3D printer commissions

3d Print Commission - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(373 relevant results)

5 Best 3D Model Commissions Providers On Fiverr (2022)

Last Updated on September 14, 2022

3D models play a significant role in modern projects as they can increase efficiency and ease of work.

Do you need a custom 3D model for 3D printing, concept art, illustration, video game, or any other project but don’t have any 3D design experience?

You’ve come to the right place. Here is our top list of 3D model designers:

Table of Contents:

How to create your own 3D models?

An artist manipulates points in virtual space with specific software to create a mesh: a collection of vertices that make up an object.

Isn’t that kind of a biggie? You don’t want to waste time learning about vertices through tutorials.

You could do so if you want, but hiring a professional 3D model artist to handle the heavy lifting is better as you’re paying for their experience and years of perfecting that skill, not simply their services and time. You might learn the basics on your own, but what you need is an artist to take your idea to the next level.

Moreover, 3D modeling necessitates the usage of a specific type of computer with specific specifications in order to access the software needed to create projects, which may not be available to you.

So, why don’t you hire a skilled artist to bring your concept to life?

There’s no better place to look for one than Fiverr. At one point or another, you should have heard or used this platform.

If you’re unfamiliar with Fiverr, it’s a freelancing website where creatives of all kinds sell their services for as low as $5. There are dozens of outstanding artists who offer design packages at or near this cheap price threshold.

Even better, by simply searching, you can easily find designers there who specialize in 3D modelling.

To do that, you begin by going to the Fiverr homepage and searching for “3D modelling” in the search field. All of the artists who offer 3D modelling services will appear in your search result. Scroll through the results, glance through several portfolios and pick a designer whose style you prefer.

What are the best 3D model commission services?

Nothing is more frustrating than investing time and money into hiring someone only to have the final output fall short of your expectations. Entrusting your project’s design to an artist is a huge step in the development process.

Entrusting your project’s design to an artist is a huge step in the development process.

While there are several 3D modelers offering their creative services on the platform, we’ve combed through to find five of the finest for hire based on our experience. Each with their own style and niche, Packages to meet a variety of budgets and delivery limits.

You won’t have to compromise quality for cost when you work with these professionals:

1. Zhoso_designs – A Rising Talent Printing Based 3D Artist

Do you require 3D modeling of characters or products for 3D printing? Miguel is the best candidate for the job.

Miguel is a rising talent artist that is just getting started on the platform and has already risen to the top of the rankings with 40 5-star reviews. He’s a seasoned 3D designer with extensive experience in product design, manufacturing, 3D modeling, rendering, and 3D printing.

He does not have a set pricing as it varies depending on the complexity of the project. As a result, you must first contact him to discuss your order before he can access and draft your custom offer.

As a result, you must first contact him to discuss your order before he can access and draft your custom offer.

You can expect a response within an hour, as it is his average response time.

2. hamzapervez91 – Top Rated Seller with Academic Credentials

Hamza is a top-rated seller as well as a Fiverr choice, holding two important roles as a proficient seller on Fiverr.

They essentially provide 3D cad modeling and product design on the platform using SolidWorks CAD software, and they guarantee to give all important CAD files that will be required, all of which can be simply opened on other CAD software.

With prices ranging from $75 to $500, you can get a fantastic 3d model of your ideas in 7-14 days. T

hey also prefer to talk about the project with you before you place an order. Send Hamza a message to talk about your concept, and you’ll hear back within an hour.

3. Latuarifian – A Seasoned 3D Character Generalist & 2D illustrator

Latu is a top-rated seller with over 200 positive feedbacks, he specializes in 3D character design, film animation, game assets, 3D printing, and other related services. Using the blender software and assuring that the finished project will be supported on other software’s.

Using the blender software and assuring that the finished project will be supported on other software’s.

With a pricing range of $80-$300, you can expect a low-poly to high-poly 3d modeling in 3-4 days, with two revisions. If needed, he also provides 2D services.

4. Khaledreese – 3D Product Render Expert with Premium Pricing

Khaled is an expert in 3D product rendering, if you’re looking to start a Kickstarter campaign, realistic renders. He’s the ideal guy for the job. if requested, he also offers 360° and custom freestyle videos to the renders.

He’s a level two seller with outstanding positive feedback, as evidenced by the sellers’ extensive reviews commending his work and recommending him. Only a pleased customer will do so, which implies Khaled makes his clients happy with his services.

Although his prices are a little on the high side, ranging from $500 to $700, the end results, however, are well worth it.

This is a good option if you have a higher budget and want a high-quality 3D product rendering. In addition, he stated in his gig description that the pricing varies depending on the complexity of the project.

In addition, he stated in his gig description that the pricing varies depending on the complexity of the project.

So, drop him a message to discuss your project, and you might not end up having to pay $500, you’ll get a response within an hour.

5. myslim47- An Experienced Architectural based 3D artist

myslim47 is a licensed architect who specializes in architectural services ranging from 2D plan drafting to 3D modeling and realistic rendering on the platform.

With prices ranging from $30 to $140, you will get a detailed rendering of a building or apartment in 5 to 14 days, with revisions.

Get in touch with myslim47 if you need architectural related service and you’ll receive a response within an hour.

What is the cost of 3D model commissions?

A 3D model commission can cost between $20 to $150 per model.

The exact pricing depends on factors such as the complexity of the model, the number of details the artists needs to create and the delivery length.

All of the artists we have mentioned above fit this price range, and I wouldn’t advise you to deviate from those prices. The quality you’d get from any of those artists is more than enough, based on my experience.

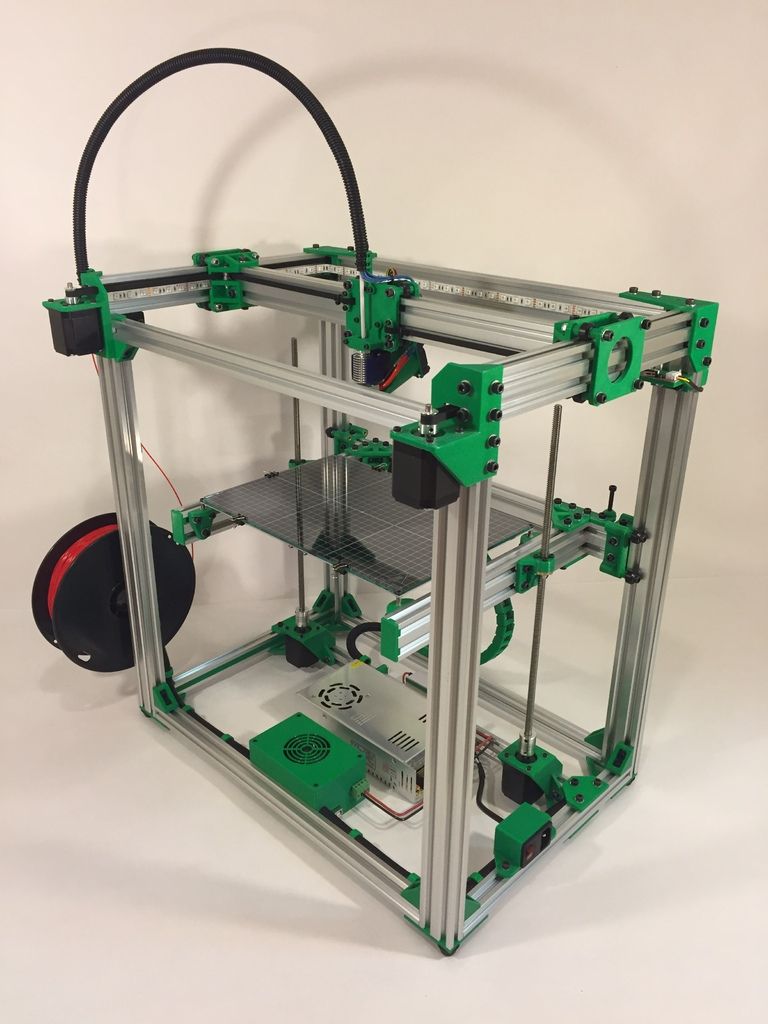

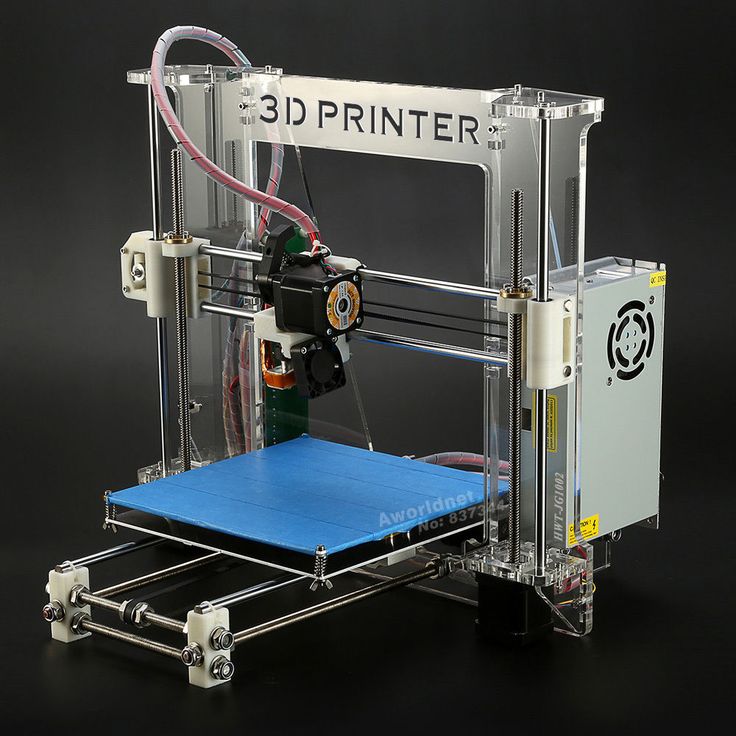

90,000 Bought a 3D printer, decided to make some money. What's next?So, you are thinking about the opportunity to make money on 3D printing. How realistic is this? Quite, although the path is thorny. We purposefully will not consider the opportunities provided by the use of expensive professional installations. This niche has been successfully developing for a long time, because there is a stable demand. The most advanced technologies even make it possible to create parts for rocket engines, but such devices cost a lot of money and are beyond the budgetary possibilities of a simple enthusiast. We will look specifically at the opportunity to earn extra money using an inexpensive FDM or SLA printer. nine0003

The first thing to stop at: forget about mass production. It just doesn't suit you. Compact printers are too slow to produce large volumes of products in a short time, alas. There can be no question of any competition with the foundry industry. And it's not just the time spent, but also the cost of production. Once the molds are made, smartphone cases can be stamped by the thousands with minimal downtime. This niche is firmly occupied. But after all, the casting molds themselves need to be made, right? This is where 3D printing can come in handy. No wonder this technology has an alternative name - "rapid prototyping". nine0003

It just doesn't suit you. Compact printers are too slow to produce large volumes of products in a short time, alas. There can be no question of any competition with the foundry industry. And it's not just the time spent, but also the cost of production. Once the molds are made, smartphone cases can be stamped by the thousands with minimal downtime. This niche is firmly occupied. But after all, the casting molds themselves need to be made, right? This is where 3D printing can come in handy. No wonder this technology has an alternative name - "rapid prototyping". nine0003

Microsoft went through hundreds of printed prototype controllers for the Xbox One. But this is a job that is too tough for a home FDM printer

Many articles about making money on 3D printers are written by the owners of these devices in personal blogs.

Prototyping using 3D printing is especially relevant for industries that are constantly changing the look of their products. That is why dentists and jewelers love 3D printing so much. Every day a new patient with their own unique set of teeth. Or another fastidious socialite who needs jewelry to be the envy of everyone. But only unique! And if the Chinese factory for the production of "real Russian nesting dolls" does not show any interest in you or your 3D-printing miracle machines (they most likely have their own), then the nearest dental clinic may well be interested. It is not yet a fact that they are ready to invest in purchasing their own SLA printer and keep a person on staff who would serve it. After all, these are extra costs, extra accounting, extra working space. Much easier and cheaper to use contractors. That is you. nine0003

Every day a new patient with their own unique set of teeth. Or another fastidious socialite who needs jewelry to be the envy of everyone. But only unique! And if the Chinese factory for the production of "real Russian nesting dolls" does not show any interest in you or your 3D-printing miracle machines (they most likely have their own), then the nearest dental clinic may well be interested. It is not yet a fact that they are ready to invest in purchasing their own SLA printer and keep a person on staff who would serve it. After all, these are extra costs, extra accounting, extra working space. Much easier and cheaper to use contractors. That is you. nine0003

It is quite possible to make money in small-scale production. Again, in order for the foundry process to pay off, it is necessary to produce large quantities of goods. The cost of small-scale production on a simple FDM printer will be lower, because you do not have to invest in the creation of molds, not to mention expensive foundry equipment, workshops, and hiring personnel. If the same private dentist comes to the same Chinese foundry with a request to cheaply cast a batch of 200 promotional souvenir key chains, then they will look at him ... askance. And here you are quite on the shoulder. You will even be able to compete in terms of the cost of end products. After all, your technological process is extremely simple: draw and print. And if you also master such subtleties as the processing of ABS models with acetone fumes, then your products will not visually differ even from cast analogues. nine0003

If the same private dentist comes to the same Chinese foundry with a request to cheaply cast a batch of 200 promotional souvenir key chains, then they will look at him ... askance. And here you are quite on the shoulder. You will even be able to compete in terms of the cost of end products. After all, your technological process is extremely simple: draw and print. And if you also master such subtleties as the processing of ABS models with acetone fumes, then your products will not visually differ even from cast analogues. nine0003

3D printer plus acetone bath. Why not a cute owl?

What is most remarkable: recently, “home” SLA / DLP printers have appeared that are in no way inferior in quality to their expensive professional counterparts. They are inferior only in performance, but not so much. But the price difference between compact and industrial devices can be enormous. Take a look at the prices of the nearest professional 3D printing shop, if there is one in your city, drop the price for the sake of competitiveness, stock up on the necessary materials and call the small jewelry business and clinics. Although, it is better to call first, ask. Make an offer, explain the essence. It is very possible that you will find customers. And if you also reinforce the words with a good example... Imagine the reaction of an old, gray-haired master jeweler, who for the first time sees a model of a ring made of burnt photopolymer resin and realizes that he no longer needs to cut out the master models with a drill and a mat. Or an auto mechanic who can offer his customers to exchange broken small plastic parts for printed parts without a long wait for spare parts and at a better price. Yes, and with the possibility of customization. Put the Ferrari logo on someone's favorite chisel? Yes, no problem. Yes, it will look like the real thing. No, not expensive. nine0003

Although, it is better to call first, ask. Make an offer, explain the essence. It is very possible that you will find customers. And if you also reinforce the words with a good example... Imagine the reaction of an old, gray-haired master jeweler, who for the first time sees a model of a ring made of burnt photopolymer resin and realizes that he no longer needs to cut out the master models with a drill and a mat. Or an auto mechanic who can offer his customers to exchange broken small plastic parts for printed parts without a long wait for spare parts and at a better price. Yes, and with the possibility of customization. Put the Ferrari logo on someone's favorite chisel? Yes, no problem. Yes, it will look like the real thing. No, not expensive. nine0003

This is such a beauty on a home SLA printer. Jewelers will be delighted, we guarantee it

The main problem in small-scale production is finding customers. Let's be honest: few people in our country even know what a 3D printer is. If they knew, then the 3D printing business would grow by leaps and bounds. Are you a minibus driver, and your passengers broke off all the plastic handles on the windows? Contact us, we'll print it. Need a pretty vase to make your best friend jealous? Let's do it. Need a 1:72 scale model of the Wright brothers plane? Can't be found during the day with fire? If there were drawings, we would make a set for the modeller. nine0003

If they knew, then the 3D printing business would grow by leaps and bounds. Are you a minibus driver, and your passengers broke off all the plastic handles on the windows? Contact us, we'll print it. Need a pretty vase to make your best friend jealous? Let's do it. Need a 1:72 scale model of the Wright brothers plane? Can't be found during the day with fire? If there were drawings, we would make a set for the modeller. nine0003

But how to find all these people? Or how to make them find you?

This is the main problem. As long as there is no developed market, there is no opportunity for trade. There is, of course, the possibility of advertising - from ads on lampposts to Yandex.Direct. But in this case, you would most likely have to start your own website. After all, it will not work to clearly demonstrate the product and explain the essence of the services in one ad. This is one option. But you don't have to create the market yourself. There is another option - to use Internet sites that sell 3D models. There everything is already done for you, it remains only to lay out your models or take orders. Of course, you will have to pay a commission for sales, but business is business. On the other hand, there is no need to spend time and money on your own website, and traffic will be higher. After all, it is better to trade in the market than in the outskirts? nine0003

There everything is already done for you, it remains only to lay out your models or take orders. Of course, you will have to pay a commission for sales, but business is business. On the other hand, there is no need to spend time and money on your own website, and traffic will be higher. After all, it is better to trade in the market than in the outskirts? nine0003

Have you signed up to be a maker?

Such markets for 3D models are developing quite successfully and include makers from all over the world. Shapeways and Thingiverse are typical examples. There are similar resources in Russia - the same Fair of Masters. Some sites generally use makers as a distributed resource - for example, makexyz.

There is another nuance that cannot be ignored. It is unlikely that you will be able to make money with a 3D printer without having 3D modeling skills. After all, most of your clients will not come with ready-made digital models, but with sketches, physical objects for cloning, even just ideas. Therefore, certain design skills will be required, which, of course, can be included in the cost of products. Can't you do it yourself? Try to arrange a co-op. There will always be a design student ready to earn extra money and practice. And with you the printer and maintenance of equipment. Who knows, over time, such a modest undertaking may well develop into a serious business - there would be orders. Again, Internet sites can be considered an exception. Some of them purposefully rent the capacity of a distributed network of makers. Orders will be provided ready-made, as long as you have the opportunity to print them and send them to the customer. nine0003

Therefore, certain design skills will be required, which, of course, can be included in the cost of products. Can't you do it yourself? Try to arrange a co-op. There will always be a design student ready to earn extra money and practice. And with you the printer and maintenance of equipment. Who knows, over time, such a modest undertaking may well develop into a serious business - there would be orders. Again, Internet sites can be considered an exception. Some of them purposefully rent the capacity of a distributed network of makers. Orders will be provided ready-made, as long as you have the opportunity to print them and send them to the customer. nine0003

Smile, it won't hurt at all

Since we mentioned cloning, it is worth remembering about 3D scanners. Large companies such as 3D Systems and MakerBot are building their own ecosystems with might and main: product kits consisting of printers, scanners and online support. Arm yourself with, say, a MakerBot Replicator 2X printer and a MakerBot Digitizer scanner. Someone needs to expand the set of favorite towel hooks that have not been sold for ten years? Here is your niche. Scan a sample and print a custom batch. And after completing the order, why not post the existing hook model in your portfolio on the makers website? Will there be other customers? 3D scanners are somewhat expensive, but they open up a lot of new opportunities, at least in the souvenir business. 3D designing is hard enough already, but to make a 3D portrait of someone, you already have to be an artist. There is no shortage of talent here. But even in this case, the project will take a lot of time. In such cases, scanners are simply irreplaceable. The same 3D Systems Sense is quite capable of scanning a person in full growth. And there will always be those who want to make action figures of themselves, loved ones. If you can Keanu Reeves, then why not everyone else? nine0003

Someone needs to expand the set of favorite towel hooks that have not been sold for ten years? Here is your niche. Scan a sample and print a custom batch. And after completing the order, why not post the existing hook model in your portfolio on the makers website? Will there be other customers? 3D scanners are somewhat expensive, but they open up a lot of new opportunities, at least in the souvenir business. 3D designing is hard enough already, but to make a 3D portrait of someone, you already have to be an artist. There is no shortage of talent here. But even in this case, the project will take a lot of time. In such cases, scanners are simply irreplaceable. The same 3D Systems Sense is quite capable of scanning a person in full growth. And there will always be those who want to make action figures of themselves, loved ones. If you can Keanu Reeves, then why not everyone else? nine0003

"I will print my case for Samsung - there will be a new iPhone"

In summary, the main strength of 3D printing lies in the ability to create unique objects quickly and inexpensively. Use it to produce souvenirs, art, mock-ups, hard-to-find or overpriced spare parts. Take on something that consumer-oriented mass production does not want to take on. Use available online resources to search for orders or sell finished products. Try to create a complete production cycle - from design to printing. It will take a long time before 3D printers appear in every home, so there is still a chance to make money on your favorite hobby. nine0003

Use it to produce souvenirs, art, mock-ups, hard-to-find or overpriced spare parts. Take on something that consumer-oriented mass production does not want to take on. Use available online resources to search for orders or sell finished products. Try to create a complete production cycle - from design to printing. It will take a long time before 3D printers appear in every home, so there is still a chance to make money on your favorite hobby. nine0003

Related Articles :

How do you make money with 3D printing?

3D printing services: only printing or complex? And a couple more myths.

How do you make money with 3D printing?

3D printers in construction: prospects for application

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure. nine0003

It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure. nine0003

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution to building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 innovations

- How can 3d printed projects help construction companies?

- 3D printing distribution

- Civil engineering 3D printing

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of medal

- How can 3D printing be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

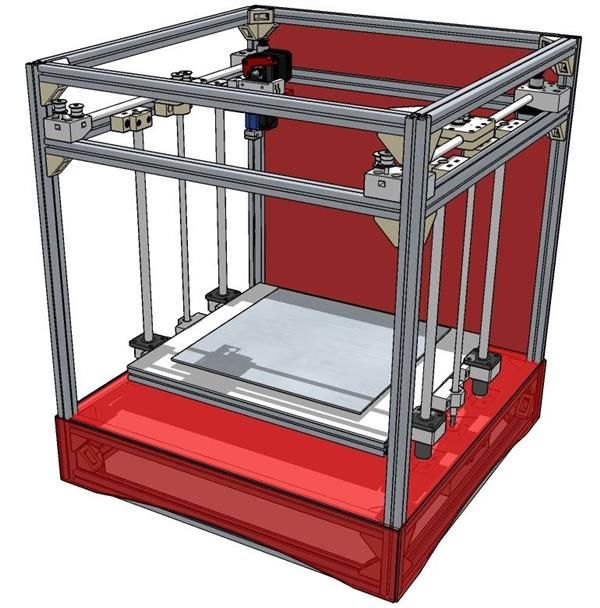

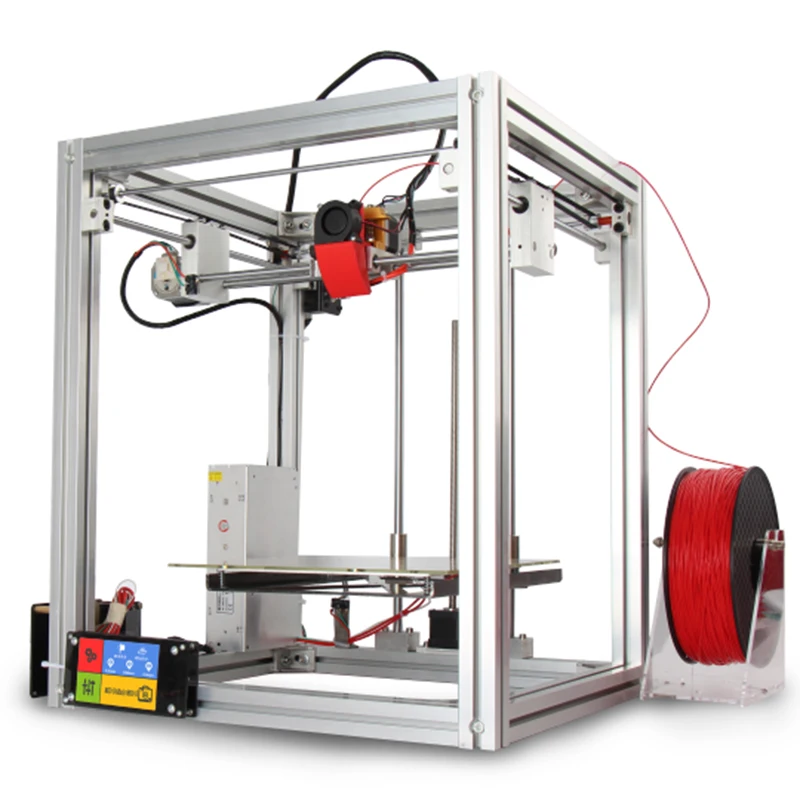

3D printing for construction uses both a 3D printer, which has a robotic "crane-arm" that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site. nine0003

nine0003

The concept of 3D printing is not new: it first appeared in the 80s. But it's only in the last decade that this technology has been improved enough (and the cost significantly reduced) to become a real mainstream.

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of various materials that, when cooled and dried, form a structure. nine0003

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine begins layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, level by level, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation. nine0003

nine0003

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company of China has also applied factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site. nine0003

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed number plate in Lewis Grand Hotel, Philippines

3D printed number plate in Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours. nine0003

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours. nine0003

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually. nine0003

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs be useful for construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste. nine0003

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste. nine0003

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs. nine0003

nine0003

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%. nine0003

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including a single, unique one. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published statistics of workplace injuries by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored. nine0003

nine0003

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products). nine0003

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products). nine0003

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology. nine0003

nine0003

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response. nine0003

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014. nine0003

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project. nine0003

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure through a new method of design and manufacturing. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the overall design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste. nine0076

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, a lot of materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs. nine0003

3D printing right on the construction site will help to avoid such additional costs. nine0003

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future more people will be able to buy houses of their own design, according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy? nine0054

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future for some time, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones. nine0003

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Lack of skilled labor

With the current problem of a shortage of skilled labor in the construction sector in general, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future. nine0003

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations nine0215

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry. nine0003

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry. nine0003

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and it is likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.