3D white light scanners

White Light Scanning | White Light Scanner

When scanning your products, we will select the right technology that delivers the accuracy, speed and resolution you need for your application. We also consider the size, color and reflectivity of the object.

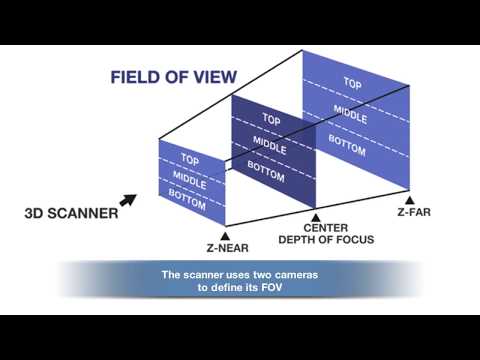

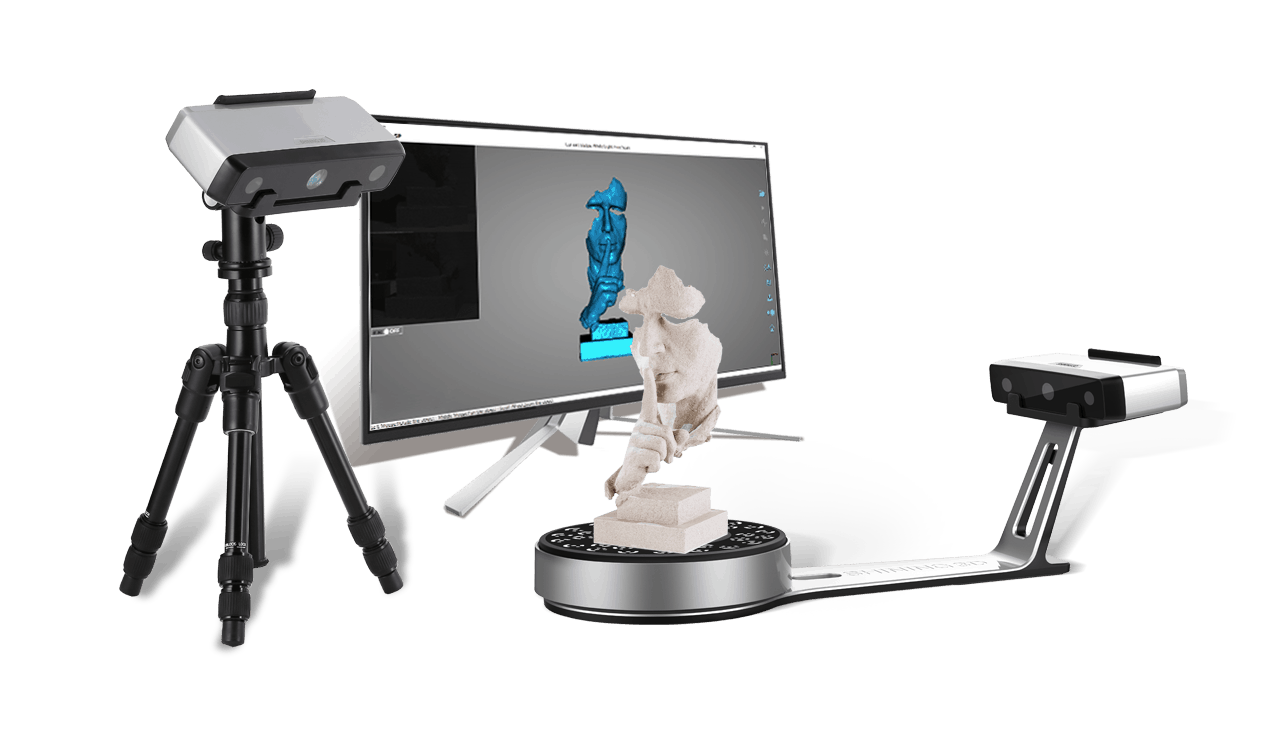

The technologies that we use include laser scanners, white light scanners and CT scanners. The laser scanners are mounted on a ROMER arm or tracked with an NDI optical system. This allows us to capture scan measurements in an area up to 18 feet in diameter and at a rate of nearly 500,000 points per second. The white light scanners, which are mounted on a tripod, capture more than 1,000,000 points per second. In a single shot, the white light scanners take measurements in an area ranging from a few square inches to a few square feet. CT scanners allow for the easy measurement of the internal structures of parts by generating a point cloud from a number of two dimensional x-ray pictures.

When it comes to a discussion about “White Light vs. Laser Scanning”, those unfamiliar with the technologies may believe that we’re about to proceed into an article rating all of the Sci-Fi flicks from the last century. But we save those debates for lunch break. One of the most frequently asked questions the Exact Metrology team gets is: “What is the difference between white light and laser scanning?” And since our customers are often unsure of which would best suit their project, we decided to devote some space in this newsletter discussing the two.

Both 3D white light and 3D laser scanners are used for inspection and reverse engineering purposes. Both are close range scanners that will record data quickly and to a sub-millimeter level of accuracy. But each type of scanner has unique properties that make them more or less fitting for certain applications.

To illustrate the difference between white light and laser scanners, we grabbed your everyday deodorant bottle off the shelf and scanned some of its components using each type of scanner. The differences are illustrated below:

The differences are illustrated below:

3D White Light and 3D Laser Scanners: The Details

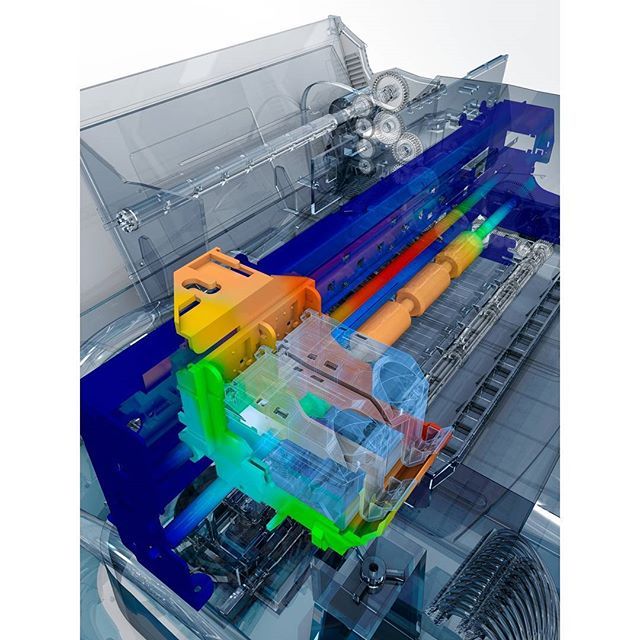

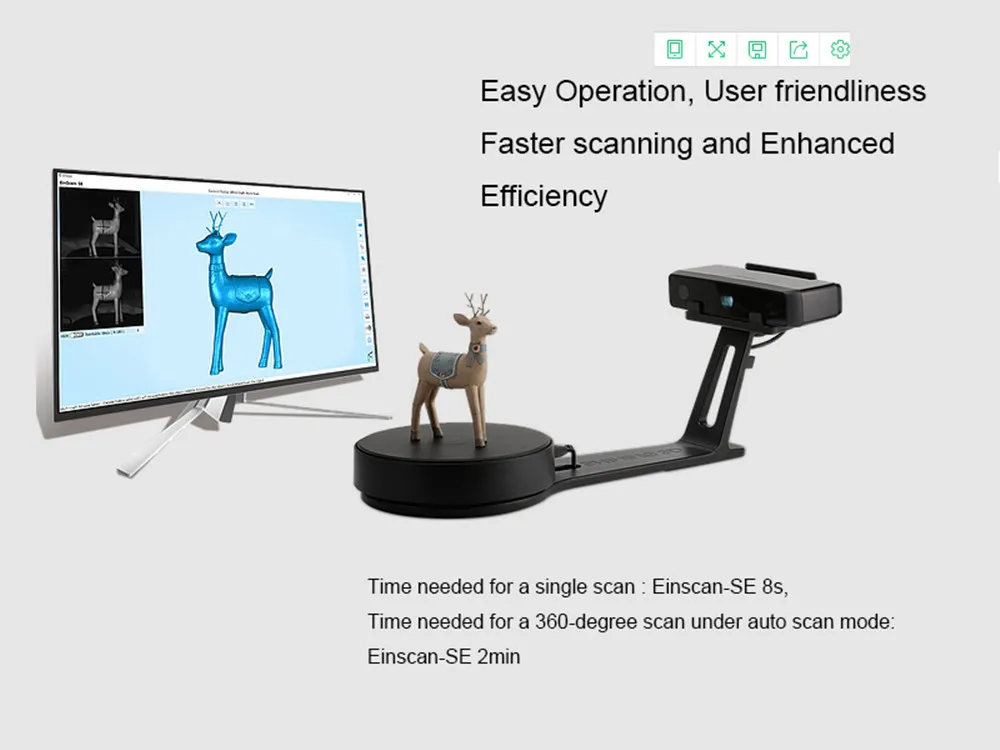

3D white light scanners are usually tripod mounted. Scan data is obtained shot by shot, as a grid of light is projected and laid over the component being scanned. As a scan is completed the grid is modified, and the scanner determines the 3D coordinates by calculating the returned patterns.

3D laser scanners are usually handheld or tripod mounted, and scan data is obtained as a laser stripe sweeps over a component or entire area. The handheld type is typically attached to an arm, which provide a constant readout of where the scanner is at any time.

So Which Do I Need for My Project?

When it comes to white light and laser scanners, there are several important differences one should take into consideration when planning their project. These include:

- Point Density

- Speed

- Accuracy

- Cost

Point Density

One significant difference in white light scanner and laser scanner results is in point density. To illustrate this example, let’s use the screw and crank from a deodorant bottle.

To illustrate this example, let’s use the screw and crank from a deodorant bottle.

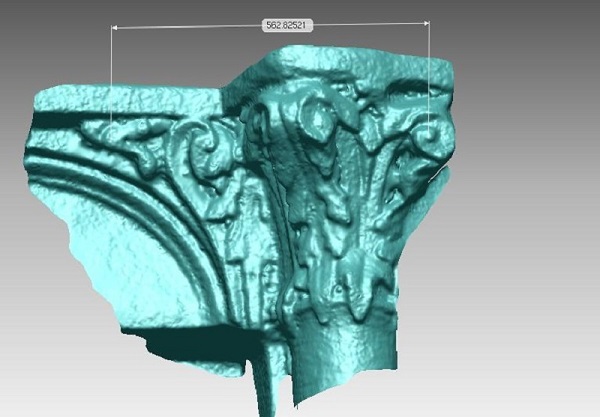

You can see from this side-by-side comparison the difference in detail the scanners are able to obtain. This detail is obtained not by accuracy but by having points closer together.

If the goal of the scan were to capture data about the general size and dimensions without the intricate details of the screw and dial, the ROMER Arm and laser scanner will capture this general shape. If the goal of the scan is to reconstruct the dial exactly, the white light scanner has point spacing that is much closer and will record the dial with greater detail.

Speed

When it comes to speed and efficiency of a scanner, laser scanners have the advantage of speed, due to the fact that they can do one sweep much more quickly than the multiple shots a white light scanner obtains. For example, the ROMER Absolute RS2 can scan 50,000 points wirelessly, with real-time exposure.

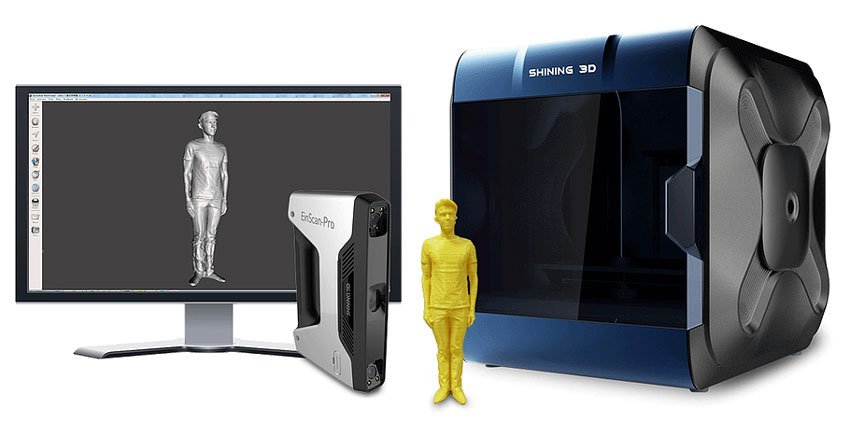

But with the next-generation cameras, electronics and processors now used, white light scanners can now obtain scan data containing over 8,000,000 points in an area as small as 30mm square and in as little as a few seconds. Due to this rapid scanning speed, white light scanners have been found to be incredibly useful in face scanning and body scanning applications, since people often find it difficult to stand still. However when many shots are required to cover the part in points additional time is required.

Due to this rapid scanning speed, white light scanners have been found to be incredibly useful in face scanning and body scanning applications, since people often find it difficult to stand still. However when many shots are required to cover the part in points additional time is required.

Accuracy

White light technology is capable of accuracies up to less than 0.001 of an inch in small volumes. Once the volume gets over roughly one foot cubed, the accuracies will match that of the laser scanner at roughly 0.003 of an inch.

Since each job is truly unique, your Exact Metrology rep will advise you on which type of scanning will achieve the greatest accuracy based on your project’s volume.

Cost

A white light scanner is typically more expensive than a laser scanner. While low-cost white light scanners are available, the data they obtain is typically not up to par with that obtained by the higher quality scanners. Therefore, if scan data provided by a laser scanner will meet the needs of a project, this is often the choice our clients go with. If scan data with greater detail is needed, then white light would be a better choice. You can talk with your Exact Metrology representative for a recommendation guaranteed to fit your requirements.

If scan data with greater detail is needed, then white light would be a better choice. You can talk with your Exact Metrology representative for a recommendation guaranteed to fit your requirements.

White Light vs Blue Light Scanning

3D scanning is an important part of quality assurance, prototyping, manufacturing, and reverse engineering. The precise 3D blueprints and rapid workflows enabled by light-based non-contact metrology solutions make them an important technology that can have measurable benefits on an organization's bottom line.

However, many organizations are unfamiliar with the details of the various 3D scanning technologies available, and what you don’t know can hurt you. As industry standards progress, competition ramps up, and regulations become more and more stringent, it becomes more and more important for organizations to understand technologies that can position them the most advantageously in the marketplace. One area of confusion related to the 3D scanning industry is the difference between white light vs blue light scanning. While the short answer is blue light scanning is the more modern and advanced version of the two technologies, the topic warrants further discussion to help build a better understanding of how the technologies can benefit you. In this article, we will provide an introduction to white light and blue light scanning, compare white light vs blue light scanning and dive into some use cases for the technology (including how AMRDEC saved up to $100 million with ATOS blue light 3D scanners).

While the short answer is blue light scanning is the more modern and advanced version of the two technologies, the topic warrants further discussion to help build a better understanding of how the technologies can benefit you. In this article, we will provide an introduction to white light and blue light scanning, compare white light vs blue light scanning and dive into some use cases for the technology (including how AMRDEC saved up to $100 million with ATOS blue light 3D scanners).

What is white light scanning?

White light 3d scanning is a type of non-contact metrology that leverages white light to produce highly accurate measurements. White light scanning enables highly accurate 3D models of physical objects to be created quickly and with a high level of precision. White light scanning technology has been on the market for over two decades. GOM’s ATOS systems, which have since evolved to utilize the more advanced blue light technology, were using white light commercially as early as 1995.

White light scanning technology has been on the market for over two decades. GOM’s ATOS systems, which have since evolved to utilize the more advanced blue light technology, were using white light commercially as early as 1995.

White light 3D scanning works by projecting the line shadows from a 2D lens to a 3D surface. Cameras are then leveraged to view the variances in the 2D lines on the 3D objects and use advanced algorithms to generate point clouds. The X-Y-Z coordinate points generated during this process are then brought together to create a precise 3D model of the physical object

When compared to traditional laser scanning, white light 3d scanning can offer a number of benefits. Laser scanners use laser beams to measure the surface area of a device and create models based on that data. Oftentimes the process of collecting measurements using a laser-based system can be tedious and labor-intensive. Laser measurement systems often require the user to leverage a portable 3d scanner or articulating arm and wave the scanner in a paintbrush style motion over the object. Not only can this process be time consuming, but it can also lead to redundancy in efforts and overlapping data. A white light-based 3D scanning system on the other hand generally uses a camera mount, tripod, or robot and enables a “point & shoot” style workflow that minimizes setup and programming.

Not only can this process be time consuming, but it can also lead to redundancy in efforts and overlapping data. A white light-based 3D scanning system on the other hand generally uses a camera mount, tripod, or robot and enables a “point & shoot” style workflow that minimizes setup and programming.

Similarly, white light 3d scanning offers workflow advantages over traditional coordinate measuring machine (CMM) based scanning systems. Traditional CMMs require that a probe touches an object’s surface in order for a measurement to be gathered. This means that as the complexity and size of an object scales, so can the measurements and programming required to use a CMM. Given that white light scanning does not depend on a physical probe touching the surface of an object and the relative ease of configuring a white light-based scanning solution, white light scanning inherently helps to mitigate many of the workflow and productivity issues associated with CMM based scanning solutions.

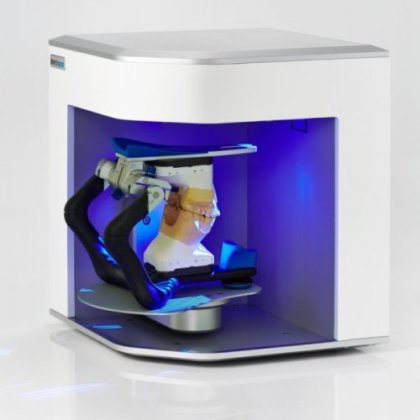

What is blue light scanning?

When comparing white light vs blue light scanning, it can be easy to become confused as to the differences between the two technologies. Sorting through the differences can become even more difficult when you consider that some marketing materials and articles related to the topic of metrology seem to use the terms interchangeably. In short, blue light scanning is an enhanced version of the white light technology discussed above. When comparing white light vs blue light scanning, they are known to be used in many of the same cases. However, blue light 3D scanners offer better precision, accuracy, and higher quality outputs.

One of the reasons blue light scanning technology is able to offer benefits over white light scanning technology is based on the fact that blue light has a narrower wavelength whereas white light is a combination of all the colors in the visible spectrum. The narrow wavelength of blue light helps enable better filtering of interference from ambient light.

ATOS technology based on blue light scanning enables users to quickly generate 3D blueprints of physical objects with a high level of accuracy. For example, the GOM ATOS Triple Scan which is capable of measuring up to 8 million points per scan won the GE High Accuracy, High Throughput Inspection Technologies Challenge where the objective was to inspect the blade of a Victorinox paring knife in under three minutes. Accuracy of the inspection had to be 10 microns or less with a repeatability of 5 microns. Despite the competition from 50 other entrants, with its advanced blue light technology, the ATOS Triple Scan was able to come out of the competition a winner.

Use case: Extending the life of C130 Aircraft

While the aforementioned inspection of a blade portion of a Victorinox paring knife during the GE competition may seem like a novel exercise with a limited practical benefit at first glance, the reality is different. The paring knife was used to serve as an affordable representation of a turbine blade. This makes sense when you consider the importance of highly accurate 3D models to the world of aviation.

This makes sense when you consider the importance of highly accurate 3D models to the world of aviation.

A great example of the importance of 3D scanning and digital twin models in the aviation industry involves the ATOS 3D Scanner and TRITOP technology. Canada’s National Research Council was tasked with a refurbishment project for aging C130 aircraft. As part of the project, they needed to update electrical and mechanical systems and develop 3D models for computational fluid dynamics (CFD) and stress analysis. By partnering with Capture 3D, the National Research Council was able to have the required measurements completed in less than two weeks. Click here for more on this case study.

Use case: How AMRDEC saved up to $100 million with blue light 3D scanners

While the idea that blue light scanning can “improve workflows” may sound like marketing buzzwords as opposed to something that can impact your bottom line, the use of ATOS blue light 3D scanners by the US Army’s Aviation and Missile Research, Development and Engineering Center (AMRDEC) demonstrate the potential in a practical way. AMDREC adopted ATOS blue light scanners as a standard for their “ inspection, reverse engineering and adaptive machining applications” and on one project alone the time savings enabled by the technology saved up to $100 million (source: advancedmanufacturing.org, May 15, 2017).

AMDREC adopted ATOS blue light scanners as a standard for their “ inspection, reverse engineering and adaptive machining applications” and on one project alone the time savings enabled by the technology saved up to $100 million (source: advancedmanufacturing.org, May 15, 2017).

Click here to watch a video of ATOS and TRITOP in action scanning a 41-foot long Cost Guard boat at an AMDREC site in Redstone Arsenal, Alabama.

Contact the experts

At this point, you may have a number of ideas about how blue light technology can benefit your business but are not sure where to start or what tools are right for you. Our dedicated team of experts at Capture 3D is ready and willing to help you find the right solution. Our solutions feature workflows that are optimized to specific industries and we specialize in helping you select the best solution for your unique use case. Contact us today to learn more!

We restore damaged parts.

History of

3D scanning technology appeared only a few decades ago, at the end of the 20th century. The first working prototype appeared in the 60s. Of course, then he could not boast of a wide range of features, but it was a real 3d scanner that did a good job with the main function.

The first working prototype appeared in the 60s. Of course, then he could not boast of a wide range of features, but it was a real 3d scanner that did a good job with the main function.

In the mid-1980s, scanning devices improved. They began to be supplemented with lasers, sources of white light and dimming. Thanks to this, it was possible to improve the "capture" of the objects under study. During this period, contact sensors appear. With their help, the surface of solid objects, which did not differ in complex shape, was digitized. To improve the equipment, the developers had to borrow a number of optical technologies from the military industry.

The use of 3d scanners was interesting not only for designers of design studios, automobile concerns, but also for film industry workers. In the 80s - 2000s, different companies produced their own models of equipment: Head Scanner, REPLICA 3D scanner and others. Since then, the units have changed, improved, become more mobile and functional. The characteristics of a 3d scanner today are significantly different.

The characteristics of a 3d scanner today are significantly different.

The 3D scanner device is engaged in a detailed study of physical objects, after which their exact models are recreated in digital format. Modern units can be stationary or mobile. A laser or a special lamp is used as a backlight (their use increases the accuracy of measurements).

The principle of operation of a 3d scanner is determined by the scanning technology. Using the backlight and built-in cameras, the device measures the distance to the object from different angles. Then the pictures transmitted by the cameras are compared. After a thorough analysis of all the received data, the finished digital three-dimensional model is displayed on the screen. If the device of a 3d scanner is based on the operation of a laser beam, then with its help distances are measured at given points. Coordinates are derived based on this information.

There are two main methods:

1) Contact. The device probes an object through physical contact while the object is on a precision surface plate. The contact 3D scanner is extremely accurate. True, when scanning, you can damage or change the shape of the object.

The device probes an object through physical contact while the object is on a precision surface plate. The contact 3D scanner is extremely accurate. True, when scanning, you can damage or change the shape of the object.

2) Contactless. Radiation or special light (ultrasound, x-rays) is used. In this case, the object is scanned through the reflection of the light flux.

1) Laser. The operation of the devices is based on the principle of operation of laser rangefinders. Laser scanners 3d are characterized by the accuracy of the resulting three-dimensional model. True, their use is difficult in conditions of object mobility. This is more of an indoor 3d scanner. Scanning a person with a 3d laser type scanner is almost impossible.

2) Optical. In this case, a special laser of the second safety class is used. Optical 3D scanner has a high scanning speed. Its use eliminates any distortion, even if the object is moving. There is also no need for reflective labels. True, such devices are not suitable for the study of mirror, transparent or shiny products. But this is a great option for a 3d human scanner.

There is also no need for reflective labels. True, such devices are not suitable for the study of mirror, transparent or shiny products. But this is a great option for a 3d human scanner.

Devices can differ in many ways: scope of use, dimensions, shape, technology. Modern units are used in both industrial and domestic areas. An industrial 3d scanner is useful in:

engineering;

medicine;

production;

design;

film industry;

· the field of creating computer games.

I would like to pay special attention to the ultrasonic 3d scanner. He is a real find for modern medicine. The devices are supplied with energy, color, tissue, continuous-wave and impulse dopplers. This unit is characterized by the highest resolution, therefore it is popular in mammology, obstetrics, urology, the study of blood vessels and muscle tissues, echocardiography, neonatology, and pediatrics.

The principle of operation of the device is also different. The market offers a stationary or portable, that is, a manual 3d scanner. In the second case, a coordinate-sensitive detector or a charge-coupled device is used as a sensor. This unit is extremely convenient in that it can be freely moved. A portable 3D scanner is ideal for scanning hard-to-reach places or large objects. The measurement can be taken at any angle, around or under the test objects.

Devices are used in conjunction with different equipment. It can be not only a 3d scanner for a 3d printer, but also a 3d scanner for ipad. Modern manufacturers of such units produce mobile devices that work not only with desktop computers, but also with tablets or even smartphones. In addition, there are special programs with the help of which ordinary phones turn into scanners. For example, you can find a 3d scanner for android. It will help design unique parts, conduct rapid prototyping and digitize objects.

Special programs for 3d scanner and data processing:

1) David-3D. Designed for 3D scanning of objects and transformation of the obtained results for the purpose of subsequent import of models into 3D editors.

2) Artec Studio 10. Professional tool for creating three-dimensional models.

3) Autodesk 123D Catch. 3D scanning for Android mobile phones.

4) Photomodeler Scanner. Allows you to create high-precision stl-models based on ordinary pictures taken with a smartphone or tablet camera.

5) 3DAround. Turns 2D photos into realistic 3D models.

Information taken from: https://make-3d.ru

3D laser scanning - definition, characteristics

Your city: Moscow

Right?

× Choose the city closest to you:

Moscow St. Petersburg Vladivostok Novosibirsk Yekaterinburg Kazan Nizhny Novgorod Chelyabinsk Omsk Rostov-on-Don Samara Krasnoyarsk Voronezh Perm

Volgograd Krasnodar Saratov Tyumen Tolyatti Izhevsk Barnaul Ulyanovsk Irkutsk Khabarovsk Makhachkala Yaroslavl

▼ Show more

Deselect

3D scanning is a technique used to capture the shape of an object with a 3D scanner. The result is a 3D object file that can be saved, edited, and even printed in 3D. Some 3D scanners can collect shape and color data at the same time. 3D scanning is compatible with computer-aided design (CAD) software, as well as 3D printing after a little training in the relevant programs.

The result is a 3D object file that can be saved, edited, and even printed in 3D. Some 3D scanners can collect shape and color data at the same time. 3D scanning is compatible with computer-aided design (CAD) software, as well as 3D printing after a little training in the relevant programs.

3D scanning technologies:

- Photogrammetry – 3D modeling from photographs. The principle of photogrammetry is to analyze several photographs of a static object taken from different viewpoints and automatically detect pixels corresponding to the same physical point. The input required from the user is camera parameters such as focal length and lens distortion. Photogrammetric technology is also capable of reconstructing objects of various scales photographed from the ground or from the air. The main advantages of 3D photogrammetry scanning technology are its accuracy and speed of data collection.

- Structured Light 3D Scan - Structured Light 3D Scan technology works by projecting a series of linear patterns onto an object.

The system is then able to examine the edges of each line in the pattern and calculate the distance from the scanner to the surface of the object. The structured light used for 3D scanning can be white or blue and is generated by numerous types of projectors such as digital light processing (DLP) technology. The projected pattern is usually a series of light rays, but can also be a random dot matrix. The main advantages of structured light technology for 3D scanning are speed, resolution and the ability to 3D scan people.

The system is then able to examine the edges of each line in the pattern and calculate the distance from the scanner to the surface of the object. The structured light used for 3D scanning can be white or blue and is generated by numerous types of projectors such as digital light processing (DLP) technology. The projected pattern is usually a series of light rays, but can also be a random dot matrix. The main advantages of structured light technology for 3D scanning are speed, resolution and the ability to 3D scan people. - 3D Laser Triangulation Scanning Technology – Laser triangulation based 3D scanners use either a laser line or a single laser dot to scan an object. Using this method, digitization begins with the emission of a rectilinear laser beam, which deforms upon contact with the object. Using a camera, the 3D scanner analyzes the deformation of the line emitted by the laser on the reliefs of the object in order to determine its position in space using trigonometric calculations.

The angle formed between the camera and the laser beam, the distance from the camera to the object, and the distance from the laser source to the object (known from the calculation of the time it takes the laser to go around) are parameters. which allow you to determine the spatial coordinates of the object. The advantages of laser triangulation technology for 3D scanning are resolution and accuracy.

The angle formed between the camera and the laser beam, the distance from the camera to the object, and the distance from the laser source to the object (known from the calculation of the time it takes the laser to go around) are parameters. which allow you to determine the spatial coordinates of the object. The advantages of laser triangulation technology for 3D scanning are resolution and accuracy. - Laser pulse based 3D scanning technology is a 3D scanning technology based on the calculation of the time required for the laser to reach the surface and return. Each measurement made by a 3D scanner reports a point on a surface, and the operation must be performed hundreds of thousands of times over the entire surface. This 3D scanning technology includes laser pulsed 3D scanners and phase shift 3D scanners. They, in addition to modulating the amplitude of the laser beam used for 3D scanning, also modulate its phase. These systems offer superior performance by combining the two types of modulation.

Advantages of pulsed laser 3D scanners: the ability to scan large objects and the environment.

Advantages of pulsed laser 3D scanners: the ability to scan large objects and the environment. - 3D Contact Scan uses contact between a probe and an object to reveal surface information measured by probe deformation. This is done using a touch probe, also called a probe or probe, connected to a 3D scanner. The probe is usually connected to a structure (for example, a robotic arm) capable of registering its deformations. The main advantages of contact technology for 3D scanning are its accuracy and the ability to 3D scan transparent or reflective surfaces.

Recommended equipment

- 3D equipment

- Accessories

3D equipment

Accessories

Application for 3D scanning

I have read the Privacy Policy and agree to the processing of my personal data.

Service Request

I have read the Privacy Policy and agree to the processing of my personal data.![]()