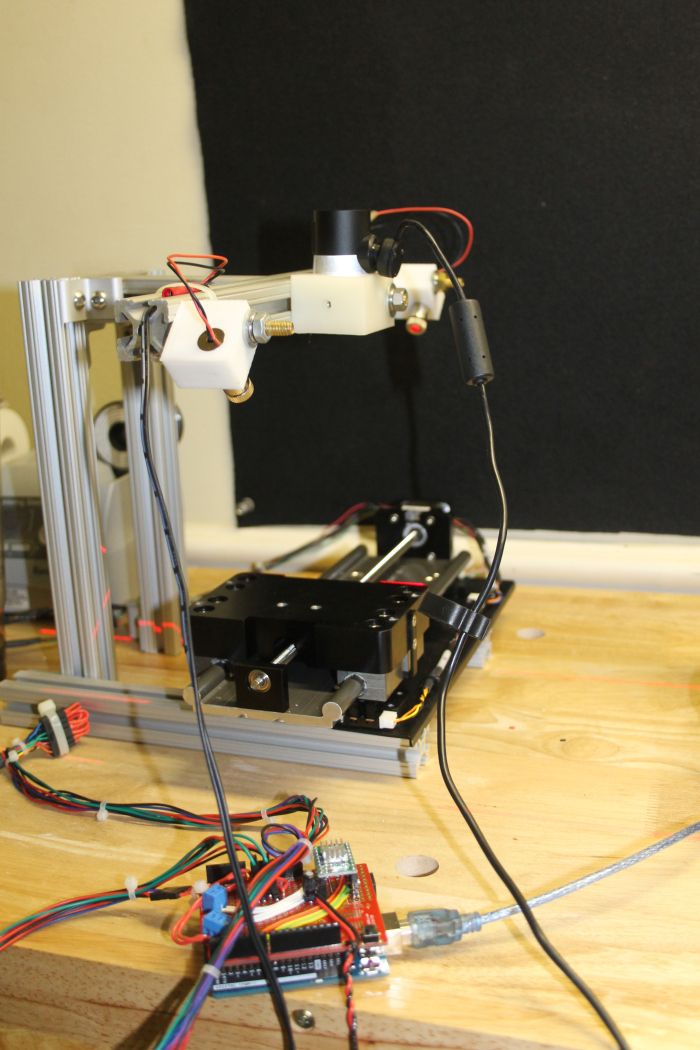

3D scanner line laser

| Dimensions | Ø12.5 x 30 mm | Ø9 x 26 mm | Ø10 x 27.1 mm | (W)14 x (H)14 x (L)26 mm | Ø10 x 26 mm | Ø10 x 38 mm | Ø10 x 40 mm | Ø10 x 40 mm |

| Operating voltage |

2. |

2.6~6 VDC | 3~6 VDC | 2.6~6 VDC | 3~6 VDC | 3~6 VDC | 3~6 VDC | 3~6 VDC |

| Operating current |

Less than 50mA / 55mA Less than 35mA / 100mA |

Less than 35mA | Less than 40mA / 60mA |

Less than 50mA Less than 35mA / 100mA |

Less than 80mA / 100mA | Less than 50mA / 100mA | Less than 50mA / 100mA | |

| Optical power |

Less than 2mW / 4~5mW Less than 2mW / 12~15mW |

Less than 2mW | Less than 5mW / 20mW | 4~5mW / 12~15mW |

Less than 2. 5mW / 20mW 5mW / 20mW

|

Less than 4~5mW / 9~10mW | Less than 5mW / 10mW | Less than 5mW / 10mW |

| Laser power output | Less than 0.39mW / 1mW | Less than 0.39mW | Less than 0.39mW / 1mW | Less than 0.39mW / 1mW | Less than 0.39mW / 1mW | Less than 0.39mW / 1mW | Less than 0.39mW / 1mW | Less than 0.39mW / 1mW |

| Laser class | Class 1M / Class 2M | Class 1M | Class 1M / Class 2M | Class 1M / Class 2M | Class 1M / Class 2M | Class 1M / Class 2M | Class 1M / Class 2M | Class 1M / Class 2M |

| Wavelength | 630~645nm / 645~665nm | 645~665nm | 635~665nm | 630~645nm / 645~665nm | 635~665nm | 630~645nm | 630~645nm | 630~645nm |

| Collimating lens | Plastic lens | Plastic lens | Plastic lens | Glass lens | Plastic lens | Glass lens | Glass lens | Glass lens |

| Line lens | Plastic lens | Plastic lens | Plastic lens | Glass lens | Plastic lens | Glass lens | Glass lens | Glass lens |

| Beam shape | Line | Line | Line | Line | Line | Line | Line | Line |

| Laser Line width |

3 ±0. 5mm at 5M 5mm at 5M6 ±0.5mm at 10M |

1.2mm at 1M | Less than 1.6mm at 40CM |

2±1mm at 5M 4±1mm at 10M |

Less than 1.2mm / 1.5mm |

3±0.5mm at 5M 6±0.5mm at 10M |

Less than 1mm | Less than 1mm |

| Laser line accuracy | 40” (±1mm @5M) | 1/100 | 4/1000(less than 1.6mm @400mm) | 20" (± 1mm @10m) | 1/100 | 40”(±1mm@5M) | 40”(±1mm@5M) | 40”(±1mm@5M) |

| Emitting angle | More than 90° | More than 60° | 60° / 90° | More than 120° | 60° / 90° | 60° | 5°, 10°, 15°, 20°, 30°, 45°, 60°, 110° | 5°, 10°, 15°, 20°, 30°, 45°, 60°, 110° |

Operating temp. range range

|

+10°C ~+40°C | +15°C ~+30°C | +15°C ~+40°C | -20°C ~+50°C | +15°C ~+40°C | -20°C ~+65°C | -20°C ~+60°C | -20°C ~+60°C |

| Storage temp. range | -20°C ~+65°C | -20°C ~+65°C | -20°C ~+65°C | -40°C ~+70°C | -20°C ~+65°C | -20°C ~+85°C | -20°C ~+85°C | -20°C ~+85°C |

| Housing material | Brass | Brass | Aluminum | Aluminum | Aluminum | Aluminum | Stainless steel | Stainless steel |

| Potential of housing | VDD(+) | VDD(+) | Insulated | Insulated | Insulated | Insulated | Insulated | Insulated |

| Electrostatic discharge (ESD) | 30KV | 30KV | 30KV | 30KV | 30KV | 30KV | 30KV | 30KV |

| Moisture sensitivity level (MSL) |

Level 1 - acc to JEDEC J-STD-020E.

|

Level 1 - acc to JEDEC J-STD-020E. | Level 1 - acc to JEDEC J-STD-020E. | Level 1 - acc to JEDEC J-STD-020E. | Level 1 - acc to JEDEC J-STD-020E. | Level 1 - acc to JEDEC J-STD-020E. | Level 1 - acc to JEDEC J-STD-020E. | Level 1 - acc to JEDEC J-STD-020E. |

| Wire type | 1007-26AWG | 1007-26AWG | 1007-26AWG | 1007-26AWG | 1007-26AWG | 2464 2-WIRE CABLE 26 AWG | 2464 2-WIRE CABLE 26 AWG | 2464 2-WIRE CABLE 26 AWG |

| Cable length | 115±15mm | 115±15mm | 250±10mm | 115±15mm | 115±15mm | 330±30mm | 330±30mm | 330±30mm |

| Mean time to failure (MTTF) 25°C | 10000hrs | 10000hrs | 10000hrs | 10000hrs | 5000hrs | 10000hrs | 10000hrs | 10000hrs |

| Application | General industrial alignment | Economic 3D scanner | Precision 3D scanner | Precision industrial alignment | Precision 3D scanner | Precision industrial alignment | Precision fine line for Automation, Machine vision and Medical | Precision fine line for Automation, Machine vision and Medical with modulation function |

| Suggestion work distance | Above 2 meters |

0. 3~1.8 meters / 1~6 feet 3~1.8 meters / 1~6 feet

|

20~60 cm / 8"~24" | 1~20 meters / 3~60 feet | 20~60 cm / 8"~24" | 1~20 meters / 3~60 feet | 0~1.2 meters / 0~4 feet | 0~1.2 meters / 0~4 feet |

| Datasheet download |

Download Download |

Download | Download |

Download Download |

Download | Download | Download | Download |

Understanding Laser Scanners | Article

Article

When complex or large environments need to be documented, Laser Scanners provide a practical and economical solution.

Traditionally, capturing large environments relied on tools that produced single point measurements, such as tape measures, piano wire, plumb bobs, laser range finders and total stations. While they are familiar tools, they are often time-consuming, often taking days, weeks or months depending on the space. Additionally, traditional tools often produce inconsistencies in measurements from user to user and ultimately data often get missed, leading to potentially cascading inaccuracies.

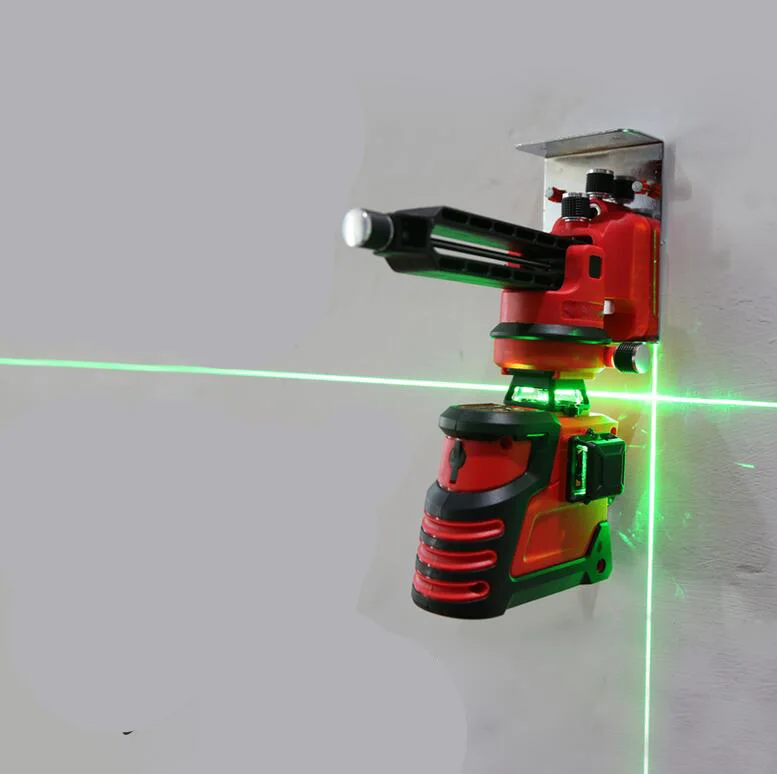

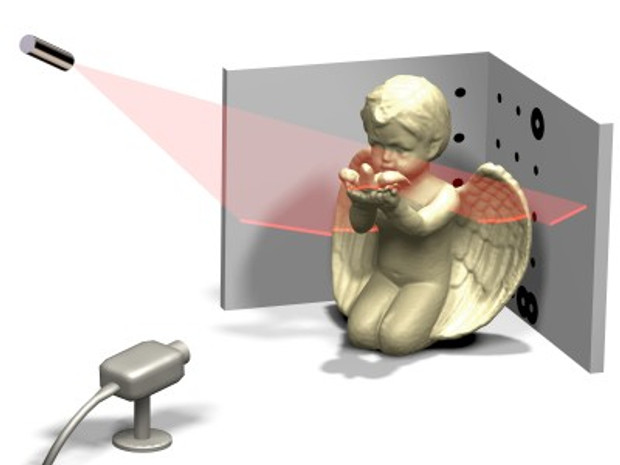

In contrast, Laser Scanners are non-contact devices that capture millions of discrete data points to measure an object or space using laser infrared technology that produces detailed 3D images in minutes. The images comprise millions of 3D data points, known as a point cloud.

So, how do they accomplish all of that so quickly? The Laser Scanner emits a beam of infrared laser light onto a rotating mirror that effectively paints the surrounding environment with light. The scanner head rotates, sweeping the laser across the object or area. Objects in the path of the laser reflect the beam back to the scanner, providing the geometry that is interpreted into 3D data. In addition to the distance measurement, Laser Scanners also capture measurements on the horizontal and vertical planes, providing a full scope of measurement data.

Objects in the path of the laser reflect the beam back to the scanner, providing the geometry that is interpreted into 3D data. In addition to the distance measurement, Laser Scanners also capture measurements on the horizontal and vertical planes, providing a full scope of measurement data.

A Laser Scanner typically captures data through two kinds of systems:

- Time-of-flight systems: Also known as a pulse measurement system, this works by emitting a single pulse of laser light and determining the distance to the end point by measuring the time it takes for the light to be reflected back to a sensor on the scanner.

- Phase-shift systems: Similarly, this system also uses an emitted laser light, but in this system, the intensity of the light is modulated with specific wave forms. The reflection of the intensity patterns is displaced by the impact on the surface of the object. Measuring the displacement between the sent out and the received laser signal provides a precise distance calculation.

Generally, Laser Scanners that use phase-shift systems are accurate, fast and provide high-resolution data.

Generally, Laser Scanners that use phase-shift systems are accurate, fast and provide high-resolution data.

Applications and Industries:

Laser Scanners are versatile, easy to use and move, and accurate, making them an ideal tool for many applications and industries:

Law enforcement & fire safety: Laser Scanners are effective tools for crime scene documentation, crash and accident scene reconstruction, fire scene analysis, forensic investigations and more. Laser scanning saves hours of documentation time and preserves a digital replica of scenes that may be environmentally vulnerable.

Safety & security: Laser Scanners capture highly detailed, valuable data used by security personnel to save lives when responding to potential threats.

Insurance: Laser Scanners are used to document the actual state of a piece of property at a point in time, helpful for setting a baseline for value and obligation, as well as documenting losses with vehicles, damaged properties or products.

Oil & gas: Laser scanning is well-equipped to assist in engineering, maintenance and planning on oil platforms and in refineries. They are also highly useful in documenting complex piping structures to avoid installation issues or errors.

Heritage & historical preservation: Laser scanning can document the complex geometries of existing buildings in order to study, preserve or restore them.

Site surveying: Laser Scanners can be used to make volume calculations as well as topographic and as-built surveys.

Construction: Laser scanning can provide continuous in-field verification at every stage of a construction project lifecycle, helping predict and prevent errors and enabling significant cost, scrap and time savings.

Architectural & civil engineering: Laser Scanners are useful for capturing as-built documentation of existing buildings and in developing 3D models as part of project planning.

Facilities management & asset documentation: Laser scanning offers precise data of complex factory and plant installations, useful in maintaining and documenting assets and facilities.

In each application scenario, a Laser Scanner produces accurate results in less time and with fewer errors than other, more traditional methods. And in some cases, such as documenting crime and crash scenes, the time saved offers downstream benefits such as being able to open roadways to the public earlier. In applications that require outdoor work, Laser Scanners can document complex areas where inclement weather is a concern.

Article

Architecture, Engineering & Construction

Public Safety Analytics

As-Built Capture & Modeling

Construction Prefabrication

Construction Quality Control

Design Layout & Projection

Digital Twin for Asset & Facility Management

Historical Preservation

Crash Reconstruction

Crime Scene Investigation

Arson Investigation

Safety Planning

Failure Investigation

Architecture, Engineering, Construction

Defense

Fire and Rescue

Forensic Engineering

Geospatial

Insurance

Law Enforcement

Measurement Service Providers

Media & Entertainment

Mining

National Security

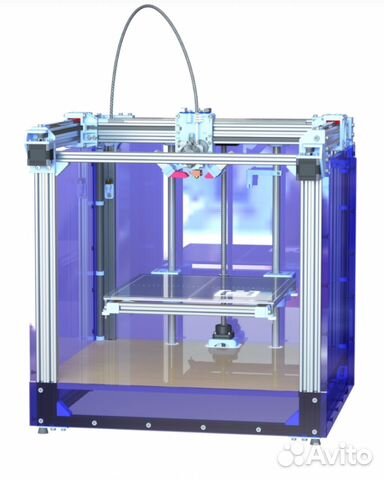

3D Scanners

Focus

Build & Construct

Awareness

Related Content

scopes and overview of models / Sudo Null IT News

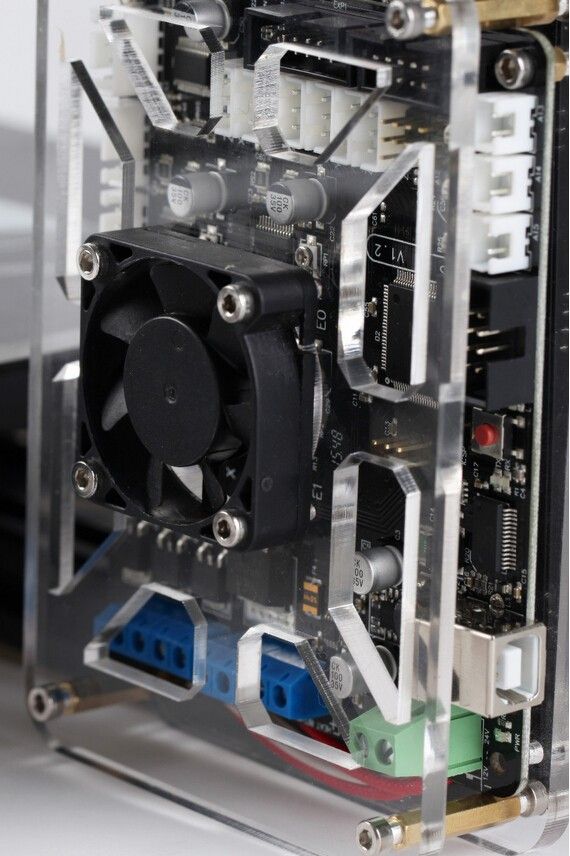

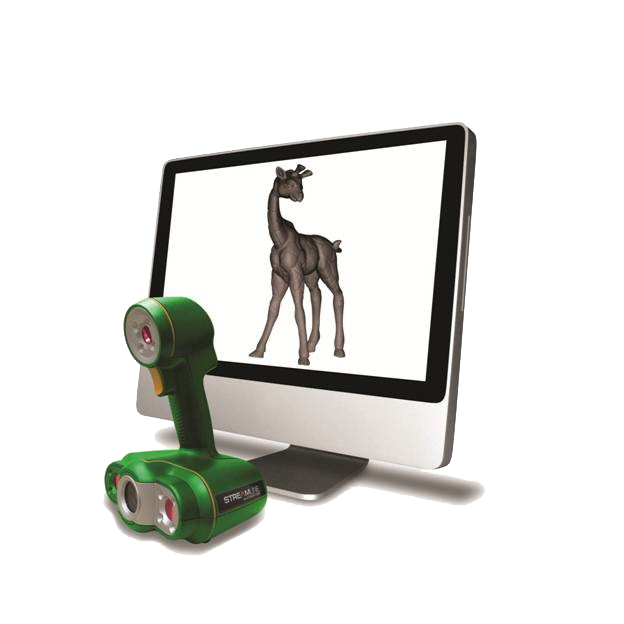

3D laser scanning - creating a digital model of a physical body using a laser beam. The technology is non-contact, works at close and long distances, eliminates damage to objects during scanning. The principle of operation of 3D laser scanners: a directed laser beam is reflected from the surface of an object, forming a cloud of points. Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data.

The technology is non-contact, works at close and long distances, eliminates damage to objects during scanning. The principle of operation of 3D laser scanners: a directed laser beam is reflected from the surface of an object, forming a cloud of points. Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data.

From the overview you will find out where laser scanning is used and what equipment is used to solve related problems.

Purpose of laser scanners

Source: newequipment.com

In comparison with traditional measurement methods, laser scanners have an important advantage - they can digitize objects with complex surfaces and work in hard-to-reach places for humans. The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas.

Construction, renovation and renovation of objects

Source: ellisdon.com

During the preparation of the building design, it is necessary to evaluate the features of the site and the cost of the forthcoming works. With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies.

The basis for an exterior or interior renovation is often an accurate digital model, on the basis of which changes and additions to the current interior or exterior are planned. Laser scanners are also indispensable in this area.

Road networks and transport

Source: autodesk.com

Laser scanning is becoming an integral part of the planning and creation of urban and suburban road networks, tunnels, pedestrian sections, railways, ports. The technology is used to assess the current state of coatings, plan and estimate the cost of repairs, to obtain models of perennial structures, such as bridges. The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships.

The technology is used to assess the current state of coatings, plan and estimate the cost of repairs, to obtain models of perennial structures, such as bridges. The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships.

Public utilities

Source: 3dscanner.es

With the help of 3D laser scanners, it became possible to quickly digitize and document engineering communications. Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Oilfield installations

Source: ramboll.com

Oil production complexes located in the water require constant monitoring of work processes. Objects are regularly exposed to adverse and changeable environmental influences: winds of different strengths and directions, currents, temperature changes, etc. 3D laser scanning is becoming an integral part of the inspection of oil production installations. The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents.

3D laser scanning is becoming an integral part of the inspection of oil production installations. The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents.

Forensic examination

Source: faro.com

Photographs and manual measurements in investigative processes and forensic examinations are being replaced by 3D laser scanning. The devices create three-dimensional models of scenes of incidents with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

Other applications

Source: news.microsoft.com

3D laser scanners facilitate and optimize workflows in the following areas:

- In cartography and geodesy - when creating terrain plans, maps, geographic information systems (GIS).

- In archeology - in the restoration and preservation of ancient artifacts.

- In paleontology, to create missing parts of excavated skeletons.

- In medicine, including plastic surgery and dentistry.

Overview of models and manufacturers

FARO Focus

Source: ifworlddesignguide.com

FARO is one of the popular manufacturers of laser scanning devices. The new Focus3D S-series instruments stand out from other scanners in lightness and compact size, as well as the ability to work in bright sunlight and keep in touch with the location using GPS.

The FOCUS 3D S 150 scanner works at a distance of up to one hundred and fifty meters, with an accuracy of up to ±2000 microns at a maximum distance. The device is used in design, architecture and construction, for digitizing equipment and other objects.

You can learn more about this model on the website.

Source: youtube. com

com

Focus3D S 350 scans with the same accuracy as the previous device, but the distance to the measurement object is increased to 0.35 km. The device is designed for outdoor use.

Source: kkgeosystem.blogspot.com

SHINING 3D

Source: shining3d.com

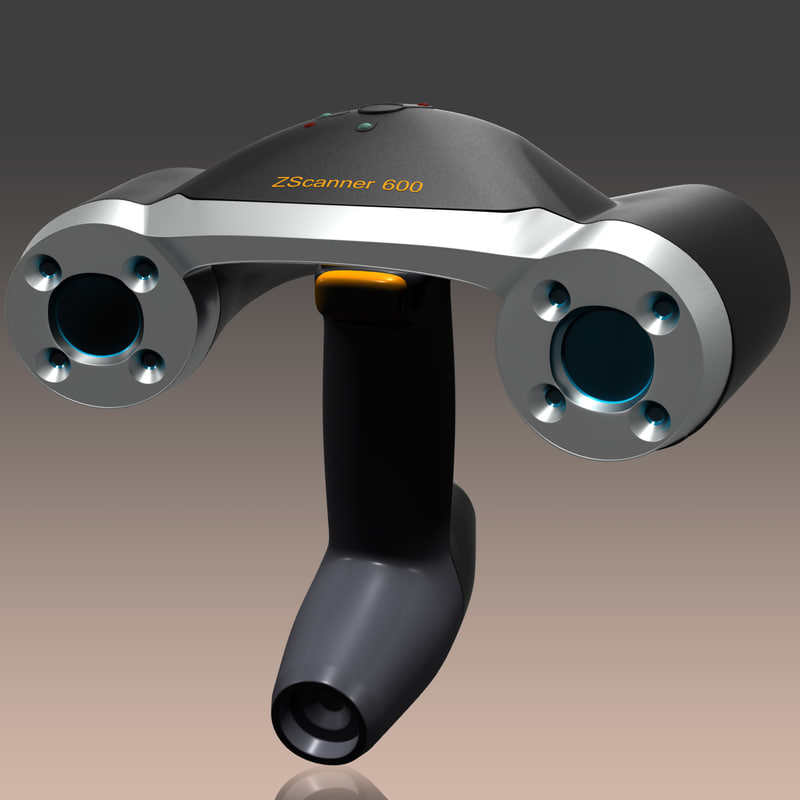

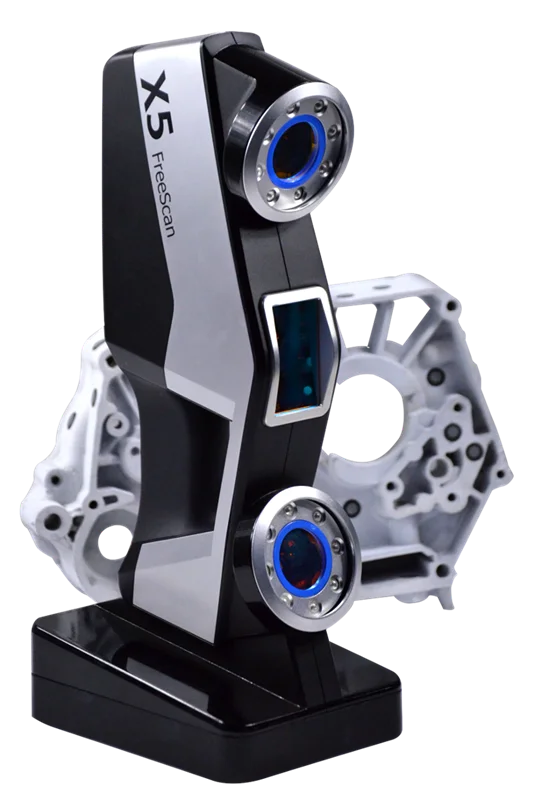

FreeScan is a line of well-known Chinese manufacturer of digital equipment SHINING 3D. These are universal laser handheld 3D scanners FreeScan X5 (X5+), FreeScan X7 (X7+) weighing up to 1 kg, with an excellent set of professional features.

Basic parameters:

Specifications

Creaform

Source: foundry-planet.com

Creaform's SCAN 3D range is characterized by high scanning quality combined with ease of use. Portable laser scanners HandySCAN 3D, MetraSCAN 3D have a clear interface, do not require special skills and complex user training.

Instrument features:

ScanTech

Handheld range

Source: cmmxyz.com

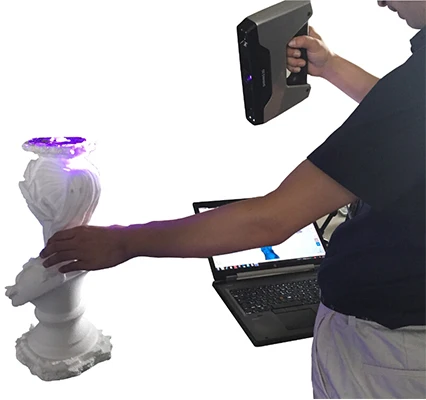

The HandHeld Prince series uses blue and red laser beams to scan large and small objects with high accuracy. Scanners can operate in bright sunlight and low light conditions. Due to its compact size, high speed and detail, the equipment is widely used in reverse engineering, quality inspection, digitization of museum, archaeological and other objects.

Key features:

Composite series

Source: twitter.com

In addition to the dual scan mode, the KSCAN20 is equipped with a photogrammetry system, thanks to which the working area of the device is 2.5 m * 3 m with an accuracy of 35 µm / m.

Blue and red lasers provide high-speed scanning of up to 650,000 measurements per second with a resolution of 0.01 mm.

Key Features:

3D Laser Scanner Applications

Reduce construction costs and time with FARO Focus

Source: autodesk. com

com

US construction company Gilbane invested $60,000 in a FARO Focus-S 350 laser scanner, software, and employee training. At first glance, the amount seems too large for a small-scale firm. But, after the calculations, the company's management came to the conclusion that the investment will pay off in the shortest possible time.

According to Gilbane's director of 3D design, John Tocci Jr., after introducing the expensive new technology, the company began to use the equipment even in areas where it was not originally planned. The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

Source: autodesk.com

Building a digital model of air ducts and other systems made it possible to avoid errors during the installation of physical objects, which could take several weeks. The use of FARO Focus in the assembly of plumbing, electrical and mechanical installations helped to optimize costs at all stages of work

Case “Modernization of the building of the University of Miami”

Source: elevar. com

com

At the time of the start of work, the architects had drawings made 85 years ago, and a little more than 4.5 thousand square meters of the old building. Using a 3D laser scanner, Gilbane digitized the training areas in one day. Modernization of load-bearing structures, as well as the main utility systems: plumbing, electrical and ventilation, was based on data obtained from scanning.

Quality Inspection with ScanTech

Source: 3d-scantech.com

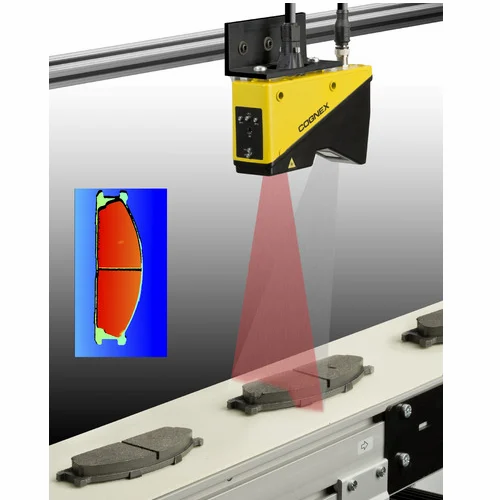

The advantage of metal stamping over forging and casting is the lower weight and thickness of the resulting parts. The use of molds gives high accuracy and maximum compliance of the obtained parts with the specified characteristics, but does not completely exclude deviations and deformations. Which, in turn, can lead to difficulties in assembling finished products and reducing product quality. Therefore, constant quality inspection is a necessary part of production.

Having understood the problems of the manufacturer, ScanTech experts proposed to check the quality of stamped parts using the PRINCE laser scanner. The ability to switch blue and red laser modes allowed the device to combine the functionality of traditional portable and metrological 3D scanners. The mode of operation with an active beam of a red laser provides fast digitization of objects. In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode.

The photo shows the stages of work:

1. Installing markers - takes about two minutes.

Source: 3d-scantech.com

2. Digitizing a part takes about three minutes.

Source: 3d-scantech.com

Source: 3d-scantech.com

3. Deviation detection - lasts 3 minutes.

Source: 3d-scantech.com

The digital model shows the parameters and deviations, allows you to correct errors at the design stage. The case clearly shows that the process required a minimum of time and effort.

The case clearly shows that the process required a minimum of time and effort.

Using FARO 3D scanners on Justin Timberlake's world tour

Source: disguise.one

Timberlake's "Man of the Woods" program features scenery brought to life on stage. First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing pictures of the Portland landscape on translucent canvases suspended in the air.

Source: faro.com

Two Faro Focus X 330 laser scanners, Faro Scene 6.2 software were used to prepare visual effects. In total it took 40 digital copies and 1 working day in the concert hall.

Source: www.esa.int

Considering the limited preparation time, the large surface areas for displaying the image and the corresponding need for high image resolution, creating visual effects in a short time without using the chosen technology was impossible.

Selection guide for 3D laser scanners

In the review, we introduced you to the equipment of market leaders with an excellent reputation. All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

FARO Focus: Focus3D S350, Focus 3D S150.

Creaform: MetraSCAN 350 (350 Elite), MetraSCAN 750 (750 Elite), HandySCAN Black (Black Elite).

SHINING 3D: FreeScan X5 (X5+), FreeScan X7 (X7+).

ScanTech: KSCAN20, PRINCE 775, PRINCE 335.

Results

Source: 3d-scantech.com

The cases discussed clearly prove that the use of 3D laser scanning optimizes workflows in many areas. The range of tasks solved with the help of 3D laser scanners is constantly expanding.

Buy a professional 3D laser scanner in Top 3D Shop — experienced specialists will help you choose the most suitable equipment, software for your business, and offer a project to modernize production.

Manufacturing Intelligence | Hexagon

Skip to Main Content

English

-

Industries

-

Solutions

-

Products

-

Support & Success

-

Resources

-

Company

English

Tab Close Content Button

Alert

The page is not available in your preferred language.

English

- English

- Czech Republic

- Deutsch

- Espanol

- Francais

- Italiano

- Magyar

- Nederlands

- Poland

- Portugues

- Romaneste

- Suomi

- Svenska

- Turkish

- Russian language

- ภาษาไทย

- 한국어

- 日本語

Select your preferred language from the list below. We will show you content in your preferred language when available, otherwise we will show English.

We will show you content in your preferred language when available, otherwise we will show English.

Preferred Language

- Bahasa Indonesia

- Czech Republic

- Dansk

- Deutsch

- English

- Espanol

- Francais

- Italiano

- Magyar

- Nederlands

- Poland

- Portugues

- Romaneste

- Suomi

- Svenska

- Turkish

- Russian language

- ภาษาไทย

- 한국어

- 日本語

To explore content available in a specific language, visit the page language directory.

100% EV: accelerating electrification

Discover a faster, more integrated, sustainable approach to the design, development and production of electric vehicles.

Make it smarter

Today's manufacturers are looking for smarter ways to improve quality and productivity.

Hexagon's Manufacturing Intelligence division empowers customers to put data to work throughout the product manufacturing lifecycle, digitally transforming operations to improve productivity and efficiency while embedding quality throughout the process.

Our technologies enable manufacturers to access, analyze and actively leverage data from all key stages of the manufacturing process to empower better decision-making. Our knowledge and experience provides customers with the tools – and the confidence – to accelerate innovation and reduce time-to-market while delivering quality products.

Industries

While specific industries have their own unique challenges and motivations, productivity is central to manufacturers across the board. Continuously improving productivity is essential for competitive success.

Continuously improving productivity is essential for competitive success.

Hexagon's Manufacturing Intelligence division helps customers put data to work to improve productivity and efficiency while embedding quality throughout the product lifecycle.

Our manufacturing intelligence technology enables manufacturers to access, analyze and actively use data from all the key stages of the manufacturing process. Through an unparalleled portfolio of digital manufacturing technologies spanning CAE solutions for design and engineering, CAD CAM and complementary software for production applications, metrology hardware and software solutions, as well as data management and analytics tools, we empower technology users throughout the process with deep and actionable insight into product quality, ensuring that quality drives productivity.

Together, our manufacturing intelligence software solutions create a digital thread throughout the manufacturing process, enabling the entire organization to take a holistic approach and work together with speed and confidence to achieve the desired outcomes.

Our hardware solutions use metrology to bring real-world physical attributes to the digital thread to improve the accuracy of operations. The digital thread ties together a connected ecosystem for manufacturing and, with the addition of domain expertise and intelligence, enables continuous learning and improvement.

-

Digitalising aircraft development and operations to keep the world in transit.

-

Helping the automotive industry embrace electric, connected and autonomous vehicles.

-

Innovation, collaboration and visualization technologies for the buildings industry.

-

Reduce operational risk, increase efficiency and meet regulatory compliance.

-

Ensuring network capacity and service reliability for critical infrastructure.

-

Get the job done across all heavy construction project phases faster, simpler and safer.

-

Smarter, more efficient and more profitable building of industrial facilities.

-

Helping consumer goods manufacturers keep pace in a fast-moving industry.

-

Software, systems and data for military planning and operations.

-

Enabling education and research institutes to inspire new generations.

-

Delivering end-to-end solutions and process autonomy in the electronics industry.

-

Reduce operational risk, increase efficiency and meet regulatory compliance.

-

Accelerate your autonomous project needs with superior engineering solutions for a variety of industries.

-

As heavy equipment becomes more complex, lighten the load with digital solutions.

-

Helping the supply chain manufacture essential materials, tooling and components.

-

Bridging the virtual and physical to accelerate healthcare innovation and autonomy.

-

Connecting all parts of your mine with technologies for safer, smarter decisions.

-

Hexagon has experience serving a number of other industries including; arts and entertainment, real estate and retail.

-

Unfurling the power of data to digitally transform the shipbuilding industry.

-

Data, systems and insights for transportation planning and operations.

Solutions

-

Hexagon’s solutions are critical to capturing, connecting and fusing the vast amounts of data required to deliver the world’s safest, most advanced autonomous mobility solutions for on-and-off-road vehicles and equipment, marine vessels, drones, robotics and more.

-

Hexagon’s solutions are changing the way buildings are planned, designed, constructed and utilised—ensuring data is captured, connected, visualized and updated throughout the lifecycle to deliver better performance and lower environmental impact and at a lower cost.

-

Hexagon’s solutions make cities and nations safe, resilient, agile and sustainable while reducing their total operating cost by connecting mission and business-critical data to make timelier, well-informed decisions.

-

Hexagon’s solutions are enabling customers to leverage data throughout the asset lifecycle—transforming industrial facilities into lean, efficient, safe operations that improve the bottom line while assuring a sustainable future.

-

Connect the vast manufacturing ecosystem via a Smart Digital Reality—a real-time 3D replica connecting product requirements with outcomes and enabling proactive corrective actions and maintenance while reducing waste and increasing productivity sustainably.

-

Hexagon’s life-of-mine solutions connect and leverage data from planning to operations—from safety to sustainable reclamation—making it possible for customers to extract 100% of a mine’s potential value safely, sustainably and profitably.

Featured products

All products

Embed quality into product design and engineering to ensure component manufacturability and downstream production productivity.

Maintain design intent throughout the product lifecycle, improve productivity and deliver high-quality components with maximum efficiency.

Capture real-world data for positioning and inspection, and gain actionable information that continuously improves efficiency, quality and productivity.

Service and support

Our global teams of local experts are here to support you with your manufacturing challenges.

Partnerships

See how our global partner network helps us innovative and provide smarter products and services for manufacturers.

Resources

Access manufacturing-related content in the resource library to explore key trends and technology for your business.

Latest news

Read moreHexagon Moves its Czech Republic Team to New Manufacturing Intelligence Division to New Center of Operations

30 Aug 2022

Global technology leader Hexagon recognizes manufacturing's best start-ups

09 Jun 2022

range laser tracker platform with wireless handheld probe from Hexagon

08 Jun 2022

Hexagon strengthens Central European support for CAM software portfolio with the acquisition of distributor Vero Solutions

23 May 2022

New wireless laser tracker automation system from Hexagon

26 Apr 2022

3

Upcoming events

Read moreCreutzwald, France

13 October 2022- 10 November 2022

Tampera, Finland

29 - 01 December 2022

$ProductName

$SustainabilityImpactLabel

$GreenGoalsLabel: $GreenGoalsContent

$ShortDescription

$SustainabilityCTABandHeadingLabel

$SustainabilityCTABandDescriptionLabel

Thank you – your preferences have been saved

To make changes please select the “Personalize Your Experience” option in the footerPersonalize your experience

Personalize your experience below.