3D scanner theory

How Do 3D Scanners Work? | Learn About Machine Vision

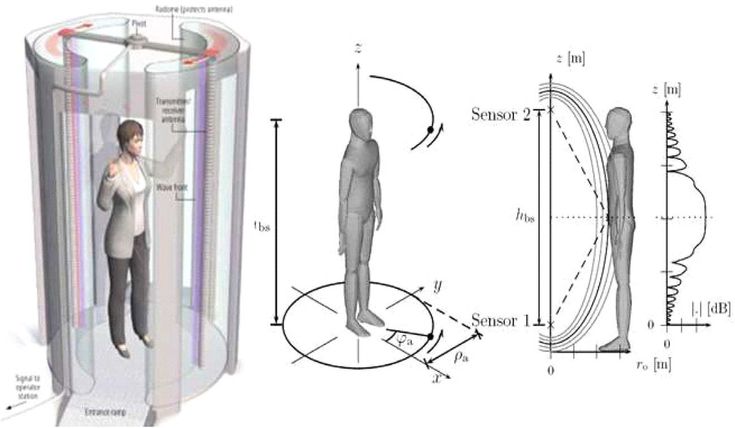

Hermary scanners and many industrial 3D scanners work on the principle of laser triangulation. A laser beam is projected at a known angle onto a target to be measured; a camera at a known offset from the laser views the projected image.

Principles of Laser Triangulation

Understanding the laser scanning process can help you choose the right industrial 3D scanners for the job. The principles of triangulation gather data points in a reference plane established by a laser fan beam. All data points will be somewhere on this plane. If the laser strikes an object at A, this will be seen by the scanner’s image sensor at location A’. If the laser strikes an object at position B, it will be seen at B’. By examining where the laser is seen by the sensor, the scanner can calculate the distance to the object.

A Typical 3D Scanner Setup

The setup below is a typical industrial setting. There are many 3D scanners that combine both the illumination source and the imaging sensor in one housing.

A typical laser triangulation setup

3D Scanner Working Principles and How Point Cloud Works

3D machine vision, more broadly known as 3D scanning technologies, empowers inspection, feature identification, object detection, and process optimization by taking three-dimensional measurements of a target object. The most widely used 3D scanning technology is powered by the principle of laser triangulation.

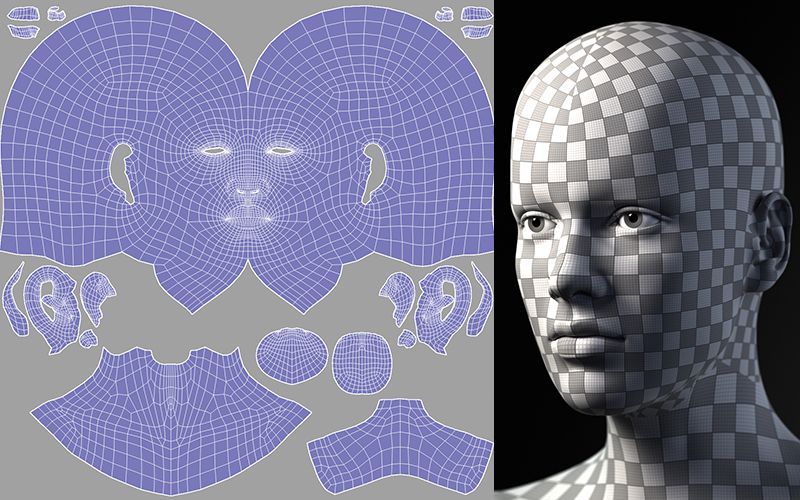

3D data is often captured in coordinates, namely, X, Y, and Z. These coordinates collectively form point clouds that represent the 3D shape of the object being scanned. Depending on the scanner position and arrangement, further data manipulation may be required.

3D Scanners Using Geometric Measurement Techniques

About The Author - Terry Hermary

Connect With Me on LinkedIn!

Co-founder of Hermary.

Terry is the customer-facing machine vision expert at Hermary with over 30 years of experience. With a background in electrical engineering, he specializes in developing 3D vision applications with system integrators and machine builders. He is passionate about solving unique automation challenges using 3D vision technologies. Over the past three decades, Terry and his team have established Hermary as the leading innovative 3D machine vision provider, revolutionizing industries from sawmilling to meat processing.

Qualifications:

- Co-founded Hermary Machine Vision in 1991

- Patent holder of many 3D machine vision inventions

3D scanning technologies - what is 3D scanning and how does it work?

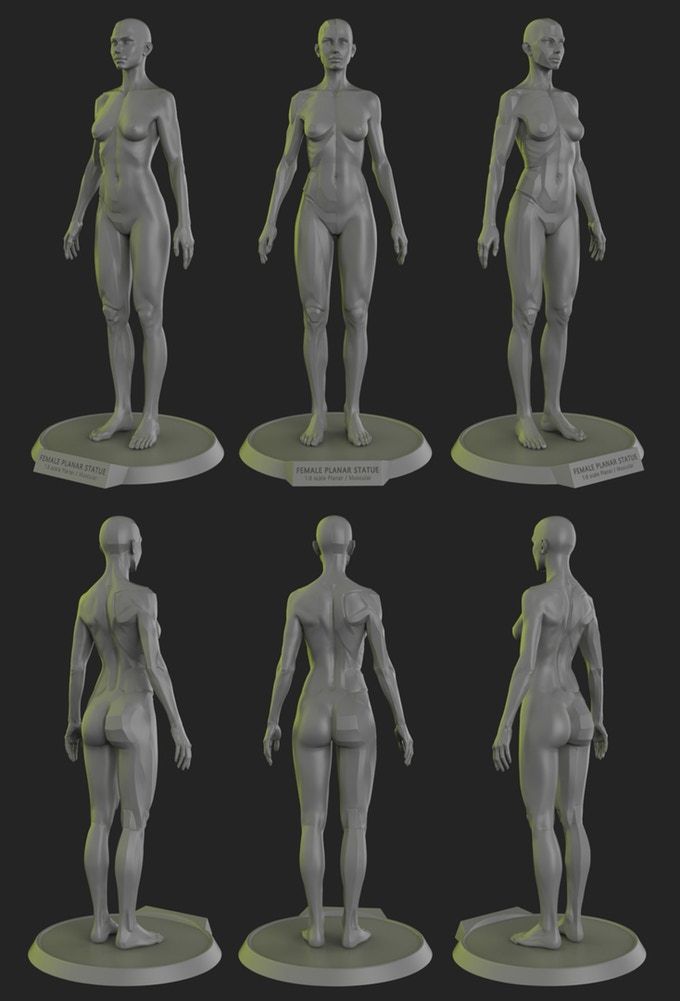

3D scanning is a technique used to capture the shape of an object using a 3D scanner. The result is a 3D file of the object which can be saved, edited, and even 3D printed. Many different 3D scanning technologies exist to 3D scan objects, environments, and people. Each 3D scanning technology comes with its own limitations, advantages, and costs.

The result is a 3D file of the object which can be saved, edited, and even 3D printed. Many different 3D scanning technologies exist to 3D scan objects, environments, and people. Each 3D scanning technology comes with its own limitations, advantages, and costs.

Table of contents

Introduction

Laser triangulation 3D scanning technology

Structured light 3D scanning technology

Photogrammetry 3D scanning technology (photography)

Contact-based 3D scanning technology

Laser pulse-based 3D scanning technology

Introduction

The basic principle of 3D scanning is to use a 3D scanner to collect data about a subject. The subject can be:

- an object

- an environment (such as a room or even a landscape)

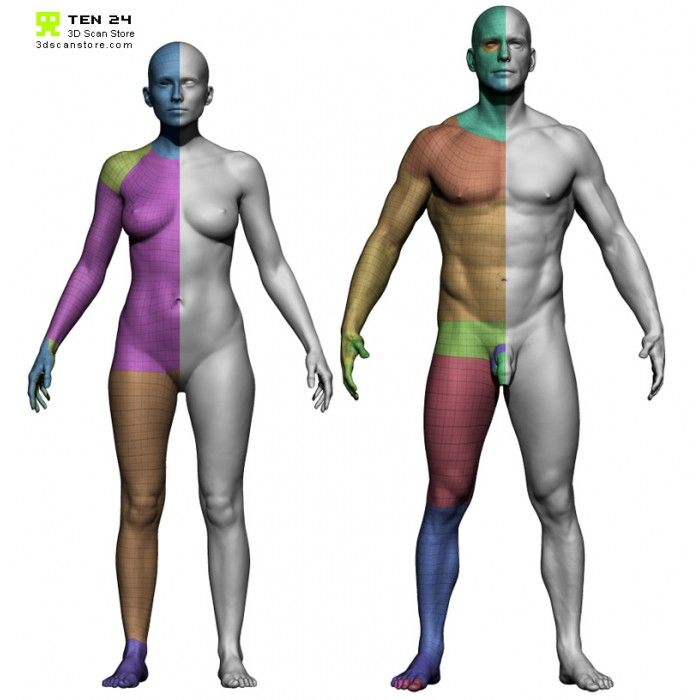

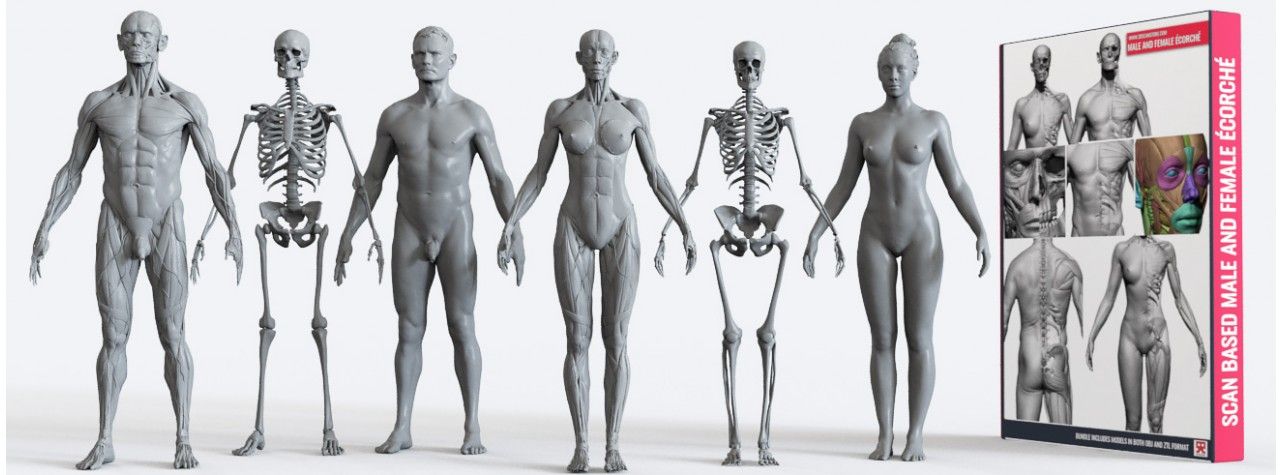

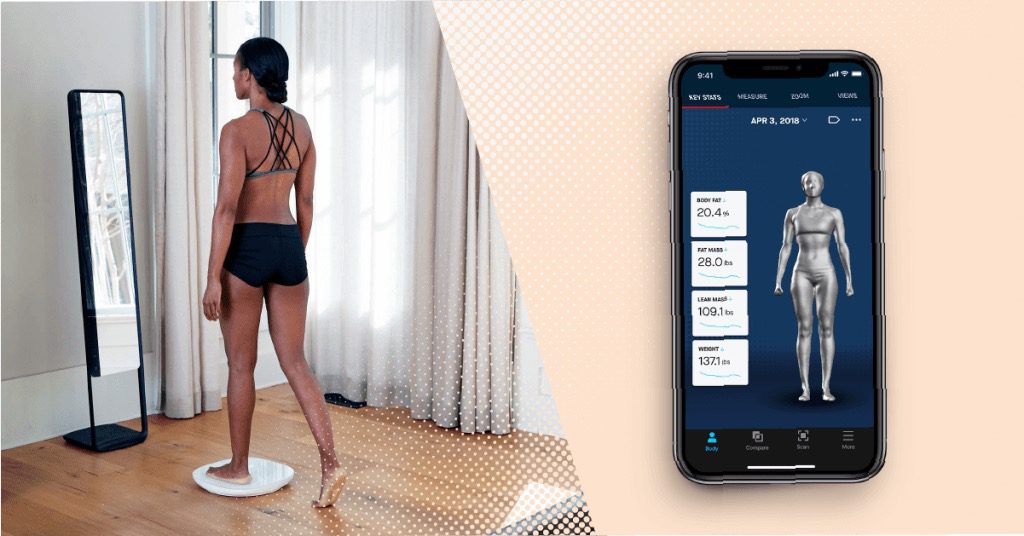

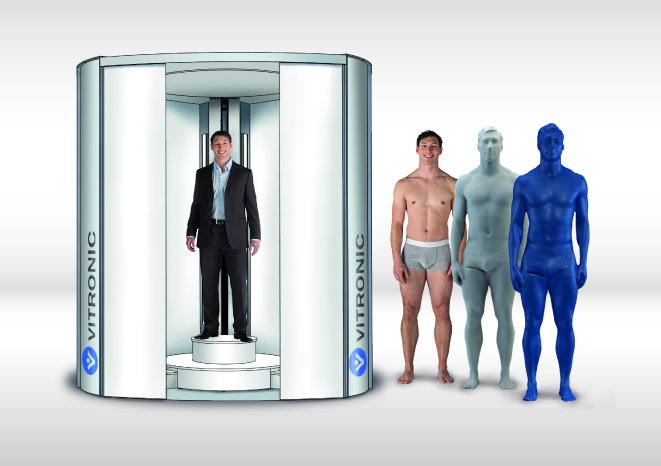

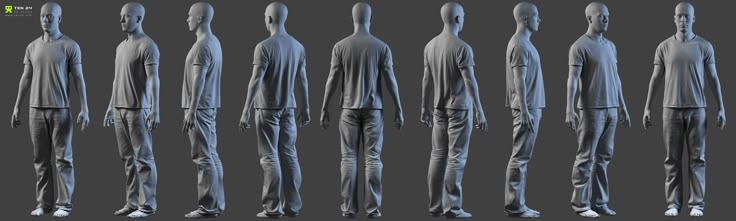

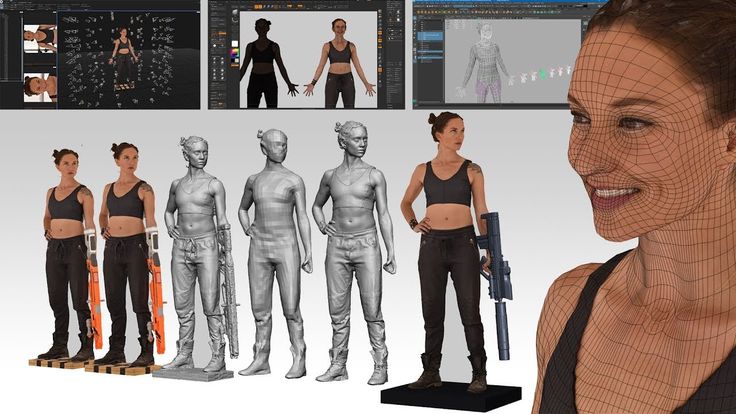

- a person (3D body scanning)

Some 3D scanners can simultaneously collect shape and color data. A 3D scanned color surface is called a texture.

3D scans are compatible with Computer-Aided Design (CAD) software and also 3D printing, after preparing the 3D model via specific software. A 3D scan can give a lot of information about the design of an object, in a process called reverse engineering.

A 3D scan can give a lot of information about the design of an object, in a process called reverse engineering.

3D scanners are powerful tools for professionals in several industries, such as automotive, aerospace, dental, and jewelry, as well as in more artistic applications such as video games, special effects, and animation movies. 3D scanning technologies rely on different physical principles and can be classified into the following categories:

- Laser triangulation: Projects a laser beam onto a surface and measures the deformation of the laser ray.

- Structured light: Measures the deformation of a light pattern when projected onto a surface to 3D scan the shape of the surface.

- Photogrammetry: Also called “3D scan from photographs”, this technology reconstructs a subject in 3D from 2D captures (photos) with computer vision and computational geometry algorithms.

- Contact-based 3D scanning technology: Relies on the sampling of several points on a surface, measured by a mechanical, optical, or physical probe.

- Laser pulse: Based on the Time of Flight (ToF) of a laser beam. The laser beam is projected onto a surface and recollected by a sensor. The time of travel of the laser between its emission and reception gives the surface’s geometrical information to the 3D scanner.

3D scanning technologies

Laser triangulation 3D scanning technology

Laser triangulation-based 3D scanners use either a laser line or a single laser point to scan across an object. First, the 3D scanner casts its laser onto the object. As the laser light reflects off of the 3D scanned object, its initial trajectory is modified and picked up by a sensor.

Then, based on this modified trajectory and thanks to trigonometric triangulation, the system can detect the laser’s deviation angle. The calculated angle is directly linked to the distance from the object to the scanner. When the 3D scanner collects enough distances, it is capable of mapping the object’s surface to recreate it in 3D.

The main advantages of the laser triangulation technology for 3D scanning are its high resolution and accuracy.

One downside to laser triangulation technology is how sensitive it is to the properties of object’s surface; very shiny and/or transparent and/or dark surfaces are particularly problematic.

Structured light 3D scanning technology

Structured light 3D scanners use trigonometric triangulation but do not rely on a laser. Instead, they project a series of linear patterns onto the object. The system is then able to examine the edges of each line in the pattern and how the lines are deformed and to calculate the distance from the scanner to the object’s surface.

The projected structured light used for 3D scanning can be white or blue and generated by numerous types of projectors, such as Digital Light Processing (DLP) technology. The projected pattern is usually a series of light rays but can also be a randomized dot matrix.

The projected pattern is usually a series of light rays but can also be a randomized dot matrix.

The main advantages of structured light technology for 3D scanning are its speed and resolution, and its non-harmful light can be used for 3D body scanning.

However, structured light 3D scanners are sensitive to lighting conditions and have trouble working outdoors in broad daylight.

Photogrammetry 3D scanning technology (photography)

Photogrammetry is the science of making measurements from photographs, especially for recovering the exact positions of surface points. Photogrammetry is based on a mix of computer vision and powerful computational geometry algorithms.

The principle of photogrammetry is to analyze several photographs of a static subject, taken from different viewpoints, and to automatically detect pixels corresponding to a unique physical point.

This 3D scanning technology’s main challenge is to examine tens or hundreds of photos and thousands of points with high accuracy. To run such photogrammetry algorithms, a very powerful computer is required.

To run such photogrammetry algorithms, a very powerful computer is required.

The main advantages of photogrammetry 3D scanning technology are its acquisition speed and ability to pick up colors and textures. Photogrammetric technology is also capable of reconstructing subjects at large scales, such as landscapes or monuments photographed from the ground or from the air, by a photography drone, for example.

The quality of the results generated by photogrammetry technology is dependent on the resolution of the input photographs. This technology can also be quite slow, depending on your software and PC setup.

Contact-based 3D scanning technologyContact-based 3D scanning is also known as digitizing. This 3D scanning technology implies a contact-based form of 3D data collection.

Contact 3D scanners probe the subject via physical touch, while the object is firmly held in place. A touching probe is moved along the surface to record 3D information. The probe is sometimes attached to an articulated arm capable of collecting all its respective configurations and angles for more precision.

The probe is sometimes attached to an articulated arm capable of collecting all its respective configurations and angles for more precision.

Some specific configurations of contact-based 3D scanners are called Coordinate Measuring Machines (CMM).

Contact 3D scanning is widely used to perform quality control after fabrication or during maintenance operations. The main advantages of the contact technology for 3D scanning are its precision and ability to 3D scan transparent or reflective surfaces.

The downsides of contact 3D scanning technology include its slow speed and inability to work with organic, freeform shapes.

Laser pulse-based 3D scanning technology

Laser pulse-based 3D scanners, also known as Time-of-Flight scanners or Lidar laser 3D scanners, measure how long a casted laser takes to hit an object and come back.

Since the speed of light is exactly known, the time it takes for the laser to come all the way back gives the exact distance between the 3D scanner and the object. In order to precisely measure the distance, the 3D scanner computes millions of laser pulses with accuracy up to the picosecond (1 picosecond equals 0.000000000001 seconds!).

In order to precisely measure the distance, the 3D scanner computes millions of laser pulses with accuracy up to the picosecond (1 picosecond equals 0.000000000001 seconds!).

Since each measure only collects one point, the 3D scanner needs to cast its laser 360 degrees around that point. To do so, the 3D scanner is usually fitted with a mirror that changes the orientation of the laser.

Time-of-Flight 3D scanners encompass both laser pulse and phase shift lasers. Phase shift laser 3D scanners are a sub-category of laser pulse 3D scanners. In addition to pulsing the laser, phase shift systems also modulate the power of the laser beam. Phase shift lasers offer better overall performance.

The main advantage of laser pulse 3D scanners is their ability to 3D scan very big objects and environments. They are, however, quite slow.

Laser pulse technology is often used by terrestrial laser 3D scanners, which are mainly destined for land surveying or to 3D scan entire buildings. Some laser pulse 3D scanners also incorporate dynamic SLAM algorithms to enhance their ability to recognize their surroundings.

Some laser pulse 3D scanners also incorporate dynamic SLAM algorithms to enhance their ability to recognize their surroundings.

04/16/2021

Content

-

- What is 3D scan and why it is used by

- How 3D scanner

- 3D scan technologies

- Methods 3D

- Contact 3D scanners

- Non-contact 3D scanners

- Types of 3D scanners according to the principle of use

- Advantages and disadvantages of 3D scanners

- Things to consider when choosing a 3D scanner

- Applications

Currently, few people are not familiar with such a concept as 3D printing. Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc. ). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

What is 3D scanning and what is it used for

Three-dimensional scanning is a technology that appeared in the 60s of the 20th century. It was created in order to transfer the physical parameters of the object into a digital format in the form of a three-dimensional model. The need for this naturally arose when people around the world increasingly began to use computers both in everyday life and in production.

The first samples of 3D scanners were quite simple and did not have wide functionality. Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers.

3D scanners allow you to transfer object data into digital format

3D scanning has opened up new opportunities in various areas of human activity - from the automotive industry and the military industry to design, medicine and cinema.

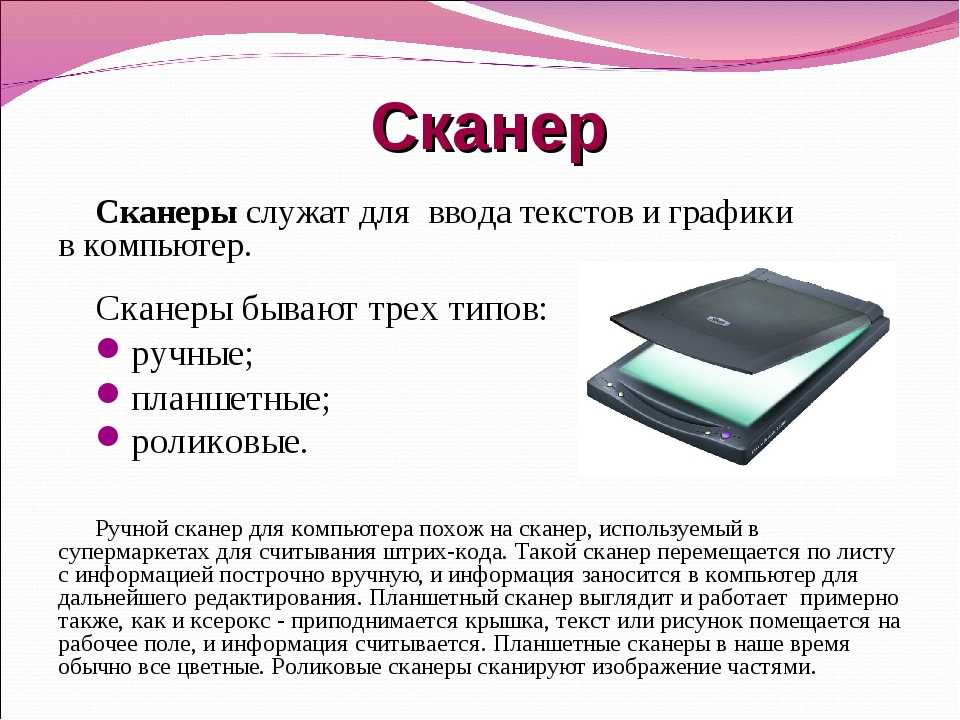

How a 3D scanner works

A 3D scanner is a device that examines an object by digitizing it using sensors and using the information received to create a three-dimensional model. In fact, a 3D scanner creates a digital copy of a physical object of any configuration and complexity. In this, it fundamentally differs from its predecessors - conventional scanners that can only read information from documents and photos.

The scanning process itself can take place in different ways - depending on the type of 3D device and the technology used, as well as on what object you want to process with it - moving or static.

3D Scanning Technologies

There are 2 main types of 3D scanners - laser and optical. Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

Laser 3D scanning, as the name implies, uses a laser and can be carried out both at short and long distances from the object.

Laser Scanner

For the most part, 3D laser scanners work on the principle of triangulation, when the camera finds a beam on the surface of an object and measures the distance to it, after which a cloud of points is created, each of which has its own coordinates in space, and a 3D model is built. Their "advantages" are affordable price and ease of use combined with high scanning accuracy. Of the "minuses" - there are restrictions on the remoteness and size of the object.

Another type of laser scanner works by measuring the response time of a beam from the surface of an object - the so-called laser range finder. They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details.

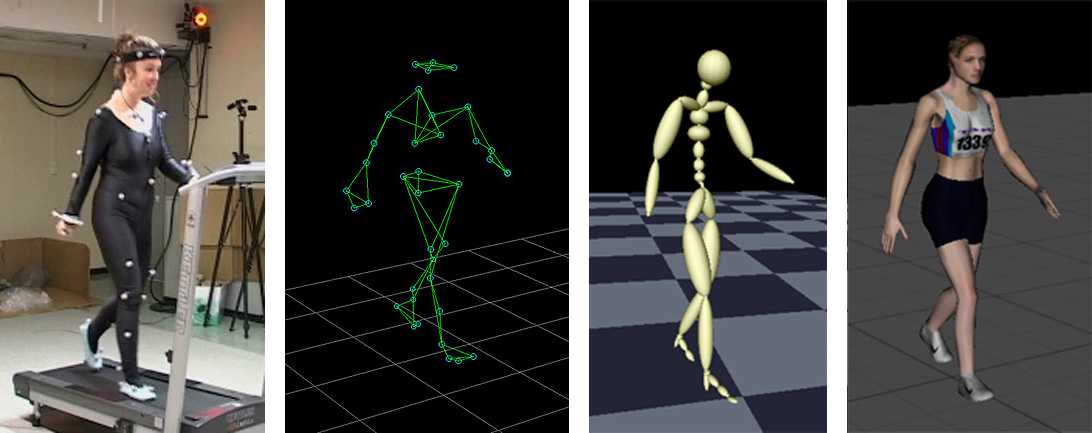

The disadvantage of laser scanners is the impossibility of their use on moving objects. Then optical 3D scanners come to the rescue, which shoot with one or more cameras from different angles an object illuminated by a special projector. Based on the received image, a three-dimensional image is built.

Optical scanner

A "contraindication" for the use of this technology are reflective and translucent surfaces - shiny, mirror or transparent. But when scanning a person, they are simply irreplaceable.

3D scanning methods

Any object can be digitized both by contact and non-contact methods. In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

Contact 3D scanners

They have a mechanical probe with a special sensor that measures parameters and transmits the collected information to the device. To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype.

To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype.

Non-contact 3D scanners

This category includes all devices capable of scanning at a distance. This is especially true for objects located in hard-to-reach places.

Non-contact 3D scanner

A stream of radiation (it can be ultrasound, light, X-rays or a laser) is directed to the object and reflected from it, it is recognized by the 3D scanner. They are similar in principle to a video camera and may require the use of additional devices for better lighting.

Non-contact 3D scanners come in 2 types:

-

Active - work with the help of a laser beam or structured light directed at an object, which, when reflected, give information about the location of the object in the form of coordinates.

-

Passive - use time-of-flight rangefinders that read the time and distance that the laser beam travels to the object, and so - for each point in space, which ultimately allows you to accurately recreate its three-dimensional image.

Desktop 3D scanners are very popular and widespread, since they are mostly simple and safe to use, do not require any special technical skills and are quite cheap. The EinScan-SE 3D scanner is one such example. It can be used both at home and in the office. It has access to the API of many popular 3D printers, which makes it possible to immediately print the created three-dimensional model.

Add to compare

Product added to compare Go

| Manufacturer | Thor3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Types of 3D scanners according to the principle of use

There is also a variety of species here. Let's highlight the main ones:

Let's highlight the main ones:

-

Manual: The are handy and simple models that are easy to use as they are quite compact and do not require special skills. True, their technical capabilities may be somewhat limited.

-

Portable: are mainly used for field work, they are convenient to take with you.

-

Desktop: have extended functionality and are used to create high-quality 3D models. Most often used in offices.

-

Stationary: are used, as a rule, in production, various enterprises, as they can scan a large number of objects of the same type at once. Mounted on special turntables.

Handheld 3D Scanner Calibry

Such a choice of products allows you to select the right model for a specific task. In some cases, scanners independently measure objects, in others - with the help of a person who sequentially moves the device until all the necessary information is collected.

Such options for hand-held 3D scanners as Calibry are in high demand among buyers. Despite the apparent simplicity of execution, it has a high resolution and scanning accuracy, due to which it is able to digitize objects with a length of 0.2 to 10 meters. Objects that have a non-standard surface - dark or shiny, with a large number of corners and small details will not become a problem either. Among other things, its undoubted advantage is its low weight, only 900 grams.

Advantages and disadvantages of 3D scanners

Surely, many of the potential buyers are wondering: do you really need a 3D scanner to invest a lot of money in it? What can this acquisition give and will such an investment be justified?

3D scanning has become an integral part of any modern manufacturing process

In order to understand how much you need this equipment, we will list its advantages and disadvantages.

Benefits:

-

They make it possible to scan objects located at a remote distance and in places inaccessible to the presence.

-

They have the ability to "read" not only colors and images, but also to convey the texture of the surface.

-

Significantly speed up the process of "taking" data from any object, even a very complex one with a large number of planes.

-

A variety of models allows you to choose the most convenient version of the scanner, including manual or portable, which can be easily taken with you.

Weaknesses:

-

Some scanners are unable to recognize transparent or black and white objects. In this case, their preliminary preparation (treatment with a special composition) is required.

-

I do not always display complex objects correctly, with a large number of inserts and partitions.

-

To obtain a high-quality result, they require skills and abilities to work with certain computer programs for creating 3D models.

-

If the rules of operation are constantly violated, it may become necessary for expensive repairs to the equipment.

If you need high-precision and high-quality three-dimensional copies of objects, then you cannot do without a 3D scanner. It makes it possible to work in almost any conditions - indoors and outdoors, and with any objects by type and size. It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

What to consider when choosing a 3D scanner

The computer equipment market offers a huge amount of all kinds of equipment, including devices for three-dimensional scanning. Navigating that variety is sometimes not at all easy: some buyers are only concerned about the cost, others are interested in the number of options (sometimes completely useless), but the most far-sighted look at the ratio of the first and second.

Choosing the right 3D scanner is a big deal

It is not always easy to take into account all the technical points that can significantly affect what result will be ultimately achieved. We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

Focus on the following parameters:

-

How high is the accuracy of the 3D scanner. This is one of the most important features. It needs to be targeted first.

-

Resolution also plays an important role. It follows from the first, since the accuracy of measurements and the quality of copying depend on the resolution.

-

In what range the device operates, how close / far it can be from the scanned object.

-

The scanning field is the parameters of that object, thing that it is able to process in 1 session.

-

Does the scanner capture various atypical types of surfaces with complex terrain - channels, partitions, holes, etc.).

-

Portability, mobility of the device - how easy it can be moved if desired, taken with you, its size.

-

The time it takes to prepare for work, as well as the duration of the digitization process itself.

-

The range of possibilities in terms of copying: are there any restrictions on shapes, textures, material, as well as operating conditions - temperature, light, etc.

Of course, the better the quality of the 3D scanner, the more expensive it is. However, you should focus primarily on the tasks that you face, and only then take into account everything else.

Applications

Three-dimensional scanners are in demand in many areas of human life. They are irreplaceable both in the industry, and for household needs. The range of their application is so wide that it is possible to list for a very long time. It's easier to say where they are not needed.

The most common areas of use are, of course, medicine, industry, architecture, construction, film industry and design.

For example, in dentistry, these devices allow you to create ultra-precise three-dimensional models of dentures. One type of such a scanner is Shining 3D's AutoScan DS-EX PRO, which does a great job with a variety of tasks while being quite affordable and reliable.

Medical 3D Scanner

In engineering, such technologies are also indispensable. Digital building prototypes are now much easier and faster to obtain than in the past, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

In cinemas, we can see with our own eyes "revived" fantastic characters, which were created using motion capture technology, which made them as realistic and impressive as possible. This would not have been possible without 3D scanners.

A few decades ago, it was even difficult to imagine all the things that we use all the time today. And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning.

We will talk more about this topic in one of our next articles. And if you want to know more about it, stay tuned.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

how to assemble a 3D scanner from scrap materials and digitize reality - T&P

The first 3D printers, which cost less than a gaming computer, have become a mandatory attribute of almost any hackspace or fablab (technical creativity and electronic art laboratories). Now 3D scanners have joined them. MIPT student and employee of the Polytechnic Museum Daniil Velovaty himself assembled a three-dimensional scanner from a laser, a webcam, and scrap materials. As part of the special project Phystech. Reader" he told T&P about the future of reality scanning.

Daniil Velovaty

It was easy to get used to 3D printers: I drew the desired part or figure on a computer, loaded it into the printer, and a few hours later I took its embodiment in plastic. Yes, what about plastic, they are already printing in metal, and even in organic matter: they recently printed a living liver. No wonder you want to go further. The next step is scanning. Oddly enough, but before the advent of 3D printers, there was no great need to transfer a real object to the digital world: the creators of games and films simply hired artists who drew whatever was needed. The need for scanners arose only when it was important to convey the relief and shape of an object with very high accuracy. At the same time, neither the duration of the scan nor the cost were often completely unimportant. This is how the first representatives of 3D scanners appeared: lidars.

Yes, what about plastic, they are already printing in metal, and even in organic matter: they recently printed a living liver. No wonder you want to go further. The next step is scanning. Oddly enough, but before the advent of 3D printers, there was no great need to transfer a real object to the digital world: the creators of games and films simply hired artists who drew whatever was needed. The need for scanners arose only when it was important to convey the relief and shape of an object with very high accuracy. At the same time, neither the duration of the scan nor the cost were often completely unimportant. This is how the first representatives of 3D scanners appeared: lidars.

Lidar (from the English Light Detection and Ranging) is an expensive but very accurate device. It allows you to build 3D models of objects with an accuracy of millimeters, the size of which can be compared with the size of a building. From the decoding of the abbreviation LIDAR, it follows that it is any rangefinder that measures distance using light. An incredible number of devices fall under this description. But most often, devices like this are called lidars:

An incredible number of devices fall under this description. But most often, devices like this are called lidars:

A special system of mirrors is placed inside the device. A phase laser rangefinder is installed here, which measures the distance using a laser, and two mirrors serve to deflect the laser beam in two planes. Thus, the ray runs through a certain sector of space and builds its 3D model. As you might guess, the speed of such a scanner depends on the speed of the rangefinder and the speed of rotation of the mirrors. And since all this is quite complex equipment that requires fine tuning, it costs quite a lot of money. It is much more profitable to order a scan than to buy the machine itself. Moreover, you still need to figure out how to use it.

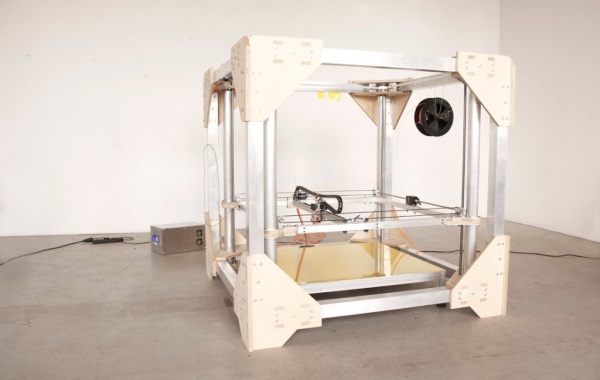

As industrial devices were, to put it mildly, beyond the reach of the average consumer, and the need to scan reality grew, cheap desktop and handheld 3D scanners appeared. The former, as a rule, have a turntable on which the object under study is placed. A few minutes after the start of the scan, we will get the finished model. Of course, the scan quality and the size of the scanned area are incomparable with lidars, but they cost several orders of magnitude cheaper. It is to this class of devices that the scanner we developed belongs. The main problem with these scanners is that the object to be scanned must fit on a turntable, which greatly limits the scope. Another significant disadvantage of these scanners is the incompleteness of scanning and blind spots. If, for example, you try to scan a vase, the scanner will only see its outer part, and not the cavity inside.

A few minutes after the start of the scan, we will get the finished model. Of course, the scan quality and the size of the scanned area are incomparable with lidars, but they cost several orders of magnitude cheaper. It is to this class of devices that the scanner we developed belongs. The main problem with these scanners is that the object to be scanned must fit on a turntable, which greatly limits the scope. Another significant disadvantage of these scanners is the incompleteness of scanning and blind spots. If, for example, you try to scan a vase, the scanner will only see its outer part, and not the cavity inside.

The second type of scanners are handheld 3D scanners. They need to be moved around the object by hand, but they build a model with the help of cameras. The operation algorithm of such scanners is much more complicated, they are more expensive, and the quality of the result is worse, but they allow you to scan large objects and spend less time on it. They look something like this:

One of the main advantages of such a scanner is that it is not limited by the scanning area. We can scan, for example, a person's face without having to place their head on a turntable. With a certain diligence, even an entire room can be scanned, if only the positioning accuracy allows it. To improve accuracy, you can stick special marks that the scanner finds and uses as reference points. Actually, in the photo above, this is what was done. This approach limits the scanning area, but, unfortunately, here either the sheep are safe or the wolves are full.

We can scan, for example, a person's face without having to place their head on a turntable. With a certain diligence, even an entire room can be scanned, if only the positioning accuracy allows it. To improve accuracy, you can stick special marks that the scanner finds and uses as reference points. Actually, in the photo above, this is what was done. This approach limits the scanning area, but, unfortunately, here either the sheep are safe or the wolves are full.

In our lab, we decided to create a cheap 3D scanner with an accuracy comparable to that of 3D printing. This was our first serious project, so we made mistakes, misunderstood a lot, and learned even more along the way. We first built a simple laser rangefinder using a laser pointer and a webcam. To understand how a 2D camera can measure distance, you have to use your imagination. Imagine a thread stretched in the air, along which a spider is crawling. If we stand close to the rope, we see how the spider is crawling straight towards us (not a very pleasant sight). And if now we shine a lamp on this whole structure from the side, we will see a shadow on the floor. Since the light comes from the side, the projection of the spider will move along the projection of the thread. By measuring the distance from the beginning of the thread's shadow to the spider's shadow, we can calculate how far the spider has crawled by multiplying by some factor, because we are creating a contraction mapping.

And if now we shine a lamp on this whole structure from the side, we will see a shadow on the floor. Since the light comes from the side, the projection of the spider will move along the projection of the thread. By measuring the distance from the beginning of the thread's shadow to the spider's shadow, we can calculate how far the spider has crawled by multiplying by some factor, because we are creating a contraction mapping.

Our scanner works in approximately the same way. Only instead of a thread - a laser beam, and instead of a screen with a shadow - a camera. Just as a spider moves along a thread, a spot moves along the laser beam, which occurs when this beam encounters an obstacle. Having found the position of the spot in the photograph, we can determine the distance to the object on which this spot is located. In words, it is difficult. It looks simpler in the picture:

The farther the wall, the closer to the dotted line will be the pfc point on the camera matrix

But such a rangefinder measures the distance to a single point, and this takes a very long time.