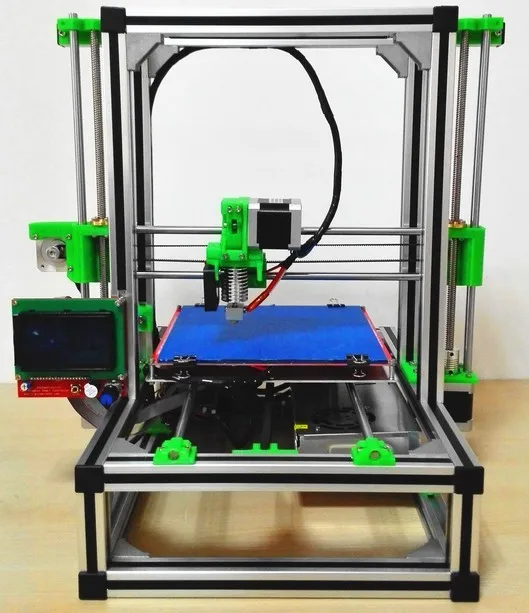

Atlas 3d scanner parts

ATLAS 3D: Getting Started with ATLAS 3D

ATLAS 3D: Getting Started with ATLAS 3D - Murobo.comThe following content instructs the user on how to assembly, calibrate, and scan with ATLAS 3D.

- Software Install (BYOP ONLY)

- Scanner Assembly

- Determining the Scanner IP Address

- Connecting to the Scanner

- Register the Scanner

- Hardware Calibration

- Getting Good Scans

- Support Forum

Note: This step is for BYOP Kit backers only. All other kits have the software pre-installed on the SD card.

An ATLAS 3D software image is provided to make it easier for BYOP Kit backers to get up and running. It is located at https://s3.amazonaws.com/atlas3d/2015-05-01-atlas3d.zip. An 8GB or larger SD card is required. Instructions for writing the image to an SD card can be found at https://www.raspberrypi.org/documentation/installation/installing-images/.

In order to connect remotely to the scanner, the IP address of the scanner must be determined. This is most easily done by attaching a monitor, keyboard, and mouse to the HDMI and USB ports. Once prompted for login information enter the following:

- pi for the username

- raspberry for the password

If you are doing a wired connection to the scanner, insert the Ethernet cable and type the following command at the prompt.

- ifconfig

The IP address of the scanner should be listed after the inet addr: for eth0. For example: 192.168.0.201. If you are connecting over Wifi, plug in the Wifi adapter and follow the instructions at Raspberry Pi Wifi Configuration. Type the following command at the prompt.

- ifconfig

The IP address of the scanner should be listed after the inet addr: for wlan0.

NOTE: Depending upon how your home network is setup, you may be able to simply enter http://atlas3d/ (no .com) instead of the IP address.

Once the IP address is known, enter it into a web browser on the same network. For example, if the IP address is 192.168.0.6 you would enter http://192.168.0.6/ in the location bar of the web browser. You may be able to simply enter http://atlas3d/. The main interface for the scanner should come up at this point.

Register your ATLAS 3D scanner with the included 8 character serial number at https://www.murobo.com/register.php. The serial number is located on the bottom of the stepper motor. Then, enter the serial number on the Setup page by navigating to SETTINGS and then clicking Setup. This will allow the scanner to receive software updates.

This video below shows how to calibrate an ATLAS 3D scanner.

Before scanning for the first time, the hardware must be calibrated. Calibration is the process of moving the lasers and camera to the orientations that the software expects. The Calibration Item Model must be printed and used for the process. Calibration is performed from the Camera page.

Calibration is the process of moving the lasers and camera to the orientations that the software expects. The Calibration Item Model must be printed and used for the process. Calibration is performed from the Camera page.

The first step in calibration is aligning the the camera.

- On the SETTINGS page, choose the Calibration preset which has a camera resolution of 640x480 to have faster video feedback.

- Click the CAMERA link at the top of the page to begin calibration.

- Place the calibration item on the table.

- Move and rotate the camera until the red horizontal line is level with all 3 peaks of the calibration item. The horizontal line should stay at the peak of the calibration item towers whether the item is in the back or front of the table. If the line moves up or down when the calibration item is moved around the table then the camera needs to be adjusted vertically.

- Rotate the camera side to side until the vertical red line is at the center point of the turntable.

This point can be more easily seen by placing a pin the the center hole.

This point can be more easily seen by placing a pin the the center hole. - The horizontal red line should stay at the peak of the towers when the item is in the front as well.

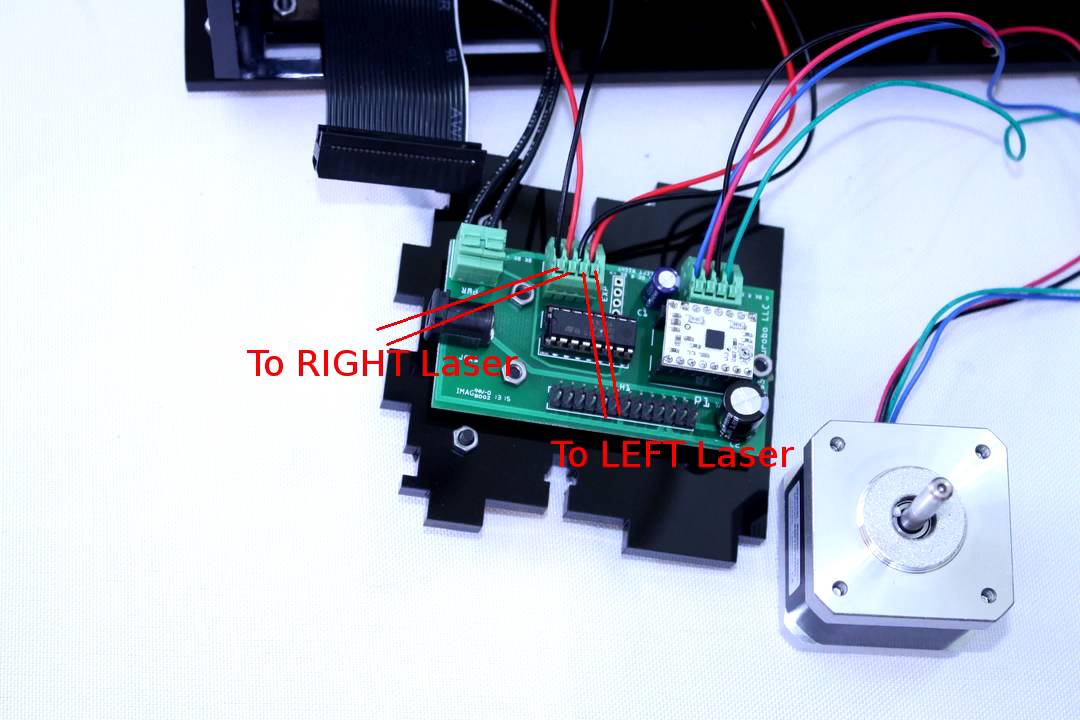

The next step is to calibrate the lasers.

- Place the calibration item on the table to where the longest side is facing the camera and the front of the wall is at the center of the hole in the table.

- Turn on the right laser.

- Rotate the right laser until it sits over the vertical red calibration line.

- Turn off the right laser.

- Turn on the left laser.

- Rotate the left laser until it sits over the vertical red calibration line.

- Turn on both lasers and recheck alignment laser.

Once calibration is complete, the next most important part of getting good scans is balancing the lighting with the laser threshold setting. If the light is too bright then it will over saturate the laser line and make it difficult for the camera to pick it up. If the light is too dim the camera image will be noisier, the laser will appear to reflect off the object more, and the resulting scan will be much darker than the object. Before scanning an object, first select the Preset that you would like. Navigate to the CAMERA page and click the test button. Suppose we are scanning the object below...

If the light is too dim the camera image will be noisier, the laser will appear to reflect off the object more, and the resulting scan will be much darker than the object. Before scanning an object, first select the Preset that you would like. Navigate to the CAMERA page and click the test button. Suppose we are scanning the object below...

Click the Test button to see if the current settings and lighting is appropriate for the object. The image below shows the resulting test image. The test image shows the detected laser line after processing the image from the camera. The gray pixels are those that are above the threshold value, while those below the threshold are yellow. The red line shows where the center of the laser was detected. To obtain a good scan, there must be a red line everywhere that the laser contacts the object. For this to occur, the threshold settings must be set appropriately. If the threshold value is too high (or there is too much direct light) then there will be gaps in the object. If the threshold value is too low then laser detection false positives can occur in the background pixels resulting in scans with lots of points floating around off the object. In the image below notice the gaps toward the bottom of the image.

If the threshold value is too low then laser detection false positives can occur in the background pixels resulting in scans with lots of points floating around off the object. In the image below notice the gaps toward the bottom of the image.

We can correct for this by lowering the laser threshold value. The laser threshold value is close to the top of the SETTINGS page. Lower the value by half, save the preset, and generate another test image.

With the new laser threshold setting there is now a much better line at the bottom of the image. The object is not ready to be scanned. From the SCAN page click Start Scan to scan the object.

Once the scan is complete, click on the file link (STL, PLY, etc) to download it from the scanner.

Support can be found on the ATLAS 3D forum at http://www.soliforum.com/forum/29/atlas-3d-freelss/.

▷ atlas 3d scanner 【 STLFinder 】

ATLAS 3D Scanner by Murobo

thingiverse

left_laser_hinge. stl left_laser_hinge_holder.stl right_laser_hinge.stl right_laser_hinge_holder.stl Assembly Video: https://www.youtube.com/watch?v=awtLSCLJ3qs Printable Instructions:...

stl left_laser_hinge_holder.stl right_laser_hinge.stl right_laser_hinge_holder.stl Assembly Video: https://www.youtube.com/watch?v=awtLSCLJ3qs Printable Instructions:...

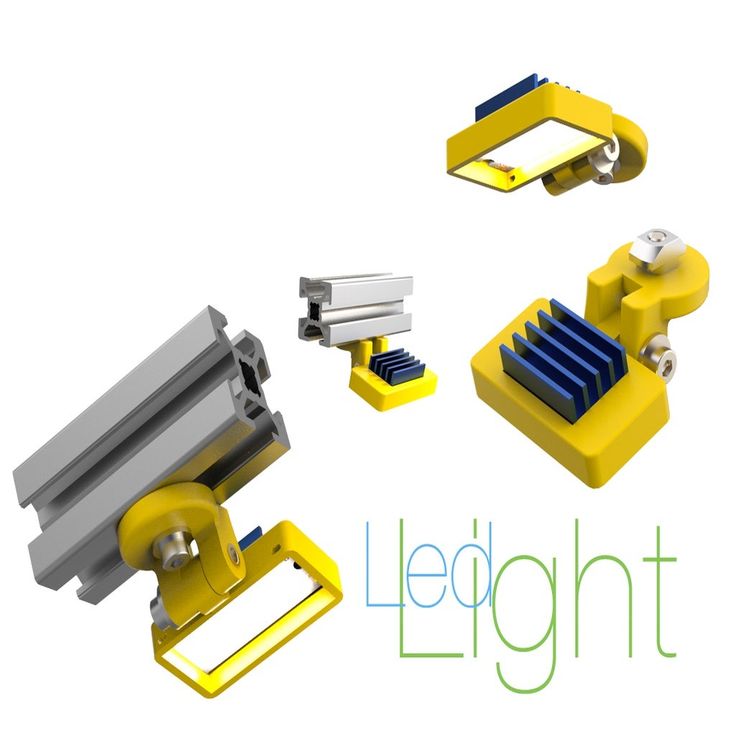

Atlas 3D Scanner lasser

thingiverse

Resized the hole from the original as i brought an Atlas Scanner kit but wanted to use the PIClop body as it looks better, this holds the laser from it.

Atlas 3D scanner upgrade

thingiverse

Wanted to try a couple of larger lasers on my Atlas 3D (FreeLSS) scannner.

Also saw a great idea on the web to use the tie rod turnbuckles from a model car to assist in precise adjustment of the lasers. This is the resulting components from...

This is the resulting components from...

Atlas 3d Scanner Enclosure Kit

thingiverse

... the files. I did 3d print the laser holders and the coupling. I do not have a list of hardware to use but: 6-32 screws for the structural (nuts are hard to push in) :/ M3 hardware of various lengths. I spray painted before I assembled. ...

12 mm laser mount for atlas 3d scanner

thingiverse

This is a quick and dirty 12mm laser mount for the atlas 3d scanner. (For the printed version of the scanner. Will not fit the acrylic enclosure) May be usable in other applications as well. Includes the .stl file and the rsdoc file that can be...

Includes the .stl file and the rsdoc file that can be...

ATLAS 3D Scanner - calibration_item for Print Faster

thingiverse

Redraw "calibration_item" by Atlas 3D for Print Faster 2mm -> 0.8mm Print Settings Rafts: No Supports: Doesn't Matter Resolution: Ultra Low (Very Fast) Infill: Hollow Thin Walls (Fastest) Notes: M3D Print(Version: 2015-08-06-v1.3.6.3) Move:X54.00...

ATLAS 3D Scanner - frame_section_3 for PRINT faster & Stronger

thingiverse

Redraw - frame_section_3 Left & Right PRINT faster & Stronger Print Settings Rafts: No Supports: No . ..

..

Raspberry Pi Case for 3D Scanner

thingiverse

Cover for Raspberry Pi 3D Scanner (PiClop) that runs FreeLSS scanning software (http://www.freelss.org/), a derivative of the Atlas 3D Scanner. ... The Piclop cover has been redesigned to work with Raspberry Pi Scanner HATs that can be found at...

Atlas run freeless laser scanner

thingiverse

the is a redesign of Altas laser scanner using Freeless https://github.com/hairu/freelss This is not goog enough Connect:https://ananasrobot.github.io/AnanasStepper/

Raspberry Pi Case for 3D Scanner

prusaprinters

Cover for Raspberry Pi 3D Scanner (PiClop) that runs FreeLSS scanning software (http://www. freelss.org/), a derivative of the Atlas 3D Scanner. You can order PCBs for the scanner from OSH Park - see https://oshpark.com/shared_projects/FvgkGJDE The...

freelss.org/), a derivative of the Atlas 3D Scanner. You can order PCBs for the scanner from OSH Park - see https://oshpark.com/shared_projects/FvgkGJDE The...

scanner 3d

myminifactory

scanner 3d con telefono

3D Scanner

grabcad

First prototype of 3D scanner

3D_SCANNER

grabcad

A 3D Scanner model with distance sensor

3D Scanner

grabcad

3d scanner based on intel realsense d435 camera

3D Scanner

grabcad

3D Scanner Concept. ...add me: twitter: @martinhajsinger linkedin: @martinhajsinger https://hajsingermartin.wixsite.com/home

...add me: twitter: @martinhajsinger linkedin: @martinhajsinger https://hajsingermartin.wixsite.com/home

3D SCANNER

thingiverse

some parts can be printed in large parts can be printed grabcad link to drop down https://grabcad.com/library/3d-scanner-14

3D Scanner

grabcad

It is a 3D scanner that is designed for Graphic Designing and Medical Purposes. ...It is a group project done by myself, Brice Veyna, Mohammad and Abdullah Alqahtani

3D Scanner

thingiverse

This project has been inspired by this project:http://www. instructables.com/id/Lets-cook-3D-scanner-based-on-Arduino-and-Proces/?ALLSTEPS Since I have a 3D Printer, I have made my own design for the turn table, the laser and camera holder. See the...

instructables.com/id/Lets-cook-3D-scanner-based-on-Arduino-and-Proces/?ALLSTEPS Since I have a 3D Printer, I have made my own design for the turn table, the laser and camera holder. See the...

3D scanner

thingiverse

was designed to not use as much material as other 3d scanner designs. Phone/camera holder not included yet. requires a 10mmx30mmx9mm bearing and a piece of paper. ... ...

3D Scanner

thingiverse

After finding the source code to a 3D scanner turntable on the internet I decided to make my own design of a 3D scanner setup.

All credits for the source code goes to Whitney Potter for making the code. Source Code can be found here

...

Source Code can be found here

...

3D scanner

pinshape

3d scanner is for making photos in 360. it's also for apps like heges, trnio, capture etc… You can rotate arm in 360, You can rotate platform (3dscantop.stl) in 360. ...You can rotate arm and phone holder up and down You can change length of...

3D Scanner

prusaprinters

After finding the source code to a 3D scanner turntable on the internet I decided to make my own design of a 3D scanner setup. All credits for the source code goes to Whitney Potter for making the code. Source Code can be found here...

3D Scanner

thingiverse

Please be cautious. *** ---------- This is a 3D scanner that can be built and assembled only with 3D-printed parts, apart from the electronics (full list of components below). The scanner is driven by two stepper-motors and a range-sensor, controlled...

*** ---------- This is a 3D scanner that can be built and assembled only with 3D-printed parts, apart from the electronics (full list of components below). The scanner is driven by two stepper-motors and a range-sensor, controlled...

Scanner 3d

thingiverse

Lo scanner è stato ingrandito al 155% modificato x utilizzare all'interno dei cuscinetti di grandezza 19 x 6mm. ... Alla base sono stati eliminati i perni e sostituiti con dei perni di metallo con testa da 6mm e incollati con colla bi-componente.

3D Scanner

grabcad

Suitable for 3D printer production.Designed for the school project.

3d Scanner

grabcad

It can be said that 3D scanning, that is, 3D scanning, is an actual object that is thrown into the computer environment in different formats that can be digitized with 3D scanning devices.

Atlas Bust 3D model

cgtrader

Atlas Bust

Atlas-Robbins 3D model

cgtrader

Atlas-Robbins

Atlas Nightstand 3D model

cgtrader

Atlas Nightstand

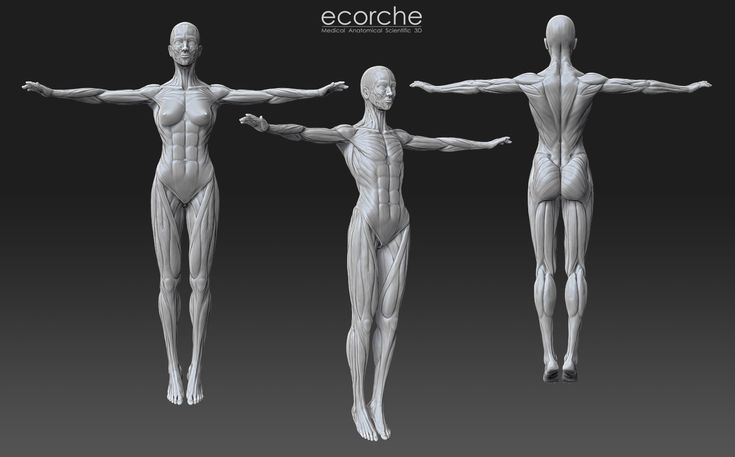

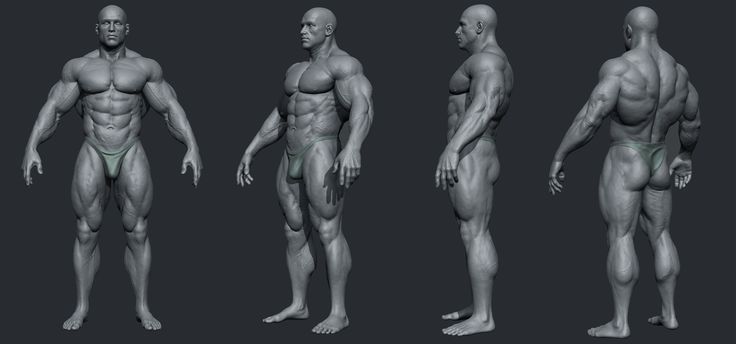

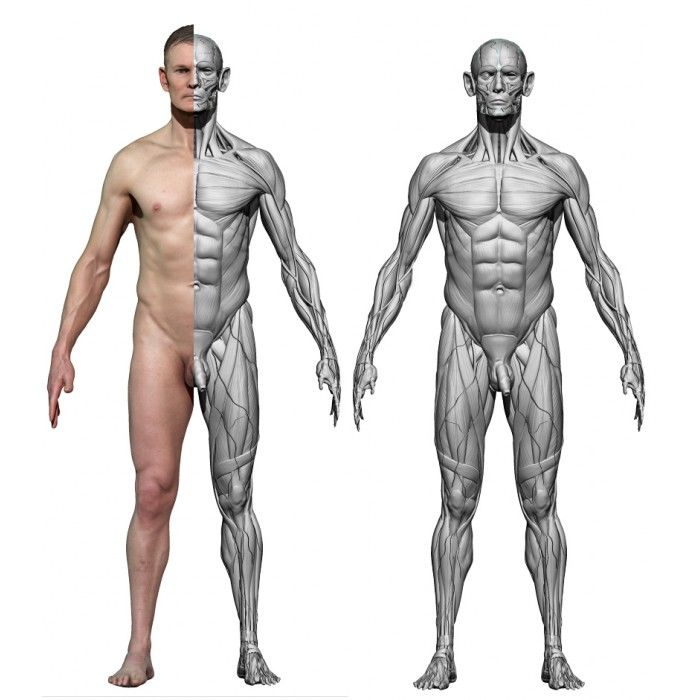

Atlas Torso 3d model

cgstudio

3D model Atlas Torso.Native scene:3dsMax2012 V-Ray render. With light rig and ready for rendering.Additional scenes:3dsMax2012 Scanline render. ...With light rig and ready for rendering.*.FBX*.OBJ- Light rig, ready to render- Clean topology- Scaled for...

With light rig and ready for rendering.Additional scenes:3dsMax2012 Scanline render. ...With light rig and ready for rendering.*.FBX*.OBJ- Light rig, ready to render- Clean topology- Scaled for...

Inexpensive but capable $200 Atlas 3D scanner

Business

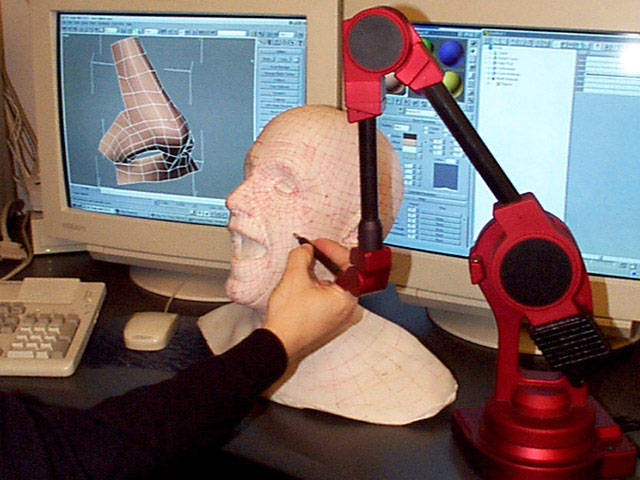

Apart from the technological nuances of the printing process, the main difficulty in introducing 3D printing to the masses is the need to prepare suitable digital models. Not all people who are ready to buy a consumer 3D printer have the 3D modeling skills necessary to provide a full production cycle. Of course, in such cases, special portals come to the rescue, offering access to a great variety of three-dimensional digital models, many of which are offered free of charge. However, the use of other people's designs, by definition, limits the individual creative possibilities of users - the flight of someone else's imagination will never become your own, and therefore the lack of the ability to create your own designs makes 3D printing much less attractive.

nine0003

nine0003 This problem can only be fixed with simpler and more convenient applications, which is done using Draw in 3D, Morphi and other programs. But there is another point: 3D printing is attractive because of the possibility of copying. This feature alone can make homemade additive manufacturing more attractive. Hanger broken? Did the neighbor have a chic vase? Cracked violet pot? To recreate interesting objects, it is not at all necessary to have 3D modeling skills. A 3D scanner is enough - the main thing is that an object is available from which you can “copy” a design. nine0003

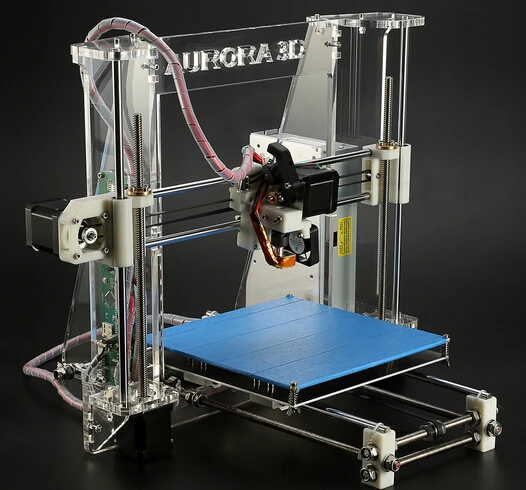

Unfortunately, most 3D scanners cost as much as decent 3D printers, which doesn't help their price appeal. An American engineer named Uriah Ligget offers his own solution to the problem: a kit for self-assembly of an inexpensive, but very capable Atlas 3D scanner. Why pay a couple of thousand dollars when you can assemble a good analogue with your own hands for $200? Why such a low price? Liggett chose to use the most inexpensive hardware and software components, the Raspberry Pi, in combination with open source hardware and software. The body of the device can be printed on a home 3D printer. nine0003

The body of the device can be printed on a home 3D printer. nine0003

Liggett explained his motivation: “Like many other 3D printers, I purchased a 3D printer for the purpose of printing everyday objects for my own home. Sites like Thingiverse offer a great selection of models, but even they are not enough for my purposes. I came to the conclusion that for my interests, a 3D scanner was needed, with which I could create models based on existing physical objects.

Not wanting to spend a lot of money on buying his own scanner, Ligget experimented with the Autodesk 123D, but the idea of a "cloud" solution did not appeal to him, especially since the quality, according to him, was unsatisfactory. And scanners of the right quality came with a hefty price tag, being for the most part intended for the commercial rather than the domestic sector. It was then that Ligget decided to create his own, inexpensive scanner. nine0003

Ligget opted for a turntable design to achieve a precise grip without too much fuss. The device uses a laser system to quickly generate high-resolution models. Measurements made by lasers are combined into a single polygonal grid to obtain a full-fledged 3D model. In fact, this is an analogue of the famous MakerBot Digitizer, which costs about $800.

The device uses a laser system to quickly generate high-resolution models. Measurements made by lasers are combined into a single polygonal grid to obtain a full-fledged 3D model. In fact, this is an analogue of the famous MakerBot Digitizer, which costs about $800.

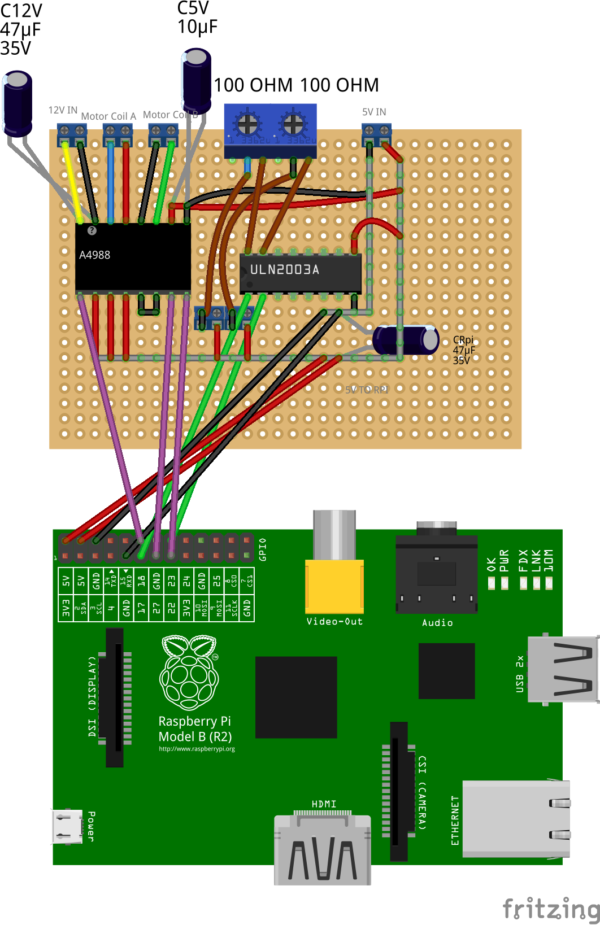

The finished model can be processed using any standard software such as MeshLab before being printed. “The Raspberry Pi was an obvious choice as it supports 5 megapixel cameras, lasers and motors, and has enough memory and performance to process 3D scans,” explains Liggett. The Raspberry Pi does not require additional drivers or other software to be installed and can connect to the scanner via a web browser or Wi-Fi. The scanner itself uses the FreeLSS open source software available on GitHub under the GNU General Public License. nine0003

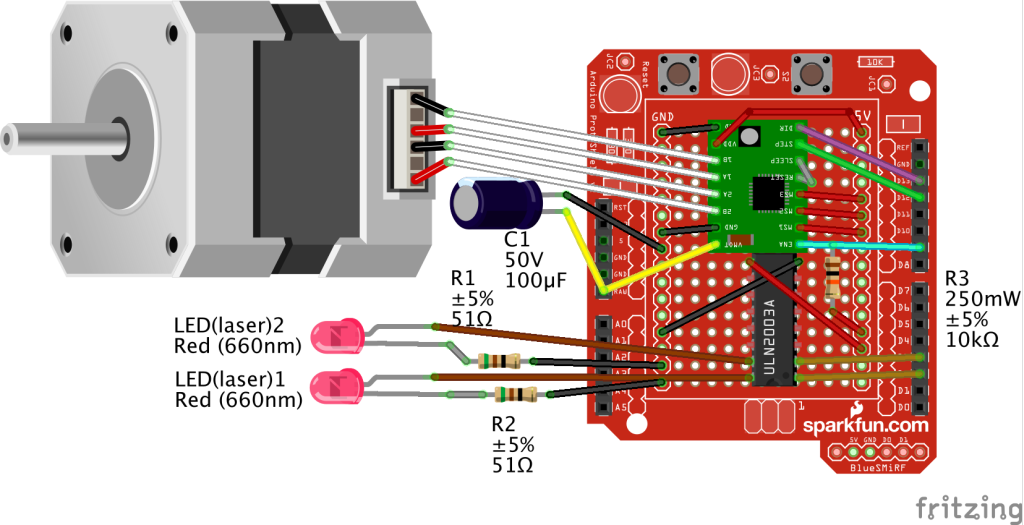

After placing an order for the device, the user will receive a set of .STL files for printing the device case from ABS or PLA plastic. All other parts will be supplied as a kit. At the moment, Ligget is considering two configurations. The first, "complete set", will include a Raspberry Pi B+, a 5MP CMOS sensor, a Wi-Fi adapter, two laser modules, an electronic board, a power supply, a stepper motor, rubber lining and feet, mounts, cables and files. for case printing. The second, reduced package will be designed for those who already have a Raspberry Pi. Whichever kit you choose, assembly is easy: no soldering is required, you just need to fasten the components with screws and ties. nine0003

All other parts will be supplied as a kit. At the moment, Ligget is considering two configurations. The first, "complete set", will include a Raspberry Pi B+, a 5MP CMOS sensor, a Wi-Fi adapter, two laser modules, an electronic board, a power supply, a stepper motor, rubber lining and feet, mounts, cables and files. for case printing. The second, reduced package will be designed for those who already have a Raspberry Pi. Whichever kit you choose, assembly is easy: no soldering is required, you just need to fasten the components with screws and ties. nine0003

Like many innovators these days, Liggett decided to go public funding by putting his designs and proposals on Kickstarter. The required amount was collected in a matter of days, and therefore the project can be considered a serious undertaking. Those who wish still have the opportunity to pre-order for $209. Deliveries of the first finished Atlas 3D scanners should start towards the middle of 2015, although the exact date has not yet been determined, and the design will be released to the general market by the end of the year. Those wishing to invest in the project can find additional information here. nine0003

Those wishing to invest in the project can find additional information here. nine0003

Subscribe to the author

Subscribe

Don't want

4

3D scanners - pre-purchase instructions

In industrial and commercial applications - for the study of building structures and making accurate spatial measurements, for digitally capturing crime scenes and cataloging works art or fossils - 3D scanning has been used for many years. Meanwhile, 3D printing was gaining more and more popularity, especially among craftsmen and enthusiasts, and people wanted to read real objects and convert them into printable 3D models. nine0003

The market has of course responded, and today there are more low and very low price 3D scanners on offer than ever before. Prices for 3D scanners range from a few hundred to several thousand dollars, which should suit just about any budget. The decision on which 3D scanner to purchase depends entirely on what exactly it will be used for and how detailed you are going to scan objects.

Software Solutions

Depending on what you want to scan, you may not need to purchase a 3D scanner. It's possible that you already have the one tool you need to create 3D models, and this tool is in your pocket. There are several programs that take ordinary pictures, even taken on a smartphone, and then extrapolate the available data, creating a completely three-dimensional image. nine0003

This process is called 3D photogrammetry and starts by taking multiple pictures of the same object from different angles. The more images involved, the sharper and more detailed the final 3D model will be. This process may work on just three images, but for very detailed objects, dozens of them may be needed. Not only is this a less expensive option, it's also the best option for scanning 3D objects in public places or in the field where you don't want to carry additional 3D scanning equipment. nine123D Catch1 work on a smartphone or tablet. This makes it ideal for digitally capturing objects in public spaces that cannot be scanned in a studio—museum pieces, large structures, and natural formations. nine0003

nine0003

Resolution: N/A

Pros: No 3D scanner needed, objects of any size can be captured, most program options are free, easy to use

Cons: Limited functionality, quality depends on lighting and number of source images ; may take several minutes to digitally capture an object, does not work well on humans or animals

Agisoft PhotoScan

Technology: 3D Photogrammetry

Agisoft PhotoScan is a stand-alone software suite specifically designed to generate high-quality 3D models from 2D photographs. It was originally aimed at museums and libraries to work for the benefit of archiving collections of artifacts and works of art, so it is able to produce exceptionally detailed 3D models.

Resolution: N/A

Pros: Can create high-resolution 3D models, one-time license is free, the program is easy to use, has many settings

Cons: Software needs to be installed on a computer, high resolution camera is required

DIY options

If you can't afford to spend a few hundred dollars on a 3D scanner, there are also cheaper DIY options .

Xbox Kinect with ReconstructMe

Price: Kinect (various), ReconstructME (free)

Technology: RGB camera, depth sensor

It's practically do-it-yourself, as it ends up assembling an inexpensive 3D scanner. Kudos to Microsoft for releasing a peripheral with a really powerful depth sensor and an RGB camera and leaving it open for use in third party applications! In this case, the combination of Xbox Kinect and free software like ReconstructMe is all you need to 3D scan people and objects.

Resolution: When like

Pros: Cheap, flexible, free software

Cons: Windows only, limited resolution, unstable quality

BQ Ciclop

Technology: Laser triangulation

Ciclop is an open source desktop 3D laser scanner. The scanner uses printed components, so it can be made quickly and cheaply. This scanner can be purchased assembled or as a set of parts, and a parts list and free STL files are available online. Since the 3D scanner laser is a very delicate technique, self-assembly can be tricky and the results may vary depending on your skills. nine0003

Since the 3D scanner laser is a very delicate technique, self-assembly can be tricky and the results may vary depending on your skills. nine0003

Resolution: 0.5mm

Pros: Open source, build kit available, easy to modify and improve

Cons: Quality depends on the user, no customer service and technical support, parts may not be as strong as traditionally made

Inexpensive 3D Handheld Scanners

A handheld 3D scanner, compared to a rotary 3D scanner, allows you to capture an object in a much wider range. These types of devices are commonly used to scan people and large objects, and even low-cost models produce amazingly detailed results. Typically, it takes three to five minutes to scan an object the size of a person, and the more information you capture, the higher quality the final 3D scan will be. Such low-cost options may not be ideal for commercial applications, but for small businesses and individuals, this is the ability to quickly capture 3D data, including colors, patterns, and even texture. nine0003

nine0003

XYZprinting 3D Scanner

Technology: Structured Illumination

XYZprinting's 3D scanner is one of the first devices to hit the market that uses the new Intel RealSense image capture algorithm. It is also the cheapest handheld spatial scanner on the market and is suitable for a wide range of applications.

Resolution: 1.5mm

Pros: Low price, Intel RealSense technology, small size, portable

Cons: Windows only compatible, low resolution

Cubify Sense

Technology: Structured Lighting

Although the Cubify ecosystem is technically gone, 3D Systems continues to offer their 3D scanners. This handheld 3D scanner is easy to use, quickly converts scans into 3D printable files, and is backed by 3D Systems.

Resolution: 0.9mm

Pros: Small price, technical support, proven technology

disadvantages: Part of the non-working ecosystem Cubife, average scanning quality, only under Windows

ISENSE 3D Scanner

Technology: Structured lighting 9000- the scanner from 3D Systems implies connection to the iPad and the presence of a powerful processor for obtaining 3D scans of quite good quality. A great option if you want maximum portability, because all you need is an iPad. nine0003

A great option if you want maximum portability, because all you need is an iPad. nine0003

Resolution: 0.9 mm

Pros: Cheap price, portable, battery powered, works with iPad

Cons: Part of broken Cubify ecosystem, average scan quality, requires iPad

Sensor Structure

Technology: Structured Lighting

TheStructure Sensor was one of the first low cost 3D scanners on the market, a successful Kickstarter project. The same technology is used in 3D Systems' iSense 3D scanner, so the two devices are almost identical. The Structure Sensor is completely portable and only requires an iPad. nine0003

Resolution: 0.9mm

Pros: Cheap price, portable, battery powered, works with iPad

Cons: Average scan quality, requires iPad

Desktop 3D scanners

3D scanners use laser triangulation to capture high-quality details of small objects. These 3D scanners usually don't read colors and patterns, but they are accurate enough for all sorts of textures and details. There are, however, several models that fully read color and pattern data using either structured lighting technology or software implementations of the inverse transformation of laser reflection into color. nine0003

These 3D scanners usually don't read colors and patterns, but they are accurate enough for all sorts of textures and details. There are, however, several models that fully read color and pattern data using either structured lighting technology or software implementations of the inverse transformation of laser reflection into color. nine0003 Zmorph 2.0

Technology: Laser Triangulation

The Zmorph 2.0 3D Scanner is one of the most popular desktop 3D scanners on the market, and it also has great software. The device can not only capture fine details and texture, it also reads colors. It takes about five minutes to completely scan an object.

Resolution: 0.43mm

Pros: Good value for the price, color capture, portability, multi-format export

Cons: Average scan quality, limited scan size, colors may be altered or inaccurate

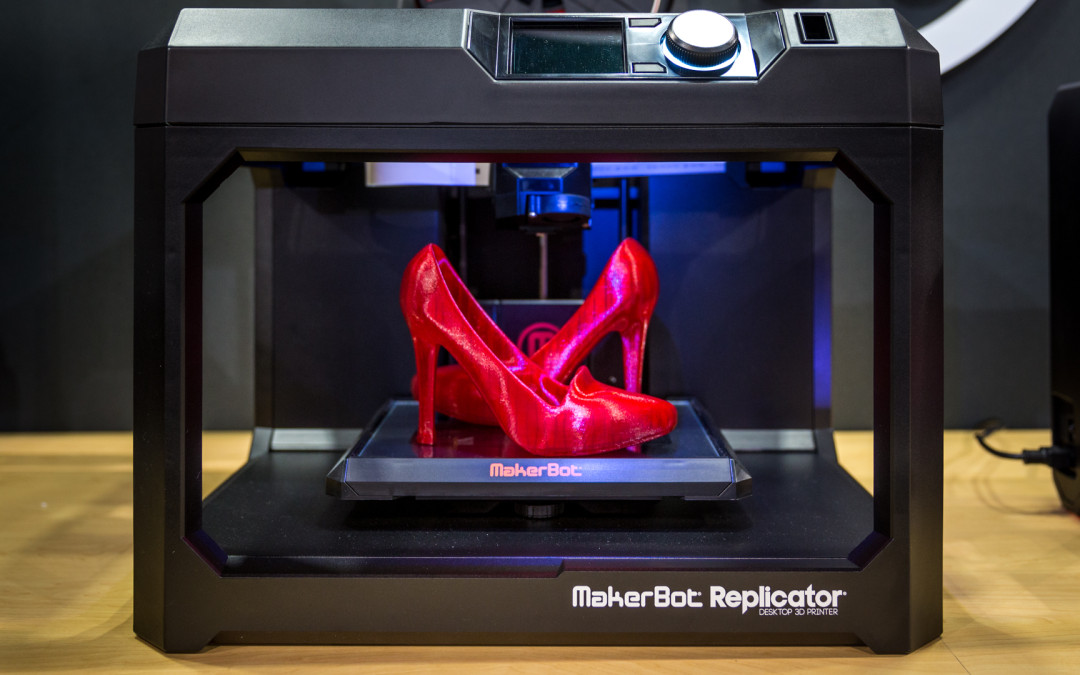

MakerBot Digitizer

Technology: Laser triangulation

The MakerBot Digitizer is an entry-level desktop 3D scanner capable of capturing fine details and textures, but does not distinguish colors. The scanner integrates seamlessly into the MakerBot ecosystem and users have access to technical support and a MakerCare service plan. nine0003

The scanner integrates seamlessly into the MakerBot ecosystem and users have access to technical support and a MakerCare service plan. nine0003

Resolution: 0.5mm

Pros: Part of the MakerBot ecosystem, lightweight

Cons: Doesn't understand colors, doesn't capture reflective or transparent objects, expensive for this scan quality, only exports to STL

EinScan- S

Technology: Structured Illumination

The EinScan-3 desktop 3D scanner is one of the best machines of its kind on the market. It distinguishes very small details, patterns and produces realistic colors. Unlike most desktop models, it uses structured lighting technology, which gives higher quality scan results. nine0003

Resolution: 0.17 mm

Pros: High quality scans, color capture, export to various formats

Cons: Works only with very small objects, not compatible with Apple OS

Top options

The best 3D scanners available in any category, if we are talking about $10,000-$30,000 industrial devices.

These models are ideal for a wide range of tasks, including scanning people, large and very detailed objects. The best available technology is at work here, these scanners offer the highest performance. However, these devices are primarily for commercial use, they are too powerful for home tasks. nine0003

These models are ideal for a wide range of tasks, including scanning people, large and very detailed objects. The best available technology is at work here, these scanners offer the highest performance. However, these devices are primarily for commercial use, they are too powerful for home tasks. nine0003 RangeVision Smart

Technology: Structured Illumination

The RangeVision Smart 3D Scanner is the most portable of the desktop 3D scanners and can be set up outdoors to scan large objects like cars with very fine scanning. It can also run on battery power, which is another plus for portability. The device has a flexibly adjustable tripod.

Resolution: 0.12 mm

Pros: Battery-powered, high quality scans, color capture, export to various formats

Cons: Generates large files, expensive additional devices and accessories

DAVID SLS-3

Technology: Structured lighting

German David's 3D scanners are one of the best professional devices from David.