3D printer 1000x1000x1000

Large Scale 3D Printers Big Enough to Print Furniture

Home / 3D Printers / Large Scale 3D Printers Big Enough to Print Furniture

Use Cases

Just like all types of 3D printing, XL 3D printing has its own strengths and tradeoffs. Users are constantly finding more applications for these gigantic machines so the XL 3D printing space is getting bigger and bigger. Let’s have a closer look.

Quick jump to:

- Request XL 3D printer quote

- Request XL service quote

When To Consider Large Scale 3D Printing

It takes a large scale 3D printer to print furniture, vehicle parts and architectural components. Obviously, size is the driving factor in choosing to use large-format printing but there’s more to it than that. Here’s a breakdown of some of the less-obvious considerations:

- Unibody Parts – Often, producers are already able to fabricate their large objects through traditional methods of assembly but those objects would perform better if they were produced as one solid piece, something only a large 3D printer can do efficiently.

- Weight Reduction – Large objects are usually made of wood, metal, or injection molded plastics. Printing the same objects in plastic will make them much lighter, especially when factoring that users can easily adjust the density infill of 3D printed objects. Consolidating large assemblies into single components also reduces weight by eliminating the need for fasteners like nuts and bolts.

- Faster Development – The larger an object, the longer it takes to create and setup the tooling to fabricate it through traditional means. With 3D printing, there are essentially no setup steps so large prototypes are significantly faster to print than to make them any other way. A large object may take a while to print, but by cutting out the time-consuming tooling step, it may also be faster to do production runs of large objects, depending upon the specifics.

- Reduced Cost – 3D printed large parts can be cost competitive with conventionally-made parts almost entirely because of the tooling costs of the latter.

Consolidated assemblies usually cost less as well because fewer materials have to be sourced from different places.

Consolidated assemblies usually cost less as well because fewer materials have to be sourced from different places. - Design Freedom – Using conventional manufacturing methods, many geometries are just not possible, such as internal channels and complex lattice structures. Many large objects, like furniture, benefit from such features and XL printers are the only way to realize those designs.

Large Scale 3D Printing Examples

- Restoration and replication – XL 3D printing has become rather popular among paleontologists as the technology allows them to both study and preserve the delicate fossils that they regularly handle.

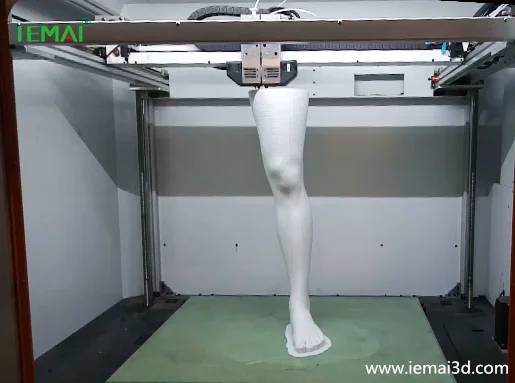

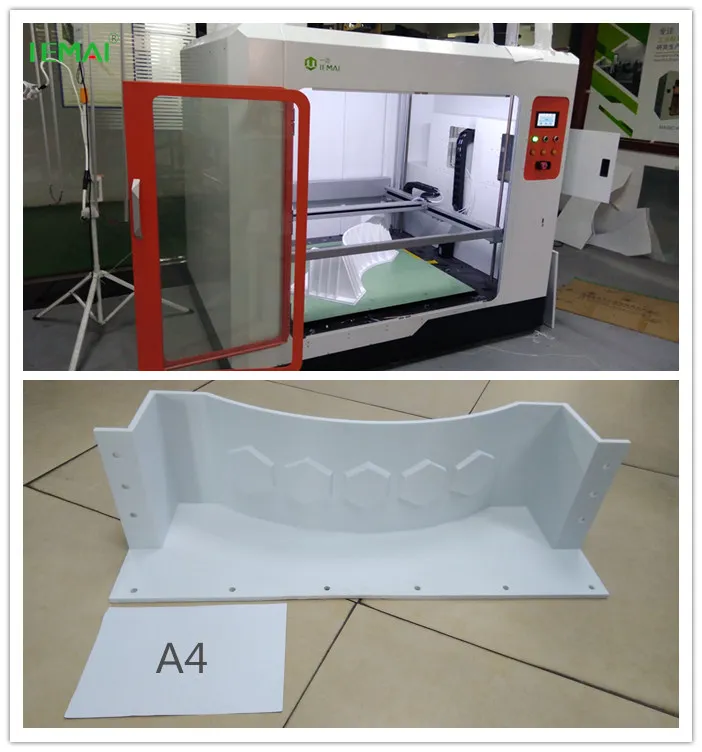

- Furniture – Thanks to large-scale 3D printers it is now possible to create complex functional designs within a fully digitized process chain. From full-size prototyping to production of 3D printed furniture.

- Display advertising – XL 3D printers are perfect for making high-quality, modern signage and lettering for retail stores, businesses and exhibitions.

- Props – With the introduction of large scale 3D printers, designers can now produce enormous set pieces – overnight. 3D printing can help designers quickly manifest their wildest imaginations into the physical reality, and the Film & TV industry has taken notice.

Pellet Extrusion

One of the differences between desktop-sized machines and XL printers is the possibility to utilize pellet extrusion systems on the large printers. Pellet extrusion doesn’t use spooled filament as feedstock but instead uses the same virgin plastic pellets that are used for injection molding, which are much cheaper than spooled filament. This makes it easy to mix different plastics to make custom polymer blends and colors. These systems can also take shredded plastics as feedstock, which enables users to directly recycle water bottles, milk jugs, and failed and unneeded prints into new objects. Such a degree of a circular ecosystem can not be achieved with any other form of manufacturing.

That’s all great but what compels most users to opt for pellet extrusion is its blazing speed as the technology enables output of several kilograms per hour. Printing times scale exponentially with part size so having a high extrusion rate is pretty important for large-format 3D printing. One drawback of pellet extrusion systems is that they struggle with retraction, a feature that filament extruders employ to improve surface finish by pulling back on the filament during non-extrusion travel moves; retraction reduces or eliminates blobs, dots, and stringing on prints. Some XL printers can operate with both filament and pellet extrusion systems, allowing users to choose the best toolhead for their specific application.

Get a Quote

Large Scale 3D Printers

Looking to implement large scale 3D printers in your production process? Get a quote from Modix or Industry

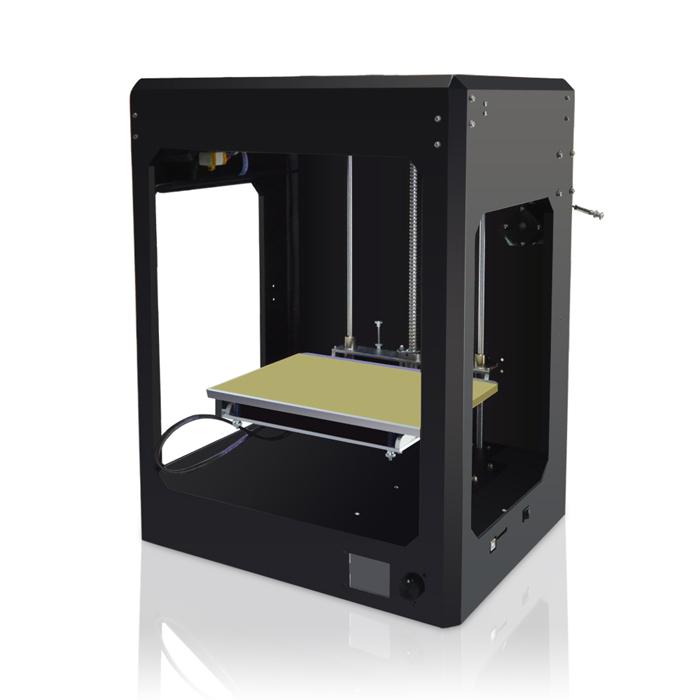

Modix BIG Meter

With the Modix BIG Meter, you are now able to manufacture objects as large as 1010 x 1010 x 1010 mm in one go!

$13,500Modix

Request a Quote

modix big meter

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1010 x 1010 x 1010 mm

- - Printer Dimensions: 1300 x 1470 x 1830 mm

- - Shipping Weight: 200kg

- - Included: Dual print head, E3D Aero & Volcano 1.

75mm

75mm - - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Automatic bed tilt calibration

- - Power Requirements: 32A, single phase, 208-240V

Mold Making, Prototyping, Research and Development, Restoration

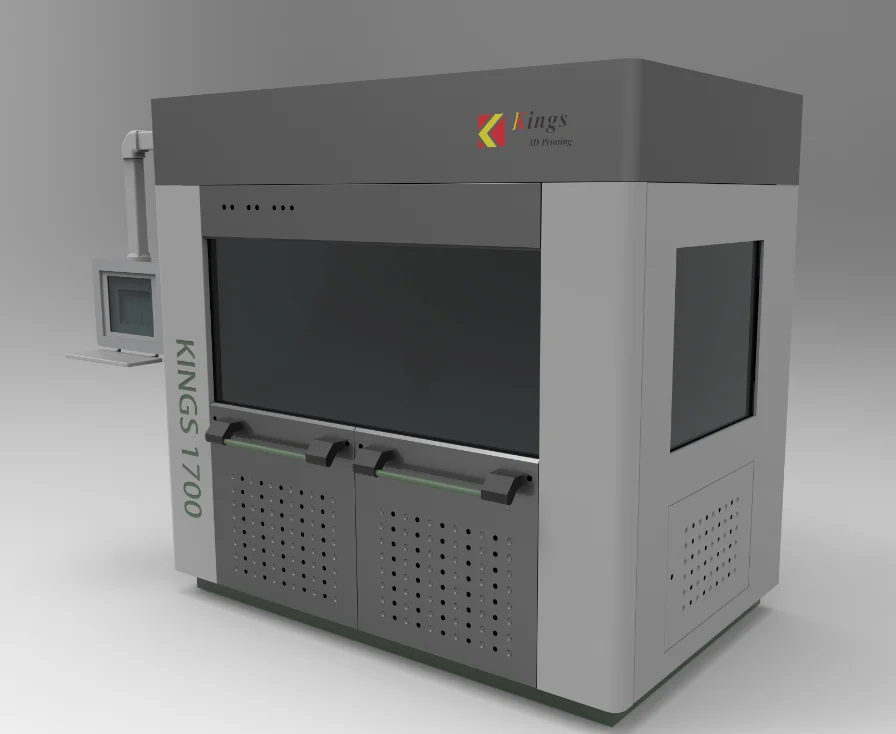

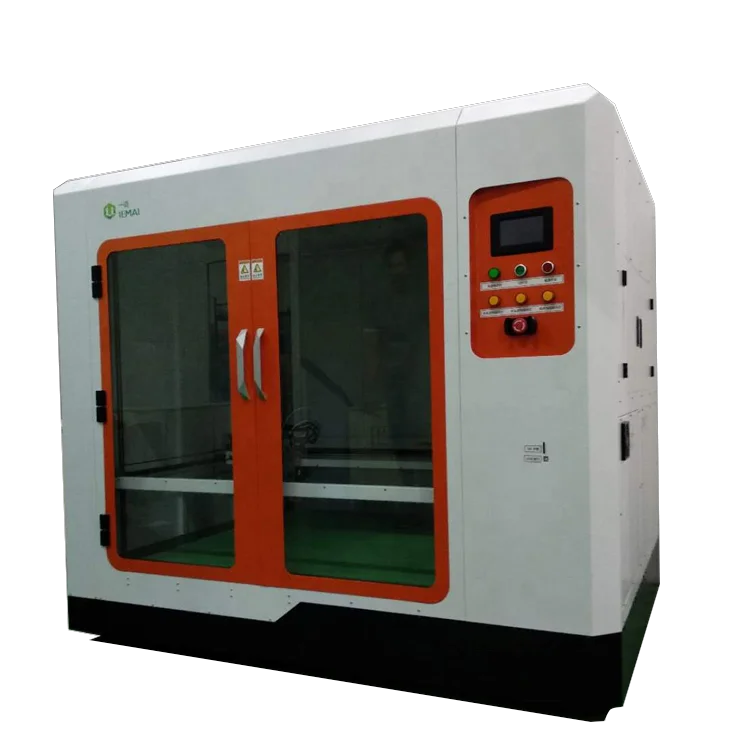

Industry MAGNUM

Hailing from Sweden, Industry is a company that has made major waves in the world of 3D printing. The new MAGNUM large scale pellet 3D printer enables you to print parts measuring 1500 x 1200 x 1200 mm.

A powerful E25 extruder manufactured to handle shredded material, granules or pellets. The MAGNUM handles nozzles between 2-8mm and has an average output between 1-8 kg / hour & a maximum output of 15 kg / hour.

MAGNUM offers powerful control features based on Bosch Rexroth MTX system control. It comes with a camera and mail/text module for external monitoring. A large touch screen display allows for easy setup and agile control.

€159,000Industry

Request a Quote

Industry MAGNUM

- Benefits

- Applications

- - Large scale pellet 3D printer

- - XL build size: 1500 x 1200 x 1200 mm

- - Granular extruder, which reduces material costs

- - Fast build rate: up to 15 kg per hour

- - Touch screen display

- - High quality linear motion modules from Bosch Rexroth MTX

Mold Making, Production, Prototyping, Research and Development, Restoration

Modix BIG-180X

The BIG-180X features a print volume of 1800 x 600 x 600 mm and comes at a competitive price of $12,000 USD. The unique extra width of the build chamber is designed per request of customers working in the automotive industry.

$15,500Modix

Request a Quote

modix 180

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1800 x 600 x 600 mm

- - Printer Dimensions: 2170 x 1060 x 1430 mm

- - Shipping Weight: ~240kg

- - Included: Dual print head, E3D Aero & E3D Volcano 1.

75mm

75mm - - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - 4 X Z axis motors are controlled individually providing automatic bed tilt calibration.

- - Minimal Electricity requirements: 32A, single phase, 208-240V

Prototyping, Research and Development, Restoration

Modix BIG-120Z

The closed enclosure of the BIG-120Z is made of aluminum composite panels and polycarbonate doors. It incorporates a premium motion system including HIWIN motion rails, Gates timing belts and IGUS signal cables. This is a smart 3D printer providing several key reliability features including power-off resume, filament runout sensor, 120 probing points based automatic bed leveling, stall detection and more. The manufacturer offers an active air filter device as an add-on.

$7,500Modix

Request a Quote

BIG-120Z

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 600 x 600 x 1200 mm

- - Z axis guides, HIWIN MGW Linear Rails

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - Dual print head

- - E3D Titan Aero extruder with E3D Volcano hotend

Displays, Fashion, Mold Making, Prototyping

Modix BIG-120X

Modix BIG-120X Version 3 represents a major leap forward with regards to the printer reliability, print quality, ease of assembly and readiness to future advanced updates. Since Modix big60 and 120X share the same core design the new update is benefiting both models.

Since Modix big60 and 120X share the same core design the new update is benefiting both models.

$7,500Modix

Request a Quote

BIG-120X

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 1200 x 600 x 660 mm

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Closed loop motion system (optional)

Mold Making, Prototyping, Research and Development, Restoration

Get a Quote

XL 3D Print Service

3D printing is a viable option for display advertising, large scale concept models, car parts, furniture, molds & tooling. We offer both cost effective solutions with thick layers and rough surfaces for rapid prototyping as well as highly detailed & post-processed end-use objects. Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

- Technologies: FDM, SLA, GDP

- Materials: From PLA to CF composites & more

- Maximum print size: 1450 x 1100 x 1800 mm

- Post-processing: Spray paints, metal coatings, assembly & many more

Large Scale 3D Printers - Builder 3D Printers

Name

Company

Phone Number

Over 1 x 1 meter in build capacity with the Extreme 3000 PRO

With a build capacity of over 1 meter x 1 meter (XY axis), it is the perfect machine for creating large and full size parts, tools, jigs & fixtures in-house and on demand. Within days you can have a fully functional high quality prototype. Features such as automatic bed leveling, a battery pack and filament detection, make large scale 3D printing worry free. Manufactured to the highest standards.

Manufactured to the highest standards.

Discover more

Your browser does not support the video tag.3D PRINT FULL SIZE PARTS - TOOLS - PROTOTYPES

IN-HOUSE PROTOTYPING

REDUCE PRODUCT DEVELOPMENT TIME BY WEEKS

Builder Extreme 3000 PRO

IN STOCK

The Extreme 3000 PRO is the perfect fit for industrial 3D printing applications. The extremely large build volume of 1100x1100x820 mm YXZ, allows you to 3D print large and complex shaped parts and prototypes on full scale. The frame has been designed in a way that you have easy access to the build plate from both sides by removing the side panels. 3 different nozzles diameters, 0.4, 0.8 and 1.2 mm, are included to optimize print quality and time for your specific needs.

Find out more

Builder Extreme 2000 PRO

IN STOCK

The Builder Extreme 2000 PRO is one of the tallest industrial 3D printers available today. With a print volume of 700 x 700 x 1700 mm (XYZ), it is the perfect 3D printer for extremely tall objects. Elements such as a 7-inch touch display, filament detection, UPS system that resumes operation after a power outage, door locking system and available extension for a BOFA air filter, make it a fully equipped large format 3D printer.

With a print volume of 700 x 700 x 1700 mm (XYZ), it is the perfect 3D printer for extremely tall objects. Elements such as a 7-inch touch display, filament detection, UPS system that resumes operation after a power outage, door locking system and available extension for a BOFA air filter, make it a fully equipped large format 3D printer.

Find out more

Your browser does not support the video tag.Business Cases

Interested to see how other companies have integrated large industrial 3D printing into their product development process?

Take a look at the different business cases. 54% of our European customers invested in a second, third or fourth Builder Extreme within 6 months after their initial purchase.

From extremely large prototypes to customized mannequins, marketing displays and dinosaurs, industrial 3D printing is great asset for all industries.

View business cases

Builder Extreme 1500 PRO

IN STOCK

The Builder Extreme 1500 PRO is one of the longest industrial 3D printers available on the market. With its unusual large X axis size, it fits perfectly into the smallest office corners. The print volume is 1100 x 500 x 820 mm (XYZ), and the machine is comes with features such as a 7-inch touch display, filament detection system and the UPS system that resumes the print job after a power cut. This combination makes it a fully equipped large format 3D printer.

With its unusual large X axis size, it fits perfectly into the smallest office corners. The print volume is 1100 x 500 x 820 mm (XYZ), and the machine is comes with features such as a 7-inch touch display, filament detection system and the UPS system that resumes the print job after a power cut. This combination makes it a fully equipped large format 3D printer.

Find out more

Builder Extreme 1000 PRO

IN STOCK

The Builder Extreme 1000 PRO is one of the biggest industrial 3D printers available on the market. With a print volume of 700 x 700 x 820 mm (XYZ), it is the perfect printer for large prototypes, molds, tooling or even functional parts. Features such as a 7-inch touch display, filament detection and a UPS system that resumes printing after a power cut, make large scale 3D printing uncomplicated.

Find out more

The Builder Extreme is preferred by industrial leaders

“We needed to print larger prototypes in 1 piece and without worrying about failed prints – the Builder 1500 ticked all the boxes”. - Eventuri

- Eventuri

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish.Accept Read More

South African printed a lawn mower in just nine hours

01/09/2015

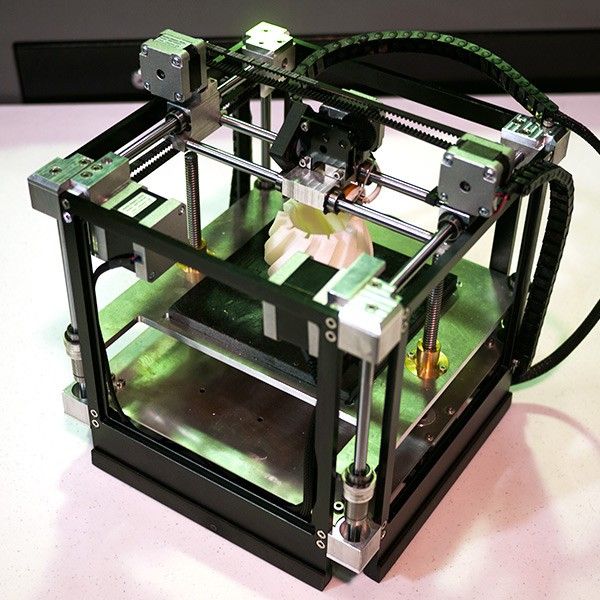

Six months ago we wrote about a designer and printer from South Africa named Hans Fouche. This person is notable for his passion for large-scale 3D printing and chocolate cakes. But you will not see anyone with giant printers. Fouche, on the other hand, has tackled another aspect of FDM printing - speed.

In April, Fouche posted a photo of an old lawnmower for which the designer had printed a new wheel. Apparently, over the past months, Hans managed to finally break the old unit. What will a real 3D printer do in such cases? Of course, he will print a new lawn mower. Remarkably, the production of the new hull and chassis took only nine hours. nine0003

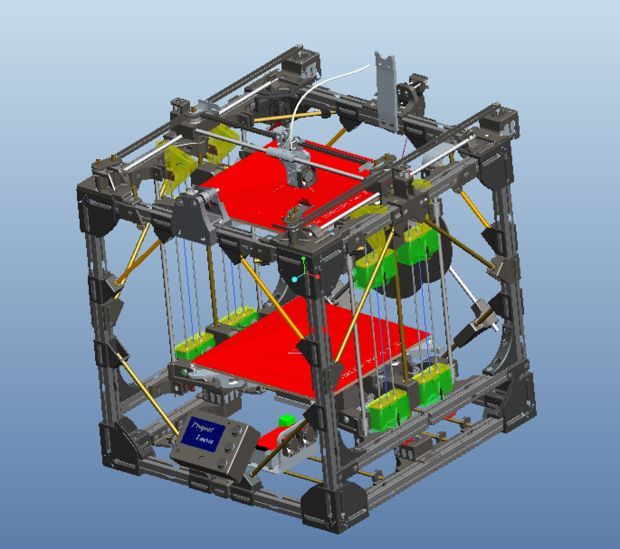

For printing, Fouchet used a 3D printer of his own design called Cheetah with an impressive build area measuring 1000x1000x1000 mm. Of course, the electromechanical components for the lawnmower were taken ready-made - for this purpose, Hans gutted the old machine. But the body and bearing elements were printed with ABS plastic.

Of course, the electromechanical components for the lawnmower were taken ready-made - for this purpose, Hans gutted the old machine. But the body and bearing elements were printed with ABS plastic.

- Four wheels: 180 minutes

- Motor cover: 10 minutes

- Chassis: 190 minutes nine0015 Chassis cover: 70 minutes

- Engine compartment: 90 minutes

- Total print time: 9 hours

“There are quite a few printers that can print parts larger than one meter, but they all print with 0.5 mm nozzles and use filament,” Fouche says. “Printing with such a setup would take a couple of days. We use pellets and a 3mm nozzle, so printing takes hours instead of days.”

Although the increase in print speed was primarily the result of using a large diameter nozzle, Fouche believes that the use of standard small diameter nozzles for FDM/FFF printers is not always necessary. nine0003

“We got print speeds 12 times faster than conventional desktop FDM printers,” Fouche says. “In exchange for speed, I had to sacrifice print resolution. The layer thickness is 2.5 mm versus 0.25 mm possible with a conventional nozzle. But why do you need gem quality when printing a lawn mower?

“In exchange for speed, I had to sacrifice print resolution. The layer thickness is 2.5 mm versus 0.25 mm possible with a conventional nozzle. But why do you need gem quality when printing a lawn mower?

In addition to high print speeds, Cheetah has another advantage: the use of granulated plastic allows significant savings. In South Africa, a kilogram of ABS rod costs about $25, while granulated plastic of the same weight costs ten times less. For the production of a lawn mower, it took about five and a half kilograms of consumables, that is, the cost was about $13-14. nine0003

Over time, Fouche intends to manufacture and sell Cheetah 3D printers for about $10,500. At the moment, the machines have been used not only for printing thermoplastics, but also chocolate. Actually, initially the printer was developed specifically for use in the confectionery business. Is the Cheetah worth that much money? It all depends on the quality requirements of the finished models. At the very least, high speed printing will allow you not to wait more than a day only to get a failure and a bunch of plastic vermicelli at the end of the process, as is often the case. nine0003

nine0003

Source

Please rate the news:

Share:

Back to news

Subscribe to receive latest news

-

A truly large 3D printer Predator-5 impresses with its capabilities!

nine0002 The print area is up to 1 m3, or up to 1000x1000x1000 mm.The basis of the 3D printer is a solid steel frame that eliminates vibration and deformation.

3D printing with almost all available materials for FDM 3D printing. Working table temperature up to 140 C. Nozzle temperature up to 350 C.

Our 3D printer combines modern electronics, precise mechanics, ease of operation and maintenance.

nine0002 Our 3D printer will open up previously unavailable opportunities for 3D printing of large objects! -

H-BOT kinematics on a wide belt proved to be robust and unpretentious.

The Z axis is based on four ball screws, synchronized with each other by a strong belt and driven by a powerful motor, eliminating table distortions! nine0003

X,Y linear guides with double Y carriages.

Additional Z-axis cylindrical shafts with double bearing units.

Thanks to these solutions, exceptional positioning accuracy is achieved in 3D printing in all axes.

-

nine0002 We equip our 3D printer with only the latest and highest quality electronic components.

Modern 32-bit control board with a powerful processor will quickly cope with any task.

3D printing is carried out from an SD card, USB flash drive or a regular PC using a wide range of software.

We are installing open firmware MARLIN 2.

XX on our printer. The firmware is constantly being improved, it supports all modern technologies. Easy to update, easy to upgrade. nine0003

XX on our printer. The firmware is constantly being improved, it supports all modern technologies. Easy to update, easy to upgrade. nine0003 -

We design and manufacture our own 3D printers ourselves.

A modern line of CNC equipment allows for precise cutting and bending of metal, printing of plastic parts.

Printer parts are painted with modern powder paints.

nine0002 We carry out quality control at all stages of production and assembly. Before sending the 3D printer is subject to mandatory testing. -

Extensive upgrade options! Printheads - single, double, control boards, drivers, nozzles, filament presence / movement sensors, power supply sensors, table calibration sensors, limit switches - all this is available in stores and is easily mounted on a 3D printer depending on your needs.

nine0003

nine0003 Your 3D printer will always keep up with the times!

If something went wrong, we will provide you with technical support wherever you are! We will answer any questions, help with configuration, diagnostics and modernization.

Reliability and precision

Steel frame 4 mm. Double carriages and bearing units. Linear rails 15 mm along the XY axes. Synchronized 4 x 20mm ball screws and 20mm polished shafts in Z axis. Robust 20mm wide belts. nine0003

Speed and power

Powerful 5:1 planetary print head. 32 bit control board. Powerful NEMA 23 motors in the XY and NEMA 34 motors in the Z axis. Separate drivers to control them.

Control and Compatibility

Type 12864 full function screen with encoder and backlight. Firmware MARLIN 2.XX. Compatible with Slic3R, Repeater Host, Cura, Simpify 3D and more. Ability to 3D print from various media such as SD, USB, or connect your PC. nine0003

Ability to 3D print from various media such as SD, USB, or connect your PC. nine0003

Variety of materials

3D print almost any FDM material from TPU to Nylon. Working table temperature up to 140 C. Nozzle temperature up to 350 C. Wide choice of nozzles from 0.2 to 2.0 mm in diameter. Bar from 1.75mm to 3mm.

Upgrading and maintenance

Deeply upgradeable, fitting virtually any printhead. Possibility of installation of a laser head. Replaceable drivers. Compatible with almost any sensors: thread end/presence, limit switches, auto-level sensors, power outages, Wi-Fi, etc. Almost all components are available on the Russian market. nine0003

Service and delivery

We will provide you with technical support wherever you are! We will answer any questions, help with assembly, configuration and diagnostics. We will deliver a 3D printer anywhere in the country. You will only have to assemble it according to the scheme of several parts. And in a few hours you will be able to use it!

Our team

Dmitry

Product manufacturer.