3D printer acceleration

How to Get the Perfect Jerk & Acceleration Setting – 3D Printerly

You’ve tried countless solutions for your bad quality prints but nothing seems to be working. You’ve now stumbled upon these magical settings called the jerk and acceleration and think it might just help out. This is definitely a possibility and it has helped many people get high quality prints.

How do I get the perfect jerk & acceleration settings? Based on trial and error it’s been found that a jerk setting of 7 for the x and y-axis and an acceleration of 700 works very well for most 3D printers to solve printing issues. This is a good baseline to start from but it could take some tweaking on your 3D printer to get the settings perfect.

This is the short answer for your jerk and acceleration settings that should get you prepared. It’s a good idea to keep reading to learn some key information about these settings such as what they actually change, what problems they solve and more.

Whether you are looking for the best jerk and acceleration settings for an Ender 3 V2 or similar 3D printer, this should be a good starting point.

I wrote an article about 8 Ways to Speed Up Your 3D Prints Without Losing Quality which you can find useful for your 3D printing journey.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

What is the Acceleration Setting?

The Acceleration setting measures how fast your print head speeds up, limited by your designated 3D printer speed in your slicer settings.

The higher the setting, the quicker the print head will get to its maximum speed, the lower the setting, the slower the print head will get to its maximum speed.

A lot of times your top speeds won’t be reached when 3D printing, especially smaller objects because there is not much distance travelled to make full use of the acceleration.

It’s very similar to a car’s acceleration, where if a car can go a maximum of 100 kph, but there are a lot of turns in your journey, you’ll find it hard to get to the maximum speed.

In the Cura slicer, they state that enabling ‘Acceleration Control’ can reduce printing time at the cost of print quality. What we can hopefully do on the other side is improve our Acceleration at the benefit of increasing print quality.

Your slicer doesn’t actually have much to do with acceleration, in so far as emitting G-code to say where the print head should go and at what speed. It’s the firmware which sets limits to speed and deciding how fast to accelerate to a given speed.

Each axis on your printer can have different speeds, acceleration and jerk settings. The X and Y axis settings are generally the same; otherwise your prints can have different features dependent on part orientation.

There are limits on how high you can set acceleration, especially when printing at angles larger than 45 degrees.

What is the Jerk Setting?

It’s quite a complex term and has different descriptions based on what firmware you are using. It’s basically an approximation value that specifies the minimum speed change that requires acceleration.

The Jerk setting measures the speed at which your print head moves from its still position. The higher the setting, the faster it will move off from a stable position, the lower the setting, the slower it will move off from a stable position.

It can also be known as the minimum speed your print head will slow down before initiating speed in a different direction. Think of it like a car driving straight, then slowing down before a turn.

If Jerk is high, your print head won’t slow down as much before making the directional change.

When the print head is told to change speed and direction in the G-code, if the difference in speed calculations is less than the specified Jerk value, it should happen ‘instantaneously’.

Higher Jerk values gives you:

- Reduced printing times

- Fewer blobs in your prints

- Increased vibrations from rapid changes in direction

- Smoother operation around corners and circles

Lower Jerk values gives you:

- Less mechanical stresses to your printer

- Smoother movements

- Better adhesion for your filament at direction changes

- Less noise from your printer

- Less lost steps as you may get with higher values

Akeric found that having a Jerk value of 10 gave the same printing time at 60mm/s speed as a Jerk value of 40. Only when he increased the printing speed past 60mm/s to around 90mm/s did the jerk value give real differences in printing times.

Only when he increased the printing speed past 60mm/s to around 90mm/s did the jerk value give real differences in printing times.

High values for Jerk settings basically mean the change of speed in each direction is too fast, which usually results in extra vibrations.

There is weight from the printer itself, as well as from the moving parts so a combination of weight and fast movement doesn’t go too well for print quality.

The negative print quality effects that you’ll see as a result of these vibrations are called ghosting or echoing. I’ve written a quick article on How to Solve Ghosting & How to Fix Banding/Ribbing which goes through similar points.

Which Problems Do Jerk & Acceleration Settings Solve?

Adjusting your acceleration and jerk settings has a whole host of issues that it solves, even things that were not known to you as an issue.

It can solve the following:

- Rough print surface

- Removing ringing from prints (curves)

- Can make your printer a lot quieter

- Eliminate the Z-wobble in prints

- Fixing the layer line skips

- Stop your printer from running too violently or shaking too much

- Many print quality issues in general

There are plenty of people who went and adjusted their acceleration and jerk settings and got some of the best print quality they’ve ever had. Sometimes you don’t even realize how good your print quality can be until you actually get it for the first time.

Sometimes you don’t even realize how good your print quality can be until you actually get it for the first time.

I’d definitely recommend trying this fix out and seeing if it works for you. The worst thing that can happen is it doesn’t work and you just change your settings back, but with some trial and error you should be able to reduce issues and increase print quality.

The video below by The 3D Print General goes into the effects Jerk & Acceleration settings have on print quality.

How Do I Get the Perfect Acceleration & Jerk Settings?

There are certain configurations which are tried and tested in the 3D printing world. This is great because it means you have to do very little testing to get the best settings for yourself.

You can use these settings as a baseline, isolate either acceleration or jerk, then increase or decrease it little by little until you get your desired quality.

Now for the settings.

For your Jerk setting you should try 7mm/s and see how it goes.

Jerk X & Y should be at 7. Acceleration for X, Y, Z should be set to 700.

You can go directly into your menu on your printer, select the control setting, then ‘motion’ you should see your acceleration and jerk settings.

- Vx – 7

- Vy – 7

- Vz – can be left alone

- Amax X – 700

- Amax Y – 700

- Amax Z – can be left alone

If you would rather do it in your slicer, Cura allows you to change these values without going into your firmware or control screen.

You’ll just have to go into Cura settings and click advanced settings, or custom settings to view your Cura jerk and acceleration values. It’s similar in PrusaSlicer, but the settings are in the “Printer Settings” tab.

It’s similar in PrusaSlicer, but the settings are in the “Printer Settings” tab.

Usually you want to do this one by one. It’s good to start off with the jerk setting.

If lowering your jerk makes things too slow, you can up your print speed somewhat to compensate. If just lowering the jerk doesn’t fix your problem, then lower the acceleration and see what difference it makes.

Some people leave the Jerk settings at 0 & have an acceleration of 500 to get good prints. It really depends on your printer and how well-tuned and maintained it is.

Binary Search Method for Getting Good Jerk & Acceleration

The binary search algorithm is commonly used by computers to search programs and it can be used in many applications such as this one here. What it does it give a reliable calibration method by using ranges and averages.

How to use the binary method:

- Establish a value that is too low (L) and one that’s too high (H)

- Work out the middle value (M) of this range: (L+H) / 2

- Try printing at your M value and see the results

- If M is too high, use M as your new H value and vice versa if too low

- Repeat this until you get your desired result

It can take some time but once you find the settings that work best for your printer, it can make the world of a difference. You’ll be able to be proud of your prints and not have weird, wavy lines and artifacts plaguing your print quality.

You’ll be able to be proud of your prints and not have weird, wavy lines and artifacts plaguing your print quality.

It’s a good idea saving them as a default profile in your slicing software. So, the next time you come to slice your next print, it will be automatically input into the settings.

I advise you to write down what the settings were before you change it so you can always change it back in case it doesn’t work. If you forgot to it isn’t a big deal because there should be a default setting to make it go back to the original settings.

Jerk & Acceleration settings do vary from printer to printer because they have different designs, weights and so on. For example, 3D Printer Wiki says to set Jerk to 8 and the Acceleration to 800 for the Wanhao Duplicator i3.

Once you’ve tuned your settings, use this Ghosting Test to analyze the levels of ghosting and whether it’s better or worse.

You want to look for ghosting of sharp edges (on the letters, dimples and corners).

If you have vibrations on your Y-axis, it will be seen on the X side of the cube. If you have vibrations on your X-axis, it will be seen on the Y side of the cube.

Slowly test and adjust to get the settings just right.

Using Arc Welder to Improve 3D Printing Curves

There’s a Cura Marketplace Plugin called Arc Welder that you can use to improve printing quality when it comes to 3D printing curves and arcs specifically. Some 3D prints will have curves to them, which when sliced, translates into a series of G-Code commands.

3D printer movements are mainly made up of G0 & G1 movements which are a series of lines, but Arc Welder introduces G2 & G3 movements which are actual curves and arcs.

Not only does it benefit printing quality, but helps to reduce print imperfections like Ghosting/Ringing in your 3D models.

Here it looks when you install the plugin and restart Cura. Simply find the setting in Special Modes or by searching for “Arc Welder” and check the box.

It brings up a few other settings that you can adjust if needed, based mainly on improving quality or firmware settings, but defaults should work just fine.

Check out the video below for more details.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools.

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish.

- Become a 3D printing pro!

A Comprehensive Guide to 3D Printer Acceleration

ADVERTISEMENT

Table of Contents

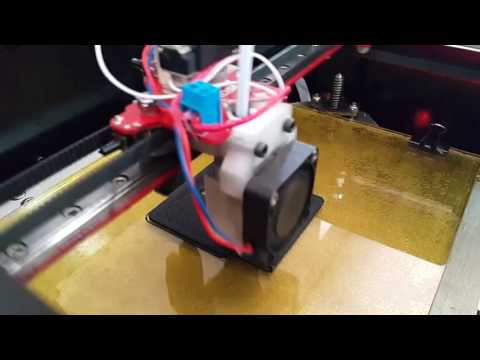

3D printer acceleration is often regarded as silly criteria that affect the print quality of a part, but it is not that silly. In fact, you might be completely unaware of the issues caused by the improper acceleration of your 3D printer.

Acceleration is one of those important firmware settings which can change the complete fate of the object that you are 3D printing. And it’s closely associated with the 3D print speed of your printer. Both of which are in turn intimately connected to the print quality.

Both of which are in turn intimately connected to the print quality.

So, let’s learn about 3D Printer acceleration. And, also find out what a perfect acceleration could do to your 3D models. So, how about starting with the details for attaining perfect acceleration. At the same time, looking at the various terms associated with it.

What are the Three Basic Terms Associated with Motion of a 3D Printer?

When it comes to the movement of any 3D printer, there are three basic terms related to it.

ADVERTISEMENT

3D Printer Speed

Speed is the easiest parameter to understand because we have experienced it in many aspects of our lives. Like driving (km/h), downloading (kB/s), etc.

Basically, if you have a 3D printer moving at 100 mm/s, it means that your printer requires 1 second to move 100 mm away from its current location.

However, the speed does not change instantaneously in the context of a 3D printer. But, it slowly gets faster until it reaches its target speed. 3. But note that, jerk is not used in the trapezoidal acceleration profile, which is actually the motion profile used in 3D printers. This also essentially means the acceleration changes abruptly.

3. But note that, jerk is not used in the trapezoidal acceleration profile, which is actually the motion profile used in 3D printers. This also essentially means the acceleration changes abruptly.

The jerk that we get to see in 3D printing has units of mm/s, which is actually the unit used for measuring speed. Actually, in 3D printing, jerk is defined as a threshold for minimum speed requiring acceleration.

For example, if you have a standard jerk value of 20 mm/s that will make any move below 20 mm/s without acceleration.

This happens often when you are building a part with an infill line very short wherein the 3D printer will vibrate extremely quickly.

What is 3D Printer Acceleration Setting?

The 3D printer acceleration settings measure how fast your printer’s print head speeds up, even after getting limited by your designated 3D printer speed in the slicer you use.

The higher these slicer settings, the quicker the print head of your printer will get to its maximum speed. Vice versa, the lower the setting, the slower the print head will get to the maximum print speed it can reach.

Vice versa, the lower the setting, the slower the print head will get to the maximum print speed it can reach.

A lot of times your printer’s top speeds won’t be reached while the 3D printing process is going on. And, this will especially happen while 3D printing smaller objects. Because while printing such objects there is not much distance traveled to make full use of the acceleration!

This can be particularly understood by taking the case of a car’s acceleration, where say the car is capable of going to a maximum of 100 kph, but there are a lot of turns in your journey, will it be able to? No, right?

The same logic applies to the print head of your 3D printer. Now the talk comes of how can you change your acceleration setting?

If you are using an open-source slicing software such as Cura, they clearly state how enabling ‘Acceleration Control’ can reduce printing time at the cost of print quality.

So, in such times, what we can hopefully do on the other side is improve the printer’s acceleration from your end and gain the benefit of increasing your part’s print quality.

No matter which slicer you are using, it doesn’t actually have much to do with acceleration, in so far as emitting G-code which will state where the print head should go and at what speed.

Actually, the player here is the firmware which sets limits to speed and decides how fast to accelerate to a given speed.

You may also note that it is possible for you to have a condition wherein each axis on your 3D printer can have different speeds, acceleration, and jerk settings. In most 3D printers, you will find that the X and Y axis settings are generally the same.

Otherwise, your 3D parts will have varying features depending on the part orientation. Also, there are limits on how high a value of acceleration you can set, especially in parts wherein the printing at angles larger than 45 degrees.

ADVERTISEMENT

What Do You Solve by Using the Correct Acceleration Settings?

Adjusting your 3D printer acceleration has a whole host of issues that it solves. In addition, this includes things that were not known to you as an issue before. Yes! It’s that surprising! It can solve the following issues:

In addition, this includes things that were not known to you as an issue before. Yes! It’s that surprising! It can solve the following issues:

- It would lessen the amount of roughness in your 3D printed part’s print surface.

- Having the perfect 3D printer acceleration would removing ringing/curves from your 3D printed part.

- It will make your 3D printer a lot quieter than before.

- The printer’s Z-axis wobbling will be eliminated which will benefit the overall quality of your printed part or a functional prototype.

- Perfect 3D printer acceleration would fix the layer line skips in your 3D printed part.

- It will stop your 3D printer from running too violently or shaking too much which can affect the quality of the object that you are about to 3D print.

- It may solve many print-quality issues in general.

There are plenty of people who hold the experience of adjusting their acceleration settings in 3D printers and get some of the best print quality they’ve ever had.

It is one of those cases wherein sometimes you don’t even realize how good your print quality can be until you actually get the things fixed for the very first time.

And hence, 3D printer acceleration settings are definitely recommended to be fixed out and then see how it works for you. And the best thing about doing this is that you know how worse it can get.

If it doesn’t work. Just change your settings back to before. And, with little trial and error, you should definitely be able to reduce 3D printing issues and increase the overall print quality.

The Conclusion

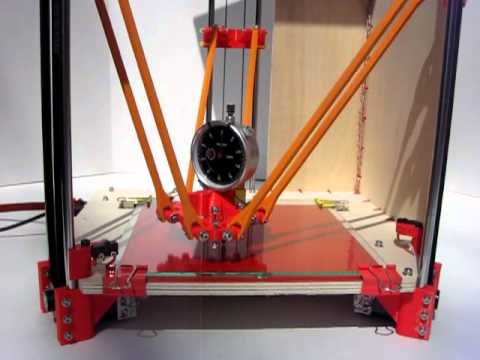

There are many factors and parts that affect the overall 3D printer acceleration of your printer. To mention a few there are hotend, extruder, motors, and printer frame.

Also, the complete arrangement of your 3D printer whether it is a Cartesian or Delta 3D printer would make a difference. The generally seen trend is that Delta 3D printers offer more speed, acceleration, and hence jerk than Cartesian 3D printers.

But having a greater acceleration is not always beneficial either. As it will increase the chances of getting jerk during turns that your 3D printer head will take while creating the geometry of part!

It is all about experimenting and finding an optimal 3D printer acceleration for your printer which can only be done by the method of trial and error.

As your experience with your 3D printer will increase, so will you be able to find the right set of settings. So, what are you waiting for? Go on and experiment with the settings and find the 3D printer acceleration value that gets you the best results.

Instructions for setting up all the mechanics of a 3D printer: from belts to speeds

The quality of the printed models directly depends on the mechanics of the printer, namely on its correct settings. Any elements of the printer wear out over time, so the printer must be set up at least once every 5-6 kg of printed filament. With the help of the short instructions described in this guide, you can quickly and easily set up the mechanics of your printer: belt tension, motor current, motor steps, acceleration, jerk and speed.

Mechanics includes

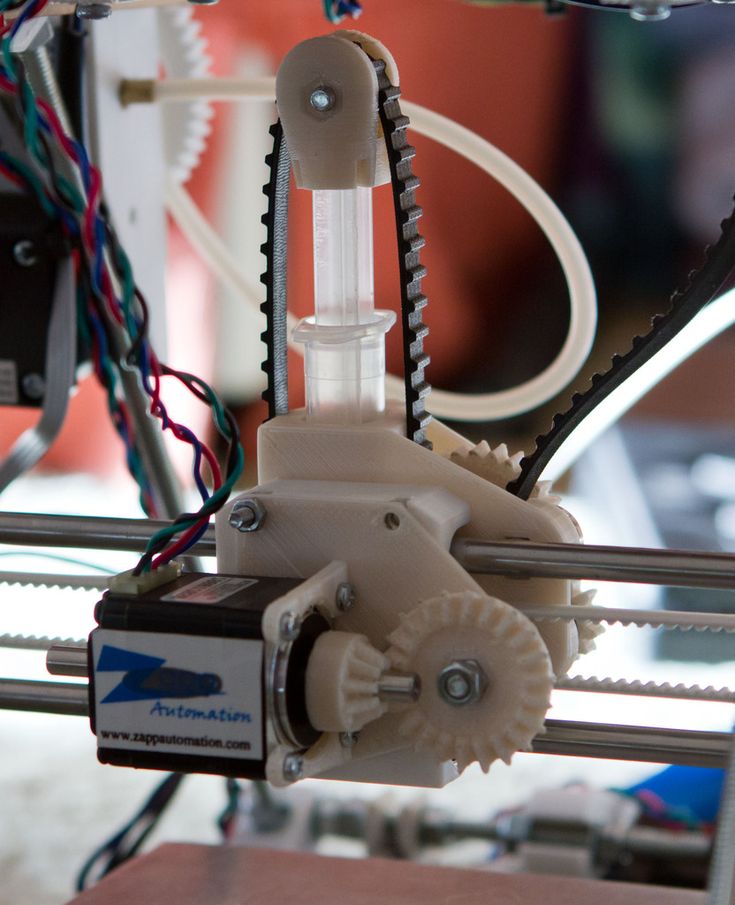

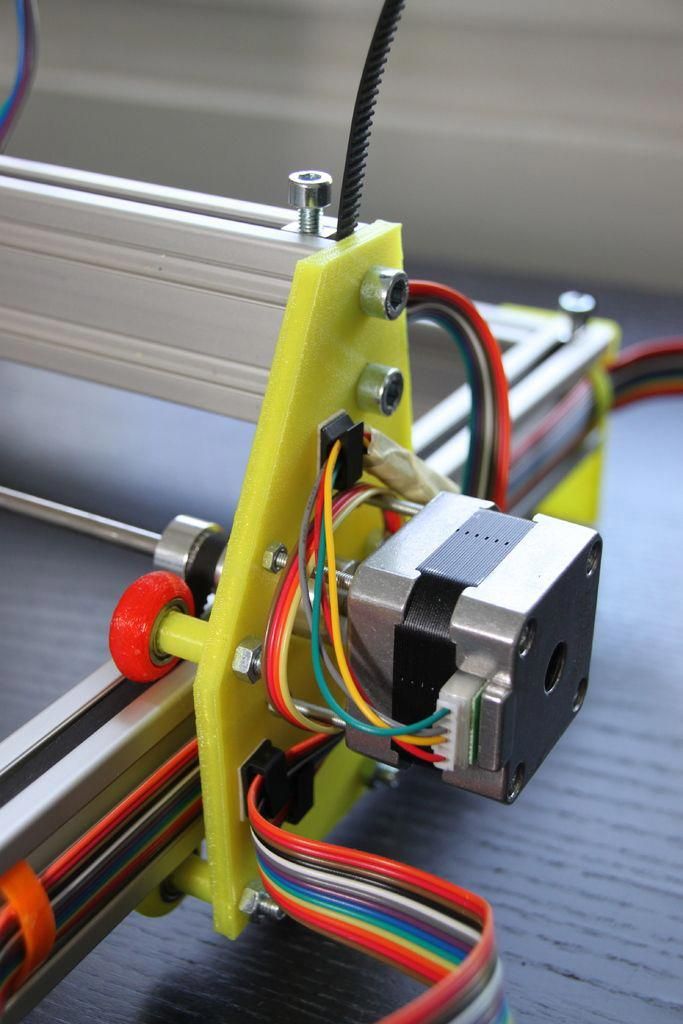

3D printers of any design always contain the same things: Axes and rails along which the elements of the printer move and motors with belts that set these elements in motion. In a classic printer design, there are at least 3 motors (one for each axis), 3 rails (one for each axis) and an electronics board that controls the motors. The latter can hardly be called part of the mechanics, but since it controls the engines, it also indirectly affects the quality of the model.

Printing defects due to mechanical problems

Before changing anything in the printer, you need to decide what exactly needs to be configured. Often defects are visible visually. Our blog has an article about most printing defects, which details the reasons for their occurrence. The following is a list of defects and what element of mechanics they are associated with:

-

Layer shifting - Belts, Motor current, Guides

-

Ringing - Guides, Speed

-

Incorrect model geometry - Guides, Motor steps, belts

As you can see, all the above problems do not interfere with the printing process itself, but the result leaves much to be desired. Sometimes mechanical errors can completely stop the printer from working. Therefore, it is better not to take the situation to extremes and, if any problems arise, immediately start checking and configuring the 3D printer.

Sometimes mechanical errors can completely stop the printer from working. Therefore, it is better not to take the situation to extremes and, if any problems arise, immediately start checking and configuring the 3D printer.

How to save settings

To fix some defects, you need to change the printer software settings. Therefore, before adjusting the mechanics, it is necessary to understand how to properly store the settings inside the printer. There are 3 ways to do this:

All settings are located in the corresponding menu of the printer

Depending on your firmware, this manual will indicate code sections for MARLIN firmware in the configuration.h file

We first enter the parameters into the printer and then store them in EEPROM - the internal memory of the microcontroller. Or paste all the necessary settings at the beginning of GCODE. To learn how to do this, read our article on working with GCODE and creating macros.

To save to EEPROM, you need to send the printer a command to change some value (which can also be inserted into the initial GCODE), and then send the M500 command (save the current settings to permanent memory). The EEPROM function must be enabled in the firmware, for this you need to remove two slashes in the line:

The EEPROM function must be enabled in the firmware, for this you need to remove two slashes in the line:

//#define EEPROM_SETTINGS

Whichever option you choose, you should be careful when using any commands. You will not be able to harm the printer in any way when changing the settings, but if you make a mistake, you will have to look for the cause of possible further problems for a long time.

Setup instructions

Now you can start setting up the printer itself. If you decide to set several parameters at once, then it is better to use the order of adjustments as in the article, since some of the settings are related to each other and if you use the wrong order, adjusting one element of the mechanics will override the settings of another element. For example, you should not adjust the motor steps before tightening the belts, as changing the length of the belts will change the "true" steps per millimeter of the motors. Also, before setting up, you must make sure that there are no backlashes in the printer frame, tighten all belts.

Belts

The first thing to start setting up the printer is the belts. They directly affect the geometry of the model and, when pulled too much, they cause a lot of problems: displacement of layers, changes in geometry, ripples. First you need to make sure the belt is intact. To do this, look at the entire belt, especially the areas where the belts bend. If the belt has outlived its usefulness, then you can see a section of the belt where the distance between the teeth has greatly increased and a metal wire (cord) is visible between them. This means that it's time to completely change the belt.

Broken belt with broken cords

If the belt is intact or you have already replaced it, then you can proceed to the next step. Depending on the design of your printer, you need to move the roller through which the belt passes. The tension should be such that the carriage or table moves effortlessly, but at the same time, when moving quickly, the belt should not slip the teeth on the motor gear. Adjust the tension of the belts on each axis of the printer using this method.

Adjust the tension of the belts on each axis of the printer using this method.

Tip: if your printer came with a belt tensioner in the form of a spring attached to the belt itself, remove it. Due to the flexibility of this tensioner, printing defects will occur, such as protruding corners on the model. It is better to adjust the belt without using this tensioner.

Belt tensioner

Current motors

As we know from the school physics course, the power of the engine depends on the voltage and current strength. Since the voltage on all printer electronics is the same everywhere, the only thing that can be changed is the current on the motor. More precisely, it should be said the maximum current that the driver will supply to the motors. To change this limit, you need to climb inside the case and find the printer board. On it you will see the printer driver. We are interested in a small potentiometer on the driver itself (in the picture below it is indicated as a tuning resistor).

Potentiometer location example on driver

For adjustment, you will need a voltmeter and a small Phillips or flathead screwdriver. Before proceeding further, it is necessary to calculate the maximum current supplied to the motors. Different formulas are used for different drivers, the most popular ones will be listed in the table below:

| Driver name | Formula | Explanations |

| A4988 | Vref = Imax * 1.25 for R100 | To understand which formula to use, you need to find a resistor with the signature R100 or R050 on the driver. They are located next to the driver chip. |

| DRV8825 | Vref = Imax / 2 | |

| LV8729 | Vref = Imax / 2 | |

| TMC2208 TMC2100 TMC2130 | Vref = Imax * 1. | One formula for all drivers |

The value of the maximum current (Imax) depends on the motor controlled by the driver. This can be found in the engine specification or on the sticker on it. The following are the currents for the most popular motor models:

17HS4401 - current 1.7 A

17HS8401 - current 1.8 A

17HS4402 - current 1.3 A

Substituting the value into the formula, we get the Vref value for the maximum current supplied to the motor. But at this value, the engine will get very hot, so the resulting Vref value must be multiplied by 0.7. For example, for a motor with a maximum current of 1.5 A and a TMC 2208 driver:

Vref=1.5*1.41*0.7=1.48V

Now the resulting value can be used when configuring on the printer itself. To do this, disconnect the wires going to the motors, turn on the printer and place one voltmeter probe in the center of the trimmer, and the second probe to the negative terminal on the power supply (you can also use the negative terminal on the printer board and the contact on the driver, labeled as GND). You will see some value on the voltmeter screen. Turn the trimmer clockwise to decrease the Vref value and counterclockwise to increase it.

You will see some value on the voltmeter screen. Turn the trimmer clockwise to decrease the Vref value and counterclockwise to increase it.

Attention: you should not specify a Vref value higher than the maximum calculated for your engine! Otherwise, the engine will soon break down!

Once you have adjusted the value on the drivers, you can turn off the power to the printer, connect the motor wires, and put the case back together. This completes the driver setup.

Motor steps

When setting up motor steps, you will need a ruler. For convenience, you can use the program Repetier-Host. The adjustment for each of the three axes occurs according to the same algorithm:

-

Set the caret to zero coordinates (Autohome or G28)

-

Move the carriage some distance

-

We measure how far the carriage has traveled

-

We calculate the correct number of steps per millimeter using the formula:

True steps per millimeter = current steps per millimeter * reported distance / distance traveled

For example, if the printer was set to 100 steps/mm, we tell the printer to move 80mm and the printer travels 87. 5mm. Then the correct steps per millimeter would be 100 * 80 / 87.5 = 91.42 steps/mm. For the convenience of measurements, you can fix a ruler on the table, and a thin object, such as a needle or pin, on the carriage. Then it will be possible to accurately measure the distance traveled. The extruder uses a partially different algorithm to measure distance:

5mm. Then the correct steps per millimeter would be 100 * 80 / 87.5 = 91.42 steps/mm. For the convenience of measurements, you can fix a ruler on the table, and a thin object, such as a needle or pin, on the carriage. Then it will be possible to accurately measure the distance traveled. The extruder uses a partially different algorithm to measure distance:

-

Inserting plastic into the extruder

-

Cut it right at the outlet

-

We give the printer a command to stretch the plastic a certain distance (at least 100 millimeters)

-

Cutting plastic again

-

We measure the length of the resulting piece of plastic

-

We use the formula from the previous algorithm

Next, the settings data must be inserted into the firmware in the line:

#define DEFAULT_AXIS_STEPS_PER_UNIT {X,Y,Z,E0}

X,Y,Z and E0 should be replaced by the steps per millimeter for each of the axes, respectively. Otherwise, you need to insert this line into the initial GCODE:

Otherwise, you need to insert this line into the initial GCODE:

M92 Ennn Xnnn Ynnn Znnn

Instead of nnn in each of the parameters, you must substitute the steps per millimeter for each axis. If you want to adjust the steps only for not all axes, then you can remove unnecessary parameters.

Acceleration

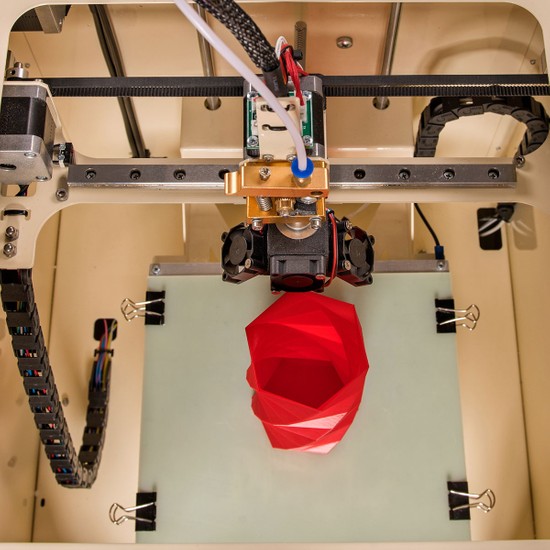

This parameter is responsible for the rate of change of speed. That is, how fast the printer will change its speed. This affects the nature of the movement of the hot end relative to the table. If the acceleration is too small, then the printer will print slowly, if it is too large, then the outer surface of the model will have visual defects: fading waves will be visible near each of the corners, as in the picture below.

To set up acceleration, you need to follow simple steps:

-

Cut a model of a standard test cube with a wall thickness equal to one nozzle diameter, without filling and top layers, bottom 2-3 layers;

-

Open GCODE file in notepad;

-

Find the G28 command at the very beginning and insert the line data after it:

M201 X5000 Y5000

M204 P500 T500

-

Save the changes, print the model according to the received GCODE and note at what parameters P and T it was printed;

-

Open the same GCODE file and change the P and T values on the second line, adding 500 to each;

-

Repeat steps 4-5 at least 3 times;

As a result, you will get several test cubes, some of which will show waves at the corners. Choose the cube that is printed with the highest P and T parameters, but that no waves can be seen on it. The number in parameter P will be the desired acceleration value. To save this value, you need to find 2 lines in the firmware:

Choose the cube that is printed with the highest P and T parameters, but that no waves can be seen on it. The number in parameter P will be the desired acceleration value. To save this value, you need to find 2 lines in the firmware:

#define DEFAULT_MAX_ACCELERATION {X,Y,Z,E0}

#define DEFAULT_ACCELERATION {nnn}

Instead of X and Y, you should put an acceleration twice as high as found earlier. And instead of nnn, you need to put the acceleration value found earlier. Otherwise, you need to insert a line in the initial GCODE:

M204 Pnnn Tnnn

In the parameters P and T, you need to put the value of the found acceleration. After that, the acceleration setting can be considered complete.

Jerk

A jerk indicates the speed with which to start accelerating. It affects the model in a similar way as acceleration: it creates ripples around the corners of the model. But it also increases the protrusion of the corners if the jerk is too small. The jerk setting is also similar to the acceleration setting:

The jerk setting is also similar to the acceleration setting:

-

Cut a model of a standard test cube with a wall thickness equal to one nozzle diameter, without filling and top layers, bottom 2-3 layers.

-

Open GCODE file in notepad

-

Find the G28 command at the very beginning and insert the line data after it:

M205 X5 Y5

-

Save the changes, print the model according to the received GCODE and note at what X and Y parameters it was printed

-

Open the same GCODE file and change the X and Y values on the second line, adding 2 to each

-

Repeat steps 4-5 at least 3 times

As a result, you will get several cubes. Find a non-rippled cube printed at the highest X and Y settings. This will be the jerk value for your printer. To save them, you need to find the line in the firmware:

#define DEFAULT_XJERKnnn

#define DEFAULT_YJERKnnn

It is necessary to substitute the jerk values for the X and Y axes, respectively. Otherwise, you need to substitute the command in the starting GCODE:

Otherwise, you need to substitute the command in the starting GCODE:

M205

Instead of nnn, you need to substitute the jerk value found earlier. This completes the jerk setting.

Speed

In fact, there are many different speed parameters, the values \u200b\u200bof which vary greatly. Let's take a look at the main ones:

This parameter is responsible for moving the nozzle without extruding plastic. The value is in the range from 80 to 120 mm/s. Limited only by the maximum speed at which the motors can rotate. Does not affect the model

This speed is important because it indirectly affects the adhesion of the model to the table. Usually lies between 15 and 30 mm/s

-Print speed of inner walls

Usually set to about 60 mm/s, it only affects the strength of the model. Depends on the maximum amount of plastic that the extruder can push through the nozzle

-Speed of printing outer walls

Usually about half the printing speed of the inner walls (30 mm / s). It affects not only the strength of the model, but also the appearance: the lower this speed, the smoother the walls will be.

It affects not only the strength of the model, but also the appearance: the lower this speed, the smoother the walls will be.

The standard value is 80 mm/s, it only affects the strength of the model

Usually set from 20 to 40 mm/s, the quality of the upper layer of the model depends on it: the lower the value, the smoother the cover.

All of the above parameters are selected experimentally. Usually there is a simple rule: higher speed - lower quality. Therefore, do not try to find the ideal value for all situations. It is better to find values for fast printing, quality printing, and an average that will be used for most models.

Check settings

The last step in setting any of the above parameters will be to check the result. If you have written parameters in firmware or saved them in EEPROM, you can use the M503 command. It will display all printer settings on the computer. To test the settings in practice, you can print several test models:

Classic Benchy

Simple calibration cube

Calibration cat

On each of the above models, defects will be clearly visible, if they still remain after the mechanics are adjusted.

Is it possible to print 10 times faster with a 3D printer? Tips for increasing the speed of your

3D printer3DPrintStory 3D printing process Is it possible to print 10 times faster on a 3D printer? Tips for Increasing 3D Printer Speed

From time to time, all 3D printing enthusiasts think about increasing the speed of a 3D printer and creating figures and models in a matter of hours, not days. Wouldn't it be great if you could 3D print 10 times faster than you can now? This article provides tips on how to increase the speed of your 3D printer without losing quality.

Before we take a closer look at the secrets that will help you print faster and share ideas for fast 3D printing, it's worth a little imagination about the incredible future. Maybe one day you will buy an affordable and fast device that turns STL files into detailed figures and models from your favorite video games and movies in just a couple of hours or even faster... And this one will really happen. But! Now let's put aside the fantasies and return to the current reality. The reality is that the following tips will actually help you speed up your 3D printing, so let's get started.

Maybe one day you will buy an affordable and fast device that turns STL files into detailed figures and models from your favorite video games and movies in just a couple of hours or even faster... And this one will really happen. But! Now let's put aside the fantasies and return to the current reality. The reality is that the following tips will actually help you speed up your 3D printing, so let's get started.

There are great guys - John Hart and Jamison Goh from MIT - the real geniuses of modernizing technology. According to MIT news, these two professors, along with their colleagues, have been working to increase the speed of a 3D printer and have developed an innovative model called Fast FFF.

The name Fast FFF stands for "Production of Fast Fibers". This model is capable of stacking material 10 times faster than any existing desktop 3D printer. In addition, the print head with fantastic 3D printing speed can work with renewable materials.

As the engineers noted, in order to increase the speed of 3D printing, three main factors had to be taken into account:

- The force applied by the print head when pushing the 3D printing material through the nozzle;

- The time required to heat the material so that it melts and can flow through the nozzle;

- Print head movement speed.

All of these things have been improved in the Fast FFF prototype. As a result, it was possible to 3D print two simple eyeglass frames in less than 4 minutes and a complex bevel gear in about 10 minutes. These models were printed with a 0.2mm layer and proved to be strong and durable.

Fast FFF prototype 3D printer cost about $15,000. This is a good price compared to expensive commercial 3D printers that cost over $100,000 and are about three times slower. But if you compare the price with an affordable home 3D printer under $300 or $500, the Fast FFF is clearly too expensive, even though it can 3D print 10 times faster than a regular FDM 3D printer. And it's currently unclear if an affordable ultra-fast 3D printer for home use will hit the market...

While you can't get your home 3D printer to 3D print 10x faster than it is now, or beat the innovative Fast FFF machine, there are secrets :).

Most of the tips that can help improve your 3D printing speed can also affect the quality of your figurine or model. However, sometimes it's worth it.

However, sometimes it's worth it.

Adjust 3D print speed

Settings is the first thing you can try if you want to increase your 3D print speed. Every hobbyist likes to work with certain slicing software. It is worth exploring all the possibilities and changing the settings to suit your needs.

The ability to control the speed of the print head is amazing. Sometimes this does not negatively affect the quality of a complex 3D printed model. And when you do something simple, you can significantly increase the speed without losing quality.

Replace nozzle

Sometimes you don't care about 3D printing accuracy. In this case, a larger nozzle may suffice. For example, you can change the nozzle on your 3D printer from 0.4mm to 0.8mm. Or you can choose even 1.0mm print head.

Much depends on your current nozzle size. Standard printheads are 0.2mm and 0.4mm. But choosing a larger size can save time and speed up 3D printing.

Increase layer height

If you increase the speed of the 3D printer by changing the nozzle to a larger diameter, you will also have to increase the layer height of the 3D print. The maximum height you can select is approximately 75% of the current nozzle diameter.

The maximum height you can select is approximately 75% of the current nozzle diameter.

So if you change the nozzle from 0.4 mm to 0.8 mm, you can increase the layer height to 0.6 mm. These settings will affect the quality of your 3D model and cause you to lose a lot of impressive detail because the layers will be thinner and the speed will be much faster. Keep this in mind when experimenting with nozzle size and layer height.

Reduce wall thickness of 3D models

100% infill models and figurines take longer to print, but are durable when finished. You've probably guessed how to make 3D print faster by playing with wall thickness and reducing infill. But in this case, you need to be careful, because the thin walls of the 3D model and less infill can lead to poor quality 3D printing.

If you have a resin based 3D printer, you can save resin and increase 3D printing speed by working with the appropriate DLP/SLA Eco version of STL files offered by Gambody - Premium 3D Printing. The Eco version ensures that your walls are thick enough to make your 3D model strong, detailed and of the highest quality.

The Eco version ensures that your walls are thick enough to make your 3D model strong, detailed and of the highest quality.

Print two 3D models at the same time

Another way to speed up your 3D printer without sacrificing product quality is to work on two projects at the same time. This is only possible if both models or figurines are small and can fit on the same 3D printer table without interfering with each other.

This option can be configured in the slicing software. Select centering and place both models for 3D printing on the work surface. The main disadvantage of this method is that both models will be printed from the same material, but the final print speed will be significantly increased.

Do not use supports

When a complex model requires a lot of support material to 3D print, the print time will increase. This way, whether you choose to do projects with fewer supports or learn how to 3D print without supports, you can speed up and print the prototypes and figures you need faster.

Change the infill pattern of a 3D model

If you don't want to adjust the infill density, but still want to improve 3D printing speed, try adjusting the infill pattern in the slicer settings. People work with different patterns, but the most popular version for speed optimization is "lines" or "straight lines".

Filling in a line pattern is very simple. Your 3D printer will make fewer moves when creating a straight infill figurine and can reduce print time by up to 20%-25%. But the models will not be as durable as those with a triangular or mesh pattern.

Adjust the jerk and acceleration settings

After making changes to the slicing software in the hope of increasing the speed of 3D printing, you can also try changing the jerk settings. They are responsible for how fast the print head can move. Of course, the print head must move smoothly, because increasing the speed can negatively affect the quality of the 3D print and even lead to problems with the mechanical part of the 3D printer.

There are also acceleration settings that need to be adjusted. They control the speed at which the print head reaches its maximum speed. It's worth playing around with these settings to find a balance between the jerk and acceleration settings to slightly increase print speed without affecting the quality of the 3D model or 3D printer.

For example, if you work with the jerk settings at 10 (low) and select a speed of 60mm/sec, you won't save much time in 3D printing, but the print quality will be ok. Increasing speed to 120mm/s and jerk to 40 will cut 3D printing time by 25%! However, the quality of the printed 3D model will also be greatly reduced.

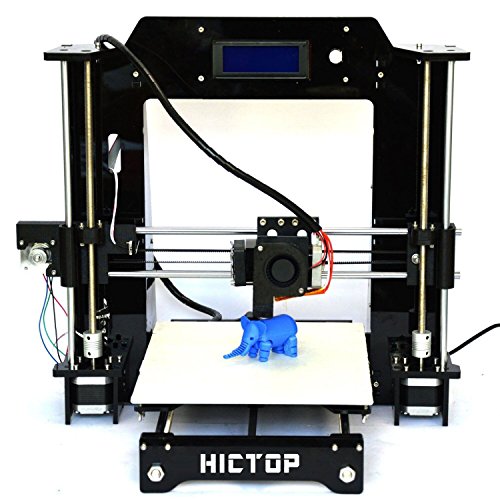

Replace 3D printer

If you are not satisfied with your current 3D print speed capabilities, you can always look for another 3D printer with higher speed. However, such a device can be expensive. Most printers designed for home use are not as fast as industrial 3D printers.

For example, the cheapest FDM printers can cost as little as $300 or even $200, and they typically print at 60mm/sec.

41

41