Alcoa 3d printing

$60 Million Arconic Facility for Metal 3D Printing to Open at Alcoa Technology Center - 3DPrint.com

There are certainly plenty of newcomers to the 3D printing industry; after all, most consider 3D printing to be a newcomer in itself when compared to the history of the world and traditional manufacturing. Between startups, spinoffs, and individuals, all throwing their hats into the ring, it’s often hard to know who to rely on when they have only just begun, and don’t have a major track record to show. Everybody has to start somewhere and begin building a foundation, but it can also these days be refreshing to find a company that has a longstanding history.

As a company, Alcoa doesn’t just have history, or experience: they are undeniable leaders. Known as forerunners in the manufacturing of aluminum and light metals, the NYC-headquartered company has been progressing into the 3D printing arena for 20 years now, from originally moving into using 3D printing for jet engine parts to investing in large facilities devoted to the cause, as well as beginning to supply 3D printed airplane components to Airbus.

As their momentum continues to grow, Alcoa is answering the need not only for a strong leader in 3D metal printing but also a need for the development of high-quality metal powders in the aerospace manufacturing industry. With all of this in mind, and more, they have opened a $60 million 3D printing metal powder production facility at the Alcoa Technology Center in Pittsburgh. There, the company will maintain a focus on producing proprietary titanium, nickel and aluminum powders optimized for 3D printed aerospace parts. Along with this is a keen interest in further development of the technology in terms of processes, product designs, and qualification procedures.

“Alcoa is forging a leadership path in additive manufacturing with a sharp focus on the critical input material—metal powders,” said Alcoa Chairman and Chief Executive Officer Klaus Kleinfeld. “We are combining our expertise in metallurgy, manufacturing, design and product qualification to push beyond the possibilities of today’s 3D printing technologies for aerospace and other growth markets.

”

While many may not be aware that this longstanding company (founded in the late 1800s) has already been working with 3D printing for two decades, they may also not realize that when it comes to the aluminum materials used in aerospace, most of that was developed and invented by Alcoa. The company will actually be splitting into two different entities this year though, with Alcoa continuing in aluminum commodities and the new company Arconic, being responsible for delving into cutting edge manufacturing technologies and techniques, as well as working to solve ‘complex engineering challenges,’ according to their website.

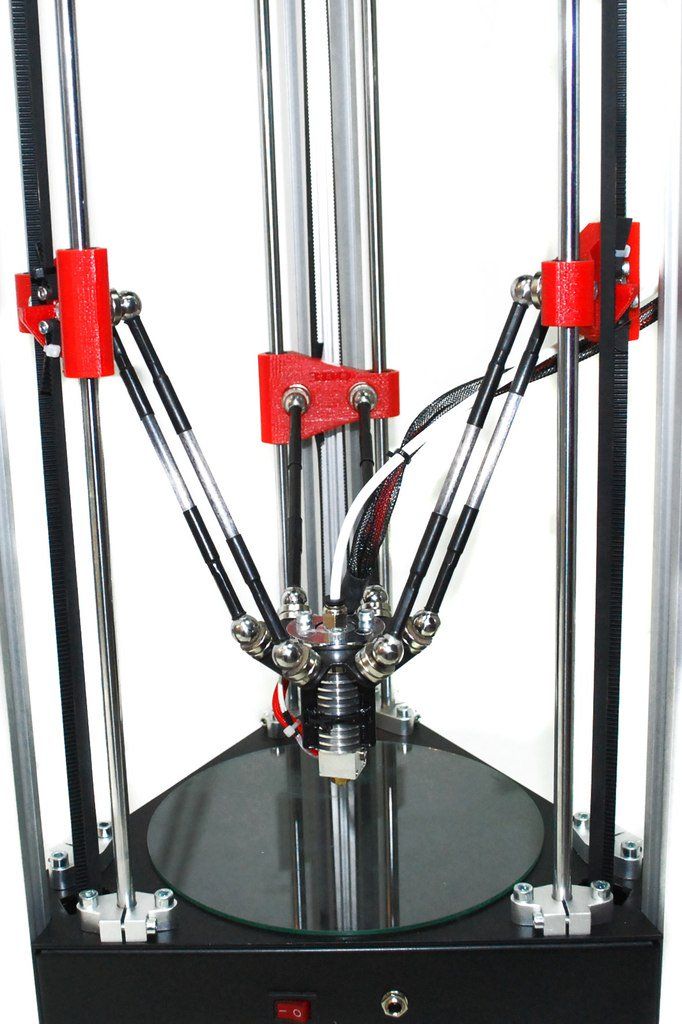

Alcoa Technology Center [Photo: Business Wire]

The new facility will be part of Arconic as they forge ahead with new and advanced 3D printing, including their unique Ampliforge technique, which employs both 3D printing and traditional methods like forging. This will be in addition to the related processes they have going on also in California, Georgia, Michigan, Pennsylvania and Texas. As the company splits, Arconic will be heavily related to the aerospace business too, with teams there working to create and innovate in the areas of materials and products as well as new solutions within the industry.

As the company splits, Arconic will be heavily related to the aerospace business too, with teams there working to create and innovate in the areas of materials and products as well as new solutions within the industry.

“The ‘Arconic’ brand fuses our extraordinary heritage with our highly promising future,” said Kleinfeld. “It echoes our 127-year history of invention – and reinvention.”

As we’ve reported on previously, Alcoa also operates a facility dedicated to Hot Isostatic Pressing (HIP) technology for their 3D printing processes, in Whitehall, Michigan. With this technology they are able to use extremely high temperatures and high pressure to strengthen components made from super-alloys such as titanium and nickel. They will also be following through on their contract with Airbus to deliver 3D printed parts for titanium fuselage and engine pylon components this year. Discuss further in the Alcoa 3D Printing Facility in Pittsburgh forum over at 3DPB. com.

com.

Alcoa will begin delivering 3D printed plane components to Airbus this year.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D printing aluminum • 3D printing facilities • 3d printing metal • airbus • Alcoa • Alcoa Technology Center. • aluminum • ampliforge • Arconic • Hot Isostatic Pressing (HIP) • metal 3d printing • metallury

Please enable JavaScript to view the comments powered by Disqus.

New 3D Printing Plant, Software and Education

Alcoa has opened its 3D printing metal powder production facility located at the Alcoa Technology Center. Source: Business Wire

Like most technologies, there is a huge wave of interest surrounding their introduction followed by a slowdown in news as users evaluate the technology and determine its usefulness through initial applications. The rate of developments through this slowdown in news often determines the staying power of the new technology. And though the news around 3D printing never slowed significantly, recent activity suggests a surge in 3D printing use across industry in the near term.

And though the news around 3D printing never slowed significantly, recent activity suggests a surge in 3D printing use across industry in the near term.

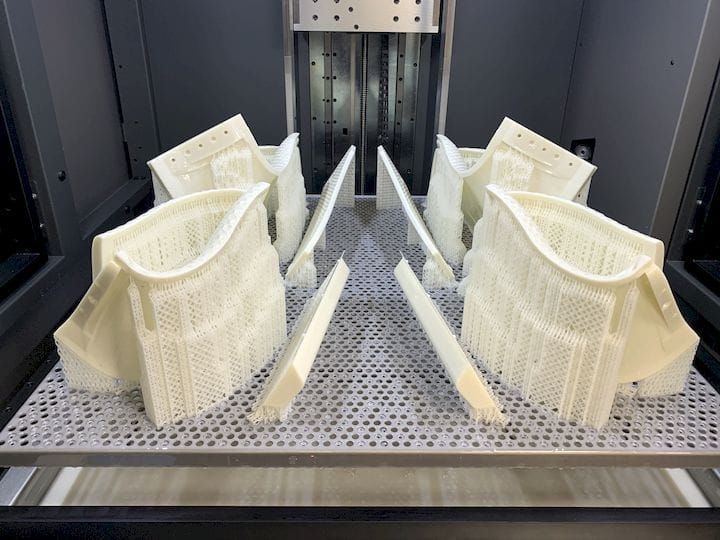

A few of these announcements I’m referring to include Alcoa’s opening of its 3D printing metal powder production facility at the Alcoa Technical Center in Pennsylvania. The facility will reportedly produce proprietary titanium, nickel and aluminum powders for 3D printed aerospace parts. Alcoa is focusing on this area because metal powders used for 3D printing durable aerospace parts are only available in limited quantities. In addition, Airbus recently selected Alcoa to supply 3D printed titanium fuselage and engine pylon parts for its commercial aircraft.

Beyond producing powders for 3D printing, Alcoa recently unveiled its Ampliforge process—a technique that combines additive and traditional manufacturing. Using this process, Alcoa designs and 3D prints a nearly complete part then treats it using a traditional manufacturing process, such as forging. The process is said to increase the toughness and strength of 3D printed parts.

The process is said to increase the toughness and strength of 3D printed parts.

Meanwhile, Stratasys Ltd., a supplier of 3D printing and additive manufacturing technologies, has released new software designed to make 3D printing easier. GrabCAD Print is an open architecture design-to-3D print workflow application that resides on the GrabCAD platform. Stratasys says this platform is supported by a community of more than 3 million designers, engineers and students.

Stratasys explains that the 3D printing design process is typically characterized by significant “model fixing” time, which forces businesses to devise manual solutions to construct an acceptable workflow. GrabCAD Print addresses this issue by eliminating the requirements to translate and repair CAD files. Using GrabCAD Print, users can send native CAD files to a Stratasys 3D Printer or service bureau directly from their familiar CAD environments.

Explaining the software’s openness, Stratasys says GrabCAD Print works with a variety of Stratasys FDM and PolyJet 3D Printers and can natively read several CAD formats from PTC Creo, Dassault Systèmes’ SolidWorks, Siemens PLM Software’s NX software, CATIA and Autodesk Inventor. The application also facilitates data sharing related to job scheduling, print queue status, material usage and historical usage.

The application also facilitates data sharing related to job scheduling, print queue status, material usage and historical usage.

There is also news from UL about its Additive Manufacturing Competency Center (UL AMCC) which UL jointly runs with the University of Louisville.

According to UL, training at the center begins with an in-depth review of metal powders, safety issues and processing considerations for a facility, as well as the requirements for personal protection. Courses then move on to cover the overall additive process—from beginning to advanced design considerations and how to build a system to support part removal and post-processing.

Students build their own metal parts before training concludes, either by using designs developed by the center or bringing their own. Instructors review them to verify they are buildable and help the students think through support strategies for the manufacturing process that might include how to incorporate a support structure when building the material.

Stratasys

Underwriters Laboratories (UL)

Alcoa bets on 3D printing - Metallurgy News

Metal Supply and Distribution

Advertisements

I will buy 18 I will sell 0

- NGO "MPK", on a permanent basis we buy more expensive than all Illiquid assets of enterprises, from the state. Reserve, individuals....

- I will buy gate valves ball valves taps valve flanges

- NGO "MPK", on an ongoing basis, we buy more expensive than all Illiquid assets of enterprises, from the state. Reserve, individuals....

- Compensators. Bellows, Starter, Omental, Lens, KSO, 2KSO, KSU.PPU, KSU.PPMi, For...

- Compensators. Bellows, Starter, Omental, Lens, KSO, 2KSO, KSU.PPU, KSU.PPMi, For...

- Compensators. Bellows, Starter, Omental, Lens, KSO, 2KSO, KSU.PPU, KSU.

PPMi, For...

PPMi, For... - Buy danfoss danfoss expensive phone 8909 166 16 21

- Buy danfoss danfoss expensive phone 8909 166 16 21

- Buy danfoss danfoss expensive phone 8909 166 16 21

- 89065532367 BUY DANFOSS DANFOSS SOCLA SOKLA JIP FF F...

All ads

Suppliers

- November 14

- Translompererabotka (Moscow)

- Dalkontinentstal (Vladivostok)

- Plant of tank structures (Zarechny)

- Steel-Don-Titan (Voronezh)

- Ryazan plant of metal structures (Ryazan)

- Promstal (Lipetsk)

- PromTechKomplekt (Beloretsk)

- November 02

- AEM-technologies (St.

Petersburg)

Petersburg) - Energy Alliance-Ural (Ekaterinburg)

- Galaxy (Podolsk)

Handbook “Metallurgy. Metal deliveries. Russia."

Add company

Alcoa , Aluminum , Nickel , USA , titanium , Arconic | July 07, 2016 | 06:00

The American corporation Alcoa announced the opening of a plant for the production of powders for 3D printing, located on the territory of its research center.

According to a press release from Alcoa, the new facility will produce titanium, nickel and aluminum powders for 3D printing of parts for the aerospace industry. Alcoa has also invested in a range of technologies to further develop additive manufacturing.

"Alcoa is committed to being a leader in additive manufacturing with a focus on 'critical materials' metal powders," said Klaus Kleinfeld, chairman of Alcoa's board of directors. “We are combining our knowledge of metallurgy, manufacturing, design and product quality assessment to advance beyond the capabilities of current 3D printing technologies for aerospace and other emerging industries.”

Related newsOctober 21, 2022 Alcoa chief advocates urgent action to limit access to aluminum from Russia

The open plant will be part of Arconic following its spin-off from Alcoa in 2H 2016 and is part of a $60M investment to build 3D printing materials production capacity in the states of California, Georgia, Michigan, Pennsylvania and Texas.

Source: IIS "Metal Supply and Sales"

Views: 168

If you find an error in the text, you can notify the site administration by selecting the text with the error and pressing the buttons Shift+Enter

Popular news

Zinc production in China was less than expected

Australian company develops copper-gold project

Chinese aluminum exports continue to decline

US Novelis to build an aluminum recycling plant in Korea

China cut copper imports

Steel Dynamics to build a rolled aluminum plant in Mississippi

News subscription

MSS survey

From November 7 to 11, the Week of Metals in Moscow and the Metal-Expo'2022 exhibition were held, where there were many events where trends and forecasts were discussed. What do you think about the metals market in 2023?

What do you think about the metals market in 2023?

It will be a difficult year: continued military clashes, economic sanctions, a pandemic, etc.

In the spring, the negotiation process between the Russian Federation, Ukraine and NATO countries and stabilization in the economy will begin

In the first half of the year everything will be bad, and in the second half everything will begin to change for the better.

State investment projects will support the demand for metal in 2023.

Today, nothing can be predicted even a month ahead.

Alcoa Rims 3D file 1:25 scale・3D printer design download・Cults

Ford Raptor - Logo

1.09 €

JETTA

0,75 €

cookie cutter

1. 24 €

24 €

Best 3D Printer Files in the Miscellaneous Category

Model Harley Davidson Bike

48.26 €

Mouse to move with your lips

Free

Passive hydroponic system for seedlings

Free

Femur Bone with Stand

Free

Sculptr Delta

Free

Tiny hands

€1.49

Foam Dart Bandolier

Free

Bestsellers in Miscellaneous category

Speeder-Pad support on FLSUN V400 and FLSUN SuperRacer

3 €

4th planet Fighting pre-Olympic god

12 €

Gremlin rail 640 mm FPV

0,97 €

Demogorgon Printed Animal (and key ring version)

3,50 €

ItsLitho "Creamy" personalized Lithophane Christmas ball

1,90 €

Adderini - 3D printed repeating slingbow / crossbow pistol

6. 25 €

25 €

Predator-inspired movable mask

6.20 €

Targaryen Crown - Viserys - Dragon House

€11.65 -twenty% 9.32 €

ItsLitho "Drop" personalized lithophane Christmas ball

1,90 €

Wolf - Flexi Articulated Animal (printed in place, without supports)

2 €

Black Phone Movie Invader 2 Piece Mask 3 Style Frowning Smile Without Mouth STL

9.65 €

3 €

Articulated pretty spider

2.49 €

Halloween haunted house lamp with 3d moon - NO PREPARATION AND PAINTING NEEDED

6.