3D printer epson

Epson Develops an Industrial 3D Printer that Can Use Commonly Available Materials (March 7, 2022) | News

- TOKYO, Japan, March 7, 2022 -

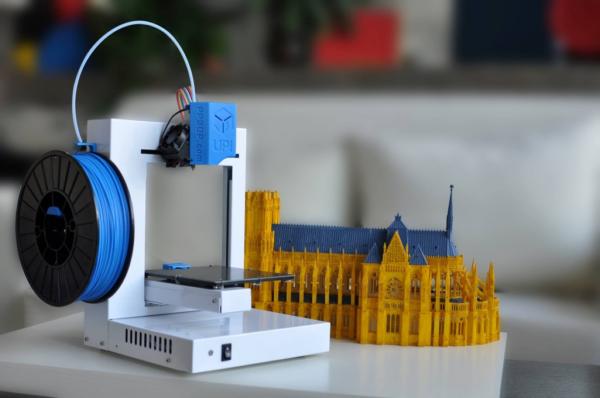

Seiko Epson Corporation (TSE: 6724, "Epson") has developed an industrial 3D printer that can use commonly available third-party materials to produce strong, accurate industrial parts of various sizes and functions. 3D printers with these features will have uses in a far wider range of applications, including in the production of parts for final products, and will enable users to mass-customize their goods in support of small-batch production.

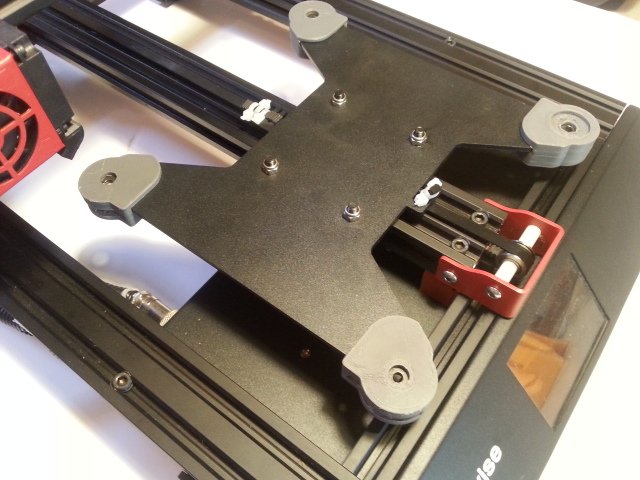

Industrial 3D printerModeling by flat screw technology3D printers can be used to fabricate a wide variety of goods in small quantities in a short period of time. Manufacturers have responded to this promise by accelerating the development and launch of 3D printers for the industrial market, which is expected to expand rapidly in the future. However, conventional industrial 3D printers require the use of special modeling materials. Moreover, they are not well-suited to the production of objects that offer both strength and accuracy, so their use in industrial parts for final products has been limited.

Epson's newly developed 3D printer employs a unique material extrusion method that is achieved using a flat screw (an inline screw with a flattened configuration) like that found in Epson's precision injection molding machines. This extrusion method enables the printer to be used with a variety of common third-party materials, such as resin or metal pellets, which are generally available at lower cost than other materials, environmentally considerate biomass pellets, and PEEK materials, which can provide high heat resistance. In addition, the amount of material injected is precisely controlled by regulating the pressure within the head and by regulating the action of a valve in concert with the modeling speed. The temperature at the surface of a piece being printed must also be controlled in order to obtain the required strength. Epson employs a unique mechanism to precisely control this temperature and achieve both strength and accuracy. This 3D printer is thus engineered to manufacture strong, accurate objects with commonly available materials, facilitating printer use in the production of industrial parts for final products. It is ideally suited to mass customization, as it can produce small batches of parts tailored to customers' needs with higher quality, shorter lead times, and at a fraction of the cost of traditional manufacturing processes.

Epson employs a unique mechanism to precisely control this temperature and achieve both strength and accuracy. This 3D printer is thus engineered to manufacture strong, accurate objects with commonly available materials, facilitating printer use in the production of industrial parts for final products. It is ideally suited to mass customization, as it can produce small batches of parts tailored to customers' needs with higher quality, shorter lead times, and at a fraction of the cost of traditional manufacturing processes.

Epson is aiming to commercialize the printer after first making needed refinements while utilizing it internally to volume-produce certain parts for commercial and industrial equipment.

This 3D printer will be shown in the Epson booth at International Robot Exhibition 2022, which opens on March 9th at Tokyo Big Sight.

In addition to industrial 3D printers, Epson seeks to innovate manufacturing by co-creating flexible, high-throughput production systems that reduce environmental impacts.

About Epson

Epson is a global technology leader dedicated to co-creating sustainability and enriching communities by leveraging its efficient, compact, and precision technologies and digital technologies to connect people, things, and information. The company is focused on solving societal issues through innovations in home and office printing, commercial and industrial printing, manufacturing, visual and lifestyle. Epson will become carbon negative and eliminate use of exhaustible underground resources such as oil and metal by 2050.

Led by the Japan-based Seiko Epson Corporation, the worldwide Epson Group generates annual sales of around JPY 1 trillion.

corporate.epson/en/

Epson Officially Enters the 3D Printing Market

Published on March 7, 2022 by Madeleine P.

It’s hard not to have heard of the Japanese group Epson, especially when it comes to 2D printers. And today, it particularly interested us because the electronics giant is taking an unexpected turn in the additive manufacturing market. The company is expected to unveil its first 3D printer in two days at the International Robot Exhibition 2022, 8 years after a first announcement made by its president, Minoru Usui, to move into the market. This new solution is an industrial machine based on an extrusion process. The main difference is the use of a flat screw as a nozzle to expand the range of materials available and the amount of material deposited.

The company is expected to unveil its first 3D printer in two days at the International Robot Exhibition 2022, 8 years after a first announcement made by its president, Minoru Usui, to move into the market. This new solution is an industrial machine based on an extrusion process. The main difference is the use of a flat screw as a nozzle to expand the range of materials available and the amount of material deposited.

In January 2014, on the occasion of the group’s 30th anniversary, Minoru Usui had revealed his intentions to enter the 3D printing market within the next 5 years. At the time, Epson considered that the technology still had many limitations, particularly in terms of compatible materials. Since then, the market has evolved significantly and we only need to see the number of companies specialized in 2D that have taken the gamble of moving into additive manufacturing. There is of course HP which is a major player in the industry, but also Canon and Xerox. It is now Epson’s turn to market its new machine after internal use.

The Epson machine is based on an extrusion process (photo credits: Epson)

Epson has remained rather discreet about this new industrial 3D printer. We know that it will be based on an extrusion method made possible by a flat screw. The manufacturer specifies that it is the same as found on its injection molding machines – so these are proven and reliable components. The use of such a screw especially allows to widen the range of compatible materials by proposing a 3D printing based on granules, plastic or metallic, but also from high performance polymers like PEEK. The manufacturer states in its press release:

In addition, the amount of material injected is precisely controlled by regulating the pressure within the head and by regulating the action of a valve in concert with the modeling speed. The temperature at the surface of a piece being printed must also be controlled in order to obtain the required strength. Epson employs a unique mechanism to precisely control this temperature and achieve both strength and accuracy

It is an industrial machine, designed for the production of high quality finished parts. It will be presented for the first time from Wednesday on the Epson booth at the international robotics exhibition in Tokyo. The Japanese giant will perhaps reveal more details that we will not fail to follow you! In the meantime, find the press release HERE.

It will be presented for the first time from Wednesday on the Epson booth at the international robotics exhibition in Tokyo. The Japanese giant will perhaps reveal more details that we will not fail to follow you! In the meantime, find the press release HERE.

What do you think of Epson’s entry into the 3D printing market? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Epsonis developing an industrial 3D printer that can use commonly available materials.

- home

- News AT

- World

- Epson is developing an industrial 3D printer that can use commonly available materials.

Seiko Epson Corporation (TSE: 6724, "Epson") has developed an industrial 3D printer that can use third-party publicly available materials to produce durable, precise industrial parts in various sizes and functions. 3D printers with these capabilities will find applications in a much wider range of applications, including the production of end-product parts, and allow users to mass-customize their products to support small-scale production.

3D printers with these capabilities will find applications in a much wider range of applications, including the production of end-product parts, and allow users to mass-customize their products to support small-scale production.

Industrial 3D Printer

3D printers can be used to produce a wide range of products in small quantities in a short amount of time. Manufacturers have responded to this promise by accelerating the development and launch of 3D printers for an industrial market that is expected to expand rapidly in the future. However, conventional industrial 3D printers require the use of special materials for modeling. In addition, they are poorly adapted to the production of objects that are both strong and precise, so their use in industrial parts for end products has been limited.

Epson's new 3D printer uses a unique material extrusion method, which is achieved with a flat screw (screw with a flattened configuration) similar to that used in Epson's precision injection molding machines. This extrusion method allows the printer to be used with a variety of common third-party materials such as resin or metal pellets, which are usually available at a lower cost than other materials, environmentally friendly biomass pellets, and PEEK materials, which can provide high temperature resistance. In addition, the amount of injected material is precisely controlled by adjusting the pressure inside the head and by adjusting the valve action according to the speed of the simulation. The temperature on the surface of the printed product must also be controlled to achieve the required strength. Epson uses a unique mechanism to precisely control this temperature and achieve both durability and accuracy. Thus, this 3D printer is designed to produce strong, precise objects from commonly available materials, making it easier to use the printer in the production of industrial parts for end products. It is ideal for mass customization as it can produce small batches of customer-specific parts with higher quality, shorter lead times and lower cost than traditional manufacturing processes.

This extrusion method allows the printer to be used with a variety of common third-party materials such as resin or metal pellets, which are usually available at a lower cost than other materials, environmentally friendly biomass pellets, and PEEK materials, which can provide high temperature resistance. In addition, the amount of injected material is precisely controlled by adjusting the pressure inside the head and by adjusting the valve action according to the speed of the simulation. The temperature on the surface of the printed product must also be controlled to achieve the required strength. Epson uses a unique mechanism to precisely control this temperature and achieve both durability and accuracy. Thus, this 3D printer is designed to produce strong, precise objects from commonly available materials, making it easier to use the printer in the production of industrial parts for end products. It is ideal for mass customization as it can produce small batches of customer-specific parts with higher quality, shorter lead times and lower cost than traditional manufacturing processes.

Epson intends to release the printer commercially after making the necessary modifications and using it internally for mass production of certain parts for commercial and industrial equipment.

This 3D printer will be on display at Epson's booth at the 2022 International Robot Show opening March 9th at Tokyo Big Sight.

In addition to industrial 3D printers, Epson is committed to manufacturing innovation by creating flexible, high-performance manufacturing systems that reduce environmental impact.

Share article:

3D printers in Izhevsk

You can quickly compare 3D printer prices and choose from over 11 offers

Epson SC-S30610 Large Format Printer

Condition: Used Year: 2012 Manufacturer: EPSON (Japan)

The printer is in excellent condition. 2012. A simple wide-format plotter, especially for beginners. There is a CISS system. Veika ink. New print head (December 2018). Served in...

2012. A simple wide-format plotter, especially for beginners. There is a CISS system. Veika ink. New print head (December 2018). Served in...

07/02/2019 Izhevsk (Russia)

450,000

Plasma cutting system IzmiR Plasma CUT 2060

condition: used year: 2014 Manufacturer: DURMA (Russia)

The Izmir Plasma Cut 2060 2014-plasmate complex is year old, the Izmir Plasma Cuts 400 XDs. + Burner height control + Ignition...

12.04.2016 Izhevsk (Russia)

9,500,000

Trumpf - sale of laser machines

Condition: Used

Trumpf laser cutting machines for sale Laser cutting machines for sale. There are 3 machines available: Trumpf Trumatic L3030Trumpf Tubermatic3D Laser Trumpf This equipment is located in Izhevsk (Udmurtskaya...

06/22/2016 Izhevsk (Russia)

Weinig Unimat, Optimization Trimming Line, Splicing Line, Biesse Rover, VOLLMER sharpener and more

Status: New

in the presence of

Capital WEINIG Unimat 23 Cardcoma Corga Optimization Corps, OMGA T-920 NC Washing Washing Machine FJ-15B semiautomatic (2 Frasers) BISESE Rover B 4. 40 ... 05/07/2019 Izhevsk (Russia)

40 ... 05/07/2019 Izhevsk (Russia)

Stationary concrete plant Sumab T-100

Condition: New Manufacturer: Sumab (Sweden)

Stationary batching plant Sumab T-100 is capable of producing more than 1000 concrete recipes. Productivity: 90-100 m3/h.

02/21/2023 Izhevsk (Russia)

Mobile concrete plant SUMAB K-30

Condition: New Manufacturer: Sumab (Sweden)

Mobile concrete plant on a container frame. It does not require a special foundation, it is enough to place it on a flat area. Concrete production can be started within 3-4 hours after delivery...

21.02.2023 Izhevsk (Russia)

Equipment for welding of reinforcing mesh, building mesh, reinforcing cages

Condition: New Manufacturer: Sumab (Sweden)

Welding equipment for the production of reinforcing mesh SUMAB W series. Using welding equipment for the production of reinforcing mesh, you can produce the following types of products:

Using welding equipment for the production of reinforcing mesh, you can produce the following types of products:

21.02.2023 Izhevsk (Russia)

Ball valve (ball valve) made of stainless steel

Condition: New Manufacturer: FITOK (Germany)

In stock

Ball valve (Ball valve). Operating pressure, max.: 207 bar (3,000 psi). Operating temperature: -54°C to 148°C (-65 °F to 300°F). End connection thread 1/4" to 1/2", crimp...

11/01/2021 Izhevsk (Russia)

3 885

Stainless steel ball valve FITOK

Condition: New Manufacturer: FITOK (Russia)

FITOK ball valve made of stainless steel. BP Series. Operating pressure up to: 10,000 psi Inch (690 bar). Operating temperature: -40°C to 232°C Bidirectional flow for 2-way...

11/01/2021 Izhevsk (Russia)

Infrared soldering station for BGA components Top Brand 862

Condition: New Manufacturer: TopBrand (China)

In stock

Solves the problems of regular medium-scale production.

Learn more