Digital printing 3d

What is 3D printing? How does a 3D printer work? Learn 3D printing

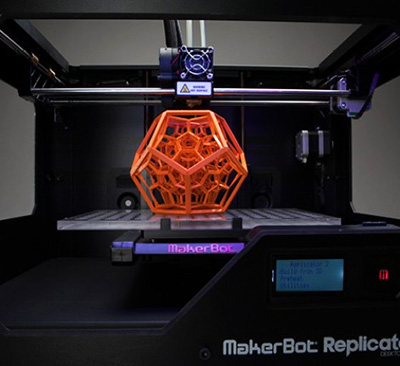

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

Table of Contents

- How Does 3D Printing Work?

- 3D Printing Industry

- Examples of 3D Printing

- 3D Printing Technologies & Processes

- Materials

- Services

Jump to your field of interest:

- Rapid Prototyping & Manufacturing

- Automotive

- Aviation

- Construction

- Consumer Products

- Healthcare

- Food

- Education

Jump to process:

- All Technologies & Processes

- Vat Photopolymerisation

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Sheet Lamination

- Directed Energy Deposition

How Does 3D Printing Work?

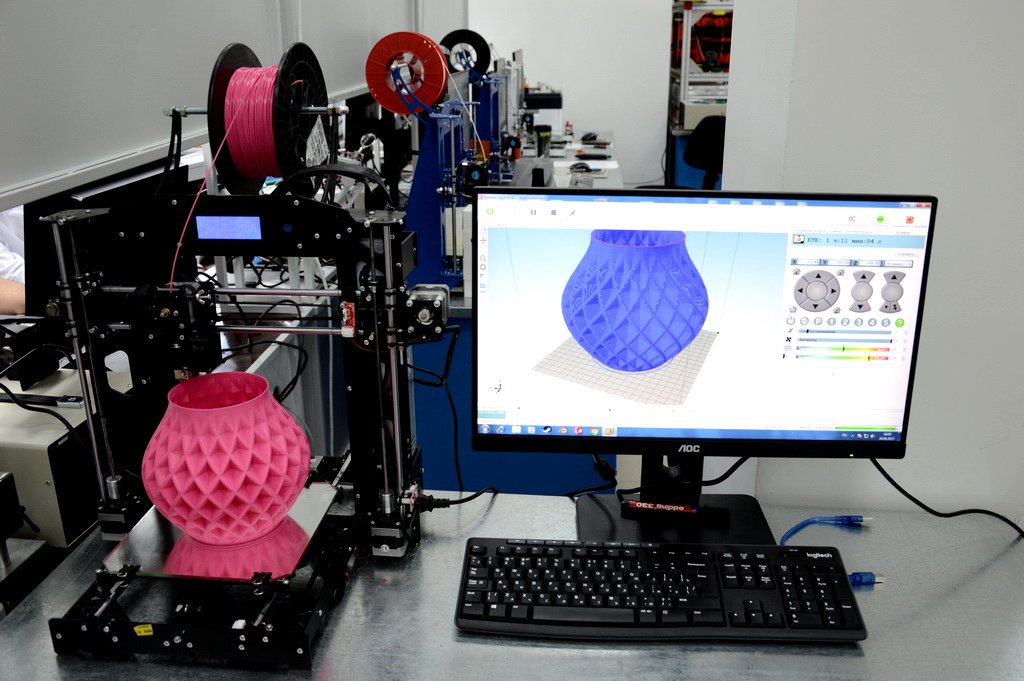

It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

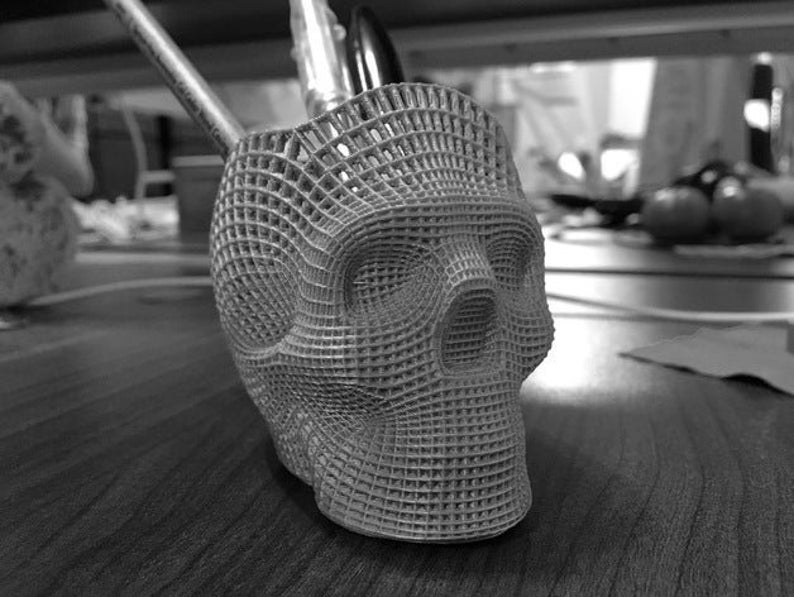

Examples of 3D Printing

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

- – consumer products (eyewear, footwear, design, furniture)

- – industrial products (manufacturing tools, prototypes, functional end-use parts)

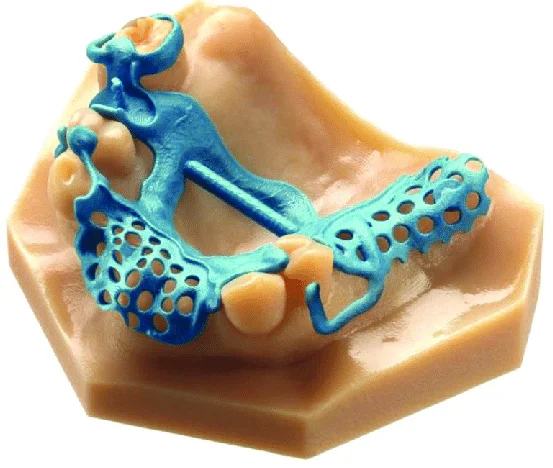

- – dental products

- – prosthetics

- – architectural scale models & maquettes

- – reconstructing fossils

- – replicating ancient artefacts

- – reconstructing evidence in forensic pathology

- – movie props

Rapid Prototyping & Rapid Manufacturing

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Automotive

Car manufacturers have been utilizing 3D printing for a long time. Automotive companies are printing spare parts, tools, jigs and fixtures but also end-use parts. 3D printing has enabled on-demand manufacturing which has lead to lower stock levels and has shortened design and production cycles.

Automotive enthusiasts all over the world are using 3D printed parts to restore old cars. One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

Aviation

The aviation industry uses 3D printing in many different ways. The following example marks a significant 3D printing manufacturing milestone: GE Aviation has 3D printed 30,000 Cobalt-chrome fuel nozzles for its LEAP aircraft engines. They achieved that milestone in October of 2018, and considering that they produce 600 per week on forty 3D printers, it’s likely much higher than that now.

Around twenty individual parts that previously had to be welded together were consolidated into one 3D printed component that weighs 25% less and is five times stronger. The LEAP engine is the best selling engine in the aerospace industry due to its high level of efficiency and GE saves $3 million per aircraft by 3D printing the fuel nozzles, so this single 3D printed part generates hundreds of millions of dollars of financial benefit.

GE’s fuel nozzles also made their way into the Boeing 787 Dreamliner, but it’s not the only 3D printed part in the 787. The 33-centimeter-long structural fittings that hold the aft kitchen galley to the airframe are 3D printed by a company called Norsk Titanium. Norsk chose to specialize in titanium because it has a very high strength-to-weight ratio and is rather expensive, meaning the reduction in waste enabled by 3D printing has a more significant financial impact than compared to cheaper metals where the costs of material waste are easier to absorb. Rather than sintering metal powder with a laser like most metal 3D printers, the Norsk Merke 4 uses a plasma arc to melt a metal wire in a process called Rapid Plasma Deposition (a form of Directed Energy Deposition) that can deposit up to 10kg of titanium per hour. A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

Construction

Is it possible to print a building? – yes it is. 3D printed houses are already commercially available. Some companies print parts prefab and others do it on-site.

Most of the concrete printing stories we look at on this website are focused on large scale concrete printing systems with fairly large nozzles for a large flow rate. It’s great for laying down concrete layers in a fairly quick and repeatable manner. But for truly intricate concrete work that makes full use of the capabilities of 3D printing requires something a little more nimble, and with a finer touch.

Consumer Products

When we first started blogging about 3D printing back in 2011, 3D printing wasn’t ready to be used as a production method for large volumes. Nowadays there are numerous examples of end-use 3D printed consumer products.

Footwear

Adidas’ 4D range has a fully 3D printed midsole and is being printed in large volumes. We did an article back then, explaining how Adidas were initially releasing just 5,000 pairs of the shoes to the public, and had aimed to sell 100,000 pairs of the AM-infused designs by 2018.

With their latest iterations of the shoe, it seems that they have surpassed that goal, or are on their way to surpassing it. The shoes are available all around the world from local Adidas stores and also from various 3rd party online outlets.

Eyewear

The market of 3D printed eyewear is forecasted to reach $3.4 billion by 2028. A rapidly increasing section is that of end-use frames. 3D printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product.

But did you know it’s also possible to 3D print lenses? Traditional glass lenses don’t start out thin and light; they’re cut from a much larger block of material called a blank, about 80% of which goes to waste. When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

Jewelry

There are two ways of producing jewelry with a 3D printer. You can either use a direct or indirect production process. Direct refers to the creation of an object straight from the 3D design while indirect manufacturing means that the object (pattern) that is 3D printed eventually is used to create a mold for investment casting.

Healthcare

It’s not uncommon these days to see headlines about 3D printed implants. Often, those cases are experimental, which can make it seem like 3D printing is still a fringe technology in the medical and healthcare sectors, but that’s not the case anymore. Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

The Delta-TT Cup designed by Dr. Guido Grappiolo and LimaCorporate is made of Trabecular Titanium, which is characterized by a regular, three-dimensional, hexagonal cell structure that imitates trabecular bone morphology. The trabecular structure increases the biocompatibility of the titanium by encouraging bone growth into the implant. Some of the first Delta-TT implants are still running strong over a decade later.

Another 3D printed healthcare component that does a good job of being undetectable is the hearing aid. Nearly every hearing aid in the last 17 years has been 3D printed thanks to a collaboration between Materialise and Phonak. Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Dental

In the dental industry, we see molds for clear aligners being possibly the most 3D printed objects in the world. Currently, the molds are 3D printed with both resin and powder based 3D printing processes, but also via material jetting. Crowns and dentures are already directly 3D printed, along with surgical guides.

Bio-printing

As of the early two-thousands 3D printing technology has been studied by biotech firms and academia for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Food

Additive manufacturing invaded the food industry long time ago. Restaurants like Food Ink and Melisse use this as a unique selling point to attract customers from across the world.

Education

Educators and students have long been using 3D printers in the classroom. 3D printing enables students to materialize their ideas in a fast and affordable way.

While additive manufacturing-specific degrees are fairly new, universities have long been using 3D printers in other disciplines. There are many educational courses one can take to engage with 3D printing. Universities offer courses on things that are adjacent to 3D printing like CAD and 3D design, which can be applied to 3D printing at a certain stage.

In terms of prototyping, many university programs are turning to printers. There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

Types of 3D Printing Technologies and Processes

The American Society for Testing and Materials (ASTM), developed a set of standards that classify additive manufacturing processes into 7 categories. These are:

- Vat Photopolymerisation

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Powder Bed Fusion

- Multi Jet Fusion (MJF)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Sheet Lamination

- Directed Energy Deposition

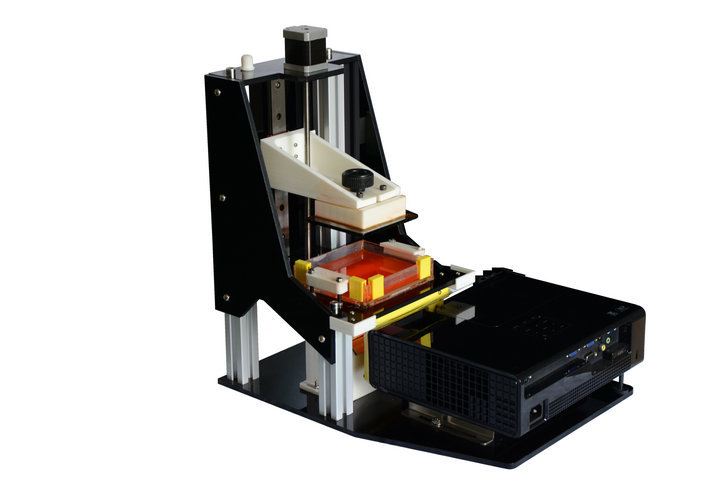

Vat Photopolymerisation

A 3D printer based on the Vat Photopolymerisation method has a container filled with photopolymer resin. The resin is hardened with a UV light source.

The resin is hardened with a UV light source.

Stereolithography (SLA)

SLA was invented in 1986 by Charles Hull, who also at the time founded the company, 3D Systems. Stereolithography employs a vat of liquid curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and fuses it to the layer below.

After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002″ to 0.006″). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. Depending on the object & print orientation, SLA often requires the use of support structures.

Depending on the object & print orientation, SLA often requires the use of support structures.

Digital Light Processing (DLP)

DLP or Digital Light Processing refers to a method of printing that makes use of light and photosensitive polymers. While it is very similar to SLA, the key difference is the light source. DLP utilizes other light sources like arc lamps. DLP is relatively quick compared to other 3D printing technologies.

Continuous Liquid Interface Production (CLIP)

One of the fastest processes using Vat Photopolymerisation is called CLIP, short for Continuous Liquid Interface Production, developed by Carbon.

Digital Light Synthesis

The heart of the CLIP process is Digital Light Synthesis technology. In this technology, light from a custom high performance LED light engine projects a sequence of UV images exposing a cross section of the 3D printed part causing the UV curable resin to partially cure in a precisely controlled way. Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Simply printing with Carbon’s hardware alone does not allow for end use properties with real world applications. Once the light has shaped the part, a second programmable curing process achieves the desired mechanical properties by baking the 3d printed part in a thermal bath or oven. Programmed thermal curing sets the mechanical properties by triggering a secondary chemical reaction causing the material to strengthen achieving the desired final properties.

Components printed with Carbon’s technology are on par with injection molded parts. Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Material Jetting

In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by-layer to a build platform and then hardened by UV light.

Material Jetting schematics. Image source: custompartnet.comBinder Jetting

With binder jetting two materials are used: powder base material and a liquid binder. In the build chamber, powder is spread in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the required shape. After the print is finished, the remaining powder is cleaned off which often can be re-used printing the next object. This technology was first developed at the Massachusetts Institute of Technology in 1993.

Binder Jetting schematicsMaterial Extrusion

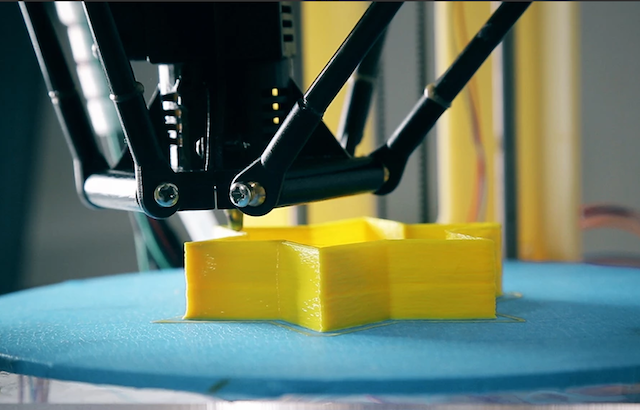

Fused Deposition Modeling (FDM)

FDM schematics (Image credit: Wikipedia, made by user Zureks)FDM works using a plastic filament which is unwound from a spool and is supplied to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

FDM was invented by Scott Crump in the late 80’s. After patenting this technology he started the company Stratasys in 1988. The term Fused Deposition Modeling and its abbreviation to FDM are trademarked by Stratasys Inc.

Fused Filament Fabrication (FFF)

The exactly equivalent term, Fused Filament Fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

Powder Bed Fusion

Selective Laser Sintering (SLS)

SLS uses a high power laser to fuse small particles of powder into a mass that has the desired three dimensional shape. The laser selectively fuses powder by first scanning the cross-sections (or layers) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

Multi Jet Fusion (MJF)

Multi Jet Fusion technology was developed by Hewlett Packard and works with a sweeping arm which deposits a layer of powder and then another arm equipped with inkjets which selectively applies a binder agent over the material. The inkjets also deposit a detailing agent around the binder to ensure precise dimensionality and smooth surfaces. Finally, the layer is exposed to a burst of thermal energy that causes the agents to react.

Direct Metal Laser Sintering (DMLS)

DMLS is basically the same as SLS, but uses metal powder instead. All unused powder remains as it is and becomes a support structure for the object. Unused powder can be re-used for the next print.

Due to of increased laser power, DMLS has evolved into a laser melting process. Read more about that and other metal technologies on our metal technologies overview page.

Sheet Lamination

Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades.

Simplified schematics of ultrasonic sheet metal process (Image credit: Wikipedia from user Mmrjf3)Directed Energy Deposition

This process is mostly used in the metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object.

Materials

Multiple materials can be used in additive manufacturing: plastics, metals, concrete, ceramics, paper and certain edibles (e.g. chocolate). Materials are often produced in wire feedstock a.k.a. filament, powder form or liquid resin. Learn more about our featured materials on our materials page.

Services

Looking to implement 3D printing in your production process? Get a quote for a custom part or order samples on our 3D print service page.

Digital Manufacturing and 3D printing

3D printing is one of the core group of digital manufacturing solutions that include Artificial Intelligence, the Internet of Things, and Robotics. Its rapidly accelerating growth is a key driver of what’s called the fourth industrial revolution, also known as Industry 4.0.

The 4th industrial revolution is the analog-to-digital shift already transforming the global manufacturing industry that’s fundamentally changing the way we conceive, design, produce, distribute, and consume nearly everything. Ultimately, it will have an enormous impact on jobs, industries, and economies.

Ultimately, it will have an enormous impact on jobs, industries, and economies.

Its leaders will be those whose who have harnessed the full power of 3D printing as a truly disruptive technology. Will you be among them?

If so, you’ll be helping to drive manufacturing to become all-digital.

Your designers will have the power to create entirely new kinds of products as the boundaries to making your idea a reality dissolve. You’ll no longer be at the mercy of overseas factories and will move closer to your consumer as you enjoy your newfound ability to custom-produce anything, anytime, anywhere.

These are exciting times.

This article offers an overview of the 4th industrial revolution, a snapshot of the place of 3D printing and digital manufacturing and design in the 4th industrial revolution as well as an overview of its potential benefits for you.

Back to menu

What is the 4

th industrial revolution?A shift towards digitalization in manufacturing began during the third industrial revolution when the computer age dawned. But, at that time, the connection between the digital and physical worlds was limited to a few mechanisms sparsely located.

But, at that time, the connection between the digital and physical worlds was limited to a few mechanisms sparsely located.

Today all that’s changed. For example, information in real-time is now delivered by wearables and augmented reality. The Internet of Things provides user data at unprecedented speeds. People can act on an abundance of information quickly and decisively, thanks to artificial intelligence and advanced analytics.

The 4th industrial revolution is founded on direct digital manufacturing and smart production, and is driven by newer technologies such as artificial intelligence, augmented reality, advanced robotics, smart devices, and 3D printing. It’s democratizing the power to connect the digital and physical at the level of individual creators and consumers, resulting in unprecedented digital lean manufacturing.

Back to menu

Where the 3D printing industry fits

Quite simply, the 3D printing industry is spearheading the way forward.

The 3D printing industry is the point where many of the technologies fueling the 4th industrial revolution intersect. First, sensors digitized the physical world. Now, 3D printing is enabling physical output from entirely digital information, resulting in levels of rapid prototyping and rapid tooling never seen before.

At the same time, 3D printing has moved away from just being a tool for prototyping and design, which was how it began. The arrival of powerful industrial 3D printers that deliver quality, functional final parts, and new levels of productivity has changed the game.

3D printing is also placing power in the hands of smaller and individual creators – the consumers themselves! Put it this way, what the personal computer was to information, 3D printing is to goods.

This revolution is manifesting in more and more, easily accessible, manufacturing centers where you can design and create your own unique products and solutions. Today, 3D printing has arrived at a point where it can open the door to digitally reinventing the manufacturing sector worldwide.

It has the power to revitalize, maintain or even create a manufacturing economy, although to do so will require strong, dynamic public/private partnerships.

But offering incentives to adopt 3D printing, particularly at the state and city level, will drive the development of a complete 3D ecosystem. This will, in turn, attract manufacturing, create strong new markets, and create prosperity and a place at the forefront of the 4th industrial revolution.

You could be one of the people leading the way.

Back to menu

How 3D printing works

With 3D printing, you can generate an almost finished part from a design file and raw materials in a matter of hours.

Unlike traditional processes such as injection molding, design is digitally connected to production: a raw 3D file containing information about dimensions is fed directly to the 3D printer.

3D printed part designs aren’t constrained by the same barriers that exist in traditional manufacturing.

For example, injection molding designs typically require a draft angle and seam so that the part can be ejected from the mold. 3D printing processes do not.

Back to menu

The benefits of 3D printing

The many benefits of 3D printing are opening up a whole new world for designers, manufacturers, and service providers.

They include:

- Increased production flexibility

- Fewer design constraints

- Faster design iteration and go-to-market timing

- The potential for local manufacturing, enabling distributed production

- Enabling fully customized products at a reasonable cost

- Print on demand with less need to carry inventory

We’re also seeing dramatic advancements in 3D printing speed, productivity, and predictability — all critical factors for manufacturing.

And it’s not just about speed. The strength and performance of 3D printed parts now rivals that of traditionally manufactured parts.

You also have a considerably increased level of power over production with 3D printing technologies like HP Multi Jet Fusion (MJF). Material and part properties can be rigorously controlled down to voxel level – the 3D equivalent of a pixel.

Read our article “What can you make with a 3D printer?” to find out more about what you can do with HP MJF 3D printing technology.

Back to menu

3D printing service providers - the HP Digital Manufacturing Network

During a revolution, we transform at different speeds, and the 4th industrial revolution is no different.

The HP Digital Manufacturing Network is made up of trusted, rigorously evaluated digital manufacturing service providers who bring the benefits of 3D printing closer to designers and manufacturers.

By, for example, designing or producing 3D printed parts for you, a member of the Digital Manufacturing Network can enable access to rapid innovation, faster time-to-market, and distributed manufacturing. This can help optimize your supply chain and accelerate your business' digital transformation.

This can help optimize your supply chain and accelerate your business' digital transformation.

Accessing the Digital Manufacturing Network also places you in the vanguard of the 4th industrial revolution.

Find out more about HP’s Digital Manufacturing Network and search for an HP endorsed 3D printing supplier here.

Back to menu

The future of 3D printing

3D printing is already changing so many of today’s complex supply chains by bringing manufacturing closer to consumption. This will only increase.

As manufacturers move ever closer to consumers, in terms of mindset and literally, this relationship will enable cost-effective customization to meet their needs more precisely than ever before. For example, 3D printed products made by the same company for the US market could, in the future, be entirely different from those made for an Indian consumer.

3D printing is also paving the way to a product lifecycle that has the environment in mind - from design to manufacturing to post-sales.

With 3D printing and digital manufacturing, digital files are sent around the world rather than physical goods. Instead of physical warehouses, manufacturers using 3D printing need only virtual warehouses and inventories that enable products to be produced locally and on demand.

This can mean fewer physical goods, less need for transportation and fuel consumption, and a smaller warehousing space requirement.

3D printing allows you to design and make efficient, lower carbon footprint parts1 that are more complex than those produced using traditional methods. These parts are lightweight, use less material, and are designed for best-in-class performance. This ultimately could help optimize the amount of energy being used in machinery or electric vehicles, for example.

3D printing technologies such as HP MJF use HP 3D Printing materials that offer industry-leading reusability and less material waste. As a result, quality parts can be 3D printed using surplus powder not used in parts from previous batches, while delivering consistent performance. 2

2

3D printing is also helping to facilitate the Circular Economy. One-off spare parts are easy to produce on demand without the need for Original Equipment Manufacturers (OEMs) to maintain space-consuming large spare parts inventories for old or obsolete products.

The future of 3D printing looks bright then.

But, as we’ve said, truly capitalizing on the enormous potential of 3D printing worldwide will depend on factors that include ecosystem development, economic environment, ongoing consumer trends, and, most importantly, which countries act quickly to lead in 3D print manufacturing.

It also requires visionary individuals who grasp the benefits of 3D printing and are excited by the opportunity to help lead the 4th industrial revolution.

If you want to learn more about how HP can help accelerate your digital manufacturing journey, reach out to us here.

Back to menu

Want to continue learning?

Footnotes and disclaimers

- Low carbon footprint per printed HP Multi Jet Fusion part for runs of 1500 or less when compared to injection molded parts.

Data comes from an ISO 14040/44 compliant and peer reviewed LCA study, January 2018.

Data comes from an ISO 14040/44 compliant and peer reviewed LCA study, January 2018. - Industry-leading surplus powder reusability based on using HP 3D High Reusability PA 11 and PA 12 at recommended packing densities and compared to selective laser sintering (SLS) technology, offers excellent reusability without sacrificing mechanical performance. Tested according to ASTM D638, ASTM D256, ASTM D790, and ASTM D648 and using a 3D scanner. Testing monitored using statistical process controls.

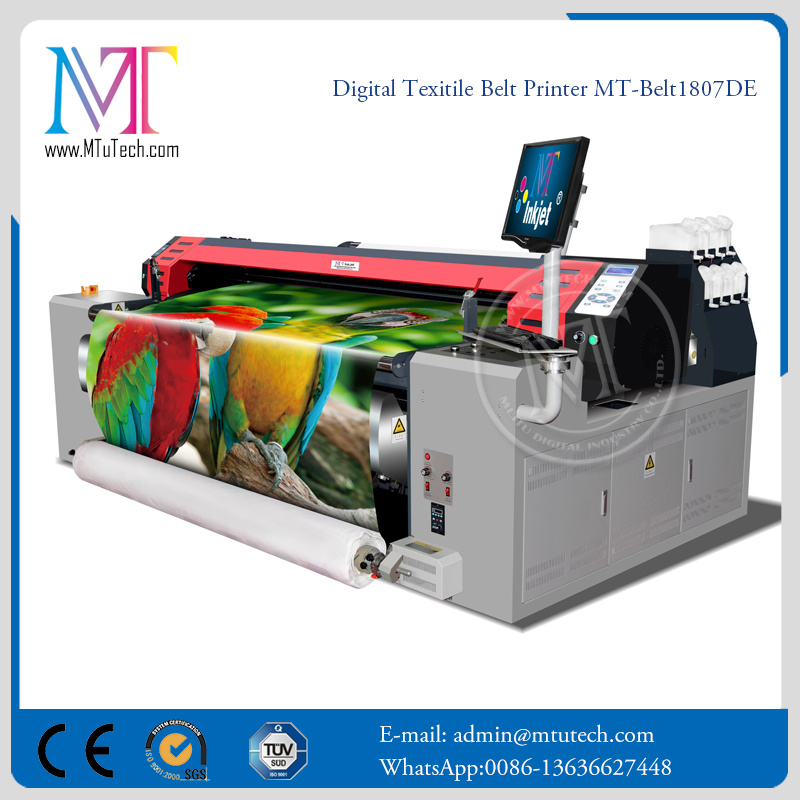

Stratasys Direct Fabric 3D Printing Technologies • Print Industry • PrintIndustry.ru

Digital printing

To read 4 min Posted by

For the first time, the possibilities of direct textile 3D printing using technology developed by Stratasys were seen by guests of New York Fashion Week two years ago. Fashion brand threeASFOUR then presented the Chro-Morpho clothing collection, which was created in collaboration with fashion guru Travis Fitch, and is decorated with many small elements that mimic the play of light and color on the wings of insects.

Fashion brand threeASFOUR then presented the Chro-Morpho clothing collection, which was created in collaboration with fashion guru Travis Fitch, and is decorated with many small elements that mimic the play of light and color on the wings of insects.

The Greta-Oto dress, named after the lepidoptera of the same name, managed to achieve a lenticular stereographic effect, so that as the model walked down the runway, it literally came to life. Thousands of transparent microspheres with colored inserts distributed over the dress would previously have had to be 3D printed and then sewn on. But the resourceful Stratasys has found a way to simplify the process.

Revealing the meaning of the proprietary technology, Naomi Kaempfer, the creative director of the firm for art, design and fashion, noted that the main task here is the harmonious combination of volumetric elements and textiles, without excesses towards 3D: “Smooth, flowing fabric comes into contact with the skin, 3D printing decorates surface. It took several months of experimental testing to offer designers bold opportunities for the implementation of creative ideas. This will revive, complicate, make brighter and more attractive their models.

It took several months of experimental testing to offer designers bold opportunities for the implementation of creative ideas. This will revive, complicate, make brighter and more attractive their models.

Naomi Kaempfer also announced Stratasys' intention to focus on haute couture apparel, where advanced forms of additive manufacturing could be in high demand. “Over the past five years, we have seen 3D printing take more and more space in fashion design. Collaborations with well-known brands prompted us to focus on promoting the aesthetics of optical illusions. Thus, thanks to 3D printing, a new trend in fashion design is emerging on the market.”

A milestone in moving its solutions to the very heights of the fashion industry for Stratasys could be the ongoing collaboration with the Italian research and development laboratory D-House. It is the scientific division of the Dyloan production agency, founded in 1987, is committed to bringing innovative solutions to high fashion and the latest such innovation was printing on Woolmark merino wool knitwear on a Stratasys PolyJet J850 3D printer.

The Knitting of the Future project for Milan Design Week involved fashion designers from all over the world, a group of students from the Royal College of Art in London and several knitters from a factory in Italy. The principle of operation of PolyJet J850 is to apply a liquid photopolymer on the basis for the layer-by-layer formation of a natural texture - under the skin, wood, accurately conveying color nuances or maintaining transparency like that of glass.

D-House co-founder Loreto Di Rienzo was impressed by the process: “What immediately surprised me about PolyJet was the color accuracy: we can achieve the desired color with maximum accuracy – this is not discussed in fashion design.” In addition, he noted, the breadth of application of the device gives incredible freedom of implementation: “Not only can we immediately print various textures and decor details on fabric, we can also include various functional elements in clothes. This allows us to offer outstanding visualization solutions to our clients. ”

”

In the knitwear collection of the future, the Illusion jacquard coat by Vittorio Brancicio and Uroš Mihic with a four-colour 3D effect stands out. The texture of the 3D print, which is an array of densely planted cubes, creates the illusion of iridescent colors that change depending on the viewing angle. The cubes on the back of the product are placed precisely so that their surface filters the light, creating a change in tones and shades. For greater strength, a reinforced thread was added to the fabric structure.

Inspired by the additive genius of Stratasys, D-House is exploring ways to use direct 3D printing to make bags, shoes, and restore vintage clothing and accessories. Negotiations with potential partners in all areas are already underway.

“3D printing allows us to create complex geometries that cannot be achieved in any other way. My dream is to create clothes completely made using 3D printing, says Loreto Di Rienz. “It seems to me that very soon, for the production of new categories of clothing, the need for traditional fabric will disappear, new materials will appear. ”

”

Source

3D printing

What is 3D printing and how it can be used! Interesting!

What is 3D printing

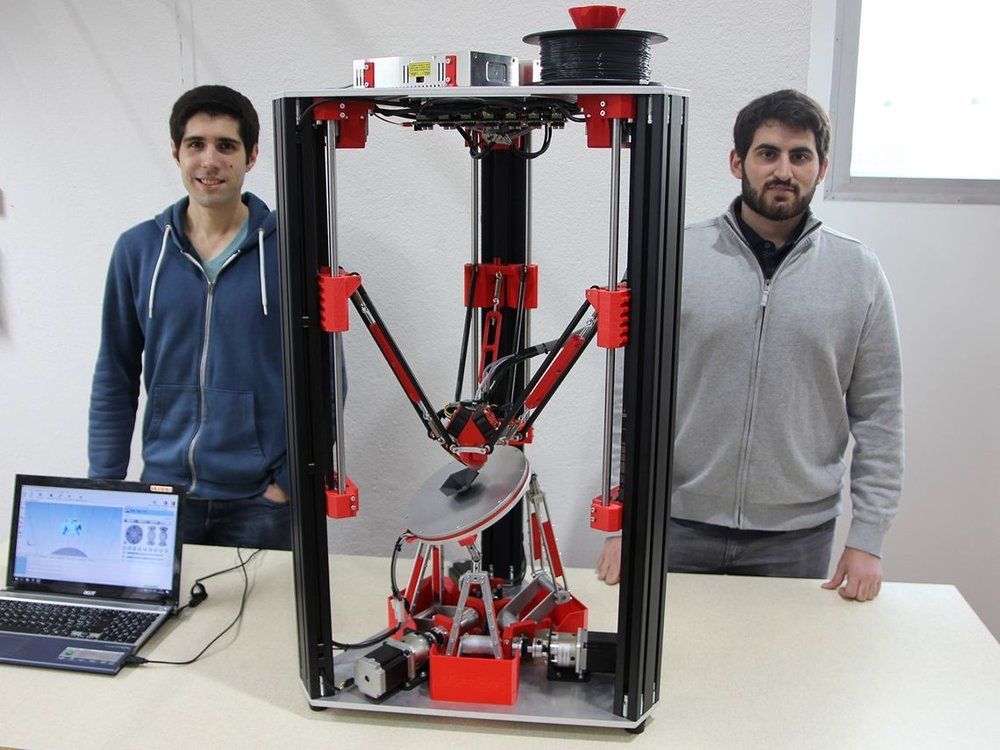

3D printing technology was patented in the 80s of the last century, but gained popularity relatively recently. New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used.

In short, 3D printing is a technique for manufacturing three-dimensional products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects.

This process uses a special device - a 3D printer, which prints certain types of materials. More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

3D printing steps

To make it clearer what 3D printing is, let's take a look at the playback process step by step. Below are the specific stages of 3D printing. How it works:

- 3D modeling of the required object is performed according to certain rules;

- The file with the digital model is loaded into the slicer program, which generates the control code for the 3D printer;

- Sets required 3D printing options;

- The code is written to a removable memory that connects to the 3D printer;

- The 3D model is reproduced.

Objects are played gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique.

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D scanning?

- Basics What is a 3D model?

3D Printing Technologies

Various 3D printing technologies are used to reproduce different objects. They differ both in the consumables used, and in the speed and accuracy of printing. Here are the main 3D printing technologies:

- Fused deposition modeling (FDM) . One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio. Printing occurs by layer-by-layer supply of a thread of molten plastic;

- Laser stereolithography (SLA) .

The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage;

The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; - Selective laser sintering (SLS) . Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements

3D Printing Applications

As you may have guessed, the applications of 3D printing are extremely wide. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

Well, that was a brief description of what 3D printing is. We hope we were able to provide the necessary information in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.