Polyjet 3d printing service

PolyJet 3D Printing Service | Full Color and High Quality 3D Printed Prototypes

CapabilitiesCustom Online 3D Printing ServicePolyJet 3D Printing Service

Prototypes, color concept models, and simulated overmold parts in days

Free shipping on all US orders

PolyJet 3D Printing

PolyJet printing is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a somewhat similar process to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions, producing parts with incredible precision and speed. It also supports the ability to print multiple materials simultaneously and can simulate rubber materials of different durometers, multi-color 3D printing, transparent or translucent parts, and simulated overmolds.

- Rigid and rubber-like options

- Multi-material 3D printing

- Color matched prototypes

- Multi-color prints

- 3D prints in as little as a business day

- Achieve complex shapes

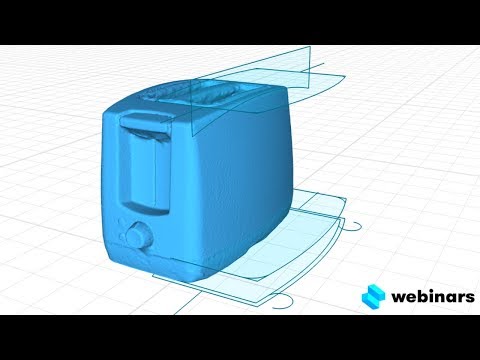

Use the 3D viewer above to preview Xometry’s part rendering features.

PolyJet Materials

| Material Name | Description | Shore Hardness | Elongation at Break (%) | Notched Impact Strength (J/m) | Data Sheets |

|---|---|---|---|---|---|

Material Name Photopolymer, Rigid | Description VeroUltra™ Black (RGD865), VeroUltra™ White (RGD825), VeroUltraClear Component (RGD820), VeroClear (RGD810) | Shore Hardness 83D - 86D | Elongation at Break (%) 7% - 12% | Notched Impact Strength (J/m) 19 - 25 J/M | Data Sheets VeroUltra, Vero |

Material Name Photopolymer, Rubber-like (Digital rubber) | Description Agilus30 + Vero | Shore Hardness 26-28A, 35-40A, 45-50A, 57-63A, 68-72A, 80-85A, 92-95A | Elongation at Break (%) 185% - 230% | Notched Impact Strength (J/m) N/A | Data Sheets Agilus30 Material Data Sheet, Digital Materials Data Sheet |

Material Name Multi-Material, Mult-Color, Digital material | Description Combination of two or more PolyJet materials | Shore Hardness Varies | Elongation at Break (%) Varies | Notched Impact Strength (J/m) Varies | Data Sheets Digital Materials Data Sheet |

Digital material properties, such as Shore A rubber-like, may vary due to their microstructure and printed geometry. More PolyJet materials and colors are available upon request! Review more information about our materials here.

More PolyJet materials and colors are available upon request! Review more information about our materials here.

New!

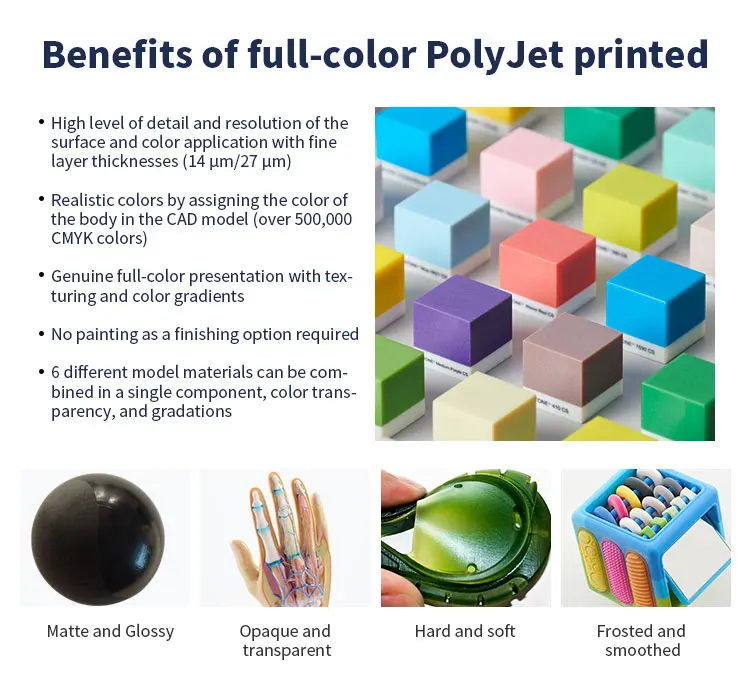

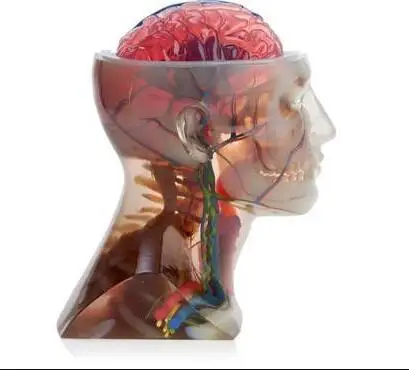

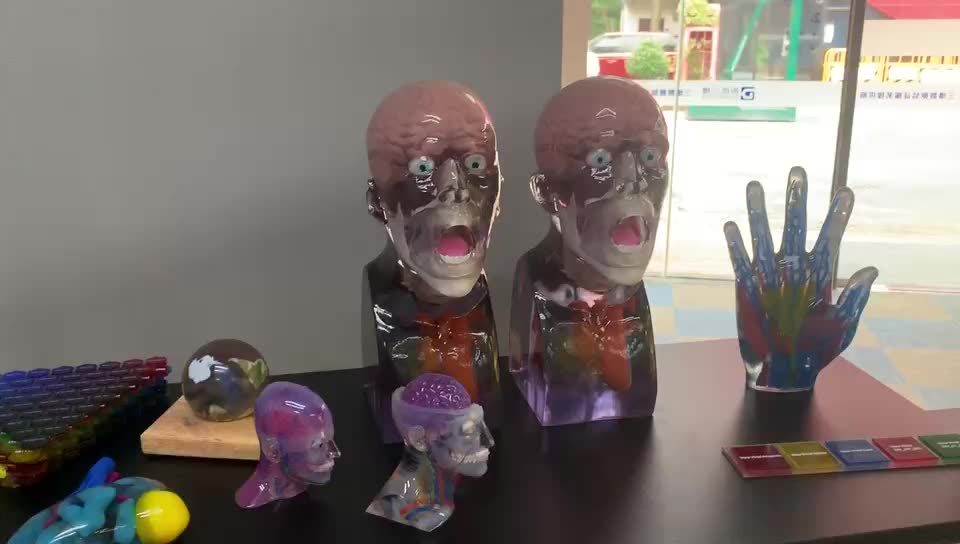

Full Color 3D Printing through PolyJet

Xometry offers a full-color, high quality 3D printing service in addition to black, white, translucent, and grayscale utilizing the latest generation of PolyJet equipment from Stratasys. With over 600,000 available colors, Xometry can print color 3MF and other 3D formats. Have a Pantone, RAL, HEX, CMYK, or other color input? Choose "Custom" and write in the combination in your notes for a Xometry quote!

- VeroUltra™ Black (RGD865)

- VeroUltra™ White (RGD825)

- VeroCyan-V (RGD845)

- VeroMagenta-V (RGD852)

- VeroYellow-V (RGD838)

- VeroUltraClear Component (RGD820), VeroClear (RGD810)

- Agilus30 and rubber-like digital materials

- Digital ABS Plus, Ivory (upon request)

- Rigur, White (upon request)

PolyJet Finishes

Standard

Support material is removed, and parts are cleaned.

Additional Finishes

Xometry can provide additional processing and finishes to meet your needs. For example, you can request the print “Glossy,” a software setting that gives any upper-facing features a glossy appearance.

Ready to get started on your PolyJet quote?

Free shipping on all 3D printing

Applications of PolyJet

Concept Models

The speed, efficiency, and range of build materials make PolyJet 3D perfect for concept models.

Rapid Prototyping

PolyJet 3D can be used to create quick-turn prototypes and test fit and finish.

Rapid Tooling

PolyJet 3D is ideal for making tools, jigs, and fixtures that can be used in production settings

Advantages of Polyjet

Efficiency

Eliminates the multi-stage processes of traditional manufacturing, such as tooling, milling, and creating molds.

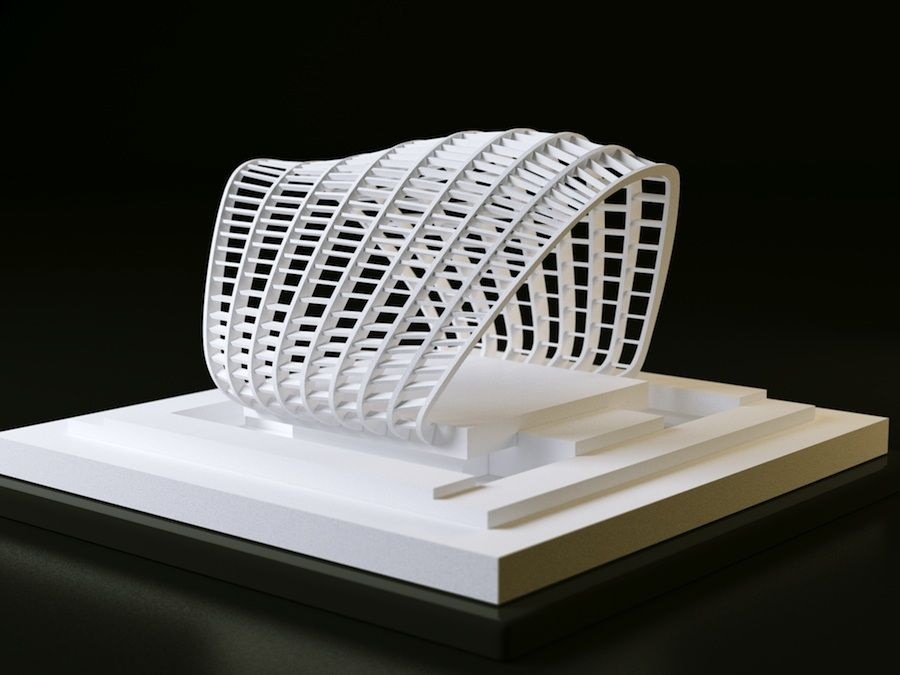

Complex Geometry

Creates complex shapes with a high degree of precision that would otherwise be impossible to build via traditional manufacturing processes.

Rubber-like Flexibility

PolyJet 3D can build vastly different part geometries, unlike traditional processes that would necessitate a complete retooling of an assembly line to produce a different part.

Material Selection

Offers a vast material selection with a range of properties, as well as the ability to print multiple materials and simulate overmolds.

Rapid Turnaround

Because PolyJet 3D can create complex and multi-material parts in a single operation, significantly less build time is needed vs. traditional manufacturing. We can have parts to you in as fast as days.

Polyjet General Tolerances

| Description | Tolerance Notes |

|---|---|

Description General Tolerances | Tolerance Notes +/- 0.004” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

Description Build Area | Tolerance Notes Build area up to 19. |

Description Minimum Feature Size | Tolerance Notes 0.050" or geater for rigid. 0.080" or greater for rubber-like. |

Description Standard Layer Height | Tolerance Notes 0.0018" layers. |

This table depicts the general tolerances and guidelines for polyjet 3D printing. General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out Xometry's Manufacturing Standards for more information on tolerances per process.

Overview: What is PolyJet 3D Printing?

Polyjet 3D Printing Basics

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials.

It also supports a wide variety of build materials.

How Polyjet Works

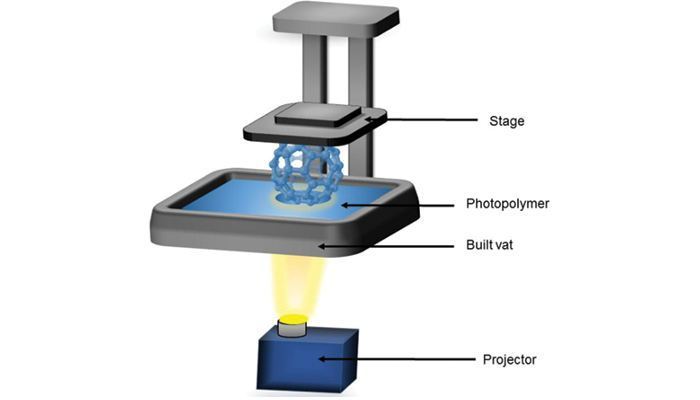

PolyJet 3D printed parts are built using photopolymer liquid resin. The printer places layers of photocurable resins onto a build tray in extremely fine layers. As the layers are placed, they are simultaneously cured via exposure to an ultraviolet (UV) light, solidifying them into solid material matching the programmed CAD file. This process repeats itself layer by layer until the entire part has been constructed. In the case of parts with complex geometries, support structures are added to the part to ensure a successful build and then manually removed during the finishing process.

Benefits of Polyjet 3D Printing

PolyJet technology is known for its customizable material properties and excellent surface finish, creating prototypes that are both detailed and smooth. Unlike traditional manufacturing processes, polyjet allows manufacturers to customize material properties, and supports various photopolymer options that can simulate a variety of different end-use materials. Combined with PolyJet’s high accuracy to CAD files and it’s overmold capabilities, this manufacturing process is a favorite for rapid prototyping.

Combined with PolyJet’s high accuracy to CAD files and it’s overmold capabilities, this manufacturing process is a favorite for rapid prototyping.

Why Choose Xometry for PolyJet?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

Download the PolyJet design guide

PolyJet 3D Printing | Get Elastomeric 3D-Printed Prototypes

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Injection Molding Material Alternatives Guide

Struggling with thermoplastic material shortages? We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics.

Download

-

Resources

Design Tips Guides and Trend Reports Success Stories Design Aids Webinars and Trade Shows

Blog Videos FAQs Educators and Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Research and Development Cool Idea Award Partnerships Sustainability and Social Impact

Careers Investors Locations Press Procurement

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Best-in-Class Online Quoting

After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. Within your quote, you can also adjust quantity and material and see price changes in real-time.

Learn More

Get a QuoteSign In

Get 3D-printed elastomeric parts within days. Request an online quote today.

UPLOAD A PART

Jump to Section→ Capabilities

→ Materials

→ PolyJet 3D Printers

→ About PolyJet 3D Printing

PolyJet is an industrial 3D printing process that builds multi-material prototypes with flexible features and complex parts with intricate geometries in as fast as 1 day. A range of hardnesses (durometers) are available, which work well for components with elastomeric features like gaskets, seals, and housings.

Common applications for PolyJet 3D printing:

- prototyping designs for overmolding or silicone rubber parts

- combining two colors or durometers into a single part

- simulating elastomers or flexible parts

If you have any issues getting your guide, click here to download.

3D Printing Surface Finish Guide

Get this quick reference guide to explore your surface finish options across our six 3D printing technologies.

United States of AmericaAfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia, Plurinational State ofBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, the Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcelandIndiaIndonesiaIran, Islamic Republic ofIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People's Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMacedonia, the Former Yugoslav Republic ofMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Federated States ofMoldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussian FederationRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSuriNameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela, Bolivarian Republic ofViet NamVirgin Islands, BritishVirgin Islands, U. S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates

PolyJet Design Guidelines and Capabilities

Our basic guidelines for PolyJet include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| US | Metric | |

| Maximum Part Size | 19.3 in. x 15.4 in. x 7.9 in. | 490mm x 390mm x 200mm |

| Layer Thickness | 0.00118 in. | 30 microns |

| Minimum Feature Size | 0.012 in. | 0.3mm |

| Minimum Freestanding Wall, Hole, or Channel Size | 0.030 in. | 0.76mm |

Tolerances for PolyJet: For well-designed parts, tolerances of ±0. 005 (0.1mm) for the first inch plus 0.1% of nominal length can typically be achieved. Note that tolerances may change depending on part geometry.

PolyJet Material Options

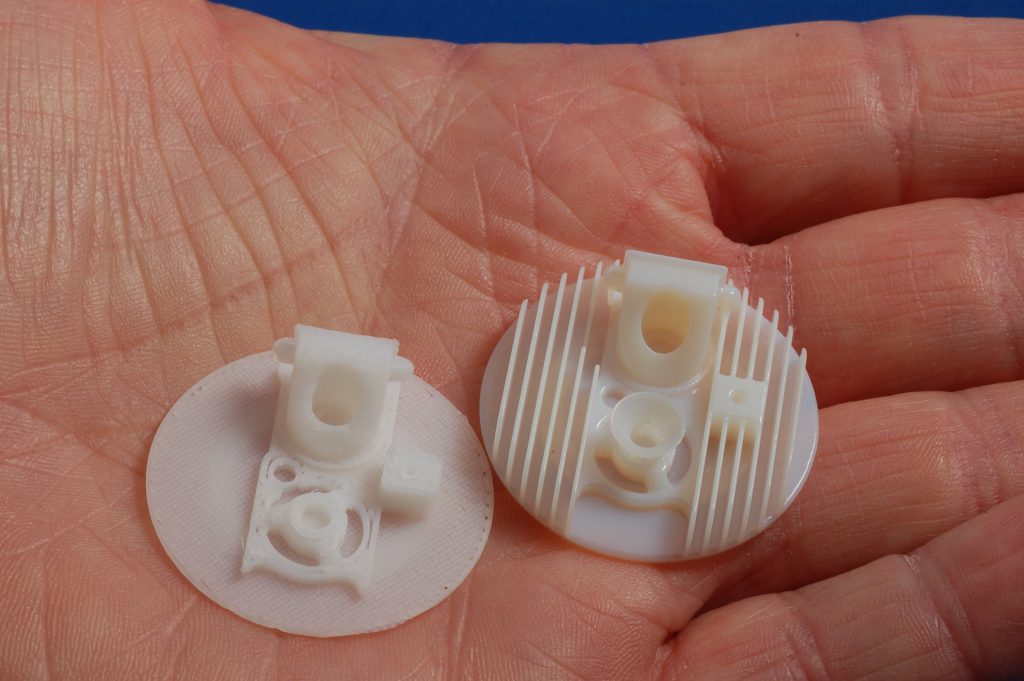

PolyJet provides the ability to choose a desired hardness or combine material properties into a single build, which makes it ideal for prototyping overmolding parts. Shore A hardnesses of 30A, 40A, 50A, 60A, 70A, 85A, 95A, and rigid are available in these colors:

- Digital Clear/Translucent

- Digital Black

- Digital White

Compare PolyJet Material Properties

- US

- Metric

| Material | Tensile Tear Strength | Tensile Strength | Elongation |

|---|---|---|---|

| 30A | 85 psi | 399 psi | 245% |

| 40A | 100 psi | 508 psi | 200% |

| 50A | 114 psi | 508 psi | 190% |

| 60A | 121 psi | 580 psi | 160% |

| 70A | 185 psi | 725 psi | 130% |

| 85A | 341 psi | 1,088 psi | 80% |

| 95A | 398 psi | 1,740 psi | 60% |

| Rigid | n/a | 8,702 psi | 17. 5% 5% |

| Material | Tensile Tear Strength | Tensile Strength | Elongation |

|---|---|---|---|

| 30A | 0.59 MPa | 2.75 MPa | 245% |

| 40A | 0.69 MPa | 3.5 MPa | 200% |

| 50A | 0.79 MPa | 3.5 MPa | 190% |

| 60A | 0.83 Mpa | 4.0 Mpa | 160% |

| 70A | 1.28 Mpa | 5.0 Mpa | 130% |

| 85A | 2.35 Mpa | 7.5 Mpa | 80% |

| 95A | 2.74 Mpa | 12.0 Mpa | 60% |

| Rigid | n/a | 60.0 Mpa | 17.5% |

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

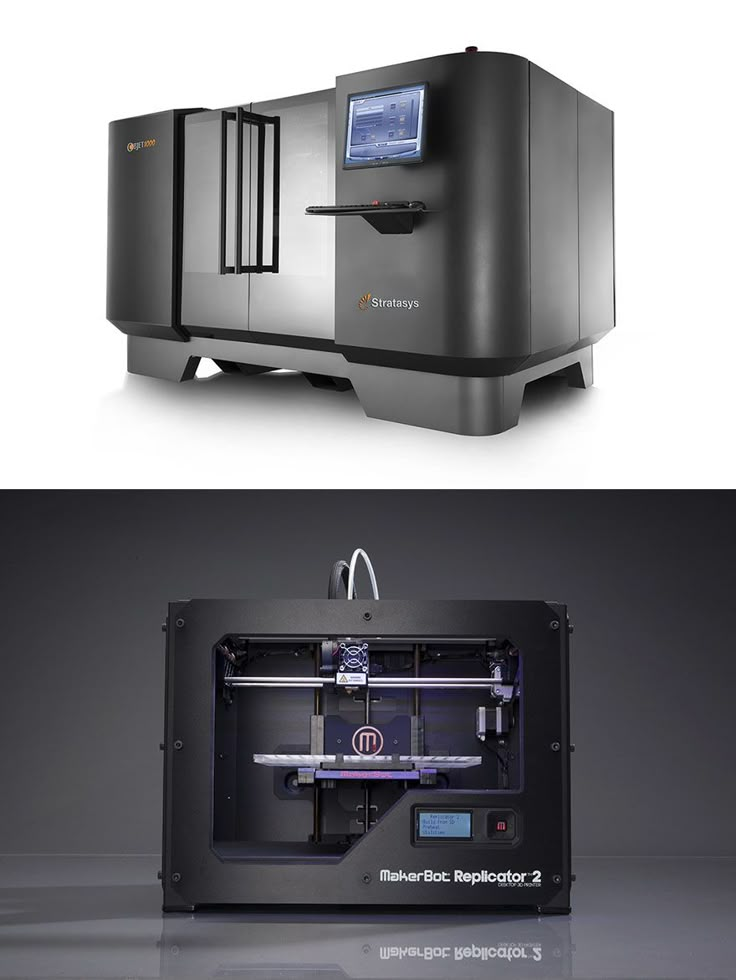

Our PolyJet 3D Printers

We use multiple additive machines that offer large build sizes, accurate parts, and quick production times. Our PolyJet equipment consists of:

- Objet260 Connex3

- Objet350 Connex3

How Does PolyJet 3D Printing Work?

The PolyJet process begins by spraying small droplets of liquid photopolymers in layers that are instantly UV cured. Voxels (three-dimensional pixels) are strategically placed during the build, which allow for the combination of both flexible and rigid photopolymers know as digital materials. Each voxel has a vertical thickness equal to the layer thickness of 30 microns. The fine layers of digital materials accumulate on the build platform to create accurate 3D-printed parts.

Each PolyJet part is completely coated in support material during the build, which ultimately is removed by hand using a pressurized water stream and a chemical solution bath. No post-curing is required after the manufacturing process.

Resources

Design Tip

Exploring Manufacturing Options for Elastomeric Components

What are your material options when designing elastomeric parts for 3D printing and injection molding?

Read Design Tip

Guide

What is 3D Printing?

Gain an understanding of additive manufacturing and how it can be leveraged to improve product development through rapid prototyping and production.

Read Guide

Design Tip

Prototyping with PolyJet 3D Printing

Use PolyJet to combine elastomeric and rigid properties together for prototyping two-material components.

Read Design Tip

Blog

Post-Printing Automation Accelerates PolyJet Process

Post-printing automation accelerates PolyJet's 3D printing process and improves efficiencies.

Read Blog

Get an instant quote on your 3D printing design.

UPLOAD A PART

TOP 1 Polyjet 3D Printing Services

What is Polyjet 3D Printing?

Polyjet 3D printing is a robust 3D printing method commonly used to produce accurate, smooth surface prototypes.

In addition, the technology is advantageous for obtaining high precision and resolution of a 0.014 mm layer with thin walls and complex geometries using microscopic layering.

Technically, the process is carried out by applying a photopolymer to droplets and curing it with UV radiation to obtain purified products.

Therefore, this method is widely applicable to the manufacture of jigs, fixtures, molds and other complex items.

Through the use of different materials and colors, this method allows the creation of a single piece with high efficiency and productivity.

How does Polyjet 3D printing work?

Polyjet 3D printing works in the same way as any other inkjet 3D printer, it consists of a container, platform and installed UV light heads.

First, photopolymer resin is poured into the container and heated until the desired viscosity is reached.

The process begins when the header moves horizontally with the build platform and releases resin in droplets.

As soon as the droplets fall, the ultraviolet light takes over and begins to turn them into solid particles.

Since there are multiple printheads, you can print on different media at the same time.

In addition, the printer proceeds to form the next layer after the layer is finished, and the process continues until the product is created.

What are the benefits of Polyjet 3D printing?

The advantages of poly inkjet 3D printing are summarized as follows:

- It produces high resolution (600dpi) products with exquisite and smooth touches.

- The technique allows users to combine any two materials and create a variety of objects.

- It offers customized products with little geometrical restrictions.

- It's also a great method for rapid prototyping.

- In addition, this method is useful for simulating multilayer molding without the use of tools.

What are the disadvantages of Polyjet 3D printing?

The disadvantages of polyjet 3D printing services include the following:

- Unfortunately, Polyjet 3D printers are not recommended for outdoor use, as additional exposure to UV radiation can damage its parts.

- In addition, this method is not suitable for high-volume production, as it is very expensive and labor intensive.

- When a water jet is used to remove support materials, plumbing is required.

What materials can be used for Polyjet 3D printing?

Materials that can be used for poly inkjet 3D printing are being developed as follows:

Agilus30

Agilus30 is a material used in poly inkjet 3D printing, known for its amazing tear resistance and resistance to bending and bending.

In addition, it is ideal for prototyping, various designs and gives rubber like feel, look and function.

ABS

Digital ABS is used to produce precise, realistic and complex high temperature resistant instruments.

In addition, they help create high-strength products with sophisticated and superior finishing touches.

Black Gray

This material is beneficial for higher speed products with moderate throughput and a smoother finish.

Subsequently, at twice the speed, objects are obtained with a thickness of each layer of 7 microns, and this is the cheapest of all.

Are Polyjet 3D printed parts resistant to high temperatures?

Polyjet 3D printed parts are resistant to high temperatures and have exceptional smoothness.

Elevated temperatures are generally beneficial for multi-jet 3D printed products to produce hard and durable materials.

This is because high temperature and heat initiate the thermal performance and strength of plastic products.

In addition, when material is being processed at 80 degrees Celsius (or higher), multi jet mixers and pipes are ideal for hot water and air flow testing.

In addition, the combination of heat in polyjet 3D printed rubber products is ideal for producing rigid materials with exceptional heat resistance.

Are Polyjet 3D printed parts durable?

Yes, Polyjet 3D printed parts are durable and strong enough to last for years.

They are generally known to produce very realistic models with added durability and authenticity.

What's more, Polyjet printers are purpose-built to ensure that consumers receive accurate and accurate output every time.

The results are not only hard and detailed, but incredibly smooth and polished materials with microscopic details.

In addition, the poly inkjet printing method uses digital media to mix multiple types of resins for added stability and durability.

Subsequently, the resulting products have increased flexibility, color and texture, effectively meeting the needs of consumers.

SLS vs Polyjet 3D printing, which is perfect for my projects?

Among SLS and Polyjet 3D printing, the ideal one for your project may be the one that meets your requirements and delivers high quality results in the material you want.

As a rule, the thickness of the layer formed in SLS 3D printing ranges from 50 to 150 microns, while in Polyjet the layer can be thinner by about 15-30 microns.

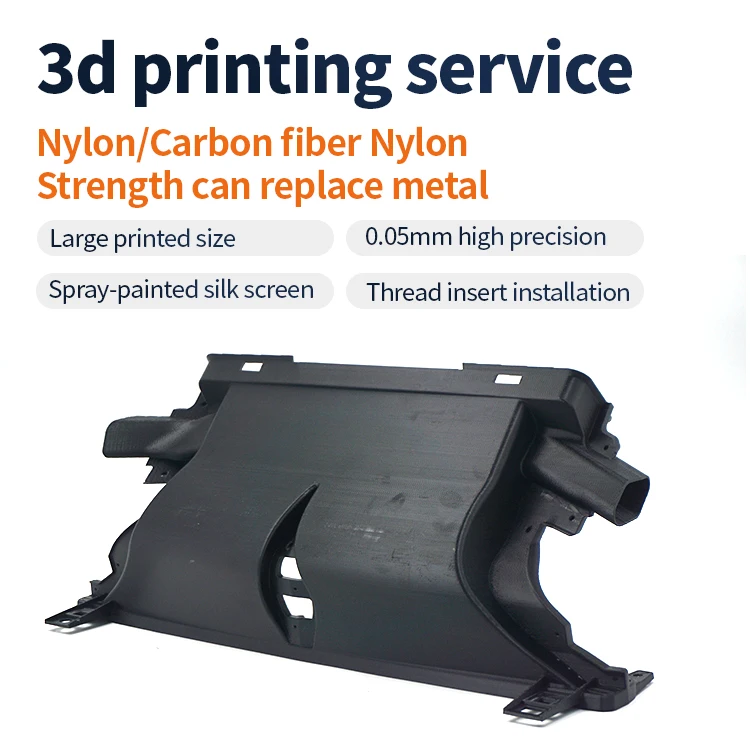

Moreover, a common material used in SLS is nylon, which is known for its versatility and high strength.

On the other hand, Polyjet printing technology uses multi-colored rubber-like resins that can be transparent or opaque depending on conditions.

Regardless of the material used in SLS, it will come together as a whole, and in Polyjet each drop develops as a separate substance.

Typically, SLS printing does not require any additional support, while Polyjet printing technology follows the traditional sequence of steps for product production.

Polyjet or DLP 3D printing: which is best for my projects?

Polyjet and DLP 3D printing, the ideal one for your project is the one that gives better and longer lasting results.

Typically, poly inkjet 3D printing is the process of applying a drop of ink to the surface of paper.

In contrast, DLP 3D printing service is a method suitable for making complex and small parts using a projector to form thin and solid layers.

In addition, the poly inkjet technique can use different materials and objects to achieve the desired shape and size.

While the DLP 3D printing service allows complex shapes to be obtained using the most appropriate Z-axis resolutions.

Typically, the polyjet process is moved by water or by hand, which saves time and post-curing objects. At the same time, DLP requires washing products after printing.

Polyjet or MJF 3D printing: which is best for my projects?

Polyjet and MDF 3D printing can be the perfect choice for your project as they are known for exceptional printing and producing superior products.

Basically, MJF is a proprietary technology that uses an inkjet printer and print head to spray multiple building materials in droplets.

The Polyjet, on the other hand, is a house with small nozzles on the print head that ejects a photopolymer onto a platform that is further cured by UV radiation.

PLA vs Polyjet 3D printing which is perfect for my projects?

Among PLA and poly inkjet 3D printing, poly inkjet 3D printing is the ideal choice for your project as both terms have a huge difference.

Generally, PLA is the material widely used in desktop 3D printing procedures, while Polyjet is the technology used to produce 3D materials.

What's more, PLA is a filament that is widely used in 3D printers because it works effectively at lower temperatures.

However, the multi-jet 3D printing process makes it possible to obtain materials with high heat-resistant properties.

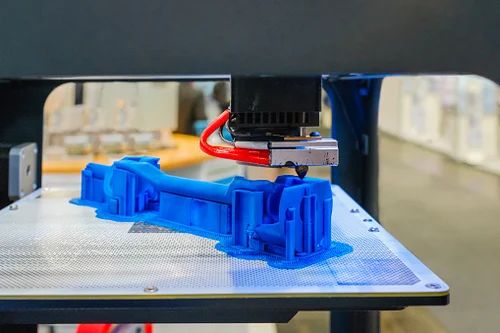

Polyjet or FDM 3D printing: which is best for my projects?

Both polyjet and FDM 3D printing can be ideal for your project due to the fact that they create layered 3D parts.

Technically, an FDM printer heats a thermoplastic filament to form layers, while a Polyjet printer uses liquid photopolymers sprayed onto the printer platform.

Moreover, FDM models are more reliable than polyjet models. However, if the materials are chosen wisely, then polyjet models can be made powerful.

In general, poly inkjet 3D printing can work with a variety of materials and provide high quality, while materials in FDM are limited.

Polyjet or SLA 3D printing: which is best for my projects?

Polyjet and SLA 3D printing are ideal for your projects if you are looking for the most efficient and reliable method to produce high performance 3D printed objects.

Typically, SLA is the oldest 3D printing method where an object is extruded from a reservoir of liquid resin and the product is created upside down.

Whereas in poly inkjet printing, the jet pours the resin into the build plate and prevents its exposure to the building material from harmful environmental substances from the bottom up.

However, both methods use UV light to cure the resin and give it the finishing touch.

What are the advantages of Polyjet 3D printing in China?

The advantages of poly inkjet 3D printing in China are briefly summarized as follows:

- Polyjet 3D printing technology can apply layers of material up to 16 microns thick and create extremely complex geometries with high precision.

- Whether you need to produce an opaque object or a transparent, rigid or flexible object, Polyjet offers a variety of materials to meet your needs.

- Poly inkjet printing technology allows you to get multi-color products. It provides over 360,000 combinations to reduce the need for post-print painting.

- Parts printed on a Polyjet 3D printer do not require post-processing techniques to ensure their accuracy and fidelity.

- In addition, the technology reduces production time, which ultimately increases the efficiency of the workflow.

How to find the best Polyjet 3D printing services in China?

To find the best poly inkjet 3D printing services in China, it is important to know your material and service needs first.

First, talk to the company's support representative and explain to them the details you need in your products.

Moreover, look for customer reviews of suppliers on various platforms to ensure good service not only before delivery of the order, but also after it.

Once you are satisfied with all the details, only then purchase the order.

Does DEK offer Polyjet 3D printing services?

DEC has been offering 21D poly inkjet printing services for 3 years with the same efficiency and reliability.

What's more, our company is a world leader in 3D printing because it uses the latest technology and modern machines to provide the best possible service.

With our expertise and outstanding services in poly inkjet 3D printing, we have over 2,300 customers worldwide.

Why is DEK's Polyjet 3D printing service so much more affordable than other companies?

DEK's poly inkjet 3D printing services are much more affordable than other companies because we use modern technology to keep prices down.

In addition, our company has installed the latest machines, which allowed us to increase their production capacity and reduce the amount of waste generated.

Why choose DEK Polyjet 3D printing services?

Choose DEK's Poly Inkjet 3D Printing Services if you are looking for durable, reliable and trustworthy manufacturers.

We understand the needs of our customers and know what it takes to produce Polyjet 3D printed parts with high quality and exquisite touches.

In addition, we have installed machines to obtain cost-effective but high quality products with the fastest possible turnaround.

If you want to get a prototype or are planning to mass-produce 3D printed parts, DEK is the best choice.

How to order?

To order from Polyjet Online 3D Printing Service Provider, choose the provider with the best and first class customer service.

What's more, if you're looking for Polyjet's leading 3D printing services, DEC should be your first choice for reliable and powerful parts.

The process is simple and straightforward; Just visit our website and fill out the form to clarify the details and requirements for your products.

Once you have completed the form, submit it. Our team will contact you shortly to discuss further details and deliver your shipment as soon as possible.

technology 3D printing Polyjet

Supplier 3D equipment since 2010

+7 495 646-15-338 800 333-12-82

3D-scanners Contacts

PolyJet is a 3D printing technology based on the layer-by-layer curing of a liquid photopolymer material under the influence of ultraviolet radiation. Used in Stratasys 3D printers.

- Principle of operation

- Advantages

- Examples of print

- Select 3D printer

- Principle of operation

- Advantages

- selection0296 product prototypes, test models, burnt-out master models, silicone casting samples.

Advantages: high surface quality, accuracy, construction speed, washable support.

Alternative: MJM technology (also based on UV illumination of photopolymer material).

What is better to print: product prototypes, test models, burn-out master models, samples for molding in silicone.

Advantages: high surface quality, accuracy, construction speed, washable support.

Alternative: MJM technology (also based on UV illumination of photopolymer material).

How it works

The 3D printer print unit sprays the model material and support material in thin layers (16/30 µm) according to the data of the 3D mathematical model. Each layer is polymerized by ultraviolet light immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used immediately after the printing process is completed.

How it works

The 3D printer print unit sprays the model material and support material in thin layers (16/30 µm) according to the data of the 3D mathematical model. Each layer is polymerized by ultraviolet light immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used immediately after the printing process is completed.

Technology Benefits

Accuracy and detail of finished products

PolyJet technology provides a high accuracy of construction in 0.02-0.085 mm for objects up to 50 mm in size. For objects larger than 50 mm, the construction accuracy varies from 0.1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used.

Large selection of materials with different properties

PolyJet grown objects have different properties depending on the material used.

Materials differ from each other in mechanical, thermal, electrical and chemical characteristics. The FullCure line of PolyJet printing media offers a choice of rigid, flexible, translucent, transparent, and certified biocompatible media.

Materials differ from each other in mechanical, thermal, electrical and chemical characteristics. The FullCure line of PolyJet printing media offers a choice of rigid, flexible, translucent, transparent, and certified biocompatible media. Soluble support material

In the process of building complex products, various cavities, overhanging structures are often present. To prevent their collapse, all voids under such elements are filled with a special material - support material. In addition, such material serves as additional insurance when printing thin walls and complex structures. FullCure705 Support is a versatile model support material that can be easily removed with water in an ObjetWaterJet flush station.

Benefits of technology

Accuracy and detail of finished products

PolyJet technology provides a high accuracy of construction in 0.02-0.085 mm for objects up to 50 mm in size. For objects larger than 50 mm, the construction accuracy varies from 0.

1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used.

1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used. Large selection of materials with different properties

PolyJet grown objects have different properties depending on the material used. Materials differ from each other in mechanical, thermal, electrical and chemical characteristics. The FullCure line of PolyJet printing media offers a choice of rigid, flexible, translucent, transparent, and certified biocompatible media.

Soluble support material

In the process of building complex products, various cavities, overhanging structures are often present. To prevent their collapse, all voids under such elements are filled with a special material - support material. In addition, such material serves as additional insurance when printing thin walls and complex structures. FullCure705 Support is a versatile model support material that can be easily removed with water in an ObjetWaterJet flush station.

Learn more

3" x 15.4" x 7.9".

3" x 15.4" x 7.9".