3D print braces

How to 3D Print Plastic Braces for $60

US Markets Loading... H M S In the news

Chevron iconIt indicates an expandable section or menu, or sometimes previous / next navigation options.HOMEPAGE Save Article IconA bookmarkShare iconAn curved arrow pointing right.Download the app

Amos Dudley An undergraduate at New Jersey Institute of Technology made his own plastic braces using a 3D printer, $60 of materials, and a healthy dose of ingenuity — and they actually worked.

Amos Dudley had braces in middle school, but he didn't wear a retainer like he was supposed to, so his teeth slowly shifted back.

He didn't want to shell out thousands of dollars for a whole new round of braces, so the digital-design major decided to make his own.

On his blog, Dudley wrote that he was an unlikely combination of two things: He was broke, but had access to a high-quality 3D printer through his university. He took full advantage of this.

The process wasn't exactly easy. He had to research orthodontic procedures and plot the route of his successive braces, so his teeth would move in the right way. But once that was done, all it took was fabricating a series of models out of relatively inexpensive plastic, and then following through on wearing them.

And it was worth it for Dudley, whose smile turned out looking remarkable.

Here is the process he went through:

Dudley ran across a photo from a "name brand clear-alignment treatment" and noticed that the plastic looked like it had the layer striations from a 3D print.

So what was to stop him from 3D-printing his own, he thought. Amos Dudley

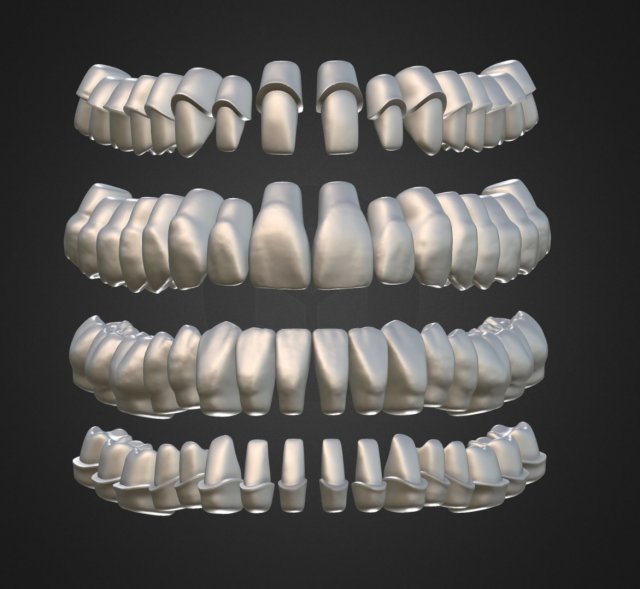

So what was to stop him from 3D-printing his own, he thought. Amos Dudley First he took a mold of his teeth with alginate powder. "These molds are very precise, and capture an amazing amount of detail," he writes. "There were some bubbles in the mold," but they wouldn't matter for the aligner.

Amos DudleyMaking this casting was simple, he says.

"I put the mold upside down in a yogurt container, and then filled it with liquid Permastone," he writes. "When it came out, I simply broke off the top to reveal the casting, and used a razor blade to smooth out the surrounding area." Amos Dudley

"I put the mold upside down in a yogurt container, and then filled it with liquid Permastone," he writes. "When it came out, I simply broke off the top to reveal the casting, and used a razor blade to smooth out the surrounding area." Amos Dudley Now he had a better sense of what was going on with his teeth. You can tell specifically that the LI-r (right lateral incisor) juts out.

Amos DudleyThe laser scanning was reasonably painless, he says, though he describes the NextEngine software interface as "awful.

" "The dimensions of the scan seemed to correspond very closely to the dimensions I measured on the physical model with calipers," he writes. He also says creating the animation, which would show the path his teeth would take through different iterations of the braces, wasn't particularly difficult either. Amos Dudley

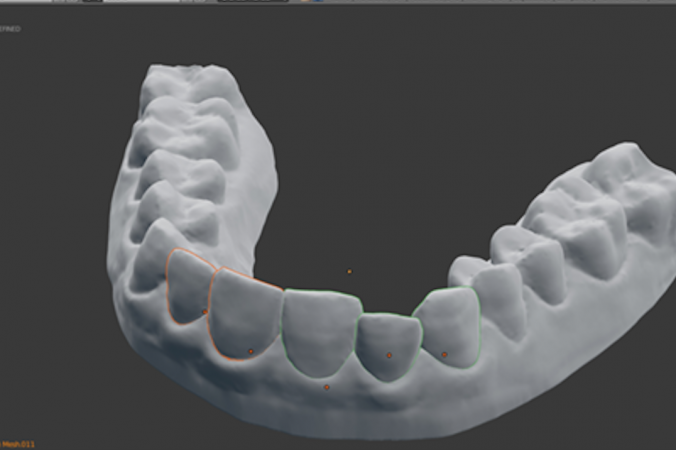

" "The dimensions of the scan seemed to correspond very closely to the dimensions I measured on the physical model with calipers," he writes. He also says creating the animation, which would show the path his teeth would take through different iterations of the braces, wasn't particularly difficult either. Amos Dudley "Here’s where it started to get very exciting," he writes. The 3D printing of the molds.

Amos DudleyAn up-close view of the 3D-printed mold.

Amos Dudley

Amos Dudley These are the "steps" all 3D-printed out. "Labeling the pieces is critical," he advises. "They look virtually identical."

Amos DudleyAfter the final versions of the braces came out of a vacuum-form machine, Dudley sanded down the edges so they wouldn’t irritate his gums.

Amos Dudley

Amos Dudley But did they work? Here was his smile before.

Amos DudleyAnd after about four months.

Amos DudleyIf you want a more in-depth look at the process, check out Dudley's blog. (Just don't ask him to print any braces for you.)

(Just don't ask him to print any braces for you.)

Read next

LoadingSomething is loading.Thanks for signing up!

Access your favorite topics in a personalized feed while you're on the go.

Features 3D Printing3D Printing for Orthodontics

Skip to Main Content

Simple print preparation

Import digital impressions directly and prepare models for printing in just a few clicks.

Download PreForm

Rigorously tested materials

Fully validated workflows with our proprietary resins give you peace of mind.

Browse Materials

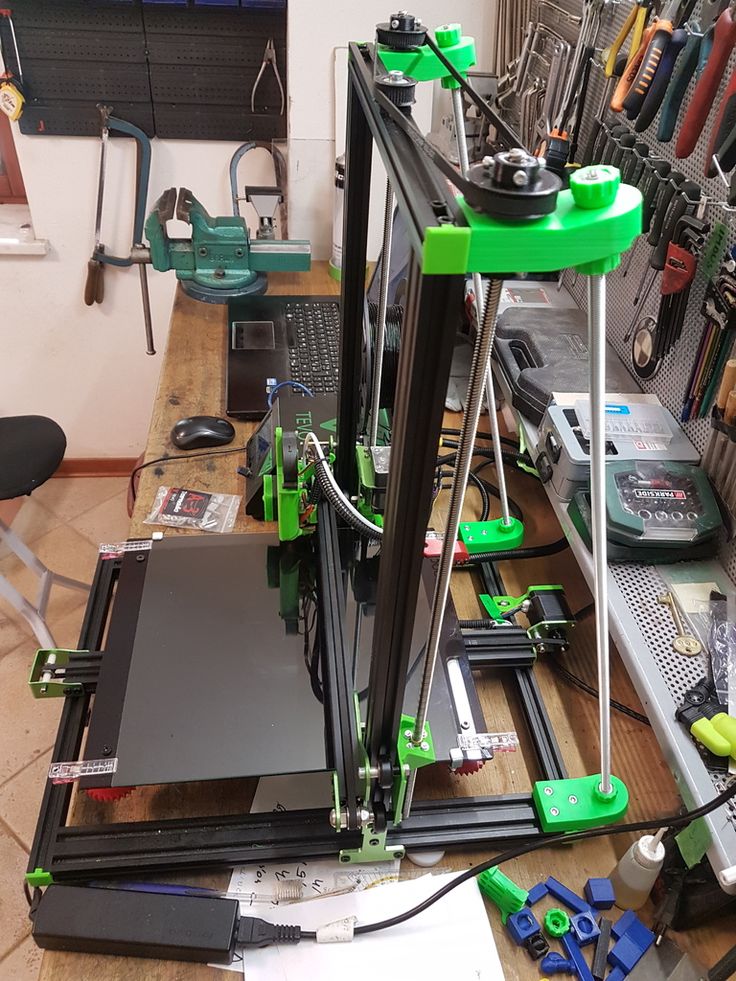

The easiest 3D printer to use

The intuitively designed Form 3B makes in-office printing clean and hassle-free.

Meet Form 3B

Hands-off post-processing

Automated washing and curing units take the guesswork out of finishing printed parts for clinical use.

Automate Your Post-Processing

“90% of the printing work in my office can be delegated. It really is ‘set it and forget it.’”

Dr. Jay Burton, Orthodontist, SmileMaker Orthodontics, Tennessee, USA

Maximum productivity, minimum intervention

The Form 3BL works full time so you don’t have to. Intuitive nesting software and automated post-processing options make custom manufacturing easy.

Designed for nonstop throughput

With cloud monitoring, automatic resin dispensing, SMS and email notifications, and in-field repairs, never waste time.

Scale production with ease

Form 3BL works on the same software and materials platform as Form 3B for maximum cross-compatibility. It’s easy to add capacity as you grow.

“We can't waste time, we create over 700 appliances per week. We don't have time for reprints of models, they need to be accurate all the time, and that is why we are Formlabs customers.”

Phil Pelligra, President, Perfect Finish Ortho Lab, New Jersey, USA

Orthodontists around the world are already saving time and money by producing their own aligners in-house.

| Time from scan to treatment start | Cost for a comprehensive case * | |

|---|---|---|

| Outsourced aligners | As much as 8 weeks | $1500-2000 USD |

| In-house aligners with Formlabs | As little as 1 hour | $300-400 USD |

| Savings per case | 8 weeks | $1100-1700 USD |

* Assuming a 10-month treatment. In-house costs include resin, thermoforming plastic, and labor.

In-house costs include resin, thermoforming plastic, and labor.

See How Much You Can Save

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs dental 3D printers.

Calculate Your Savings

Produce highly accurate models for retainers, clear aligners, or patient case presentations for only $2-3 USD per model with Draft Resin.

One model in under 20 minutes

Up to 8 models per print in ~1 hr

Up to 24 models per print in ~2.5 hrs

Up to 52 models per print in ~9 hrs

Print times are estimates, based on print settings with 200 micron layer heights. 100 microns also available.

Want to see Draft Resin for yourself? Request a sample print and we’ll ship one to you at no cost.

Request a Free Sample Part

Indirect bonding trays

Reduce Chairtime and Increase Accuracy in Orthodontic Bonding

Brackets and other direct-bonded appliances

Validating 3D Printed Direct Bonded Orthodontic Appliances

Occlusal guards and splints

How to 3D print Occlusal Splints and Orthotic Appliances

Workflows using biocompatible resins may not be available in all regions. Check regional availability.

Check regional availability.

Explore More Indications

From CE-certified courses to quick videos that can quickly teach you a new skill, learn with Formlabs Dental Academy.

Browse Educational Content

Don’t want to learn one more software program?

Ask if your lab will do appliance design for you. Otherwise, fully digital services can take this off your plate.

Our Dental Service Plan (DSP) includes personalized onboarding training, proactive check-ins, and the best phone and email support in the industry.

Learn More About Dental Service Plan

Learn how digital dentistry is transforming orthodontic workflows and how you can integrate 3D printing into your lab or practice with our free resources.

Explore Orthodontic Resources

The Form 3B+ Complete Package includes all of the tools required to bring high-precision 3D printing into your office.

Order nowRequest a Sample Part

IBT Resin - fast and easy bracket placement

Formlabs is pleased to introduce IBT Resin resin, which is designed to print a matrix for indirect adhesive bonding to simplify the placement of orthodontic brackets. In addition to rapid model building resins such as Draft Resin, Formlabs now offers a comprehensive range of 3D printing materials that save time, money and labor for professional orthodontists.

In addition to rapid model building resins such as Draft Resin, Formlabs now offers a comprehensive range of 3D printing materials that save time, money and labor for professional orthodontists.

3D printing continues to prove its worth in orthodontics

Digital technology began to change orthodontics over a decade ago. With the widespread use of 3D printing to produce clear aligners, the industry has ushered in an era of mass-produced, affordable, custom-fitted products, allowing professionals to deliver healthcare services faster and easier, and improving the comfort of professionals and patients.

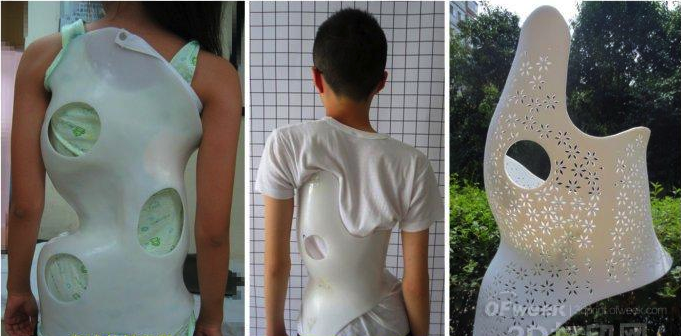

Aligners continue to gain popularity with patients, with so-called "invisible braces" appealing to adults and young adults alike. In the meantime, technology is allowing professionals to create their own aligners, making the treatment available to more patients. However, clear aligners remain clinically limited, and traditional orthodontic brackets are still indicated and preferred in many cases.

3D-printed indirect bonding matrices are now available to reduce the labor and cost of placing brackets.

Save time and money on bracket placement

Indirect Adhesive Matrices are a custom made product that fits your individual teeth exactly and allows you to place multiple brackets at once. Since preparation and precise placement can be provided virtually in advance, the length of time a patient spends in the dentist's chair can be cut in half, thereby saving the orthodontist's valuable time.

Compared to other 3D matrix printing resins, Formlabs IBT Resin has optimum tensile strength, transparency and flexibility. Products printed from this polymer are easier to use in the dental office. They save practitioners time and money.

What makes Formlabs photopolymer different?

- Enhanced color for clearer visualization of brackets against teeth.

- Manufacture of end products without taste, odor and sticking.

- The minimum amount of material required to create supporting structures.

- No need for final polymerization using glycerol or nitrogen.

What are its advantages over other brands?

- Convenient use in the dental office with fewer errors.

- Comfortable conditions for patients.

- Reduce waste and reduce post-processing activities.

- Simple and convenient post-processing.

This polymer is a Class I material. It has been rigorously tested by Formlabs and industry experts. Beta testers of the material liked its accuracy, printability, and ease of use in the dental office.

Lisa Alvetro, an orthodontist at a private clinic in Sydney, Ohio, USA, tested the polymer before its release.

“Clinically, indirect adhesive luting matrices printed with Formlabs IBT Resin have demonstrated accuracy and ease of insertion and removal” , she noted.

Dr. Alvetro has found that digital workflows such as 3D printing allow her to outsource much of her day-to-day work to highly skilled employees such as Patricia Mitchell, the digital workflow specialist used in their orthodontic clinic.

“With several years of experience printing indirect bonding dies, I have found that Formlabs IBT Resin can easily create accurate models using PreForm software. I really like that IBT Resin has almost no smell. The printed matrices for indirect adhesive luting are easily removed from the work platform and their post-processing procedure is very simple. IBT Resin printing left a very positive impression!” - Patricia Mitchell, Digital Workflow Specialist, Alvetro Orthodontics

How to use IBT Resin

Working with IBT Resin is easy if your orthodontic practice or lab is already using digital instruments.

With intraoral scanning and a digital treatment plan, an orthodontist, technician or assistant can create a 3D matrix model in just a few minutes using any of the various orthodontic design software. The resulting STL file can be directly imported into the easy-to-use PreForm software and prepared for 3D printing.

3D printing a model on a Formlabs SLA 3D printer is an automated process. After setting up the printer, installing the cartridge, Resin Tank, and build platform, and uploading the 3D file via Wi-Fi, Ethernet, or USB cable, you can start printing with just a push of a button. There is no need to monitor the Formlabs 3D printer until the print is complete.

After setting up the printer, installing the cartridge, Resin Tank, and build platform, and uploading the 3D file via Wi-Fi, Ethernet, or USB cable, you can start printing with just a push of a button. There is no need to monitor the Formlabs 3D printer until the print is complete.

After printing the model, it is necessary to perform post-processing: washing in isopropyl alcohol (≥ 96%) and final polymerization. These steps can be automated with Formalbs post-processing tools, Form Wash and Form Cure. After polymerization, the matrix for indirect adhesive fixation is ready. It can be cleaned, disinfected, and reprocessed with tools commonly used in orthodontic practices.

Complete Orthodontic 3D Printing Solution

With the addition of IBT Resin to the Formlabs product portfolio, the company offers a complete orthodontic 3D printing solution. With the industry-leading Form 3B printer, easy-to-use Form Wash and Form Cure post-processing devices, powerful and free PreForm and Dashboard software, and expert assistance, you won't find a better platform for digital orthodontics!

Innovation in Dentistry - Using 3D Printing in Aligners

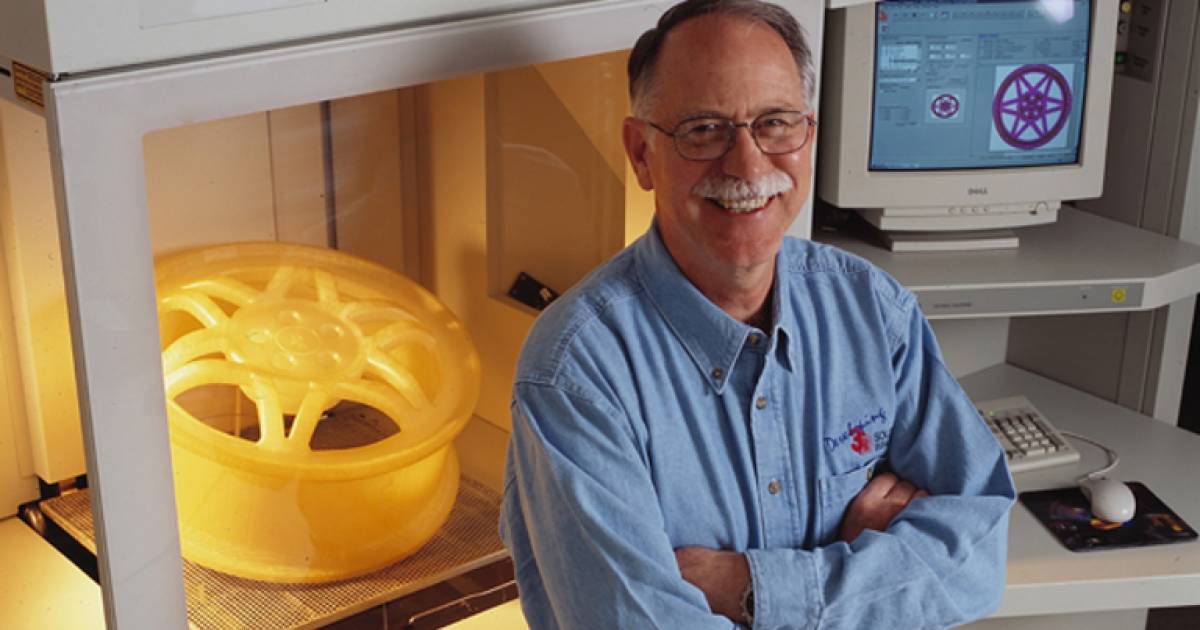

The first attempts to use 3D printing in dentistry were made a long time ago, back in the late 1990s. Now high-tech 3D printers successfully solve many problems in dentistry, for example, they print aligners (transparent caps) for orthodontic treatment.

Now high-tech 3D printers successfully solve many problems in dentistry, for example, they print aligners (transparent caps) for orthodontic treatment.

The first attempts to use 3D printing in dentistry were made quite a long time ago, back in the late 1990s. Now high-tech 3D printers successfully solve many problems in dentistry, for example, they print aligners (transparent caps) for orthodontic treatment.

How are aligners printed with a 3D printer?

- At the first visit, the orthodontist takes all the necessary pictures, including an orthopantomogram and lateral X-ray of the head, and takes casts of the patient's dentition. All information is sent to the laboratory, where the aligners will be made using 3D printing.

- A special computer program creates a virtual model of tooth movement at all stages of orthodontic treatment until the desired result is obtained.

- An orthodontist prepares a treatment plan, after which a set of files is ready for subsequent printing on a 3D printer.

- First, molded models are printed on a 3D printer. And then the aligners are created by molding the printed models with a special material.

- Sets of ready-made aligners are sent to the orthodontist, who hands them over to the patient at a scheduled visit.

What are the benefits of 3D printed aligners?

- The use of 3D printing has reduced the cost of manufacturing aligners and made this treatment more accessible to patients.

- 3D printing guarantees high accuracy – the percentage of errors is reduced to a minimum, therefore, the effectiveness of this type of orthodontic treatment has become even higher.

- Modern 3D printers can now print aligners in less than an hour. These are truly impressive results compared to traditional aligner manufacturing methods.

Recall that orthodontic treatment with aligners for adults has become a modern breakthrough method of orthodontic treatment. When correcting the bite on the aligners, the patient receives maximum aesthetics, since transparent caps are completely invisible on the teeth, and at the same time high efficiency. The period of orthodontic treatment on aligners averages from 1.5 to 2, which is comparable to the average period of treatment with braces.

The period of orthodontic treatment on aligners averages from 1.5 to 2, which is comparable to the average period of treatment with braces.

The use of 3D printing in the manufacture of aligners has allowed us to combine high quality products with lower costs and bring the demand for aligners in patients to a whole new level.

Back to article list- Oral hygiene

- Diagnostics

- Treatment under anesthesia

- Orthodontics

- Recommendations

- Therapy

- Implantation

- Surgery

- Whitening

- Orthopedics

Other related articles

Adult bite correction

According to statistics, 8 people out of 10 have malocclusion. It is believed that it is best to correct defects of this kind in childhood. But what about adults who also want to shine with a Hollywood smile?

It is believed that it is best to correct defects of this kind in childhood. But what about adults who also want to shine with a Hollywood smile?

December 11, 2019

A little about aligners

If you have long dreamed of straight teeth, but were embarrassed to wear braces, there is a way out - aligners, which are not in vain called the most aesthetic method for straightening teeth. Aligners are transparent caps that are made individually for each patient and completely repeat the shape of the teeth.

January 27, 2020

Braces during pregnancy

There are no contraindications for the installation of braces during pregnancy, and even more so, they do not need to be removed if you find out that you are pregnant during the process of orthodontic treatment. In the article, we want to tell you that pregnant women may face a number of difficulties that it is better to know about in advance.

February 10, 2020

Why it is important to have a correct bite

Statistics show that more than 80% of the population of developed countries have malocclusion. Sometimes this is only a cosmetic defect or minor deviations, but there may be serious pathologies that provoke the appearance of headaches and many other problems.

February 19, 2020

Differences between aligners and braces

We continue our series of interviews with CrocoDent clinic dentists, in which our doctors will answer a number of the most common questions. Today our dentist-orthodontist Victoria Sergeevna Kulikova talks about the main differences between aligners and braces.

March 12, 2020

Features of orthodontic treatment with aligners

Today in an interview, the orthodontist of the dental clinic CrocoDent Kulikova Victoria Sergeevna will tell you how orthodontic treatment is carried out on aligners.