3D printer house amsterdam

3D Print Canal House (Amsterdam)

Detailed Reviews: Reviews order informed by descriptiveness of user-identified themes such as cleanliness, atmosphere, general tips and location information.

4.0

12 reviews

Excellent

Very good

Average

Terrible

Drew

Ko Pha-Ngan, Thailand36 contributions

Is it still there?

Sep 2019 • Couples

Not sure if this is still open, we went to the direct location of the house but couldn’t find it. I was really looking forward to it.

Written September 1, 2019

This review is the subjective opinion of a Tripadvisor member and not of Tripadvisor LLC. Tripadvisor performs checks on reviews.

Rasmus B

1 contribution

Great place for a school trip with tech-minded students.

Sep 2017 • Business

Great and engaging short tour and eager to answer questions, though most of them seamed to be answered by the tour. Exciting reseach going on here in the field of 3D printing.

Written September 25, 2017

This review is the subjective opinion of a Tripadvisor member and not of Tripadvisor LLC. Tripadvisor performs checks on reviews.

Adam T

Ho Chi Minh City, Vietnam12 contributions

Sadly you can't just turn up now

Mar 2016 • Solo

When I found out about this place I was desperate to visit. All materials online pointed towards it being a simple case of turning up. Its not like that anymore, you need to book a full tour (up to a week in advance) or turn up on their open day (I think Weds) but not even sure if they are doing that anymore. Was disappointed as really wanted to see this technology in action and to find out in more detail how its being applied.

Written March 7, 2016

This review is the subjective opinion of a Tripadvisor member and not of Tripadvisor LLC. Tripadvisor performs checks on reviews.

FionaL_11

Amsterdam, The Netherlands822 contributions

Great potential!

Sep 2015 • Solo

Don't get your hopes up - the full scale 3D printed house isn't built yet. You can see the scale models, the plans and chunks of 3D printed building blocks - less than I expected, but on the other hand the possibilities are really excitng. Imagine the potential for constructing emergency housing in disaster zones using recycled plastic. A really inspiring architectural experiment. I will return again when there is more to see.

You can see the scale models, the plans and chunks of 3D printed building blocks - less than I expected, but on the other hand the possibilities are really excitng. Imagine the potential for constructing emergency housing in disaster zones using recycled plastic. A really inspiring architectural experiment. I will return again when there is more to see.

It is a bit of a jaunt to make a ferry crossing just to see the 3D canal house. I would recommend combining with a visit to the EYE film museum. It is about 15 minutes walk from there to the Canal House construction site.

Written September 18, 2015

This review is the subjective opinion of a Tripadvisor member and not of Tripadvisor LLC. Tripadvisor performs checks on reviews.

pctl

Atlanta, GA34 contributions

Interesting concept

Jul 2015 • Couples

Interesting use of 3D printing technology for housing. Smaller than what we expected. Unrelated, but across the street is a school built using prefab containers.

Written July 4, 2015

This review is the subjective opinion of a Tripadvisor member and not of Tripadvisor LLC. Tripadvisor performs checks on reviews.

IndiraIra

Hoofddorp, The Netherlands406 contributions

Futuristic idea in printing and architecture, must see

Jun 2015 • Solo

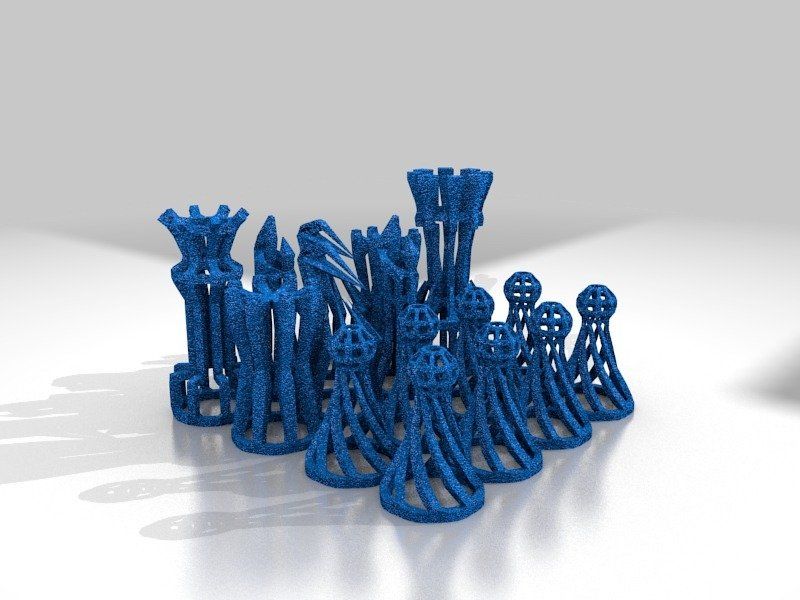

This is unique in terms of architectural experiment as well as 3D printing. The research here is path breaking, into various aspects such as printing materials for outdoor, construction techniques for printed material etc. The place exhibits, as it researches. Very few research facilities show their work, as they work this is one of them. You can see the printed working, as it makes the latest part of the house. There are other objects like chairs and models which are also on display. There is a shop, and you get a variety of objects on sale, which have been printed at site. There is a small fee of 2.50 euro, which includes an audio tour. This is a must see place for designers and architects.

This is a must see place for designers and architects.

Written June 6, 2015

This review is the subjective opinion of a Tripadvisor member and not of Tripadvisor LLC. Tripadvisor performs checks on reviews.

LWL3333

Wellington, FL18,100 contributions

A view into the Future

Jul 2014 • Couples

I can't say enough positive about this construction site just across the ferry behind Centraal Station. A crew of international architects and students is constructing an entire Amsterdam-style canal house with a giant 3D printer. So far they have printed out one room of the 9 rooms planned, and some furniture. The process extrudes liquid plastic in strips which are fashioned into walls, floors, etc. We bought a set of 4 wine glasses made on a smaller 3D printer, each thin plastic glass very different from the others. Highly recommended as a look into the future of housing construction.

Written October 15, 2014

This review is the subjective opinion of a Tripadvisor member and not of Tripadvisor LLC. Tripadvisor performs checks on reviews.

Tripadvisor performs checks on reviews.

LWL3333

Wellington, FL18,100 contributions

Fabulous look into the Future

Jul 2014 • Couples

This attraction is difficult to describe. They have a large 3D printer set up outdoors and little by little they are printing an entire Amsterdam-style canal house from extruded liquid plastic including the furniture and housewares, in addition to the actual structure itself. So far they have printed one room plus some furniture. The process is fascinating. There is an international cast of university architecture and science students on hand to run the place and answer (in English) any questions. I am shocked that no one has written a review of this wonderful attraction thus far, but I'm sure there will be lots more in the near future as word spreads about what they are doing here. To get there you need to take the free ferry behind the Centraal Station and walk about 10 minutes. Their website provides good directions. You can buy various items made on the printer. We bought a set of 4 different styles and colors of fully functional wine glasses as a one-of-a-kind gift for friends.

You can buy various items made on the printer. We bought a set of 4 different styles and colors of fully functional wine glasses as a one-of-a-kind gift for friends.

Written September 14, 2014

This review is the subjective opinion of a Tripadvisor member and not of Tripadvisor LLC. Tripadvisor performs checks on reviews.

DUS Architects builds 3D-printed micro home in Amsterdam

- Photograph by Ossip

- Photograph by Ossip

- Photograph by Ossip

- Photograph by Ossip

- Photograph by Ossip

- Photograph by Sophia van den Hoek

- Photograph by Sophia van den Hoek

- Photograph by DUS Architects

- Photograph by DUS Architects

- Photograph by DUS Architects

- Photograph by Sophia van den Hoek

- Photograph by Sophia van den Hoek

- Photograph by Sophia van den Hoek

- Photograph by Ossip

- Photograph by Ossip

Amy Frearson | 9 comments

Dutch studio DUS Architects has 3D printed an eight-square-metre cabin and accompanying bathtub in Amsterdam, and is now inviting guests to stay overnight (+ slideshow).

DUS Architects used sustainable bio-plastic to create the 3D Print Urban Cabin, which is intended to demonstrate how additive manufacturing can offer solutions for temporary housing or disaster relief.

Photograph by Sophia van den HoekWhen the cabin is no longer needed, it can be destroyed and almost all the materials can be reused.

"The building is a research into compact and sustainable dwelling solutions in urban environments," said the team.

Photograph by Sophia van den Hoek"3D printing techniques can be used particularly well for small temporary dwellings or in disaster areas," they said.

"After use, the bio print material can be shredded entirely and re-printed into new designs."

Photograph by Sophia van den HoekThe Amsterdam-based architecture studio is currently in the final stages of a project to build a full-size 3D-printed canal house. This smaller project offers an insight into what that structure will look like.

Located in a former industrial area, the tiny gabled cabin contains just 25 cubic metres of area – far less than the average micro home.

Dutch EU building features a facade combining tensile fabric and 3D-printed bioplastic

A window punctures one end, while the other integrates both an entrance and a stepped porch seating area. Its walls are patterned with angular protrusions that create a three-dimensional surface, giving the building extra structural stability.

Photograph by DUS ArchitectsAll of these surfaces are black, thanks to the bio-based 3D-printing filament – a product with linseed oil as its main component, which the architects have been developing with major consumer manufacturing company Henkel.

A small amount of concrete was also used, to provide a durable flooring surface. It infills a patterned grid, which extends out from the cabin to form a pebbled pathway across a small garden.

Photograph by Sophia van den Hoek"Entirely 3D printed with black coloured bio-based material, it showcases different types of facade ornament, form-optimisation techniques, and smart solutions for insulation and material consumption," said the team.

Inside, the cabin contains enough space for a bed, although this can be folded up into a seat during the day. There is no space for a bathroom, but a large 3D-printed bath is located in the garden.

"In the green around the cabin you can enjoy the sculptural printed bathtub, and watch the sunset surrounded by waving poplar trees," added the architects.

Photograph by OssipDUS Architects first unveiled designs for the 3D printed canal house back in 2013 and is aiming to complete the project early next year.

But the 3D Print Urban Cabin isn't the first completed example of the studio's 3D printing expertise – earlier this year it created a sculptural facade for a European Union meeting building, which was the first public reveal of its so-called "XXL 3D prints".

Photograph by OssipThis technique uses fused deposition modelling, the same form of additive manufacturing used by most household 3D printers.

The cabin is available for short-term lets.

Project credits:

Architects: DUS architects

Design team: Hans Vermeulen, Martine de Wit, Hedwig Heinsman, Martijn van Wijk, Inara Nevskaya, Ivo Toplak, Peter Hudac, Foteini Setaki

3D printing and assembly: Martine de Wit, Jasper Harlaar, Sven de Haan, Ina Cheibas, Joe Platt, Nathalie Swords

Material development: Henkel

IT hardware: Lenovo

Concrete work: Heijmans

Bath spout: Vola

Textiles: Borre

Landscape: Delva Landscape, Boomkwekerij Ebben

Accessories: Misc store

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

New! Dezeen AgendaSent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Plus occasional updates on Dezeen’s services and breaking news.

A daily newsletter containing the latest stories from Dezeen.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Dezeen AwardsNews about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

What the first 3D printed steel bridge looks like

Trends

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Mashable / YouTube

The world's first 3D printed steel bridge has been installed in Amsterdam. The project was ready three years ago, but the installation of the bridge was constantly delayed

What's happening

- On July 15, the world's first 3D printed steel bridge was opened in Amsterdam.

It connects the embankments of the Oudesijds Achterburgwal canal. The grand opening was attended by Queen Maxima of the Netherlands.

It connects the embankments of the Oudesijds Achterburgwal canal. The grand opening was attended by Queen Maxima of the Netherlands. - The structure weighs 6 tons and is 12 meters long.

- The bridge was printed by four robots by welding layers of stainless steel wire, it took them 4.5 tons of steel and six months to make a span of 12 meters. Then coastal supports and decorative elements were made.

- This project was developed by the laboratory of Joris Laarmann and ABB, Air Liquide, ArcelorMittal, Autodesk, AMS Institute and Lenovo, while the Amsterdam-based company MX3D was fabricating and installing the structure.

- More than ten sensors are built into the bridge, with the help of which it will be possible to monitor its condition and deformation. Thus, he will himself indicate the need for repair. The sensors will also count the number of pedestrians crossing the bridge each day.

- The structure was installed for two years as a replacement for the conventional bridge, which will be under reconstruction at that time.

- This bridge was first presented at Dutch Design Week Eindhoven 2018, where the project won the Dutch Design Award and the Audience Award. After that, the finished bridge lay in storage for another three years: first, in anticipation of the reconstruction of the canal, then due to the coronavirus pandemic and lockdown.

What does it mean

In recent years, there has been an active development of 3D printing technology in construction. The Netherlands seems to be on a roll with this trend, with the first fully 3D-printed residential building in the EU populated in the suburbs of Eindhoven in early May, followed by the opening of the world's first 3D-printed steel bridge.

We have already said that 3D printing is the future of construction and design. Compared to classic buildings, 3D printing has a number of undeniable advantages, such as short construction times, reduced economic and environmental costs, and ease of execution of complex shapes.

“This is not just about reducing and optimizing construction costs, but about giving architects and designers a new tool, a very cool new tool, with which they can rethink the design of their architecture and their projects,” notes Tim Görtjens, co-founder of MX3D, a bridge builder.

Mika Mos, member of the council of the municipality of Amsterdam, expressed the hope that this construction will also help the city attract quality new tourists:

“This could attract a new type of visitor, those more interested in architecture and design, which will change the perception of the area (famous for nightclubs and noisy parties. — RBC Trends ).”

Updated on 10/18/2022

Text

Ksenia Yanushkevich

Top of the trend

Related materials

3D printed Canal House, Amsterdam

On a 3D printer, you can print a part for a car, a piece of furniture, jewelry, a medical prosthesis and much more. But all this is not a very big thing. How large can items be made this way? Why not, for example, "print" a house?

But all this is not a very big thing. How large can items be made this way? Why not, for example, "print" a house?

For an answer to this semi-fantastic question, we went to Amsterdam. There, boarding a ferry at the Central Station, they moved to the other side of the Gulf of Hey and ended up in the northern part of the Dutch capital, where not only tourists, but even most local residents rarely stop by unnecessarily. Meanwhile, here, behind the futuristic building of the Museum of Cinema, in the middle of grassy wastelands, next to an unfinished construction site and unremarkable barrack-type structures, architects from the DUS Architects bureau are printing “House on the Canal” on a printer.

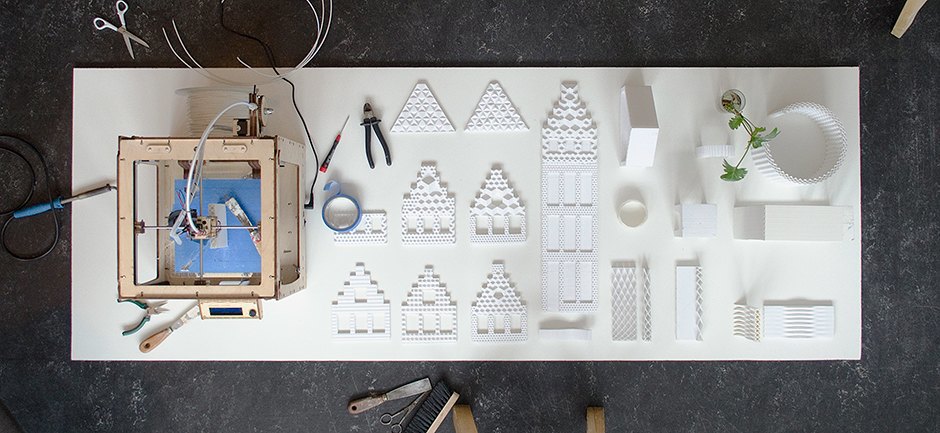

WASTE-FREE PRODUCTION

In the courtyard near the small office from which the entire process is run, there are many colored blocks and parts of different sizes and shapes that defy description. It is obvious that some of them will be used during construction, but it is not yet clear in what order they will be assembled. All blanks are designed and made here, on the spot. This allows not only to speed up the process, but also to avoid transportation costs, as well as to minimize the amount of waste.

All blanks are designed and made here, on the spot. This allows not only to speed up the process, but also to avoid transportation costs, as well as to minimize the amount of waste.

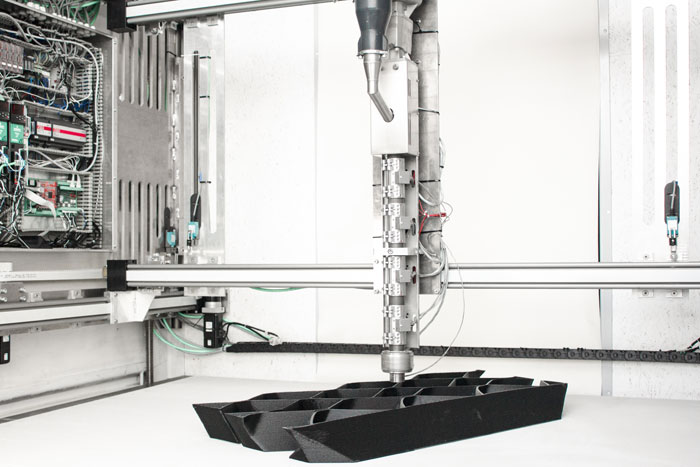

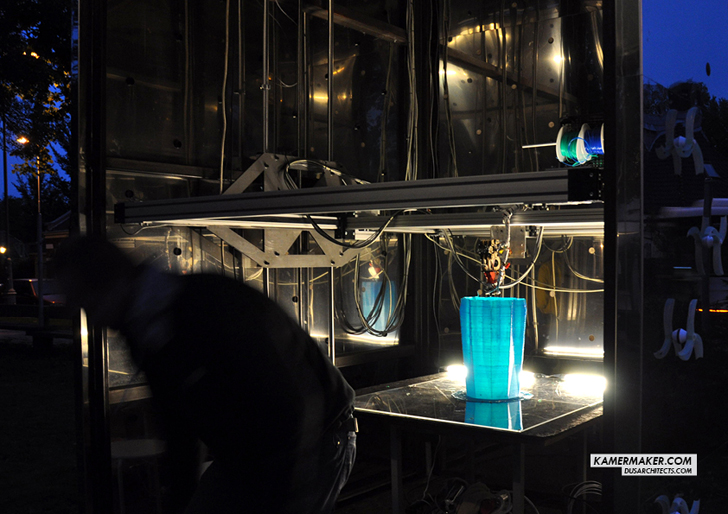

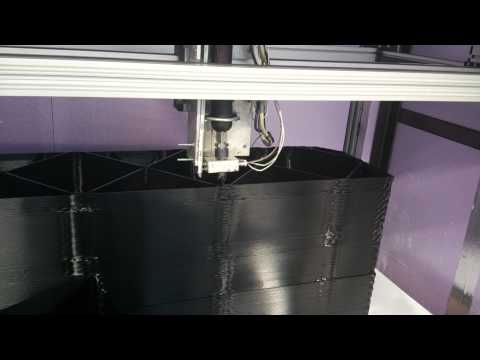

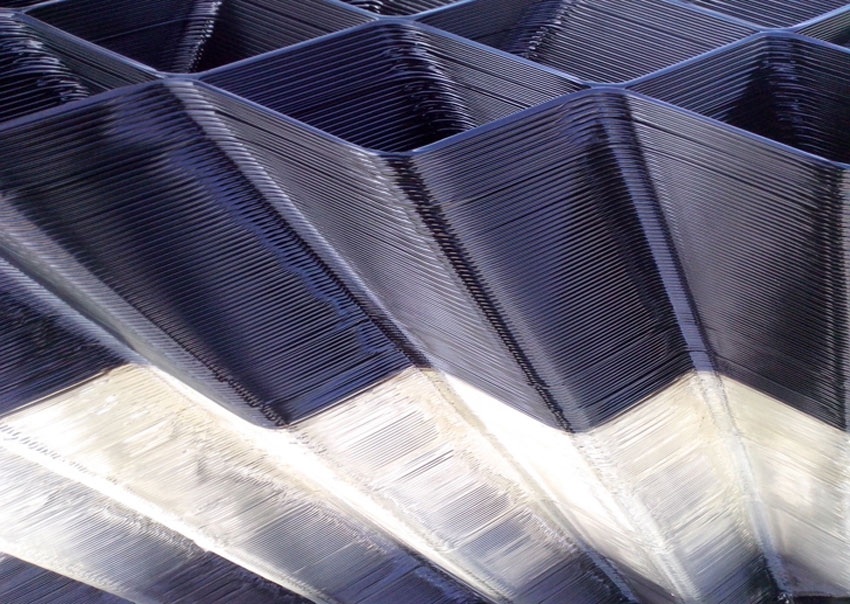

Printing is carried out using a specially made and placed in a spectacular silver six-meter case KamerMaker 3D printer. In fact, this is a multiply enlarged copy of a conventional desktop 3D printer. The dimensions of the finished parts are set strictly (2 × 2 × 3 meters), but their appearance is limited only by the imagination of architects and designers. The granulated plastic is fed into the extruder, where it is heated up to 170 °C and turns into a homogeneous liquid. Through heated tubes, the molten mass is sent to the printing device, the head of which moves to create the desired parts in a three-dimensional coordinate system.

By the way, the main material for printing is not ordinary plastic, but Macromelt bioplastic, developed by Henkel based on an industrial adhesive consisting of 75–80% vegetable oil. Obviously, the choice was made in favor of an environmentally friendly material of biological origin, capable of melting at a relatively low temperature and at the same time being sufficiently strong. At the moment, bioplastics are best suited for printing, although technically the KamerMaker printer can use any material that melts and subsequently hardens well, such as silver. However, other recyclable materials are also suitable for printing, however, only in the form of impurities: wood waste (they are ground into powder, and products made from such material really smell like wood), natural stone chips, clay. Even ... potato peel is used - it is with it (and with some other materials) that Dutch researchers are now conducting experiments.

Obviously, the choice was made in favor of an environmentally friendly material of biological origin, capable of melting at a relatively low temperature and at the same time being sufficiently strong. At the moment, bioplastics are best suited for printing, although technically the KamerMaker printer can use any material that melts and subsequently hardens well, such as silver. However, other recyclable materials are also suitable for printing, however, only in the form of impurities: wood waste (they are ground into powder, and products made from such material really smell like wood), natural stone chips, clay. Even ... potato peel is used - it is with it (and with some other materials) that Dutch researchers are now conducting experiments.

Many prototypes can be seen and touched. For example, translucent golden parts or matte black blocks are made of bioplastic, and those that are white or yellow are made of an inorganic material that melts at too high a temperature (it was eventually abandoned). Dyes can be added to plastic - the houses of the future do not have to be the same color. However, more importantly, the properties of bioplastics are constantly being improved with the help of various additives to make the material even more durable, waterproof and fireproof. To improve the latter quality, a mixture is poured into the cells of the printed blanks, which inside have a zigzag hollow structure, similar in physical and chemical properties to foam concrete. Technologists assure that thanks to this, if the house catches fire from the outside, then no one will feel the temperature changes inside.

Dyes can be added to plastic - the houses of the future do not have to be the same color. However, more importantly, the properties of bioplastics are constantly being improved with the help of various additives to make the material even more durable, waterproof and fireproof. To improve the latter quality, a mixture is poured into the cells of the printed blanks, which inside have a zigzag hollow structure, similar in physical and chemical properties to foam concrete. Technologists assure that thanks to this, if the house catches fire from the outside, then no one will feel the temperature changes inside.

Architect Hedwig Heinsman, who co-founded DUS Architects with Hans Vermeulen and Martine de Wit in 2004, says: “When we first started, we were just excited about the idea that we could print whatever we want, with whatever we want. But later we learned to select only the highest quality materials. It is very important to us that the printed house is safe and comfortable, which is why we devote so much time to research. We took three years to build the house, and very soon we will proceed directly to its assembly. However, all subsequent houses like ours will be built much faster. We are already seeing how much more efficient 3D printing is compared to conventional construction techniques.”

We took three years to build the house, and very soon we will proceed directly to its assembly. However, all subsequent houses like ours will be built much faster. We are already seeing how much more efficient 3D printing is compared to conventional construction techniques.”

By the way, 3D printing is an almost waste-free production: unsuccessful castings and accidentally formed remnants of materials are remelted.

As for the operational qualities of the "home from the printer", they are still unknown. DUS Architects are experimenting with thermal and acoustic insulation materials and say that they want to create a special foundation, corresponding to the lightness of the main material from which the house will be built, and making it possible to assemble and disassemble the structure without difficulty.

AMSTERDAM SYMBOL

Hedwig does not hide the fact that the use of traditional methods, for example, in the laying of engineering systems and communications, cannot be avoided. However, we understand that the elements that are ready, but still lying idle in the yard, from which the rooms will first be assembled, and then the whole house, symbolize the rise of the construction business to a new level. “One of the main advantages of building with a 3D printer,” Heinsman continues, “is the ability to produce an incredible amount of parts in absolutely incredible variations. Instead of using standardized elements, 3D printing allows us to modify and improve them to suit the needs and tastes of any of us. This made it easier to create unique objects with a minimum of effort.”

However, we understand that the elements that are ready, but still lying idle in the yard, from which the rooms will first be assembled, and then the whole house, symbolize the rise of the construction business to a new level. “One of the main advantages of building with a 3D printer,” Heinsman continues, “is the ability to produce an incredible amount of parts in absolutely incredible variations. Instead of using standardized elements, 3D printing allows us to modify and improve them to suit the needs and tastes of any of us. This made it easier to create unique objects with a minimum of effort.”

In DUS Architects, not without reason, they believe that today unique architectural structures are available either to large companies or to very rich people. The Dutch, on the other hand, are ready to offer individual projects to completely different clients and seem to be really able to democratize architecture.

A house printed on a 3D printer will not look at all like another miracle of modern architecture. What's more, DUS Architects' project, which combines a look at the future of construction with an appeal to the past, is reminiscent of the classic Amsterdam canal houses, the universally recognized symbol of the Dutch capital. Such houses can perform different functions: some houses shops with warehouses, others - housing or workshops. And the canal network itself, although it has lost its significance as the main transport artery of the city, after its inhabitants began to use cars and bicycles, still continues to be a universal center of attraction.

What's more, DUS Architects' project, which combines a look at the future of construction with an appeal to the past, is reminiscent of the classic Amsterdam canal houses, the universally recognized symbol of the Dutch capital. Such houses can perform different functions: some houses shops with warehouses, others - housing or workshops. And the canal network itself, although it has lost its significance as the main transport artery of the city, after its inhabitants began to use cars and bicycles, still continues to be a universal center of attraction.

Specialists in Russia also agree that the projects of residential buildings should not only meet modern standards, but also be turned to the future. For example, Grigory Altukhov, commercial director of FGC Leader, is sure that the organization of the internal space of a house, including public areas, should be relevant even in 10, 20 and even 30 years. Essentially, a printed home is an open-plan dwelling that can cater to the needs of occupants regardless of their age or personal interests.

At DUS Architects, when designing their home, they try to combine local traditions and advanced technologies, using the archetype in the context of a modern city. It is no coincidence that a huge mirror has been installed in the courtyard of the construction site that has not yet begun, which reflects the Westerkerk bell tower, located on the Prinsengracht canal, abundantly “seated” with houses of the 17th–18th centuries. This canal in the old part of the city, according to Heinsman and her colleagues, should find its visual “continuation” in the North Holland Canal, on the banks of which we are talking. And someday both shores of the Hey Bay, not least thanks to the initiative of DUS Architects, will be connected not only by the reflection in the mirror, but also quite “substantially”.

In the long term, many printed houses will grace the banks of the canals, and so far, an international team led by architects has proven that the “explore and do” method works great. Anyone can be convinced of this: the construction site of the DUS Architects house can be not only a kind of exhibition, open from Tuesday to Saturday from 11.00 to 17.00, but also a place of short-term "employment", since on some days anyone can become an assistant, but most those who are able are offered an internship here.

Anyone can be convinced of this: the construction site of the DUS Architects house can be not only a kind of exhibition, open from Tuesday to Saturday from 11.00 to 17.00, but also a place of short-term "employment", since on some days anyone can become an assistant, but most those who are able are offered an internship here.

By the way, already now the place where the printed house will stand is working as an important public space, and in two years there will be a research center where construction innovations will be studied, new ideas will be discussed and optimal solutions will be searched for their implementation.

WORLDWIDE

DUS Architects were not the first to print houses. There are enthusiasts of using a 3D printer in construction in many countries. For example, the Italian Enrico Dini, who is called “the man who prints houses,” although he has not yet completely built a single house. Dini uses sand as a material for creating his samples, hardening under the influence of a binder based on magnesium chloride. He patented this technology about 10 years ago, and now the Italian is being offered to build bases on the Moon, since there is plenty of sand-like regolith there.

He patented this technology about 10 years ago, and now the Italian is being offered to build bases on the Moon, since there is plenty of sand-like regolith there.

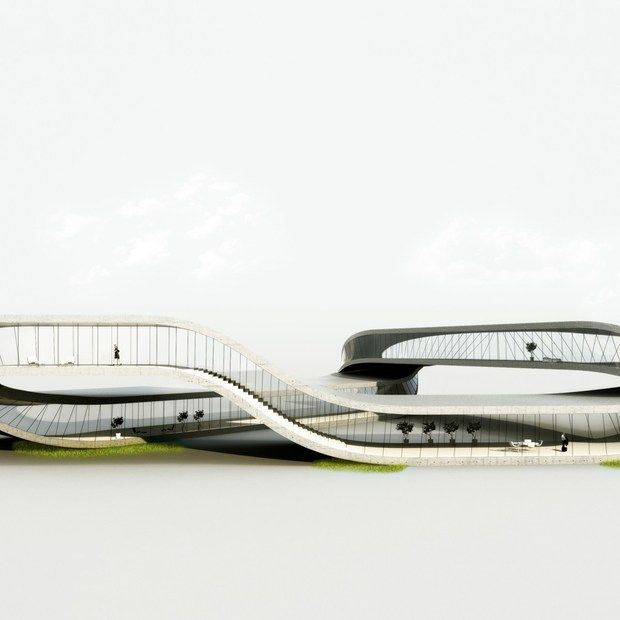

The Dutch architect Yanyap Reussenaars, who developed the project of the Landscape House, is seriously interested in the developments of his Italian colleague. This house is a huge Mobius strip, which, in fact, should be printed and then reinforced with metal and concrete inserts.

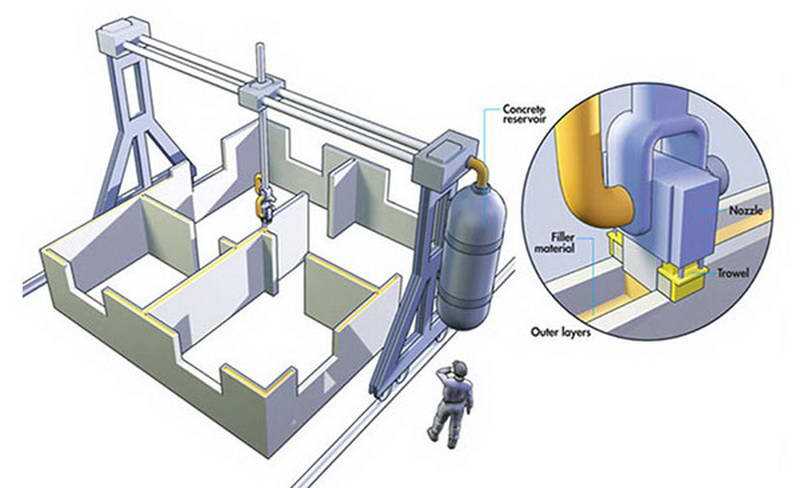

Technology similar to that used in the construction of Canal House is used at the University of Southern California during the Contour Crafting program, which is the result of serious scientific research. A massive robotic device, resembling a bridge-type crane, lays cement mortar layer by layer along a predetermined trajectory.

First of all, researchers involved in the program pay attention to its commercial benefits: the cost of building construction will decrease due to staff reduction, waste-free production and its acceleration. The creators of the device propose to use it not only for the construction of social housing for the poor or temporary shelters for people affected by natural disasters, but also during the settlement of other planets.

The creators of the device propose to use it not only for the construction of social housing for the poor or temporary shelters for people affected by natural disasters, but also during the settlement of other planets.

The Chinese company Shanghai WinSun Decoration Design Engineering has achieved the greatest success to date. Her printer is even more impressive: 40 meters long, 10 meters wide and six meters high. It is mounted on a 150-meter platform and is able to print an entire house from high-quality concrete with the addition of fiberglass in a matter of hours. Shanghai houses are not distinguished by a variety of decor, but even before printing begins, it is taken into account where windows and doors, holes for water pipes and electrical wiring will be located. WinSun is not going to sell its houses yet, prototypes will be given for social housing. However, the company is still on the path to expansion, as it has already planned the construction of about a hundred processing plants across China, which will produce consumables for printing such houses.