Aerosud 3d printer

South Africa's Giant Aeroswift 3D Printer Gearing Up for Commercial Production - 3DPrint.com

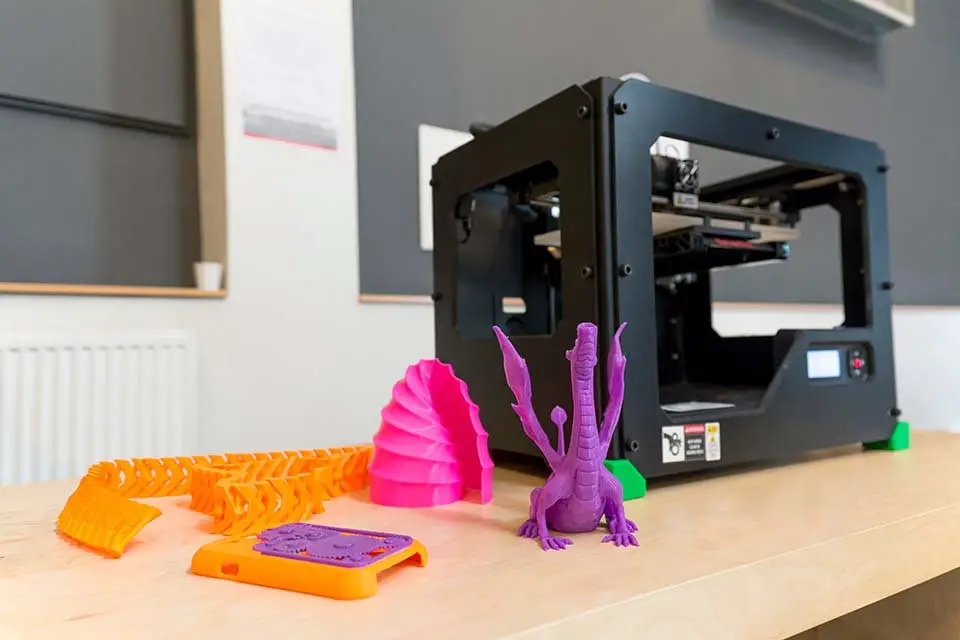

3D printing technology has been on the rise in South Africa recently, and while the country isn’t one of the most commonly talked-about in the industry, South Africa has been working on some advanced 3D printing applications for years. In 2011, a government-backed project called Aeroswift was launched in collaboration between aviation manufacturing solutions provider Aerosud and the South African Council for Scientific and Industrial Research (CSIR). Funded by the Department of Science and Technology, the project’s goal is to build the world’s largest and fastest additive manufacturing system that can 3D print titanium aircraft parts from powder.

Right now, the largest metal additive manufacturing system on the market is the Xline 2000R from Concept Laser, a massive machine of which there are only five models in the world. With a build volume of 800 x 400 x 500 mm, the Xline 2000R dwarfs all other metal printers, but waiting quietly in the wings is the Aeroswift printer, with a build volume of 2000 x 600 x 600 mm.

[Image: Business Day]

Last year, the Aeroswift team showed off three titanium parts printed by the machine: a throttle lever, a condition lever grip, and a fuel tank pylon bracket. According to Hardus Greyling of CSIR, who is working as Aeroswift’s contract coordinator, the printer has shown itself in proof of concept trials to print up to 10 times faster than other commercially available laser melting machines.

“Our machine is unique and the only one in the world,” he said. “We have developed new technologies and patents which allows us to upscale the additive process to go significantly faster and significantly larger than other systems.”

Now Aerosud and CSIR are gearing up for commercial production and are in talks with Boeing and Airbus about using 3D printed titanium parts in their aircraft, significantly reducing weight and lowering costs. Airbus already sources parts for their A400M military transport aircraft from South Africa, and is currently offering consulting and advice to Airswift in the interest of ensuring commercial success and creating jobs in South Africa, where the unemployment rate is currently at 25 percent.

“How best to commercialise the process is a discussion we are currently having with the Aeroswift partners and relevant government agencies,” said Simon Ward, Airbus’ vice president for international cooperation in Toulouse.

South Africa is in a good place, literally, to succeed in such an endeavor as the country ranks fourth in world titanium reserves, after China, Australia and India, according to the US Geological Survey. The Aeroswift team is planning to commence test flights with the first parts produced by the machine this year, with the goal of commercial application by 2019.

[Image: CSIR]

3D printing industry expert Terry Wohlers of Wohlers and Associates said he initially had his doubts about such an ambitious project, but after seeing the stage Aeroswift is at right now, he’s impressed.

“It looks like the people at Aerosud and CSIR are on track and making very good progress toward carving out a slice of what is set to become a 3D printing market valued at tens of billions of dollars,” Wholers explained to Reuters.

The Aeroswift project is poised to become a huge 3D printing news story as the team gets closer to marketing the technology, so we’ll be keeping a close eye on it as it develops further. We’ll keep you updated! Discuss in the Aeroswift forum at 3DPB.com.

[Source: Reuters]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed aircraft • 3D printed titanium components • 3d printing south africa • Aerosud • Aerosud ITC • Aeroswift • airbus • boeing • Council for Scientific and Industrial Research • CSIR • Project Aeroswift • south africa • titanium 3d printing • titanium 3D printing aircraft parts

Please enable JavaScript to view the comments powered by Disqus.

Aerosud — 3D Printing Business Directory

Own This Company?

Contact Details

| Name | Aerosud |

| ZIP code | 0045 |

| Full Address | South Africa, 520 Van Ryneveld Avenue Centurion, Pretoria |

| Phone | +27 (0) 12 662 5000 |

| Fax | +27 (0) 12 662 5001 |

| Website | www. aerosud.co.za/ aerosud.co.za/ |

| [email protected] |

Message Us

Share This Listing

Aerosud Innovation & Technology Centre (Aerosud ITC) has for some years now been involved in the building of the world’s largest and fastest Additive Manufacturing (AM) system that can print Titanium parts from powder. The project, named Aeroswift, is a collaborative project between Aerosud ITC and the CSIR National Laser Centre and is being funded by the Department of Science and Technology.

The objective of Aeroswift is to design and construct a high speed, large area, laser-based additive manufacturing platform. The system is unique in the world and will shift the boundaries of additive manufacturing technology to include large components and to build at high forming speeds. The technology will enable the manufacturing of large titanium aerospace parts directly from powder.

The Aeroswift technology, developed over the last number of years, started producing its first test parts in 2016. The technology is delivering on expectations of producing high quality material at improved production rates. The first titanium parts produced on the Aeroswift machine will undergo flight testing in 2017 on the South African developed aircraft, AHRLAC www.ahrlac.com.

Aerosud Aviation is actively involved in this exciting new technology and has been working at establishing the capability to design for additive manufacturing. The process under development is defined by a design cycle process which incorporates 6 key tasks:

CAD

Optimization

Internal features and Surfacing

Manufacturability review

Convert back to solid

Finite Element Modeling

The process was benchmarked against a technology demonstrator project, the CFRTP rudder, where two hinge fittings were designed and manufactured by additive manufacturing in titanium. The project yielded two fittings that were designed by the AM process. Key features of the Aerosud AM design capabilities are:

Key features of the Aerosud AM design capabilities are:

Part count reduction: multi part assemblies reducing to single parts

Structural optimization and validation

Prismatic design concepts: Optimized weight to ratio components that are post machined to desired tolerance and finishing with minimal material wastage.

Biomimetic design concepts: mimics natural occurring structural aspects, efficient strength to weight ratios are attained.

Manufacturability validation on both printability and machinability validation of the design concepts.

Conversion of the engineering data back to solid geometry capability

Volumetrically optimized design conceptualization

Original design optimisation conceptualization

Autodesk Ember 3D Printer Discontinuation, Victoria Hand 3D Printed Prostheses in Cambodia and New South African Industrial 3D Printer

News

In this issue, we'll cover the discontinuation of Autodesk Ember desktop DLP printers, the 3D printed Victoria Hand for mine victims, and a new industrial 3D printer being developed in South Africa.

Autodesk Stops Production of Ember 3D Printers

Autodesk has announced its intention to stop production of Ember desktop DLP printers, developed in 2014 and released to the market a year later. Ember was originally created as an open system, so all drawings and other developments will remain available to everyone. Theoretically, you can even build your own device: as noted by Autodesk, the design of the prototype consisted almost entirely of 3D printed parts. From the developer's point of view, this project was just a successful experiment, now completed.

“When we launched Ember printers in 2014, our goal was to advance the industry by demonstrating the power of an open system—software, hardware, and supplies developed in a single project. We've inspired new companies to develop new, never-before-seen materials for stereolithography. We have worked with many of you on new, efficient web 3D printing processes. We have demonstrated the positive effect of the network model on print speed and sub-pixel resolution capability. We hope that all these developments will be useful to you in your further work to improve DLP printing technologies,” commented support engineer Owen Smithiman in a message to users.

We hope that all these developments will be useful to you in your further work to improve DLP printing technologies,” commented support engineer Owen Smithiman in a message to users.

Victoria Hand 3D printed prostheses in Cambodia

ARC Hub PNH, the first and so far only 3D printing studio in Cambodia, has joined forces with Canada's Victoria Hand project to produce affordable 3D printed prostheses. The company's first patient was Boon Wibol, 51, who lost his arm in a mine explosion.

The studio has already produced more than twenty artificial arms, all of which are intended for people injured in the many forgotten and uncleared minefields. Cambodia occupies one of the leading places in the world in terms of the number of mine explosions: every year, up to forty thousand citizens of this country undergo amputation of damaged limbs. The Victoria Hand project is a kind of analogue of the Russian company Motorika, using the work of Victoria University professor Nikolai Dechev.

South Africa develops metal 3D printing technology

South African state corporation IDC has invested $1.2 million in a domestic start-up Metal Heart, which is developing a 3D printer for printing metal products. The industrial partner of the startup is a large foundry from Gauteng, which needs equipment for additive manufacturing tooling.

This is not the first South African project for industrial additive technologies: a month ago it became known that the development of the world's largest 3D printer using selective laser metal powder deposition (SLM) technology by the South African company Aerosud was announced a month ago, and a pilot plant is already being tested. Interest in the large-format printer was shown by the Airbus concern, which orders components for the A400 transport aircraft in South Africa.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru.

ru.

Follow author

Follow

Don't want

1

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

Startup NewStep of the North-Western Nanocenter has developed and patented the first device in Russia to...

Read more

four

Subscribe to the author

Subscribe

Don't want

Hello everyone!

82

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci. ..

..

Read more

South Africa tests the world's largest powder alloy 3D printer

News

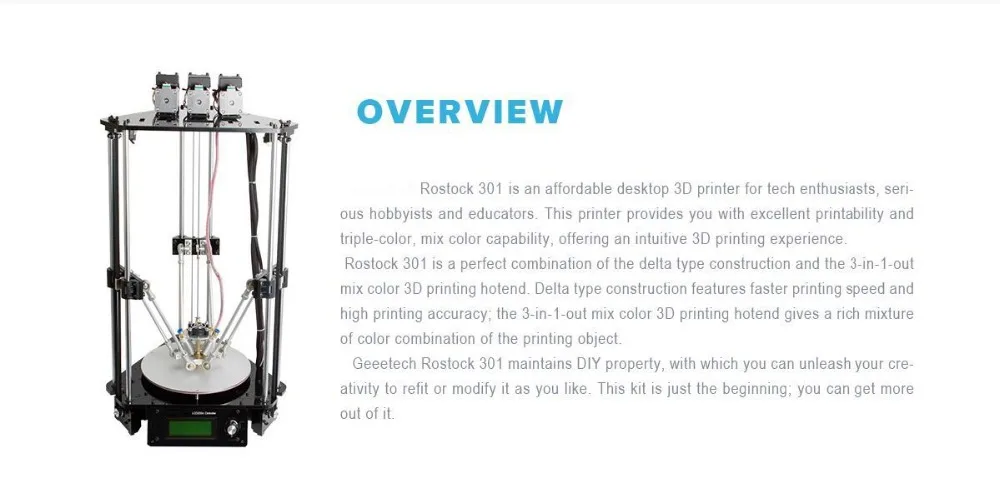

South African engineers are developing the world's largest 3D printer for printing using selective laser metal powder deposition (SLM).

The Aeroswift large-format industrial 3D printer project has been carried out by the Aerosud Aerospace Innovation Center with the support of the Council for Scientific and Industrial Research (CSIR) of South Africa since 2011.

The size of the construction area of the new printer reaches 2000x600x600 mm against the current record holder X-Line 2000R manufactured by Concept Laser, which is capable of producing 800x500x400 mm parts and exists only in five copies. In addition, the new installation is characterized by increased productivity, according to the developers, exceeding the performance of the closest analogues by about ten times. The main direction of the project is the printing of aerospace components from titanium alloys. “Our installation is unique, one of a kind. We have developed new proprietary technologies that allow additive manufacturing to scale up and speed up significantly compared to other systems,” says SCIR coordinator Hardus Grayling.

“Our installation is unique, one of a kind. We have developed new proprietary technologies that allow additive manufacturing to scale up and speed up significantly compared to other systems,” says SCIR coordinator Hardus Grayling.

Last year, the developers demonstrated the first 3D printed parts produced on a pilot plant - two control sticks for the cockpit and a bracket for attaching an external fuel tank. The greatest interest in the development of South African engineers was shown by the Airbus concern, which is currently ordering components for the assembly of A400 military transport aircraft in South Africa. “As for the best approach to commercialize the process, we are in discussions with Aeroswift partners and relevant government agencies,” explains Simon Ward, Airbus group vice president for international cooperation. In addition to Airbus, negotiations are underway with the Boeing Corporation.

South Africa's interest in 3D printing with titanium is not accidental, because here are the fourth largest deposits of raw materials, and the country's economy requires a serious push in the field of high-tech production against the backdrop of high unemployment, reaching 25%. The first flight tests using parts printed on the Aeroswift 3D printer are scheduled for this year, and it is planned to bring the project to the commercial market in a couple of years.

The first flight tests using parts printed on the Aeroswift 3D printer are scheduled for this year, and it is planned to bring the project to the commercial market in a couple of years.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Subscribe to the author

Subscribe

Don't want

4

Article comments

More interesting articles

5

Follow author

Follow

Don't want

Compared to traditional casting, 3D printed sand casting technology has a number of advantages...

Read more

5

Subscribe to the author

Subscribe

Don't want

Anodizing is a process aimed at creating protective oxide layers on the surfaces of products.