3D printed house clay

Tecla house 3D-printed from locally sourced clay

James Parkes | Leave a comment

Bologna-based architecture studio Mario Cucinella Architects and 3D printing specialists WASP have collaborated to create a low-carbon housing prototype that is 3D printed using clay.

Named Tecla, a combination of the words technology and clay, the home was designed by Mario Cucinella Architects and was constructed and engineered by Wasp using clay sourced from a nearby riverbed.

Top: Tecla was made by Mario Cucinella Architects and Wasp. Above: the prototype was printed using 350 layers of clayPrinted in Massa Lombarda, Italy, the home is formed of two connected dome-shaped volumes with a ribbed outer wall that is made up of 350 stacked layers of 3D-printed clay.

The clay is arranged in undulating layers that not only provide structural stability but also to act as a thermal barrier.

The prototype was constructed using a multilevelled, modular 3D printer that uses two synchronised arms, each with a 50-square metre printing area that can print modules simultaneously.

Mighty Buildings plans neighbourhood of 3D-printed homes for California

By using this technology, housing modules can be built within 200 hours while consuming an average of six kilowatts of energy and reducing typical construction waste almost entirely said the construction team.

The prototype has a ribbed exteriorAccording to the studio, the housing prototype combines ancient building techniques with modern technology to form recyclable, low-carbon, climate-adaptable housing.

"TECLA responds to the increasingly serious climate emergency, to the need for sustainable homes and to the great global issue of the housing emergency that will have to be faced," said Mario Cucinella Architects.

"Particularly in the context of urgent crises generated, for example, by large migrations or natural disasters. "

"

The 60-square-metre structure is 4.2 metres in height and comprises a living space, kitchen and sleeping area and is fitted with services and a circular skylight on its roof.

Although mainly windowless, its entrance is marked by a glazed door within a large lancet arch.

A large lancet arch marks the entrance to the housing prototypeOn its roof, large circular skylights were fitted within its narrowest point allowing light to enter the space throughout the day.

Its interior has a similar organic aesthetic as the walls were left bare with a lancet archconnecting the different zones.

Furnishings were also partly printed using locally sourced earth to unite the space and were designed to be reused or recycled to align with the circular values of the prototype.

The prototype was developed as a response to climate emergency. Photograph is by ItaldronThe geometry of its envelope can be adapted and modified to work with different types of raw earth and respond to a variety of different climatic conditions.

"The aesthetics of this house are the result of a technical and material effort," said Cucinella. "It was not an aesthetic approach only. It is an honest form, a sincere form."

The prototypes can be constructed in 200 hours. Photograph is by ItaldronTecla was developed as part of an eco-sustainability research study that looked to bioclimatic principles and vernacular architecture and construction to produce low-carbon homes.

"TECLA shows that a beautiful, healthy, and sustainable home can be built by a machine, giving the essential information to the local raw material," said Wasp founder, Massimo Moretti.

Undulating curved layers provide structural stability. Photograph is courtesy of Wasp"We like to think that TECLA is the beginning of a new story," added Mario Cucinella Architects founder and creative director, Mario Cucinella.

"It would be truly extraordinary to shape the future by transforming this ancient material with the technologies we have available today. "

"

In 2019, WASP used its Crane Wasp 3D printer to create a small home constructed using soil and agricultural waste.

Elsewhere, 3Strands and ICON collaborated to build four 3D-printed homes using disaster-proof concrete.

Photography is by Iago Corazza unless stated otherwise.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

New! Dezeen AgendaSent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Plus occasional news.

News about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

TECLA Technology and Clay 3D Printed House / Mario Cucinella Architects

TECLA Technology and Clay 3D Printed House / Mario Cucinella Architects

© Iago Corazza+ 8

- Curated by Paula Pintos

Text description provided by the architects. The first eco-sustainable housing model 3D printed entirely from local raw earth. This genuinely innovative and pioneering approach was conceived from the start as a joint project between the two firms, who worked closely throughout the project’s design and construction.

The first eco-sustainable housing model 3D printed entirely from local raw earth. This genuinely innovative and pioneering approach was conceived from the start as a joint project between the two firms, who worked closely throughout the project’s design and construction.

Metaphorically inspired by one of Italo Calvino's ‘invisible cities’ - the city in continuous construction - the name TECLA evokes the strong link between past and future by combining the matter and spirit of timeless ancient homes with the world of 21st-century technological production.

© Iago CorazzaLocated in Massa Lombarda (Ravenna, Italy), TECLA has become a reality thanks to the eco-sustainability research of the SOS - School of Sustainability (training center founded by Mario Cucinella), the pioneering research projects of Mario Cucinella Architects and the collaborative 3D printing technology of WASP.

TECLA is an innovative circular housing model that brings together research on vernacular construction practices, the study of bioclimatic principles and the use of natural and local materials. It is a nearly zero-emission project: its casing and the use of an entirely local material allows for the reduction of waste and scraps. This and the use of raw earth make TECLA a pioneering example of low-carbon housing.

It is a nearly zero-emission project: its casing and the use of an entirely local material allows for the reduction of waste and scraps. This and the use of raw earth make TECLA a pioneering example of low-carbon housing.

For this project, Mario Cucinella Architects not only explored housing solutions in formal aesthetic terms, it also studied the building’s shape in relation to its climate and latitude. In addition, the composition of the earth mixture responds to local climatic conditions and the filling of the envelope is parametrically optimised to balance thermal mass, insulation and ventilation according to the climate needs.

© Iago CorazzaBorn from a research project by Mario Cucinella (Founder and Creative Director of Mario Cucinella Architects) and through the vision of Massimo Moretti (Founder of WASP), TECLA responds to the increasingly serious climate emergency, to the need for sustainable homes at Km0 and to the great global issue of the housing emergency that will have to be faced - particularly in the context of urgent crises generated, for example, by large migrations or natural disasters.

TECLA is a composition of two continuous elements that through a sinuous and uninterrupted sine curve culminate in two circular skylights that convey the ‘zenith light’.

© Iago CorazzaThe atypical shape, from the geometry to the external ridges, has enabled the structural balance of the construction - both during the 3D printing phase of the envelope and once the covering is completed - giving life to an organic and visually coherent design.

With an area of about 60 square meters, it comprises a living zone with a kitchen and a night zone which includes services. The furnishings - partly printed in local earth and integrated into the raw-earth structure, and partly designed to be recycled or reused - reflect the philosophy of a circular house model.

Floor planSectionThe technological research of WASP, specialised in Km0 3D printing from raw earth, has led to an innovative 3D printing technology called Crane WASP, the first in the world to be modular and multilevel, designed to build construction works collaboratively. TECLA uses two synchronised printer arms simultaneously, thanks to software capable of optimising movements, avoiding collisions and ensuring streamlined operation. Each printer unit has a printing area of 50 square meters which therefore makes it possible to build independent housing modules in a few days.

TECLA uses two synchronised printer arms simultaneously, thanks to software capable of optimising movements, avoiding collisions and ensuring streamlined operation. Each printer unit has a printing area of 50 square meters which therefore makes it possible to build independent housing modules in a few days.

In brief: TECLA can be delivered with 200 hours of printing, 7000 machine codes (G-code), 350 12 mm layers, 150 km of extrusion, 60 cubic meters of natural materials for an average consumption of less than 6 kW.

© Iago CorazzaCite: "TECLA Technology and Clay 3D Printed House / Mario Cucinella Architects" 27 Apr 2021. ArchDaily. Accessed . <https://www.archdaily.com/960714/tecla-technology-and-clay-3d-printed-house-mario-cucinella-architects> ISSN 0719-8884

WASP builds sustainable clay 3D printed house

News

clay mixture using the Crane 3D printer, reminiscent of the development of the Irkutsk company Apis Cor.

The TECLA project (named after the mythical city from Italo Calvino's novel "The Invisible Cities" - ed.) is based on OOH data, which predicts that the world's population will grow to 11.2 billion by the beginning of the next century people, while already in 2030 about five billion will live in cities. The numbers indicate the likelihood of a worsening housing crisis, so the development of technologies that can provide people with massive and affordable housing from environmentally friendly and renewable raw materials is on the agenda.

WASP works in two directions, developing and manufacturing 3D printers, and at the same time saving the world. Actually, the name of the enterprise is an abbreviation that stands for "World's Advanced Saving Project" or "Advanced Project to Save the World." But "wasp" is also an English word meaning "wasp", and this is not a coincidence: in their projects, the company is inspired by eumenes - the so-called "potter wasps" who build nests from lumps of clay.

The company sells and operates specialized clay extruders and various large format industrial and building additive systems. Basically, WASP prefers delta robot 3D printers, but last fall it rolled out a new system called Crane, which is conceptually similar to the 3D printer of the Irkutsk company Apis Cor, which recently printed a record-breaking building in Dubai. In these systems, the extruder is mounted on a rod that rotates around a vertical axis and is adjustable in height. There are also differences: in the Irkutsk 3D printer, the extruder is mounted on a telescopic rod, while in the Italian system the head moves along guides.

According to the authors, the house is built exclusively using local materials, mainly clay. The project is planned to be adapted for different climatic conditions. The emphasis is on low cost, including through the highest possible automation, simplicity, environmental friendliness and high energy efficiency.

The building was designed by Mario Cucinella Architects, a dedicated School for Sustainability, with MA students from the Architectural Association of London working to find affordable housing solutions for the homeless. The structural analysis was carried out by the Milanese engineering and consulting firm Milan Ingegneria, who proposed a number of solutions to optimize the shape of the unsupported structure.

The structural analysis was carried out by the Milanese engineering and consulting firm Milan Ingegneria, who proposed a number of solutions to optimize the shape of the unsupported structure.

Construction work began in September and is expected to be completed early next year. If successful, the experimental house can become the basis for larger construction projects, up to entire villages. More information about the activities of the WASP company can be found on the official website at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

More interesting articles

9

Subscribe to the author

Subscribe

Don't want

Igor Kostusev, an employee of the Arktika shipbuilding enterprise, received the Lomo Regional Prize. ..

..

Read more

four

Follow author

Follow

Don't want

0003

Read more

56

Subscribe to the author

Subscribe

Don't want

Dear friends!

3D printers, makers and just caring people in Russia connect...

Read more

3d clay and sand house

So, the third piglet (Naf-Naf) squeals with delight. A clay house created using 3D printing technology and an Italian company with the telling name World's Advanced Saving Project (WASP) was presented in Italy. The house was named Tecla. But not in honor of Tesla, but in honor of Thekla, a mythical city invented by the Italian writer Italo Calvino. Of course, you have read and know this story well. I - no, so I thought it was a sinful thing that the authors wanted to cling to the glory of Elon Musk.

I - no, so I thought it was a sinful thing that the authors wanted to cling to the glory of Elon Musk.

That is, since yesterday we can not only build, but also print houses. Yes, even from penny material.

But actually, clay is not really clay. The secret composition of the building material is as follows: the soil of the region in which Tekla is being built, rice husks (in the Russian Federation from 300 rubles per ton) and 5% of the binding component. The latter is by no means egg white, but good old cement. But, as they say, a little bit does not count, we continue on.

According to the concept, housing from such material can be built anywhere in the world using local resources. According to the manufacturer, this is especially true in rural areas, where it is not easy to find building materials. And digging up a dump truck of earth is, of course, a trifle and, most importantly, no one will notice.

When you get the ingredients for the mixture, know that the house is almost ready. TECLA can be constructed from/from 200 hours of 3d printing, 7000 machine codes (G-code), 350 layers of 12mm, 150 km of extrusion, 60 cubic meters of natural materials with an average electricity consumption of less than 6 kWh. However, here you will need such a trifle as the Wasp starter kit. It is impossible to do without it, since Tekla is designed using several simultaneously working 3D printers. Buy them on sale in the supermarket will not work.

TECLA can be constructed from/from 200 hours of 3d printing, 7000 machine codes (G-code), 350 layers of 12mm, 150 km of extrusion, 60 cubic meters of natural materials with an average electricity consumption of less than 6 kWh. However, here you will need such a trifle as the Wasp starter kit. It is impossible to do without it, since Tekla is designed using several simultaneously working 3D printers. Buy them on sale in the supermarket will not work.

The kit includes everything you need for construction - from a 3D crane printer capable of building houses, to a multi-tool printer for designing furniture and even vertical gardens. In addition to printers: systems for cutting, extrusion and recycling of materials, crushing and processing of plastics or crushed stone. The manufacturer did not show the price out of modesty anywhere.

Oh yes, here's another one. Clay clay, but you need a foundation. And for it you have to use concrete slabs.

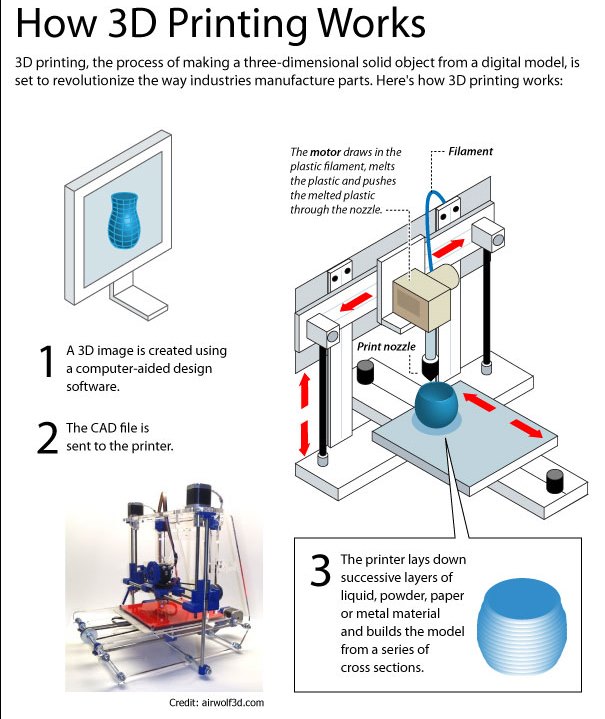

How it works.

I understood very little. During construction, the two synchronized print arms are coordinated by proprietary software and controlled by a human, literally at the click of a mouse. Are you ready to be that person? Look at the diagram and you will quickly understand.

The prototype, built in Italy, consists of two interconnected domes and includes a living room and a bedroom equipped with a small toilet.

With regard to heating, it is expected that the need for both heating and cooling will be kept to a minimum due to the natural insulation of the material that regulates the indoor temperature.

Outside, a small artificial lake to collect wastewater and rainwater. Swimming is strictly prohibited here, but watering the garden with a hydrococktail is welcome. By the way, vegetable gardens are vertical and also 3d.

A separate structure with solar and thermal panels provides energy supply and, according to the manufacturer, potentially turns a dwelling into a completely autonomous from the benefits of civilization.

And what about the care, cosmetics of the facade, insides, etc.?

Clay structure requires regular maintenance.

Without special protection, it will simply spread in the rain. All compressed earth block structures require regular maintenance. And this is, at a minimum, the annual application of sealant to ensure moisture resistance. And not just any silicone, but a strictly waterproofing product supplied by a partner company.

The manufacturer grudgingly admits that supplying a branded sealant or similar could be an obstacle to Tekla's construction in remote areas with poor transportation and even in urban areas with no established supply.

Volumes and cost of sealant, as well as the maintenance itself, are not announced.

However, the cost of Tekla is not known, since it has not yet entered the market.

What is the main idea behind this project? According to the designers, the design and method of 3d-building using local soil (clay, sand) radically solves the problem of housing shortage, which, according to the promises of demographers, will be aggravated as the population of the earth approaches the projected 11 billion in 2100.