Best 3d printer for mechanical engineering

7 Best 3D Printers for Engineers & Mechanical Engineers Students – 3D Printerly

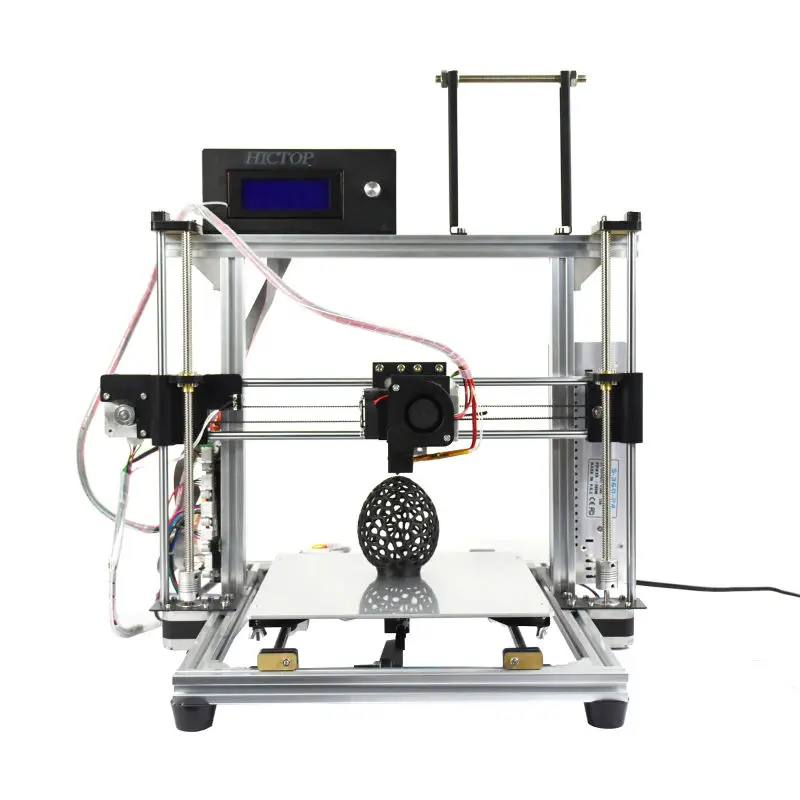

3D printing is slowly becoming an essential part of our everyday lives. Various professions are incorporating the use of 3D printers in their workplaces.

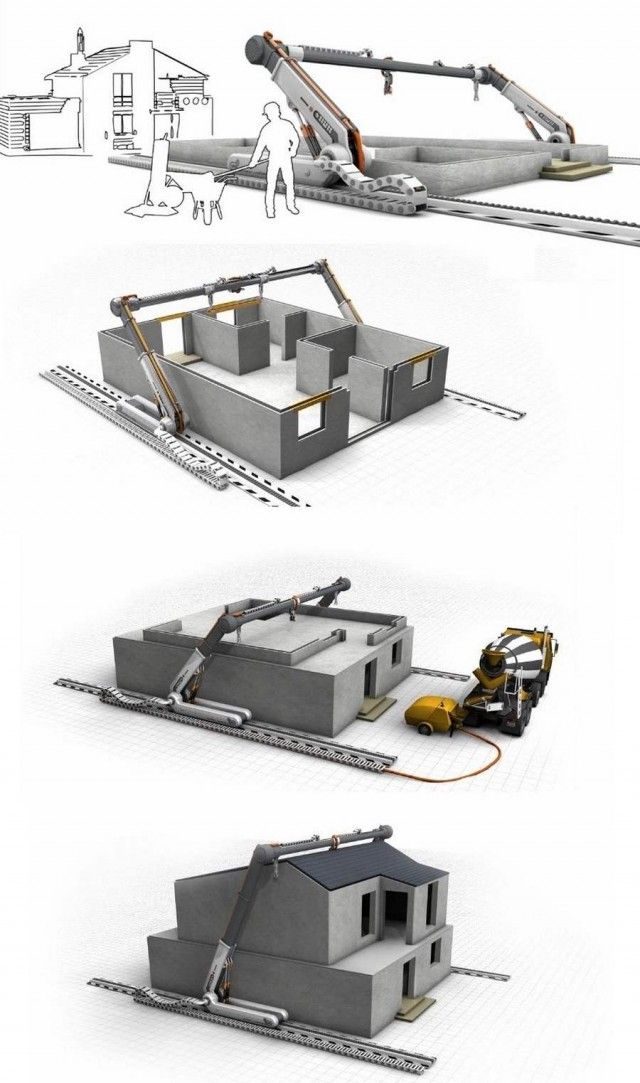

No profession benefits from the application of 3D printing as much as engineering, whether it is electrical, mechanical, civil, structural, or mechanical.

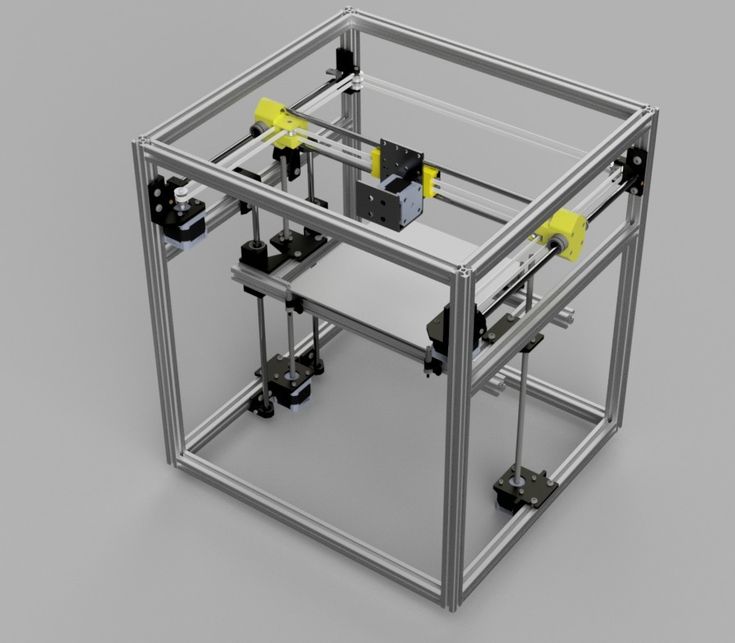

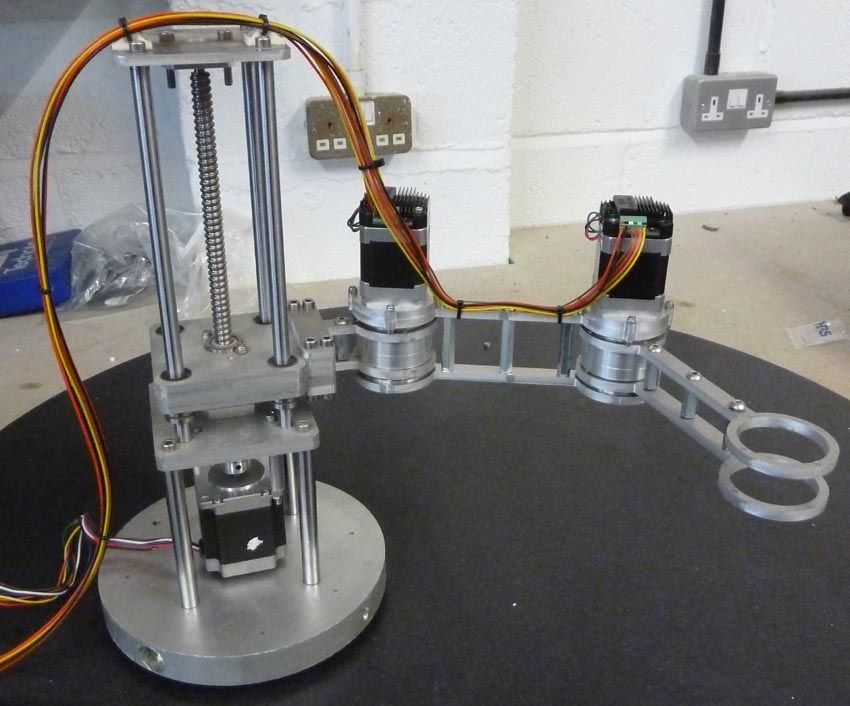

3D printing plays a crucial role in the designing and production phases of any engineering project. With a 3D printer, engineers are able to create visual prototypes to bring out their design ideas.

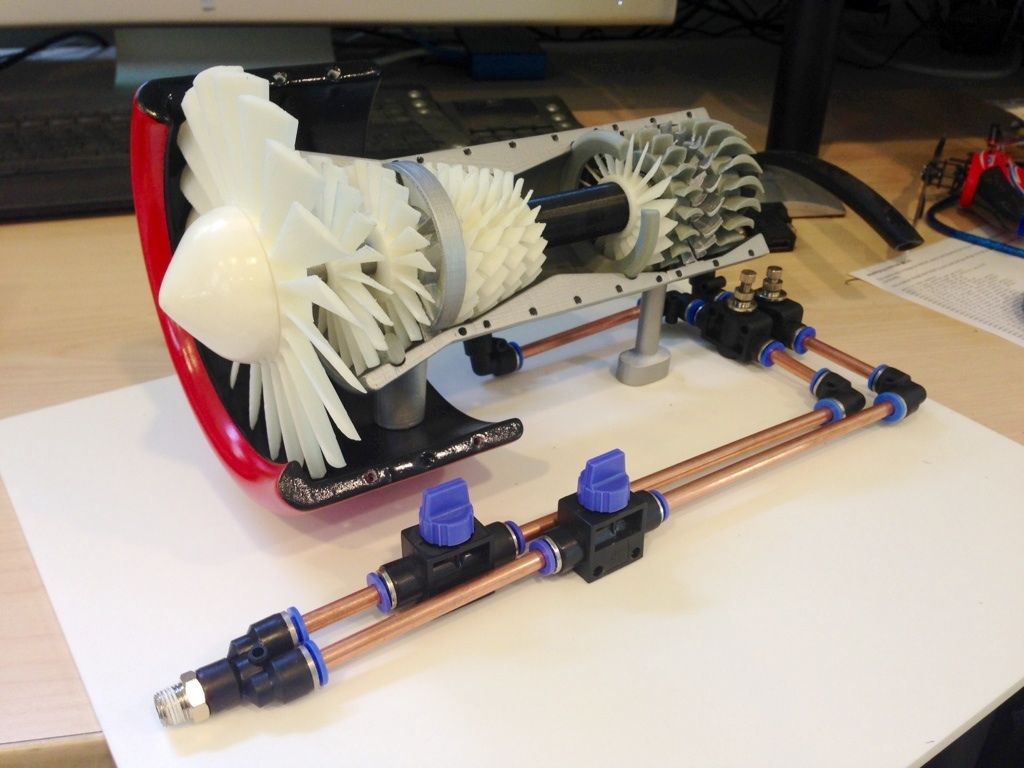

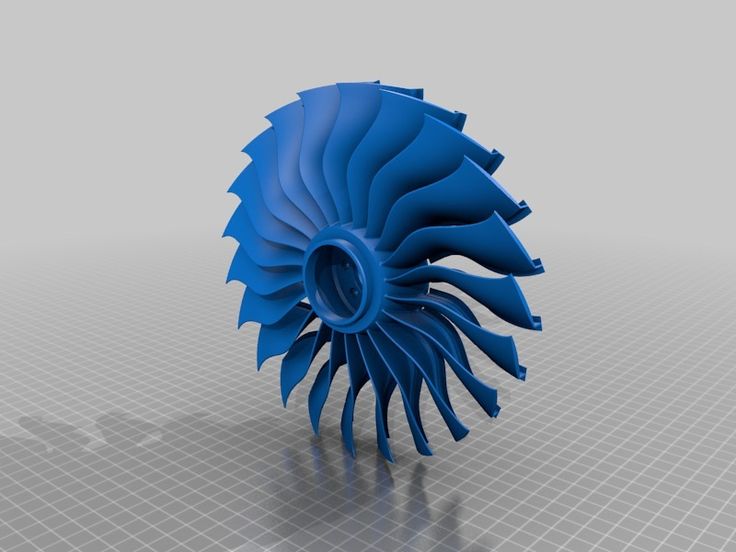

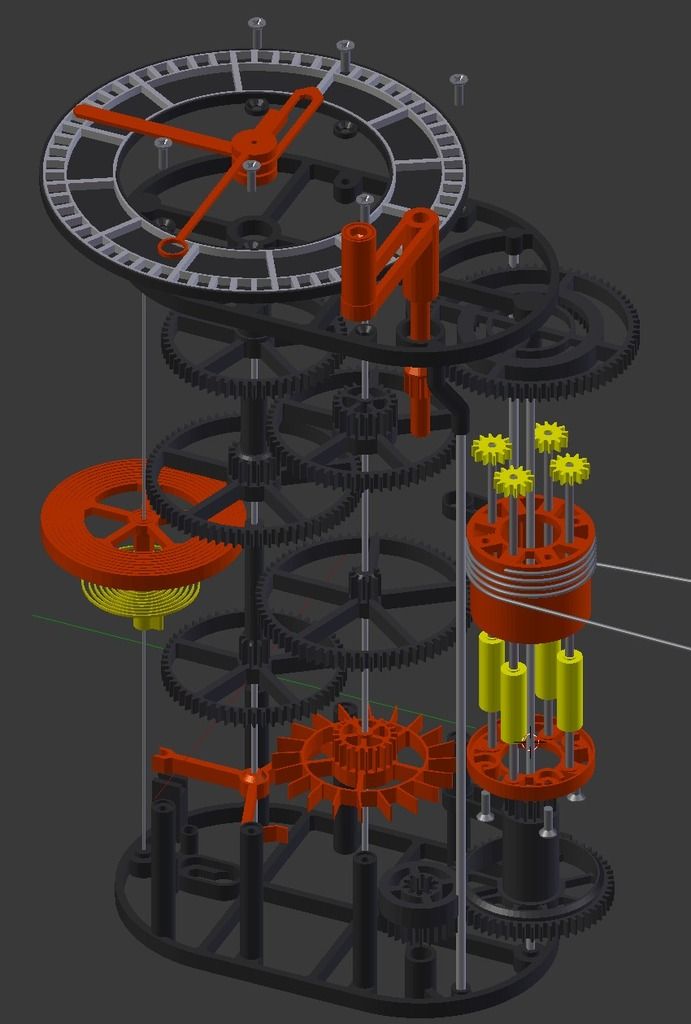

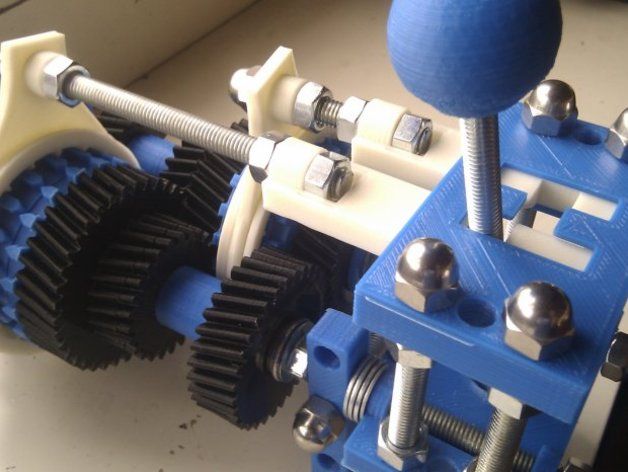

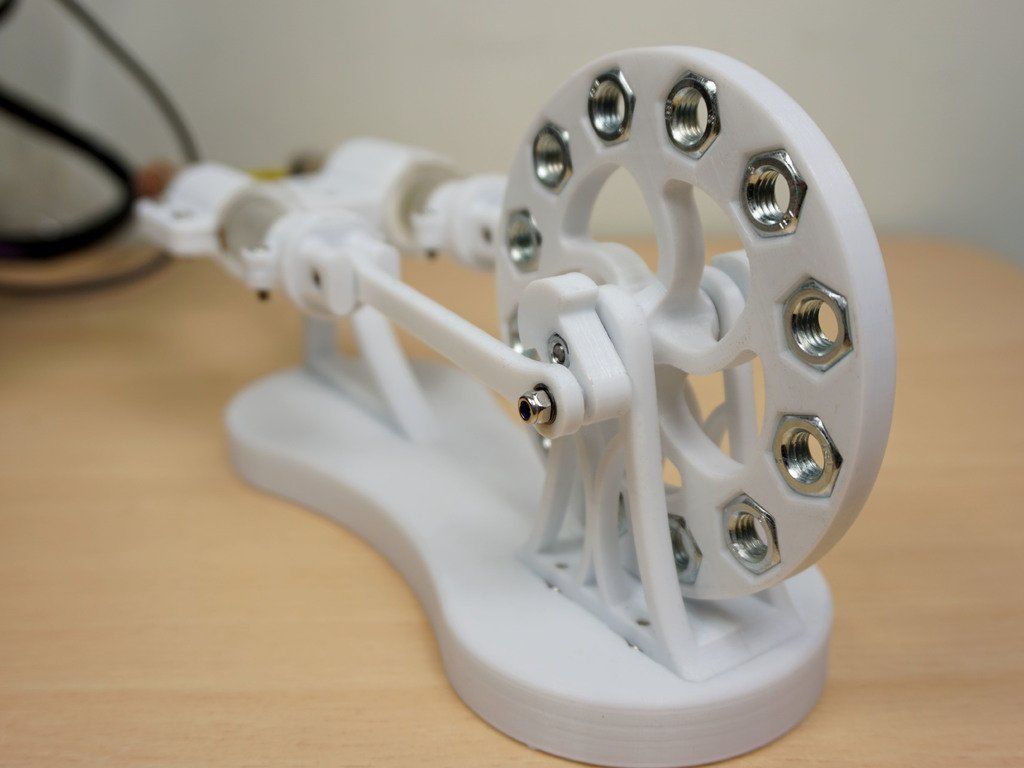

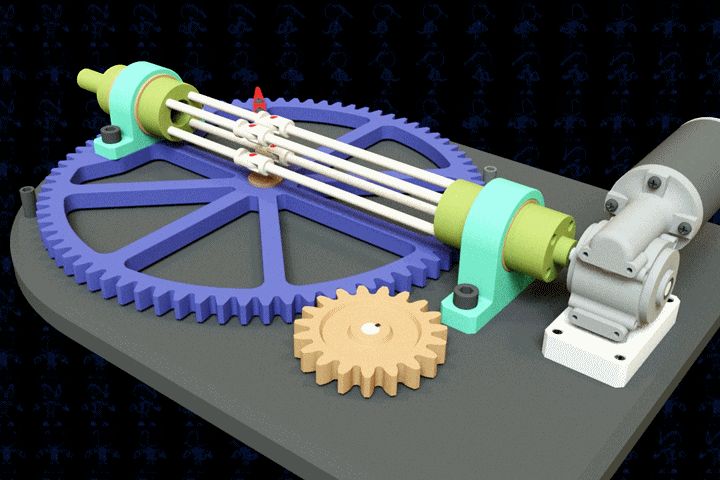

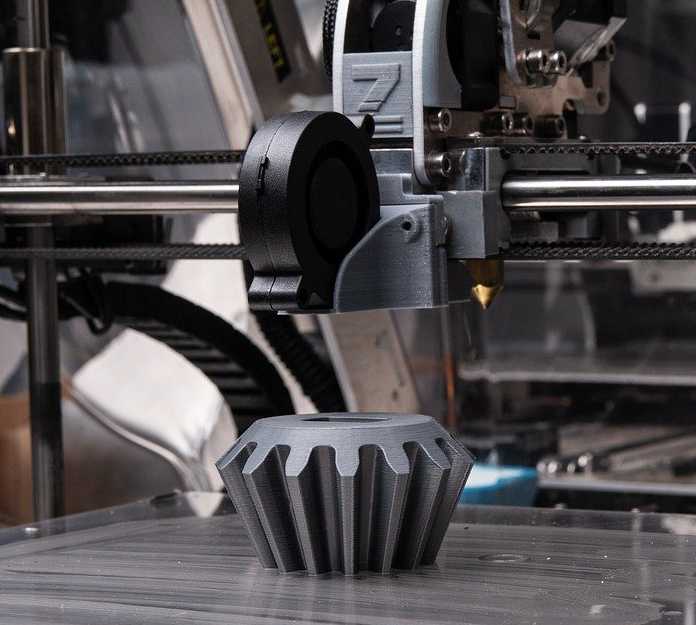

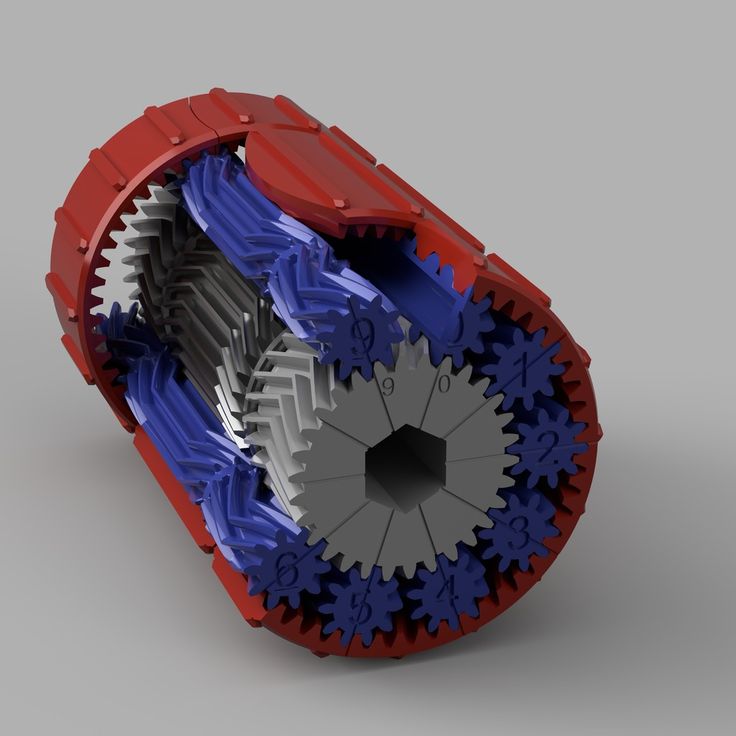

Mechanical engineering students can easily create various mechanical components of their products e.g. gears through 3D printing. Structural engineers can easily create scale models of buildings to get a clearer view of how the various parts of the structure would interlink and look.

The applications of 3D printing by engineers are limitless. However, to create accurate models for your designs, you will need a solid printer. Let’s have a look at some of the best printers for engineers and mechanical engineering students.

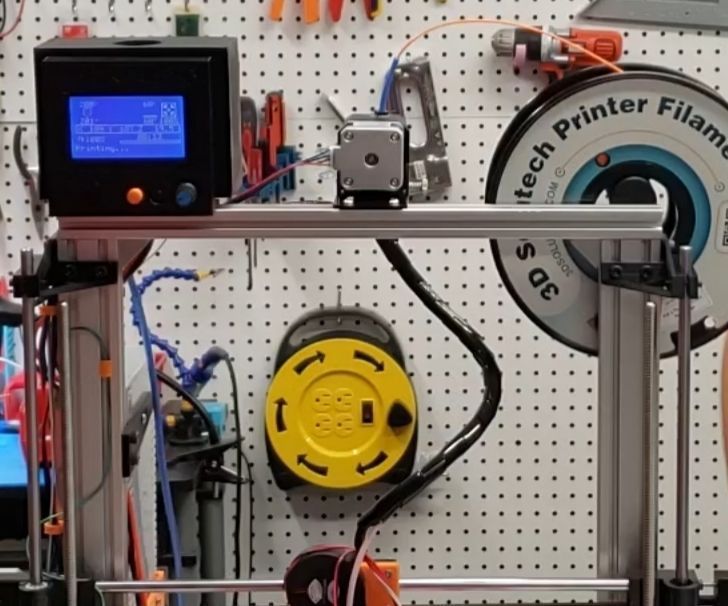

We’ll start our list with the Qidi Tech X-Max. This machine is solely designed to handle more advanced materials like nylon, carbon fiber and PC, without compromising on the speed and quality of production.

This makes it one of the favorites among mechanical engineering students. Let’s take a closer look at some of its features.

Features of the Qidi Tech X-Max

- Solid Structure and Wide Touchscreen

- Different Types of Printing for You

- Double Z-axis

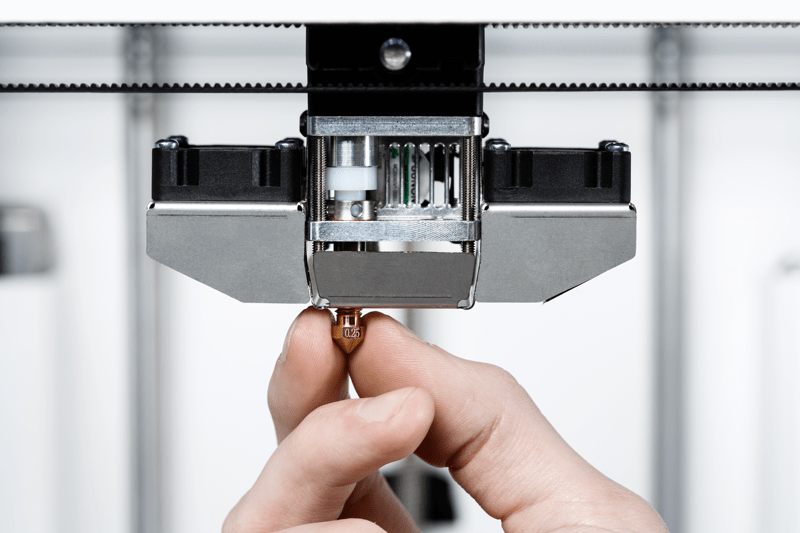

- Newly Developed Extruder

- Two Different Ways for Placing the Filament

- QIDI Print Slicer

- QIDI TECH One-to-One Service & Free Warranty

- Wi-Fi Connectivity

- Ventilated & Enclosed 3D Printer System

- Large Build Size

- Removable Metal Plate

Specifications of the Qidi Tech X-Max

- Build Volume: 300 x 250 x 300mm

- Filament Compatibility: PLA, ABS, TPU, PETG, Nylon, PC, Carbon Fiber, etc

- Platform Support: Double Z-axis

- Build Plate: Heated, removable plate

- Support: 1-Year with infinite customer support

- Filament Diameter: 1.

75mm

75mm - Printing Extruder: Single extruder

- Layer Resolution: 0.05mm – 0.4mm

- Extruder Configuration: 1 set of a specialized extruder for PLA, ABS, TPU & 1 set of a high performance extruder for printing PC, Nylon, Carbon Fiber

Giving this printer an edge over its competitors is a set of Qidi Tech third-generation extruder assembly. The first extruder prints general material like PLA, TPU, and ABS, while the second one prints materials that are more advanced e.g. Carbon fiber, Nylon, and PC.

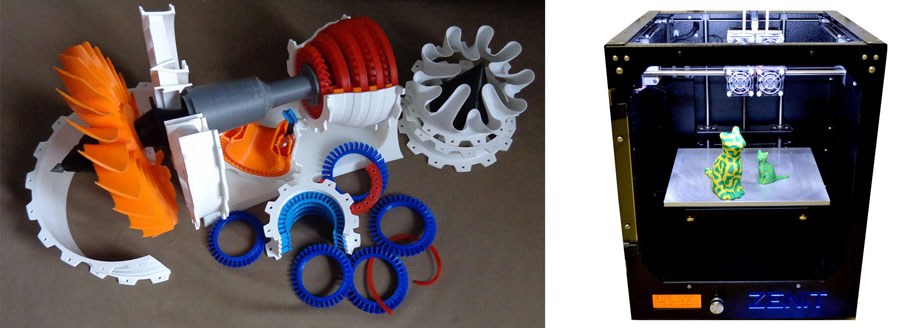

This makes it possible for mechanical engineering students to print out mechanical components for the machine they are trying to develop, be it shafts, gears, or any other parts.

The Qidi Tech X-Max (Amazon) has a double Z-axis, which stabilizes the printer when it prints large models.

What impressed me the most is the flexible metal plate which makes it easier to extract a printed model. Both sides of the plates are usable. On the front side, you can print general material and on the backside, you can print advanced material.

It also has a 5-inch touchscreen with a more practical user interface, making it simpler to operate than its competitors.

User Experience of the Qidi Tech X-Max

One user liked how well-packaged the printer came. He said that he was able to unpack it and assemble it for use in less than half an hour.

Another user said that the Qidi Tech X-Max was one of the most reliable printers for producing prototypes because of its large print area. She said that she had already printed over 70 hours of prints without any complications.

When it comes to safety, the Qidi Tech X-Max doesn’t compromise at all. A customer could not hold his excitement when he saw an air filter on the back of the print chamber’s wall. This feature is noticeably absent from most 3D printers.

One user liked that they didn’t have to use any adhesives since the coating on the build plate was able to hold his prints firmly in place.

Pros of the Qidi Tech X-Max

- Amazing and consistent 3D print quality that will impress many

- Durable parts can be created with ease

- Pause and resume function so you can change over the filament anytime

- This printer is set up with high-quality thermostats with more stability and potentiality

- Excellent UI interface that makes your printing operation easier

- Quiet printing

- Great customer service and helpful community

Cons of the Qidi Tech X-Max

- Doesn’t have filament run-out detection

- The instructional manual isn’t too clear, but you can get good video tutorials to follow

- The internal light can’t be turned off

- Touchscreen interface can take a little getting used to

Final Thoughts

The Qidi Tech X-Max does not come cheap, but if you got a few bucks to spare, then this massive machine will definitely give you a return on your investment.

Check out the Qidi Tech X-Max for a 3D printer able to help handle your mechanical engineering projects.

The Dremel brand is known for producing products that help people to get acquainted with 3D printing technology. The Dremel 3D45 is one of their ultra-modern 3rd generation 3D printers designed for heavy usage.

Let’s see some of the features that make the Dremel 3D45 a good fit for engineers.

Features of the Dremel Digilab 3D45

- Automated 9-Point Levelling System

- Includes Heated Print Bed

- Built-In HD 720p Camera

- Cloud-Based Slicer

- Connectivity Through USB and Wi-Fi Remotely

- Fully Enclosed With Plastic Door

- 5″ Full-Color Touch Screen

- Award-Winning 3D Printer

- World-Class Lifetime Dremel Customer Support

- Heated Build Plate

- Direct Drive All-Metal Extruder

- Filament Run-Out Detection

Specifications of the Dremel Digilab 3D45

- Print Technology: FDM

- Extruder Type: Single

- Build Volume: 255 x 155 x 170mm

- Layer Resolution: 0.

05 – 0.3mm

05 – 0.3mm - Compatible Materials: PLA, Nylon, ABS, TPU

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Bed Levelling: Semi-Automatic

- Max. Extruder Temperature: 280°C

- Max. Print Bed Temperature: 100°C

- Connectivity: USB, Ethernet, Wi-Fi

- Weight: 21.5 kg (47.5 lbs)

- Internal Storage: 8GB

Unlike many other 3D printers, The Dremel 3D45 doesn’t need any assembling. It is ready for usage straight out of the package. The manufacturer even provides 30 lesson plans, which could be useful for mechanical engineering students who are using it for the first time.

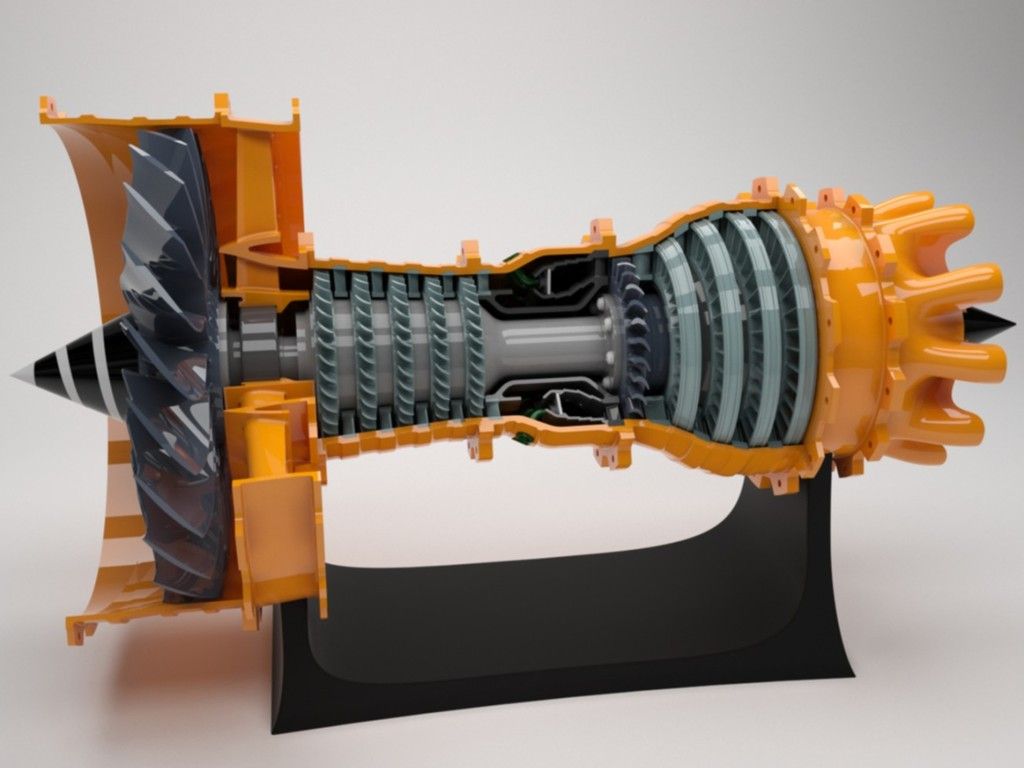

It has an all-metal direct drive extruder that can heat up to 280 degrees Celsius. This extruder is also resistant to clogging ensuring that you can print a designed product freely e.g. a car engine model.

Another standout feature is the filament run-out detection system. It ensures that you can continue printing from the last position anytime the filament finishes, and you feed in a new one.

With the Dremel 3D45 (Amazon), you don’t have to worry about adjusting knobs to do your leveling as it comes with a built-in automatic leveling sensor. The sensor will detect any variation in the bed level and adjust it accordingly.

To interact with the printer, you have a 4.5” colored touch screen that you can operate effortlessly.

User Experience for the Dremel 3D45

What the majority of the users seem to concur with is that setting up the Dremel 3D45, after purchasing it, is a straightforward task. You can start with its pre-loaded print in less than 30 minutes.

One user who owns two Dremel 3D45 printers said that they never cease to amaze him. He has printed in virtually all colors of Dremel’s filaments, and they were still simple to use.

He added that the nozzle works perfectly. However, you will need to upgrade to a hardened nozzle if you want to print carbon fiber, which is preferred by mechanical and automotive engineers due to its good weight to strength ratio.

Using the 4.5” touch screen was a pleasant experience for one user who could read and operate everything easily.

A satisfied customer said that this printer was very silent even with its door open. The enclosed design definitely plays a big role in that

Pros of the Dremel Digilab 3D45

- Print quality is very good and it’s easy to use as well

- Has powerful software along with being user-friendly

- Prints through a USB thumb drive via Ethernet, Wi-Fi, and USB

- Has a safely secured design and body

- Compared to other printers, it is relatively quiet and less noisy

- Easier to set up and use as well

- Provides a 3D comprehensive ecosystem for education

- The removable glass plate allows you to remove prints easily

Cons of the Dremel Digilab 3D45

- Limited filament colors compared with competitors

- The touch screen is not particularly responsive

- There is no nozzle cleaning mechanism

Final Thoughts

Knowing that they had an almost 80-year reputation to maintain, Dremel did not compromise when it came to the 3D45. This robust printer is the epitome of reliability and quality printing.

This robust printer is the epitome of reliability and quality printing.

You can always count on the Dremel 3D45 to create perfectly molded prototypes.

Find the Dremel Digilab 3D45 on Amazon today.

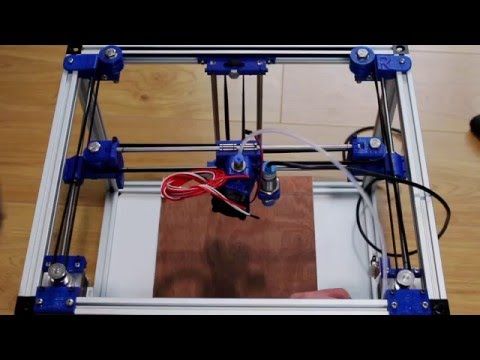

The Bibo 2 Touch laser which is popularly known as the Bibo 2 was first released in 2016. Since then, it has slowly gained popularity among 3D printing fanatics in the engineering fraternity.

Additionally, it has a lot of good reviews on Amazon and has been appearing in many bestseller lists.

Let’s find out why this machine is an engineer’s favorite.

Features of the Bibo 2 Touch

- Full-Color Touch Display

- Wi-Fi control

- Removable Heated Bed

- Copy Printing

- Two-Color Printing

- Sturdy Frame

- Removable Enclosed Cover

- Filament Detection

- Power Resume Function

- Double Extruder

- Bibo 2 Touch Laser

- Removable Glass

- Enclosed Print Chamber

- Laser Engraving System

- Powerful Cooling Fans

- Power Detection

- Open Build Space

Specifications of the Bibo 2 Touch

- Build Volume: 214 x 186 x 160mm

- Nozzle Size: 0.

4 mm

4 mm - Hot End Temperature: 270℃

- Temperature of Heated Bed: 100℃

- of Extruders: 2 (Dual Extruder)

- Frame: Aluminum

- Bed Leveling: Manual

- Connectivity: Wi-Fi, USB

- Filament Materials: PLA, ABS, PETG, flexible etc.

- File Types: STL, OBJ, AMF

At first glance, you might mistake the Bibo 2 Touch for a 3D printer from a different era due to its outdated look. But, don’t judge a book by its cover. The Bibo 2 is a beast in its own right.

This printer has a 6mm thick composite panel made of aluminum. So, its frame is stronger than more the conventional plastic ones.

The Bibo 2 Touch (Amazon) has dual extruders that will enable you to print a model with two different colors without having to change the filament.

Impressive, right? Well, it can do more than that. With dual extruders, you can print two different models at the same time. This will be very important for engineering projects with time constraints.

You can control all aspects of the printing from your phone or computer thanks to its Wi-Fi control feature. This is suitable for mechanical engineering students who love using their PC for more than just design.

As the name suggests, the Bibo 2 Touch has a color touch screen with a friendlier user interface.

User Experience of the Bibo 2 Touch

According to one user, setting up the Bibo 2 Touch is an amusing experience. The user said that she only had to do minimal work as the printer was already 95% assembled.

She also said that the printer came with, and SD card with a tonne of information that helps her carry out her first test print with ease. It also helped her learn the basics of operating the machine.

In one review, a user stated how they have been able to print with PLA, TPU, ABS, PVA, and nylon without any issues. She added that the laser engraver worked perfectly.

One user loved how the Filament Sensor enabled printing to continue from where it left off immediately after a blackout. Therefore, he didn’t have to worry about wasted filament, time or crooked prints.

Therefore, he didn’t have to worry about wasted filament, time or crooked prints.

This can be important for engineers when printing out more intricate designs such as car models.

Bibo’s tech support has been lauded by many consumers for its fast and direct way of addressing problems.

The only downside is that they are in a different time zone, so you will have to find out the best times for sending inquiries, or else you’ll wait for a long time for a response. The screen is also a bit buggy, and the user interface can be improved.

Pros of the Bibo 2 Touch

- Dual extruder improves 3D printing capabilities and creativity

- Very stable frame which translates to better print quality

- Easy to operate with the full-color touchscreen

- Known for having great customer support based in the US & China

- Great 3D printer for high volume printing

- Has Wi-Fi controls for more convenience

- Great packaging to ensure a safe and sound delivery

- Easy to use for beginners, giving out high performance and much enjoyment

Cons of the Bibo 2 Touch

- Relatively small build volume compared to some 3D printers

- The hood is quite flimsy

- The location to put the filament is at the back

- Leveling the bed can be a little difficult

- Has quite a learning curve because there are so many features

Final Thoughts

The Bibo 2 Touch doesn’t have many positive reviews for no good reason. If you ignore the small issues here and there, you’ll get a highly efficient printer that will serve you for quite some time.

If you ignore the small issues here and there, you’ll get a highly efficient printer that will serve you for quite some time.

If you want a good printer for handling your undergraduate engineering degree projects, check out the Bibo 2 Touch on Amazon.

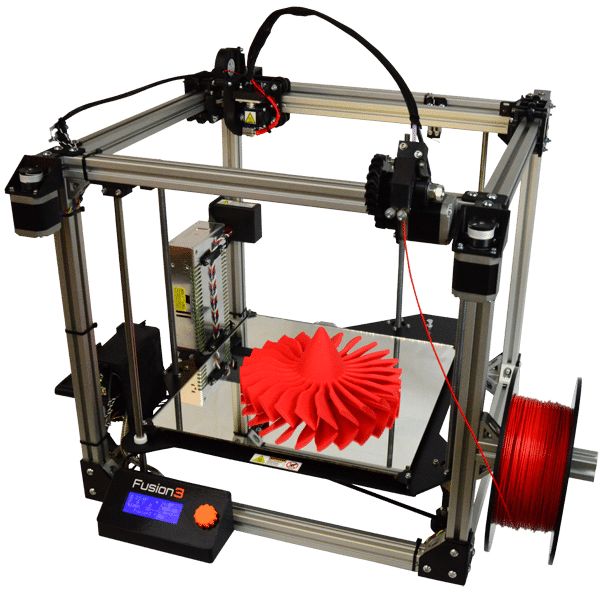

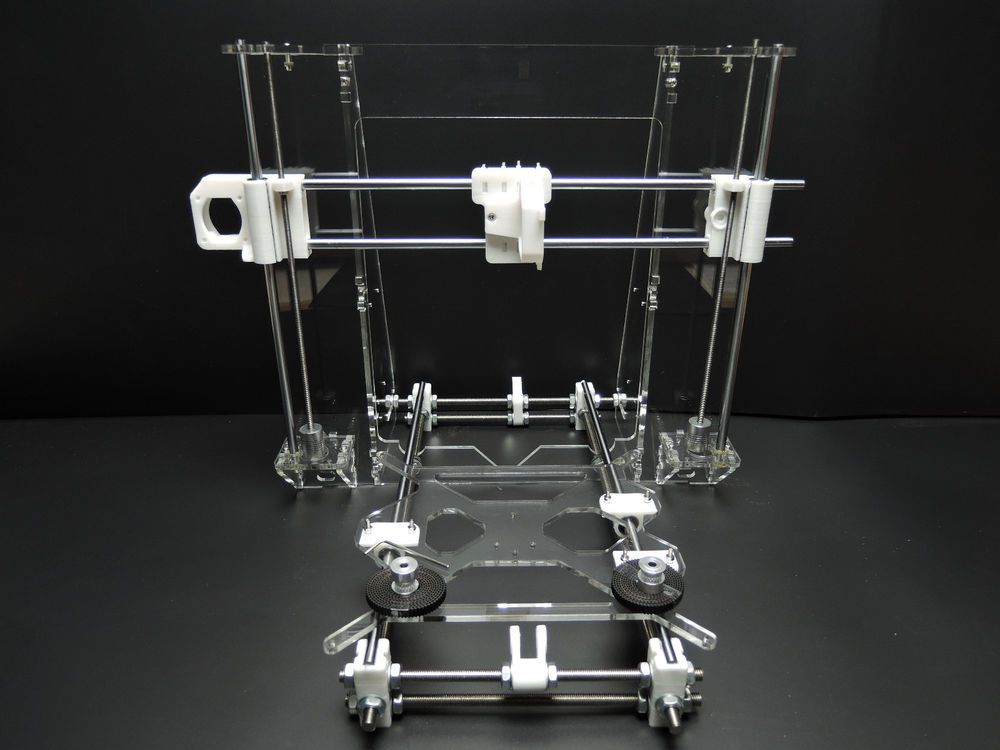

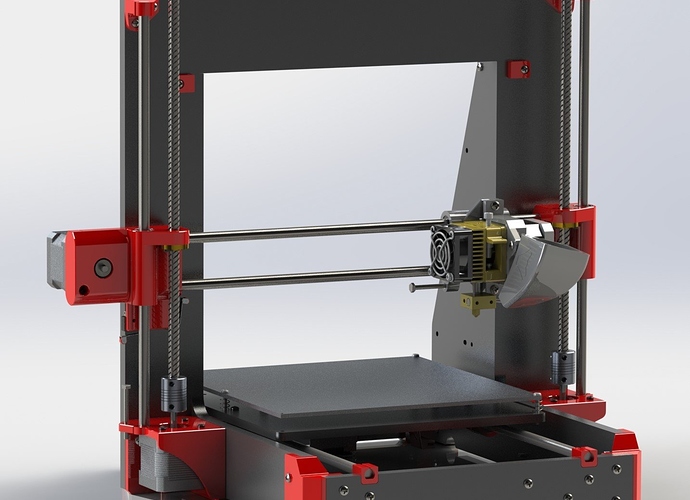

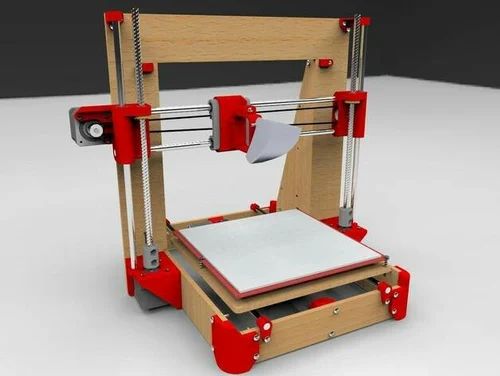

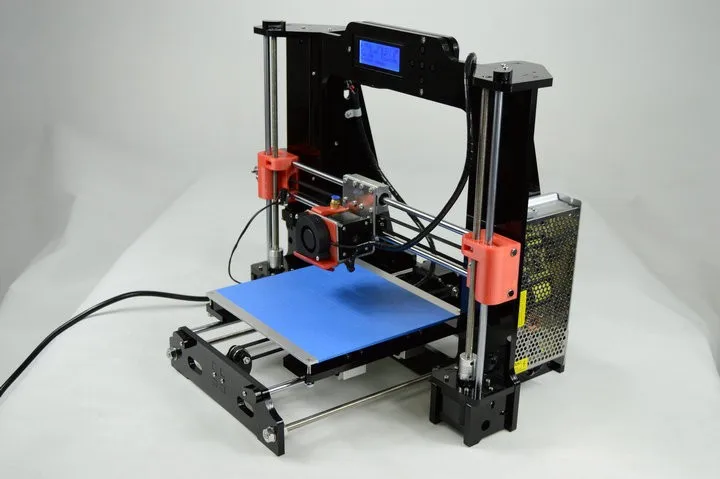

The Ender 3 V2 is the third iteration of the Ender 3 line by Creality.

By tweaking certain of its predecessors (the Ender 3 and Ender 3 Pro), Creality was able to come up with a machine that is not only a good size, but also has excellent print quality at a good price.

In this section, we’ll dive into the specifics of this printer.

Features of the Ender 3 V2

- Open Build Space

- Carborundum Glass Platform

- High-Quality Meanwell Power Supply

- 3-Inch LCD Color Screen

- XY-Axis Tensioners

- Built-In Storage Compartment

- New Silent Motherboard

- Fully Upgraded Hotend & Fan Duct

- Smart Filament Run Out Detection

- Effortless Filament Feeding

- Print Resume Capabilities

- Quick-Heating Hot Bed

Specifications of the Ender 3 V2

- Build Volume: 220 x 220 x 250mm

- Maximum Printing Speed: 180mm/s

- Layer Height/Print Resolution: 0.

1mm

1mm - Maximum Extruder Temperature: 255°C

- Maximum Bed Temperature: 100°C

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Extruder: Single

- Connectivity: MicroSD Card, USB.

- Bed Levelling: Manual

- Build Area: Open

- Compatible Printing Materials: PLA, TPU, PETG

The most noticeable upgrade is the silent 32-bit motherboard which is the spine of the Creality Ender 3 V2 and reduces the noise produced when printing to below 50 dBs.

If you set up the Ender 3 V2, you will not fail to notice the V-guide rail pulley system which stabilizes movement while increasing the wear resistance. This will enable you to use your printer to produce 3D prints for prototypes for longer.

When it comes to printing 3D models, you need a good filament feed-in system. Creality 3D has added a rotary knob to make it simpler for you to load the filament.

On the XY-axis you have a new injection tensioner that you can use to conveniently adjust the tension in the belt.

On the software side, you have a new user interface that has been designed to improve the user’s experience. All this is projected on a 4.3” color screen which you can detach easily for repair.

For engineers, who are more hands-on, there is a toolbox on the machine where you can store your tools and retrieve them easily at any time.

User Experience of the Ender 3 V2

One user liked how clear the instructions for helping to set up the printer were. By following them and watching a few videos on YouTube, she was able to set up the printer in a relatively shorter time.

Another user states that he has been able to print PLA models with no complications using the test filament the company provides. He was able to do the test print successfully, and after that has been printing without problems.

This means that mechanical engineering students can print out things like brushless motors without any challenges.

In one five-star review, the customer states that the Ender 3 V2 was his second printer and he was impressed with how easy it was to use the print bed.

The bed adhesion was a bit off at first but he was able to fix this issue by increasing the rate of extrusion and slightly sanding the Carborundum glass bed.

He also appreciated that the Ender 2 came with a little drawer under the print bed which allowed him to keep his micro USB cards, nozzles, Bowden tubes, and card readers.

Pros of the Ender 3 V2

- Easy to use for beginners, giving out high performance and much enjoyment

- Relatively cheap and great value for money

- Great support community.

- Design and structure look very aesthetically pleasing

- High precision printing

- 5 minutes to heat up

- All-metal body gives stability and durability

- Easy to assemble and maintain

- Power supply is integrated underneath the build-plate unlike the Ender 3

- It is modular and easy to customize

Cons of the Ender 3 V2

- A bit difficult to assemble

- Open build space is not ideal for minors

- Only 1 motor on the Z-axis

- Glass beds do tend to be heavier so it may lead to ringing in prints

- No touchscreen interface like some other modern printers

Final Thoughts

If you’re looking for a low-budget printer with pretty standard capabilities, the Ender 3 V2 will do the trick. However, if you want to print more advanced materials, you should consider looking for a different printer.

However, if you want to print more advanced materials, you should consider looking for a different printer.

The Ender 3 V2 can be found on Amazon.

The Dremel Digilab 3D20 is every hobbyist or engineering student’s first choice printer. Its relatively low cost and high performance make it a better choice to purchase as compared to other 3D printers in the market.

It’s similar to the Dremel Digilab 3D45, but with a few less features and at a much cheaper price.

Let’s take a look under the hood.

Features of the Dremel Digilab 3D20

- Enclosed Build Volume

- Good Print Resolution

- Simple & Easy to Maintain Extruder

- 4-Inch Full-Color LCD Touch Screen

- Great Online Support

- Premium Durable Build

- Established Brand With 85 Years of Reliable Quality

- Simple to Use Interface

Specifications of the Dremel Digilab 3D20

- Build Volume: 230 x 150 x 140mm

- Printing Speed: 120mm/s

- Layer Height/Print Resolution: 0.

01mm

01mm - Maximum Extruder Temperature: 230°C

- Maximum Bed Temperature: N/A

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Extruder: Single

- Connectivity: USB A, MicroSD card

- Bed Levelling: Manual

- Build Area: Closed

- Compatible Printing Materials: PLA

The Dremel Digilab 3D20 (Amazon) has a fully enclosed design that is essential for extra safety. This design also maintains the stability of temperature inside the machine to ensure that every print is successful.

Children cannot poke their fingers into the print area, which can come in handy for engineers working on projects on a part-time basis at home.

This printer comes with a non-toxic plant-based PLA filament, which has been designed to produce strong and precisely finished prints and is less harmful.

The only downside is that the Dremel Digilab doesn’t come with a heated bed, which means that you can mostly print with just PLA.

On the software, you have a full-colored LCD touch screen with a more modern interface. You can perform functions such as modifying the printer setting, obtaining files from the micro SD card, and printing easily.

You can perform functions such as modifying the printer setting, obtaining files from the micro SD card, and printing easily.

User Experience of the Dremel Digilab 3D20

This printer comes fully pre-assembled. You can just unbox it and immediately start using it. This, from reviews, has been helpful to many people who were beginners.

One user who wanted to undertake a project he called “Dabbing Thanos” with his son said that using the Dremel Digilab 3D20 was his best decision yet.

The Dremel software which he put on an SD card was simple to use. It sliced the file and added supports where necessary. This will help when printing prototypes with complex designs.

The final result was a nicely printed “Dabbing Thanos” which his son took to school to show his friends. He only had to clean up the final print with sandpaper.

Another user mentioned how precise the printer was thanks to its precise nozzle. Although it needed regular cleaning, he was more than happy to do it.

Pros of the Dremel Digilab 3D20

- Enclosed build space means better filament compatibility

- Premium and durable build

- Easy to use – bed leveling, operation

- Has its own Dremel Slicer software

- Durable and long-lasting 3D printer

- Great community support

Cons of the Dremel Digilab 3D20

- Relatively expensive

- Can be hard to remove prints from build plate

- Limited software support

- Only supports SD card connection

- Restricted filament options – listed as just PLA

Final Thoughts

The Dremel Digilab 3D20 is an easy-to-use printer with the ability to print out high-quality models. Since it comes fully assembled, you can use the time you would have used to set it up to come up with more innovative designs to print out.

You can check out the Dremel Digilab 3D20 on Amazon if you need a 3D printer to serve your engineering prototyping needs.

The Anycubic Photon Mono X is a resin 3D printer larger than most that you will get on the market today. While it may not have been the first resin 3D printer to be manufactured, it is slowly overtaking its competitors.

While it may not have been the first resin 3D printer to be manufactured, it is slowly overtaking its competitors.

Let look at some of its features to see how it fares.

Features of the Anycubic Photon Mono X

- 8.9″ 4K Monochrome LCD

- New Upgraded LED Array

- UV Cooling System

- Dual Linear Z-Axis

- Wi-Fi Functionality – App Remote Control

- Large Build Size

- High Quality Power Supply

- Sanded Aluminum Build Plate

- Fast Printing Speed

- 8x Anti-Aliasing

- 3.5″ HD Full Color Touch Screen

- Sturdy Resin Vat

Specifications of the Anycubic Photon Mono X

- Build Volume: 192 x 120 x 245mm

- Layer Resolution: 0.01-0.15mm

- Operation: 3.5″ Touch Screen

- Software: Anycubic Photon Workshop

- Connectivity: USB, Wi-Fi

- Technology: LCD-Based SLA

- Light Source: 405nm Wavelength

- XY Resolution: 0.05mm, 3840 x 2400 (4K)

- Z Axis Resolution: 0.

01mm

01mm - Maximum Printing Speed: 60mm/h

- Rated Power: 120W

- Printer Size: 270 x 290 x 475mm

- Net Weight: 10.75kg

This is pretty large even by 3D printer’s standards. The Anycubic Photon Mono X (Amazon) has a respectable size, measuring 192mm x 120mm x 245mm, easily double the size of many resin 3D printers out there.

Its upgraded LED array is unique to only a few printers. The UV matrix of LEDs distributes light evenly across the entire print.

The Anycubic Photon Mono X is 3 times faster than the average 3D printer. It has a short exposure time of between 1.5 to 2 seconds and a top print speed of 60mm/h. This is important when you’re trying to shorten the design-test-revise cycle time in challenging mechanical engineering projects.

With a Dual Z-Axis, you won’t have to worry about the Z-Axis track becoming loose. This makes the Photon Mono X very stable and improves the quality of printing.

On the operating side, you have an 8. 9” 4K monochrome LCD with a resolution of 3840 by 2400 pixels. Its clarity is really good as a result.

9” 4K monochrome LCD with a resolution of 3840 by 2400 pixels. Its clarity is really good as a result.

Your machine can often overheat especially when you use it continually to complete a fairly long engineering project. For that, the Anycubic Photon Mono X has a UV cooling system for efficient cooling and longer run times.

This printer’s bed is purely made out of anodized Aluminum to improve its adhesive properties so your 3D prints stick down to the build plate well.

User Experience for the Anycubic Photon Mono X

A satisfied customer from Amazon states how well the Anycubic resin works with the machine especially when you follow the recommended exposure settings that it usually comes with.

Another user says that his prints stuck to the print bed quite well because of the material used to make it (anodized aluminum).

He added that the Z-axis had never wobbled in the short duration that he had been printing. Overall, the mechanics were pretty solid.

One user who was printing at 0.05mm was thrilled that the Photon Mono X was able to capture the most intricate patterns for her prints.

A frequent user of the Anycubic Mono X said that its slicer software could use some improvements. However, he liked its auto-support function which enables every print to come out great despite its complexity.

A great thing about the software complaint though is how other slicers have stepped up to the plate to deliver amazing features that Anycubic missed out on. One such software is the LycheeSlicer, a personal favorite of mine.

You can export the specific .pwmx files needed for this 3D printer, as well as do plenty of functions that automate most of the slicing process.

Pros of the Anycubic Photon Mono X

- You can get printing really quickly, all within 5 minutes since it’s mostly pre-assembled

- It’s really easy to operate, with simple touchscreen settings to get through

- The Wi-Fi monitoring app is great for checking on the progress and even changing settings if desired

- Has a very large build volume for a resin 3D printer

- Cures full layers at once, resulting in quicker printing

- Professional looking and has a sleak design

- Simple leveling system which stays sturdy

- Amazing stability and precise movements that lead to almost invisible layer lines in 3D prints

- Ergonomic vat design has a dented edge for easier pouring

- Build plate adhesion works well

- Produces amazing resin 3D prints consistently

- Growing Facebook Community with plenty of helpful tips, advice, and troubleshooting

Cons of the Anycubic Photon Mono X

- Only recognizes .

pwmx files so you may be limited in your slicer choice

pwmx files so you may be limited in your slicer choice - The acrylic cover doesn’t sit in place too well and can move easily

- Touchscreen is a little flimsy

- Fairly pricey compared to other resin 3D printers

- Anycubic doesn’t have the best customer service track record

Final Thoughts

For a budget-friendly printer, the Anycubic Photon Mono X offers high accuracy during printing. Its big build volume and high resolution make it possible to print large models. I definitely recommend it to any engineer or mechanical engineering student.

You can get yourself the Anycubic Photon Mono X directly from Amazon today.

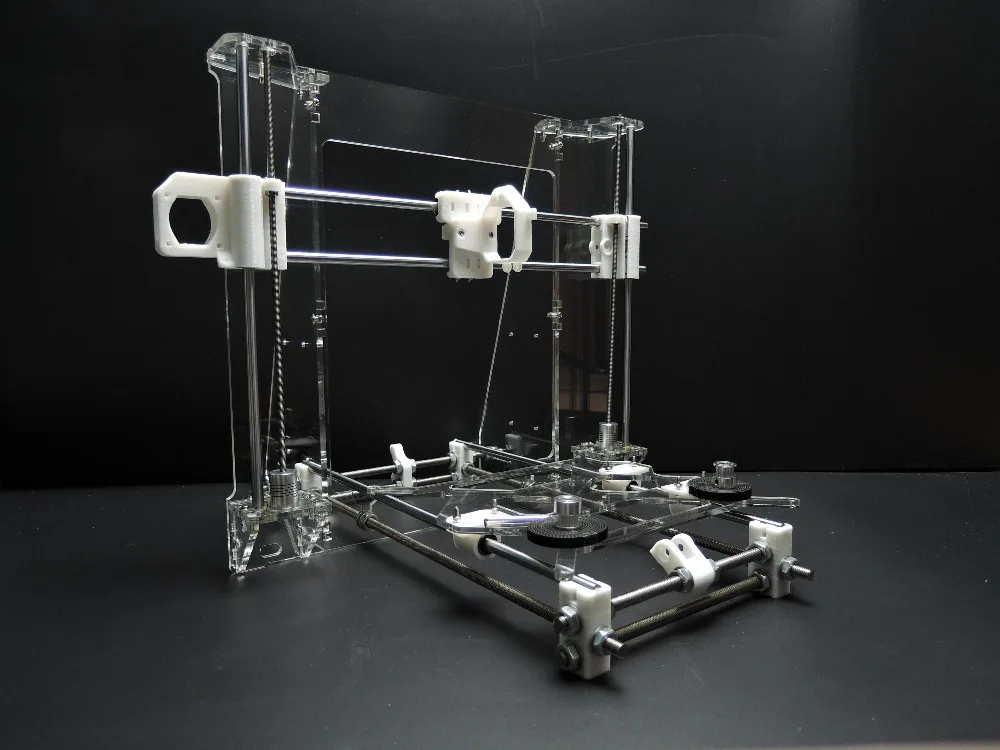

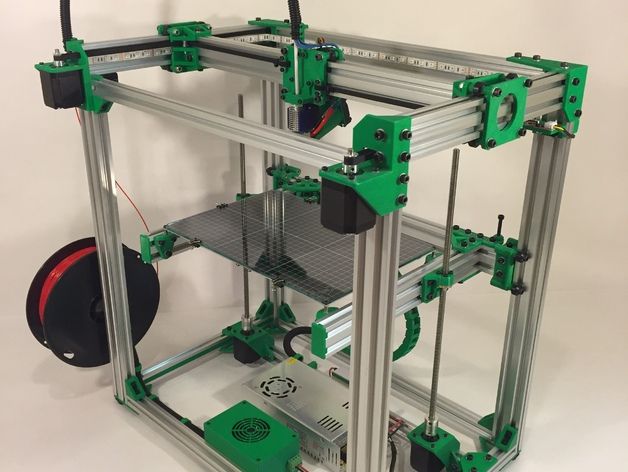

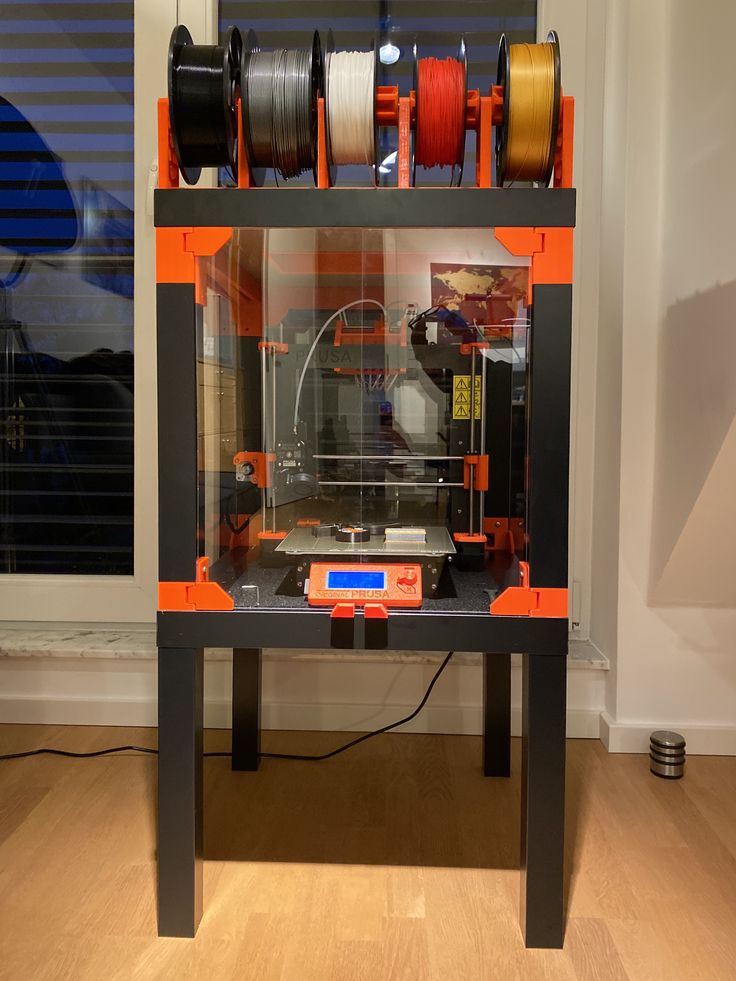

The Prusa i3MK3S is the crème de la crème when it comes to mid-range 3D printers. After successfully upgrading the Original Prusa i3 MK2, Prusa was able to come up with a newly designed 3D printing machine that is popular among engineering students.

Let’s have a look at some of its features.

Features of the Prusa i3 MK3S+

- Fully Automated Bed Leveling – SuperPINDA Probe

- MISUMI Bearings

- Bondtech Drive Gears

- IR Filament Sensor

- Removable Textured Print Sheets

- E3D V6 Hotend

- Power Loss Recovery

- Trinamic 2130 Drivers & Silent Fans

- Open Source Hardware & Firmware

- Extruder Adjustments to Print More Reliably

Specifications of the Prusa i3 MK3S+

- Build Volume: 250 x 210 x 210mm

- Layer Height: 0.

05 – 0.35mm

05 – 0.35mm - Nozzle: 0.4mm

- Max. Nozzle Temperature: 300 °C / 572 °F

- Max. Heatbed Temperature: 120 °C / 248 °F

- Filament Diameter: 1.75 mm

- Supported Materials: PLA, PETG, ASA, ABS, PC (Polycarbonate), PVA, HIPS, PP (Polypropylene), TPU, Nylon, Carbon filled, Woodfill etc.

- Max Travel Speed: 200+ mm/s

- Extruder: Direct Drive, BondTech gears, E3D V6 hotend

- Print Surface: Removable magnetic steel sheets with different surface finishes

- LCD Screen: Monochromatic LCD

The Prusa i3 has an MK25 heatbed. This heatbed is magnetic and can be switched any time you like, you can decide to go with a smooth PEI sheet, or a textured powder coated PEI.

To enhance stability, Prusa remodeled the Y-axis with aluminum. This not only provides the i3 MK3S+ with a sturdy frame but also makes it look sleeker. It also increases the total Z height by about 10mm. You can print a prosthetic arm without struggling.

This model has an improved filament sensor that doesn’t wear off mechanically. A simple mechanical lever is used to trigger it. It can function well with almost all filaments.

A simple mechanical lever is used to trigger it. It can function well with almost all filaments.

Prusa i3 MK3S+ has Trinamic 2130 Drivers and a Noctua fan. This combination makes this machine one of the quietest 3D printers available.

You can choose from either two modes, the normal mode, or the stealth mode. In the normal mode, you can achieve incredible speeds of approximately 200mm/s! This speed slightly reduces in slight mode, thus decreasing the noise levels.

For the extruder, there is an up-to-date BondTech drive extruder. It holds the filament firmly in place, increasing the reliability of the printer. It also has an E3D V6 hot end capable of handling very high temperatures.

User Experience for the Prusa i3 MK3S

One user said that he had fun assembling the Prusa i3 MK3S+, and it helped her learn the basic principles that applied when constructing 3D printers. He added that he could now repair his broken machine by himself.

Another user said that they had never seen a 3D printer operate for more than one year with 4-5 different transitions without being calibrated again.

According to a review from a satisfied user on their site, the user was able to get the print quality he desired with the i3 MK3S+ after being disappointed by many other printers before. The user added that he could switch between different materials effortlessly.

One customer said that he had printed out about 15 objects using different filaments like PLA, ASA, and PETG.

All of them worked alright although he needed to change the temperature and flow rates for quality results.

You can purchase this 3D printer as a kit, or the fully assembled version to save you the building, but you’ll have to pay a fairly hefty amount extra for the benefit (over $200).

Pros of the Prusa i3 MK3S+

- Easy to assemble with basic instructions to follow

- Top level customer support

- One of the largest 3D printing communities (forum & Facebook groups)

- Great compatibility and upgradability

- Quality guarantee with every purchase

- 60-day hassle-free returns

- Produces reliable 3D prints consistently

- Ideal for either beginners and experts

- Has won many awards for best 3D printer in several categories.

Cons of the Prusa i3 MK3S+

- No touchscreen

- Doesn’t have Wi-Fi inbuilt but it’s upgradable

- Fairly pricey – great value as stated by its many users

Final Thoughts

The Prusa MK3S is more than capable of competing with other top 3D printers when it comes to print quality. For its price tag, it performs above expectation.

It is great for civil engineers, electrical engineers, mechatronics engineers, and mechanical engineers alike.

You can get the Prusa i3 MK3S+ directly from the official Prusa website.

Engineering-Grade 3D Printers | MatterHackers

- Home

- Store

- 3D Printers

- Engineering-Grade 3D Printers

Exacting and accurate 3D printers that can 3D print with a variety of advanced materials to achieve their prototyping and production needs. These 3D printers are also capable of reaching temperatures of up to 400°C for robust material applications. For companies and businesses looking to get started in additive manufacturing and prototyping with 3D printing, while using advanced materials like PEI, PEEK, Polycarbonate, polypropylene and carbon-infused nylons like NylonX, these 3D printers are an excellent choice.

For companies and businesses looking to get started in additive manufacturing and prototyping with 3D printing, while using advanced materials like PEI, PEEK, Polycarbonate, polypropylene and carbon-infused nylons like NylonX, these 3D printers are an excellent choice.

Engineering-Grade 3D Printers Collections

All Engineering-Grade 3D Printers 3D Printers

Engineering-Grade 3D Printers

Ultimaker

Professional, engineering-grade 3D printers for rapid digital manufacturing.

Intamsys 3D Printers

3D Printers capable of printing high-performance functional materials.

MakerBot

High-performance, reliable, tinker-free 3D Printers

Raise3D

All Raise3D products: 3D printers, nozzles, filament, parts, etc

BCN3D

Accurate & Reliable IDEX 3D Printers and branded filament and accessories

LulzBot 3D Printers

Open-Source, Robust 3D Printers

MakerGear 3D Printers

Precise, Compact 3D Printers

Phenom 3D Printers

Fast, large-format MSLA 3D printers from Peopoly.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

Best Small Business 3D Printer 2022: The Best Professional-Grade Printers

Whether you're looking to jump into professional 3D printing for the first time or upgrade an existing print farm, we're ready to push you in the right direction with our guide to the best 3D printers for business. small business.

Nowadays, a business-ready printer must not only create affordable, high-quality parts and prototypes; it should actively increase productivity and optimize workflows. Below you'll find a selection of the most reliable and user-friendly mid-range printers on the market today, for start-ups and established businesses alike.

We have selected proven working machines suitable for applications ranging from rapid prototyping to end-use parts and everything in between. Let's dive in.

Contents

- Best Small Business 3D Printers

- Formlabs Form 3+ / 3L - Professional Resin Printer

- Ultimaker S5 / S5 Pro Bundle

- Raise3D Pro2 / Pro2 Plus Prusa3-MK+ - Best Inexpensive small business printer

- Desktop Metal Studio System - Best small business metal 3D printer

- Things to consider when buying a small business 3D printer

- Software and workflow

- Materials

- Resolution

- Workpiece size and volume Sphere

- Applications

- Small Business 3D Printer FAQ

Best Small Business 3D Printers

Formlabs Form 3+ / 3L - Professional Resin Printer

The Formlabs 3+ and Formlabs 3L resin printers are designed from the ground up for the fast-paced, productivity-oriented small business that wants to go without outsourcing. They allow companies to easily implement streamlined, affordable prototyping and in-house manufacturing of functional end-use parts.

They allow companies to easily implement streamlined, affordable prototyping and in-house manufacturing of functional end-use parts.

Print quality is nothing short of industrial quality with fast, accurate printing that features rich features and a flawless surface. These printers excel in areas where highly precise and functional parts are required, such as jewelry making, hybrid visual effects, mechanical engineering, medical, and miniature/figure making.

The two printers are basically the same, except that the FormLab 3L offers a larger build volume of 335 x 200 x 300 cm and two light processing units to compensate for the larger build platform. If your job involves large models or prototypes, or if you need to batch print large quantities of small parts, we recommend FormLab 3L. Otherwise, FormLab 3+ offers the same reliable accuracy and speed at a more affordable price.

Formlabs Form 3+ and 3L's focus on productivity extends to the surrounding ecosystem to ensure a seamless end-to-end workflow. You can switch between 30 different types of resins, each with different characteristics and properties, in seconds with the easy-to-change Formlab cartridges. Formlabs Form Wash and Form Cure accessories fully automate resin print post-processing with a “set it and forget it” feature.

You can switch between 30 different types of resins, each with different characteristics and properties, in seconds with the easy-to-change Formlab cartridges. Formlabs Form Wash and Form Cure accessories fully automate resin print post-processing with a “set it and forget it” feature.

Formlabs PreForm SLA software is equipped with automated features such as adaptive layer thickness, mesh recovery and one-click support generation for true printing. The cloud-based print monitoring and management panel also means you can scale up with multiple printers or queue multiple prints from anywhere without much hassle.

Investing in a complete Formlabs ecosystem is expensive, which can be prohibitive for some businesses. In this case the Prusa SL1S Speed is a great low cost alternative. Since it bears the Prusa name, you are buying 3D printing royalties. It's fast, easy to use, delivers professional-quality prints and keeps running costs low.

Ultimaker S5 / S5 Pro Bundle

The Ultimaker S5 and S5 Pro are working FDM printers for high precision rapid prototyping of functional parts for the arts, medicine, mechanical engineering, automotive, consumer goods and architecture industries.

Like consumer-grade Ultimaker printers, the S5 and S5 Pro are designed with ease of use in mind to increase productivity without the hassle while reducing costs. At the heart of this is a dual extrusion system, compatibility with a wide range of materials, easy network printer management, and near-zero one-click printing speed with Ultimaker Digital Factory software.

With desirable and identical specifications, the Ultimaker S5 and S5 Pro produce industrial-grade prints with a level of detail and smoothness that conventional FDM printers rarely achieve. The Ultimaker S5 and S5 Pro allow you to produce durable and precise parts such as mock-ups, prototypes, functional parts, tools and proof samples.

The Ultimaker S5 Pro is an S5 with an enclosed, temperature controlled material feed station. The station filters out toxic fumes and maintains a dust and moisture free environment with a reliable air filtration system to keep materials in optimum condition.

In addition, the station can simultaneously hold up to six different front-loading spools of thread. Automatic media handling manages spool changes and runtime switching to ensure trouble-free printing. It really is a handless print.

Automatic media handling manages spool changes and runtime switching to ensure trouble-free printing. It really is a handless print.

Although smaller in footprint and build volume than its S5 sibling, the Ultimaker S3's more affordable price, smaller footprint and identical specifications make it a great choice for smaller businesses with less cash to spare.

Raise3D Pro2 / Pro2 Plus

Raise 3D calls the Raise3D Pro2 and its more expensive Pro2 Plus counterpart the "best industrial-grade 3D printers" under the sun, delivering fast, highly detailed prints backed by a durable and strong frame. Both will make a solid addition for performance-oriented small businesses looking for a reliable and versatile solution for manufacturing and rapid prototyping.

Features include dual extruders, a comprehensive HEPA air filtration system, and end-to-end control of the entire print process with RaiseCloud software, making it easy to manage a flock of printers remotely.

Raise3D Pro2 and Pro2 Plus material compatibility is extensive: PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, nylon, as well as fiberglass, carbon fiber, metal-filled, wood-filled and filled are supported.

With the same basic hardware and specifications as the Raise3D Pro2, the Raise3D Pro2 Plus differs in build volume. It increases the build volume with single extrusion to 305 x 305 x 605mm and dual extrusion to 280 x 305 x 605mm, adding verticality for taller prints.

Raise3D E2 should also be mentioned in passing. With a smaller footprint and build volume, combined with the IDEX system, the Raise3D E2 takes on the form of a desktop printer. It's a great choice for small design studios that don't need as much print area as the industrial-strength Pro2 machines.

Prusa i3 MK3S+ is the best low cost 3D printer for small businesses

A favorite of hobby makers around the world, the Prusa i3 MK3S+ makes our list as a low cost savior for the smallest businesses that are put off by the exorbitant prices of the Form 3+ and Ultimaker S5.

While the Prusa i3 MK3S+ is a workhorse of its kind, it's not a production tool or design powerhouse like the other best small business 3D printers we've rounded up. Its footprint is significantly smaller than most professional grade printers for business use. If you're working from home, the Prusa i3 MK3S+ won't take up an entire room.

More compact and less ambitious, it is a reliable companion for companies that want to produce one high-quality prototype quickly or focus on producing small, highly detailed, limited-edition parts.

The Prusa i3 MK3S+ does just that without compromising the quality of the finished product. Print results come close to what you'd expect from other printers on our list, but at a fraction of the cost. Multiple built-in failsafes and sensors ensure easy printing with high hardware quality and decent media compatibility, including PLA, PETG, ASA, PC, HIPS and more.

Easy printing and software equally appeal to aspiring entrepreneurs getting into 3D printing for the first time. You won't get tired of managing your printer fleet with a cloud-based management system.

You won't get tired of managing your printer fleet with a cloud-based management system.

Desktop Metal Studio System - the best metal 3D printer for small businesses

Despite the ridiculous name, Desktop Metal Studio System is a reliable, advanced metal printing solution suitable for prototyping, manufacturing, automotive design , consumer products and even small disposable parts designed for heavy industry applications.

As the name suggests, this is a desktop-friendly solution with the same approach as the native Fabricate software. The software covers all aspects of part creation, reducing the complex, often confusing, not to say intimidating, metallurgy into a well-managed, step-by-step process. Like the other printers on our list, Fabricate is workflow aware and you can easily manage and control multiple printers for consistent and productive printing.

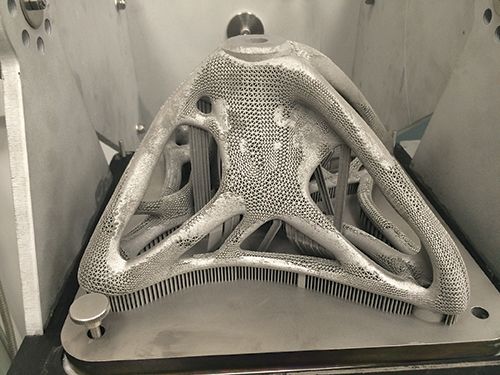

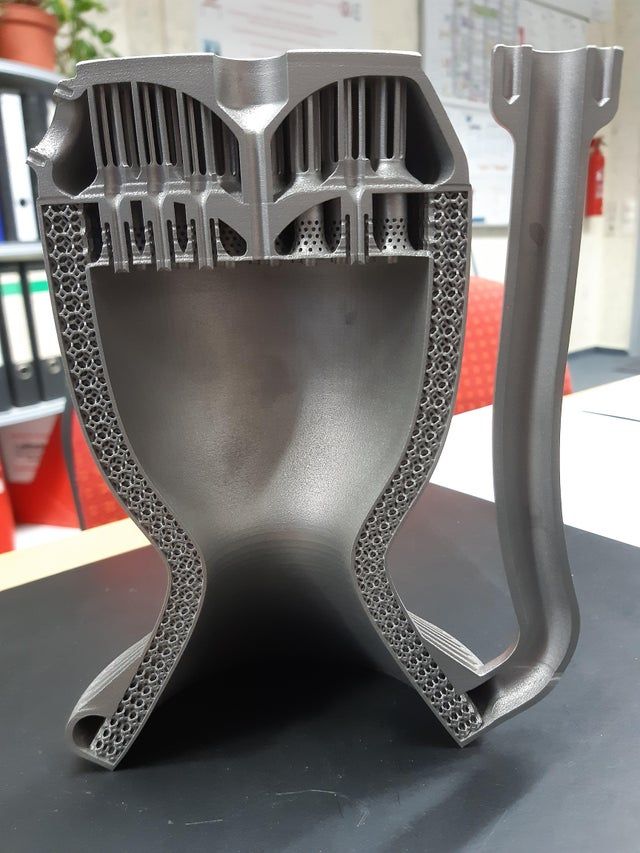

It's amazing how it makes it easy to create difficult-to-machine parts with a high level of geometric complexity. The results often surpass traditional casting in terms of density and accuracy, while still allowing fine undercuts and internal channels to be produced, resulting in superior surface finish in every print.

The results often surpass traditional casting in terms of density and accuracy, while still allowing fine undercuts and internal channels to be produced, resulting in superior surface finish in every print.

Desktop Metal Studio System comes with a sintering oven in an office-friendly package. The latter has temperature profiles that match the type of material and design, ensuring industrial sintering strength with every print. In addition, the print is much less messy than most powder-based metal systems and has many safety features, not least a fully enclosed chamber.

Things to Consider When Buying a Small Business 3D Printer

Software and Workflow

Time is money, as the old saying goes, and the software installed on a 3D printer plays a huge role in determining workflow and efficiency . Whether you're looking to scale up production, quickly complete an order, or reduce manual steps to improve productivity, look to robust software suites that allow you to monitor and manage multiple printers via the cloud.

One-click printing, Wi-Fi connectivity, automated slicing processes - all worth considering if productivity is your number one priority. An intuitive user interface and ease of use are also important to efficiency.

Materials

When choosing a small business 3D printer, look for material compatibility, especially if your application requires more exotic and abrasive filament types. Generally, professional printers offer wider compatibility than hobbyist printers: PLA, ABS, PETG, and flex materials come standard.

You may also want to consider purchasing a dedicated metal or resin printer if these materials are in your printing plans. Dedicated machines tend to produce better results with selected media than general purpose printers.

Resolution

Resolution, often referred to as layer height, is a measurement in mm (or microns) that determines the thickness of each printed layer. The lower the resolution, the better the details and textures.

For small businesses, 20 to 100 microns is sufficient in most cases. If you want the most accurate results, look to resin printers, high-resolution machines that excel at printing richly detailed parts.

Stock size and volume

Print volume refers to the available printable area, or in other words, the maximum print size. The best small business 3D printers have a higher build volume than standard consumer printers, but it's worth checking if they have a high enough build volume if you're planning on making large prototypes or if you plan on mass printing.

The physical footprint of the printer is probably not that important, but it's worth considering if you're planning to set up a print farm and have limited space in your workshop, lab, or office.

Applications

While most professional 3D printers are suitable for a variety of applications, we recommend that you find out if a particular machine is suitable for your preferred use case. A compact printer like the Prusa i3 MK3S+ is well suited for printing small prototypes and limited edition parts in a small home office environment.

A compact printer like the Prusa i3 MK3S+ is well suited for printing small prototypes and limited edition parts in a small home office environment.

The Metal Studio System is ideal for making disposable metal parts for heavy industry. The Ultimaker S5 Pro makes it easy to print with multiple filament types, automatically switching between them as needed to create complex, detailed parts. You got the idea; make sure the printer meets your needs.

Small Business 3D Printer FAQ

What is the best 3D printer for starting a small business at home?

Although 3D printers, even professional-grade ones, have shrunk considerably since the early days of the technology, they are still bulky machines. To save space and reduce costs, we recommend the Prusa i3 MK3S+ as the best 3D printer for starting a small business at home. The print quality of the Prusa i3 MK3S+ approaches that of three times the price of printers, and its compact size, along with its elegant orange and black color scheme, fits perfectly into a home office environment.

What is the best small business metal 3D printer?

Several printers on our list allow metal 3D printing, but one printer stands out above the rest, the Desktop Metal Studio System. The printer is designed from the ground up to work exclusively with metal for a variety of professional applications. The results are excellent and the Fabricate software greatly simplifies the normally complex art of metallurgy. The printer also comes with an industrial-grade perfect sintering oven.

What is the best resin 3D printer for small businesses?

We recommend Formlabs Form 3+ and Formlab Form 3L for small businesses that want to work exclusively with resin. As ecosystem printers, they have everything you need from design to post-processing to help you set up a reliable, productivity-focused workflow. The print results are excellent, replete with fine detail and a smooth surface. Choose the Formlab Form 3L if you need more build volume to print larger parts or for faster batch printing.

Large format FDM printers Discovery 3D Printer

Rapid prototyping

Experts recommend

3D printers

Author: Semyon Popadyuk

Author: Semyon0003

Key Benefits of Discovery 3D Printer | Technology and features of the 3D printing process | Applications | Equipment line | Implementation History: FDM Printing for the Navy | Results: briefly

We are already seeing real examples incredible flexibility and efficiency of additive manufacturing in the context of the global economic crisis. Experts argue that the pandemic will bring the Fourth Industrial Revolution closer, and many businesses today see digital technologies as a means of survival, and not just to increase competitiveness in the market.

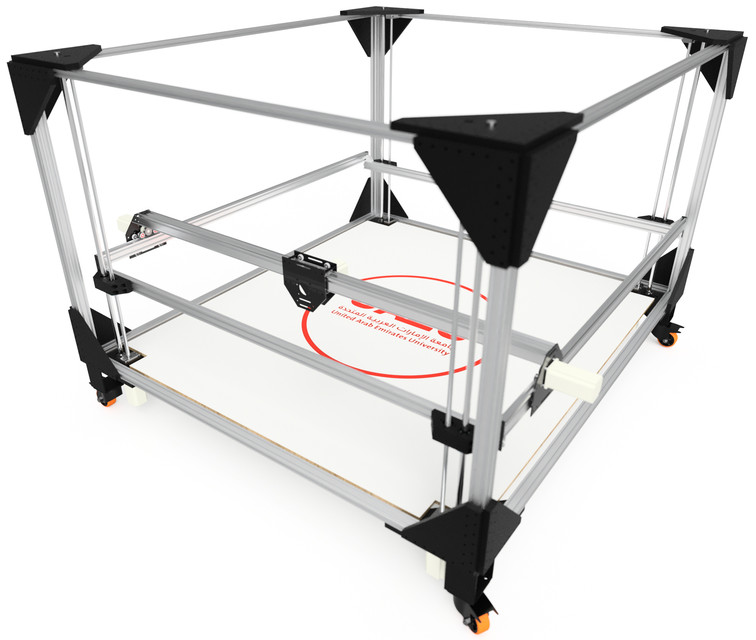

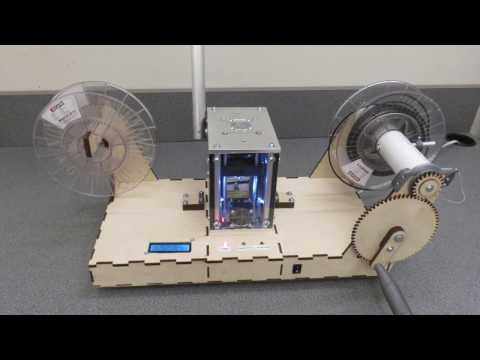

iQB Technologies continues to expand its product portfolio: in April 2020, our company became the exclusive distributor in Russia of Discovery 3D Printer industrial 3D printers from the Spanish manufacturer CNC Barcenas. For the first time, we present equipment for 3D printing of large-sized products and prototypes based on FFF/FDM technology.

For the first time, we present equipment for 3D printing of large-sized products and prototypes based on FFF/FDM technology.

CNC Barcenas is a rather young business: it is a little over ten years old. Since 2009, the company has been specializing in the production of CNC machines (milling, engraving and laser cutting), and in 2014 it expanded its capacity by starting the development, design and production of unique industrial 3D printers.

Bumper

Equipment: Super Discovery 3D Printer, material: ABS with carbon fiber, dimensions: 1800 x 600 x 4500 mm, weight: 12 kg

The first solution for the 3D printing market was the Discovery 3D Printer, followed by the even more innovative and large-format Super Discovery 3D Printer, based on the direct extrusion of polymer pellets. In 2019, the Super Discovery 3D Printer Workstation, an industrial 3D printing and post-processing system, was introduced. In 2021, an updated and improved modification of the Discovery 3D Printer 2021 was released, as well as the Super Discovery 3D Printer Compact and Hybrid models.

CNC Barcenas continues its pioneering work and is today one of the leaders in the European large format 3D printing market with many large scale projects to its credit.

Submit the online application and we will advise you in detail on the implementation of 3D printing in the industry!

Key Benefits of Discovery 3D Printer

-

Much lower cost printers than competitors offering the same technology and quality.

-

Constant development of technologies and expansion of experience in the areas of 3D printing and machine tool building.

-

All equipment is completely designed and manufactured at CNC Barcenas facilities in Spain.

-

The ability to customize the printer for the tasks of each individual client.

-

The best drive and motor components for quality and fast printing.

-

Correction of irregularities during printing (calibration of nozzles and platform).

-

Debugging equipment up to 100% result.

-

The open material system allows a significant reduction in operating costs.

-

Internal cameras in printers that provide remote monitoring of the production process from any device.

-

Easy to operate hardware and intuitive Simplify 3D software.

Cover prototype

Equipment: Discovery 3D Printer, material: 3D850, dimensions: 29 x 19 x 4.5 cm, weight: 146 g

Technology and features of the 3D printing process

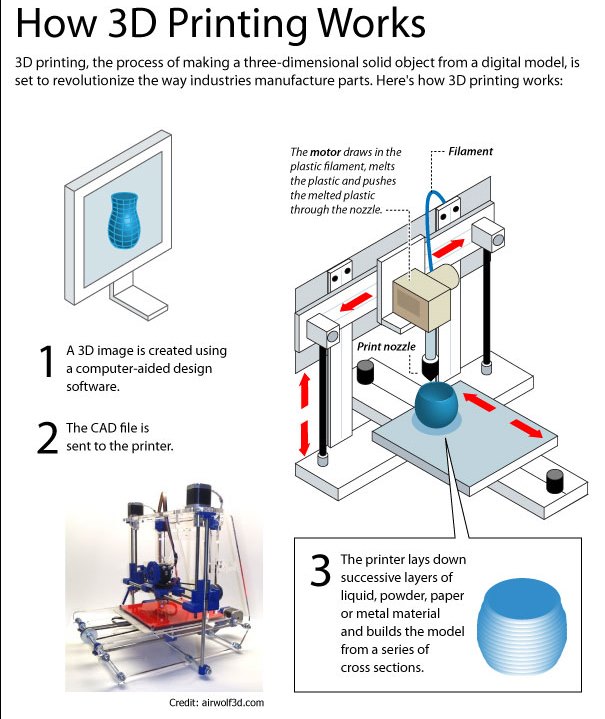

The FFF (Fused Filament Fabrication) technology used in Discovery 3D Printers is a complete analogue of FDM (Fused Deposition Modeling - layer-by-layer deposition modeling). This is the most accessible and popular additive technology, it is familiar to all users of home 3D printers, but it is also widely used to solve serious production problems. Its undoubted advantages include high productivity, the ability to produce large-sized products and the relatively low cost of equipment and consumables.

Its undoubted advantages include high productivity, the ability to produce large-sized products and the relatively low cost of equipment and consumables.

The disadvantages of this method are the highest degree of surface roughness among all additive technologies (the quality depends on the nozzle diameter and materials), the risk of plastic spreading and increased sensitivity to temperature changes. Note that the Super Discovery 3D Printer model equipped with a cutter will immediately correct the roughness and post-process the product right in the printer chamber.

As consumables, thermoplastics or composites are used in the form of threads wound on spools (so-called filaments), or granules. Their range is very diverse and allows you to choose the most suitable materials for the tasks to be solved in terms of physical and mechanical properties - ABS, PLA, nylon, polycarbonates, polyamides, polystyrene, polyethylene and many others.

Building an object in Discovery 3D Printer

The process of creating a product using FDM/FFF technology includes the following steps:

-

Export 3D model to 3D printer software in .

stl format.

stl format. -

Preparation for printing: division of the model into layers and orientation on the construction platform, if necessary, the creation of supports. The result is a G-code containing all print settings.

-

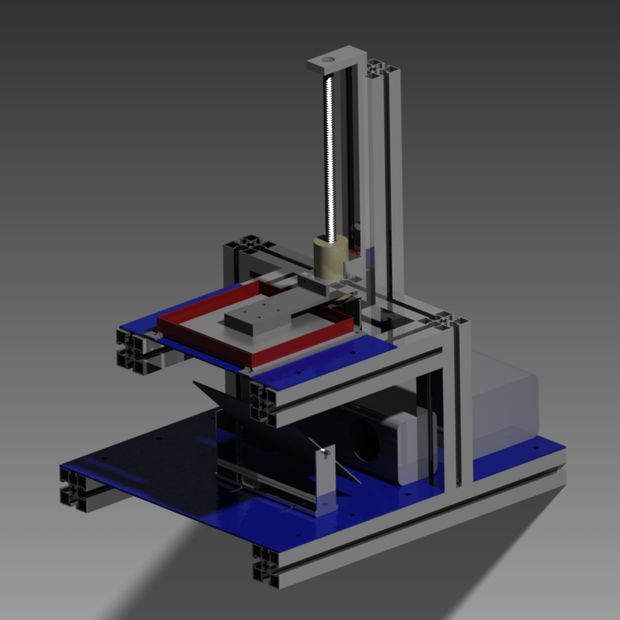

Printing process by layer-by-layer extrusion (extrusion) of molten material. The extruder (print head) moves from bottom to top along the X and Y axes, the working platform moves along the Z axis.

-

Extraction of the printed object from the 3D printer, removal of supports, post-processing.

The filament printing method is used in the junior model of the Discovery 3D Printer line. The Super Discovery 3D Printer and Super Discovery 3D Printer Workstation implement the innovative Direct Extrusion of Pellet technology. The difference from standard FDM is that the consumables are in the form of granules rather than filaments. This method makes it possible to speed up and make more economical the production of large objects.

Helicopter seat

Equipment: Super Discovery 3D Printer, material: ABS with carbon fiber, dimensions: 120 x 70 x 45 cm, weight: 20 kg

Statue

Equipment: Super Discovery 3D Printer, material: ABS with cellulose fiber, height: 1.87 m, weight: 45 kg

Discovery 3D Printer Applications

Every industry is different, which is why CNC Barcenas tailors the 3D printers it produces to the requirements of specific applications and projects that require rapid prototyping or rapid production of end products. Discovery 3D Printer can be successfully used in the following industries:

-

automotive industry;

-

aerospace industry;

-

shipbuilding;

-

defense sector;

-

railway industry;

-

household goods and equipment;

-

furniture industry;

-

architecture;

-

the medicine;

-

education;

-

Industrial Design;

-

3D printing services.

We printed large-sized parts and saved about 70% of the costs that are usually spent on prototyping by subcontractors

Juan Galindo Perez, Prototyping Manager, BSH Spain

Equipment line

Discovery 3D Printer 2021

The industrial 3D printer based on FFF technology is designed for the production of large parts from technical plastics within the framework of complex and long-term projects. As consumables, all filaments available on the market that conform to the standard 1.75 mm format can be used. The printer is equipped with a built-in dual extrusion system that can be used to create supports and parts from different materials in different colors. Discovery 3D Printer is one of the most attractive solutions on the market in terms of price and quality, given the dimensions of the printed products.

-

Works with ULTEM, PLA, ASA, ABS, PA, HIPS, 3D850, PETG, ABS Medical, ABS Hi and many more

-

Fully enclosed chamber and heated bed (up to 175°C) with auto leveling function that automatically compensates for minor unevenness during printing

-

Build Chamber Size (W x D x H): 1150 x 800 x 500 mm

-

Printer size: 1150 x 800 x 500 mm

-

Weight: 300 kg

-

Extruder (max.

temperature): 450 °C

temperature): 450 °C -

Working load: 80-140g/h

-

Print speed: up to 400 mm/s

-

Layer thickness (minimum): 0.1mm

-

Software: Simplify 3D

Super Discovery 3D Printer

The machine was designed as a one-stop solution for Industry 4.0 to produce large-format parts up to 2.5 m in size. general expenses. Individual configuration is possible for any needs of large industry.

-

Works with all thermoplastics e.g. ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Fully enclosed chamber and heated platform (up to 175°C) with automatic leveling function for the most demanding materials

-

Automatic supply of granules, no restrictions on the amount of material and, as a result, on the weight of the product.

-

Build Chamber Size (W x D x H): factory standard 1300 x 2500 x 1000 mm, custom configuration available

-

Printer dimensions with feed funnel and electrical cabinet: 2000 x 3590 x 3000 mm

-

Weight: 1200 kg

-

Extruder (max.

temperature): 450 °C

temperature): 450 °C -

Working load: <6kg/h

-

Print speed: up to 200 mm/s

-

Layer thickness (minimum): 0.5mm

-

Software: Simplify 3D

Super Discovery 3D Printer Compact

Compact and high performance industrial grade 3D printer for pellet extrusion printing. The machine is designed to create small and medium-sized products up to 1100 x 800 x 500 mm, and at the same time has all the advantages of the previous model Super Discovery 3D Printer, allowing you to reduce costs and increase print speed.

-

Fully enclosed chamber and heated platform (up to 150°C)

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Polymer Granule Direct Extrusion Technology

-

Build chamber size: 1100 x 800 x 500 mm (modifiable)

-

Automatic feeding of granules and no restrictions on the amount of material

-

Weight: 450 kg

-

Extruder (max.

temperature): 410 °C

temperature): 410 °C -

Working load: 2 kg/h

-

Print speed: up to 100 mm/s

-

Layer thickness (minimum): 0.5mm

-

Software: Simplify 3D

Super Discovery 3D Printer Hybrid

A combined solution that implements two additive technologies at once - the filament printing method and direct extrusion of polymer granules, which can also be used separately. The innovative 3D printer works with any thermoplastics and has a build chamber up to 1100 x 800 x 500 mm, which can be modified to suit your individual needs if desired.

-

Combined solution for printing with filaments and polymer granule extrusion technology

-

Fully enclosed chamber and heated platform (up to 150°C)

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Build chamber size: 1100 x 800 x 500 mm

-

Automatic feeding of granules and no restrictions on the amount of material

-

Weight: 300 kg

-

Extruder (max.

temperature): 410 °C

temperature): 410 °C -

Working load: granules - 2 kg/h, filaments - 80-100 g/h

-

Print speed: granules - up to 100 mm/s, filaments - up to 400 mm/s

-

Layer thickness (minimum): granules - 0.5 mm, filaments - 0.1 mm

-

Software: Simplify 3D

Super Discovery 3D Printer Workstation

The perfect combination of a large format industrial 3D printer and a milling system. The plant is designed for the production of large batches of large parts and prototypes. The principle of operation, just like that of the Super Discovery 3D Printer model, is based on the direct extrusion of granules. The special design allows the entire production process to be carried out, including post-processing, since both the extruder and the milling motor are present on the working platform. The Super Discovery 3D Printer Workstation is capable of performing large-scale post-processing jobs, as well as cutting, punching or 3D engraving on plastic, photopolymer, foam, wood and other materials.

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Fully enclosed chamber and heated platform (up to 175°C) with automatic leveling function for the most demanding materials

-

Automatic feeding of granules, no restrictions on the amount of material and, as a result, on the weight of the product

-

Build Chamber Size (W x D x H): factory standard 1500 x 2000 x 1000 mm, custom configuration available

-

Printer size: 2000 x 3590 x 3000 mm

-

Weight: 1500 kg

-

Extruder (max. temperature): 450 °C

-

Working load: <6kg/h

-

Speed: up to 200 mm/s

-

Layer thickness (minimum): 0.5mm

-

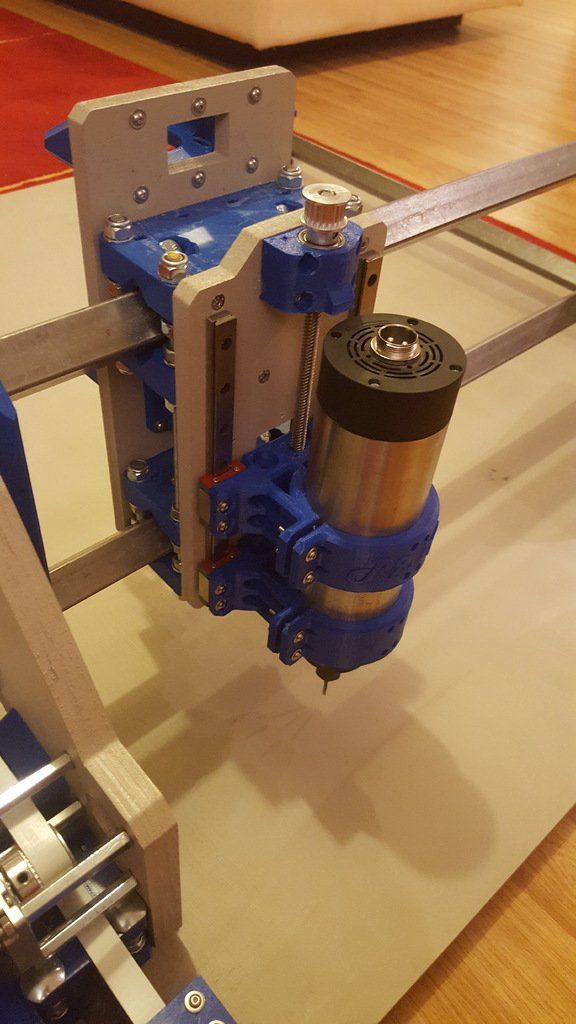

Milling motor: high-frequency brushless motor with air-cooled ceramic bearings, speed 4500-18000 rpm.

-

Software: Simplify 3D + CNC software

Case History: FDM Printing for the Navy

By order of the Spanish Navy, the state-owned shipbuilding company Navantia has developed and implemented the Shipyard 4. 0 strategy (“Shipyard 4.0”). The goal of the new business model is to optimize the production process using Industry 4.0 technologies, including 3D printing, robotization, digital twins, big data, artificial intelligence, the Internet of Things, etc. Read more about Shipyard 4.0 in the article.

0 strategy (“Shipyard 4.0”). The goal of the new business model is to optimize the production process using Industry 4.0 technologies, including 3D printing, robotization, digital twins, big data, artificial intelligence, the Internet of Things, etc. Read more about Shipyard 4.0 in the article.

CNC Barcenas has been involved in two R&D projects for additive manufacturing. The first of these is called 3DCABINS and involves the production of fully equipped ship cabins through research and selection of the most suitable materials. For example, on the Discovery 3D Printer and Super Discovery 3D Printer installations, prototypes of a modular toilet for a naval ship were made. Compared to traditional production methods, the weight of the products has been reduced by almost 50% and their cost has been significantly reduced. The second project, ADIBUQUE, uses 3D printers to manufacture complex components for the navy sector, which are installed and tested on ships under construction.

Objects printed on the Super Discovery 3D Printer for the 3DCABINS project:

- modular toilet, material: flame retardant ABS, dimensions: 2200 x 1700 x 1200 mm, weight: 250 kg

– ventilation grille, material: ABS with carbon fibre, dimensions: 59 x 89 x 4.5 cm, weight: 3500 g

Using the Discovery 3D Printer enabled Navantia to:

-

modernize the production process and increase productivity;

-

reduce production and assembly time;

-

reduce labor costs;

-

reduce the amount of work on processing and painting;

-

increase the energy efficiency of production;

-

improve product quality.

Summary: briefly

The Discovery 3D Printer is a Spanish-made range of additive machines with an excellent price/performance ratio for creating large-sized products and prototypes.