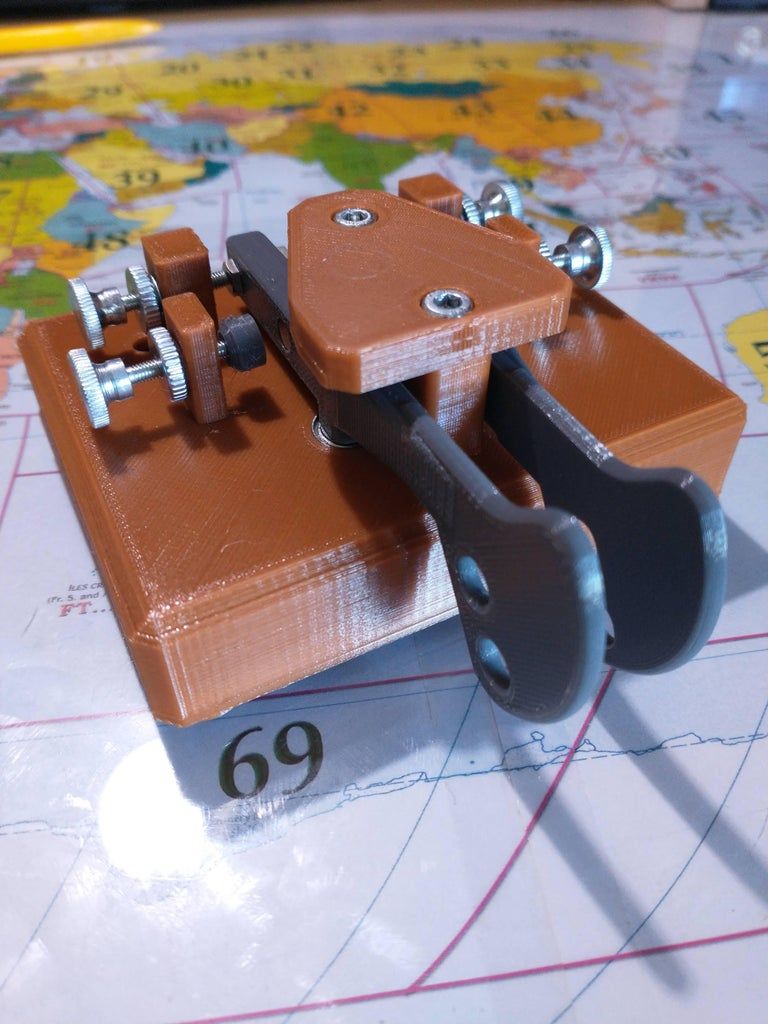

3D printed cw paddle

New 3D Printed CW Paddles by CR6K (video)

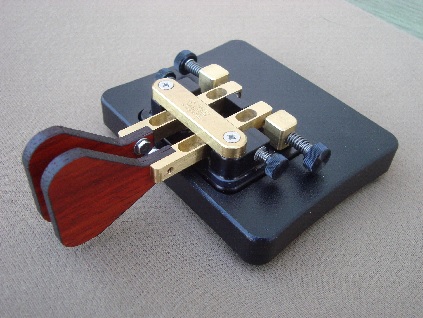

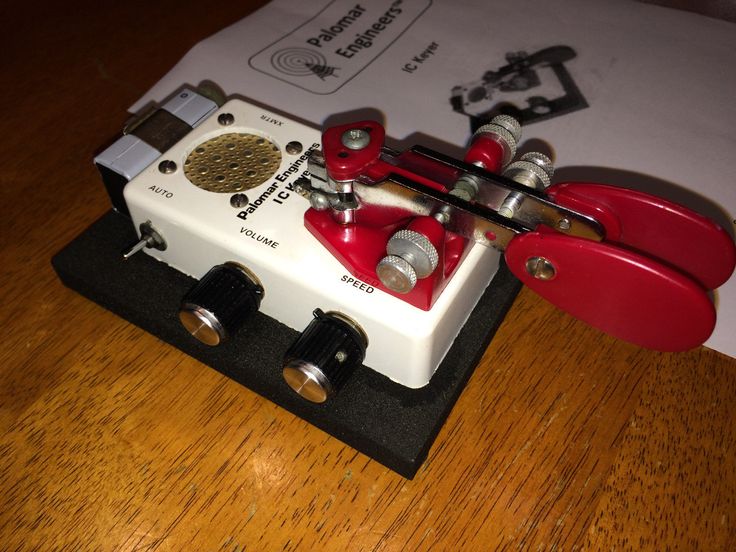

One shortcoming we had at SZ1A was the lack of a dedicated CW Paddle “key” for every station operating position. Usually operators would bring their own. But we wanted to have our own “keys” in for the station, as a matter of honor! Most operators use the computer for the entire CW contest. However, everyone wants to feel the security of having a CW paddle key. Operators will often want to manually send something: for example a TU, or CFM, or even a couple of dots…without using the PC.

Unfortunately, CW keys / paddles are expensive. The cheapest will start at around €100 and at that price it often won’t be very good. Usually, more than €150 is needed to purchase something satisfactory. So far we have only owned one Bencher ΒΥ1, donated by Kostas SV1DPI and we definitely need more.

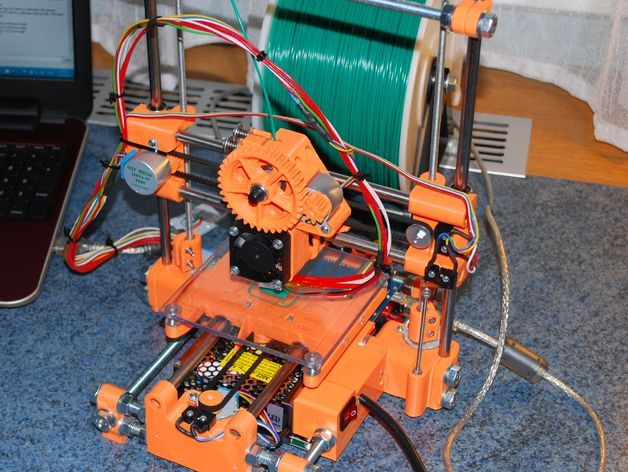

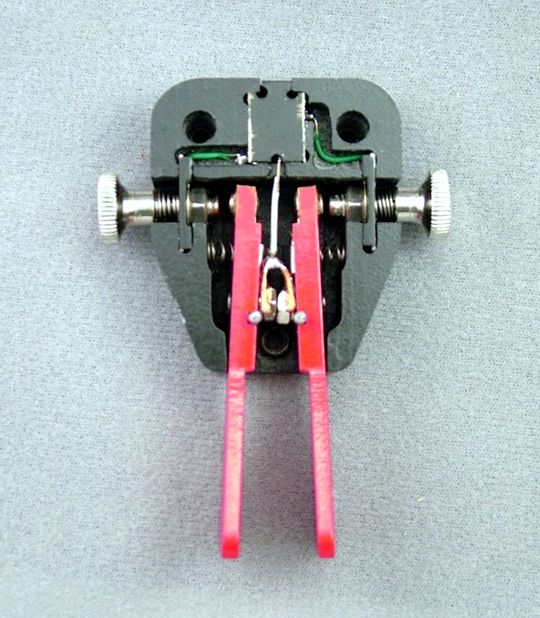

Recently, on the web one can find various designs of CW Paddles & Keys that can be… printed! 3D Printers have entered our lives for good. You might have already heard in the media that someone even printed a house! So why not a CW Paddle or Key? Due to the lack of a 3D printer but mainly because we wanted something tried and tested, we chose to buy a ready-made paddle.

We ordered three to cover the fully equipped stations. The project was funded by Vassilis SV1BJW who made the required donation. Filipe offered a fourth CW paddle as a gift for SZ1A! We thank them both!

So we turned to CT1ILT (CR6K), a very good and well-known contest operator, who makes and sells CW keys printed on a 3D printer. Filipe sells these keys for just €40 each. We ordered three to cover the fully equipped stations. The project was funded by Vassilis SV1BJW who made the required donation. Filipe offered a fourth CW paddle as a gift for SZ1A! We thank them both!

About a month and a half after our order, the CW paddles arrived at the station. Before the order, we were worried if we made the right choice was. We were afraid that they might be a very cheap construction, therefore, of poor quality.

Before the order, we were worried if we made the right choice was. We were afraid that they might be a very cheap construction, therefore, of poor quality.

Would they handle contest conditions? Could someone key fast enough with them? Would they look good? or would they look like cheap plastic?

First of all, they are beautiful!

The colors were very nice! And the overall finish and their exterior was excellent. In fact, the colors chosen by Filipe made them look even better. They also have the station callsign engraved on them! Amazing! They definitely pass this test!

The biggest problem with Morse keys is that they have to be relatively heavy so that they do not move with the force exerted by the operator. A normal key’s weight is often from 1200 to 1500 grams! How much can a plastic counterpart be? We weighed them!

Here, friends, was the weak point: only 148 grams! Compared to the 1. 5 kg that BY1 weighs, it was an issue. Of course, Filipe had warned us earlier that it is light and requires a metal surface to “stick” on. These keys have an innovative solution to the specific stability problem, they come with 4 neodymium magnets installed in its base. Therefore all you need is a metal surface to place them on to make them stable.

5 kg that BY1 weighs, it was an issue. Of course, Filipe had warned us earlier that it is light and requires a metal surface to “stick” on. These keys have an innovative solution to the specific stability problem, they come with 4 neodymium magnets installed in its base. Therefore all you need is a metal surface to place them on to make them stable.

These keys have an inovative solution to the specific stability problem, they come with 4 neodymium magnets installed in its base. Therefore all you need is a metal surface to place them on to make them stable.

And now what;

We cut a galvanized metal plate 8 mm thick in the dimensions of the key, approximately 10×9 mm (cost of only €6 for all 4). At the same time, we bought some antislip PVC matting (just €1 for a large piece). By the way, PVC matting is perfect for all keys and stabilizes them very well.

We glued the PVC to the bottom of the metal plate, and the CW Paddle – Key sat on the top. The result was perfect! The controller is completely stable and clearly better than the BY1!

The key’s contacts can be easily adjusted, as well as the exerted force required by the operator. They use neodymium magnets and not on coil-spring returns. One thing that is missing is the cable, you’ll need to either make or buy it. This isn’t an issue since most keys are provided without a cable. These key’s have a standard 1/8″ female stereo plug that you can easily connect your cable to.

We used the keys during the CQ WPX CW 2021 contest. Everyone’s impressions were more than positive. The keys served 100% of the purpose for which they were purchased. Everyone agrees that their value for money is absolutely excellent. They can definitely not be compared to keys that cost maybe ten times more. However, they are very good and look good in the shack too, which is always important to most Radio Amateurs. They also seem to be quite durable.

However, they are very good and look good in the shack too, which is always important to most Radio Amateurs. They also seem to be quite durable.

Everyone’s impressions were more than positive. The keys served 100% of the purpose for which they were purchased. Everyone agrees that their value for money is absolutely excellent

Some have already expressed interest in buying one. There are reservations about the contacts: it is just a screw, neither platinum nor gold. Ok, well it’s just a screw, so if it breaks at some point you can replace it easily and at almost zero expense. One observation is that although the metal base does not move, the key does in some cases. This happens when sending under high speed and the stress of the operator is greater, they may exert more pressure, moving the key. The operator may feel more comfortable by securing the key by holding it with their hand, otherwise, it may move a little and you might miss a dot. You will see in the video that this happens sometimes but not always…

You will see in the video that this happens sometimes but not always…

To solve this issue entirely we will add 1-2 neodymium magnets more, so that it is secured even more to the base and it will be perfect!

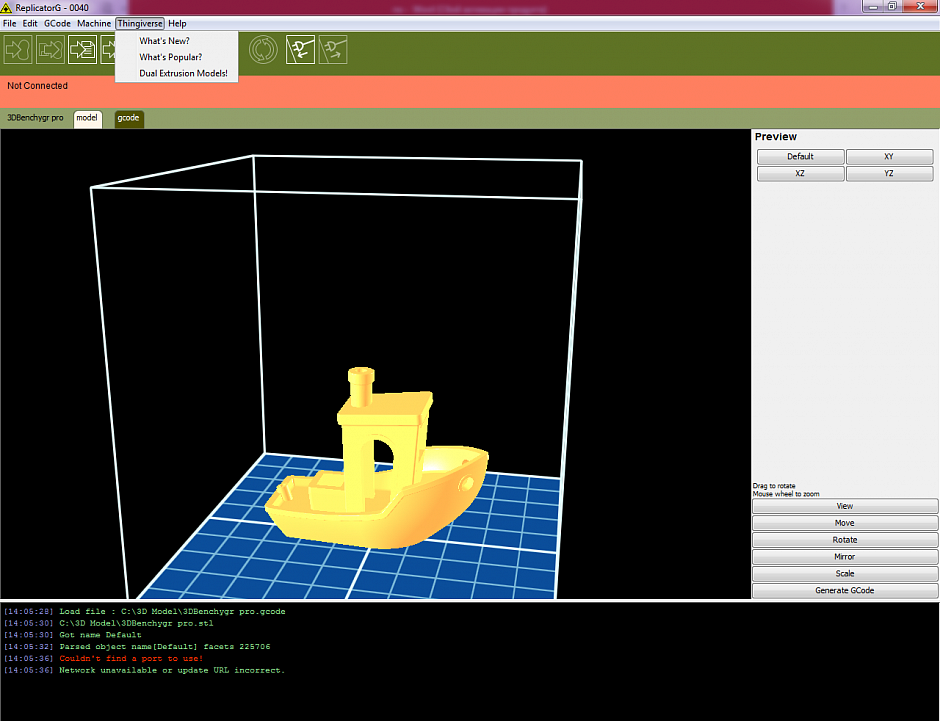

▷ iambic paddles 3d models 【 STLFinder 】

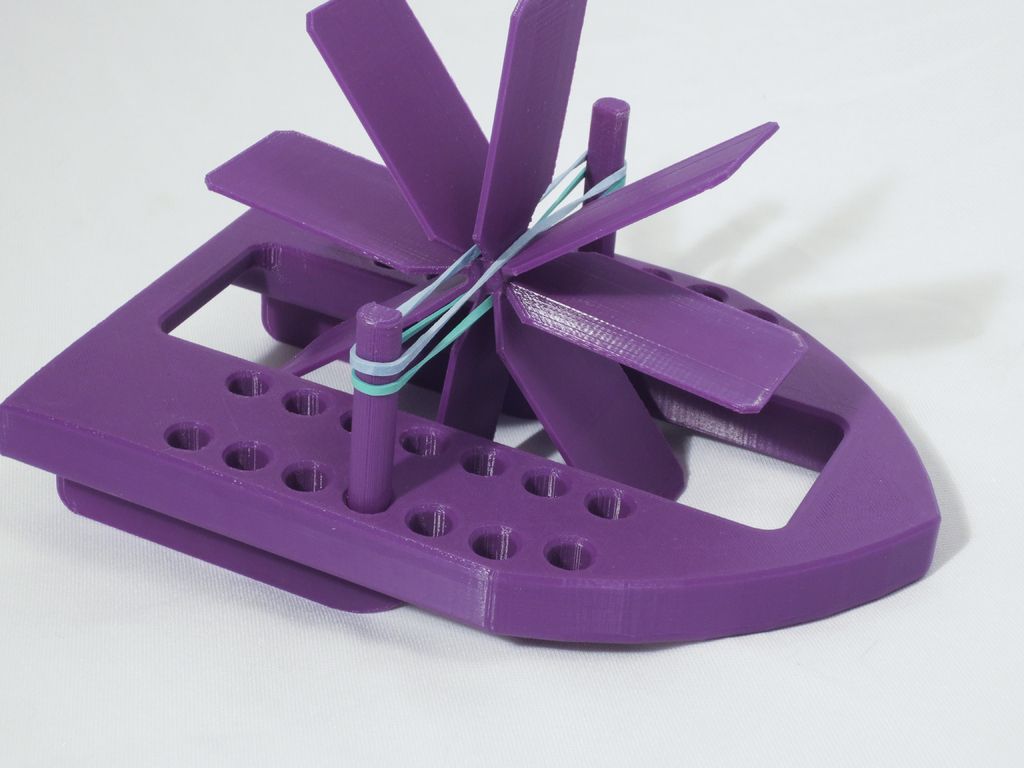

Iambic Paddles remix

thingiverse

Really enjoyed building ReallyBigTeeth's iambic paddles, but I was having some issues getting the return spring to stay put. My solution is to add a little nub inside each recess on the paddles so that the end of the spring can't slip out. I also...

I also...

Iambic Paddles (Narrow Version)

thingiverse

Remixed from an excellent design by Thingiverse user and certified amateur radio operator Loren Butler (V01PWF), the intent of this project was to make a set of 3D printable iambic paddles that were as portable as possible, yet comfortable enough to...

Iambic Paddles (Mini Version)

thingiverse

If you like what you see here, consider leaving a tip. Remixed from an excellent design by Thingiverse user and certified amateur radio operator Loren Butler (V01PWF), the intent of this project was to make a set of 3D printable iambic paddles that. ..

..

Iambic Paddles

thingiverse

I have added a m3 screw nut.

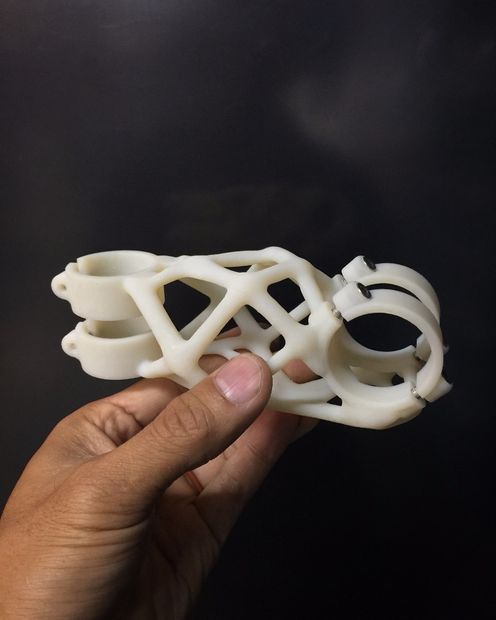

Iambic Paddles (For resin printing)

thingiverse

Iambic paddles for CW (morse code). Very similar to others out there, but designed to be printed on a resin printer and with stuff I had already lying around. Uses M3 socket head cap screws, washers, and nuts. Spring is 0.21in OD. Pockets...

Iambic Paddles (Base Mountable Version)

thingiverse

Remixed from an excellent design by Thingiverse user and certified amateur radio operator Loren Butler (V01PWF), the intent of this project was to make a set of 3D printable iambic paddles that were as portable as possible, while still comfortable. ..

..

Leg Strap Base for Iambic Paddles

thingiverse

A Leg Strap Base for ReallyBigTeeth's Iambic Paddles (Base Mountable). ... https://www.thingiverse.com/thing:2054230 Nice snug fit.

Iambic Paddles morse key

thingiverse

Remix of https://www.thingiverse.com/thing:2054230 Changes: - replaced screws for the axes of the paddles by plastic rods from the base to the roof - paddles new designed for: M3 screws with M3 nut; recesses for mounting repulsing magnets...

Mini Iambic Paddles (With Bearings)

thingiverse

I had some really small bearings, ID 3mm OD 6mm, 2mm height. And thought Hmmm I should remake the Morse paddle that had melted in my car and use those bearings.

You should look here: https://www.thingiverse.com/thing:2333019 for the original since...

And thought Hmmm I should remake the Morse paddle that had melted in my car and use those bearings.

You should look here: https://www.thingiverse.com/thing:2333019 for the original since...

Oversize Paddles for Vibroplex Iambic

thingiverse

I find the paddle grips on the Vibroplex Iambic a bit too "dainty". ...These are quite a bit larger, similar to the conversion paddles Vibroplex sells for $15.

Replacement Paddles for CW Morse Iambic

thingiverse

I broke my paddles on my CW Morse Iambic Paddles, so I reverse engineered the broken ones, and created these. They seem to work well. ...Be careful when resoldering the brass contacts, because if you take too long, you will melt and bend the paddle.

They seem to work well. ...Be careful when resoldering the brass contacts, because if you take too long, you will melt and bend the paddle.

Non-iambic Morse code key with paddles V2

thingiverse

I created a paddle a number of years ago but decided to streamline it and make the paddles more secure so this is a V2 of my previous non-iambic paddle.This design uses a portion of a common hacksaw blade as the spring for the key. It is based on...

Base for QRPguys Iambic or Single Lever Mini Paddles: Morse Code, Ham Radio

thingiverse

. .. magnets with a thin coat of rubber cement gives them enough traction that the key feels bolted on. Note the .stl file names to be sure you are printing the correct base for the paddle you have (iambic or single lever) See you on the bands and 73.

.. magnets with a thin coat of rubber cement gives them enough traction that the key feels bolted on. Note the .stl file names to be sure you are printing the correct base for the paddle you have (iambic or single lever) See you on the bands and 73.

Iambic Keyer

thingiverse

It is a iambic morse code keyer Instructions Pint 2 of each parts and put them together. ...Rubber bands may be used to hold it together.

Micro Iambic CW Key

thingiverse

This is a small Iambic morse key I designed for mobile use. It uses a hacksaw blade and three M3 screws. ...Version 2 with better wire routing, strain relief, and mounting holes.

Iambic Paddle spring

thingiverse

This is an addition for the iambic paddles posted by ReallyBigTeeth, I believe it should work on any of the models he has posted. Printed with 100% infill at .04 layer height. ... It fits nicely between the in the recess holes of the paddles.

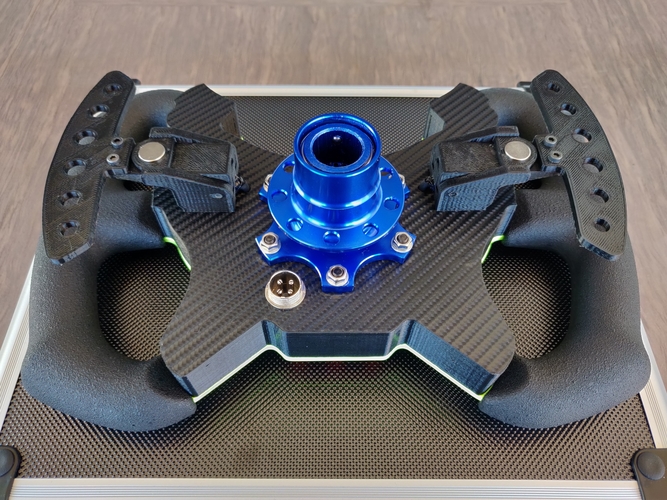

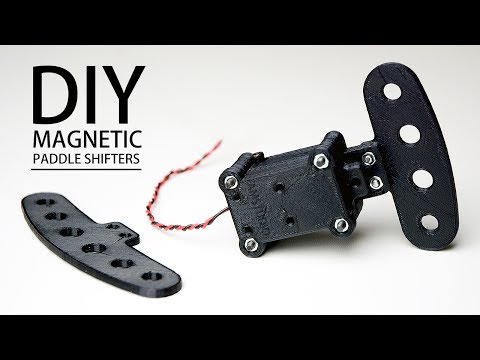

Overcomplicated magnetic iambic paddle

prusaprinters

This is a somewhat overcomplicated, but nice, iambic key for portable radio operation. It has a magnetic base to attach to your radio's chassis, allowing for easier use in the field without needing a heavy base of its own. </p><p>It uses a...

</p><p>It uses a...

Morse Code Iambic Keyer

thingiverse

This is an iambic keyer using commonly available hardware. I generally use this by holding it in my left hand and keying with my right hand for SOTA and POTA activations. Gap spacing adjustment is a bit crude, but once you have it set, no adjustments...

mini iambic paddle by OK1IAK

thingiverse

mini iambic paddle by OK1IAK

Yet another iambic CW paddle

thingiverse

Iambic CW paddle Material: 4 x M5x20mm 3 x M5x30mm 7 x M5 nuts 2 x M4x10mm 4 magnets 5x5x1mm for the paddle return The base was printed with supports. ...

...

Mini Iambic Magnetic Morse Paddle

thingiverse

Mini Iambic Magnetic Morse Paddle is designed for portable or SOTA operation. The original design was made by Vojta OK1IAK. I made some changes and description how to make it. There is OpenScad source available, you modify files if you like. Material...

Iambic Keyer Free 3D print model

cgtrader

It is a iambic morse code keyer

Yet another iambic CW paddle V2

thingiverse

Iambic CW paddle Material: 4 x M5x20mm 3 x M5x30mm 7 x M5 nuts 2 x M4x10mm 4 magnets 5x5x1mm for the paddle return This V2 version has thinner paddles and they are closer to each other. ...

...

Large CW Morse Code Iambic Key

thingiverse

This is a full sized Iambic Key that uses flat Package strapping (the metal ones) and 1/4" Misc. Hardware to make an Iambic Key. You could also use a sawblade as the paddles. I designed this after seeing how expensive an iambic key is. I am 17 years...

Compact Morse iambic paddle

thingiverse

Compact design, easy to build, magnetic baseplate with rubber pads seats.

• Compact design

• Adjustable clearance

• Magnetic baseplate option with non-slip rubber pads

• Easy to print and to build; few standard and widely available parts (2x. ..

..

Morse Code Iambic Keyer

thingiverse

I used M3 screws of various sizes. I liked the design but I changed a few things to make it more adjustable and I added a slotted bolt and nut to hold the cable without ties. I only had 10mm square magnets so I changed that and used small tabs that...

non-iambic key

thingiverse

I was working on a portable radio configuration and wanted a smaller key that was essentially disposable. Print the model, add a hacksaw blade and a few screws and you have a serviceable keyer, Is it the greatest keyer in the world - no. But for...

Iambic Key Paddle

thingiverse

Hi,

My v1 of 3D printed key. I needed one for a Arduino project I was working on so quickly designed and printed this one.

...

It feels ok and works but will make some slight changes to v2.

I needed one for a Arduino project I was working on so quickly designed and printed this one.

...

It feels ok and works but will make some slight changes to v2.

3D-Printed Leg Mount for N0SA iambic Key

pinshape

... PLA plastic) leg mount. ...It is designed to fit the N0SA iambic Key (the machined Aluminum one). Handy for QRP operation to mount the key to operator's leg. ...The nominal internal dimensions of the cavity are 28.5 side-to-side and 28.75 front-to-back

Morse Paddle Key for Ham Radio - Iambic type

thingiverse

Here you have an Instructable to learn how to set it properly: https://www. instructables.com/Morse-Key-Paddles-Iambic-Type/ 73s from EA3HTH ----------------------------------------------------------------------------------------------------- [CAT]...

instructables.com/Morse-Key-Paddles-Iambic-Type/ 73s from EA3HTH ----------------------------------------------------------------------------------------------------- [CAT]...

Build a house and transplant a heart: what 3D printers are capable of

Is it possible to print anything, including clothes and food, and how 3D printers helped save lives during a pandemic, we understand the new episode of the RBC Trends podcast “What has changed? »

Your browser does not support audio player .

Listen to us on any convenient platform: Apple Podcasts, CastBox, Yandex Music, Google Podcasts, Spotify and VK Podcasts. And also follow us on Telegram and Instagram "What has changed?" - there we share interesting materials on the topic. nine0003

Guests of the issue:

Sergei Nefedov, technical director and founder of Arfin. Sergey explained how 3D printers print entire houses and why such construction has not yet taken root in Russia.

Alexander Kornveits, founder and CEO of Tsvetnoy Mir. Alexander told how modern medicine uses 3D printing and when it will be possible to transplant printed organs.

Alexander told how modern medicine uses 3D printing and when it will be possible to transplant printed organs.

Host of an artificial intelligence podcast from the future especially for RBC Trends. nine0003

Conversation timeline

1:34 — How 3D printing works

6:58 — Is it possible to print an organ: bioprinting

8:14 — Why don't we print clothes?

17:30 — How and from what do they print at home?

21:54 — Should the state regulate 3D printing technologies

25:27 — The future of additive technologies

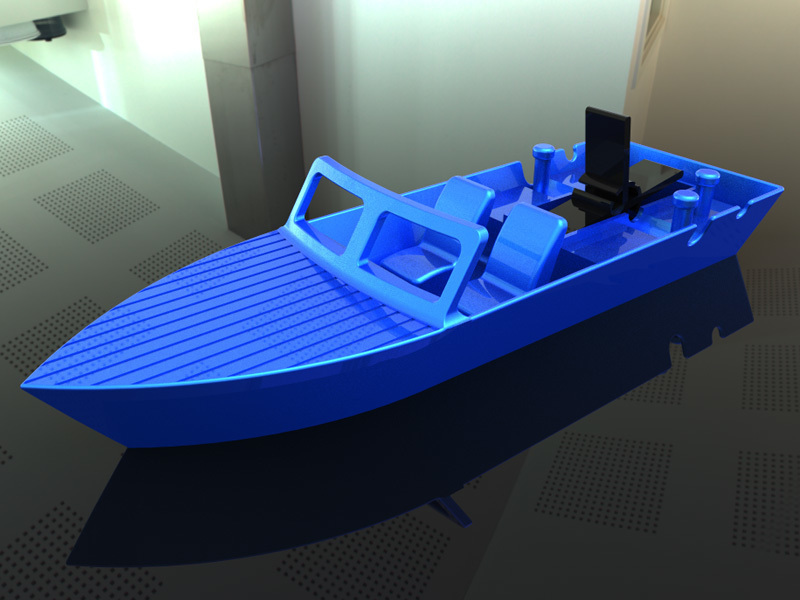

How 3D printers work

The basic principle of a 3D printer is layer-by-layer application of material. At the same time, you can print anything: concrete, living cells, plastic, chocolate. 3D printing is simply the principle of creating an object, along with any other method of production. nine0003

The main use of 3D printing in life is prototyping and creating unique objects. When prototyping, you can print several versions of a product and choose the one that turned out better than the rest. There are industrial enterprises that print plastic items, but it is too early to talk about the widespread use of 3D technology. She has two problems: slow production speed and not high enough quality. Indeed, you can print anything you want, but now it is not economically feasible to launch such mass production, Alexander Kornveits explains. nine0003

There are industrial enterprises that print plastic items, but it is too early to talk about the widespread use of 3D technology. She has two problems: slow production speed and not high enough quality. Indeed, you can print anything you want, but now it is not economically feasible to launch such mass production, Alexander Kornveits explains. nine0003

On the other hand, 3D printing can be used to create unique, design elements, sculptures, monuments. For example, in Moscow you can see printed sculptures like “Girl with an oar”. Often, such sculptures are additionally processed to give the appearance of a monument we are used to, made of marble or plaster.

Prospects for 3D printing for medicine

In the medical industry, the most active use of 3D printing is in dentistry. If you go to the dentist now, you will be faced with a 3D scan; or you will be offered 3D printed aligners. This is no longer prototyping, but the creation of final products or blanks for final products. nine0003

nine0003

Bioprinting - organ printing - is currently under development. First, a cell of a damaged organ is taken from a person - skin, liver, kidney. After that, the cell multiplies in a special solution, and then, using a special bio-3D printer, the organ that needs to be replaced is produced. In this case, layer-by-layer stacking of living cells on top of each other also occurs, resulting in living tissue. The ability of such an organ to take root is much higher than that of a donor organ. According to the guests, this technology will be able to be used to treat specific patients in 5-10 years. nine0003

Printing a house: 3D printers in construction

Building 3D printing developments are very popular because there is a shortage of housing in the world. In Russia, this area is also developing, but many construction companies work abroad, since there is a higher demand for 3D technologies, Sergey Nefedov explains. For example, the founders of the California startup Mighty Buildings are from Russia. The essence of 3D printing is that it is effective where labor resources are expensive. For example, Australia and New Zealand have a norm that allows construction to be done only for 6 hours a day. This is based on the loads that a person can withstand. The cost of housing in these regions is very high, so it is advisable to replace a person with a robot. nine0003

The essence of 3D printing is that it is effective where labor resources are expensive. For example, Australia and New Zealand have a norm that allows construction to be done only for 6 hours a day. This is based on the loads that a person can withstand. The cost of housing in these regions is very high, so it is advisable to replace a person with a robot. nine0003

The problem with 3D construction is that automation and robotization of this industry has not yet occurred, in contrast to the automotive industry, where production is divided into separate operations. 3D building at the moment is a layered construction of walls, which is not difficult to handle. The portal system allows you to print the entire house: first, a portal is built that is larger than the house in size, and the building is printed inside it. But at the stage of finishing and engineering, problems begin. If a company can streamline all this R&D and replace people with machines, then it might work. nine0003

3D printing eliminates the human factor: for example, building mix will always have the right consistency thanks to the settings. But in Russia, all cities are growing skyward, and 3D printing technologies are more applicable to low-rise construction. Unlike the markets in the US and the Netherlands, our market is still unfavorable for 3D construction.

But in Russia, all cities are growing skyward, and 3D printing technologies are more applicable to low-rise construction. Unlike the markets in the US and the Netherlands, our market is still unfavorable for 3D construction.

The future of 3D printing: orthopedic insoles and space colonization

The main advantage of 3D printing is customization, the ability to create a unique product, says Kornweitz. For example, the creation of orthopedic insoles will soon be actively developed. Another example is the frames and lenses of glasses, which take into account all personal characteristics. That is, the entire development of 3D technology will take place in areas where a personalized product is created for each individual person. nine0003

The second promising direction is to use 3D printing where there is a gain in time and a shortage of something. For example, if there is a shortage of housing in the country, and classical technology does not allow it to be repaid, Sergey Nefedov adds. During the pandemic, a similar situation occurred with a shortage of valves for ventilation. 3D printer owners around the world have teamed up and started printing ventilator parts and sending them to hospitals. The same thing happened with the seal of PPE for doctors.

During the pandemic, a similar situation occurred with a shortage of valves for ventilation. 3D printer owners around the world have teamed up and started printing ventilator parts and sending them to hospitals. The same thing happened with the seal of PPE for doctors.

Finally, 3D printing is essential for colonizing other planets. It is impossible to predict what may be needed during a space mission, but if there are materials and apparatus, then at any time you can print what you need. nine0003

Related reading:

- How 3D printers work

- From bunkhouses to palaces: ten 3D printed buildings

- First fully artificial heart transplanted in the USA

- Is it safe to 3D print aircraft engines

- VR models and surveillance drones: how technology is changing construction sites

17 real 3D printed buildings

3D printing technologies are developing extremely fast and are being used in various areas of human life. nine0003

Recently, much attention has been paid to the printing of buildings, and printed houses are increasingly appearing in recent years in different countries of the world - in the USA, Saudi Arabia, Mexico, France, Russia, the United Arab Emirates and others. I have prepared a list of existing 3D printed buildings for 2020.

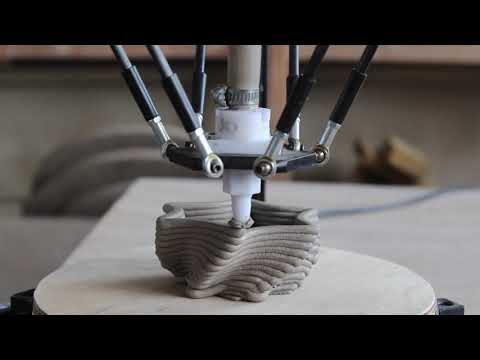

What is a 3D printer for construction.

Today's 3D construction printers differ in designs and wall construction methods. The most common printers are portal construction, two- and four-support construction, based on a manipulator arm or a circular design. The equipment allows you to create small architectural forms and elements of structures for their subsequent assembly on site, or allow you to print the entire building on the construction site. The height and dimensions of the printed building depend on the specifications of the printer being used. nine0003

How the printing process works.

The extruder extrudes a fast-hardening concrete mixture with various additives. Each subsequent layer is applied on top of the previous one, due to which a vertical structure is formed. The concrete layers below are thus compacted, thereby increasing their ability to withstand the next layers, and hence the entire weight of the structure. To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete. nine0003

Each subsequent layer is applied on top of the previous one, due to which a vertical structure is formed. The concrete layers below are thus compacted, thereby increasing their ability to withstand the next layers, and hence the entire weight of the structure. To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete. nine0003

Advantages of 3D printing over other construction methods.

3D printing of structures opens up great opportunities for construction and related industries. Practical application has revealed the following advantages of additive manufacturing:

- It removes the limits from the imagination of designers and architects who design buildings, as it provides opportunities that are not available with the construction methods we are used to.

- High speed of construction of buildings and structures. nine0066

- Complete process automation.

- Low power equipment.

- Significant savings compared to conventional construction methods by reducing labor and energy costs and accelerating construction time.

- The formation of waste building materials is completely eliminated.

- Minimization of human intervention in the construction process not only allows building in places inaccessible to people, but also in ordinary areas eliminates the human factor and reduces the likelihood of error. nine0066

1. June 2014. China. Chinese company Shanghai WinSun Decoration Design Engineering Co presented houses built using 3D printing techniques in an industrial park in China's Jiangsu province. A total of ten houses were created, each of which cost a little more than three thousand pounds sterling. Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors. nine0003

nine0003

2. August 2014. USA. The company Totalkustom Andrey Rudenko printed the lock. The printing took a total of 2 months. The machine's printing speed was 50 cm in 8 hours. The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

3. July 2015. China. Chinese company Zhuoda assembled a two-story house in record time. The modular home, made up of six 3D printed modules, was assembled on site in less than 3 hours. Of course actually about 90% of the work was carried out in the company's workshops, and on the site they were only assembled into a single building.

4. September 2015. Philippines. The company Totalkustom Andrey Rudenko built apartments on the territory of a hotel in the Philippines, 10.5 m x 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5. May 2016. UAE. Chinese company Shanghai WinSun Decoration Design Engineering Co printed prefabricated structures for the subsequent assembly of an office building in Dubai. The area of a one-story building is about 250 square meters. m.

6. March 2017. Russia. Apis Cor introduced the first 37 sq. m.. The printed house has an interesting shape, but as the participants themselves say: this is just to show the flexibility of printing technology, the shape of the buildings can also be the usual square. Compared to other construction 3D printers, this printer is very compact (4×1.6×1.5 m), weighs 2 tons, and can be easily transported to the construction site. nine0003

7. October 2017. Russia. In Yaroslavl, the company Spetsavia presented the first residential building in Europe and the CIS, built using construction 3D printing technology. Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

8. March 2018. France. nine0084 Yhnova presented a five-room one-storey house with an area of 95 square meters. For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

9. March 2018. USA. American Company Icon has built a prototype home in Texas to prove the technology works. The area of the building was 32 sq.m., printing was performed by a portal type 3D printer moving along rails installed on the site.

10. July 2018. Spain. Be More 3D printed a 24 m2 concrete building. For the construction, a two-support 3D printer was used, the width of which is 7 meters and the height is 5 meters.

11. September 2018. Denmark. nine0084 3D Printhuset printed a 50 square meter office in Nordhavn. The 3D printer used for printing is of the portal type and has a size of 8 x 8 x 6 meters. Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete, made largely from recycled tiles and sand.

12. October 2018. Italy. The company Crane Wasp , using a three-bearing 3D construction printer, erected a building in ten days. The house uses passive solar heating technology and natural ventilation. The composition for printing was created on the basis of waste from rice cultivation (it was 25% local soil (clay and sand), 40% straw, another 25% - from rice husks and 10% - from hydraulic lime). nine0003

13. November 2018. Italy. The company Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq. m. The building was printed in segments with subsequent assembly at the construction site.

m. The building was printed in segments with subsequent assembly at the construction site.

November 14, 2018. Saudi Arabia. The Dutch company CyBe Construction has completed the construction of a building with an area of 80 sq.m. It took about a week to 3D print the necessary elements, and a little more than a day to assemble. The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make. nine0003

15. August 2019. USA. S-Squared 3D Printers (SQ3D) showed a prototype residential building that can be built from floor to roof in just twelve hours. The house has an area of 46 m2. During the printing process, a 3D printer of a two-support design was used.

16. October 2019. UAE. Apis Cor announced the completion of the world's largest building using 3D printing technology. Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

17 December 2019 Mexico. The American company Icon erected two residential buildings for the non-profit organization New Story, in southeastern Mexico. The printed buildings have a flat roof, curved walls and an area of 46.5 square meters

As can be seen from the impressive list of completed projects, progress in the field of construction 3D printing clearly does not stand still, new techniques are constantly being introduced, various materials are being created, including from recycled raw materials, and high-tech equipment is being developed. In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework.