3D shapes for printing

Shapes best STL files for 3D printer・Cults

Polymer Clay Cutter zig zag vase

€1

Circles

€1

Red Heart Emoji

€5

Wolf Wall Decor. Animal Wall Decor. Wall Art Decoration

€1.87

Cat Wall Decor - Animal Wall Decor - Wall Art Decoration - Cat Wall Art - Nursery Wall Decor - Geometric Figure Decor

€1.87

F1 firefighter helmet

€0.50

Stacking Toy House Toddler Shapes

€3.47

Cookie stamp fir tree

€0.50

Shape Game (Pre-2)

Free

Geometric shapes for decorating (triangle, square, hexagon)

€2. 70

Crafting Mold Collection #1

€1.39

train-puzzle toy for the youngest

€2.99

Toddler Shapes Puzzle

€0.56

CubeSphereShellsBank

Free

Basic shapes // STL File

€0.71

Cernit clay cutouts

€0.51

Set of 5 Honeybee / Bee / Beehive Cookie Cutters, Bonus Plaque Classic Shapes

€0.93

3D model – CUTTERS Modern Artisan (set of 10)

€5

BEAR SHAPED PILL

€0.50

Snowman gingerbread cutter

€0.50

19 Deer Silhouettes, Deer Outlines, Projection Shapes, Wall Art

€5. 61

Geometric Christmas Ornaments Set

€2.81

Didactic cube geometric shapes

€0.73

Polygon cutters

€4.44

Clay Cutters

€8

Simple shapes

Free

Shape Drawing Templates

Free

CHEVRON CLAY CUTTER

€2

CHEVRON CLAY CUTTER

€2

Shape Tray Mini

Free

Long Live The New Fresh (Just Shapes And Beats, Articulated)

Free

Planetary Gear Fidget Toy

€0.99

Tree of Life Symbol, Sacred Geometry

€0. 94

Seed of Life Symbol, Sacred Geometry

€0.94

Egg of Life Symbol, Sacred Geometry

€0.94

Tetrahedron

€0.94

5Pcs Pumpkin Outline cookie cutter set

€1.86

DONUT PILL

€0.50

CURVED SMILEY PILLS

€0.50

Conical Shape Silicone Mold Housing

€1.49

ROUND PILL

€0.50

Key Hanger 'Impossible'

€0.50

BASIC SMILEY PILL

€0.50

1/12 Doll house rows of balustrades

€3.05

Triangle clay cutter | Digital STL file | sharp cutter | 7 sizes | polymer clay cutter | Triangle 2

€2

Triangle clay cutter | Digital STL file | sharp cutter | 7 sizes | polymer clay cutter | Triangle 1

€2

Star clay cutter | Digital STL file | sharp cutter | 7 sizes | polymer clay cutter

€2

Square clay cutter | Digital STL file | sharp cutter | 7 sizes | polymer clay cutter | Square 2

€2

3d Printed Shapes - Etsy.

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

3D printing mold making

Desktop 3D printing molding allows engineers and designers to get more functionality out of a 3D printer beyond prototyping. Molding opens up a world of production materials and provides the opportunity to produce small batches and sample test molds before using expensive

tools.

This booklet covers the following three mold making strategies: injection molding, high temperature molding and injection molded elastomers. Typically, molds are made from Formlabs clear resin, which is preferred for its transparency, although any standard resin can be used, and high temperature resin is ideal for processes with high temperature requirements. It should be noted that these processes are best suited for stereolithographic 3D printing (SLA) because the printed parts are isotropic and waterproof.

Prototyping and small-scale production with 3D printing tools

| Process | Equipment | Run time | Material cost (for example: 300 ml/cm3) |

| Do-it-yourself mold making and parts making | Mold 2 and injection molding machine | 5 to 24 hours (form print time) | Approximately $50 for High Temperature Resin |

| Outsourced SLA Form | injection molding machine | 3-5 days | Approximately $700 for back office printing on industrial SLAs |

| Outsourced metal mold | injection molding machine | 1-2 weeks | Approximately US$6,400 for office desk, aluminum finish |

| Outsourced mold Creation and production | no - full outsourcing | 1-3 weeks | $4,000 to $15,000 depending on volume and materials |

Silicone molding and some desktop molds are available using Formlabs Standard Resins High Temp, which has the highest HDT at 0. 45 MPa for any 3D printed media currently on the market and allows print parts that can be used for high temperature forming such as thermoforming and injection molding materials with higher melt temperatures

Injection molding

High-resolution SLA 3D printing on the Form 2 can be used to quickly prototype inexpensive injection molds that can be used to make real parts from a wide variety of

thermoplastic materials. Injection molds can be used to test mold designs prior to metal tooling or to produce low-volume parts

3D Printed Injection Molding covers injection molding using Formlabs clear resin printed molds. Following the release of Formlabs High Temperature Resin, designed to achieve higher heat resistance and stiffness, the booklet has been updated to describe the benefits of High Temperature Resin plates that are less likely to break due to thermal shock or temperature-related deformation

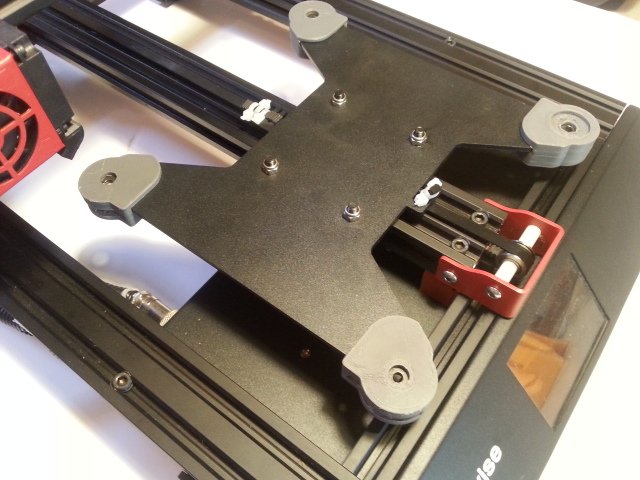

USB Device Enclosure Mold, 3D Printed on Form 2 High Temperature Resin

This mold contains a core, a cavity, and two "gates" leading to the two halves of the enclosure. High temperature resin molds can be used to mold a wide range of thermoplastics without thermal stress or temperature-related deformation

Formlabs High Temperature Resin can be used to injection mold a wide range of plastics.

3D printed mold tools reproduce the exact quality of the SLA print finish on the Form 2. Forms can be printed at 100 microns for faster prototyping or the recommended 50 microns for fine detail and smoothness

electronics molded in HDPE with a High Temp tool.

This shape of the USB case has been adjusted over three iterations to remove pits, entrapped air, and partial shrinkage. Total cost of materials for prototyping this high temperature resin mold tool: $25

Thermoforms

Form 2 3D printed thermoformed dies are a fast and efficient way to create high quality vacuum formed parts for low volume production. Printed thermoformed dies can be used to make packaging prototypes, clean orthodontic retainers, and food-safe molds for chocolate confectionery.

Thermoforming dies experience less pressure than injection molds, but still reach high surface temperatures.

High temperature polymer resists deformation and surface degradation from the combined heat and pressure of thermoforming for most plastics. Standard resins may also be suitable for thermoforming with some low temperature plastics such as vinyl.

APPLICATION EXAMPLE

Formech thermoformed prototype packaging.

Thermoforming a thin sheet of polycarbonate over a high temperature polymer matrix produces a transparent detail by matching the geometry and detail of the matrix. Thermoformed packaging can be easily prototyped and incorporated into the design process along with 3D printed product prototypes, and all this is achievable on the Form 2. The printed matrix was used without additional processing and the need for UV curing. Texture is recommended in thermoforming design to prevent air trapping under the sheet - layer lines on the printed thermoforming die can be helpful in this regard.

TEMPERATURE CONTROL

High Temperature Polymer Cycle Thermoforming

The surface temperature of the die reaches 130°C. The high temperature resin is highly resistant to deflection, whereas with standard resins you must allow the print matrix to cool between cycles, otherwise warping and degradation may occur.

If temperature rise becomes a limiting factor in molding efficiency, cooling channels are an effective way to remove heat from the print. When used in conjunction with an automated thermoforming machine, the water-cooled die can produce more parts with shorter cycle times.

Conformal water channels visible in the thermoforming high temperature die.

Thermoforming die surface temperature

Conformal cooling channels are easy to implement when designing for SLA 3D printing and print successfully without any internal supports to interfere with flow. After printing, the channels are flushed with uncured resin using isopropyl alcohol. The mold is connected to a pump and a source of cold water.

Integrated water cooling as a strategy can also be applied to standard and rigid polymer parts to reduce heat dissipation when used in higher temperature environments.

Elastomer casting

Precision molds for most flexible elastomers such as silicone and urethane rubber can be printed on the Form 2 using standard resin. The transparency of Clear Resin allows the material to be observed during the pouring or injection process. Flexible materials can be easily removed from rigid SLA printing plates, and applications from model production to functional molding can be obtained. Silicone molding can also be used to quickly replicate master prints, greatly reducing production time when multiple rigid parts and objects are needed.

APPLICATION EXAMPLE

Forms printed on Form 2 are used to create composite parts with advanced built-in features. Assembly subcomponents such as electronic, metal and SLA printed elements can be embedded and sealed in soft surface molds.

RightHand Robotics used the Form 2 to create the production blocks of their robotic gripper using urethane molding. The forms were printed in clear resin, with black resin inserts forming the internal structure.

The Form 2 printer allowed RightHand Robotics to move from prototypes to small-scale production without the need for expensive tooling. The rapid transition from original printed prototypes to production materials that have longer flex cycle life was done with 3D printed plates on the same Form 2 hardware they used for initial prototyping.

The first layer applied from RightHand Robotics' multi-stage process includes urethane compounds that can withstand multiple flex cycles while still providing the high elasticity needed to securely return the gripper to its open state.

The outer layer provides improved tactile grip and control, as well as sealing the sensor electronics with softer, lower durometer rubber.

SLA 3D printed parts can also be encapsulated inside molds to provide a rigid structure for flexible materials. The overlay can be mechanically bonded to the insert by adding holes, recesses, and columns to the printed parts, which enhances assembly and reduces the need for chemical adhesive.

Conclusion

Form 2 molding is a powerful strategy for the production of parts in small batches, as well as production from commonly used plastic and elastomer materials. 3D printing tools allow engineers and designers to easily prototype parts that look and function exactly like the final product, with geometries and material configurations that are quite complex, using 3D printing, such as in the case of encapsulated electronics and thin packaging. For high temperature forming, high temperature polymer offers superior thermal properties at a lower cost and with shorter lead times than process outsourcing

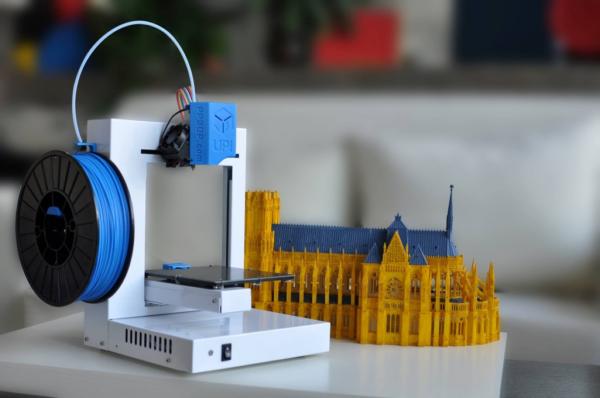

3D printer for silicone molds and products

With a 3D printer, you can create many complex and unusual products from various materials. In recent years, silicone 3D printing has become increasingly popular, which allows you to create implants, organ prototypes, and other useful products. Let's take a closer look at silicone printing, products that can be created with its help, the necessary equipment and the prospects for the development of new technology.

What is 3D printing silicone?

Silicone is a polymer that consists of chains of alternating silicon and oxygen atoms. This material is resistant to various temperature ranges and various chemicals.

In 2016, Wacker Chemie found the most efficient way to 3D print silicone products. Based on this technology, Fripp Design, Envisiontec, Carbon 3D developed and produced equipment and materials that made it possible to work with silicone on a 3D printer.

Silicone is most often used in the medical industry to create objects that are resistant to changing environmental conditions. Until 2016, it was possible to create medical objects from silicone only with the help of injection molding of thermoplastics (injection molding). However, the new technology of additive 3D printing allows you to create smaller parts at an acceptable cost compared to injection molded products.

3D silicone printing technology

The 3D printer, which can print silicone products, has a similar principle of operation to an inkjet printer. Liquid molten silicone is fed through the extruder in small droplets that are superimposed on each other, forming layers. The printer software is responsible for the correct formation of lines and shapes as a whole.

A vulcanization process is required for the silicone to cure. It is performed using ultraviolet radiation, which forms cross-links between sections of the polymer chain. Due to this, the silicone is strengthened and becomes heat resistant.

3D printed silicone inside a microgel

Silicone 3D printed inside a microgel was developed at the University of Florida. This technology makes it possible to create more durable, but at the same time flexible and comfortable implants. At the same time, the cost of their production will be significantly lower, as well as the final cost for buyers. In the future, silicone printing inside the microgel will allow the creation of various therapeutic devices and very complex structures, such as human organs and tissues.

This 3D printing method allows you to create individual products of various shapes. The printing nozzle moves along a predetermined path and extrudes liquid silicone drop by drop onto the microorganic gel substrate. Depending on the complexity of the finished product, the printing process can take from several hours to several days.

Silicone Mold Printer Applications

3D silicone mold printer is applicable to the following industries:

- Medicine. Silicone is biologically compatible with the human body, does not have a toxic effect on it and is resistant to the influence of an aggressive environment. Thanks to this, the material is used for the production of:

- individual implants;

- respiratory masks;

- hearing aids;

- ear prostheses;

- training preoperative organ models;

- spectacle nose pads;

- contact lenses.

- Automotive industry. Due to the resistance of silicone to extreme temperatures and solar radiation, it is used for the production of automotive plugs, hose. The presence of waterproofing properties also allow the use of silicone for the manufacture of seals in hydraulic systems and materials for sealing automotive joints.

- Manufacture of everyday or sports articles. The elasticity of silicone and the safety of its use makes it possible to produce insoles for running shoes, ear plugs for headphones, and wristbands.

- Manufacture of souvenirs and jewelry.

Which 3D printer is suitable for silicone products?

What to look for when choosing?

When choosing a 3D printer for printing silicone products, you should pay attention to three main parameters of the device:

- Extruder. It must be inkjet, as liquid silicone is used for printing.

- Integrated heater and pump.

To prevent liquid silicone from cooling down during printing and not clumping, the printer must have a heater that will constantly maintain the same temperature. It is also important to have a pump. It will help to evenly supply liquid filament to the work surface from the extruder.

- Closed print area. It is necessary for the vulcanization of the printed blank. An ultraviolet emitter is located in the printed area, and the area itself is closed with a darkened glass dome.

German RepRap LAM PRE-SERIES 3D printer

Ideal for printing silicone products. It adopts FDM technology, in which two-component liquid silicone rubber (LSR) is mixed by a pneumatic piston and extruded by an extruder. Then each layer of material is thermally cured under the action of an infrared rod.

The FDM technology used by the printer has increased print speed, reduced waste during production, completely eliminated post-processing of the product and accelerated time to market.

The operation of the device is controlled by a touch screen. The printer uses Simplify3D software to process 3D models.

3D printer German RepRap LAM PRE-SERIES

- Base platform heated

- Weight 80

- Material LC-3335

- Seal FDM

- Working chamber area 390 x 400 x 330 mm

- Speed 6000 mm/m or 100 mm/s

- Number of print heads 1

- Layer thickness from 100 µm

- Nozzle diameter, mm 0.

4

Go to product

Top 9 Silicone 3D Printers0199

The following professional silicone 3D printers have proven themselves in the market:

- EnvisionTEC - printing medical and dental parts (Perfactory Micro, Vida HD CROWN & BRIDGE and Xede 3SP Ortho lines).

- Structo - creation of dental products (OrthoForm, DentaForm series).

- Total Z - printing of advertising, souvenir, layout and educational products (Anyform line).

- Stratasys - creation of parts for the automotive, aerospace, defense industries (Connex Objet series), printing of dental products (J720 Dental line).

- 3D Systems - printing of souvenirs, models, promotional items and educational products (sPro series).

- Sinterit Lisa Set is a system for creating advertising, souvenir, mock-up and educational products.

- Intamsys FUNMAT PRO 610 HT is an industrial printer for printing large items and testing functional parts under critical conditions.

3D printer Intamsys FUNMAT PRO 610 HT

- Software IntamSuit, Simplify 3D, Cura

- Control connection interfaces WiFi, Internet, USB

- Material PEEK, PEKK, PEI, PPSU, PC, Nylon, ABS, PLA, PVA, TPU, Carbonfiber Reinforcement

- Seal FDM

- Supported file formats STL, OBJ

- Z-axis resolution 0.0016 mm

- Resolution X and Y 0.016 mm

- Platen Temperature 300°C

- Extruder temperature 500°C

- Working chamber area 610 x 508 x 508 mm

- Number of print heads 2

- Layer thickness from 50 µm

- Thread diameter 1.

75

- Nozzle diameter, mm 0.4 (0.25, 0.5, 0.6, 0.8, 1.2 mm)

- Display 7" color touch screen

Go to product

Sinterit Lisa Set

- Control connection interfaces WiFi

- Laser IR 5W

- Maximum Layer Height 0.15 mm

- Maximum consumer power 24 W

- Maximum build chamber temperature 105 °C

- Maximum Print Platform Temperature 190 °C

- Max extruder temperature 275 °C

- Material PA12 smooth, flexa Black

- Minimum Layer Height 0.

06 mm

- Seal SLS

- Nutrition 110/120 V or 220/230 V

- Supported software Sinterit Studio 2016

- Dimensions (mm) Sinterit Lisa - 650x550x450; Sinterit Sieve - 600x340x330; Sinterit Sandblaster - 480x370x360

- Accuracy along X, Y axes, mm 0.1

- Speed 15 mm / hour

- Layer thickness from 75 µm

- Weight, kg Sinterit Lisa - 35;Sinterit Sieve - 22.

5;Sinterit Sandblaster-15

- Data output format STL, OBJ, 3DS, FBX, DAE, 3MF

- Max workpiece size PA12: 90x110x130 mm, flexa Black: 110x130x150 mm

- Print area Sinterit Lisa - 150x200x150 mm; Sinterit Sandblaster - 410x310x200 mm

- operating system Microsoft Windows

Go to product

The future of silicone 3D printing

Silicone printing was originally developed for medical applications. Therefore, the most promising goal is the development and creation of silicone tissues and human organs that imitate real ones with great accuracy.

Help.

![]()

Learn more