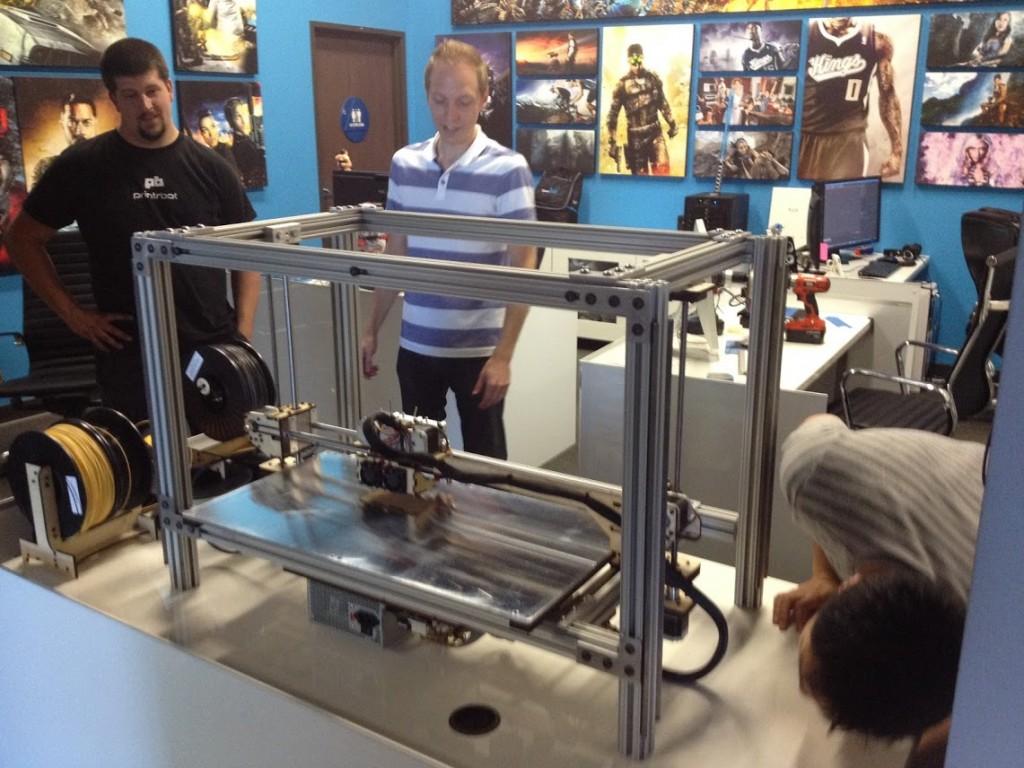

3D printer prototype

What is Rapid Prototyping with 3D Printing?

What is Rapid Prototyping with 3D Printing? - Stratasys Stratasys Invests in Axial3D to Make Patient-Specific 3D Solutions Available to All - Learn MoreUSA & Canada

Select your country and region

- Americas

- English

- Español (México)

- Português (Brasil)

- EMEA

- English (United Kingdom)

- Deutsch

- Español

- Français

- italiano

- APAC

- 中文(简体)

- 日本語 (日本)

- 한국어(대한민국)

- English (India)

USA & Canada

What is Rapid Prototyping?

Rapid prototyping with 3D printing is the quick, easy, cost effective way to turn great ideas into successful products. Do you need concept modeling to put your newest ideas to the test? What about functional prototyping to gauge performance before committing to costly production tooling? Rapid prototyping solutions from Stratasys will give you the flexibility to create, test and refine in ways you never thought possible so you can go to market faster than ever before.

See how 3D printed rapid prototypes are changing the way the world does business

"Every time we avoid cutting a tool, we save 8 to 12 weeks."

Randy Larson, Polaris Industries

How to improve your manufacturing process?

3D Learning Hub

See all categories

Contents:

- Introduction

- What are the advantages of 3D printing prototypes?

- How to 3D print prototypes

- What materials should you choose to 3D print your prototypes?

Introduction

What are the advantages of 3D printing prototypes?

Create various iterations

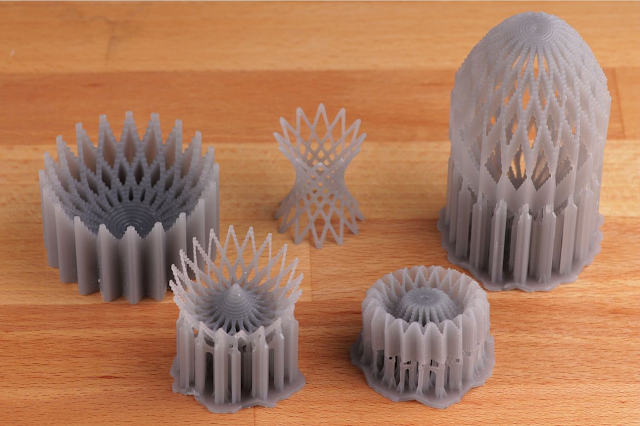

3D printing gives you more freedom than any other manufacturing technique. As your object is created from a digital 3D model, using a 3D modeling software, you can easily create all the designs you want, from the most simple to the most intricate ones. It is possible to create any project from scratch, get a good visualization, and to adjust your 3D model whenever you want to.

As your object is created from a digital 3D model, using a 3D modeling software, you can easily create all the designs you want, from the most simple to the most intricate ones. It is possible to create any project from scratch, get a good visualization, and to adjust your 3D model whenever you want to.

Thanks to 3D printing, you can give life to your 3D model by printing it to create a prototype or even a final product. But let’s focus on the prototyping process: 3D printing is really convenient as you don’t have to create a whole mold for each iteration of your project. You are free to make different iterations, so the prototype can perfectly match your expectations for the final product.

Save money

Compared to traditional manufacturing techniques such as injection molding, additive manufacturing is much cheaper. But why? First, as we’ve just said, when using 3D printing, you don’t have to create a mold to create your object, which is a significant advantage. Time and money are precious for your company, that is why 3D printing is helping you to go straight to what is essential to you.

Save time

With 3D printing, you can do as many iterations as you need. Moreover, the process itself is quite faster. Instead of the creation of the mold and waiting for the whole injection molding process, additive manufacturing skips these steps. This manufacturing technique is perfect for rapid prototyping and can help you accelerate your whole product development.

Run tests with functional prototypes

Thanks to the variety of 3D printing materials now available on the market and our online 3D printing service, it is possible to access advanced materials. While many materials are adapted for production, they can also be used for your prototyping process. Indeed, if you need to run tests, these materials will allow you to make the most of the impressive properties to manufacture advanced functional prototypes.

How to 3D print prototypes

Are you ready to use additive manufacturing to develop your prototypes, but you don’t know how? Using an external 3D printing service is the perfect solution.

If you are looking for the most cost-effective technique to manufacture your prototypes, it is clear that investing in professional 3D printers is not part of your plan, and desktop printers leave much to be desired in terms of quality. Using a service such as Sculpteo will give you access to industrial technologies and materials, but you will also benefit from the advice of our 3D printing experts. They will help you implement 3D printing in your strategy and answer all your questions.

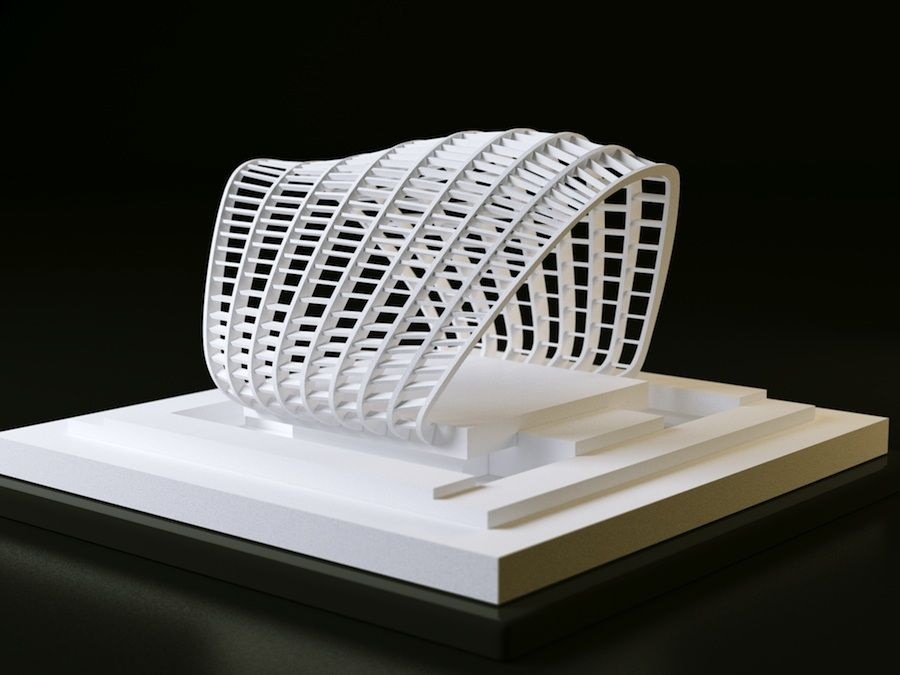

It is important for us to help our customers to improve their manufacturing process and their whole prototyping process to get the best products in the end. We have a 3D printing solution for all kinds of projects, from models for architecture to prototypes for mechanical parts, there is a material on our 3D printing service that will meet your expectations.

The process is simple: once your 3D model is ready, you just need to upload your 3D file on our platform, you will get an instant quote and receive your 3D printed prototype in a few days! But before that, here are the first steps you need to take in order to successfully 3D print your prototypes.

What materials should you choose to 3D print your prototypes?

What do you have to check first?

While using an online 3D printing service such as Sculpteo to improve your prototyping process, you can access a wide range of materials and technologies, with different properties and prices. But while choosing your material for prototyping you will have to check various aspects.

The price

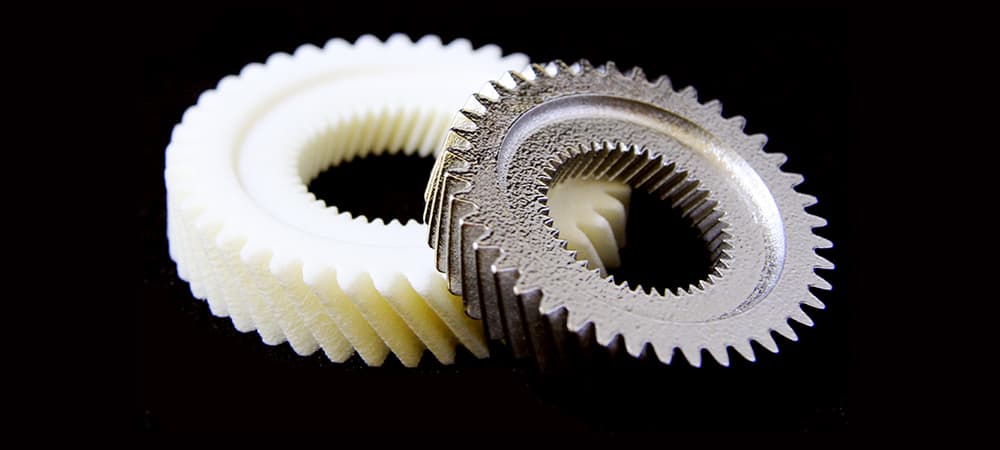

It is certainly the most important point for your company. How to reduce costs but still improve your manufacturing process? For example, if you need to create a metal object, making your prototype with plastic will be quite interesting. Indeed, it would be more cost-effective to begin the early prototypes with plastic and then shift to metal 3D printing for the final validation. Choosing among the different plastic materials and the various options will help you to find the most economical solution for your prototyping project.

The accuracy and the quality of the material

A prototype is a way to get a perfect overview of the project to spot the last problems. You certainly want to create a functional prototype. That is why, if you have a complex project or an object with an elaborated design, be sure to check that the material and 3D printing technique is precise enough to help with your prototyping process. However, you obviously have to keep in mind the mechanical properties of the final material that you will use.

You certainly want to create a functional prototype. That is why, if you have a complex project or an object with an elaborated design, be sure to check that the material and 3D printing technique is precise enough to help with your prototyping process. However, you obviously have to keep in mind the mechanical properties of the final material that you will use.

With the right material, you should be able to manufacture a functional object. Do you need to get an object with the same weight as your final product? With the same dimensions? Able to have the same applications? You will have to ask yourself several questions before you make the final choice, in order to see all the aspects of your prototype that you need to check.

The design guidelines of the material

All materials have different design guidelines. While choosing your material, be sure to check them, to get a perfect object. It could be a reason why your 3D file is not 3D printable, you really have to be sure that everything is ok regarding the dimension and the geometry of your project. Indeed, if the wall is too thin, the file could be non-printable or could break in no time, which would be counterproductive.

Indeed, if the wall is too thin, the file could be non-printable or could break in no time, which would be counterproductive.

The best materials to 3D print your prototypes at Sculpteo

The choice of your 3D printing material really depends on your project. Here is a selection of our most used materials for prototyping projects! Plastic materials are obviously the cheapest solution for this stage of your product development; let’s see what you can do with them.

- Nylon PA12

This white plastic material is one of the most affordable materials with a lot of great mechanical properties. This material is made from fine polyamide powder, and is perfect for both prototyping and production. It will create your parts thanks to the Selective Laser Sintering technology.

If you choose this material for your prototyping project, you will see that you will have the choice between various options and finishes, but you can also get raw parts. Prototyping with Nylon PA12 (plastic) is a good solution because this 3D printing material is one of the cheapest options, so you will be able to make many iterations with a resistant material, that gives you a lot of freedom in terms of geometry.

- Multi Jet Fusion PA12

Our Multi Jet Fusion PA12 is a grey plastic. This material is perfect both for prototyping and production and its raw version is clearly the cheapest option you will get! It will allow you to make many iterations at a lower cost. The objects printed with this material are well suited against scratches and abrasion, which could be great to make tests. It is also light stabilized, U.V. stabilized and stable to weather, which is perfect if you need to make an experiment in outdoor conditions.

- Prototyping resin

This resin is specifically developed to prototypes and is well suited for non-functional prototypes. Indeed, if you need to manufacture highly detailed parts this material will be the perfect option. Prototyping resin offers a smooth surface finish, quite similar to objects manufactured using plastic injection molding. This resin is 3D printed using the Stereolithography (SLA) process.

- PLA

Fused Deposition Modeling techniques are particularly useful in the development of prototypes. Using this option, you will not get the most detailed prototypes. However, for some oversized project, this technique can be interesting. Indeed, at Sculpteo, we are using BigRep 3D printers to 3D print our PLA filament, allowing to print parts with the maximum size of 1 x 1 x 1 m.

- TPU

You need a really flexible plastic for your 3D printing project? TPU will be the perfect solution for you. This rubber-like material has a high elasticity and a high strength. That could perfectly fit your project if you need something really flexible for fully functional prototypes. As this material creates parts really resistant to stress and fatigue, it can even be used for your final products. Think about it! On our online 3D printing service, you will have the opportunity to choose between two TPU: Ultrasint® TPU01 and Ultrasint® TPU 88A.

- 3D printing metal for your prototypes ?

If you are planning to create 3D printed prototypes with metal materials, you have to know that it is totally possible but that it is not the most economical option for you. However, we recommend you to use our Ultrafuse 316L Stainless Steel if you need to manufacture metal prototypes. This affordable material is printed using FDM technology; it is resistant and can be used to run tests of functional prototypes.

However, we recommend you to use our Ultrafuse 316L Stainless Steel if you need to manufacture metal prototypes. This affordable material is printed using FDM technology; it is resistant and can be used to run tests of functional prototypes.

Binder jetting technology, can also be used to print your prototypes parts, with Steel / Bronze 420SS/BR and Stainless Steel 316.

Keep in mind that Direct Metal Laser Sintering is also used to make prototypes for the aerospace industry using Titanium 6AI-4V but is not a cost-efficient method for prototypes. It’s good to know if you have such projects, but most of the time, plastic will be used as the most convenient material for prototypes.

We hope that this article helped you to understand all the benefits and possibilities offered by additive manufacturing to develop prototypes. Do you have more questions about these materials? Feel free to contact our sales team for more information.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

3D printed prototypes for functional testing

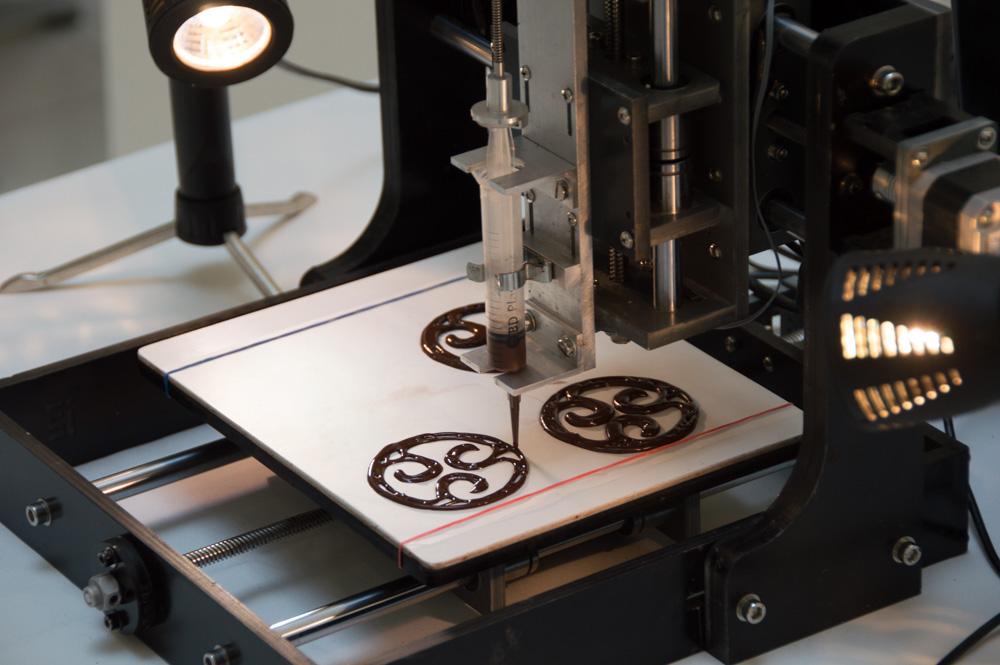

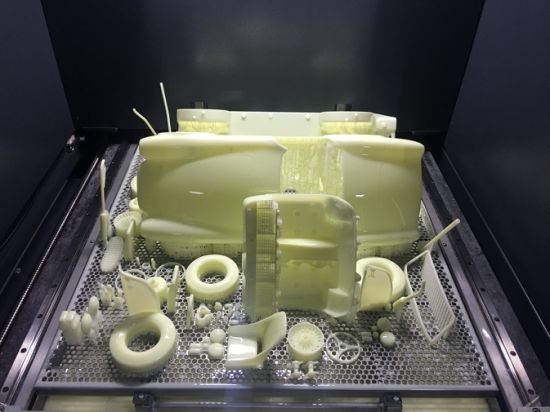

Testing product prototypes, individual assemblies and parts is an essential part of any production chain. With 3D printing, you can quickly obtain high-precision and low-cost samples of future products for various tests and tests.

Which tests can you carry out on the received products:

- check the assembly for assembly;

- study the behavior of various materials in the working environment; nine0008

- test new design solutions;

- test strength, wear resistance;

- blow through objects in a wind tunnel.

Which tests can you carry out on the received products:

- check the assembly for assembly;

- study the behavior of various materials in the working environment;

- test new design solutions;

- test strength, wear resistance;

- blow through objects in a wind tunnel.

nine0008

nine0008

Benefits of functional prototyping with 3D printing

- Speed. You don't have to wait weeks for contractors to build a prototype for you.

- High precision. Test samples match your CAD model to within 15-20 microns.

- Low cost.

- Equipment versatility. With the help of 3D printing, you can get not only prototypes for tests, but also solve other production problems. nine0015 Information security. Your know-how will not get to competitors if third-party contractors are not involved in the production chain.

Example: 3D printing for Nascar racing engines

Ford's Nascar racing team is actively using 3D printers to upgrade and test new engine, exhaust and fuel system components.

Thanks to 3D printing, our engineers have the unique ability to quickly get full-fledged prototypes of their designs, test them, make changes and implement them in our machines.

This allows us to change the characteristics of cars incredibly quickly and prepare for the race. nine0003

Victor Martinez, Chief Engineer, Ford Team

Benefits of Functional Prototyping with 3D Printing

- Speed. You don't have to wait weeks for contractors to build a prototype for you.

- High precision. Test samples match your CAD model to within 15-20 microns.

- Low cost.

- Equipment versatility. With the help of 3D printing, you can get not only prototypes for tests, but also solve other production problems. nine0008

- Information security. Your know-how will not get to competitors if third-party contractors are not involved in the production chain.

Example: 3D printing for Nascar racing engines

Ford's Nascar racing team is actively using 3D printers to upgrade and test new engine, exhaust and fuel system components.

Thanks to 3D printing, our engineers have the unique ability to quickly get full-fledged prototypes of their designs, test them, make changes and implement them in our machines. This allows us to change the characteristics of cars incredibly quickly and prepare for the race. nine0003

Victor Martinez, Chief Engineer, Ford Team

Example: 3D printing a prototype stepper motor for testing

Example: 3D printing a prototype stepper motor for testing

Stratasys F370

Total-Z AnyForm 650 PRO

3DLAM Mid

UnionTech RSPro 800

0003

Stratasys F370

Total-Z Anyform 650 Pro

3DLAM MID

UnionTech RSPRO 800

PROTOPITIONS PRODUCATIONS-CREATIONS OF PRODUCTIONS-CREATIONS OF PRODUCTIONS-CREATIONS OF PRODUCTIONS-CREATE plastics and polymers up to 10%

What is 3D prototyping?

21. 02.2018 powernic

02.2018 powernic

What is 3D prototyping?

More recently, 3D printing and 3D technology in general were beyond fantasy. It never occurred to anyone that 3D printing would be used on an industrial scale, and even ordinary people could afford such small devices for household needs and hobbies. But today additive technologies are actively used even by children, drawing with a 3D pen or working with a 3D printer in a circle or at school. But a completely natural and not understandable question arises, what is 3D prototyping? And the answer to it is not so difficult. nine0137

3D prototyping is the process of creating a three-dimensional prototype of an object. Initially, it was carried out by removing excess material from the workpiece. These are methods of milling, forging, turning, etc. But in the 80s, scientists developed a different approach, which became a real breakthrough. It consisted in the layered formation of the object. It is this technology that formed the basis of modern 3D printers.

How does it work?

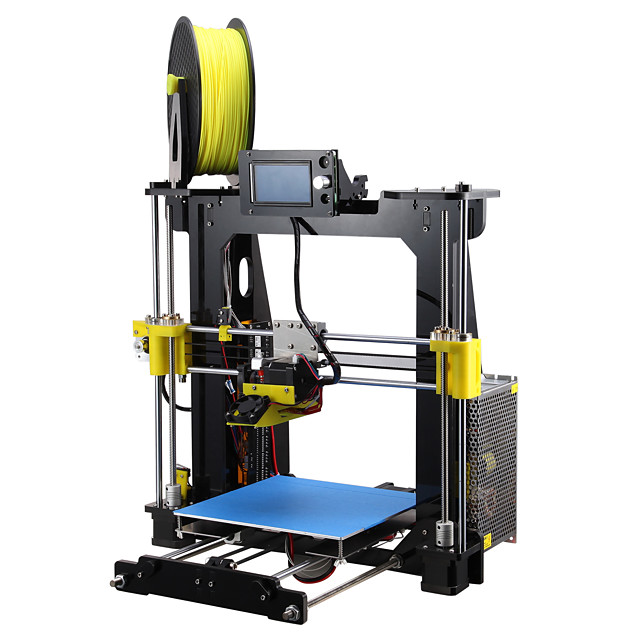

How does 3D prototyping work? Initially, 3d prototyping involves modeling an object on a computer. In a special program, a model is created with parameters specified in three-dimensional space. This model is sent for printing to a special device - a 3D printer, where a prototype is formed in layers. nine0003

There are many 3D printing technologies:

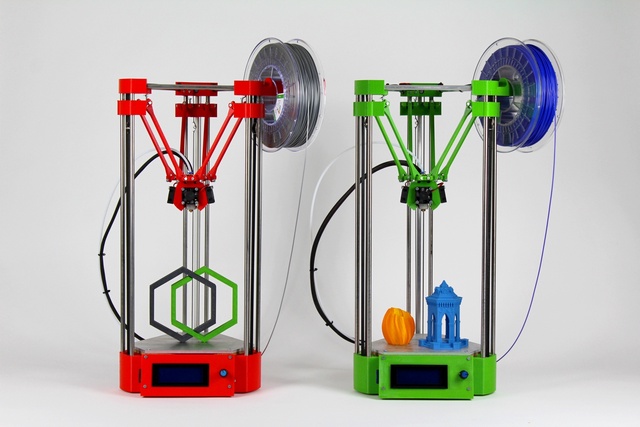

- FDM is the easiest printing method;

- stereolithography;

- photopolymer printing and many more.

Depending on the technology, different materials are used for prototyping: plastics, photopolymer resins, gypsum and even powdered metals. But the essence remains the same - the object is formed layer by layer in the camera of the device. In this case, the thickness of the layer will characterize the accuracy of 3d printing and, in many respects, its quality.