3D printer dehumidifier

Heated DryBox Banishes Filament Moisture For Under $20

- by: Donald Papp

There has been a lot of activity from [Richard Horne] regarding 3D printing filaments lately; most recently he has shared two useful designs for upping one’s filament storage and monitoring game. The first is for a DIY Heated DryBox for 3D printing filament. It keeps filament dry not just by sealing it into a plastic box with some desiccant, but by incorporating a mild and economical heater intended for reptile habitats inside. Desiccant is great, but a gently heated enclosure can do wonders for driving away humidity in the right environment. The DryBox design also incorporates a handy little temperature and humidity sensor to show how well things are working.

Spool-mounted adapter for temperature and humidity sensor (and desiccant) to monitor storage bag conditions.The second design is a simple spin-off that we particularly liked: a 3D printed adapter that provides a way to conveniently mount one of the simple temperature and humidity sensors to a filament spool with a desiccant packet. This allows storing a filament spool in a clear plastic bag as usual, but provides a tidy way to monitor the conditions inside the bag at a glance. The designs for everything are on Thingiverse along with the parts for the Heated DryBox itself.

[Richard] kindly shares the magic words to search for on eBay for those seeking the build’s inexpensive key components: “15*28CM Adjustable Temperature Reptile Heating Heater Mat” and “Mini LCD Celsius Digital Thermometer Hygrometer Temperature Humidity Meter Gauge”. There are many vendors selling what are essentially the same parts with minor variations.

Since the DryBox is for dispensing filament as well as storing it, a good spool mounting system is necessary but [Richard] found that the lack of spool standardization made designing a reliable system difficult. He noted that having spool edges roll on bearings is a pretty good solution, but only if one doesn’t intend to use cardboard-sided spools, otherwise it creates troublesome cardboard fluff. In the end, [Richard] went with a fixed stand and 3D printable adapters for the spools themselves. He explains it all in the video, embedded below.

In the end, [Richard] went with a fixed stand and 3D printable adapters for the spools themselves. He explains it all in the video, embedded below.

Not long ago we saw [Richard] share his thoughts on making 3D printer filament packaging more sensible, an excellent topic that saw a lot of good discussion. And within a few hours, at least one German filament company was already shipping out zip-tied bundles. That’s fast.

3D77 - Dry Box Storage for 3D Printing Filament

Filament Dehumidifier Cabinet for 3D Printing Filament

Eureka Dry Tech manufactures humidity & moisture controlled dry cabinet and dry box products. These products are suitable for storage of various types of 3D printing filament materials, especially hygroscopic filament polymers like nylon and PVA.

These products are suitable for storage of various types of 3D printing filament materials, especially hygroscopic filament polymers like nylon and PVA.

Eureka Dry Tech’s ADL-3D77 Filament Dry Box is the perfect moisture control solution for 3D Printing Filament Storage. Our automatic humidity control dry cabinets provides a quick and simple way to store filament without hassle. Simply set the desired humidity level, store the filaments and our dehumidifier dry unit will take care of the rest. Your filament will stay completely dry, easily accessible, perfectly identifiable (i.e. no need to open every box to find the right kind of filament you are looking for) and ready to be used anytime you need them for a print.

We offer cabinets in a range of sizes and shapes and storage capacity from 20 liters to 1300 liters and relative humidity control in a variety of ranges from 5%RH to 55%RH, we can provide you with custom or OEM cabinet designs that will suit you or your client's filament dry storage needs.

ADL-3D77 3D Printing Series Filament Dry Cabinet

Eureka Dry Tech's 3D Printing Filament Storage Dry Cabinet features:- Low humidity environment

- Four filament feed ports allows direct printing from the cabinet while in dry storage.

- Adjustable hanging rod hanging up to 33 cm diameter spools.

- Air tight cabinet prevents moisture and dust.

- Low energy consumption (13 W Avg., 100 W Max).

- No consumable parts, desiccants to replace, no water tanks to empty.

- Dries your filament without heat to weaken filament tensile strength.

For more info please visit https://www.eurekadrytech.com/application/3d-printing-filament-storage-dry-cabinet

For product details please visit https://www.eurekadrytech.com/products/auto-dry-box/eureka-dry-tech-adl-3d77-3d-printing-series-filament-dry-cabinet?v=70

Most may not realize, moisture absorption in filaments could be a significant cause of failure in 3D printing.

Some filament materials (like nylon, and PVA) are more hygroscopic than others, which means it has an inherent quality to attract ambient moisture. When filament spools are exposed to ambient humidity for long periods of time without any humidity controlled storage solution in place, moisture related problems will soon appear during printing. A complicated project could take hours or even days to complete but when a project has been set to run on its own, discovery of problems are often too late. Moisture absorbed in the filament could cause obstructions to the printer’s hot end and may require it to be replaced. Furthermore, moisture absorption can also affect the tensile strength of the filaments and the output objects.

Moisture Sensitivity of Filament Material

Sensitivity to moisture and the rate of absorption could vary depending on the type of filament material.

For example, nylons exposed to moisture in the ambient environment will absorb its maximal capacity of water molecules in only 18 hours.

PVAs are extremely hygroscopic and needs to be stored in a sealed box or a special container.

Conductive graphene is a new filament material on the market and is also moisture sensitive.

Ultem is another popular new filament that provides great tensile strength but recent studies has shown moisture absorption will decrease tensile strength. (see https://www.sciencedirect.com/science/article/pii/S2214860418304779)

PLA and ABS also attract water from the air, even if it is to a lesser degree. Proper storage for these various types of filament is important when not in use and Eureka Dry Tech offers various storage solutions for this.

Effects of Water Absorption by 3D Printing filament material may result in the following problems:

- Brittleness and breakage of filament,

- Diameter inconsistency

- Hissing steam or bubbling when filament reaches the hot-end,

- Filament degradation,

- Higher extruding temperature

Some "Makers" has come up with creative ways to address these problems, all of which has its own setbacks.

"Makers" in the 3D printing world often have multiple spools of filaments that are made of different materials like nylon, PVA, ABS, PLA, and in different colors. Rolls of filaments usually comes in 1kg spools, the filament spools often lasts for a long time. Soon the collection of filament polymer spools begin to grow and proper storage could become an issue as moisture absorbs in different types of filament material. This is of a concern especially with nylon and PVA, which are quick to absorb moisture.

Containers with light bulb or other heat source: A constant draw of power is required to maintain drying without control for a set humidity level, moisture will reabsorb when ever heat from light bulb or other heat source is removed.

Vacuum bags and silica gel desiccants: Moisture can enter the bag if not sealed properly. Silica gel desiccants are able to absorb so much before requiring replacement and can create too dry of condition initially. If not monitored constantly, silica desiccants can actually maintain moisture inside the bag with the filament.

If not monitored constantly, silica desiccants can actually maintain moisture inside the bag with the filament.

Baking filaments in ovens: There are no specific recommendations for best temperature for curing filaments in an oven. Filaments are made of thermoplastic, any heat source could present changes to the filament material's properties. And if not properly monitored the filament that are being dried could melt in the oven.

Repeatedly drying filaments with an active heat source will irreversibly degrade the plastic. Preventing moisture absorption in the first place will eliminate the need to dry your filament and ensure your filament's print quality is maintained till the end of the spool.

Please click the following link for more information regarding our Filament Dry Cabinet or please visit our or for pricing details.

Photo Source:

http://forums.vr-zone.com/chit-chatting/2904838-review-portabee-3d-print...

http://3dprint. com/49058/filament-moisture-damage/

com/49058/filament-moisture-damage/

http://stephanfr.com/2014/09/07/printing-with-taulman-bridge-nylon/

Tags: 3d printing, 3d printing filament, filament storage, 3d printing filament dry box, 3d filament dry box, filament dry box, humidity control filament cabinet, nylon filament storage, PVA filament, moisture absorption, extruding problem, hotend bubble, how to store filament, printer filament storage, keep filament dry, how to dry filament, how to dry nylon, how to store nylon, how to store pva filament, how to dry pva filament, how to keep pva dry, how to dry pva

Prev post Next post

3D Printed Water Extractor from Air

Researcher Javat Patel from India recently spoke at the TEDx event held in Hyderabad in 2017, where he presented his new development - a device for extracting water from air ( Dewdrop), the case of this device is quite complex for traditional production methods and it was decided to print it using a 3D printer, which greatly accelerated and simplified production.

In many parts of India, people suffered from severe water shortages. This was due to the lack of monsoons in previous years. Interestingly, in the earth's atmosphere there is a significant amount of water in the form of water vapor, anywhere on the earth. What if it was possible to collect this water regardless of location using a small and portable device?

An Indian engineering studio invented such a device and called it "Dewdrop", this device converts atmospheric moisture into drinking water. It looks like a simple bottle of complex shape, filled by itself. The capsule draws in air with a fan, filters dust, condenses moisture using the Thomson and Peltier effect, mineralizes water and keeps it drinkable. This is a 3D printer.

The capsule weighs about 900 g, making it easy to carry anywhere. The device is equipped with a 12 V 6000 mAh lithium-ion battery, which allows the production of about 1.86 l/h of drinking water. Jawwad claims to be able to generate at least 1. 2L/hr in desert areas. He also developed an interface to control the operation of the device, which includes sensors that detect humidity, temperature and other factors.

2L/hr in desert areas. He also developed an interface to control the operation of the device, which includes sensors that detect humidity, temperature and other factors.

Javat is already working on the next version of the product, which will include a solar cell for power, as well as the ability to select hot or cold water. The invention of such a device was inspired by a visit to Latour, a small town in the Marathwad district of Maharashtra, where people literally survived without water.

Fontus and Water-gen are companies that have already invented similar devices, they convert atmospheric moisture into water, but using a different technology. Their product "Fontus Airo" is a solar-powered water bottle consisting of a condenser connected to a series of hydrophobic surfaces that repel water, which eventually collects in the bottle.

Water-gen is an Israeli company looking for a water supply solution for defense and civil applications. Their product, the Atmospheric Water Generator (AWG), works as a dehumidifier, just like in air conditioners. AWGs suck in air, cool it down, thus condensing the water and recirculating cold air that can be used to cool the water. AWGs can be mounted on the ground and even in vehicles. AWG is capable of producing up to 450 liters of water per day.

AWGs suck in air, cool it down, thus condensing the water and recirculating cold air that can be used to cool the water. AWGs can be mounted on the ground and even in vehicles. AWG is capable of producing up to 450 liters of water per day.

This article is another confirmation that 3D printers and 3D printing are increasingly penetrating our lives and making things easier even for the world of science.

Air pollution in 3D printing

Main page

Articles

Smoke from a 3D printer

Smoke from a 3D printer

Introduction How does the printer pollute the air How does BOFA filter

What is 3D printing

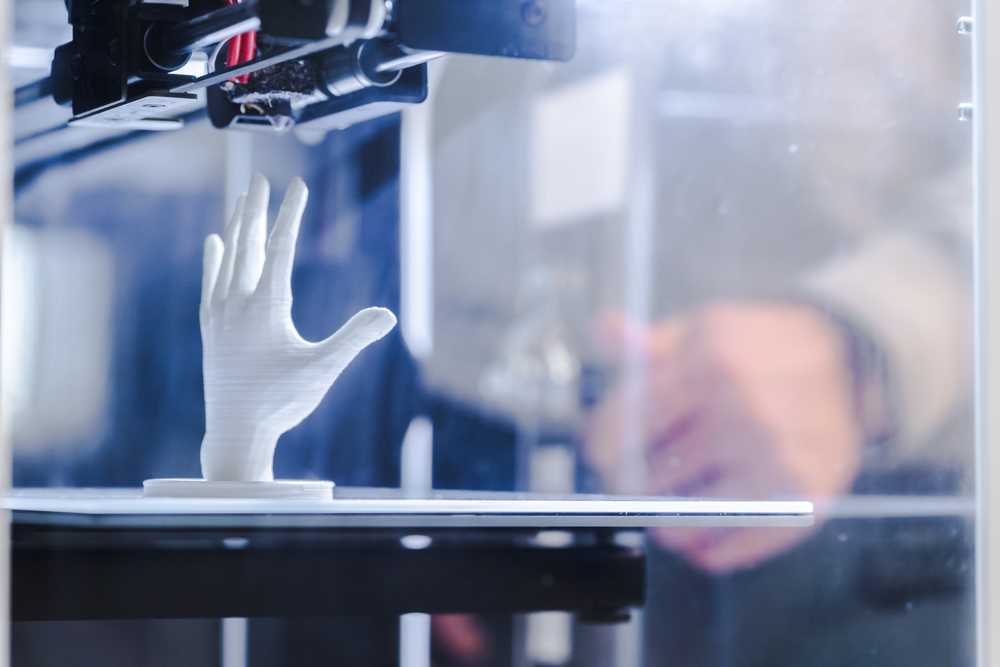

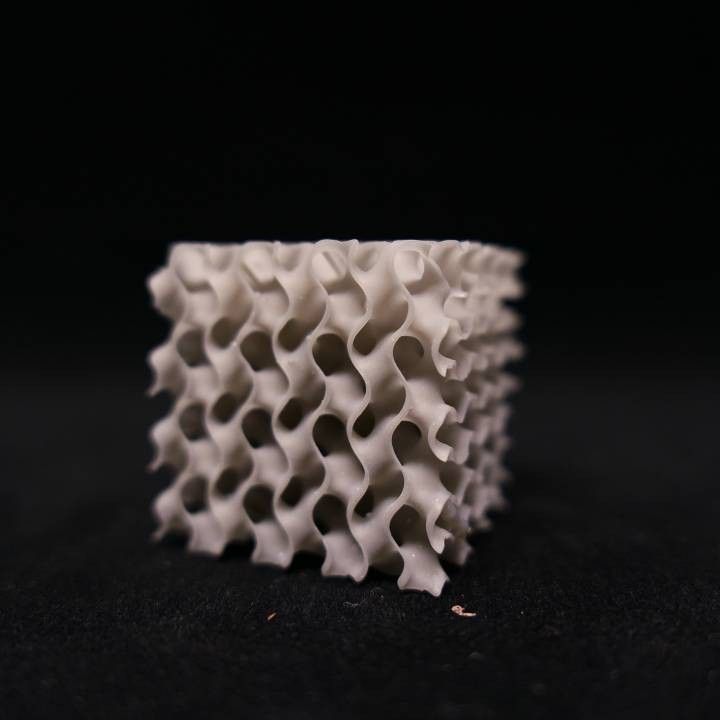

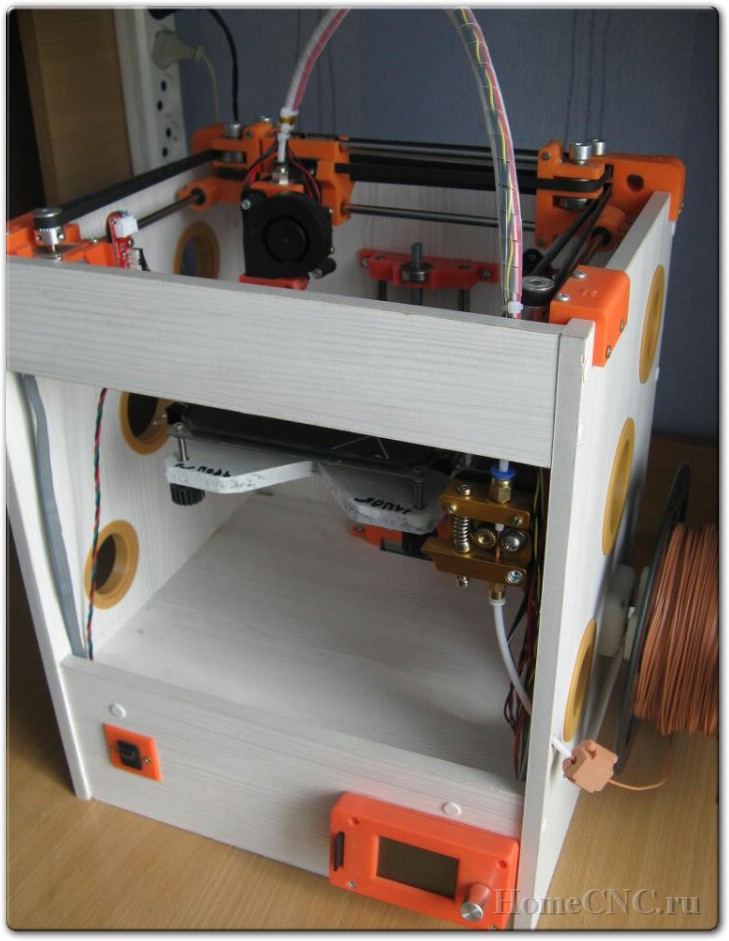

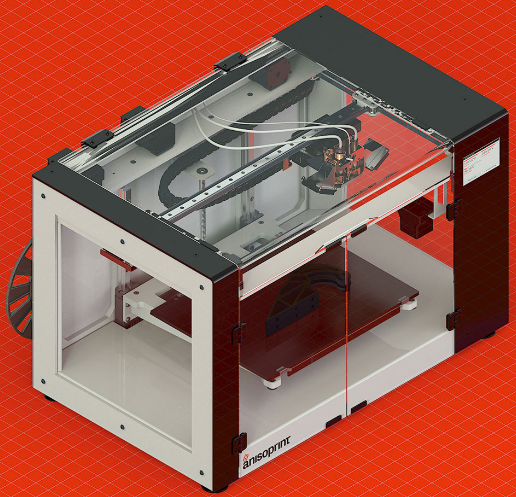

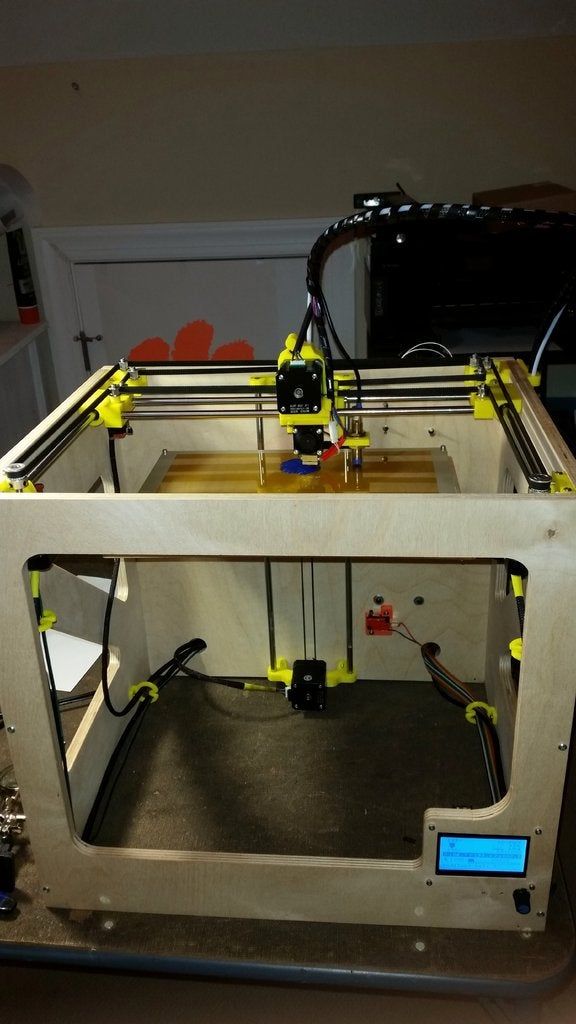

3D printing is also known as additive manufacturing. This means that the product is created by adding material in layers. The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base.

The printer is melting the material. Then it connects to the previously applied base.

A 3D printer will produce objects of complex shape. This favorably distinguishes the additive process from the subtractive one, when excess is removed from a large piece of material. Machining, laser processing, soldering or welding generate more contamination. And a lot of material is wasted. 3D printing does not consume a lot of extra material. It appears to be a clean process, but it still pollutes the air.

Anyone using 3D printing needs to be aware of the health risks. The 3D printer seems safe. But it can generate toxic fumes and hazardous substance particles. Technological processes that transform the material pollute the air in the workplace. This applies to cutting, engraving, thermal decomposition in a laser machine, soldering with a toxic flux, etc. Molten metals and polymers are no exception.

Why is a 3D printer dangerous?

Ultrafine particles

Heating a substance causes the release of solid particles, droplets and vapors. They may be harmful if inhaled.

They may be harmful if inhaled.

European scientists are gradually revealing the dangers of 3D printing to health. According to the 3D Printer Emission Report , plastic melting releases small nanoparticles of material into the air. They cannot be seen without special equipment. But that doesn't mean they are safe.

PLA plastic nanoparticles are used in pharmaceuticals as a means of delivering drugs to various organs, including the brain. Cosmetics use the same effect. Ultrafine particles penetrate the skin. By themselves, PLA particles are not toxic. But no one knows about the consequences of accumulation in human organs. Nanoparticles condense into relatively large formations. It is known for certain about the harmfulness of soot nanoparticles from automobile exhausts . They are associated with degenerative brain diseases, such as Alzheimer's disease.

ABS plastic is toxic when melted. Nanoscopic ABS particles are just as toxic. These particles are very small. During inhalation, they enter the brain through the olfactory nerve. They spread throughout the body through the bloodstream. Most organs can get rid of them naturally, but the brain and lungs become clogged for a long time.

During inhalation, they enter the brain through the olfactory nerve. They spread throughout the body through the bloodstream. Most organs can get rid of them naturally, but the brain and lungs become clogged for a long time.

In fact, particles as small as 10-200nm easily enter the bloodstream through the lungs. Their toxic action differs from the original substance in the usual shapes and sizes. According to study by the Italian Institute of Health and Consumer Protection nanoparticles are deposited in the lungs in greater quantities than e-cigarette smoke.

Gases or vapors

Molten ABS gives off a particularly unpleasant odor. Other plastics including nylon, HIPS and HDPE emit the same toxic fumes but have less odor.

Polymer materials can vaporize some of their constituents. Dioctyl phthalate is often added to them for flexibility and mold resistance. During high heat or laser treatment, benzene is released in hazardous quantities. And while working with PVC, HCl aerosol condenses in the air.

And while working with PVC, HCl aerosol condenses in the air.

The high temperature in the area of the printer head causes the air to expand. Vapors quickly spread in the work area along with plastic particles. Thermal degradation products of polymers are shown in the diagram below.

How does BOFA work?

A smoke extractor is an extractor hood with filters placed in one device. She got her name at the time when she removed the smoke of a soldering iron or a laser engraver. But these same devices with special filters are also suitable for a three-dimensional printer. The smoke extractor block for the printer is not much different from the soldering block.

3D printing is sensitive to changes in air temperature. Therefore, he is afraid of drafts. If you are using a small open printer, then the polluted air can be removed with a conventional smoke extractor. In order not to disturb the climate in the printer, select the minimum air suction speed.

If your 3D printer model is closed, there is a protective cover, then you can install a cleaning curtain. During operation, while the printer window is closed, it can be turned off. But it will clean the outgoing air when you open the box to take out the finished product.

If your printer is large and completely enclosed, then it will most likely have built-in pipes for connecting the hood. They can be connected to a smoke extractor with large filters. It can operate continuously or turn on at the command of the printer. The fume extractor captures dirty air and returns it back to the printer so as not to change the air temperature during the printing process.

3-stage filtration

A complete smoke extractor is equipped with three filters. The first is the pre-filter. It does not let in coarse dust, so as not to clog the main fine filter with it. The fine filter is HEPA. Particles of all sizes, including aerosols and nanoparticles, settle on its fibers. The gas filter completes the cleaning. It consists of densely packed activated carbon granules with interlayers of fiberglass. Activated carbon traps VOCs and nanoparticles that HEPA missed.

Particles of all sizes, including aerosols and nanoparticles, settle on its fibers. The gas filter completes the cleaning. It consists of densely packed activated carbon granules with interlayers of fiberglass. Activated carbon traps VOCs and nanoparticles that HEPA missed.

Smoke extractor against exhaust

The cheapest way to remove smoke is a duct fan and air ducts. The emission of polluted air through the window is prohibited by SanPin norms. And the smoke extractor has advantages.

- Good air purification from all kinds of solid particles and aerosols

- There will be no odors from melted plastic or metal in the room

- You will be sure that your health will not suffer

- The microclimate in the 3D printing machine will be stable

- Supply ventilation with heating or air conditioning is not needed, as for the hood in the window

Eliminate the harmful agent

The hood with filters will solve the problems with harmful emissions from 3D printing with polymers and metal powder.