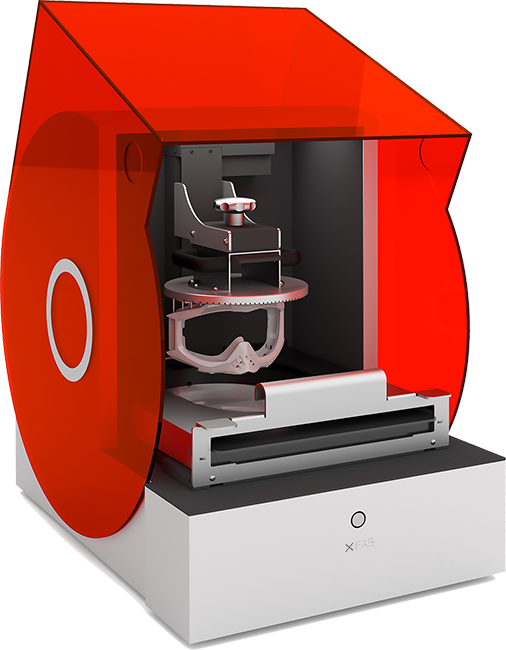

Objet eden260v 3d printer

The Stratasys Objet Eden260VS PolyJet 3D Printer for Rapid Prototyping and Design

THE STRATASYS

Build Precise Prototypes With Outstanding Productivity

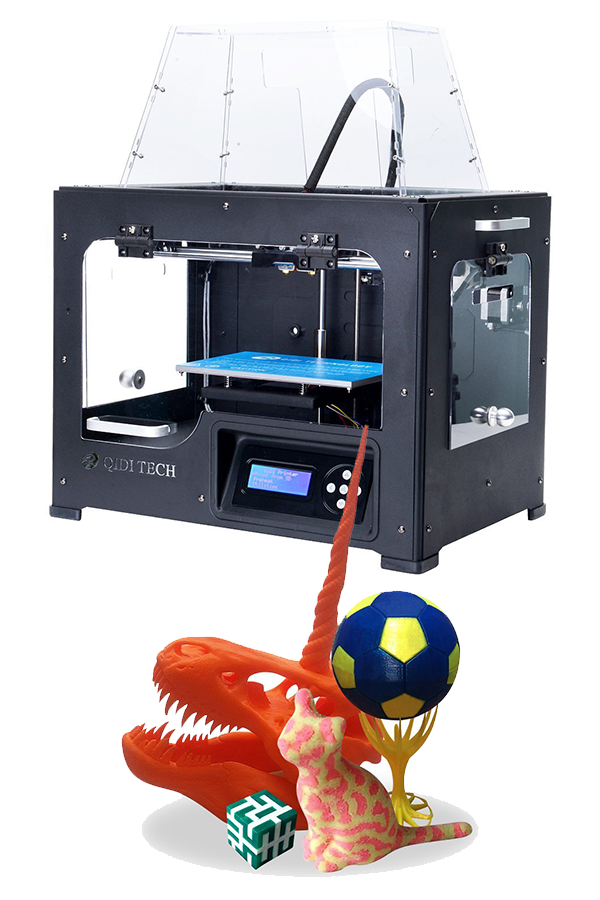

Objet Eden260VS delivers greater prototyping throughput and faster production while producing a better surface finish. With its fifteen materials and soluble support, create complex parts and prototypes with fine, delicate features and hollow tubes. Soluble support on the Eden260VS enables easy post-processing and a lower cost per part.

Brochure Request Demo

- Overview

- Key Features

- Advantages

- Materials

- Specifications

- Request a Quote

High-Resolution Polyjet 3D Printing with Soluble Support Removal

The Objet Eden 260V Is the latest in PolyJet technology with the same surface resolution and speed but now with soluable support removal. Automated support removal reduces post-processing steps and reaches internal voids that water-jetting can miss, making it ideal for models with delicate features or hard-to-reach cavities.

Material Variety

Based on Polyjet technology, the Eden260VS offers 15 distinct printing materials including: transparent, rigid opaque, simulated polypropylene, rubber-like, and high temperature

Compact Productivity

With a build tray of 255 x 252 x 200 mm, the Eden260VS is a clean, quiet 3D printer that fits in your creative environment

Soluble Support Removal

Automated support removal reduces post-processing steps and reaches internal voids that water-jetting can miss. Ideal for models with delicate or hard-to-reach features.

With PolyJet technology you are able to produce smooth and accurate models for a variety of modeling and prototyping applications.

LEARN MORE ABOUT POLYJET

Precision Prototyping in the Office

The Objet Eden 260V Is the latest in PolyJet technology with the same surface resolution and speed but now with soluable support removal. Automated support removal reduces post-processing steps and reaches internal voids that water-jetting can miss, making it ideal for models with delicate features or hard-to-reach cavities.

Automated support removal reduces post-processing steps and reaches internal voids that water-jetting can miss, making it ideal for models with delicate features or hard-to-reach cavities.

Material Diversity

Design prototypes and conceptual models that embody your product vision down to the finest detail. Stratasys’ Objet Eden260VS works with 15 materials to produce outstanding results with a variety of uses. Unlike most printers, the Eden260VS boasts a compact footprint and can support up to four 3.6 kg cartridges of material, allowing at least 72 hours of continuous unattended printing.

Driven by Powerful Polyjet Technology

Take advantage of Polyjet 3D printing to achieve smooth surfaces on your parts. Its advanced accuracy allows for hyper-realistic aesthetics including the ability to delivery properties such as transparency, flexibility and even biocompatibility.

The 260VS is also the first 3D printing system to offer Polyjet technology with soluble support. Automated support removal reduces post-processing time and reaches internal cavities and features that water-jetting techniques can miss.

Automated support removal reduces post-processing time and reaches internal cavities and features that water-jetting techniques can miss.

Transparent

With a combination of clarity, dimensional stability & surface smoothness, Transparent Polyjet photopolymer lets you prototype clear and tinted products.

Rubber-Like

Simulate rubber with different levels of hardness, elongation and tear resistance.

Rigid Opaque

Combine dimensional stability and fine detail. these materials simulate the appearance of production parts, and are even suitable for rapid tooling.

High Temperature

This heat-resistant material simulates the thermal performance of standard plastics and is ideal for thermal testing of static parts.

Bring Outstanding Quality In-house.

Get a Quote on the Objet Eden260VS 3D Printer Today

Get a quote

Technical Specifications

Build Tray Size | Build Tray Size255 x 252 x 200 mm [10. 0 x 9.9 x 7.9 in] 0 x 9.9 x 7.9 in] |

Build Modes | Build ModesHigh Speed: 30 micron [0.001 in]High Quality: 16 micron [0.0006 in] |

Layer Thickness | Layer Thicknesshorizontal build layers as fine as 16 microns [0.0006 in] |

Build Resolution | Build ResolutionX-axis: 600 dpiY-axis: 600 dpi Z-axis: 1600 dpi |

Model Materials | Model MaterialsRigid Opaque: VeroWhitePlus, VeroBlackPlus, VeroGray, VeroBlueRubber-Like: TangoPlus, TangoBlackPlus, TangoBlack, TangoGray Transparent: VeroClear, RGD720 Simulated Polypropylene: Endur, Durus High Temperature |

Support Material | Support MaterialSUP705 and SUP707 |

Workstation Compatibility | Workstation CompatibilityWindows 7+ |

Network Connectivity | Network ConnectivityLAN - TCP/IP |

Power Requirements | Power Requirements100-200 VAC, 50/60Hz, 14A; 200-240 VAC, 50-60Hz, 7A |

System Size and Weight | System Size and Weight87 x 120 x 73. 5 cm [34.2 x 47.2 x 29 in] 5 cm [34.2 x 47.2 x 29 in]254 kg [559 lbs] |

Objet Eden 260VS 3D Printer In-Depth Review

ADVERTISEMENT

8.1Expert Score

Objet Eden 260VS 3D Printer

This printer offers outstanding productivity in a size that fits your creative environment. Eden260VS is one of those printers that deliver greater prototyping throughout and faster production even while producing a better surface finish.

Affordability

5

Quality

8

Speed

8

Capability

9

Practicality

8

User Expectations

9

PROS

- Objet Eden 260VS is a cost-effective solution to the needs of 3D printing.

- Using this printer you can create parts and functional prototypes quickly.

- Designers can do functional testing before the final product.

CONS

- The cost of the printer, seeing the build volume is more than SLA or FDM printers

Based on polyjet technology, Object Eden 260VS is a very reliable 3D printer offering high precision and accuracy while building 3D models. Aimed at ...

Add to wishlistAdded to wishlistRemoved from wishlist 0

Add to compare

|

Table of Contents

This printer offers outstanding productivity in a size that fits your creative environment. Eden260VS is one of those printers that deliver greater prototyping throughout and faster production even while producing a better surface finish.

Eden260VS is one of those printers that deliver greater prototyping throughout and faster production even while producing a better surface finish.

With as many as 15 materials and soluble support, you can create complex parts and prototypes with fine, delicate features and hollow tubes.

Soluble support in the Eden260VS enables easy post-processing of parts and prototypes that are printed using this printer.

Also the part or functional prototype that’s printed using this printer cost lower than compared to other printers.

Called as the economical, small-footprint, the Objet Eden260VS rapid prototyping and 3D printing system are among the many ideal solutions that are used to compress your product design-to-manufacturing cycle.

The printer is based on Stratasys’ innovative PolyJet technology. The printer provides a complete solution for the accurate building of any geometry – easily, quickly, and cleanly.

Models produced on the Eden260VS are known for having smooth and durable characteristics, with fine details and an outstanding surface finish.

ADVERTISEMENT

Features

Apart from the amazing list of features that are present in this printer, Objet Eden260V features a soluble support option.

The function of this feature is that it empowers you to easily produce delicate and complex models, and automate support removal for great efficiency.

The printer gives you the freedom to express your product vision with models up to a specific build volume range with ultra-fine layer thickness, smooth surfaces, and thin walls.

Object Eden260VS features 15 distinct 3D printing materials that have a combination of both rigid and flexible materials.

Whilst the Vero family of these materials offers multiple color options. They include white, gray, blue, and black.

The Tango family is ideal for a wide range of applications that requires flexible or soft-touch components.

Using Simulated Polypropylene and transparent materials, the printer creates not only the tough, durable prototypes with living hinges but also snap-fit parts, and clear models with great dimensional stability.

Post Processing is Easy

Along with the selected model material, Eden 260VS users also jets a gel-like support material designed to uphold overhangs. When printing is done, this nontoxic support material can be easily removed with a water jet.

Models made using this printer can be handled and used immediately, without additional post-curing also.

ADVERTISEMENT

Fast & Cost-Effective 3D printing

With the Objet Eden260VS and particularly when the printing is done in-house, it enables the design teams to quickly produce a high-quality, realistic prototype with moving parts at relatively low cost.

This is when the printer is compared to other methods such as machining or outsourcing. Overall, the design teams can use prototyping on projects where it wasn’t feasible in the past due to time or cost considerations.

And this is not just a feature of this printer but an overall achievement of 3D printing technology as a whole.

Quickly create Product Mockups

This printer can quickly produce real working prototypes that design teams can see and touch. The nature of the printer helps bridge the gap between the virtual CAD design and seeing the final product.

The nature of the printer helps bridge the gap between the virtual CAD design and seeing the final product.

When design and manufacturing engineers cannot only use these prototypes as a tool to better communicate how a design looks, but also feels, and operates.

Doing this allows for the product design to integrate with manufacturing at an earlier stage in the development lifecycle and avoid all the flaws that can be otherwise made.

Small and High-end machine that prints with Exceptional detailing

The Objet Eden260VS offers outstanding productivity in a size that fits your creative environment. Users can express your product vision with models up to 255 x 252 x 200 mm with ultra-fine layer thickness, smooth surfaces, and thin walls that the printer promises to offer.

The printer produces ultra-fine detail, ones that are usually only available with high-cost systems.

ADVERTISEMENT

Product Functional Testing

It is no secret how more prototyping means more opportunity to evaluate whether or not a part will function as intended.

Nothing else but prototypes gives designers the freedom to catch potential flaws before incurring the exponentially higher costs of re-tooling and rework.

So more product functional testing means reducing some of the risks of introducing new products.

For products that include narrow tolerances or intricate details, the printer builds in layers as fine as 16 microns to produce complex geometries, smooth surfaces, and thin walls.

Specifications

The maximum build size that can be printed using this printer is 255 mm * 252 mm * 200 mm.

The resolution along its X and Y axis is 600 dpi, whilst along the Z-axis is 1600 dpi. Accuracy levels offered by this printer are 20-85 microns for features below 50 mm, while 200 microns for full size.

Horizontal layers that can be build using this printer will possess fineness as much as 16 microns.

There are two build speed options offered by this printer i.e. High speed which gives a resolution of 30 microns and High quality which gives a resolution of 16 microns.

The operating conditions of this printer are 18 to 25 degrees Celsius. The relative humidity is 30 to 70 percent. Power requirements are 100 – 200 VAC, 50/60Hz, 14A, 200-240 VAC, 7A.

The build materials with which you can print using this printer are Rigid Opaque: VeroWhitePlus, VeroBlackPlus, VeroGray, VeroBlue. Rubber-like: TangoPlusTM, TangoBlackPlus, TangoBlack, TangoGray. Transparent: VeroClear and RGD720. Simulated Polypropylene: Rigur and Durus. High-Temperature Bio-compatible.

Support materials for printing parts and functional prototypes using the printer are SUP705 (WaterJet removable) and SUP707 (soluble).

ADVERTISEMENT

Price

The market price of this printer is $19,800.

First Impressions

Credit: .exapro.comThere are three parts that the printer consists of:

- Printer

- A built-in computer that comes along with the printer

- The server workstation is provided by the customer.

The basic installation and adjustment of this printer take one day. The operating and training period for this printer takes one more day. More than one and a half-day are required for product design training and practice under supervision.

The operating and training period for this printer takes one more day. More than one and a half-day are required for product design training and practice under supervision.

However, if you are an expert on a 3D printer and know this technology you can speed up this process. The printer has an enclosed design and is sturdy in look.

You have the resin tank and the bottom and print head above it, the mechanism of this printer is pretty much like that of other poly jet printers.

Setup

The printer comes with a start-up kit that includes tools and accessories. The reason behind this is that tools and accessories should be available during the printer’s installation and operation procedure.

There is an exhaust adapter that is supplied with the printer. When attached to the back of the printer and connected to an external ventilation fan with a duct, the air is expelled from the printer is discharged directly outdoors.

To set up this printer some requirements are provided by the manufacturer.

The installation area where the printer would be kept should be free of sources of vibration and electromagnetic interference that could affect the proper functioning of the printer.

The floor gradient of the space should be less than 0.5%. And the floor should stay stable in the way it should be able to bear the load of the printer.

The primary requirement, if you are operating this printer through the Internet should be that the server workstation and the printer should be located in the same room.

The cable that is used for connecting them both should not exceed 5 meters.

The communication cable that is provided with the printer should not be extended or replaced with a longer cable. Speaking of the clearance around and above the printer, it should ensure convenient access and service.

The work area around the printer should remain dry all the time. And you should not place the cleaning station within 5 meters.

Shelves and cabinets are recommended to have near the printer. However, they are for convenient storage of tools, parts, accessories, manuals, and materials. So if you do not have one, don’t worry.

However, they are for convenient storage of tools, parts, accessories, manuals, and materials. So if you do not have one, don’t worry.

ADVERTISEMENT

Printing Type/Cost

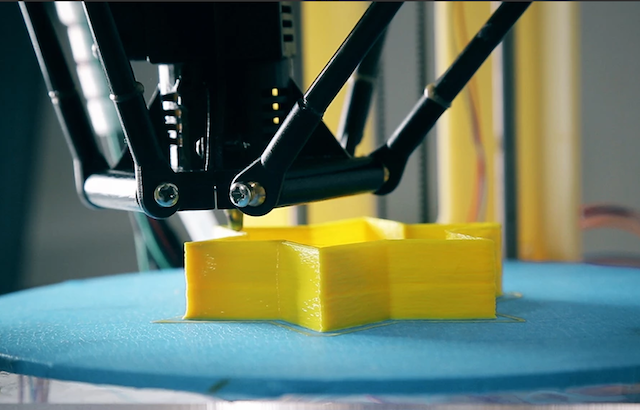

PolyJet 3D Printing is that 3D printing technology which is famous for creating smooth surfaces, fine precision using diverse material properties in parts and functional properties.

It works similar to inkjet document printing, the primary difference is instead of jetting drops of ink onto paper.

The print head sprays or jets the microscopic layers of liquid photopolymer onto a build tray and instantaneously cures them with UV light.

The fine layers then, build up to create a prototype or production part.

Print Quality

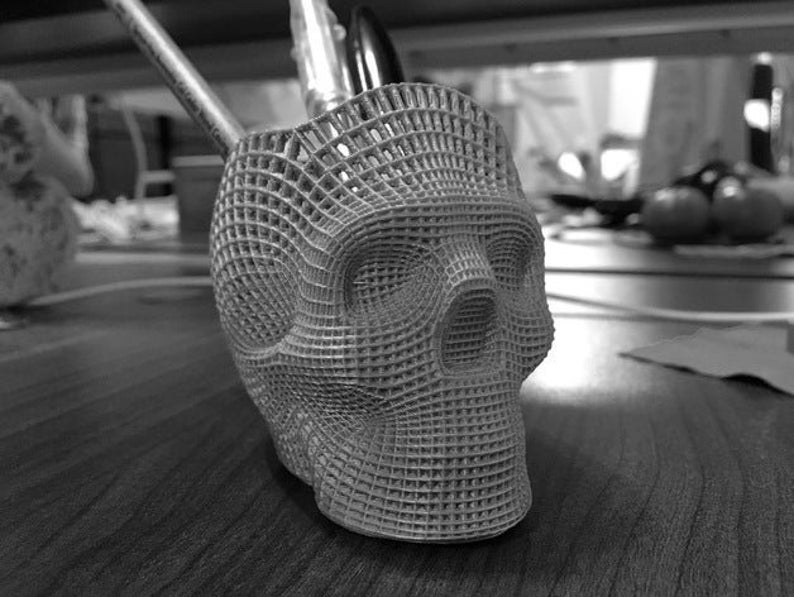

Credit: proto3000.comMany websites cite beautiful pictures of a coral, hourglass, nested cubes, interlocking cubes, Klein bottle, statues, made by this printer.

One thing in common between all those photographs is the detailing in design that is done in the parts.

Minute structures which were impossible to 3D print using any other technology are done using Objet Eden 260 VS.

The peculiarity that is brought with Poly Jet technology for 3D printing is hugely used and reflected in the parts and functional prototypes that are manufactured using this printer.

Software

If you are looking for software that can slice files for this printer, the best choice is 3DPrinterOS. With this software, you can remotely manage your Objet Eden260VS 3D Printer and even the whole fleets of Objet Eden260VS 3D Printers (if you are running a print farm).

Not only can you fix and orient your STL model, but also you can slice it with more than 300 slicing parameters in the cloud using saved before slicing profile.

Also, there is version control, which allows users to get back any of their previously tried modifications.

3DPrinterOS is the best choice, whether you are a hobbyist, or you have your 3D hub, or are managing whole fleets in universities or enterprises.

ADVERTISEMENT

Customer Service

The company has made a printer that is very easy to rely on. So, first of all, it’s not a printer that is supposed to be not bought just because the customer support is not good.

Having said that, the printer can be bought in many ways and there are many ways to access customer support.

First of all, for the service to their customer, the manufacturers have got an installation manual which is detailed enough, that once read, any user would not need any support.

However, you can get in touch with the manufacturers via email, phone, or skype.

Parameters Influencing Buying Decision

These are little pointers that you must undergo before buying Objet Eden 260 VS.

3D Printer Cost: As mentioned in the cons section of this review, users of SLA and FDM printers might find a little more to invest in this printer at the initial stage.

3D Print Quality: Above average of any FDM or SLA printer that falls in the same price range. Small parts with even more detailing can be printed with this printer at ease.

Small parts with even more detailing can be printed with this printer at ease.

3D Print Speed: As said in the specification section before, there are two print speeds that the printer operates on.

3D Printer Capability: Multiple materials can be used to print using this 3D printer so the capability of this printer is commendable.

3D Printer Practicality: Objet Eden 260 VS is known for printing practical dental parts in specific the most.

3D User Expectations: Users can expect their money invested, return to them in terms of the quality that they offer to their clients using this printer.

The Verdict

With its surprisingly real looking aesthetics and ability to deliver special properties, Eden 260VS offers a competitive edge in consumer products prototyping, precision tooling, and specialized production parts. These properties include transparency, flexibility, and even biocompatibility.

3D printer Objet Eden260V

3D printer Eden260V

The new 3D printer - Eden 260V takes an intermediate position in the line of Eden printers. Like any of Eden's professional series printers, the Eden260V can handle a full range of media, including the rubber-like Tango family and polypropylene-like DurusWhite.

Also, this printer has an increased volume of material cartridges, which allows it to work without operator intervention up to 72 hours. In addition, for more flexibility in operation, in addition to the high quality mode, this printer has a high performance mode, which is in demand when growing large-sized prototypes.

At the same time, it has a moderate price, close to office series printers. The Eden260V comes with Objet Studio software for maximum convenience when sending files to print. Like all Eden printers, the Eden260V is based on the well-known PolyJet™ technology - printing with liquid photopolymer with a layer thickness of 16 microns. By using this technology, high accuracy of building prototypes is ensured - up to 0.1 mm, excellent surface quality and the ability to accurately reproduce fine details, in particular, growing walls with a thickness of up to 0.6 mm. The Eden260V occupies a small footprint and is designed for use in a typical office environment.

By using this technology, high accuracy of building prototypes is ensured - up to 0.1 mm, excellent surface quality and the ability to accurately reproduce fine details, in particular, growing walls with a thickness of up to 0.6 mm. The Eden260V occupies a small footprint and is designed for use in a typical office environment.

Specifications

| Eden 260V | |

| Technology | PolyJet™ |

| Print area size | 255 mm x 252 mm 200 mm |

| Layer thickness | 16 µm (1600 dpi) |

| Approval | X-axis: 600 dpi (42 µm), Y-axis: 600 dpi (42 µm) |

| Precision | 0.1-0.2mm |

| Number of print heads | 8 |

| Supply of consumables | 4 x 3. 6 kg cartridges 6 kg cartridges |

| Connection interface | Ethernet 10/100 BaseT |

| File formats | STL and SLC files |

| Power input | 1.5 kW max |

| Dimensions | 870x735x1200 mm |

| Weight | 280 kg |

| Materials | FullCure®720, VeroWhite, VeroBlue, VeroBlack, FullCure®705?, Tango Black, Tango Gray, Tango+, Durus White; Support |

| Print modes: | HQ (high quality) - 16 µm, HS (high speed) - 30 µm |

Materials

The Eden260V 3D printer supports the following materials:

- Clear materials (VeroClear) for checking the assembly and shape of highly detailed clear parts and simulating clear thermoplastics such as PMMA

- A family of elastic materials (Tango family) that is suitable for a wide range of applications requiring non-slip and soft surfaces

- Clear material (RGD720) for emulating standard plastics requiring dimensional stability and surface smoothness

- A family of rigid opaque materials (Vero family) in white, grey, blue and black.

- Propylene-like material (DurusWhite) for applications requiring snap-on parts

- High temperature material (RGD525) for advanced functional testing, hot air and water flow testing, static applications and exhibition models.

Software

Objet Studio 9 software0003

Objet Studio software makes it easy to create high quality and accurate 3D models. It automatically converts STL and SLC files from any 3D CAD application into layers for building a 3D model, placing model material and support material on them. With the click-to-build wizard, you can quickly change trays, assign materials, manage job queues, and perform scheduled system maintenance.

Objet Studio 9 Features0156

- Easy adjustment of the build tray, even when working with multiple materials

- Automatic support generation

- On-the-fly layering so you can start printing immediately

- Automatic tray positioning for accurate and consistent positioning

- Multi-User Network Collaboration

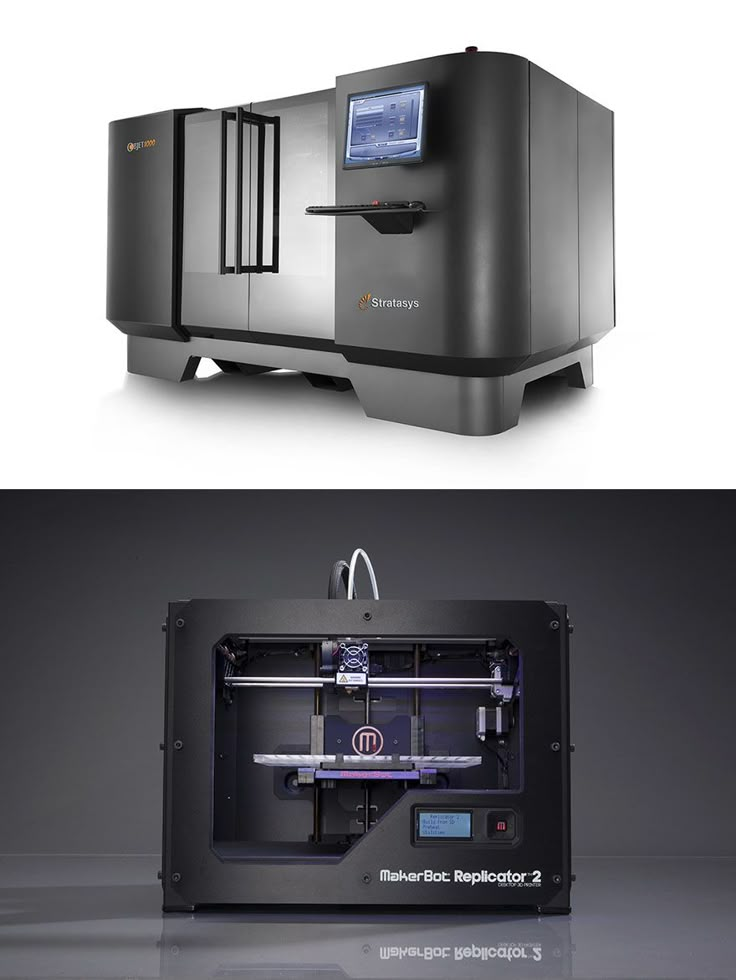

Stratasys strikes a warning | 3D Print Expo

Stratasys announced the expansion of its line of 3D printers with a good dozen new devices. Understanding all this diversity can be somewhat difficult, but let's start in order.

Understanding all this diversity can be somewhat difficult, but let's start in order.

The first new platform was the Objet30 Prime desktop 3D printer. The device uses PolyJet multi-jet printing technology and is an evolution of the acclaimed Objet30 printer. The new model has an expanded range of consumables, consisting of 12 items. This includes rubber simulants TangoGray and TangoBlack, as well as biocompatible materials like MED610. Objet30 Prime also allows you to print soft objects up to 194x192x148.6 mm. In addition, Prime offers a Draft mode that allows you to "draft" in 36 micron layers, saving time and materials in the early stages of prototyping. The cost of the device will remain at the level of its predecessor.

Several systems from the Connex family were further introduced using PolyJet technology. At the beginning of the year, Stratasys launched the Objet500 Connex3, a color multi-jet printer capable of creating models from materials with a variety of physical characteristics. The device itself is expensive and intended for industrial use, but Stratasys decided to make the technology more accessible.

The device itself is expensive and intended for industrial use, but Stratasys decided to make the technology more accessible.

As a result, the company offers six new variants of the Connex platform. The first three are called Objet 260 Connex 1, 2 and 3. These devices are compact and designed for office use. Those who need a larger working chamber can use three more printers using the same technology: Objet 350 Connex 1, 2 and 3. The most capable platform will remain the same Objet 500 Connex, also offered in options 1, 2 and 3. In order not to to get confused in all these setups, use 260/350/500 as indicators of chamber size and Connex 1/2/3 as indicators of platform capability.

One interesting feature of the Connex line was the introduction of the VRML format in addition to the familiar STL. The bottom line is to facilitate multi-color printing, since previously the individual color of each part of the model had to be specified manually. Now you can save a lot of time and nerves.

It is worth noting that the Connex line can be considered a pre-cooked answer to Hewlett Packard's still-developed Multijet Fusion 3D printer. Stratasys still has a couple of years to perfect the line, and then will have to face HP in the fight for the market.

And the latest new PolyJet printer is the Objet Eden260VS. The novelty allows the use of soluble materials for the construction of support structures, which has hitherto been observed only among FDM printers. Dissolvable supports allow you to create complex, detailed models with internal cavities. In addition, the process of removing the soluble material at the end of printing will, apparently, be automated. The new dissolvable material SUP707 can be used with VeroGray, VeroBlue, VeroClear and VeroWhitePlus.

If the above models are mainly for prototyping, then the Fortus family has always been focused on small-scale production. Here, too, there were some new products: Fortus 450mc and Fortus 380mc. Both machines have been designed with reliability and ease of use in mind. The units are equipped with touch screens. The interface allows you to make changes to the settings without interrupting the production process. The Fortus 380mc is designed for rapid prototyping and production using a variety of standard and engineering thermoplastics.

Both machines have been designed with reliability and ease of use in mind. The units are equipped with touch screens. The interface allows you to make changes to the settings without interrupting the production process. The Fortus 380mc is designed for rapid prototyping and production using a variety of standard and engineering thermoplastics.

The Fortus 450mc features a larger build chamber and the ability to use the most advanced FDM thermoplastics. This machine is ideal for rapid prototyping of medium-sized functional prototypes and small batches of finished products made from specialized materials.

Stratasys' taciturn reaction to Hewlett Packard's announcement of its incursion into the 3D printing market is now understandable. While 3D Systems was throwing a glove in the face of an eminent office equipment manufacturer, Stratasys was quietly preparing a presentation of new models of 3D printers. The official position of Stratasys is identical to the view of 3D Systems and boils down to the following: there are no universal 3D printers.

1 mm 0.004 in

1 mm 0.004 in