3D printing interview questions

8 Most Frequently asked 3D Printing Questions

8 Most Frequently asked 3D Printing Questions - Answered!

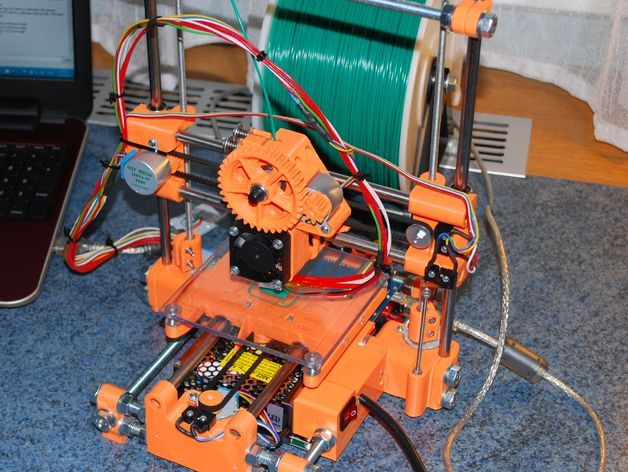

3D printers are becoming an essential tool in the workflows of many businesses and industries. The technology is evolving fast and it is now possible to 3D print objects which were unheard of 10 years ago. 3D printing is becoming the largest disruptive technology shift since the internet. It is fascinating to see where the technology will take us in the future and it’s definitely something to look forward to. Keep reading as we answer the 8 most frequently asked 3D printing questions.

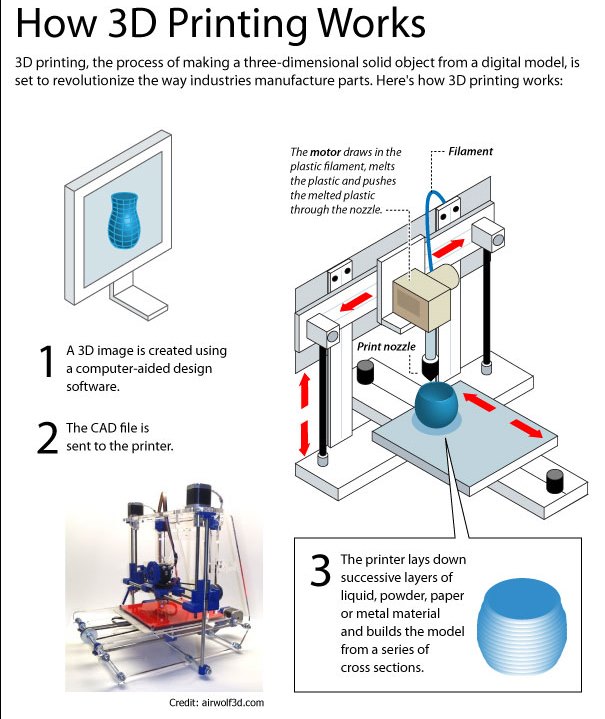

1. What is 3D printing?

3D printing also known as additive manufacturing is a process of creating three dimensional physical objects from a computer model or digital file. The physical object is made from the printer nozzle laying down consecutive layers of material such as plastic filament until the entire part is fully formed. The technology makes It possible to create any geometry imaginable, taking your creativity to the next level.

2. What types of 3D printers are there?

The most popular and reliable 3D printer brands today are Markforged, Ultimaker and Formlabs. These 3D printers have different types of technologies for different applications. The Markforged brand offers Desktop, Industrial and Metal 3D printers. The technology used for their Metal 3D printer ‘Metal X’ is ADAM (Atomic Diffused Additive Manufacturing), which is a hybrid of metal injection moulding and 3D Printing. Markforged 3D printers are more suitable for companies who want to manufacture industrial strength parts in-house.

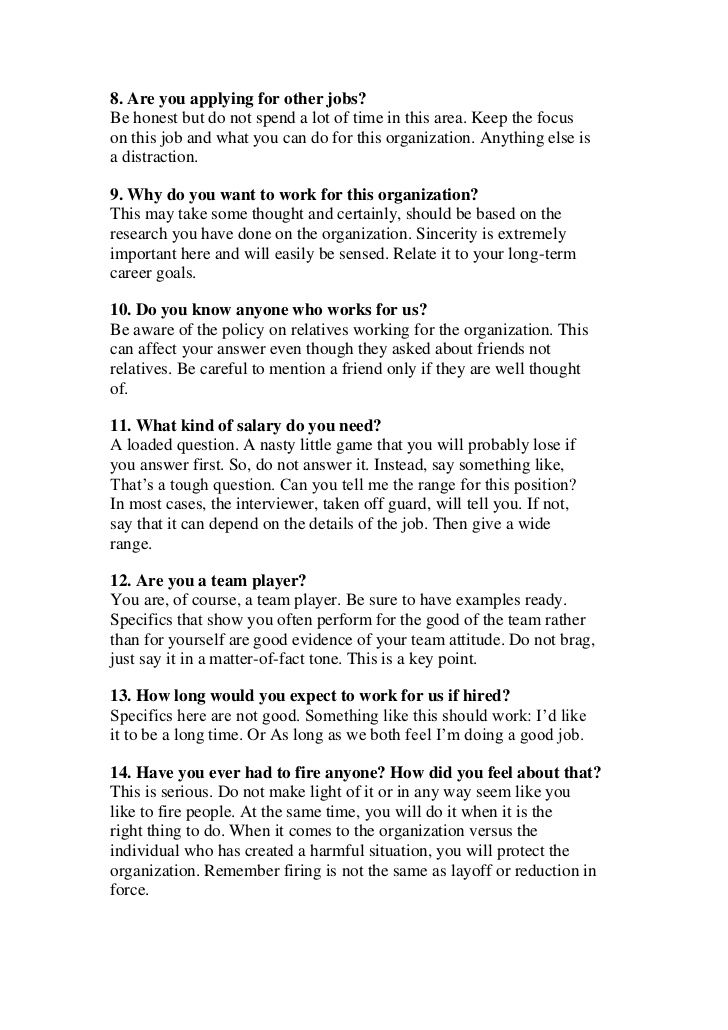

Ultimaker uses the 3D printing technology FFF (Fused Filament Fabrication). The FFF process extrudes the filament through a heated nozzle and the melted filament is placed onto the build platform. Layers are formed and the process is repeated until the whole object is completed. FFF is the most commonly used 3D printing technology. Ultimaker printers such as the Ultimaker 2, Ultimaker S3 and Ultimaker S5 are ideal to those who want versatile, user friendly, reliable and affordable machines to use in the comfort of their own office.

FFF is the most commonly used 3D printing technology. Ultimaker printers such as the Ultimaker 2, Ultimaker S3 and Ultimaker S5 are ideal to those who want versatile, user friendly, reliable and affordable machines to use in the comfort of their own office.

Formlabs uses SLA (Stereolithography) for their Form 2 3D printers. The SLA process uses a UV laser to solidify liquid resin into hard plastic. The upgrade from SLA is LFS (Low Force Stereolithography), a technology used in the Formlabs Form 3. The innovative LFS utilises a flexible tank and linear illumination to deliver a more accurate print. Both 3D printers, the Form 2 and Form 3, are extremely well suited to print parts that require complex geometries while delivering consistent results.

Click here to check out our blog "The 5 3D Printing Technologies that are taking over the world"

3. What types of materials can you print with?

An extensive range of materials can be used for 3D printing. The Markforged industrial (X3, X5, X7) and desktop range 3D printers (Onyx One, Onyx Pro, Mark Two) can print parts made from Onyx, Carbon Fiber, Fiberglass, Kevlar and HSHT Fiberglass (High-Strength High-Temperature Fiberglass). The Metal 3D printer (Metal X) from Markforged can print parts made from Stainless Steel, Aluminum, Tool Steel, Inconel and Titanium. Ultimaker 3D printers can print with PLA, PVA (Polyvinyl Alcohol), Nylon, CPE (Copolyester), ABS, Polycarbonate, Polypropylene etc. The Formlabs 3D printers can print with a variety of resins and waxes such Rigid Resin, Tough Resin, Durable Resin, High Temperature Resin, Flexible Resin, Castable Resin and Castable Wax Resin etc.

The Markforged industrial (X3, X5, X7) and desktop range 3D printers (Onyx One, Onyx Pro, Mark Two) can print parts made from Onyx, Carbon Fiber, Fiberglass, Kevlar and HSHT Fiberglass (High-Strength High-Temperature Fiberglass). The Metal 3D printer (Metal X) from Markforged can print parts made from Stainless Steel, Aluminum, Tool Steel, Inconel and Titanium. Ultimaker 3D printers can print with PLA, PVA (Polyvinyl Alcohol), Nylon, CPE (Copolyester), ABS, Polycarbonate, Polypropylene etc. The Formlabs 3D printers can print with a variety of resins and waxes such Rigid Resin, Tough Resin, Durable Resin, High Temperature Resin, Flexible Resin, Castable Resin and Castable Wax Resin etc.

4. What objects can you 3D print?

3D printing is being applied in many different areas to manufacture components and end use parts. Some of the countless objects you can 3D print are:

- Aircraft Bracket

- Pump Impeller

- Sprocket

- End Effector

- Soft Jaws

- Welding Fixture

- CMM Fixture

- Assembly Jig

- Brake Lever

- Metal Bracket

- Stainless Steel Clevis

- Motor Housing

- Engine Block Model

- Oil Pan

- Gear Set

- Spaceship Model

- Vase

- Jewelry

- Water Bottle

Click here to check out our 3D printed parts gallery

5. Which industries use 3D printing?

Which industries use 3D printing?

A growing number of industries and companies are utilizing 3D printing in their production process. The few industries that we believe benefit most from 3D printing are Aerospace, Automotive, Manufacturing, Robotics, Education, Construction, Engineering, Architecture, Dentistry, Jewelry and the Health Sector. Its simple to understand why 3D printing is becoming the largest technology shift since the internet just by looking at these industries.

6. What are the benefits of 3D printing?

3D printing offers a plethora of benefits. Two of the main advantages of 3D printing are:

- Cost effectiveness – the most amount of money to be spent in developing a product is decided on human labour. Conventional prototyping methods such as injection molds and production runs are more expensive as they require many hours of labour. Technicians, specialists, laborers and machine operators are required to handle the production using expensive machinery.

The labor in 3D printing can be as minimal as one person operating the printer and computer.

The labor in 3D printing can be as minimal as one person operating the printer and computer. - Faster production – 3D printing is extremely faster compared to traditional manufacturing methods such as injection molds and subtractive production. Testing ideas and designs with conventional manufacturing methods can take weeks or months. Complex CAD (Computer Aided Design) models can be 3D printed into a solid object in a matter of hours. Going from prototype to end-product in a short amount of time allow you to test and verify designs quickly, saving you more time and hassle in the long run.

One example combining cost effectiveness and speed of production is a 3D printed End Effector shown below. The part was printed in Carbon Fiber on-site and completed on the same day using the Markforged X7. Having a 3D printer such as the Markforged X7 in your production line or workflow makes it possible to print both new tools and functional replacements for worn out parts. There is clearly a huge difference in cost with the typical machined cost being $285.61 AUD compared to the 3D printed cost of $9.45 AUD.

There is clearly a huge difference in cost with the typical machined cost being $285.61 AUD compared to the 3D printed cost of $9.45 AUD.

7. Is there a Limitation to what shapes you can 3D print?

Traditional manufacturing methods rely on molds and cutting technologies to produce the desired shapes. Designing complex and intricate shapes with these methods can be difficult and expensive. 3D printing easily handles this challenge as you can print unlimited shapes and geometries imaginable depending on the size. Combined with an innovative software such as Generative Design, the sky is the limit.

8. Which 3D printer should I buy?

This comes down to your budget and what your workflow requires as each 3D printer and its technology has its own unique use.

- Formlabs Form 2 – this 3D printer utilises SLA (Stereolithography) and is ideal for smaller objects with intricate features such as jewelry.

- Formlabs Form 3 – this 3D printer is powered by LFS (Low Force Stereolithography) and is great for high-volume production that consistently delivers quality results without the need of extra labour.

- Ultimaker S5 – Ultimaker 3D printers are powered by FFF (Fused Filament Fabrication) and are ideal for those who are budget conscious and are looking for user-friendly, and versatile 3D printers.

- Markforged X7 – this machine is ideal for businesses who wants to quickly manufacture industrial grade composite parts in-house.

- Markforged Metal X – powered by ADAM (Atomic Diffused Additive Manufacturing), the Metal X system is a manufacturing solution that covers the entire production process. It is ideal for businesses who wants to manufacture industrial grade metal parts in-house.

3D Printing Technology and Material: 7 Questions to Ask | Stratasys Direct

7 Questions to Ask Yourself When Choosing a 3D Printing Technology and Material

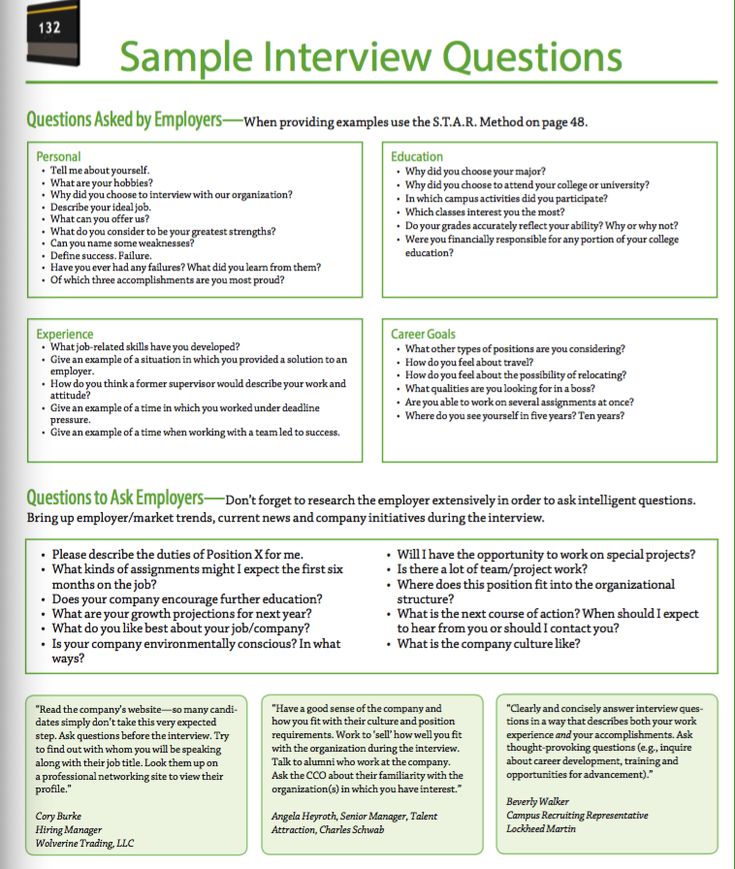

Today there are a plethora of 3D printing processes and materials to choose from and it’s only growing. The dynamic additive manufacturing market is often difficult to navigate, especially if you’re still learning about the processes. At Stratasys Direct Manufacturing, our project and applications engineers try to learn as much as they can about customer’s part application to accurately guide them to the best technology and materials.

At Stratasys Direct Manufacturing, our project and applications engineers try to learn as much as they can about customer’s part application to accurately guide them to the best technology and materials.

To help you start to filter out certain processes and materials, we put together a selection methodology:

Application – What is the purpose of the end product? You may need to build a small volume of complex end-use parts which would require strong materials, dimensional accuracy and repeatability. Whereas a sacrificial investment casting pattern is one-time use and needs to burnout clean.

Function – What does the part need to do? It may just serve aesthetic purposes in which it just needs to look and feel like an end-use part. Or perhaps you have a hard-working part that needs to hinge, snap, or bear a load which requires an accurate process and stronger materials.

Stability – Where does the part need to function? For example, holding up and maintaining strength in high temperatures rules out a lot of processes and materials. Does it need to function outdoors? In that case you would need a UV-stable material. Will the part interact with the human body? Then your application requires a biocompatible material.

Does it need to function outdoors? In that case you would need a UV-stable material. Will the part interact with the human body? Then your application requires a biocompatible material.

Durability – How long does the part need to last? Consider the number of use cycles and the application duration. For example, a mold or tool may need to go through hundreds of cycles and prolonged friction, but may only need to last a week for prototyping. Some 3D printing materials are very functional over a short period of time and others can maintain mechanical properties for years.

Aesthetics – How does the part need to look and feel? Photopolymer processes, such Stereolithography (SL) and PolyJet, can produce smooth parts right off of the machine, but aren’t the most stable and durable materials. While thermoplastic and powdered plastic processes like Laser Sintering (LS) and Fused Deposition Modeling (FDM) can create stronger and more durable parts, they often require finishing processes to achieve a smooth surface.

Economics – What is your budget and timeline? If you have a set budget and need to get a part for X amount, then your decision will weigh on price more than value. Time and quality can often contradict one another as well – if you need a quick-turnaround, it may be at the expense of a certain level of quality. However we have found ways to reduce lead time and cost without sacrificing quality, including batching, nesting, scaling, sectioning, shelling, ID-Light builds and adjusting orientation to reduce material consumption.

Priorities – What is the most important decision-making factor? Consider the primary objective and ultimate project goals. Often there are multiple, but your main priorities should drive your decision tree and filter the 3D printing technology and material options.

Here are some examples of how we have put this methodology to use with our customers:

Archie Handheld Studios

investment casting patternsApplication: Investment cast metal trophy

Function: Burned out pattern

Stability: The pattern needed to hold shape and be water-tight

Durability: One-time use

Aesthetics: The pattern had to be completely smooth for the casting process

Economics: Cost wasn’t a concern, but there was a short three week timeline

Priorities: Surface finish and speed

Selection: Stereolithography Investment Casting Pattern out of SC 1000

Read the full story.

NASA JPL Satellite Parts

aerospace Application: Satellite antenna array

Function: Holds radio antenna wires

Stability: Exposure to extreme temperatures in outer space, and pressure and vibration on the space shuttle

Durability: Indefinite lifespan

Aesthetics: The parts had to be compatible with a protective paint

Economics: The customer reduced lead time by consolidating multiple assemblies into one part design

Priority: Stability

Selection: Fused Deposition Modeling (FDM) and ULTEM™ 9085 resin

Read the full story.

Choosing the right additive manufacturing technology and material for your application is critical to part performance and results. The main thing to remember is “one-size-fits-all” doesn’t apply to additive manufacturing. It’s imperative to know the pros and cons of each process and material or partner with an expert who does. Asking yourself these qualifying questions will help you start to navigate the dynamic market.

ULTEM™ is a registered trademark of SABIC or its affiliates or subsidiaries.

Asking yourself these qualifying questions will help you start to navigate the dynamic market.

ULTEM™ is a registered trademark of SABIC or its affiliates or subsidiaries.

3d modeling and 3d artist

- Golovna /

- Blog /

- Expert opinion /

- How is the interview for the position of 3D artist

All articles

Do you want a call from your dream company? Often this happens suddenly, so get ready now. We will tell you how the interview for the position of a 3D artist in GameDev world-class companies goes.

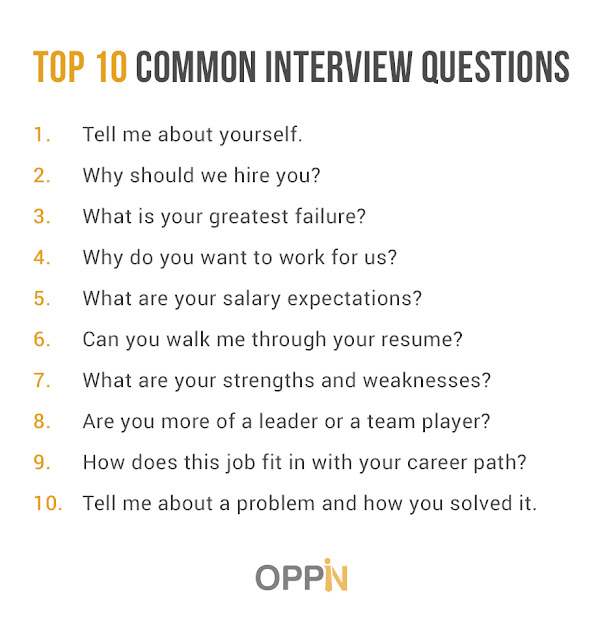

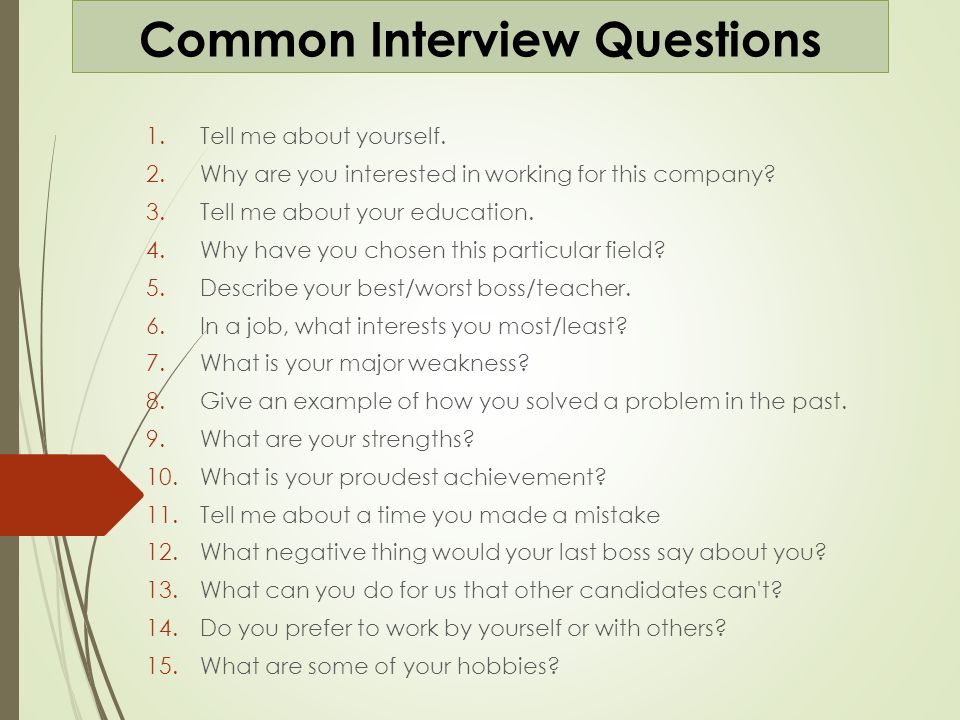

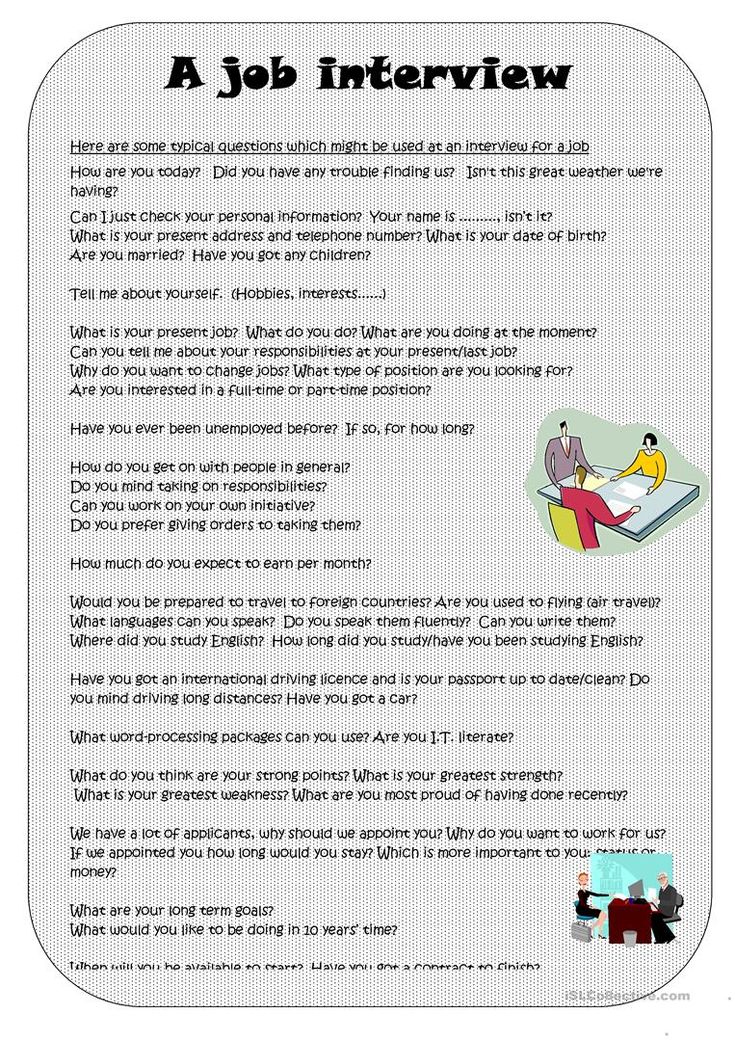

The most interesting questions

As time goes on, the top five most common questions are still on the go. To tell about yourself, about your achievements and plans for the future - this is asked to assess personal rather than professional qualities.

They also ask tricky questions:

— What would you do if the art director sent your project to other artists for revision?

- Do you consider it acceptable to change the mood of the leader?

- How would you feel if the project that the whole team worked on was put into a "long box"? nine0023 — Which product of our company do you like the most and why?

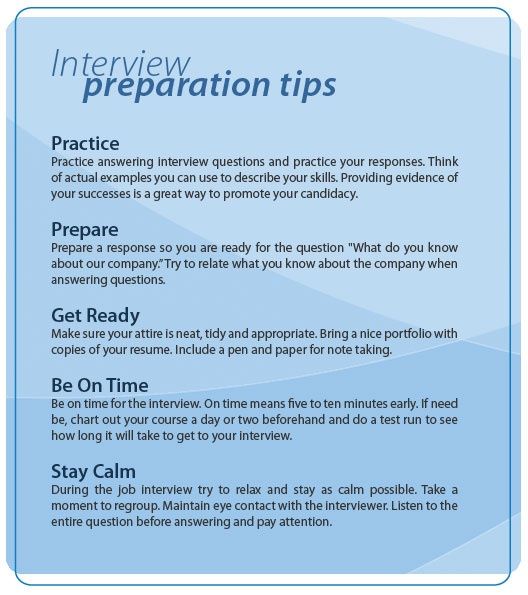

An interview is already a job

An employer can ask you to do a test right in the office. They do this based on the portfolio of the 3D artist. Do you specialize in characters or vehicles? Be ready to create a hero or an entire tank, and in a short time. Are you interviewing over the phone? You will be reminded of the deadline in a few hours.

They do this based on the portfolio of the 3D artist. Do you specialize in characters or vehicles? Be ready to create a hero or an entire tank, and in a short time. Are you interviewing over the phone? You will be reminded of the deadline in a few hours.

Do not come without a laptop

You will need it to show your portfolio in a presentable way, to explain how you worked on a particular model. Not all projects make it to Sketchfab, so find some cool stuff and put it all in one folder. Also, the laptop will save in case of an unexpected test task. Agree that it will be more convenient to work on "native" hardware and software.

Who should I talk to?

Interviews are most often conducted by technical HR specialists, art directors or department heads. Questions may vary depending on the competence of the employee. But as the practice of recent years shows, 3D artists rarely ask about something deeply technical. Best of all, your skill will be shown by a portfolio and a test task. nine0013

nine0013

Forget your evening plans!

It is never possible to predict how long an interview will last. In some companies, you can spend no more than an hour, in others - to spend a 5-hour marathon. It all depends on how many employees you will communicate with and what “surprises” the future employer has prepared.

Do you want to learn how to model for games in 2 months and get a job in your dream company closer? Sign up for Pavel Medvedev's course "3D graphics for games"

Online intensive: https://artcraft.net.ua/courses/3d-dlya-igr

Course in Kyiv: https://artcraft.net.ua/courses/3d-grafika-dlya-igr-onlajn

Other courses

marvel allTRADITIONAL online ANATOMY FOR AN ARTIST IN 3D 10 of 20

TRADITIONAL online ACADEMIC DRAWING 18 out of 20

2D START online Series of workshops "MATERIALS" 100 out of 100

Divitisya all

Current statistics

marvel allmarvel all

Questions and answers about 3D printers and 3D printing

This section contains all the most frequently asked questions and answers about 3D printers and 3D printing. If you did not find the answer to your question in this section or using the portal search, ask it on blogs and get answers from community members: /questions/

If you did not find the answer to your question in this section or using the portal search, ask it on blogs and get answers from community members: /questions/

- 1 Frequently Asked Questions

- 1.1 Bought a 3D printer - what's next?

- 1.2 3D printer does not see/print STL file

- 1.3 Which program is used to prepare an STL file for printing?

- 1.4 What is a 3D printer and how does it work?

- 1.5 What is the kinematics of a 3D printer?

- 1.6 What are stepper motors and drivers?

- 1.7 What is 3D printer firmware and where is it uploaded? nine0118

- 2 Questions about defects and 3D printing issues

- 2.1 Related Articles

- 2.2 PLA does not choke and the extruder clicks

- 2.3 Waves appear on the walls when printed.

- 2.4 At the start of printing, the table/carriage starts banging against the wall.

- 3 Questions about adhesion (sticking the model to the table)

- 3.1 Plastic does not stick to the table.

- 3.2 The part is very stuck during printing and cannot be removed from the table. nine0004

- 3.3 Bends corners when printing.

- 4 Consumable questions

- 4.1 How to print with PLA

- 4.2 How to print with ABS

- 4.3 Plastic has uneven diameter

- 4.4 Foreign inclusions are observed in the plastic.

- 4.5 Plastic tangles occur when printing

- 4.6 Is ABS plastic harmful? nine0004

- 4.7 Why does the bar feed stop after several layers when printing with soft plastics (Flex)?

- 5 3D printer assembly and calibration questions

- 5.1 Axle moves in the wrong direction

- 5.2 When replacing stepper motor drivers from A4988 to DRV8825, do I need to change something in the firmware?

- 5.

3 After installing the TMC2100/2208/2130, layer shifts occur during printing.

3 After installing the TMC2100/2208/2130, layer shifts occur during printing. - 6 3D printer firmware questions

- 6.1 Can't understand Marlin

- 7 Preparing the model for printing. Slicers

- 7.1 CURA program - how to use it

- 7.2 KISSlicer - how to use it

- 7.3 Repetier-Host program - how to use it

- 7.4 Simplify3D - how to use it

- 7.5 Slic3r - how to use it

- 7.6 Craftware - how to use it

- 8 Questions about G-CODE

- 8.1 What is G-CODE?

- 9 3Dtoday Help

- 9.1 how to use the portal and what is there?

- 9.2 Where can I read information about 3D printers and 3D printing?

- 10 Search for questions and answers on the portal

FAQ

Bought a 3D printer - what's next?

answer: read the article - For the smallest: how to start printing

3D printer does not see / print STL file

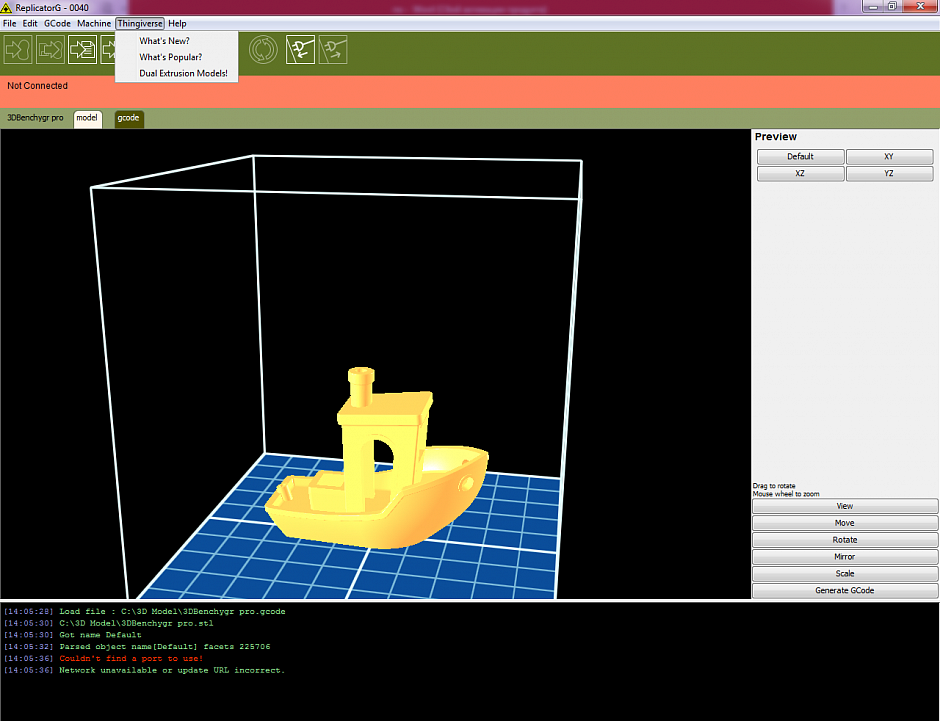

answer: almost all 3D printers should not see or print STL files (although there are exceptions) as this file type contains model geometry in the form of a mesh, obtained as a result of polygonal modeling or export from CAD programs. STL files are loaded into the program for preparing the model for printing (slicer) and converted into a control code (g-code) for the printer. The resulting "slicing" file is what the 3D printer sees. Details here

STL files are loaded into the program for preparing the model for printing (slicer) and converted into a control code (g-code) for the printer. The resulting "slicing" file is what the 3D printer sees. Details here

What program is used to prepare the STL file for printing?

answer: To prepare an STL file for printing, you need to use a slicer - a program with which you set the print settings for the model for the printer. Such a program (slicer) can be either common and not tied to a specific printer, for example, Cura, slic3r, KISSlicer, etc., or individual for a specific 3D printer (supplied with the printer). In this program, many parameters are set - print speed, layer thickness, temperature, and many others. Information on slicers here

What is a 3D printer and how does it work?

answer: read the article - what is a 3D printer

What is the kinematics of a 3D printer?

answer: read the article - 3D printing for the newest. From A to Z. Kinematics.

From A to Z. Kinematics.

What are stepper motors and drivers?

answer: read the article - 3D printing for the newest. From A to Z. Steppers, drivers and some magnetic field.

What is 3D printer firmware and where is it uploaded? nine0212

answer: read the article - 3D printing for beginners. From A to Z. Boards and firmware.

Questions about defects and 3D printing issues

Related articles

Most of the questions and answers are given in the articles. Please read:

- 3D Printing Defects - Let's try to classify

- 20 Most Common 3D Printing Problems (Part 1)

- The 20 Most Common 3D Printing Problems (Part 2)

PLA does not choke and the extruder clicks answer: The problem is insufficient cooling of the thermal barrier of the extruder.

Waves appear on the walls when printed.

answer : waves on the walls, so-called. wobbles (from wobble (eng.) fluctuations) are associated with the presence of backlash in the mechanisms for moving the printer. In Prusa-type kinematics, wobble is associated with a non-rigid connection of the Z-axis screws to the motors. To solve this problem, it is necessary to put balls from ball bearings in the couplings connecting the screws and the motor shafts, and install the split coupling into an interference fit. nine0023

answer : waves on the walls, so-called. wobbles (from wobble (eng.) fluctuations) are associated with the presence of backlash in the mechanisms for moving the printer. In Prusa-type kinematics, wobble is associated with a non-rigid connection of the Z-axis screws to the motors. To solve this problem, it is necessary to put balls from ball bearings in the couplings connecting the screws and the motor shafts, and install the split coupling into an interference fit. nine0023 When printing starts, the table/carriage begins to knock against the wall.

answer: To fix the problem, you need to check the limit switch, whether it is pressed by the carriage / table and the integrity of the switch wires.

Adhesion questions (sticking the model to the table)

Plastic does not stick to the table.

answer: when printing on glass surfaces, to improve adhesion, it is necessary to use various adhesives (for example, glue from The 3D or Picaso, you can use glue stick or BF-2). Printing is recommended on glass surfaces (preferably mirrors) due to their flat surface, which ensures an even first layer. nine0013

Printing is recommended on glass surfaces (preferably mirrors) due to their flat surface, which ensures an even first layer. nine0013

A part is stuck to the printout and cannot be removed from the table.

answer: the problem is related to a very small gap when printing the first layer, and it "smeared" into the glass surface. You need to increase the clearance. And to remove the part from the glass, it can be placed in the freezer of the refrigerator.

Part curls up when printed.

answer: when printing, it was necessary to close it from drafts. The bending of the corners is associated with a strong shrinkage of the material when it is cooled. For uniform shrinkage, which all plastics have, it is necessary to maintain a stable temperature using a heat chamber. A box with which you can cover the printer, as well as installing a door in the printer can serve as a thermal chamber. nine0013

nine0013

Questions about consumables

How to print with PLA

Answer: PLA has operating temperatures ranging from 200 to 230 degrees (depending on the composition of the material used by the manufacturer). If your 3D printer has a heated table, then no additional funds are required to stick the model to the table. If your table is not heated or the model does not stick to the table, then check the table calibration and use adhesion agents (varnish / glue for printing, etc.). nine0013

How to print with ABS plastic

Answer: ABS plastic has printing temperatures from 230 to 250 degrees (depending on the composition of the material used by the manufacturer). Printing with ABS plastic implies the presence of a heated table and means for adhesion (varnish / glue for printing, ABS juice, etc.).

Plastic has an uneven diameter

answer: Diameter fluctuations of more than 0. 05 mm are considered defective. In this case, it is necessary to contact the manufacturer with a request to replace the coil with a quality one. nine0013

05 mm are considered defective. In this case, it is necessary to contact the manufacturer with a request to replace the coil with a quality one. nine0013

There are foreign inclusions in the plastic.

answer: this is a defect, you must contact the manufacturer with this defect. Such defects can lead to clogging of the printer nozzle.

When printing, plastic entanglement is observed

answer: the so-called overlap is due to the fact that during operation you relaxed the coil winding, and the upper turns fell under the lower ones. We recommend unwinding part of the coil to a place with even winding and carefully winding it back, observing the tension. nine0013

Is ABS plastic harmful?

Answer: When printed, ABS emits an unpleasant odor and the room must be ventilated. There is no harm, the discharge does not exceed the MPC (maximum permissible concentration).

Why does the bar feed stop after several layers when printing with soft plastics (Flex)?

Answer: If your printer has a Bowden bar feed system, the soft plastics are experiencing too much resistance as they pass through the tube to the print head. Try increasing the nozzle temperature to keep the resistance to a minimum. nine0013

3D printer assembly and calibration questions

The axis moves in the wrong direction

answer: if the movement occurs in the wrong direction, then you need to turn the stepper motor connector 180 degrees.

When replacing stepper motor drivers from A4988 to DRV8825, do I need to change something in the firmware?

answer: If you want to use them with the same divisor (1/16), then nothing is needed. If you want to use it with a 1/32 divider, then in the firmware you need to double the number of steps on those axes where these drivers are installed. Also, do not forget about the correct adjustment of the driver current. nine0013

Also, do not forget about the correct adjustment of the driver current. nine0013

After installing the TMC2100/2208/2130, layer shifts occur during printing.

Answer: This type of driver requires good cooling and a fairly accurate Vref voltage regulation.

Questions about 3D printer firmware

I can’t understand Marlin

answer: read articles about firmware:

- Set up Marlin firmware and upload it to the 3D printer

- Firmware and printer setup0209 Preparing the model for printing. Slicers

CURA program - how to use it

answer: read articles written especially for you. List:

- What is Cura, how to cook it and what it is eaten with.

- "CURA" is your caring assistant in the world of printing.

- The path to excellence. Cura

KISSlicer program - how to use it

answer: read articles written especially for you. List:

List:

- KISSlicer - learning to work. Part 1.

- KISSlicer - learning to work. Part 2.

- KISSlicer - learning to work. Part 3.

- KISSlicer (user manual) Part 1

- KISSlicer (user manual) Part 2

Repetier-Host program - how to use it

answer: read the articles written especially for you. List:

- Let's help beginners: Repetier-Host - first steps.

- Let's help beginners: Repetier-Host - first steps. Slic3r settings. Part 2

- Let's help beginners: Repetier-Host - first steps. Cura settings. Part 3

Simplify3D program - how to use it

answer: read articles written especially for you. List:

- Simplify3D “For Dummies”. Part 1. “Program interface”

- Simplify3D “For Dummies”. Part 2 “Creating a workflow”

- Getting started with Simplify3d or I learned what a slicer is, and what's next?

- Using different print settings for different parts of the model in Simplify3D, print acceleration

Slic3r - how to use it

answer: read articles written especially for you.