 is the best option, allowing the extruder to cope with the required degree of extrusion. The gear ratio increases resolution and promotes smooth 3D printing at low layer heights.

The gear ratio increases resolution and promotes smooth 3D printing at low layer heights.

The extruder supports 3D printing with 1.75 mm and 3 mm filaments and allows the use of materials such as abrasive carbon fiber, TPU, TPE and a number of other harder plastics. The E3D Titan has a solid construction thanks to injection molded parts. Unlike other more clumsy extruders, the design details eliminate the possibility of wiggle and improve accuracy. In addition to being lightweight for more torque, the E3D Titan has been built to be easy to assemble or disassemble.

LulzBot Taz Single Extruder Tool Head v2

LulzBot TAZ Single Extruder Tool Head v2 comes with a solid metal hex and can withstand temperatures up to 300°C (572°F). Thus, you will not have problems with materials such as ABS, PLA and HIPS. You can also use materials such as T-Glase, polycarbonate, nylon, as well as various types of threads filled with stone and wood.

The extruder comes with two fans, one for the nozzle to help produce highly detailed prints, and one for the heatsink. The LulzBot Taz has gone through countless hours of testing and is a suitable replacement for the Anet A8 extruder.

The LulzBot Taz has gone through countless hours of testing and is a suitable replacement for the Anet A8 extruder.

Single Flexion Retrofit Kit Extruder

This extruder is much better than the standard Anet A8 extruder and guarantees high resolution and fewer failures. The Extruder Upgrade Kit includes precision machined components that give you the ability to print at full speed on flexible materials, using adjustable fine filament tension to maintain high 3D printing accuracy.

The Flexion extruder pushes the filament harder and the self-cleaning drive ensures no clogging during long 3D prints. This extruder uses a high rigidity lever to compress the filament, and an adjustable screw and cam is used to control the compression - for precise tension control. The Flexion extruder will work well with TPU, TPE, flexible PLA, Filaflex and Ninjaflex in addition to standard materials like PLA, PETG or ABS.

Flex3Drive Extruder

The Flex3Drive extruder is compatible with a wide range of hot ends and has a ratio of 40:1. With this ratio, it will print great first layers. It provides a direct feed to the hotend, but the motors are spaced apart to reduce moving mass and lighten the extruder. This results in smoother print head movement and reduces vibration.

With this ratio, it will print great first layers. It provides a direct feed to the hotend, but the motors are spaced apart to reduce moving mass and lighten the extruder. This results in smoother print head movement and reduces vibration.

This shaft-driven extruder is compact, small and fairly light. The extruder is equipped with cam-lock tensioners for constant material tension without the use of springs or screws. This is particularly suitable for tough materials, but there is an adjustable thread tension lever that does not require a firm grip.

Material loading is greatly simplified and the filament can be changed without stopping the 3D printing process.

Mounting the Flex3Drive hot end on the bottom of the extruder can be a pain, but worth it. This extruder is suitable for working with nozzles of the widest diameter. The drive gears are made on high-precision CNC machines, so there are no questions about the quality of the manufacture of these extruders.

Bowden Type Extruders

Well, here's the holi comrade on our list of the best Anet A8 extruders. Bowden type extruder. An extruder in a Bowden layout means that the hot end is physically separate from the extruder. Typically the extruder is mounted on the inside or back of the Anet A8 3D printer and works like a "remote" extruder in the same way as a direct extruder: grabs the material and pushes it. However, the main difference is that the thread must pass through the tube before it reaches the hot end.

The Bowden Extruder significantly reduces the weight that the carriage needs to move during 3D printing and reduces carriage vibration, backlash and twitching. This is because when the extruder (with its mounts and motor) is out of the way, only the hot end can move. Therefore, less momentum needs to be overcome, and this makes Bowden designs the best choice for 3D printing complex parts.

But this type of extruder has a downside. The separation of the hot end and extruder usually causes a delay or hysteresis. A longer material path means longer contact and more friction that the extruder must counteract. Therefore, the motors will need more torque to deliver the filament to the hot end. This makes it difficult to use Bowden extruders with flexible filaments. The longer path also means that the filament can warp, shrink, or stretch, resulting in inconsistent 3D printing.

A longer material path means longer contact and more friction that the extruder must counteract. Therefore, the motors will need more torque to deliver the filament to the hot end. This makes it difficult to use Bowden extruders with flexible filaments. The longer path also means that the filament can warp, shrink, or stretch, resulting in inconsistent 3D printing.

While the Bowden extruder may work well on the Anet A8 3D printer, it may require some technical knowledge to install as the above issues may require certain settings in the 3D printer firmware. Hence, buying a Bowden type extruder can cause problems if you are not a true 3D printing enthusiast.

On the other hand, if you are confident in your skills and have no problem setting up your 3D printer, the Bowden Extruder may come in handy. With the right settings, you can get cleaner and smoother 3D models.

Direct extruder for a 3d printer: an overview of the best types and types, which one is better to choose

The extruder is called the working head of a 3D printer. The plastic thread passes through it, melts and is squeezed out through the nozzle onto the work table. This is how objects are built layer by layer.

The plastic thread passes through it, melts and is squeezed out through the nozzle onto the work table. This is how objects are built layer by layer.

Types of extruders for 3D printer

There are two types of extruders: direct and bowden. They are slightly different in design and have their pros and cons.

Direct extruder

Direct extruders are located directly above the hot end. Due to this, the distance from the gear train is minimal, which ensures more reliable work with flexible threads.

If a direct head is installed on the printer, this does not mean that it will print well with flexible filaments. In order for the print to be of high quality, it is necessary to monitor the position of the clamp, as well as pay attention to the gear device.

Direct extruders have more precise retraction control compared to Bowden. Positioning above the hot end significantly reduces the distance between the thread and the clamp. Therefore, the thread has less room for bending.

Therefore, the thread has less room for bending.

The direct printhead is bulkier. Because of this, inertia increases. Good print quality requires a solid rail design. Also, large head sizes affect print speed.

Main advantages of direct extruders:

- Media can be changed quickly and easily;

- minimum feed distance reduces error;

- can use flexible heads at relatively high speeds.

Disadvantages:

- increased weight compared to bowden;

- head design is more complex.

Bowden Extruder

When using the Bowden Extruder, the gear train and the motor are assembled on the machine frame. The weight of such a print head is less than with a direct extruder.

Bowden's main disadvantage is that as the thread travels through the Teflon tube that connects the hot end and the feed mechanism, it can deviate. The amount of deflection depends on the length of the tube. This disadvantage is especially pronounced during the use of flexible plastics. The print settings and the amount of retraction must be selected empirically.

The amount of deflection depends on the length of the tube. This disadvantage is especially pronounced during the use of flexible plastics. The print settings and the amount of retraction must be selected empirically.

The problem of friction must also be solved. The thread must be pushed through the tube. It is important that the torque is sufficient to carry out this process.

REFERENCE. Most home delta 3D printers come with bowden extruders.

Advantages:

- reduced weight of the carriage due to the fact that the engine is located on the frame;

- The print head is small.

Disadvantages:

- Printing with flexible plastic is difficult;

- needs a powerful motor to feed material;

- Printer error increases in proportion to tube length.

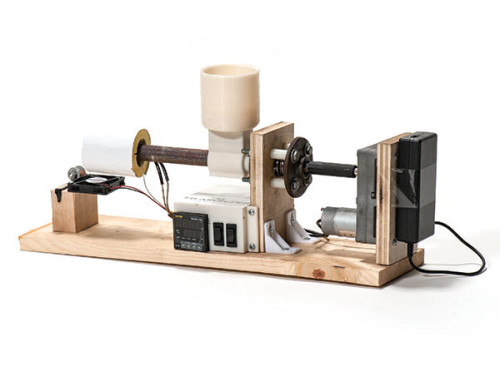

What is the best filament extruder to buy?

Now the cost of 1 kg of the cheapest thread is about $20. And the price of plastic from trusted manufacturers can reach up to 50% per 1 kg. Therefore, the issue of self-manufacturing of the filament is very relevant.

And the price of plastic from trusted manufacturers can reach up to 50% per 1 kg. Therefore, the issue of self-manufacturing of the filament is very relevant.

Filament extruders:

- Liman extruder. This device was invented by Hugh Liman. It can make filament with a diameter of 1.75 and 3 mm with an error of 0.01 mm and saves about 80% on the purchase of filament.

- Fischer extruder or STRUdittle. This is a compact device that allows you to make thread from ABS plastic. The speed of work is 30-60 cm per minute. The error does not exceed 0.05 mm if the filament is freely output. If you use a spool that automatically winds the thread, then the error is reduced to 0.03 mm.

- Filabot Original. The most famous development, which has good performance. Can work with ABS, HIPS and PLA. The starting material can be granulated plastic or plastic waste. If waste is used, the particle size should not exceed 5 mm.

- FilaMaker. The device combines the functions of a crusher and an extruder. It has a neat design, high functionality and good performance. Can produce up to 1 m of filament per minute with an accuracy of 0.05 mm. The only drawback is the high price - $1200.

- Filastruder. Relatively cheap extruder, with which you can get 1 kg of thread in 12 hours. The speed of work is from 15 to 60 cm per minute. Speed depends on operating temperature, nozzle diameter and material used. The device is designed for ABS, but it can also be used for PLA, HIPS and nylon.

Overview of 3D printer extruders

Below are the most popular 3D printer extruders with detailed specifications.

MK8

This is the most popular direct extruder. It is easy to install and easy to use, suitable for most 3D printers. Costs approximately $15.

Device specifications:

- Thread diameter 1.75 mm;

- nozzle diameter can be from 0.

2 to 0.5 mm;

2 to 0.5 mm; - 12 V and 40 W heater;

- operating speed - 4 cm per second;

- device weight 450 g;

- operating temperature - from 190 to 250 degrees.

E3D TITAN AERO

Key features of the E3D TITAN AERO:

- direct drive;

- all-metal thermal barrier;

- maximum temperature - 285 degrees;

- gear ratio - 3 to 1;

- is suitable for flexible plastics.

The device is easy to install and easy to use. The original costs about $170, but you can buy a Chinese equivalent for about $40.

Includes:

- standard or mirror housing;

- heat sink;

- mounting connectors;

- fan;

- heating block;

- nozzle;

- Teflon tube;

- thermal paste;

- idle lever;

- thermistor cable and cartridge.

Learn more