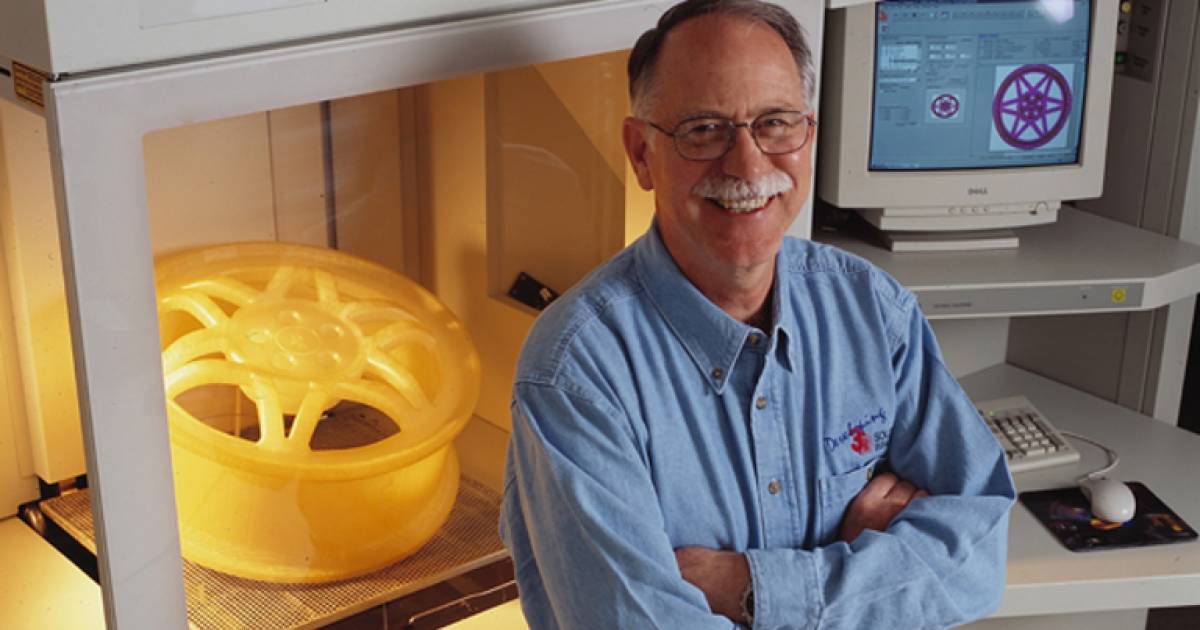

Zcorp 3d printer

Zcorp 3D Printer Review 2022

We reviewed the popular Zcorp 3D printer. Find out if this 3D printer is the right one for you or if you are better off with another one.

By Thomas Bardwell

3.9

See Price

Although manufacturer ZCorporation no longer exists, the company’s range of printers stays a reference in the annals of 3D printing history for bringing full-color printing to the forefront of 3D possibilities.

Among the shining lights of this revolutionary series of printers is the ZCorp Z450 and today we’ll focus on this very model to determine how well it stacks up to trials and tribulations of time. Let’s jump in and find out what this 3D printer has to offer.

| Printing Area | 203 mm x 254 mm x 203 |

| Layer Resolution | 90 – 100 microns |

| Supported Filament | ZP130 Powder and ZB59 Binder |

| Printing Technology | 3DP/ZPrinting/ColorJet Printing |

| Resolution | 300 x 450 dpi |

Table of ContentsShow

Design & Features

Visually, the ZCorp Z450 isn’t the most appealing and is very much a product of tech production of the early 2010s with a rather uninspiring grey scheme covering the entire unit only interrupted by a questionably stylish orange near the control panel.

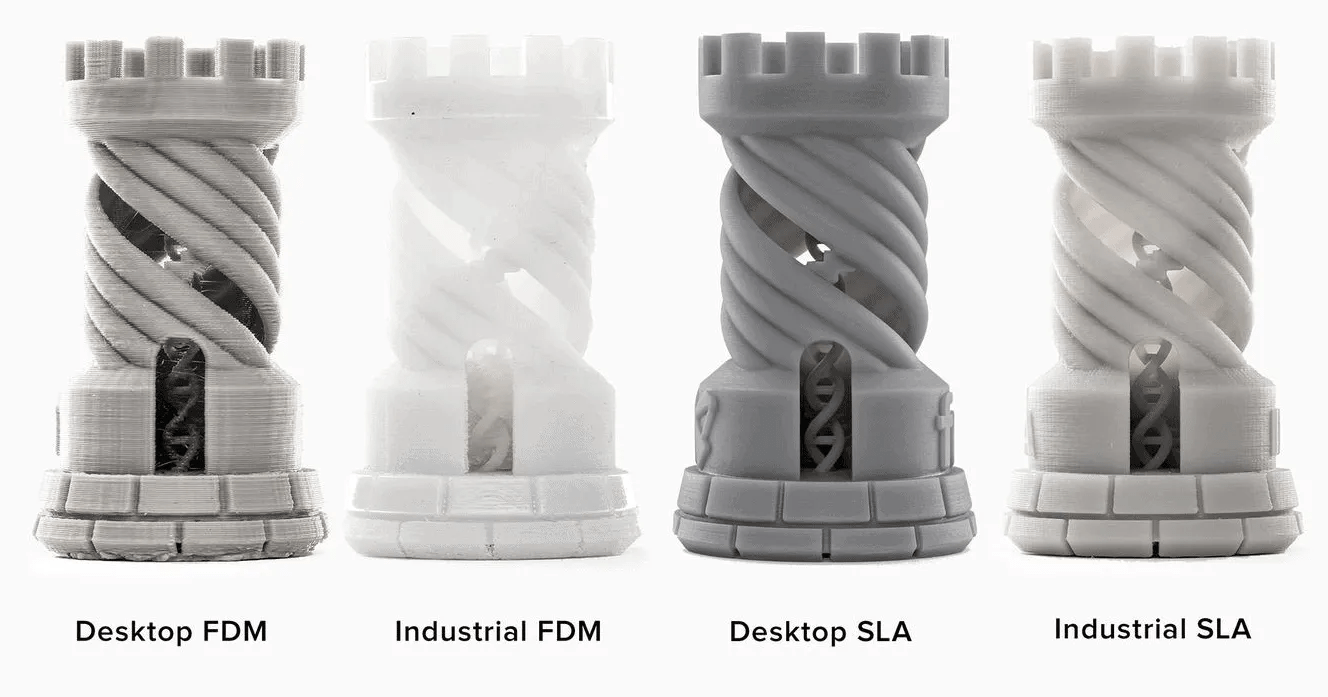

Rather than relying on Fused Deposition Modelling, the Zcorp Z450 is based on a patented additive manufacturing technology known as 3DP, ZPrinting, or ColorJet Printing depending on who you ask.

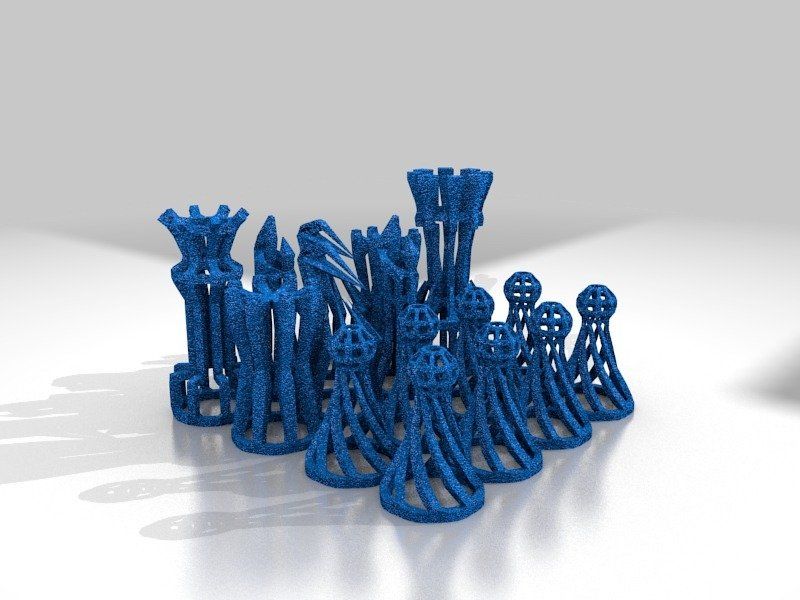

The basic tenet of the process involves a print head – very similar to that found in traditional inkjet printers – selectively laying down a liquid binding material on a thin layer of powder causing it to solidify into a specific shape and design. The main upside of the technology is a near limitless use of color because the inkjet selectively colors the binder from a range of 180,000 individual shades before applying it to the powder.

When the shape has been etched into the powder, the print bed lowers down ushering in a fresh layer of powder spread thanks to a roller for the process to repeat itself. Add up all these layers, dust off any extra powder, and you get a full-color 3D model. The results can include graded color fades, intricate patterns, and near lifelike color renditions.

The innards of the printer are divided into two chambers one for building and one for fine-powder removal. Nearing the end of the build process the first chamber runs a cursory powder removal cycle that removes the bulk of the excess powder. When the model is dry, it is moved to the second chamber where a stronger, deeper removal process cleans off any remaining powder.

The build area of the Z450 totals in at 203 mm x 254 mm x 203 for an entirely respectable surface area that is in line with similarly sized printers, but doesn’t set any records. A happy middle ground if you will. It can print up to 23 mm per hour with a layer resolution range of 90 to 100 microns and a print resolution of 300 x 450 dpi.

In what is undoubtedly the most significant negative of the Z450, the printer is only compatible with ZP130 Powder and ZB59 Binder materials. In itself, this isn’t an issue as there are many printers on the market with proprietary material limitations. The problem here is that buying the powder and binder is a bit like finding a needle in a haystack. Vendors are out there, but they charge a pretty penny for the materials.

Vendors are out there, but they charge a pretty penny for the materials.

An LCD controlled by a wheel knob sits on the front of the printer providing an array of functions ranging from de-powdering, status details, and platform raising controls. Connectivity is assured via Ethernet.

The printer runs alongside the ZPrint software that acts as both a slicer and interface to communicate with the printer. It can read STL, VRML, PLY, 3DS, ZPR file types and is compatible up to Windows 7 or older. The software isn’t innately shoddy but does show its age with an absence of functions and tinkering options we’ve come to expect from modern slicing software.

Assembly & Unpacking

Due to its 193 kg total weight and 122 cm x 79 cm x 140 cm dimensions, the Z450 falls into the crate shipped printer category, and this is precisely how the model was delivered when it was still being manufactured and how we took custody of it second hand.

The printer comes fully assembled other than fitting a new printhead and replacing the binder/powder cartridges. Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Printing

The Z450 produces high-quality prints with an eye-watering range of colors that put standard FDM 3D printers to shame. The printing process is also extremely streamlined due to the arrangement of the chambers and their various dry, vacuum, and print functions. The printer is also very waste conscious and automatically reuses excess powder. The added vacuum nozzle also works admirably for manual powder clearing.

Where this printer truly shines is in the speed of the printing process. In what is near enough twice the rate of traditional 3D printers, the Z450 is the fast prototypers dream with the ability to produce conceptual parts very quickly.

The models look and feel amazing, but there is a certain frangibility to them that is absent in PLA or ABS models for example. There’s a distinct sense that beyond being a visual representation of an idea or model, the prints from the Z450 won’t fare well being handled for practical uses or mechanical purposes, even as a functional proof of concept.

Support

In light of 3D Systems taking over Z Corporation and manufacturing of the Z450 long since abandoned, official support is unavailable. Any warranties for new units have long since expired with the chances of obtaining one is confined to merchants and auction sites flogging the printer second hand. These vendors may offer other warranties so check before committing to a purchase.

It is, however, possible to successfully hew through successive Google search pages to find advice and tips for using the Z450. Among these are niche communities of users who vow by the Z450 for all their printing needs. The difficulty lies in tracking them down.

The user manual is also a great source of information for troubleshooting problems and maintenance guidelines.

Verdict

In our eyes, the Zcorp Z450 is geared towards fast prototyping for design concepts, architectural models, form-and-fit prototypes, and demonstration pieces. Within these spheres, the Z450 performs admirably, but the questionable reliability of the end product with a propensity for being unduly brittles means practical uses are out of the picture.

Equally, a hobbyist who wants reliable models for either ornamental purposes will find use in the Z450 but venture even slightly into application based printing, and this model falls short.

The real allure of the Zcorp 3D printer is that it is possible to pick one up for a fraction of the retail price (approximately around $40,000 at its peak price). We are talking less than a $1000, if not less.

A hobbyist who wants a printer with powder/binder-based technology to add to their workshop should strongly consider the Z450 for its reliability and low cost.

Form 2 Review

3D Systems Zcorp 3D Printer

Properties

| Build Volume | 254 x 381 x 203 mm (10 x 15 x 8 in.) |

| Layer Resolution Low | 100 micron (0.004 in.) |

| Layer Resolution High | 100 micron (0. 004 in.) 004 in.) |

Documents

- 09537 Spectrum User Manual_RevF.pdf

| Brand | 3D Systems |

| Machine type | 3D Printer |

| Technology | CJP (ColorJet Printing) |

| Materials | Full-color sandstone (VisiJet PXL) |

| Website | http://www.zcorp.com/en/Products/3D-Printers/Spectrum-Z510/spage.aspx |

| Average Price | Contact manufacturer |

The Spectrum Z510 Full Color System produces high-definition, full-color prototypes quickly and affordably. Superior inkjet printing technology creates parts with crisply defined features, enhanced accuracy, and precise color, so you can print and evaluate physical models of design concepts in their nearly finished state.

Rapid 3D printing of high-definition models means you no longer have to wait for prototypes. This unique, 24-bit color, 3D printing capability produces color models that accurately reflect your original design data. Color models communicate more information than any other type of rapid prototype, providing you with a strategic advantage in product development.

Only Z Corporation’s 3D printers are capable of printing in multiple colors. Other 3D printers billing themselves as color capable are in fact monochrome machines that can only print one color at a time, requiring the user to laboriously assemble various monochrome parts into something that resembles a full color model.

Specifications:

- Build Speed: 2 layers per minute

- Build Size: 10" x 14" x 8"

- (254 x 356 x 203 mm)

- Layer Thickness: User selectable at the time of printing; 0.0035"-0.008" (.089-.203 mm)

- Material Options: High performance composite, elastomeric, direct casting

- Resolution: 600 x 540 dpi

- Number of Print Heads: 4

- Equipment Dimensions: 42" x 31" x 50"

- (107 x 79 x 127 cm)

- Equipment Weight: 450 lbs. (204 kg)

- System Software: Z Corporation’s proprietary software accepts solid models in STL, VRML PLY, and 3DS file formats as input. ZPrint™ software features 3D viewing, text labeling, and scaling functionality. The software runs on Microsoft Windows* NT, 2000 Professional, XP Professional and Vista.

Zmorph is the most multi-head 3D printer. Investigation from REC.

Hello everyone! Not so long ago, we got to see the unique multifunctional Zmorph platform. This article will tell you about our experience, observations and technical aspects revealed during 3D printing. However, since the Zmorph is not just a simple single extruder 3D printer, there will be additional articles about each interchangeable head describing the work, nuances and results.

This article will tell you about our experience, observations and technical aspects revealed during 3D printing. However, since the Zmorph is not just a simple single extruder 3D printer, there will be additional articles about each interchangeable head describing the work, nuances and results.

General information about the device.

1. External dimensions - 530 mm x 555 mm x 480 mm.

2. Printable area - 250mm x 235mm x 165mm.

3. Number of printheads - 1

4. Weight is ~ 25 kg.

5. The printer is equipped with a thermal table, card reader, ethernet port and touch monitor.

6. Maximum nozzle temperature: ~260

7. Nozzle diameter: 0.4 mm, resolution: 200 to 70 microns

8. Build speed 60-150 mm/s

9. Printing materials declared by the manufacturer: PLA, ABS, PETG, Laywood, nylon, rubber, etc.

10) Features - the main bonus of this printer is interchangeable heads. In our kit there are 1.75 single extruder head, 1.75 double extruder head, milling cutter, laser and extruder-syringe,

In our kit there are 1.75 single extruder head, 1.75 double extruder head, milling cutter, laser and extruder-syringe,

11) The printer has its own software, called Voxelizer. The program provides all the options for the heads of this device and has many settings.

Review

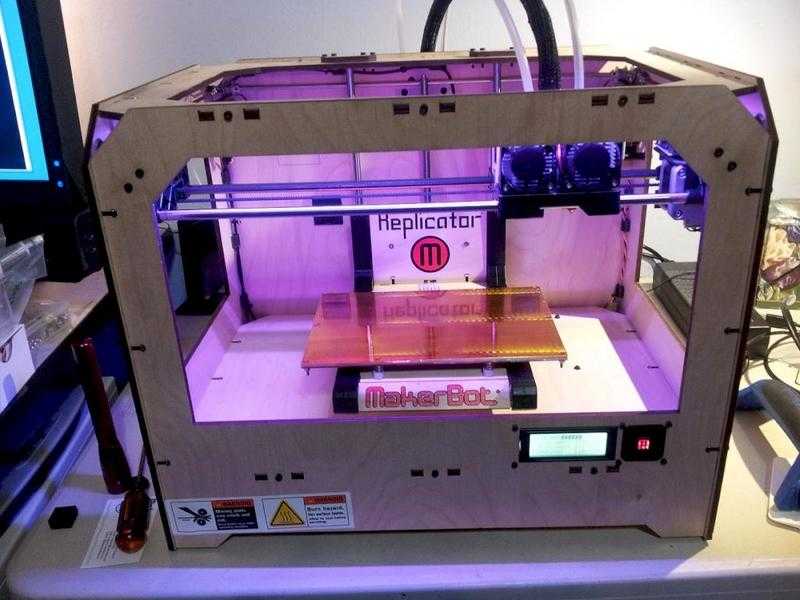

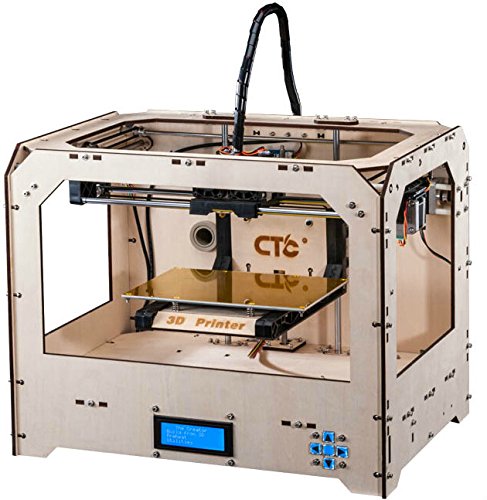

The printer itself looks quite serious, thanks to the metal and transparent plastic, it evokes the feeling of some kind of device from sci-fi films, although in principle we see a Prusa i2, but with a very rigid body.

The extruder looks serious, the carriage itself is assembled from metal and a small number of printed parts. The airflow of the model is attached with magnets, which is very convenient.

Thermotable moves on two belts and rails, adjustable with 3 screws. Fastening is realized through magnets.

The axle guides are also made of sheet metal. No backlash, everything is very rigid.

No backlash, everything is very rigid.

The printer has a nice touch screen display with its own menu.

Cable management is perfectly arranged in the printer body itself. All wires are perfectly protected from breaking and bending. All connectors that the user will have to work with are signed and marked.

The printer has an interesting implementation of the spool attachment mechanism and the filament channel.

This is how 0 is implemented on the Z axis.

Very pleased with the highlighting and marking of important elements on a 3D printer. There is a feeling of working with an expensive industrial device.

Diode illumination of the printed model is a very nice element.

Like many other units, the outer protective case is also attached with a magnet.

Software

Voxilaser looks like this

this is the first menu of transformations and settings, here we place objects, set their sizes, and also select the work area. In this case, workflow costs as 3D printer.

press voxilase and go to voxel editor. It has the usual print settings for all of us.

after we click generate g-code

here we see the generated task, it remains to press play

save it to a USB flash drive and print it.

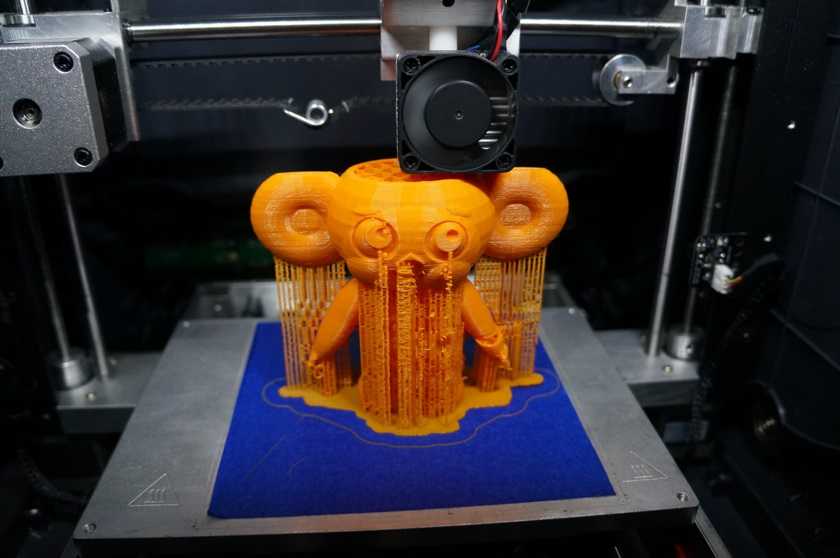

Print.

First print on a ZMorph 3D printer. A single extruder print head is used. Material natural REC PLA. Before printing, I had to calibrate the table.

Model can be found here: https://www.thingiverse.com/thing:1803617

Material red REC PLA plastic, print speed 90 mms

Material red REC PLA plastic, print speed 70 mms. (outer wall)

(outer wall)

Relax

Material natural REC RELAX plastic, print speed 60 mm with 0.4 mm nozzle and 0.2 mm layer.

Bicycle pedals made of natural and white REC RELAX plastic. Layer height 0.15 mm, speed 30. In total, it took 48 hours to print, the result is stable.

Bonus

And now an unexpected bonus - ABS + HIPS printing test on the Dual PRO head.

It differs from the previous one by the ability to print two materials through one nozzle.

The slicing is not much different, all you need to do is set extruder 2 in some places. Thanks to the software, the head is able not only to create supports from another material or to imprint parts from different materials into each other, but also to mix them.

Now let's look at "two-color" printing.

The algorithm of actions is described here, but in general, it's very simple.

The result is just wonderful.

Now let's try blending. Let's fiddle a little with the settings again.

This tutorial describes how to do it.

Looking at the result

Unfortunately we overlooked the amount of pink ABS and ran out of it during the printing process, leaving most of the vase under extruded, but the resulting part shows that the mixing occurs without any problems according to the given program.

Anyway, we did it again.

And now the result:

Conclusions.

Pros:

- Rigid frame, good design and very high quality assembly and components.

- Very precise kinematics.

- The ability to quickly remove and put on additional elements such as protective screens, a model air cooler, a working head and even a heating table.

- Easy-to-learn software with lots of settings and features.

- Convenient printable area.

- The printer has all the necessary warnings and markings, heated table, extruder and powered Z and X axes are illuminated by diodes. The printed object itself is also illuminated, which helps to keep track of the printing process.

- User-friendly interface with a set of useful features. Fine-tuning printing is easy enough, all the icons are unambiguous and large enough not to miss them.

- The printer produces excellent results at low to medium speeds from PLA and RELAX

Cons:

- It is very easy to calibrate the table because of the magnetic mount, you will not only have to level the table plane but also very likely to set zero on the Z axis, after removing the part or detaching the table.

- This printer is conceived and designed as an MFP, not as a 3D printer, so it has a high margin of safety and rigidity, while at the expense of print speed there may be traces of underextrusion or, conversely, excessive drops on the surfaces of models, especially when it comes to a large number of retracts.

- The spool mounting on the printer is interesting, but practice has shown that the filament supply channels can get stuck in the case, stretch and thereby interfere with the plastic supply.

- The software calculates the print time very accurately, but not the amount of plastic required.

- Printing with flexible materials is difficult, again due to thermal distribution, difficulty in feeding the plastic through the tube, and too much pressure that compresses the bar.

Pro Dual PRO

This head has been tested for the main tasks conceived in the design. This system is capable of printing solvent-based supports in PLA+PVA and ABS+Hips combinations, and also allows two-color printing. and The ability to mix colors with a gradient comes as a special feature.

Plug&play head, we installed it, filamented it, and started the job. Slicing in Voxeliser, even for this mode, is very simple and intuitive. If you don’t figure it out yourself, there are good tutorials on working in text and video format on the manufacturer’s website.

If you don’t figure it out yourself, there are good tutorials on working in text and video format on the manufacturer’s website.

Conclusion.

Zmorph is a unique platform with many possibilities. Our practice of using it as a 3D printer has shown that this device requires very thoughtful use. This is also due to the software, in which the interface is very clear, but overloaded with elements, which makes it easy to miss something in the settings. It is worth noting a very tough and thoughtful case filled with useful features, markers and indicators. Despite its robust and simple design, the Zmorph printer is not one of the best offerings on the market, as it is built solidly and reliably to handle a range of versatile tasks, not just printing. Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects.

At the same time, working with Zmorph is very simple, in order for the device to behave like a plug and play you just need to remove the printed models very carefully, trying not to pull the table off its mounts and thereby violate its calibration.

In general, the printer produced the best results at speeds from 30 to 70 mm s (infill and outer contour, travel from 120 to 180 mm s) with REC PLA and REC RELAX plastics. When printing ABS and ETERNAL, it is necessary to install protective screens, as they are enough to avoid delamination of the object.

Summing up, we note that Zmorph is a unique machine that will give the user great opportunities, and in return they will only ask you to follow the instructions. This device will find its well-deserved place in various workshops, design bureaus, and especially in educational institutions.

If you have any questions, write comments, call, contact us in the social. networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

Website: https://rec3d.ru/Phone: +7 (800) 775-7331 (free of charge from anywhere in Russia)

http://www.viber.com/rec3d https://telegram.me/Rec3d_bot https://vk.com/rec3dcompanyhttps://www. instagram.com/rec3dcompany/Office: Moscow, st. Godovikova d. 9, building 1, entrance 1.19, office 2.3. Technopark "Caliber".

instagram.com/rec3dcompany/Office: Moscow, st. Godovikova d. 9, building 1, entrance 1.19, office 2.3. Technopark "Caliber".

Thank you for your attention and happy printing!

Z Corporation Introduces First Automated Monochrome 3D Printer

Z Corporation announces the launch of the world's first automated monochrome 3D printer, the ZPrinter 350.

Z Corporation's most affordable 3D printer today makes advanced fast modeling technology even more accessible to a wide range of engineers and architects. Like all Z Corporation 3D printers, the ZPrinter 350 converts electronic data about a 3D object into a physical model in the same way that a conventional printer turns a text file into a paper document.

Unlike other 3D printers, only ZPrinter 350 provides the following top quality 3D printing functionality:

- automatic media loading;

- quick release binder cartridges;

- complex processing of unused structural materials;

- self-diagnosis during operation;

- control from both a computer and a printer;

- vertical build speed 20 mm/h;

- working chamber size 203×254×203mm;

- resolution 300×450 dpi;

- consumables safe for indoor use; active dedusting, no liquid waste.

Available today, the ZPrinter 350 is the ideal choice for organizations looking for the best way to quickly create monochrome models in an office environment.

« ZPrinter 350 will bring cutting-edge 3D printing technology to a much larger number of design departments at an affordable price, says CEO Z Corporation John Kawola. "Our 3D printing technology is designed to improve the quality of the products we develop, grow companies faster, and ultimately increase profits."

All the benefits of 3D printers from Z Corporation are incorporated into the new device :

- The has the lowest running cost of its kind, five times lower than other technologies.

- Fastest print speed - Create models 5 to 10 times faster than other systems.

- Revolutionary ease of use - performs most operations automatically.

Learn more