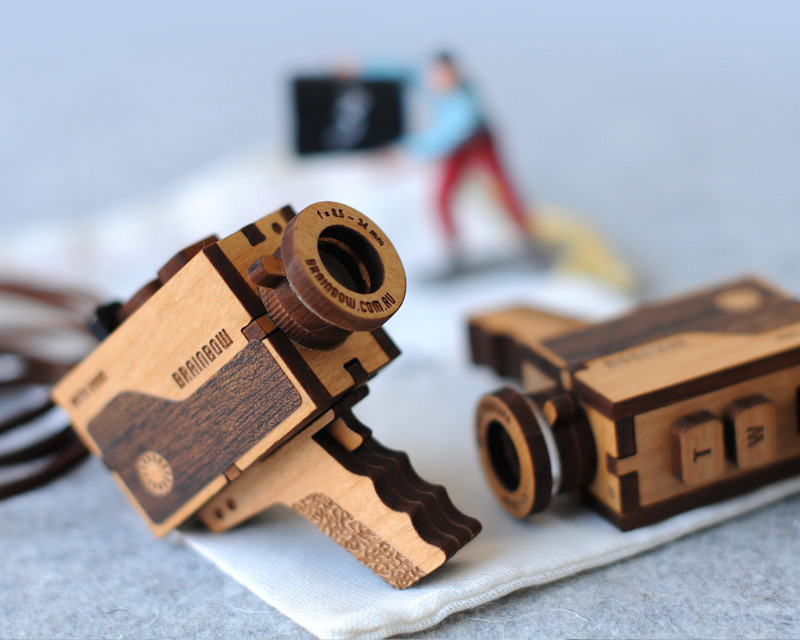

4X5 3d printed camera

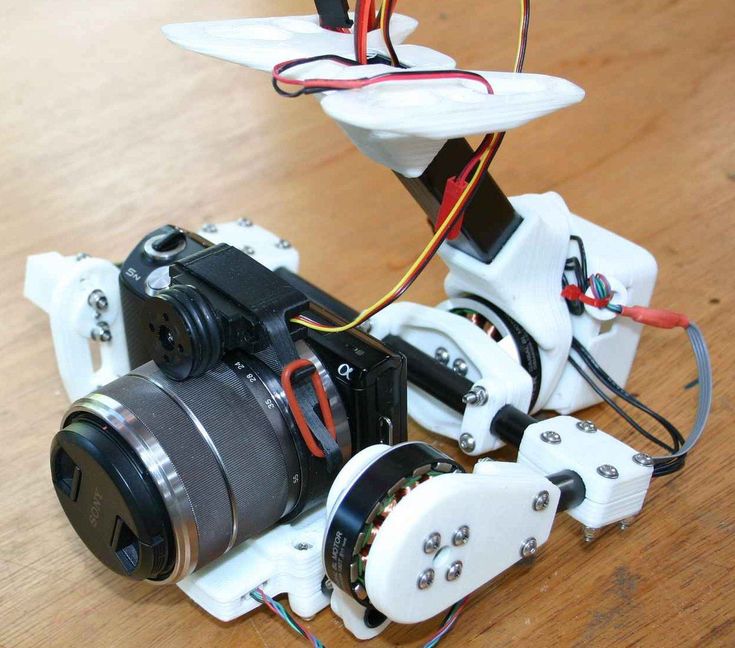

Awesome 3D printed large format camera!

I always had awesome customers, but from time to time, I get really surprised when they casually show me project so great, I could never imagine it’s possible. Long story short, let me introduce you to Peter Ivancak who is bringing back to life almost forgotten photography format with 3D printing!

It’s a perfect example how a new technology like 3D printing can revive techniques we almost forgot. I bet, you can find another example where 3D printing helps to revive traditional methods for sure…

Just check out the photos you can get from this 3D printed compact 4×5” large format camera – no wonder these pictures are awesome when imaging area is almost 15 times bigger than 35mm full frame. One more time, 4×5” film is whopping 100x125mm! That is bigger than build area of original MakerBot Cupcake 😀

Entry 58 camera

You can find the link to the campaign at the end of the post, but first I have asked Peter couple of questions when he was visiting my office.

4×5” film size

What are the benefits of large format cameras compared to standard SLR cams?

Large format (LF) photography is a completely different experience than a common SLR photoshooting. Regarding the technical quality of the images, the size of the image area is about fifteen times greater than standard 35 mm full-frame with the 4×5 ” large-format photography size. With such huge image data you have the possibilities that classical SLR can’t provide.

The most important thing is the incredible experience of photo shooting – the pure and unspoiled picture taking. Aperture, shutter speed, ISO and incredible depth of field options are all you have. So the strange tension holds not only when you’re taking a picture – it holds until the photography is in your hands ready for the show. LF is simply the true essence of photography.

© Peter Ivancak

How long did it take from first idea to the successfully printed model?

It took quite a lot of time. I started working on camera more than two years ago. I had to learn everything from the basics of optics to the 3D modeling and printing. Following the first successful printed prototype it took an incredible 18 months to get the camera design to be easily printable. The model is optimized for ABS filament and its quite large dimensions brought in various complications. However, troubles solved and the camera is finally available.

I started working on camera more than two years ago. I had to learn everything from the basics of optics to the 3D modeling and printing. Following the first successful printed prototype it took an incredible 18 months to get the camera design to be easily printable. The model is optimized for ABS filament and its quite large dimensions brought in various complications. However, troubles solved and the camera is finally available.

© Peter Ivancak

How was your experience with the Original Prusa i3 and what was the number of prototypes before the final one you’ve been satisfied with?

I must say my Prusa i3 is a faithful guide with this adventure. Its versatility has allowed me the really deep insight into the secrets of 3D printing. The recent upgrade is particularly excellent it accelerated the finalization of the camera. The printer is very robust and can withstand even a rough and improper treatment. I examined the other brands but it turned out that i3 is hardly beatable in any aspect. The only thing I’m missing is the closed box, but I heard it’s planned. Meanwhile, I use a plexiglass box of my own production that’s all I can say. 🙂

The only thing I’m missing is the closed box, but I heard it’s planned. Meanwhile, I use a plexiglass box of my own production that’s all I can say. 🙂

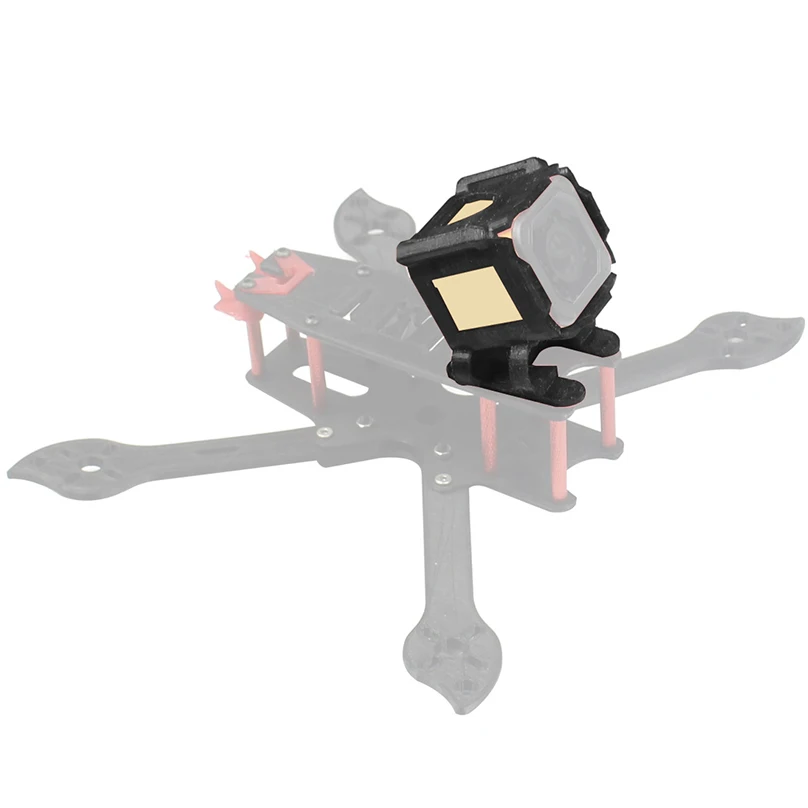

Entry 58 on Prusa i3 buildplate

When and how we can get your LF camera?

You can get the camera as a digital STL file you print with the 3D printer by yourselves. Or you can purchase the printed body of the camera. There are two versions of the focal length – 58 and 90 mm. Each version comes with a standard body enabling variable focus or a simple body focused from about 3 meters to infinity for a “point and shoot” photography. You can order the camera directly from my website http://ivancak-cameras.com or visit the the campaign on the IndieGoGo page.

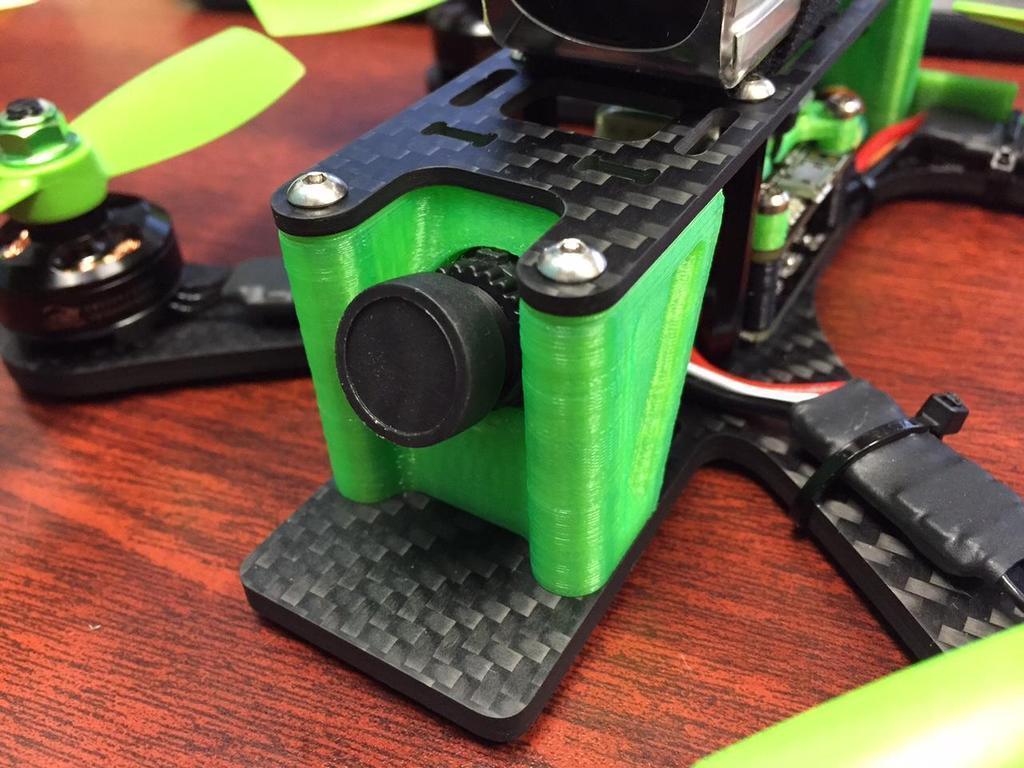

CAMERADACTYL OG 4X5 Hand Camera — CAMERADACTYL

$240. 00

00

The CAMERADACTYL OG is a 4x5 Handheld camera with a ground glass or acrylic focusing screen as well as scale focusing.

The camera can be focused by scale (marked by user on the focusing ring) or through the ground glass. The focusing ring has a locking screw tab that can be used to aide focusing, and lock the focusing ring in place - for example at a hyperfocal distance, infinity, or a predetermined distance for flash or portrait photography.

The OG takes standard 4x5 film holders, and will hold a film holder on the outside of the focusing screen to protect it in your bag.

CUSTOM OPTIONS:

As always, You may choose an accent color for your camera. The body, nosecone, inner helix/lensboard, and viewfinder will be printed in black for practical considerations. The grip, focusing screen frame, and focusing ring can be printed in just about any color, from discreet black or grey, to hot pink, yellow, purple, safety orange, or even some color changing options.

The OG can be ordered with a variety of ground glass options:

Plain Ground Glass - please note that this is much more fragile, recommended for studio use, but not for throwing in a bag and climbing up a mountain. it is only marginally brighter than a ground acrylic focusing screen.

Plain Ground Acrylic focusing screen

Gridded Ground Acrylic focusing screen - 1cm square gridlines

The OG is available in many different nosecone sizes. Currently already available are nosecones for:

Schneider 90mm f6.8 Angulon / Wollensak 90mm f6.8 Raptar (85 mm from lensboard to film plane when focused at infinity)

Schneider 90mm f8 Super Angulon (94 mm from lensboard to film plane when focused at minimum extension)

Kodak Ektar 127mm f4.7 or Optar 135mm f4.7 (116mm from lensboard to film plane when focused at infinity)

Kodak Super Anastigmat 127mm f4.

7 (XXX mm from lensboard to film plane when focused at infinity)

7 (XXX mm from lensboard to film plane when focused at infinity)Schneider G Claron 150mm f9 ( XXXX mm from lensboard to film plane when focused at inifinty)

Schneider Symmar-S 150mm f5.6 ( 142 mm from lensboard to film plane when focused at inifinty)

Nikon Nikkor W 105mm f5.6 (108mm from lensboard to film plane at minimum distance)

Nikkor W 135mm f5.6 (133mm from lensboard to film plane when focused at infinity)

Schneider Super Angulon 65mm f8 (62mm from lensboard to film plane when focused at minimum extension)

Schneider Super Angulon XL 47mm (59mm from lensboard to film plane when focused at infinity)

Custom length nosecones are available, by selecting a custom option, and filling out the form for your lens of choice. PLEASE CONTACT US BEFORE ORDERING A CUSTOM SETUP, so we can make sure that a compatible setup is possible to make. You will need to know:

The infinity flange distance of your lens (distance from the front of your lensboard to the film plane, when your lens is focused at infinity

The copal size of your shutter - so we can make you a helical /lensboard with the proper sized hole

The maximum diameter of the rear element of your lens, so we can make sure that everything will fit together nicely.

The distance from the very rear of your lens to the front of the lensboard it is mounted in (or alternately the distance from the rear of the lens, to the rear of the shutter)

RECOMMENDED ACCESSORIES:

You will need (or want) some accessories to be able to use your CAMERADACTYL OG 4x5 Hand Camera. Accessories NOT INCLUDED ARE:

a large format lens

a mechanical cable release (7mm diameter under the button of the release, and threads to fit your lens) . - not 100% necessary but recommended

a loupe for focusing on the ground glass - not necessary, but recommended. Very useful for calibrating your focus scale.

an accessory uncoupled rangefinder - Very unnecessary, but useful for precise scale focusing, particularly with longer lenses at close range.

TO CALIBRATE YOUR CAMERADACTYL OG 4X5:

Set your camera up on a tripod, a measured distance from a clearly lit high contrast object.

I like to use the tip of my lighting umbrella, but anything you can see clearly will work. I like to measure to the hot shoe on top of the camera, rather than to the lens, so that my focusing marks will match the reading of an accessory uncoupled rangefinder.

I like to use the tip of my lighting umbrella, but anything you can see clearly will work. I like to measure to the hot shoe on top of the camera, rather than to the lens, so that my focusing marks will match the reading of an accessory uncoupled rangefinder.Open your lens to its maximum aperture and focus on that object in the focusing screen. A dark cloth or blanket or coat over your head helps with this.

When the object is in focus, mark your measured distance with a thin sharpie marker on the rear face of your focusing ring.

Repeat this process for all the distances you will commonly focus at. I like to make markings for 3feet, 4, 6, 8, 10, 15, 25, and infinity. When calibrating for infinity, its best to take your camera outside and focus on something very far away, like a tree, a clocktower, a telephone pole, etc..

*You can rub off sharpie from the plastic with an alcohol soaked cotton swab with just a bit of patience, if you need to re-calibrate your distance scale.

Quantity:

Add To Cart

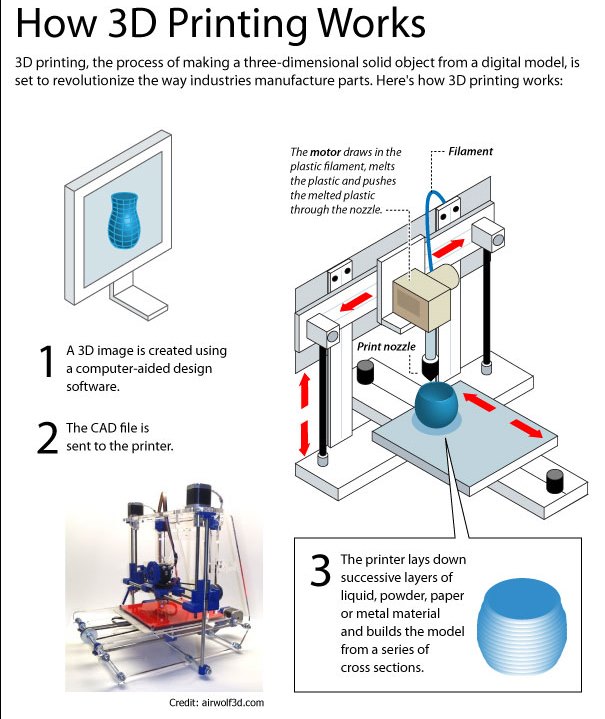

Overview of high-temperature 3D printers with Formnext 2017 Today, we note the significantly increased number of 3D printers since last year for working with high-temperature engineering plastics, starting with polycarbonate and further to polyamides, Ultem, PEEK, PPSU and composites based on them.

These materials are used in the aerospace industry, the chemical industry, and medicine, where properties such as low weight, high temperature resistance, mechanical strength, chemical inertness, and biocompatibility are in demand. We wrote more about engineering filaments and their application here.

Differences between industrial 3D printers

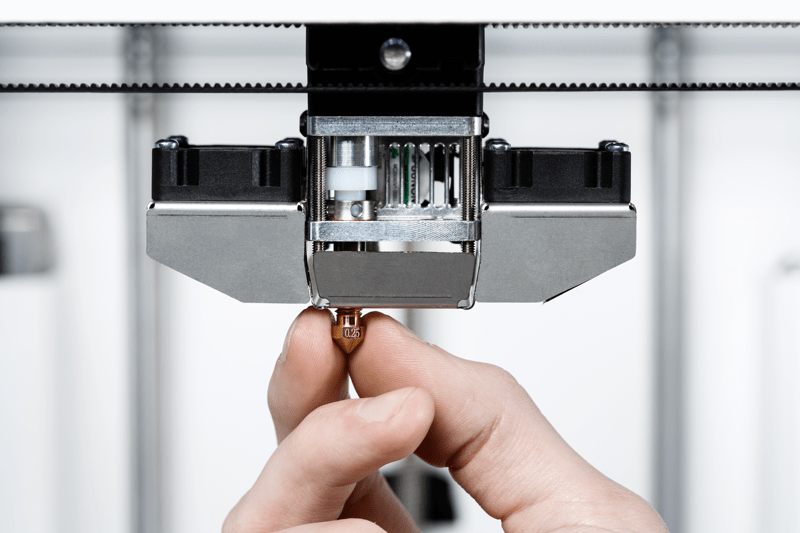

To work with engineering plastics, the printer must have a high-temperature extruder. There are two classes of equipment here. Junior - up to 300 ° C, this is enough for modifications of ABS, polycarbonate and polyamides. Senior - above 300 ° C. For PEEK or Ultem you need about 400.

Senior - above 300 ° C. For PEEK or Ultem you need about 400.

Extruder is not everything. A heated platform or vacuum table is a must to keep the part in place. And printing should take place in a working chamber isolated from the outside world, maintaining a predetermined temperature. Failure to comply with the mode leads to deformation or violation of the integrity of the printed object.

So, let's look at the patterns we've seen.

Intamsys

The Chinese manufacturer offers four models of 3D printers. The basic Funmat and Funmat Pro work with common plastics, from PLA to nylon, and composites. Funmat HT and Funmat Pro HT are already capable of printing in PEEK, Ultem and PPSU.

Intamsys FUNMAT, FUNMAT HT

- Working chamber: 260 x 260 x 260 mm;

- layer thickness: from 50 microns;

- nozzle diameter: 0.4mm;

- FUNMAT: extruder up to 280°C, bed up to 150°C;

- FUNMAT HT: extruder up to 450°C, bed up to 160°C.

Compact printers with a closed working chamber, in the HT version it is equipped with heating, maximum temperature 90 °C.

Intamsys FUNMAT PRO, FUNMAT PRO HT

- Working chamber: 450 x 450 x 600 mm;

- layer thickness: from 50 microns;

- nozzle diameter: 0.4mm;

- FUNMAT PRO: extruder up to 280°C, bed up to 150°C, chamber up to 60°C;

- FUNMAT PRO HT: extruder up to 450°C, bed up to 160°C, chamber up to 120°C.

Industrial printers for printing large parts with high-temperature plastics, equipped with a heated working chamber.

ROBOZE

One of the leading companies producing high-temperature 3D printers, we wrote more about it here. Offers three printers for engineering filaments. Roboze One is the basic model for common plastics - from PLA to polyamide inclusive. Roboze One +400 - with a high-temperature extruder, Roboze Argo 500 - a large installation, with a working chamber of 500 x 500 x 500 mm. Roboze printers are interesting in the rejection of drive belts and the use of a rack-and-pinion transmission to move the print head.

Roboze One +400 - with a high-temperature extruder, Roboze Argo 500 - a large installation, with a working chamber of 500 x 500 x 500 mm. Roboze printers are interesting in the rejection of drive belts and the use of a rack-and-pinion transmission to move the print head.

Roboze One +400

- Working chamber: 200 x 200 x 200 mm;

- extruder temperature: up to 400 °C;

- layer thickness: from 50 µm.

The printer is designed with an emphasis on reliability, all parts of the extruder are made of metal.

Roboze Argo 500

- Working chamber: 500 x 500 x 500 mm;

- layer thickness: from 50 microns;

- extruder temperature: up to 550 °C;

- chamber temperature: up to 180 °C.

The older Roboze model has a vacuum table to hold the part. Compartments for filament are equipped with heating. When one coil runs out, the machine automatically switches to the next one.

When one coil runs out, the machine automatically switches to the next one.

VSHAPER

A Polish manufacturer whose product range includes high-temperature printers for medical applications and five-axis 3D printing machines.

VSHAPER 270 Med

- Working chamber: 270 x 270 x 200 mm;

- extruder temperature: up to 450 °C;

- layer thickness: from 50 µm.

A medical-grade printer with an anti-microbial chamber coating and a built-in UV sterilizer that sterilizes every layer as it prints. The main purpose is the printing of implants and additional equipment for surgical operations.

VSHAPER 5-Axis Machine

- Working area: cylinder 300 mm in diameter and 300 mm high;

- automatic change of hotends;

- heated working chamber;

- the ability to print one model with several materials.

The five-axis design allows complex shapes to be printed without supports. The ability to print one model with several materials with different properties allows you to create parts with complex composition, for example, with an inner core made of a stronger material, or with a coating or inserts made of flexible. For the convenience of printing with different materials, the platform is also optimized - it is divided into cells that can be set to different heating temperatures.

The printer is already available for pre-order, and shipments will begin, according to the manufacturer, from January 2019.

3DGENCE INDUSTRY F340

- Working chamber: 260 x 340 x 340 mm;

- layer thickness: from 150 microns;

- chamber temperature: up to 85 ˚C;

- extruder temperature: up to 500 ˚C.

The printer can be equipped with one of three printing modules. Standard - up to 265 ˚C, medium - up to 350 ˚C, high temperature - up to 500 ˚C. Printed modules - with two hotends, for the main and auxiliary materials. Among other interesting features, we note the preheating of the plastic and the coil mass sensor.

Standard - up to 265 ˚C, medium - up to 350 ˚C, high temperature - up to 500 ˚C. Printed modules - with two hotends, for the main and auxiliary materials. Among other interesting features, we note the preheating of the plastic and the coil mass sensor.

Apium

Apium Additive Technologies GmbH is a German manufacturer of small printers for high temperature PEEK, Ultem and PPSU filaments and composites. Apium is translated from Latin as "celery". For products, support for printing with metal-filled filaments is declared for further baking.

Apium P155

- Working chamber: 155 x 155 x 155 mm;

- extruder temperature: up to 520 °C;

- table temperature: up to 160 °C;

- layer thickness: from 100 µm.

Desktop high temperature printer with a small printable area. It is the successor to the Indmatec HPP 155. Apium also offers a slightly larger model - P220, with a print area of 200 x 160 x 160 mm.

GEWO 3D

The German manufacturer offers one high-temperature printer, with a very serious margin for the heating temperature of the printing platform and the working chamber.

GEWO HTP 260

- Working chamber: 350 x 150 x 165 mm;

- layer thickness: from 20 microns;

- extruder temperature: up to 450 °C;

- table temperature: up to 270 °C;

- chamber temperature: up to 260 °C.

Prints with all common engineering plastics, equipped with two extruders. Possibility of installation of a spindle for machining of a detail is provided.

MiniFactory Innovator 2

- Working chamber: 300 x 160 x 160 mm;

- layer thickness: from 30 µm.

Finnish dual extruder printer, the manufacturer focuses on PEEK printing. Other engineering plastics such as ABS, polycarbonate or Ultem are also supported.

Omni3D Factory 2.0

- Working chamber: 500 x 500 x 500 mm;

- layer thickness: from 140 microns;

- extruder temperature: up to 360 °C;

- table temperature: up to 130 °C;

- chamber temperature: up to 70 °C.

An industrial printer from Poland is equipped with two extruders and can print large parts from ABS, polycarbonate, polyamide and composites based on them.

DynamicalTools DT600

- Working chamber: 600 x 450 x 450 mm;

- layer thickness: from 140 microns;

- extruder temperature: up to 500 °C;

- table temperature: up to 150 °C.

The Spanish printer with two independent printheads, in addition to normal printing, supports printing modes for two identical or mirror parts at the same time. Works with all high temperature filaments up to PEEK, Ultem, PPSU. Equipped with systems for heating plastic and automatic change of coils.

Equipped with systems for heating plastic and automatic change of coils.

HAGE3D 140L

- Working chamber: 700 x 500 x 400 mm;

- layer thickness: from 50 microns;

- extruder temperature: up to 450 °C;

- chamber temperature: up to 85 °C.

Austrian industrial machine that supports most engineering filaments and composites. Heated working chamber, three-zone heating table.

AIM3D

The company offers a complex of equipment for the manufacture of metal objects. At the first stage, the part is printed on a 3D printer, at the second stage it is placed in an oven, where the binder plastic burns out and the metal filler is sintered.

AIM3D ExAM 255

- Working chamber: 255 x 255 x 255 mm;

- layer thickness from: 20 µm;

- table temperature: up to 120 °C.

The printer does not work with filament, but with granules. This allows the use of raw materials for FDM printing, which are usually used in MIM installations, Metal Injection Molding. You can also print with plastic pellets, which is usually cheaper than using filament.

This allows the use of raw materials for FDM printing, which are usually used in MIM installations, Metal Injection Molding. You can also print with plastic pellets, which is usually cheaper than using filament.

AIM3D ExSO 90

- workpiece diameter, up to: 90 mm;

- 6-sided heating;

- isolation and collection of fumes generated during sintering;

- temperature: up to 1350 °C.

Furnace for high-temperature sintering of parts printed on AIM3D ExAM 255 in an inert gas atmosphere.

How to purchase an industrial 3D printer

Looking for an industrial 3D printer? Top 3D Shop is the official representative of most of the manufacturers mentioned in the review, we are ready to supply equipment, commissioning, training and maintenance.

We have made a comparison table for these machines, with technical nuances - print and camera temperatures, materials used, number of extruders and estimated cost.

Prices for 3D printers that print with high temperature plastics, as for industrial equipment, often depend on the manufacturer's very flexible pricing policy.

The price may vary from delivery to delivery, depending on many factors, and some manufacturers are categorically against the publication of final prices in the public domain, therefore we do not indicate prices in the article, but we provide a table on request.

For more information and assistance in choosing an industrial high-temperature 3D printer, please contact Top 3D Shop.

Want more exciting news from the world of 3D technology?

Follow us on social. networks:

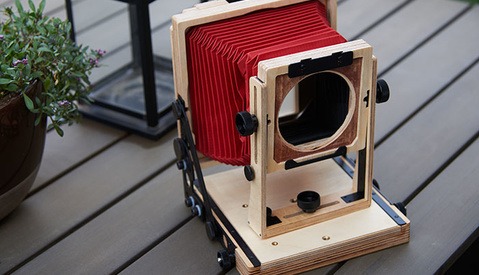

Aleksi Koski, large format, film, DIY

Photographer Aleksi Koski created what he calls the world's first 4x5 inch camera equipped with an autofocus system. Koski called the camera Conflict AF45 and put all his 15 years of experience shooting on large format film into its development.

Based on a passion for classic 4×5 press photography.

From the very beginning of his passion for photography, Kosky had an interest in 4x5, inspired by a press photograph from the 1930s

“I really like the Weegee* style and the crime photography of that era,” says Kosky. “The 4×5” format was the main format that photojournalists worked with. And only in our time has it become a clumsy system on a tripod.0005

(*ed. note: Weegee is the pseudonym of the photographer and photojournalist Arthur Fellig (June 12, 1899 – December 26, 1968), famous for his black and white street photography in New York)

His first camera there was a regular Speed Graphic with a Kalart rangefinder, which he calibrated for several lenses and used for handheld shooting. However, Kosky has always been obsessed with the dream of the perfect compact large format film camera. This dream led him to create a 4x5 camera that is free from all the shortcomings that Kosky has identified over the years of working with this format.

Modernization of the classic

Koski called the camera Conflict AF45. Its most notable feature is its autofocus system, which uses a motorized actuator to move the bellows back and forth. Another important component is the ability to easily adjust frame lines for any lens and format.

“You can calibrate almost any lens in the Conflict AF45 and get accurate frame lines on 4x5” film and other formats like 6x12 roll film,” explains Koski. “The camera uses a laser focusing system with an accuracy of up to 2mm.”

The focus drive stroke is 62mm, allowing you to zoom in close to approx. 50cm with a 150mm lens and 10-20cm with a wide-angle lens. At the same time, the laser system facilitates focusing at close distances.

“Close focus has always been something lacking in rangefinder cameras. Since rangefinders do not work very well at close distances. But the laser system solves it. Accuracy improves as you get closer,” says Koski.

In addition, the camera is capable of automatically calculating bellows expansion compensation for close-ups, has a built-in light meter, built-in accelerometer and gyroscope for electronic horizon, and is equipped with Wi-Fi and includes upgradable firmware.