3Ds 3d printer

Careers at 3D Systems | 3D Systems

Why 3D Systems?

Meaningful work, passionate and bright people, and a company that supports your life from day one. There’s a lot to explore at 3D Systems, we hope you’ll join us.

Be part of a team with brainpower, heart, and grit.

We have a diverse team with some of the world’s most dynamic and forward-thinking talent. Not only do we have the brainpower, we have people with heart, grit and a ton of curiosity. And the cornerstone of our work is to lead, explore, and innovate with the utmost integrity.

Be you, at your best.

We care about treating people right and we know that life is more than work. This is why we approach rewards and benefits at a personal level so that you have the resources you need to take care of yourself and be you, at your best. See a few of the rewards and benefits we offer.

Write your own story.

-

E-Verify

3D Systems participates in E-Verify ENGLISH/SPANISH (PDF)

Right to Work (English)

Right to Work (Spanish)

Equal Employment Opportunity

3D Systems is an Equal Opportunity Employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, disability, or status as a protected veteran.

EEO is the Law

3D Systems Employment Opportunity, Anti-Discrimination, & Anti-Harassment Policy

Pay Transparency Nondiscrimination Provision

-

Accessibility and Accommodations

In compliance with the ADA Amendments Act, if you have a disability and would like to request an accommodation in order to apply for a position with 3D Systems, please call 803-326-3933.

Federal Employment Laws

Applicants have rights under Federal Employment Laws:

Family and Medical Leave Act (FMLA)

Employee Polygraph Protection Act (EPPA)

3D Systems commitment to gender equality in the workplace 2021 – Phenix Systems, Riom-France

Equality in the workplace means ensuring the absence of any discrimination within a company.

The challenge for any company is to achieve true equality between men and women at work, in particular through action against day-to-day sexism at work, equal pay, gender parity at management level, and a gender-balanced workforce.

The challenge for any company is to achieve true equality between men and women at work, in particular through action against day-to-day sexism at work, equal pay, gender parity at management level, and a gender-balanced workforce. Under the law on freedom of choice in professional careers, the index uses five indicators for companies to monitor their commitment to workplace gender equality. These are:

- Equal Pay

- Pay Increase between the genders

- Promotions of each gender

- Pay increase when returning from maternity leave

- Number of woman amongst the 10 most highly paid employees in the company ( in France)

For 2021, 3D Systems has achieved 60/100.

Link to the gender equality website: https://www.gouvernement.fr/index-de-l-egalite-femmes-hommes-comment-ca-marche

Plastic 3D Printers I 3D Systems

Productive and cost-effective digital manufacturing solutions

Figure 4® delivers ultra-fast additive manufacturing technology with systems that offer the expandable capacity to meet your present and future needs. With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts, as well as ultra-fast same-day rapid prototyping.

With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts, as well as ultra-fast same-day rapid prototyping.

Discover more in this white paper >>

Stereolithography Printers (SLA)

Prototypes, tools and production parts with the gold standard in 3D printing

3D Systems—the inventor of Stereolithography (SLA) and the only SLA manufacturer offering the total solution with integrated hardware, software and materials fine-tuned to achieve renowned SLA parts quality—brings you legendary precision, repeatability and reliability in SLA 3D printers. SLA printers work with a wide range of materials, with a range of sizes and price points, which are designed for prototyping, end-use part production, casting patterns, molds, tooling, fixtures and medical models.

Learn more about the benefits of Stereolithography (SLA) >>

Selective Laser Sintering Printers (SLS)

Production thermoplastic parts with ProX

® and sPro™ SLS 3D printersExpand your manufacturing capabilities with production-grade nylon materials to produce tough, functional complex parts with excellent surface finish, resolution, accuracy, repeatability and low total cost of operations. SLS printers print in thermoplastic materials designed to offer you the full range of capabilities and isotropic properties, from rigid to elastomeric, high elongation, high impact strength, and high-temperature resistance.

SLS printers print in thermoplastic materials designed to offer you the full range of capabilities and isotropic properties, from rigid to elastomeric, high elongation, high impact strength, and high-temperature resistance.

Learn more about the benefits of Selective Laser Sintering (SLS) >>

Extrusion Printers

Extra-large Format, High-Speed Production Thermoplastic Extrusion 3D Printers

A large-scale, hybrid and modular additive manufacturing solution that offers a combination of pellet extrusion, filament extrusion and spindle subtractive tooling. Ideal for when you need low-cost, large-scale parts, printed at very high speeds, with manufacturing-level accuracy, surface quality and repeatability. Ideal for large-scale patterns, molds, production batch runs and functional prototypes.

MultiJet Printers (MJP)

Precision plastic, elastomeric, wax and composite parts with MJP 3D printers

MultiJet Printing (MJP) technology produces high fidelity, true-to-CAD parts, with fast print times, easy operation and simple post-processing for high productivity and true simplicity, from file to finished part. The wide range of VisiJet® materials for the ProJet MJP Series enables a broad set of applications for concept modeling, form and fit testing, functional prototyping, fluid flow analysis, rapid tooling, jigs and fixtures, casting patterns and medical applications requiring USP Class VI and/or ISO 10993 certification.

The wide range of VisiJet® materials for the ProJet MJP Series enables a broad set of applications for concept modeling, form and fit testing, functional prototyping, fluid flow analysis, rapid tooling, jigs and fixtures, casting patterns and medical applications requiring USP Class VI and/or ISO 10993 certification.

Learn more about the benefits of MultiJet Printing (MJP) >>

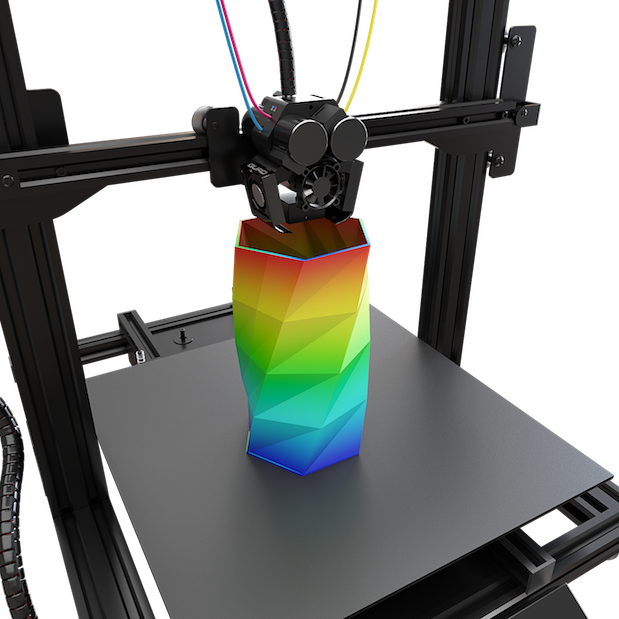

Full Color 3D Printers

Affordable, photo-realistic full-color parts with ProJet

® CJP 3D printersBest known for its unparalleled color capabilities, 3D Systems’ family of ProJet CJP x60 3D printers delivers models faster, at low operating costs. From educational settings to the most demanding commercial environments, 3D Systems’ family of ProJet CJP x60 3D printers provides unparalleled, full-color 3D printing at exceptional print speeds and efficiency.

-

3D printing with plastics offers many choices for engineering grade materials, elastomers and composites.

Do you need flexibility? Strength? Bio-compatibility? More?

Do you need flexibility? Strength? Bio-compatibility? More? -

3D print with plastics to build almost anything - used for prototyping, manufacturing, anatomical models and more. Select a plastic material and 3D technology to deliver the characteristics you need.

what a 3D printer can do

3D printing possibilities

Unfortunately, the current level of awareness in 3D technologies leaves much to be desired. It happens that even with a basic knowledge of 3D printers, the actual application of 3D printing remains incomprehensible to a number of users. To avoid such situations, we have prepared this article and will consider in detail all the possibilities of 3D printing.

3D printing application

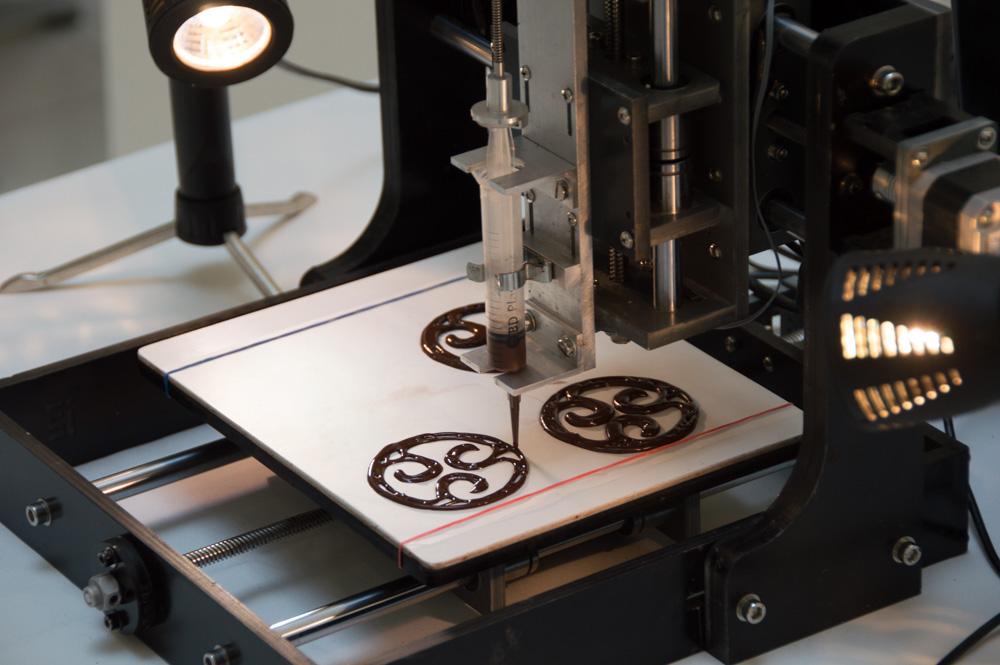

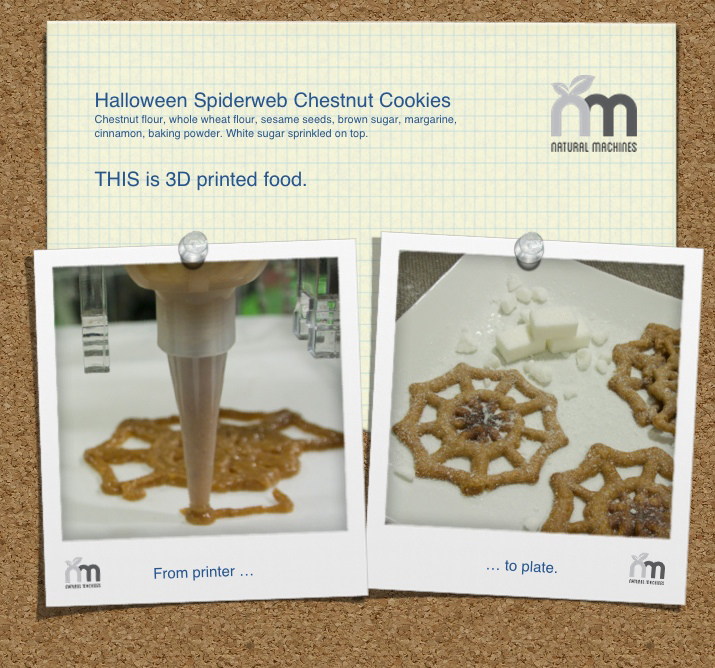

When it comes to 3D printing applications, it is worth considering not only the existing possibilities, but also the prospects. Already today, the application of 3D printing technology is extremely extensive and does not stop expanding. Of course, in the future we expect a large-scale distribution of additive techniques, but the practical application of 3D printing is available to everyone today. We will not delve into narrowly specific aspects of technology, such as 3D food printing, or bioprinting. Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers. nine0005

Of course, in the future we expect a large-scale distribution of additive techniques, but the practical application of 3D printing is available to everyone today. We will not delve into narrowly specific aspects of technology, such as 3D food printing, or bioprinting. Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers. nine0005

1. Prototyping

The best way to use 3D printing is for its intended purpose. Rapid prototyping is not only the second name of the technique, but also the original goal of its development. Creating prototypes using 3D printing significantly reduces production time and costs. And thanks to the possibilities of 3D modeling, the range of designed parts is practically unlimited. Prototyping allows you to visually assess the possible shortcomings of the product at the design stage and make significant changes to the design of the part even before its final approval. nine0005

2. Small-scale production

For small-scale production, 3D printing is a godsend. The properties of many materials allow the production of finished components at minimal cost. Compared to traditional production methods, small-scale production using 3D printing is very profitable from a financial point of view. The manufacture of molds, for example, is a lengthy and costly process. At the same time, injection molding itself takes a lot of time. On a 3D printer, you can print a batch of the necessary products in a matter of hours. This application of 3D printing is extremely relevant for frequent orders for small batches of parts. nine0005

The properties of many materials allow the production of finished components at minimal cost. Compared to traditional production methods, small-scale production using 3D printing is very profitable from a financial point of view. The manufacture of molds, for example, is a lengthy and costly process. At the same time, injection molding itself takes a lot of time. On a 3D printer, you can print a batch of the necessary products in a matter of hours. This application of 3D printing is extremely relevant for frequent orders for small batches of parts. nine0005

3. Repair and restoration

Another application of 3D printing is the repair and restoration of damaged parts. For these purposes, 3D printing is ideal. You can carry out such a procedure both independently, with the appropriate skills and equipment, and in specialized 3D printing services, such as 3DDevice. First, a correct 3D model is built on the basis of the damaged product. 3D scanning can also be used to simplify design. Next, the finished model is sent to print and reproduced on a 3D printer in the required number of copies. Repair and restoration of damaged parts using 3D printing is fast, and the presence of a digital model of the component allows you to reprint it at any time. nine0005

Next, the finished model is sent to print and reproduced on a 3D printer in the required number of copies. Repair and restoration of damaged parts using 3D printing is fast, and the presence of a digital model of the component allows you to reprint it at any time. nine0005

4. Production of functional models and finished components

One of the industrial applications of 3D printing is the production of functional models and finished components. Making products on a 3D printer from a transparent material allows you to see the work of a functional part “from the inside”, which is very useful when developing various engineering samples. In addition, a wide range of different materials for 3D printing turns it into a full-fledged production tool. Industrial 3D printers are gradually becoming a part of every industry, allowing the production of durable metal components. nine0005

Other questions and answers about 3D printers and 3D printing:

- Opportunities What is the future of 3D printing?

- Finance How to choose the right 3D printer?

5.

Household items

Household items Need an office organizer? Or a knife holder? Any household items can be printed on a 3D printer. The advantage of this application of 3D printing is that there are no restrictions when developing 3D models. That is, if you want to show imagination and create something original - all the cards are in your hands. Thanks to 3D printing, your home can be decorated and made more functional easily and inexpensively. nine0005

6. Toys and souvenirs

Having a 3D printer makes it very easy to make a child happy – just make cute 3D toys. There are already some pretty interesting projects of collective 3D printed games, and in the future this list will only expand. This application of 3D printing will please not only children, but also enthusiastic collectors, because on a 3D printer you can print figures of any characters and attributes of computer games and films. And color 3D printing will make it possible to produce exclusive full-color souvenirs - miniature figurines of real people. To do this, a digital model of a person is formed on the basis of 3D scanning data. In this case, all textures and color data are preserved. Everyone will definitely like such a gift, because getting a tiny copy of yourself is so unusual. nine0005

To do this, a digital model of a person is formed on the basis of 3D scanning data. In this case, all textures and color data are preserved. Everyone will definitely like such a gift, because getting a tiny copy of yourself is so unusual. nine0005

7. Design products

For creative people, there is another use for 3D printing. 3D technology in general is a unique opportunity to show your talent in the most unusual way. Artists, sculptors, fashion designers and designers from all over the world use 3D printing to create exclusive pieces of art that would be impossible to produce with standard methods. Such designer pieces impress with their beauty and originality, often fusing digital and traditional art. In addition, 3D printing techniques for clothing and footwear are being actively developed. Some models have even gone on sale, but it's too early to talk about mass production. nine0005

8. Capabilities of a 3D printer

We have listed the main capabilities of a 3D printer, but they do not end there. 3D printing finds application in a wide variety of industries. With its help, electronics, various components, food and even living tissues are printed. Of course, this list will be replenished in the future, but already now it impresses with its scale. We hope that we were able to provide information about the existing application of 3D printing in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team. nine0005

3D printing finds application in a wide variety of industries. With its help, electronics, various components, food and even living tissues are printed. Of course, this list will be replenished in the future, but already now it impresses with its scale. We hope that we were able to provide information about the existing application of 3D printing in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team. nine0005

In addition, our company provides 3D printing, 3D scanning and 3D modeling services of any complexity at the best prices on the Ukrainian market. The 3DDevice online store offers a wide range of products (3D printers, 3D scanners) and consumables (plastics and resins). For any questions please email us or call one of these numbers. We look forward to collaborating!

Back to homepage

How a 3D printer works, what can be printed on a 3D printer

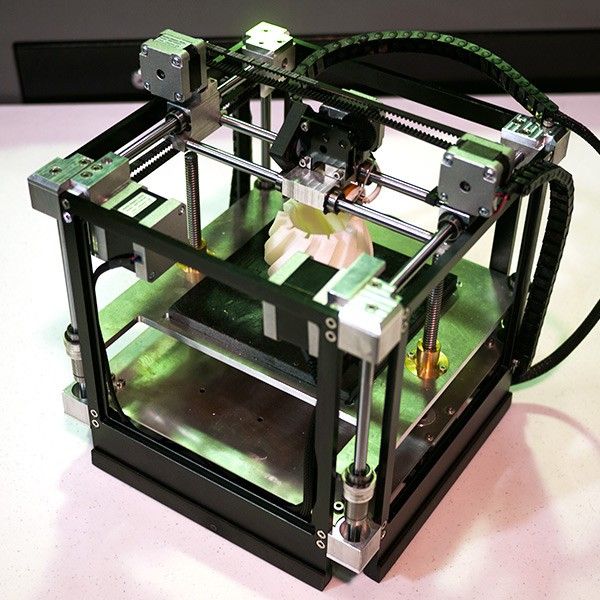

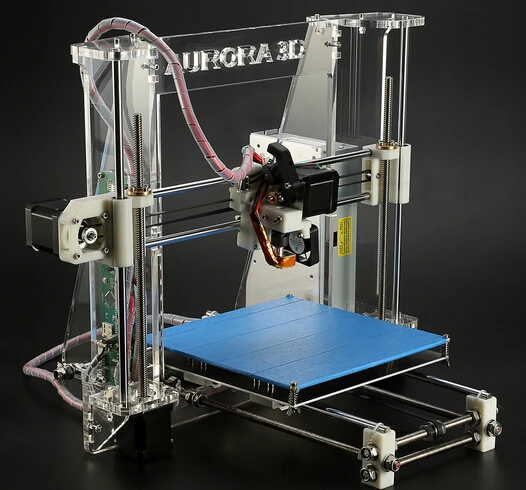

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing?

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer - that is, builds or grows.

- In the first stage of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are joined together to form the final shape.

With limited production of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors. nine0005

In order to print something you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you have to do is import it into the Slicer, a program that adapts the model into codes and instructions for a 3D printer, most of the programs are open source and distributed free of charge. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print. nine0005

The whole process can take several hours and sometimes even days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

How does a 3D printer work?

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts into the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Once the printer starts printing, all you have to do is wait - it's easy.

Of course, as you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed? nine0003

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture. Here are some typical use cases:

Custom Models

Create custom products that perfectly fit your needs in terms of size and shape. Do something that would be impossible with any other technology.

Rapid Prototyping

3D printing allows you to quickly create a model or prototype, helping engineers, designers and companies get feedback on their projects in a short time.

Complex geometry

Models that are hard to imagine can be easily created with a 3D printer. These models are good for teaching others about complex geometry in a fun and useful way.