3D printing billings mt

3D Printing Service for Billings, Montana

CapabilitiesCustom Online 3D Printing ServiceMontanaBillings

High Quality Billings, Montana 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Billings, Montana 3D Printing Service: 3D Prototypes and Production Parts

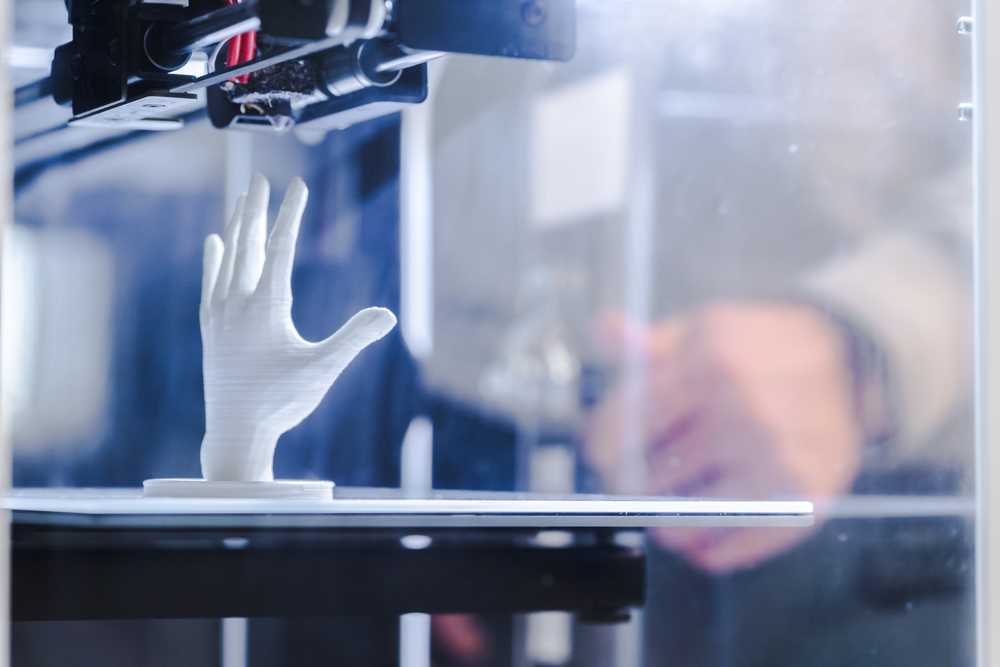

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

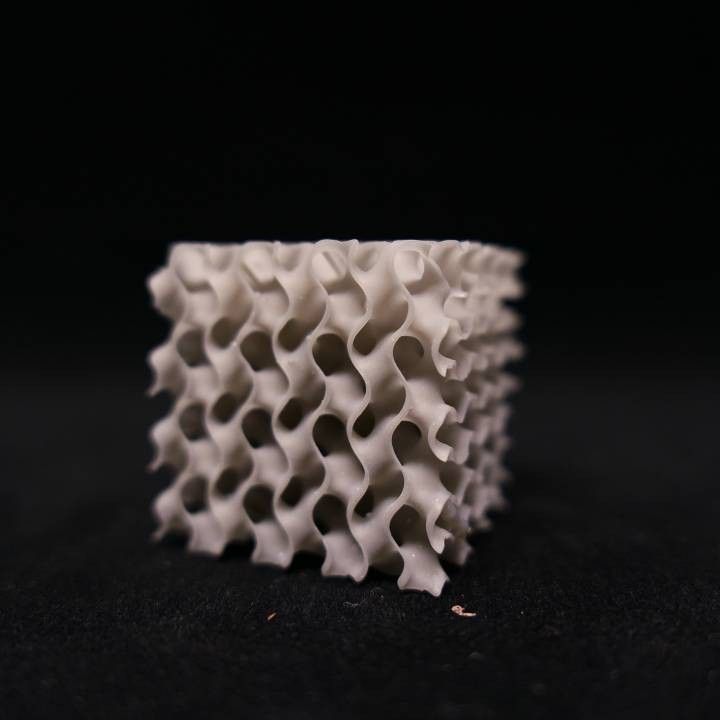

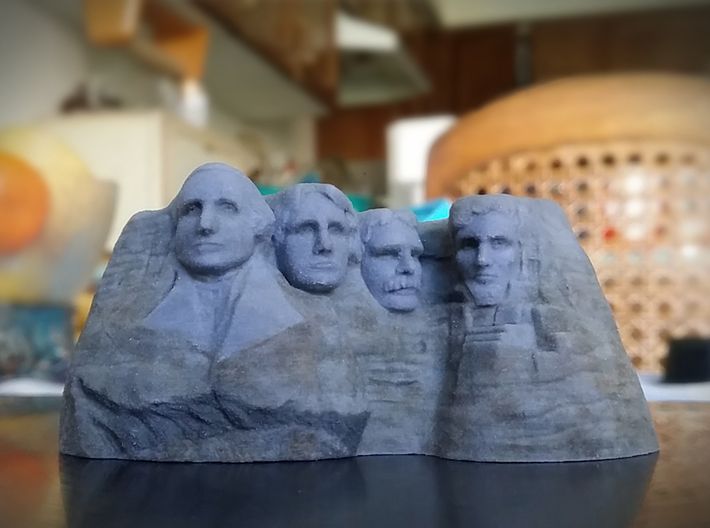

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

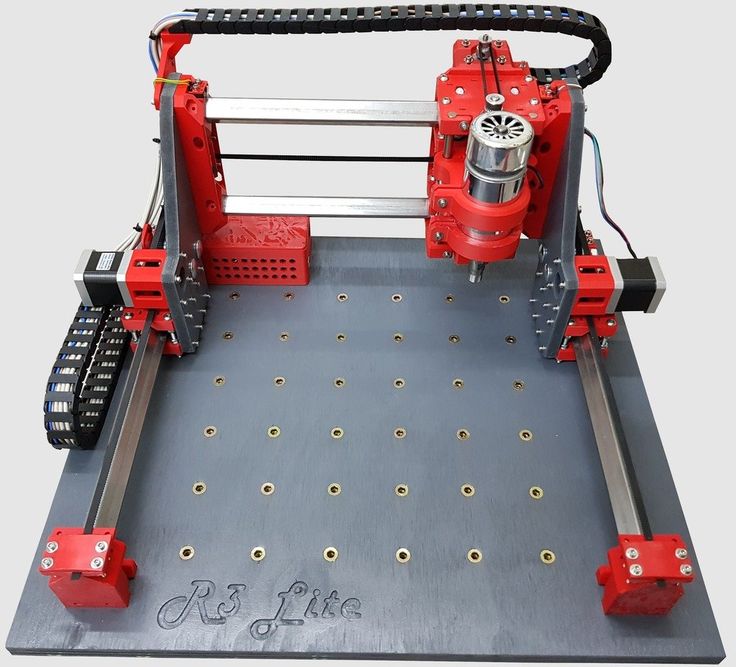

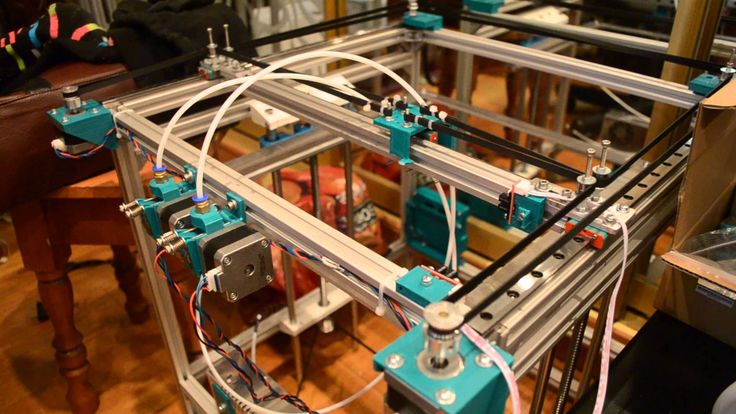

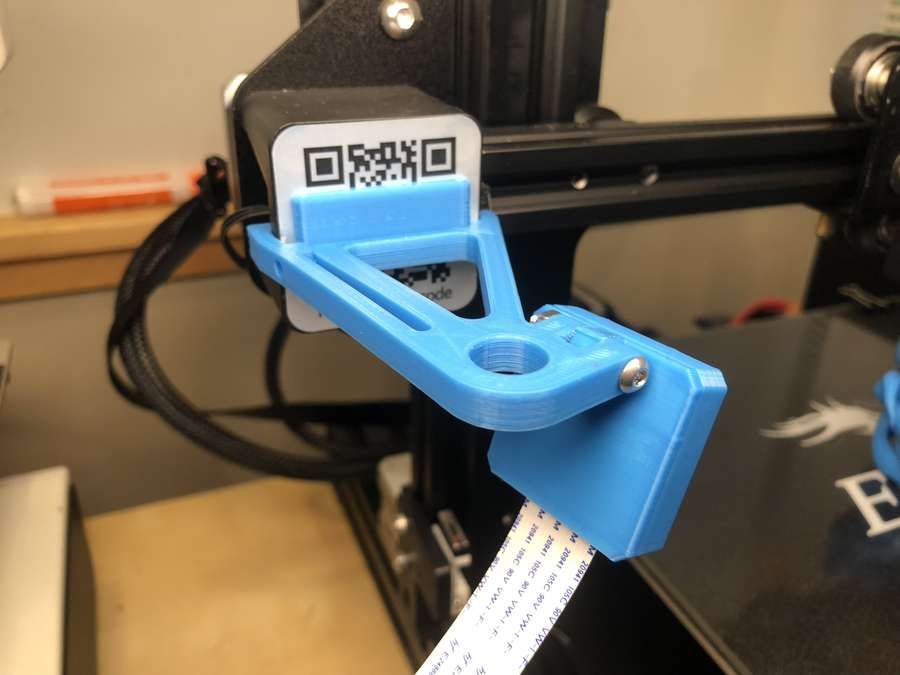

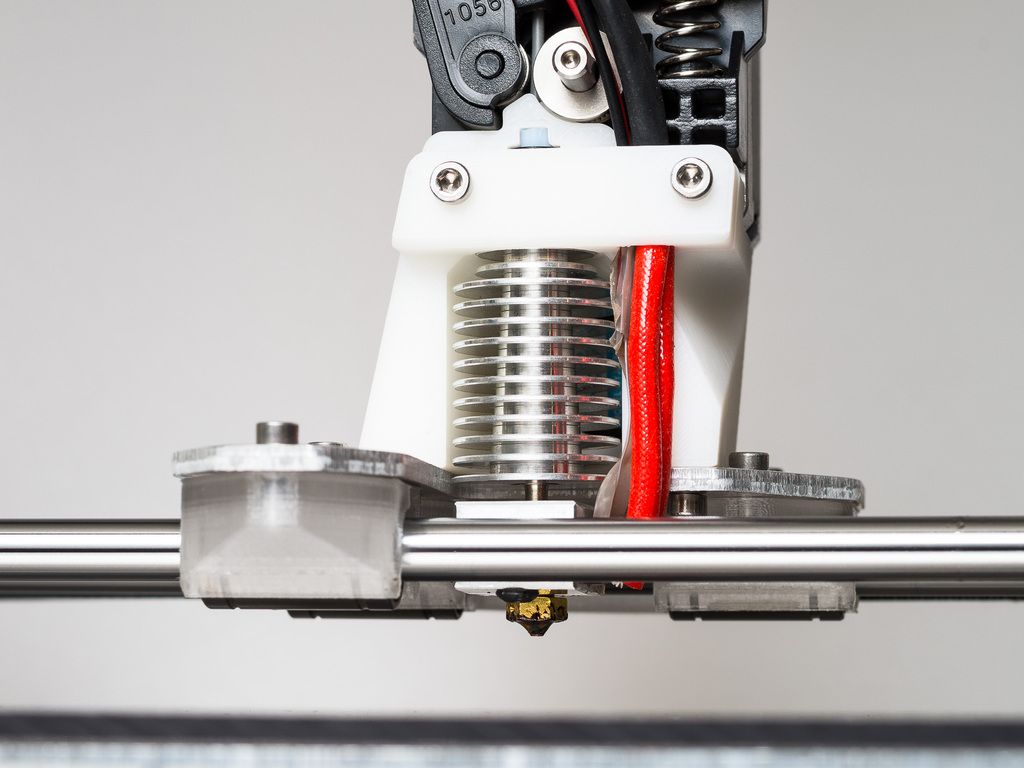

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

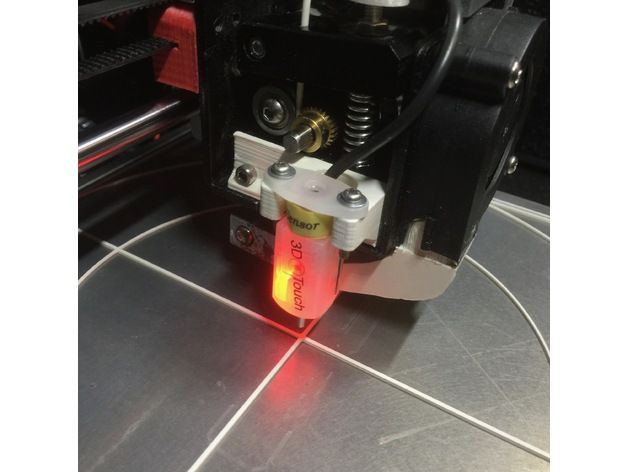

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Billings, Montana

Bozeman

MontanaHelena

MontanaWilliston

North DakotaRapid City

South DakotaLaramie

WyomingCheyenne

WyomingSalt Lake City

UtahFort Collins

ColoradoBoise

IdahoProvo

UtahMeridian

IdahoBoulder

ColoradoSpokane

WashingtonDenver

ColoradoAurora

ColoradoGrand Junction

ColoradoColorado Springs

ColoradoFargo

North DakotaYakima

WashingtonSioux Falls

South Dakota

Ready to start making custom 3D printed parts?

Billings developer using 3D printing to cut cost and time for homebuilding

NewsLocal News

Billings developer launching new 3D homebuilding project

By: Russ Riesinger

Posted at 8:41 PM, Aug 26, 2022

and last updated 2022-08-29 11:01:43-04

Montana is getting in on the ground floor of what could become the next big game-changer in building construction.

The state is the first to give regulatory approval for homes with 3D printed walls—which could save money and time it takes to build a home.

“3-D printing has been around since the ’80s, but in construction, it is not even 10 years old,” says Billings-based contractor Tim Stark, who made the application to the state to gain approval for the construction method.

Stark hopes to soon begin constructing houses in Billings using a large portable robotic machine that prints walls from a concrete and sand material.

“We use a puller printer, where you can just pull it up on a trailer and pull it with a three-quarter-ton pickup. We can pull it off the trailer and be printing in 30 minutes,” he says.

Q2 News

Tim StarkThe technology is developed by Apis Cor, a Florida construction company that has designed 3-D printed walls that comply with international building codes.

Stark says there are a lot of advantages to this type of construction, and he thinks it could make a real difference as Montana struggles to keep up with demand for housing and a shortage of labor.

“Time. It uses less people. So, a 2,000-square-foot house, we could print that in 40 hours or less. Let's say you start out and print in one corner. By the time you get to the other side, it is already set up enough to take the other layer," Stark said.

The 3-D printer makes a lot of designs possible.

“If we want to do a curved wall, you just put in the design and the printer prints it,” he says,

Another advantage is cost. Construction costs are cut significantly by using 3D printing, and there’s a lot less waste that ends up in the landfill.

“Right now, when we print a structure, it's 30 percent less. And expect that to go up as time goes on, as technology advances,” says Stark.

Color can also be added into the mixture to save money on painting and the need for drywall.

Q2 News

3-D printed housesWhile he plans to use concrete for the walls he’ll print for now, he says there’s a lot of talk about other materials that could one day be used, such as geopolymer, hemp, and even soil in some countries.

Stark says trades will still be needed to complete the construction, but the method provides a lot of exciting opportunities for what could be ahead in the future.

Stark calls this the next big advance when it comes to home construction, and he hopes to be printing homes in Billings within the next year.

Q2 News

3-D printed housesCopyright 2022 Scripps Media, Inc. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed.

Sign up for the The Big Sky Blend Newsletter and receive up to date information.

now signed up to receive the The Big Sky BlendNewsletter.

Click here to manage all Newsletters🚲 Best Bicycle 3D Printable STL Files・Cults

🚲 Best Bicycle 3D Printable STL Files

Free Download Bicycle Accessories 3D Files

A selection of valve covers, mounts, holders and racks for your bike that you can make with 3D printer. There are so many bike accessories out there and they can be very expensive, 3D printing is a great way to cut costs! 3D printing is also a great solution for inventing ideas that will make everyday life on your bike easier.

There are so many bike accessories out there and they can be very expensive, 3D printing is a great way to cut costs! 3D printing is also a great solution for inventing ideas that will make everyday life on your bike easier.

Customizable Bike Mount for Modular Mounting System

Free

3D Printed Bike

Free

Wall Rack

Free

mountain bike wall mount

Free

GoPro bike mount

Free

Bicycle Water Bottle Cage

Free

Stand Phone For Bike

Free

Water Bottle Holder

Free

Pizza Valve Cap

Free

Stormtrooper Valve Cap

Free

Coffee Cup Holder

Free

Brompton logo tap

Free

Presta valve cap with thread _ Presta Cap valve with thread

Free

Smartphone Support Magnetic Bike

0,50 €

GoPro Handlebar Mount (customizable)

Free

bike flashlight mount

Free

MOUSQUETON

Free

Handelbar mount for Samsung S5 with wireless Qi charging - weather proof

Free

bike support go pro diameter 32 mm

Free

SR Suntour fork top cap socket (FAA122 replacement)

Free

Bike Light

Free

Triathlon extension

Free

Smartphone bike holder

Free

Bar-End bike Plugs

Free

Saddle mount for "Smart LED / Planet Bike" lights

Free

Bike FlashLight Quick Release Mount

Free

iPhone 6 Holder

Free

Draisienne bike (IKEA hack collection) by Andreas Bhend and Samuel N.

Bernier

Bernier Free

The Bicycle Bubble Machine

Free

iPhone XS/6s Holder for GARMIN Mount (eTrex/Oregon/Colorado Series)

Free

Pinces pantalon pour le velo - Cycling Trouser Clips

Free

bike holder

Free

TUTUGO | Coffee Cup Valve Caps

Free

Mud Bike

Free

Fizik ICS Integrated Clip System Saddle adapter for Planet Bike / SMART Led Lights

Free

Clamping Knob For M8 Nut

Free

Deer Bike Rack

Free

iPhone 6 Plus Holder

Free

bike cleaning wheel

Free

Bead buddy for bicycle tire installation

Free

Bicycle Stand - 2 Part for use on the Road

Free

Graziella Back Light Mount

Free

Lightweight press-fit MTB handlebar plugs

Free

Yet Another Bicycle Flashlight Holder

Free

Beach umbrella holder for your bike

Free

Bike Attachment for iPhone 5, 4 and 4S

Free

GoPro clamp mount

Free

Bike Handlebar Cup Holder - Pint Glass or Coffee

Free

Here is our selection of best stl files for bike, all these accessories are taken from 3D Cults library files and 3D printed beautifully .

This collection includes free 3D files of bicycle accessories. Numerous 3D models of are perfect for all types of bikes: mountain, city or racing bike . There are no restrictions on the type of bike, so you can even resize or reshape the 3D files to match the shape of your bike or frame.

In this way, 3D designers offering their creations on the Cults 3D file upload platform compete in ingenuity to make your everyday life on a bike easier . For example, you can easily attach your phone to the handlebar, carry water bottles, or attach your GoPro to the bike. Once you get home, there are 3D printable solutions that will allow you to store your bike. You can even stand out by 3D printing custom decorations for your bike, like 3D printed valve caps in the shape of a pizza or a Lego man head!

All about 3D printing: FAQ

Many have already heard about the innovative 3D printing technology. But until now, not everyone understood what it is, and what it is eaten with. Therefore, most forums and other online communities are simply overwhelmed with a flurry of messages in which people are trying to find out more interesting facts and possibilities of 3D printing.

But until now, not everyone understood what it is, and what it is eaten with. Therefore, most forums and other online communities are simply overwhelmed with a flurry of messages in which people are trying to find out more interesting facts and possibilities of 3D printing.

We are also often asked about this innovation. Thus, we decided to give answers to the most popular questions, so that everyone can deal with this relatively new technology, understand what it is for, and clarify a few interesting points for themselves. So, let's begin.

Is 3D printing magic?

No, of course not. 3D is far from magic, but an ordinary technological process, the same as the usual ones, casting or stamping for all of us, only the technology for creating objects is very different.

- How new is 3D printing technology?

In this case, the concept of "new" is rather loose. If you compare this technology with many others, then yes, it is new. However, this does not mean that it is among those that have been developed in the next few years. No, this is far from true. After all, for the first time they started talking about 3D printing about 40 years ago, and at 19In 87, the first products created using 3D technology appeared at all.

However, this does not mean that it is among those that have been developed in the next few years. No, this is far from true. After all, for the first time they started talking about 3D printing about 40 years ago, and at 19In 87, the first products created using 3D technology appeared at all.

— Where is 3D printing used?

Scope too broad. Products of this type are used in production, at home, and, perhaps, even in the future will be used in medicine to create prostheses and artificial organs. However, today 3D printers cannot be called popular, since they are of little use in everyday life and are only needed for modeling, designing and creating jewelry.

— Why is this technology called 3D printing?

The fact is that the process itself is really somewhat reminiscent of laser or inkjet printing. But here, instead of paper, a special container is used, filled with various materials (plastic, various types of metals, gypsum, wax, ceramics, etc. ). Also, it is worth considering that in this case, 3D does not mean something virtual. Indeed, with the help of this technology, real volumetric products are created. In addition, there are several different 3D printing technologies (about 10), thanks to which you can create absolutely any product, even such as houses or food.

). Also, it is worth considering that in this case, 3D does not mean something virtual. Indeed, with the help of this technology, real volumetric products are created. In addition, there are several different 3D printing technologies (about 10), thanks to which you can create absolutely any product, even such as houses or food.

- How long does it take to print one 3D model?

There is no exact answer to this question. After all, the speed of printing depends on many factors, such as: the material of which the product will consist, the printer model, the size of the print object, technology, and so on. For example, a medium-sized plaster craft can be created within four hours. Accordingly, if it is something small, then it will be printed many times faster than a huge object.

- Then a 3D printer costs a fortune?

Naturally, against the background of other devices for printing, the cost of such products will clearly stand out. However, home 3D printers are built with a simpler design than production machines, and are therefore more than affordable.