Are 3d printers worth it

Are 3D Printers Worth It in 2022? (Pros & Cons Compared)

Are 3D printers worth it? A question likely on the lips of many makers on the cusp of shelling out for their first printer.

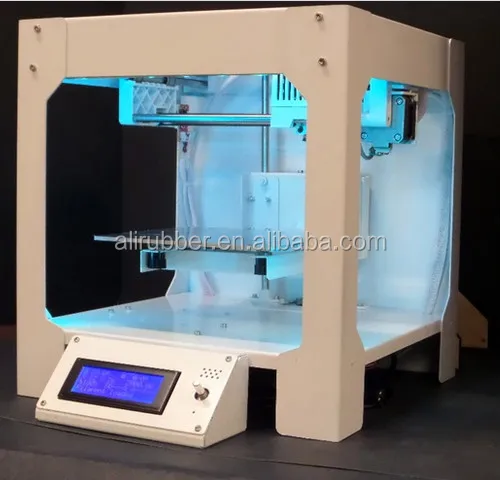

With 3D printing more accessible than ever before, and prices at their lowest since consumer-friendly machines exploded onto the scene, now seems like an ideal time to take the plunge. There’s a 3D printer for all budgets and skill levels.

As a site dedicated to 3D printing, we’re more than a little biased. But, we’re well aware that 3D printing isn’t for everyone. Though owning a printer opens the door to creative possibilities and myriad applications, it can be demanding and frustrating.

To help you avoid nursing pangs of regret a few months down the line, or conversely, give you the confidence to kickstart what can be a deep and gratifying hobby, here’s what’s worth considering before buying your first 3D printer.

Table Of Contents

- Is a 3D Printer Worth Having?

- 3D Printer Pros and Cons

- Pros

- A World of Possibilities

- A Hobby for the Curious Tinkerer

- Enable and Expand Other Hobbies and Skills

- Money-Making and Business Potential

- Personal Satisfaction

- Cons

- Time Consuming

- 3D printers are complex and can have issues

- Expensive

- Pros

- What to Print?

- What Can You Use a 3D Printer For?

- 3D Printing Costs

- FAQs

- Are 3D Printers a Waste of Money?

- Is 3D Printing an Expensive Hobby?

- Is It Profitable to Buy a 3D Printer?

Is a 3D Printer Worth Having?

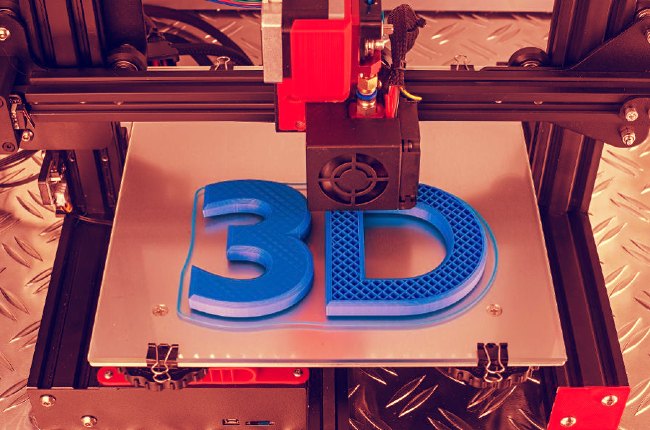

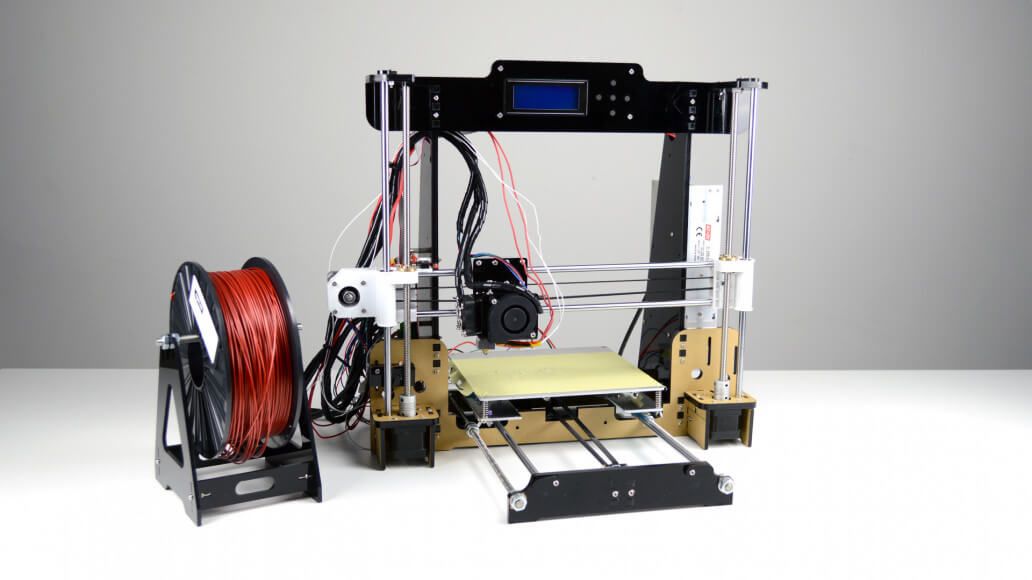

A 3D printer is worth having: you can 3D print almost anything at home even with a $200 3D printer, including replacement parts for broken appliances, action figures and other toys for your kids, and almost anything else you can imagine. There are millions of free STL files online for you to download and print, or you can even design your own files to 3D print.

3D Printer Pros and Cons

Pros

A World of Possibilities

One of the biggest advantages of owning a 3D printer is the possibilities it opens up. A 3D printer is first and foremost a tool, and chances are, if you can think it up, a 3D printer can bring it to life in three-dimensional glory.

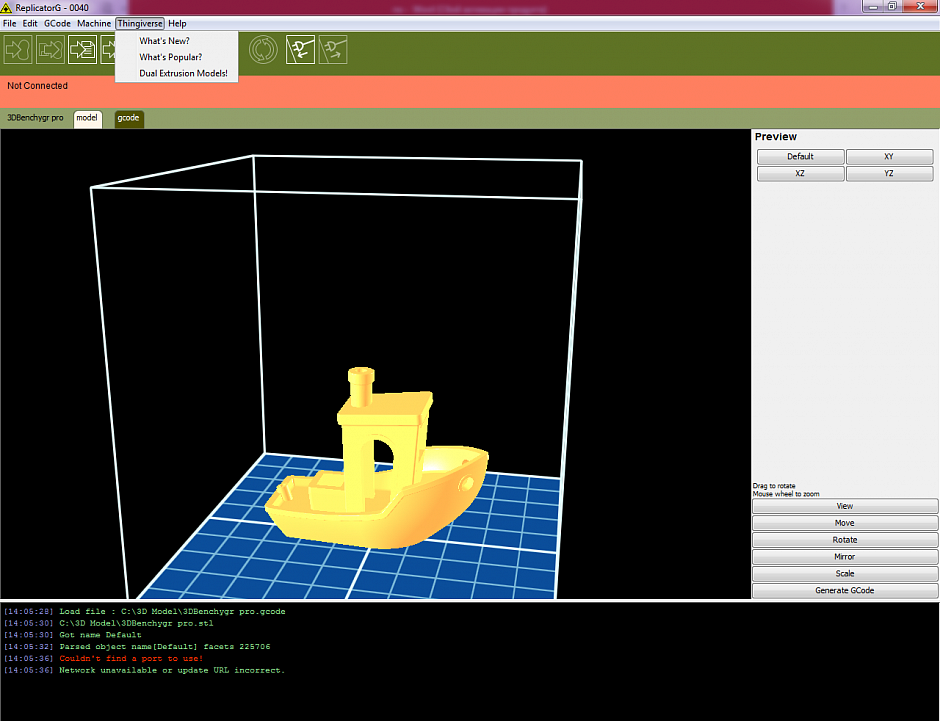

While you’ll initially head over to Thingiverse to bring to life all manner of wacky bits and bobs, the real magic happens when you let your imagination run wild and make the step to designing and printing your own ideas.

A Hobby for the Curious Tinkerer

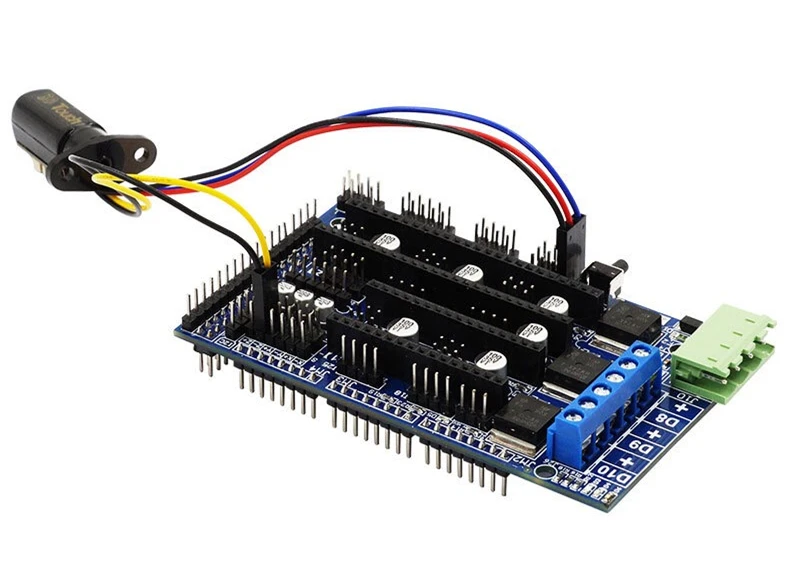

Though manufacturers have done well to democratize the technology and make it more accessible, 3D printing remains a tinkerer’s hobby. There’s a sizable chasm between owning a 3D printer and producing quality prints. So, there’s plenty to learn along the way. The skill set required will see you branch out into other fields, including design, electronics, and computing.

While this might not suit everyone, those who enjoy immersing themselves in a complex hobby and letting their curiosity guide them will find plenty of pleasure in demystifying the art and technical underpinnings of 3D printing.

Enable and Expand Other Hobbies and Skills

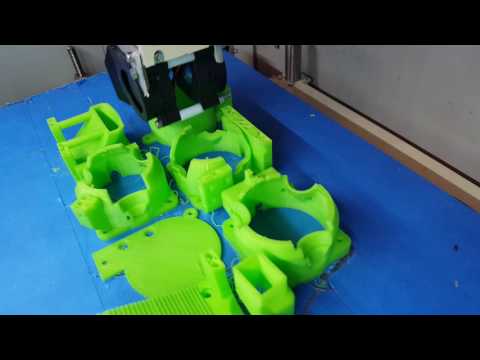

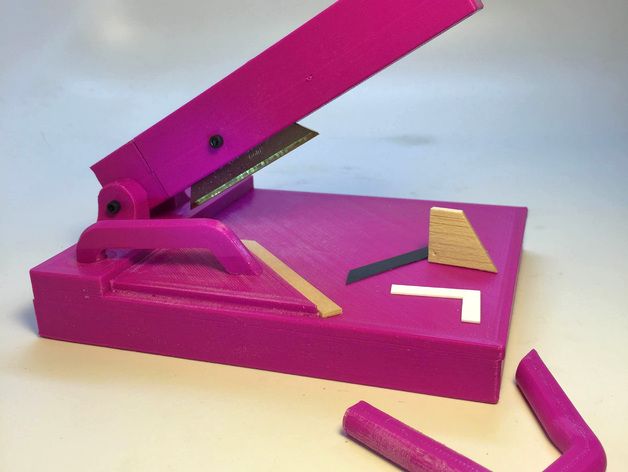

3D printing can be leveraged to bolster and enable other hobbies, making it an extremely versatile addition to any maker’s tool kit. There’s no end to how 3D printing fosters other hobbies, and that’s one of the best reasons to get a 3D printer.

For example, if you’re into tabletop gaming, you can produce no end of figurines or terrain. If you like to express your love for this or that pop culture icon, from Marvel characters to your favorite anime, a 3D printer can churn out customized models.

Love collecting retro games? You can 3D print decorative storage solutions. Want to spruce up your interior design with bespoke pieces? 3D print vases, decorative pieces, and so much more.

Money-Making and Business Potential

As with any business venture, using a 3D printer for money-making and business ends comes with its share of uncertainty. But with planning, a little luck, and a clear business plan, it’s possible to leverage a 3D printer to fuel a small business.

But with planning, a little luck, and a clear business plan, it’s possible to leverage a 3D printer to fuel a small business.

Etsy is awash with creators who make a living selling their 3D printed creations, and a quick Google search reveals a glut of 3D printing services fueled by industrial-grade 3D printers.

Personal Satisfaction

3D printing rubs shoulders with the likes of woodworking and pottery as one of the most rewarding hands-on hobbies.

From assembling the printer to firing off that first print, by way of tweaking settings and making modifications to getting over those troubleshooting humps, there’s a genuine pleasure in chasing down that perfect print, acquiring skills, and learning the ins and outs of your 3D printer.

If you’re the type of person who loves self-led discovery and finds learning fun, few hobbies deliver quite as much personal gratification as 3D printing.

Cons

Time Consuming

From multiple-hour prints for simple projects, not to speak of mammoth 24-hour or more sessions for larger parts, to hours spent perusing forums and watching YouTube tutorials by way of endless slicer tweaking, 3D printing gobbles up your time.

Other than using your 3D printer periodically every few months, in which case you may want to question whether it’s buying in the first place, there’s no way around the fact you’ll need to invest substantial amounts of time to get the best out of your machine.

With the pace of life already moving as rapidly as it is, investing so much time in yet another pursuit, especially one that will fall firmly into the hobby category for most, simply isn’t on the cards. That’s probably why eBay, Facebook Marketplace, and Craig’s List are awash with second 3D printers with barely a scratch on them.

3D printers are complex and can have issues

3D printing is synonymous with troubleshooting. Encountering issues is not a question of if but when they’ll pop up.

Regardless of whether you buy an entry-level machine or a $1,500 premium 3D printer, you’ll invariably spend quite a bit of time solving problems. Whether that’s leveling the bed correctly, improving first-layer adhesion, tweaking retraction settings in the slicer, or tightening up belts on the printer itself.

If the thought leaves you cold, 3D printing may not be for you. But, if you’re open to solving problems and enjoy overcoming an often steep learning curve, there’s plenty of satisfaction in detecting, assessing, and fixing issues.

Expensive

3D printing is expensive, and the costs continue to mount the more you print. Prints will fail, and you’ll eat through spool after spool of filament in no time. Parts will fail and need replacing. And, of course, there’s the initial cost of the printer itself.

That said, a $20 1kg spool of PLA houses enough material to produce dozens if not hundreds of models, which if you were to buy them retail, would cost you vastly more money.

In that respect, 3D printing can an extremely affordable hobby, if you’re replacing a costly buying habit.

Read more:

- How much does a 3D printer cost (buying, and running over time)

- How much electricity does a 3D printer use? (Explained)

What to Print?

Printer’s paralysis is real. What do we mean by this? Let’s set the scene.

What do we mean by this? Let’s set the scene.

You’ve printed a handful of objects, likely pulled from Thingiverse or courtesy of a ‘best 3D print ideas’ lists. Then a few more bits of glorified plastic that serve no actual purpose, yet more pieces of arbitrarily molded junk thrown into the world to slowly find their way into the environment. And a few more.

What’s next? Knowing what to print becomes a tough task with so many possibilities at your fingertips. Before long, the 3D printer’s been left to gather dust for weeks on end and is starting to look like a rather bulky paperweight.

Unless you have a clear idea of what you want to print and the creative desire to match or have an ancillary hobby that you can enable and expand upon with a 3D printer, the initial shine and appeal of 3D printing can rub off rather quickly.

What Can You Use a 3D Printer For?

When asking yourself, ‘is 3D printing worth it?’ it’s essential to understand what a 3D printer can and can’t do. Though 3D printing opens the door to many possibilities, there are hard limits to what you can do, defined by the natural properties of materials, printer specifications, and build volume.

Though 3D printing opens the door to many possibilities, there are hard limits to what you can do, defined by the natural properties of materials, printer specifications, and build volume.

To avoid disappointment, we recommend establishing a firm idea of what projects you want to undertake and checking that a printer is indeed up to the task. To help, here’s a quick breakdown of typical 3D printing applications possible with a consumer-grade 3D printer. This is a loose list and there are countless niche applications and inventive ways people use 3D printers out there.

- Decorative models, figurines, statues, and miniatures

- Art and crafts

- Household items like vases, clips, storage solutions, phone cases, replacement plastic casing parts for home electronics

- Cosplay parts and costumes

- Tabletop gaming terrain and pieces

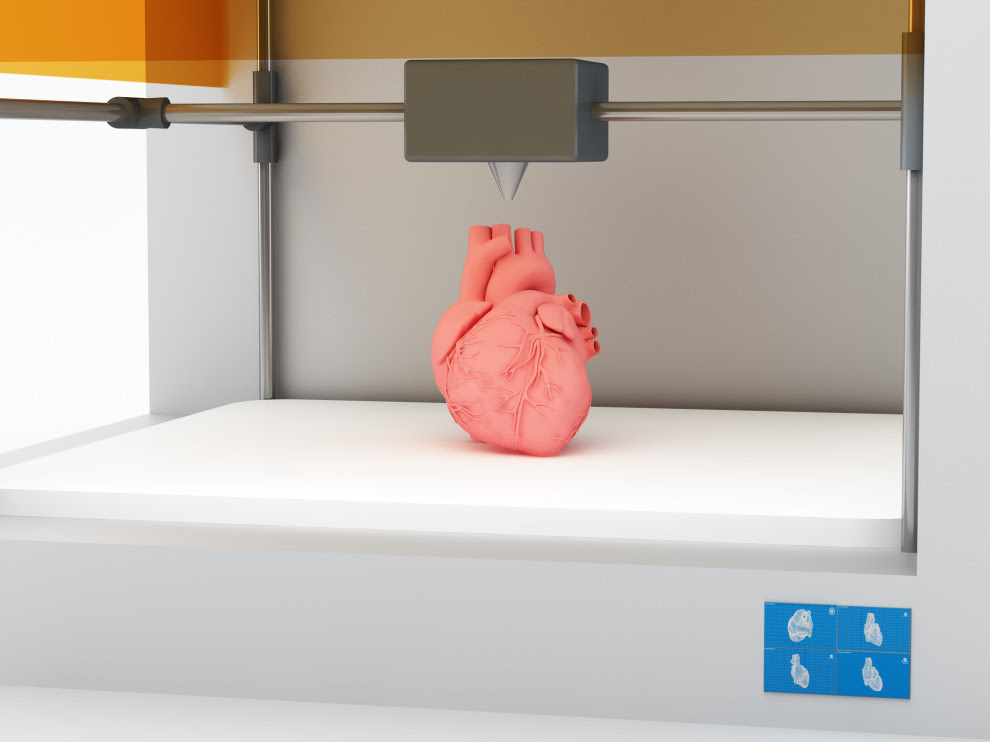

- Rapid prototyping

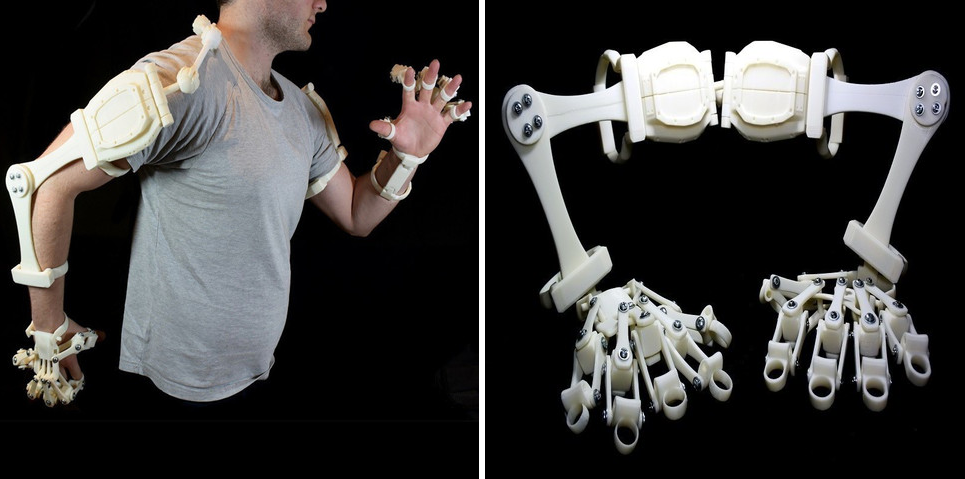

You may have read articles about 3D printed houses, medical equipment, jewelry, clothes, sneakers, prosthetics, and dental solutions. While these are possible, they are generally beyond the capabilities of most 3D printers under $1000 and require industrial-grade machines.

While these are possible, they are generally beyond the capabilities of most 3D printers under $1000 and require industrial-grade machines.

3D Printing Costs

- 3D Printer – Anywhere from $200 for an entry-level FDM printer like the Ender 3 up to $1000 for a premium consumer printer like the Original Prusa i3 MK3S+. Expect to pay roughly the same for a resin printer.

- Filament – Anywhere from $15 to $100 for a 1 kg spool depending on the type and quality of the material. More exotic filaments tend to cost more, which is worth keeping in mind.

- Replacement Parts – This varies depending on the component, but a set of decent nozzles cost around $30, and you can expect to pay over $50 for a replacement hot end.

- Upgrades and Modifications – For example, a new build plate costs around $40, a metal extruder will set you back around $15, and a new mainboard costs at least $60.

- Accessories – A filament dry box costs upwards of $50, while an enclosure will generally set you back over $80.

We’re just scratching the surface of available accessories and costs can rapidly swell.

We’re just scratching the surface of available accessories and costs can rapidly swell.

For a more detailed analysis of the costs involved, check out our dedicated How Much Does a 3D Printer Cost To Buy & Maintain guide.

FAQs

Are 3D Printers a Waste of Money?

The cost of the printer, the ongoing cost of filament, replacement parts, and buying good quality STL part files if you aren’t designing them yourself means you’ll sink a hefty sum into 3D printing if you stick with it.

But, this won’t come as a surprise for those accustomed to spending money on hobbies. Whether spending the money is worth it depends on whether you’ll derive satisfaction, develop new skills and gain knowledge over time, and, ultimately, have fun with 3D printing. For many, this is priceless and well worth the investment.

When asking yourself, ‘should I buy a 3D printer?’, it’s worth thinking honestly about whether it’s a flight of fancy or something that could evolve into a long-term hobby – why do I need a 3d printer?

Is 3D Printing an Expensive Hobby?

Absolutely, even an entry-level 3D printer sets you back around $200, with higher prices for better and more performance-oriented machines. On top of that, you have to factor in ongoing costs, such as materials, replacement and modification parts, the cost of design software, electricity, and less tangible costs such as space, time, and effort.

On top of that, you have to factor in ongoing costs, such as materials, replacement and modification parts, the cost of design software, electricity, and less tangible costs such as space, time, and effort.

Is It Profitable to Buy a 3D Printer?

For most, buying a 3D printer isn’t profitable. Only a tiny fraction of owners successfully turn a 3D printer into a thriving business. The market is already saturated with professional part printing services, Etsy stores selling all manner of artistic and functional pieces, and STL file designers/sellers.

For business, the story is a little different. A 3D printer can be a robust product development and prototyping tool that’s much cheaper than traditional casting and modeling methods. But, this depends on a product going to market, mass production, and sustained sales to turn your investment into profit. So even here, profitability isn’t guaranteed.

Related articles:

- Main Types of 3D Printer

- Best FDM 3D Printers

- Fastest 3D Printers

- Best Open Source 3D Printers

- Best 3D Printers

Are 3d printers worth it? Their Pros and Cons explained – 3D Solved

Some years ago, the idea of having a machine in your own house that can transform a digital model into a real tangible object looked like something out of a sci-fi movie. If you wanted to have in your own hands a figure of let’s say, Batman, there was no other option than going to a local shop and buying it. None of us thought about having our own toy-making machine, with thousands of options to print and collect.

If you wanted to have in your own hands a figure of let’s say, Batman, there was no other option than going to a local shop and buying it. None of us thought about having our own toy-making machine, with thousands of options to print and collect.

Even more, a device that allows you to replace a broken part of a home appliance that you can’t get at a spare parts store.

Do you need to hang your headset under your desk but you don’t have the right hook for it? Just explore the web, search for the one you like the most and print it. Just like that.

Well, nowadays we know 3d printers are real and anyone can have one at home. There are hundreds of different models for every budget available. With some learning, you can start creating (almost) anything.

3d printing technology offers a new way of making things, and its applications are vast: rapid prototyping, research, bio-printing, automotive/aerospace applications, education, art, you name it.

But, if you’re interested on becoming a member of this community, there are some considerations to do before you spend your hard earned cash on a printer.

So, In Short: Once you get over the learning curve and are capable of producing quality prints that can be used for prototyping, repairing household items, and even for making money (in some cases), 3D printing is definitely worth it. However, 3D printers are expensive, as is the filament, you will need to learn to design the models and even troubleshoot the printer, which may lead you to stop using it.

Let’s explore a little of the 3d printing world so you can decide for youself.

Table Of Contents

- Advantages of owning a 3d printer

- Disadvantages of owning a 3D printer

- Myths about 3d printing

- Technical difficulties of 3d printing

- Are your other hobbies and interest somehow related?

- Is a 3d printer worth it for yourself?

- Check out our recommended products section

Advantages of owning a 3d printer

There are some clear advantages to owning a 3D printer as well as disadvantages, so let’s go over some of them.

Just keep in mind that some of these points may not apply to you specifically, but I think that they are worth mentioning.

It improves your creativity

A 3d printer won’t transform you into a creative person, although it may help the creative juices start flowing over time, but it will let you transform those ideas into something real.

As you get more experienced with this tool, new ideas will come to you. Eventually, you’ll learn that a 3d printer can make complex pieces which can’t be made by traditional modeling, and this way you can create prototypes, fun and intricate 3D models, or just replace broken things in your home by printing a replacement part, such as a gear.

It’s fun

Just watching a 3d printer running is something hypnotic. The way the extruder moves across the bed, the “futuristic machine” sounds, the electronic parts with sparkling lights… Every person’s first encounter with a 3d printer is unforgettable.

If you haven’t seen one working yet, just do it… You’ll know what I mean.

In addition to being actually useful, this is one of the reasons I decided to get one, since I love watching it print, plus you get to learn quite a lot (more on this later one since you actually will need to learn more than you probably thought).

You can save time and money

Specific spare parts can be very expensive. Sometimes, they are sold as a pack, so you have to buy parts you don’t need just to replace one. With a 3d printer, you only print what you want, at a very low cost and really fast.

If you don’t care much about the aesthetics of the print, a small piece can be printed in less than an hour.

Now, when I say that it can save you money, I don’t mean “go out and buy a printer just to stop buying a couple replacement parts at the hardware store”, since this wouldn’t make much financial sense, but over time, since you can fix so many things that might break at home or in your car, it may end up paying for itself.

It could help you develop a profitable venture

You can start your own business by selling your prints. Decorative objects, toys, lamps, keychains, dog tags… just find out what’s needed in your neighborhood and offer it, or you could start an online store, Etsy shop… the possibilities are endless.

Decorative objects, toys, lamps, keychains, dog tags… just find out what’s needed in your neighborhood and offer it, or you could start an online store, Etsy shop… the possibilities are endless.

Many people have succeeded by finding original ideas to sell. As you don’t necessarily need to have items in stock, you can avoid sticking with objects that no one wants to buy and just print whatever someone orders.

Disadvantages of owning a 3D printer

Source: 3DNatives.comNow that some of the pros are out of the way, let’s get into the cons, since not everything about 3D printing is all sunshine and rainbows.

3d printers take up a lot of space

Each printer needs at least 60 cm2 of free space on a stable desk or piece of furniture exclusively dedicated to it. If you live in a small apartment, it will be very difficult to find a proper space to place your brand new 3d printer.

Besides that, if you wish to use some particular plastics, like ABS or Nylon, you can’t have your printer running in the same room with you or other people since they emit fumes and toxic gases when heated.

They are noisy

When sitting next to a working 3d printer, you’ll be hearing about 60 dB of sound. That’s comparable to a vacuum cleaner.

Sometimes, you’ll have to print big objects that require approximately 10 or more hours, so you’ll probably end up with the printer running at night. I hope your partner shares your passion… or both you and your new 3d printer will soon have to find a new home.

Important Note: Some printers, like the Prusa Mini which I own, are nowhere near as loud as some of the other printers. The newly released Elegoo Neptune barely makes a sound and you’ll find yourself checking it quite often because you’ll think that it stopped printing.

You can’t print creativity

3d printers are the perfect tool for creative people. Most people buy a printer, they place it on a rigid stable base and… they don’t know what to print.

Even if you had a lot of ideas, sooner or later you’ll have to create something new unless you want your 3d printer to become an expensive paperweight.

If you have any experience in design and using CAD software, then a 3D printer will be extremely useful and fun for you.

You will have to learn more about 3d printing than you initially thought

Even the most expensive 3d printers require you to invest some time to learn the basics. There is no “plug and play” in 3d printing: you must get over the “learning curve” before getting started.

Of course, getting an extremely affordable printer will only make things harder, which is why sometimes getting a printer that comes with a couple extra features, such as automatic bed leveling, can make your life that much easier.

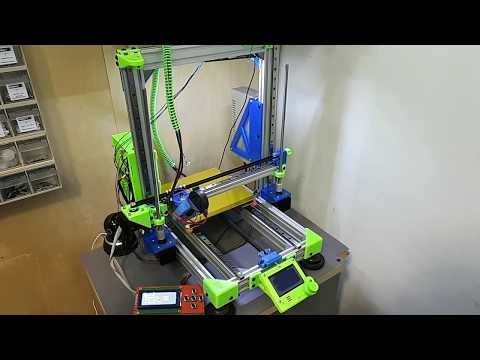

That’s the reason why I got the Ender 3 v2, since the assembly is straightforward and all the settings that come in the slicer software are specifically tailored for that printer, meaning that you put it together and you’re ready to print without much fuss. It is not due to chance that this printer is one of the most popular entry-level machines.

If you are not a handy person, then I’d recommend spending a little more and getting one that will get you printing fast, since lots of people end up selling their printers after one or two months of failed attempts.

Fortunately, the 3d printing community is huge, and it’s full of gentle people that will help you get through this initial learning stage.

They increase the risk of fire at home

3d printers and pets, small children or even a curtain, are bad combinations. The use of high temperatures and moving parts may lead to a fire if you don’t supervise your printer.

An incorrect assembly or the lack of fire protection on a 3d printer are the main causes of accidents related to these machines.

You should keep your children and pets as far from the printer as possible, not only because of the fire hazard, but because they could get hurt, break the printer, ruin the filament, etc.

Myths about 3d printing

3D printers are oftentimes viewed as the end all be all solution for all your needs, but they aren’t genies that grant you wishes.

So, here are I will debunk a couple myths about 3D printing so that you don’t get disappointed if you decide to purchase one.

You can print anything

In some sense, this might be true. But, you depend on having the digital model you want to print.

So, besides learning how to print objects with your new printer, you’ll have to learn about digital design. And that’s even more difficult than learning the basics of 3d printing.

If you still haven’t developed your design skills and how to properly operate a CAD software, you will end up using some of the designs found on websites like Thingiverse, which will get old pretty quickly, plus the feeling of creating your own designs if much more fulfilling.!

3D printing will save you money

Unless you start your own business, 3d printers (still) can’t print money. So, if you bought one thinking about making money, you better have a really good idea that will make a products that people will love and buy. After all, it’s just like any other business.

After all, it’s just like any other business.

However, like I mentioned before, if you own a 3D printer you can replace broken gears, repair many things in your home or car, and more, which will make you save money in the long run… I just wouldn’t get a 3D printer for this sole purpose. But it’s a nice bonus.

You can print with every material out there

When you search for 3d printing on the internet, there are lots of articles about biomedical implants, aircraft innovations or machines that can print an entire house or a car in one day… yes, a house!

Your FDM 3d printer, however, is limited to some plastics, and some materials need temperatures so high to be printed that a regular printer can’t even handle them. Other thermoplastics require an enclosure (not very common among cheap 3d printers), otherwise, they will start warping or cracking.

Before buying one, think well about what do you want to print and check if your machine meets the necessary requirements.

Some very cheap printers may only be able to print with PLA, for example.

If you want to know what temperatures each filament type requires to be printed properly if a heated bed is needed if the printer should have an enclosure, etc. then check the table I included in this article.

Technical difficulties of 3d printing

As I said before, there’s no “plug and play” here: you’ll have to learn new skills if you want to succeed. At first, you won’t be satisfied with the quality of your prints… if you get to print something, that is. A 3d printer will give you the results you desire after you learn some of of the basics, otherwise you’ll get frustrated soon and leave your printer there, gathering dust.

Again, this will vary depending on what printer you get: The cheaper ones usually will take more time to learn, you’ll have to do a lot more troubleshooting, etc.

Design skills

Unless you know how to design your own pieces or how to modify existing models, 3D printing will be an uphill battle. A complete designer must manage both organic (Blender, Zbrush…) and parametric (Solidworks, Solid Edge…) modeling software in order to deal with any situation required.

A complete designer must manage both organic (Blender, Zbrush…) and parametric (Solidworks, Solid Edge…) modeling software in order to deal with any situation required.

And that means hours and hours of practice in front of the screen.

Repair skills

3d printers are complex machines from the “computational” point of view, but they are simple from a “mechanical” standpoint. So, some issues can be solved just by adjusting screws or changing simple two-wired components.

In fact, most models are open-source: they were created under the idea of building your own printer with little knowledge. You can search for tutorials on YouTube explaining every single aspect of a 3d printer. There’s no excuse for not being able to learn how to calibrate and fix your machine.

Otherwise, you’ll end up spending even more money on a technician.

Computational skills

You don’t need to know about programming to start printing, but when the mechanical problem is solved and still your prints are ugly, or you want to get some upgrades for your printer, it’s time to modify other settings, like PID control, acceleration and jerk or the steps of each motor.

Some basic Arduino programming may be enough to handle this.

Sometimes, you’ll also need to modify G-codes. Again, getting all this knowledge demands lots of time, so consider it well.

Are your other hobbies and interest somehow related?

Getting into 3d printing can make developing your current activity a lot easier. As you know more about this technology and its capabilities, you’ll eventually find out how to make it work with your projects.

Many cosplayers print parts of their costumes with great accuracy, obtaining pieces that fit exactly to their bodies. Excellent helmets and other armor parts, as well as weapons, are printed in a very economical way.

As an engineering student, a 3d printer can be used for rapid prototyping of mechanisms for testing and size/movement verification.

A 3d printed object can be used as a foundry model for metal casting. It replaces traditional wood models, being stronger and faster to make.

If you love playing board games or role-play games (RPG), you can print trees, bridges, animals, vehicles and other miniatures for your scenarios to create the perfect atmosphere.

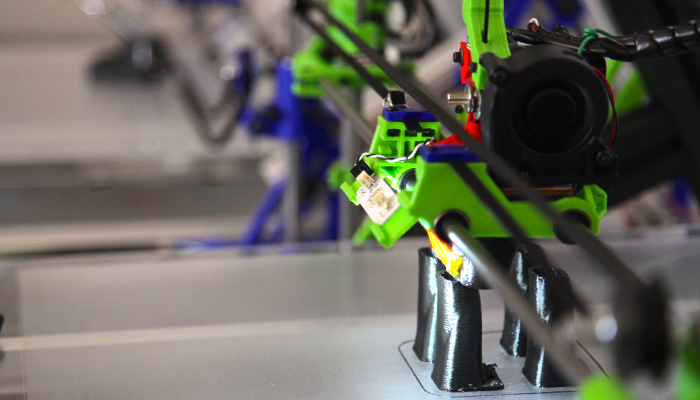

Nowadays, industries are turning to automation and robotics. If you already work in this, you’ll find 3d printing helps you complementing all the electronic parts.

New types of artists are using 3d modeling to create complex shapes that can’t be made with traditional tools.

Maybe it can be better to get started by buying a used 3d printer, so you don’t have to spend too much money on something that could not be what you were looking for. But, this can lead you to other issues, like dealing with worn parts or battered components.

Building your own printer is a great option too: DIY kits are the cheapest option if you want a brand new machine.

You’ll learn every part’s function as you assemble it, so you’ll save time and money while getting through the learning curve. I highly recommend you this, especially because repairing it later on will be second nature to you.

With all this in mind, the main question still floats in the air: Is it worth it?

Is a 3d printer worth it for yourself?

At this point, you should decide if the cost and time spent will be worth it.

There are some additional costs associated with 3D printing such as buying filament spools, some tape or hairspray to improve adhesion to the bed, even a decent glue to stick pieces together.

And that’s just the beginning, later you will have to buy additional cooling fans, PTFE tubes, new nozzles, and some spare parts to repair your printer when something does eventually go wrong.

In my opinion, yes. Getting a 3D printer is worth it for many people since it’s so versatile: Not only can you fix stuff at your house or create prototypes for your work, but you can even use it to have some fun, like making an RC boar or plane, printing shoes… yes, shoes!

The possibilities are endless!

Now, I know that it’s easy to buy into the hype, but really question whether or not you’re going to give the printer the required use to make the investment worth it, otherwise, like I mentioned earlier, you’ll just be buying a very expensive paperweight.

I hope this information was useful!

Have a wonderful day!

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

How much does a 3D printer cost?

3D printing is a one-stop solution for a wide range of applications, from high-resolution model production to rapid prototyping, rapid tooling for traditional manufacturing processes, production of aids and end-use models.

However, when you consider investing in a 3D printer, the viability of a solution usually boils down to a simple question: Is it cost-effective for your business? How much does a 3D printer cost and how much time and money can it save your business? nine0003

3D printer prices range from $200 to $500,000 depending on the printing process, materials, and complexity of the solution.

In this guide, we'll break down 3D printing costs by technology, compare outsourcing versus in-house manufacturing, list factors to consider when calculating the cost of each model, and look at what else to look for when comparing different solutions. for 3D printing and other production methods. nine0003

for 3D printing and other production methods. nine0003

Interactive

This interactive ROI tool will help you find out how much time and money you can save by 3D printing with a Formlabs 3D printer.

Calculate Your Costs

The three most well-known plastic 3D printing technologies today are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technology has its advantages and disadvantages - take a look at the infographic:

Download this high resolution infographic here. Interested in learning more about FDM, SLA and SLS 3D printing technologies? Check out our detailed guide.

Prices for 3D printers have dropped significantly in recent years, and today all three technologies are available in compact, low cost systems.

FDM generally produces models at a lower cost if you only print relatively simple prototypes in limited numbers. SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models. nine0003

SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models. nine0003

Comparing the total cost of different 3D printers by price tags alone will not give you a complete picture of how the cost of a 3D printer and a printed model will compare. The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

Let's look at the different factors and costs for each process.

FDM, also known as Fused Filament Manufacturing (FFF), is a printing method where the parts of a model are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer onto the model being made. nine0003

nine0003

FDM is the most popular form of consumer grade 3D printing, fueled by the proliferation of hobbyist 3D printers. However, professional and industrial FDM printers are also popular among professionals.

The cheapest 3D printers are FDM printers. DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that require a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience. nine0003

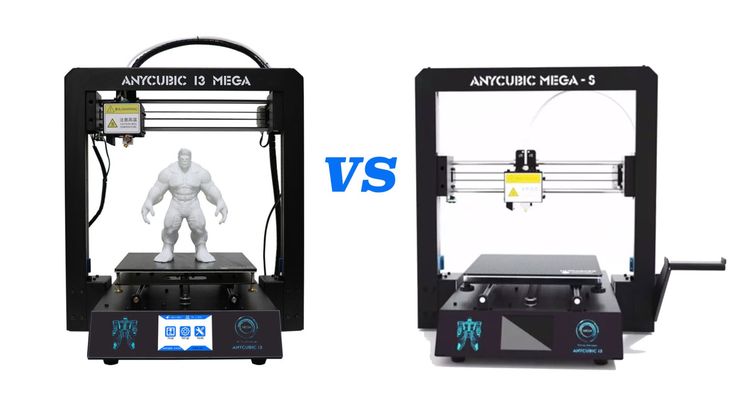

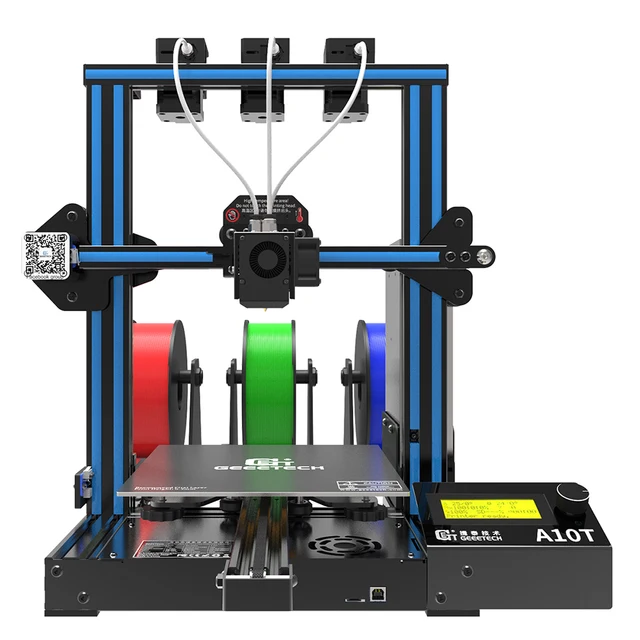

Hobbyist FDM 3D printers cost between $500 and $1,500, come pre-assembled or unassembled, require less setup, but have the same disadvantages as the cheapest 3D printers. More expensive models are capable of large print volumes and work with a wide variety of materials besides low temperature ones such as PLA.

Professional 3D FDM printers start at $2,500 and large format professional FDM printers are available from $4,000. The cost of the most modern industrial FDM printers can exceed 10,000 US dollars. Most of these printers come pre-assembled and calibrated in the box, or they can be automatically calibrated. Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting. nine0003

Material costs for FDM 3D printing range from $50 to $150/kg for most standard and engineering filaments, and $100 to $200/kg for auxiliary materials. There are also cheaper alternatives, but they are of lower quality.

In addition, FDM printing can be very labor intensive. Successful printing of complex models requires support structures that must be removed manually or dissolved in water. To obtain a high quality surface and remove layer lines, lengthy manual post-processing of models, such as sanding, is necessary. nine0003

nine0003

SLA 3D printers use the process of photopolymerization, that is, the conversion of liquid polymers into hardened plastic using a laser. SLA is one of the most popular processes among professionals due to its high resolution, accuracy and material versatility.

Models printed on SLA printers have the highest precision, sharpest detail and smoothest surface possible of any plastic 3D printing technology. But the main advantage of the SLA method is its versatility. SLA polymers have a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics. nine0003

SLA 3D printers can handle a wide range of resin materials for a wide variety of applications.

SLA used to be used only in large and complex industrial 3D printers costing over $200,000, but the process is now much more affordable. With the Formlabs Form 3+ Printer, businesses can now use industrial quality SLA printing for as little as $3,750. With Form 3L, large format SLA printing starts at just $11,000. nine0003

With Form 3L, large format SLA printing starts at just $11,000. nine0003

Stereolithographic 3D printers will be shipped in a box assembled and calibrated. These are professional tools that are highly reliable and require virtually no maintenance. Technical support is also always available. It provides troubleshooting in a critical situation (but its probability is extremely small).

Most standard and engineered polymers for SLA technology cost between $149 and $200 per liter. nine0003

SLA printers are easy to use and many workflow steps such as rinsing and final curing can be automated to reduce labor costs. Printed models have a high quality surface immediately after printing and require only simple post-processing to remove supporting structures.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. nine0003

This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. nine0003

Models produced using SLS printing have excellent mechanical characteristics - their strength can be compared with the strength of injection molded parts. As a result, SLS technology is the most popular plastic 3D printing process for industrial applications.

SLS printed nylon models are ideal for a range of functional applications, from consumer product design to healthcare applications.

Like SLA, SLS was previously only available in large format, complex 3D printing systems costing $200,000 or more. With the Formlabs Fuse 1 stereolithography printer, businesses can now solve industrial-scale tasks with SLS technology starting at $18,500. The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

As with SLA printers, stereolithographic printers are shipped assembled and calibrated in the box. They are reliable and can operate 24/7. The package includes in-depth training and fast technical support. nine0003

The package includes in-depth training and fast technical support. nine0003

SLS nylon print materials cost about US$100/kg. SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS is the least labor-intensive plastic 3D printing process in the production environment, because the printed models are of high quality right away, and to remove excess powder, they simply need to be cleaned.

There are several processes for 3D printing not only plastics but also metals. nine0003

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held together by a resin binder. The finished parts of the model are sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. 3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries. nine0003

nine0003

Prices for metal 3D printers have also begun to decline, ranging from $100,000 to $1 million today. However, these systems are still out of reach for most businesses.

SLA 3D printing is available as an alternative for casting workflows that allow metal models to be produced cheaper and faster than traditional methods and provide greater design freedom.

Technical report

Get design guides for 3D printing samples, see the step-by-step direct investment casting process, and study guides for indirect investment casting and sand casting.

Download white paper

Different plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Below is a comparison of different printing technologies.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM Printing | Selective Laser Melting (SLM) and Direct Metal Sintering (19008) 9008 | |

|---|---|---|---|---|---|

| Permission | ★☆ | ★ opa ★ ution | ★ opa | ★cle | ★cle ★ MyQUTION | SUMPLE | 1112 HICE | ★ opa ☆ | 1111111 ☆☆☆ | 1 ☆ | ★ opa |

| Ease of use | x 300 x 600 mm (Desktop and Workshop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (3D - workshop printers) | Up to 300 x 200 x 200 mm | Up to 400 x 400 x 400 mm |

| Price range | DIY kits for 3D printers start at $200 and hobby printers cost $500-1500. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. | Professional desktop printers start at $3,750 and high-volume large format desktop printers are available from $11,000. nine0112 | Workshop industrial printers start at $18,500 and traditional industrial printers start at $100,000. | Metal FDM printers start at $100,000, but complete solutions including an oven are much more expensive. | DMLS/SLM solutions start at around $200,000. These printers require special infrastructure conditions, which can further increase costs. |

| Cost of materials | US$50-150/kg for most standard and engineering yarns and US$100-200/kg for auxiliary materials. | US$50-150/L for most standard and engineering polymers. | US$100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. | Depends on material and technology. Significantly higher than plastic. Significantly higher than plastic. | Depends on material and technology. Significantly higher than plastic. nine0112 |

| Labor | Manual removal of support structures (soluble support structures may be used in some cases). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. | Washing and sintering (both can be automated). It is possible to use mechanical processing and other types of surface treatment. nine0112 | Stress relief, support structure removal, heat treatment, and mechanical and other surface treatments. |

| Materials | Standard thermoplastics such as ABS, PLA and their various blends. | Various polymers (thermosetting plastics). Standard, engineering (similar to ABS and PP, similar to silicone, flexible, heat resistant, rigid), injection molding, dental and medical (biocompatible). nine0112 nine0112 | Engineering thermoplastics - typically nylon and its composites (nylon 12 biocompatible + sterilizable). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt-chromium, copper, aluminium, nickel alloys. |

| Applications | Basic experimental models, low cost rapid prototyping of simple parts. | Prototypes with a high level of detail requiring close tolerances and smooth surfaces: molds, tooling, templates, medical models and functional parts. nine0112 | Complex geometries, functional prototypes, low volume production or limited trial production. | Strong and durable models, tools and production aids. | Strong and durable models with complex geometries; ideal for the aerospace, automotive and medical industries. |

When calculating the cost of one model, the cost of ownership of equipment, material costs and labor costs are usually taken into account. It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs. nine0003

It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs. nine0003

Hardware ownership costs are fixed costs: 3D printer price, service contracts, installation and maintenance. These amounts must be paid whether your printer is idle or produces dozens of models per week.

Add up all projected fixed costs over the lifetime of the equipment, then divide by the number of models you plan to make. As a rule, the higher the performance and efficiency of your 3D printer, the lower the cost of ownership of equipment per model. nine0003

In recent years, desktop 3D printers have shown excellent results in reducing the cost of ownership of equipment. With a price 10 to 100 times lower than traditional industrial 3D printers and the ability to produce thousands of models over a lifetime, the cost of ownership can be negligible.

Questions:

-

Are there installation, training or additional initial costs other than the cost of the machine itself? nine0003

-

Do I need to sign a (mandatory) service contract? What does it include?

-

What accessories and tools are needed to make the final models?

-

What kind of maintenance is required for the machine to function properly? What is the expected annual maintenance cost? Will it change with an increase in production volumes?

The 3D printing raw materials and consumables you need to create models at an affordable price. These costs largely depend on the number of models you produce. nine0003

These costs largely depend on the number of models you produce. nine0003

When calculating the cost of materials, determine how much material is required to create one model, and multiply this figure by the cost of the material. Count the amount of waste and any other consumables. As production grows, the cost of ownership of equipment decreases, and the cost of 3D printing materials tends to become more balanced.

Be sure to check what materials you need to create specific models, as the cost of 3D printing consumables can vary greatly. Please note that some 3D printers only work with their proprietary materials and thus limit your ability to use third party materials. nine0003

Questions:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create one particular model, including waste?

-

What is the shelf life of the materials?

-

Do I need other consumables to create models?

-

Can the machine work with third-party materials?

While 3D printing can replace complex traditional manufacturing methods and provide significant time savings, depending on the 3D printing technology, it can still be quite labor intensive. nine0003

nine0003

Professional desktop 3D printers are generally optimized for ease of use. DIY kits for 3D printers and hobby printers often require additional effort to adjust settings, while regular maintenance or material changes on traditional industrial machines can involve time-consuming tasks that require the assistance of a skilled operator.

Post-processing workflows vary depending on the 3D printing process, but in most cases include cleaning up models and removing support structures or excess material. However, there are solutions to automate some specific tasks. For example, Formlabs Form Wash and Form Cure simplify the wash and finish process for Formlabs SLA 3D printers, while Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer. nine0003

More complex processes such as SLA and SLS do not take long to achieve high quality models, while FDM models require lengthy manual post-processing to improve quality and remove layer lines.

Questions:

-

What is the whole model production workflow? What specific steps are required to set up printing, change materials, and post-process models?

nine0298 -

How long does it take to post-process one specific model?

-

Are there any tools or devices available to automate some of these tasks?

Outsource production orders to 3rd party service bureaus or labs when you use 3D printing only occasionally or to produce large models in non-standard materials. Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes. nine0003

The main disadvantages of outsourcing are the high cost and duration of production. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced if the delivery of the model produced by the involved organization takes several days or even weeks. And as demand and capacity grow, the costs of outsourcing are rising rapidly.

And as demand and capacity grow, the costs of outsourcing are rising rapidly.

Desktop 3D printers are the perfect solution for fast model production. Depending on the number of parts needed and the volume of prints, the investment in a professional 3D printer can pay for itself in just a few months. nine0003

With desktop and workshop printers, you can pay for the capacity that matches your business needs and scale your production by adding more devices as demand grows, without the heavy investment of a large format 3D printer. Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue. nine0003

Investment, material and labor costs are relatively easy to calculate. But what about indirect costs and hard-to-calculate factors that affect your business? Let's look at some of the main considerations when comparing a desktop 3D printer to outsourcing or other manufacturing methods.

Save time: What if you could get products to market a few months faster? Or reduce the delivery time of your products by a few days or weeks? 3D printing simplifies traditional prototyping and manufacturing workflows, helping you save time and stay ahead of the competition. nine0003

Top results: 3D printing allows you to create more iterations, overcome failures faster, and produce better end products. Troubleshooting a design early on also helps avoid costly redesign and the use of additional tools.

Interaction: Having high-quality prototypes and models allows you to communicate more effectively with customers, clients, suppliers and other stakeholders. Avoid misunderstandings and costly mistakes. nine0003

Intellectual Property Protection: Do you work with confidential information? Making your own models means you don't have to transfer intellectual property (IP) to third parties, reducing the risk of IP leakage or theft.

Usually, calculating cost per part, lead time, and comparing alternatives to see if a solution is right for your business is a tedious task of creating a complex spreadsheet in an attempt to collect all of the often hidden information from a manufacturer. nine0003

Use our simple online tool to calculate cost per model and order lead time when printing with a Formlabs stereolithographic 3D printer and compare time and cost savings with other manufacturing methods.

Calculate cost and time

Home desktop 3D printers

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix FlashForge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao FlashForge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN iBridger Peopoly snapmaker Voltera Voxelab ZENIT nine0003

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry nine0003

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm nine0003

75 mm 2.85 mm 3.00 mm nine0003

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH) nine0003

Number of extruders (print heads)

Heating table

Yes No

Wi-Fi or other wireless network

Yes No

Country of origin

China Russia USA Taiwan Hong Kong nine0003

Netherlands Poland

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | Goods in transit |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods in transit |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | nine0111 Goods in transit|

| Construction area size | 180 x 163 x 102 mm |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 220x220x270 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods in transit |

| Construction area size | 200x200x200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Flyingbear |

| Custom/Transit | Goods in transit |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods in transit |

| Construction area size | 250x250x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods in transit |

| Construction area size | 350x350x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | Goods in transit |

| Construction area size | 197 x 122 x 245 mm (5. 9 l) 9 l) |

| Chamber volume | 5.9 L |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | Goods in transit |

| Construction area size | 450 x 400 x 400 mm (capacity 72 l) |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory. nine0003

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop.