Additive 3d printer

Industrial Additive Manufacturing Platform | Markforged

The Digital Forge Platform

Our smart platform makes it easy to solve tough manufacturing problems.

Precision machines that consistently improve.

See all printers

Metals. Continuous fiber. Composites. All at your command.

See all materials

Software that dovetails into your workflow.

Learn more

Turnkey Simplicity

The Digital Forge is purpose-built to integrate quickly and seamlessly into your manufacturing ecosystem.

Robust Parts

Print repeatable, production-quality parts using materials curated for durability and strength.

Perpetual ROI

See returns in weeks, not years. Keep increasing your bottom line with consistently improving machines and streamlined operations.

Unlocked Potential

Transform your supply chain, unleash workforce creativity, and create a culture of innovation.

News & Insights

Resources

-

Learn Blog

Additive Manufacturing in 2022: Why Additive, and Why Now?

Read our new white paper to learn how additive manufacturing has grown in recent years, what today's 3D printers are capable of, and how 3D printing is solving a new set of problems.

-

Learn Blog News & Events

Introducing Simulation from Markforged

With Simulation, you can now virtually test the strength and stiffness of your parts right from Eiger.

Validate your part’s performance before you hit print.

Validate your part’s performance before you hit print. -

Learn Blog

5 Supply Chain Makeovers Powered by 3D Printing

Learn how 5 organizations are using 3D printing to solve supply chain issues.

-

News & Events

Markforged to Expand into Mass Production of End-Use Metal Parts Through Digital Metal Acquisition

-

Learn Blog

What is Additive Manufacturing? Understanding the Technology and its Impact

Your 101 guide to understanding the current landscape of additive manufacturing from the ground up.

-

Learn Blog

Why Integrate Factory Systems With 3D Printing Software?

We all have software systems that drive our day to day operations on the shop floor. What problems would it solve to integrate yours with 3D printing software?

-

Learn Blog

What are the Benefits of Adopting Metal 3D Printing? Business Side and Technical Benefits

Metal 3D printing correctly can greatly improve business efficiency and agility — whether through eliminating the need for detail drawings and machine programming, or drastically shortening lead times that bog down product development processes.

Learn about the full range of business and technical benefits.

Learn about the full range of business and technical benefits.

We work with

Talk to an expert Request a demo Try the softwareLet’s get started.

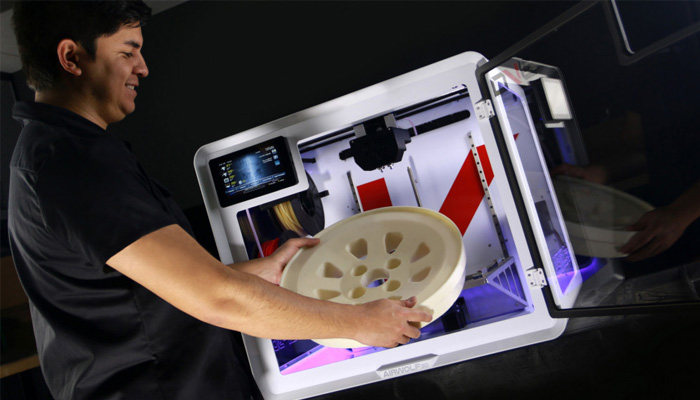

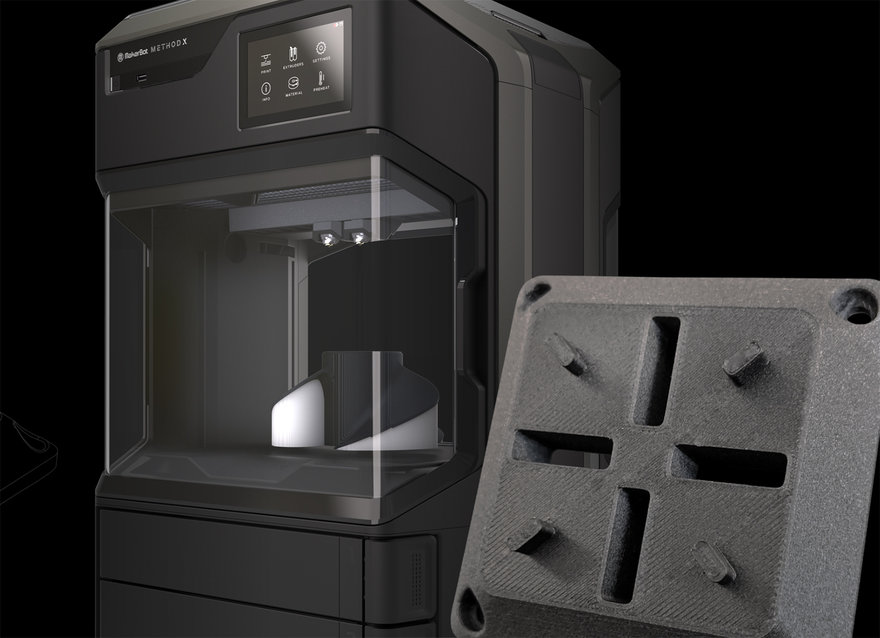

Carbon Fiber Composite 3D Printer: Markforged Mark Two

Flagship Continuous Fiber Composite 3D Printer, built to revolutionize your manufacturing operation.

Request a Quote

A leading way to make aluminum-strength parts on your desktop — the Mark Two carbon fiber composite 3D printer enables engineers to generate massive value for their business.

Carbon Fiber Strength

Print Continuous Carbon Fiber reinforced parts on your desktop – stiff, strong, extremely durable, and capable of replacing machined aluminum.

Built to Last

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

Precise and Beautiful Parts

Print precise parts with best-in-class surface finish thanks to Onyx, Markforged’s extremely versatile micro carbon fiber filled nylon material.

Specs

Precision-built so you can 3D print precise parts.

Physical Dimensions

| Width | 584 mm |

| Depth | 330 mm |

| Height | 355 mm |

| Weight | 16 kg / 35 lbs |

Build Volume

| Width | 320 mm |

| Depth | 132 mm |

| Height | 154 mm |

Printer primary Specs

- Printing Process

- Continuous Fiber Reinforcement (CFR)

- Z Layer Resolution

- 100 μm - 200 μm

- Printing Media

- Composite Base Filaments, Continuous Fibers

- Internal Part Geometry

- Closed Cell Infill with Continuous Fiber Reinforcement

- Print Bed

- Precision Ground Composite

Materials

Compatible Materials

System Details

About the Mark TwoThe Mark Two is the award winning professional carbon fiber composite 3D printer – built around the Continuous Fiber Reinforcement (CFR) process to reliably produce strong parts for you. It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Mark Two to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. The machine is built to be easy to operate and maintain — from easy-to-reach wear components (like nozzles and feed tubes) to usability focused features like the print bed, which can be removed and replaced with 10 μm repeatability.

It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Mark Two to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. The machine is built to be easy to operate and maintain — from easy-to-reach wear components (like nozzles and feed tubes) to usability focused features like the print bed, which can be removed and replaced with 10 μm repeatability.

In addition to more common FFF features, the Mark Two has a 2nd-generation fiber reinforcement system that enables you to lay down continuous fiber into parts. Markforged composite printers are capable of printing continuous fiber reinforced parts, which can be as strong as machined aluminum.

Download Datasheet

Materials

Print beautiful Onyx parts reinforced with Markforged's full range of Continuous Fibers.

What is additive technologies? The most important thing about 3D printing

Basics of 3D

Author: Semyon Popadyuk

Author: Semyon Popadyuk

What is additive manufacturing | Processes | 3D printing technologies | Consumables | Applications | Additive manufacturing in Russia

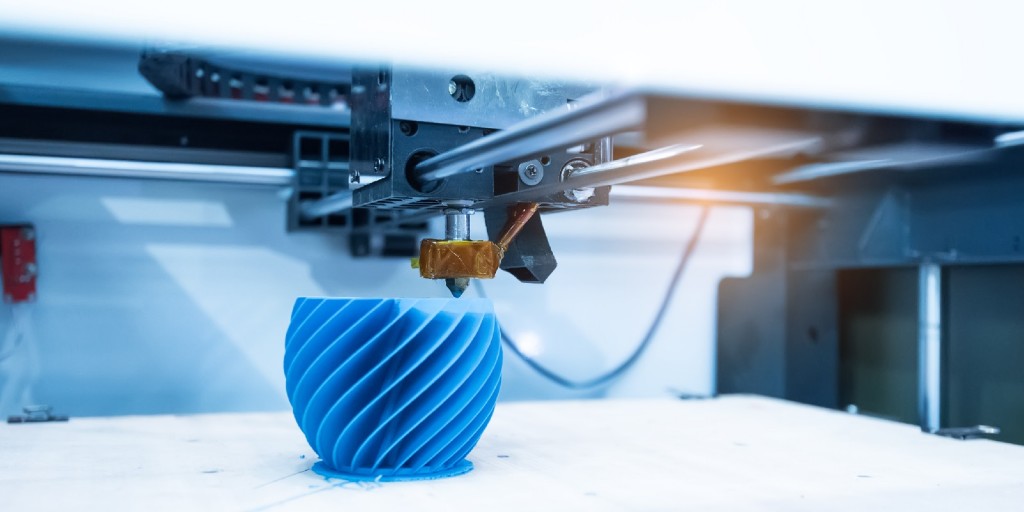

Additive manufacturing is the process of combining materials to create objects based on 3D model data, usually in layers, as opposed to the subtractive method and the molding method. Terms such as additive manufacturing, additive processes, additive methods, additive layer-by-layer manufacturing, layer-by-layer manufacturing, freeform solids manufacturing, and freeform manufacturing have been used at various times. nine0003

In this dynamic industry, new terms are rapidly emerging. 3D printing, according to the ISO/ASTM 52900 standard, is the production of objects by applying material with a printhead, nozzle, or other printing technology. In the past, the term was associated with low cost, low productivity machines. However, this is no longer the case: the terms "additive manufacturing" and "3D printing" mean the same thing.

In the past, the term was associated with low cost, low productivity machines. However, this is no longer the case: the terms "additive manufacturing" and "3D printing" mean the same thing.

"Additive Manufacturing" is an official industry term approved by the ASTM and ISO standards bodies, but "3D printing" is more common and has become the de facto standard. It is especially widely used in the media, the terminology of startups, investors and other communities. nine0003

Can 3D technology help you optimize production in your organization? Order iQB Technologies services: expert consultation, training, test 3D printing/3D scanning, equipment demonstration, site visits and others:

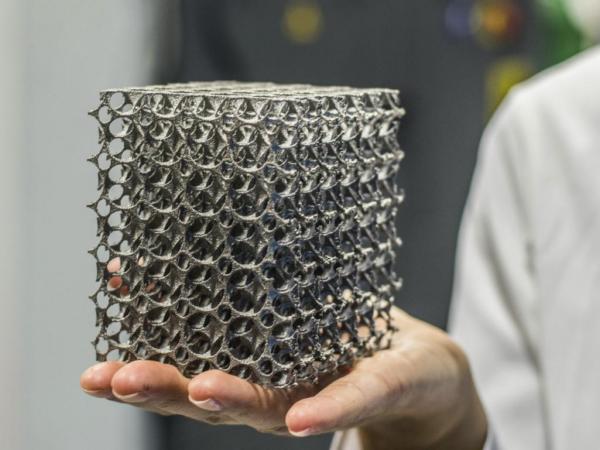

One of the advantages of additive technologies is the ability to create objects of complex shape and structure with high accuracy.

Processes

Additive manufacturing (AM) includes seven different processes. Products can be created in layers by: nine0003

- extrusion,

- spray (jet spray),

- UV Curing,

- lamination,

- fusion materials.

3D printing technologies

Modern FDM installations, such as the Discovery 3D Printer, allow you to print one-piece large-sized products up to 2.5 m

The main technologies used in the creation of products on additive installations: nine0003

- SLM (Selective Laser Melting) - selective laser melting of metal powder according to mathematical CAD models using an ytterbium laser;

- FDM (Fused Deposition Modeling) - a method of layer-by-layer deposition using a plastic thread or granules;

- SLA (Laser Stereolithography) - laser stereolithography, based on the layer-by-layer curing of a liquid material under the action of a laser;

- DLP (Digital Light Processing) - a stereolithographic 3D printing method using digital LED projectors; nine0028

- LCD (Liquid Crystal Display) - another type of photopolymer printing, when the photopolymer resin is illuminated by an LED UV matrix through an LCD screen mask;

- SLS (Selective Laser Sintering) - selective laser sintering under laser beams of particles of powdered material until a physical object is formed according to a given CAD model;

- Binder Jetting - layer-by-layer bonding of a composite powder (sand, polymer, metal, etc.

) with a binder; nine0028

) with a binder; nine0028 - MJP (MultiJet Printing) - multi-jet modeling with photopolymer or wax;

- CJP (ColorJet Printing) is a full-color 3D printing technology by gluing a special gypsum-based powder.

Consumables

The main materials used in additive processes are:

- thermoplastics in the form of filaments or granules;

- UV and photocurable liquid photopolymers; nine0028

- ceramic-filled liquid photopolymers;

- polystyrene powder;

- glass-filled, carbon-filled and metal-filled polyamides in powder form;

- wax;

- gypsum powder;

- sand in powder form;

- metal alloys in powder form, etc.

Applications of additive technologies

Additive technologies are used to create physical models, prototypes, samples, tooling and production of plastic, metal, ceramic, glass, composite and biomaterial components. The principle of operation of additive installations is based on the construction of thin horizontal layers from 3D models created using computer-aided design (CAD) systems and 3D scanners. nine0003

The principle of operation of additive installations is based on the construction of thin horizontal layers from 3D models created using computer-aided design (CAD) systems and 3D scanners. nine0003

Design and manufacturing enterprises use AP for the manufacture of consumer, industrial, medical and military products, and that's not all. Cameras, mobile phones, engine parts, car interiors, aircraft parts and components, machine tools and medical implants are just the beginning of the vast list of additive manufacturing products.

AM simplifies and speeds up the product development process. Companies are turning to additive technologies to reduce production time, improve product quality and reduce costs. As a visualization tool, 3D printing helps businesses determine the likelihood of creating defective or unsatisfactory products. In addition, methods, processes and systems for tooling are being developed. nine0003

3D printing is actively used in the aerospace, automotive, oil and gas industries, shipbuilding, medicine, jewelry and many other industries.

3D printing is actively used to improve the quality of injection molding tooling. In some areas, AM is used to obtain results that are unattainable using conventional machines. In other industries, AM is being used to create fabrication and assembly tools such as fixtures, fixtures, templates, and guides for drilling and cutting. nine0003

3D printing has a big impact on the production of many products. Enterprises, large and small, successfully apply technology to the production of finished products. According to experts, direct manufacturing will become the largest application area for additive technologies. This technology can affect production more than other traditional methods.

The industry continues to evolve with new methods, technologies, materials, applications and business models emerging. The geography and scope of industrial application of AP is expanding. Additive technologies have already had a huge impact on the development of design and manufacturing; in the future, their role will increase more and more. nine0003

The geography and scope of industrial application of AP is expanding. Additive technologies have already had a huge impact on the development of design and manufacturing; in the future, their role will increase more and more. nine0003

Additive manufacturing in Russia

The laboratory of additive technologies of Samara University performs unique metal 3D printing projects using the SLM Solutions installation / Photo: Ekaterina Vinokurova

In Russia, the 3D technology market is quite young, but it is already showing dynamic growth (according to Rosnano, about 30% per year). More and more companies are realizing the need to apply additive methods in manufacturing and research. There are organizations that are actively involved in the certification of materials and are already testing 3D printers of their own production. At the enterprises there are laboratories for the development and implementation of 3D solutions in certain sections of the technological cycle. nine0003

nine0003

Today, we are not talking about a complete transition to additive technologies - so far they are able to effectively complement classical processes or replace them at some particular stage of the cycle. However, industry experts argue that in the near future, additive manufacturing will become an integral part of the technological processes in the enterprise.

Want to learn more about 3D technology? Subscribe to our blog and get advice from iQB Technologies experts: +7 (495) 223-02-06.

Article published on 08/16/2017, updated on 12/12/2022

What are additive technologies

The use of new technologies is the main trend of recent years in any area of industrial production. Every enterprise in Russia and the world strives to create cheaper, more reliable and high-quality products using the most advanced methods and materials. The use of additive technologies is one of the clearest examples of how new developments and equipment can significantly improve traditional production. nine0003

nine0003

- What are additive technologies

- Advantages

- Technologies and materials

- Additative technologies in Russia

- What are additive technologies

- Advantages

- Additive technologies in Russia

-

Improved finished product properties. Due to the layered construction, products have a unique set of properties. For example, parts created on a metal 3D printer in terms of their mechanical behavior, density, residual stress and other properties are superior to analogues obtained by casting or machining.

-

Great savings in raw materials.

Additive technologies use almost the amount of material that is needed to produce your product. Whereas with traditional manufacturing methods, the loss of raw materials can be up to 80-85%. nine0003

Additive technologies use almost the amount of material that is needed to produce your product. Whereas with traditional manufacturing methods, the loss of raw materials can be up to 80-85%. nine0003 -

Ability to manufacture products with complex geometry. Equipment for additive technologies makes it possible to produce items that cannot be obtained in any other way. For example, a part within a part. Or very complex cooling systems based on mesh structures (this cannot be obtained either by casting or stamping).

-

Mobility of production and acceleration of data exchange. No more drawings, measurements and bulky samples. At the heart of additive technologies is a computer model of a future product, which can be transferred in a matter of minutes to the other side of the world - and production can immediately begin. nine0003

-

Great savings in raw materials. Additive technologies use almost the amount of material that is needed to produce your product. Whereas with traditional manufacturing methods, the loss of raw materials can be up to 80-85%.

-

Ability to manufacture products with complex geometry. Equipment for additive technologies makes it possible to produce items that cannot be obtained in any other way. For example, a part within a part. Or very complex cooling systems based on mesh structures (this cannot be obtained either by casting or stamping). nine0003

-

Mobility of production and acceleration of data exchange. No more drawings, measurements and bulky samples.

At the heart of additive technologies is a computer model of a future product, which can be transferred in a matter of minutes to the other side of the world - and production can immediately begin.

At the heart of additive technologies is a computer model of a future product, which can be transferred in a matter of minutes to the other side of the world - and production can immediately begin.

. ?

Additive manufacturing technologies make it possible to produce any product in layers based on a 3D computer model. This process of creating an object is also referred to as "growing" due to the gradualness of the production. If in traditional production at the beginning we have a workpiece, from which we cut off everything superfluous in bulk, or we deform it, then in the case of additive technologies, a new product is built from nothing (more precisely, from an amorphous consumable material). Depending on the technology, an object can be built from the bottom up or vice versa, receiving different properties. nine0003

The general scheme of additive manufacturing can be represented as the following sequence:

The first additive manufacturing systems worked mainly with polymeric materials. Today, 3D printers, which represent additive manufacturing, are able to work not only with them, but also with engineering plastics, composite powders, various types of metals, ceramics, and sand. Additive technologies are actively used in mechanical engineering, industry, science, education, design, medicine, foundry and many other areas. nine0003

Today, 3D printers, which represent additive manufacturing, are able to work not only with them, but also with engineering plastics, composite powders, various types of metals, ceramics, and sand. Additive technologies are actively used in mechanical engineering, industry, science, education, design, medicine, foundry and many other areas. nine0003

What is additive technology?

Additive manufacturing technologies make it possible to produce any product in layers based on a 3D computer model. This process of creating an object is also referred to as "growing" due to the gradualness of the production. If in traditional production at the beginning we have a workpiece, from which we cut off everything superfluous in bulk, or we deform it, then in the case of additive technologies, a new product is built from nothing (more precisely, from an amorphous consumable material). Depending on the technology, an object can be built from the bottom up or vice versa, receiving different properties. nine0003

nine0003

The general scheme of additive manufacturing can be represented as the following sequence:

The first additive manufacturing systems worked mainly with polymeric materials. Today, 3D printers, which represent additive manufacturing, are able to work not only with them, but also with engineering plastics, composite powders, various types of metals, ceramics, and sand. Additive technologies are actively used in mechanical engineering, industry, science, education, design, medicine, foundry and many other areas. nine0003

Advantages of additive technologies

Schematically, the differences between conventional and additive manufacturing can be depicted as follows:

Advantages of additive technologies

Improved finished product properties. Due to the layered construction, products have a unique set of properties. For example, parts created on a metal 3D printer in terms of their mechanical behavior, density, residual stress and other properties are superior to analogues obtained by casting or machining. nine0003

Due to the layered construction, products have a unique set of properties. For example, parts created on a metal 3D printer in terms of their mechanical behavior, density, residual stress and other properties are superior to analogues obtained by casting or machining. nine0003

Schematically, the differences between conventional and additive manufacturing can be depicted as follows:

Additive manufacturing technologies

Additive manufacturing is the process of growing products on a 3D printer from a CAD model. This process is considered innovative and is opposed to the traditional ways of industrial production.

Today, the following additive manufacturing technologies can be distinguished:

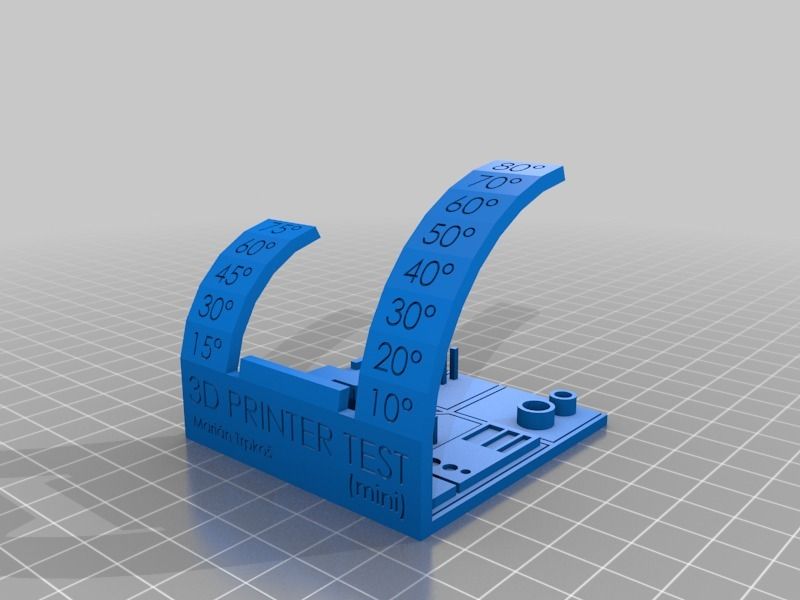

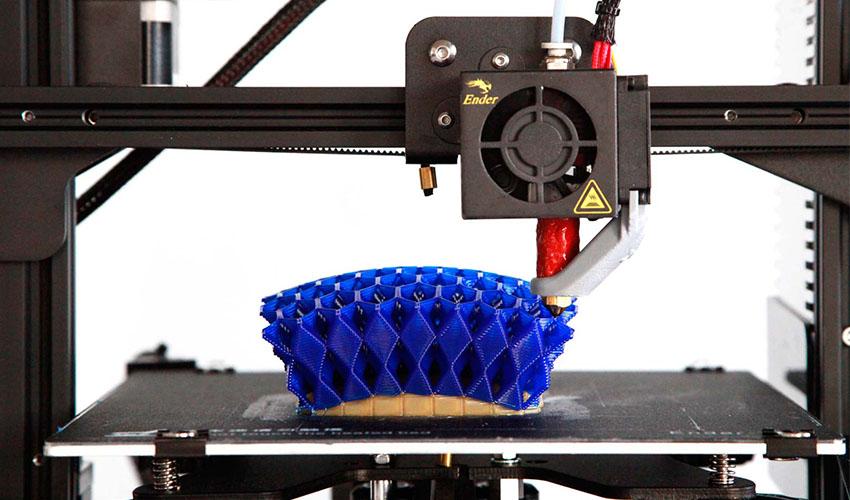

FDM (Fused deposition modeling)

Layer-by-layer construction of a product from a melted plastic thread. It is the most widely used 3D printing method in the world, and is used by millions of 3D printers, from the cheapest to industrial 3D printing systems. FDM printers work with various types of plastics, the most popular and affordable of which is ABS. Plastic products are highly durable, flexible, and are great for product testing, prototyping, and for making ready-to-use objects. The world's largest manufacturer of plastic 3D printers is the American company Stratasys. nine0003

Plastic products are highly durable, flexible, and are great for product testing, prototyping, and for making ready-to-use objects. The world's largest manufacturer of plastic 3D printers is the American company Stratasys. nine0003

See all FDM printers >>

Additive manufacturing technologies

Additive manufacturing is the process of growing products on a 3D printer from a CAD model. This process is considered innovative and is opposed to the traditional ways of industrial production.

Today, the following additive manufacturing technologies can be distinguished:

FDM (Fused deposition modeling)

Layer-by-layer construction of a product from a melted plastic thread. It is the most widely used 3D printing method in the world, and is used by millions of 3D printers, from the cheapest to industrial 3D printing systems. FDM printers work with various types of plastics, the most popular and affordable of which is ABS. Plastic products are highly durable, flexible, and are great for product testing, prototyping, and for making ready-to-use objects. The world's largest manufacturer of plastic 3D printers is the American company Stratasys. nine0003

The world's largest manufacturer of plastic 3D printers is the American company Stratasys. nine0003

See all FDM printers >>

FDM example, ULTEM material 9085

FDM example, PEEK material

FDM example, ABS material

FDM example, ULTEM material 9085

3 Example

3 FDM printing, PEEK material

Example of FDM printing, ABS material

SLM (Selective laser melting)

Selective laser melting of metal powders. The most common metal 3D printing method. Using this technology, it is possible to quickly produce metal products with complex geometries, which are superior in their qualities to foundry and rolling production. The oldest manufacturers of SLM printing systems are the German companies SLM Solutions and Realizer. In Russia, 3DLAM is manufacturing such 3D printers. nine0003

See all SLM printing systems >>

SLM (Selective laser melting)

Selective laser melting of metal powders. The most common metal 3D printing method. Using this technology, it is possible to quickly produce metal products with complex geometries, which are superior in their qualities to foundry and rolling production. The oldest manufacturers of SLM printing systems are the German companies SLM Solutions and Realizer. In Russia, 3DLAM is manufacturing such 3D printers. nine0003

Using this technology, it is possible to quickly produce metal products with complex geometries, which are superior in their qualities to foundry and rolling production. The oldest manufacturers of SLM printing systems are the German companies SLM Solutions and Realizer. In Russia, 3DLAM is manufacturing such 3D printers. nine0003

See all SLM printing systems >>

SLM printing example, material - steel

SLM printing example, material - titanium alloy

SLM printing example, material - aluminum

SLM printing example, material - steel

SLM printing example, titanium alloy material

SLM printing example, aluminum material

SLA (short for Stereolithography)

Laser-assisted stereolithography, the curing of a liquid photopolymer material by laser action. This additive digital manufacturing technology is focused on the manufacture of high-precision products with various properties. One of the leading manufacturers of professional SLA printers is the Chinese company UnionTech. nine0003

nine0003

See all SLA printers >>

SLA (short for Stereolithography)

Laser-assisted stereolithography, the curing of a liquid photopolymer material by laser action. This additive digital manufacturing technology is focused on the manufacture of high-precision products with various properties. One of the leading manufacturers of professional SLA printers is the Chinese company UnionTech.

See all SLA printers >>

SLS (Selective laser sintering)

Selective laser sintering of polymer powders. Using this technology, it is possible to obtain large products with different physical properties (increased strength, flexibility, heat resistance, etc.). The largest manufacturer of SLS printers is the American concern 3D Systems.

See all SLS printing systems >>

Rapid prototyping technologies

Rapid prototyping technologies should be placed in a separate category. These are 3D printing methods designed to obtain samples for visual evaluation, testing, or master models for creating molds. nine0003

nine0003

MJM (Multi-jet Modeling) - multi-jet modeling using photopolymer or wax material. This technology makes it possible to produce burnt or smelted master models for casting, as well as prototypes of various products. Used in 3D Systems ProJet series 3D printers.

PolyJet - Liquid photopolymer curing with UV light. It is used in the Objet line of 3D printers from the American company Stratasys. The technology is used to obtain prototypes and master models with smooth surfaces. nine0003

CJP (Color jet printing) - layer-by-layer distribution of the adhesive on powdered gypsum material. Gypsum 3D printing technology is used in the ProJet x60 series 3D printers (formerly called ZPrinter). To date, this is the only industrial technology for full-color 3D printing. With its help, bright colorful prototypes of products are made for testing and presentations, as well as various souvenirs, architectural models.

SLS (Selective laser sintering)

Selective laser sintering of polymer powders. Using this technology, it is possible to obtain large products with different physical properties (increased strength, flexibility, heat resistance, etc.). The largest manufacturer of SLS printers is the American concern 3D Systems.

Using this technology, it is possible to obtain large products with different physical properties (increased strength, flexibility, heat resistance, etc.). The largest manufacturer of SLS printers is the American concern 3D Systems.

See all SLS printing systems >>

Rapid prototyping technologies

Rapid prototyping technologies should be placed in a separate category. These are 3D printing methods designed to obtain samples for visual evaluation, testing, or master models for creating molds. nine0003

MJM (Multi-jet Modeling) - multi-jet modeling using photopolymer or wax material. This technology makes it possible to produce burnt or smelted master models for casting, as well as prototypes of various products. Used in 3D Systems ProJet series 3D printers.

PolyJet - Liquid photopolymer curing with UV light. It is used in the Objet line of 3D printers from the American company Stratasys. The technology is used to obtain prototypes and master models with smooth surfaces. nine0003

nine0003

CJP (Color jet printing) - layer-by-layer distribution of the adhesive on powdered gypsum material. Gypsum 3D printing technology is used in the ProJet x60 series 3D printers (formerly called ZPrinter). To date, this is the only industrial technology for full-color 3D printing. With its help, bright colorful prototypes of products are made for testing and presentations, as well as various souvenirs, architectural models.

Additive technologies in Russia

Every year, domestic enterprises are increasingly using 3D printing systems for industrial and scientific purposes. Additive manufacturing equipment, intelligently integrated into the production chain, allows not only to reduce costs and save time, but also to start performing more complex tasks.

Globatek 3D has been supplying the latest 3D printing and 3D scanning systems to Russia since 2010. The equipment installed by our specialists works in the largest universities (MGTU named after Bauman, MEPhI, MISIS, Privolzhsky, SSAU and others) and industrial enterprises, institutions of the military-industrial complex and the aerospace industry. nine0003

nine0003

Report of the Rossiya TV channel on the use of the SLM 280HL installed by Globatek 3D specialists at the Samara State Aerospace University:

Additive technologies in Russia

Every year domestic enterprises increasingly use 3D printing systems for industrial and scientific purposes. Additive manufacturing equipment, intelligently integrated into the production chain, allows not only to reduce costs and save time, but also to start performing more complex tasks. nine0003

Globatek 3D has been supplying the latest 3D printing and 3D scanning systems to Russia since 2010. The equipment installed by our specialists works in the largest universities (MGTU named after Bauman, MEPhI, MISIS, Privolzhsky, SSAU and others) and industrial enterprises, institutions of the military-industrial complex and the aerospace industry.

Rossiya TV channel report on the use of SLM 280HL installed by Globatek 3D specialists at Samara State Aerospace University:

GLobatek 3D experts help professionals from various fields to choose 3D equipment that will most effectively solve the problems facing the enterprise.