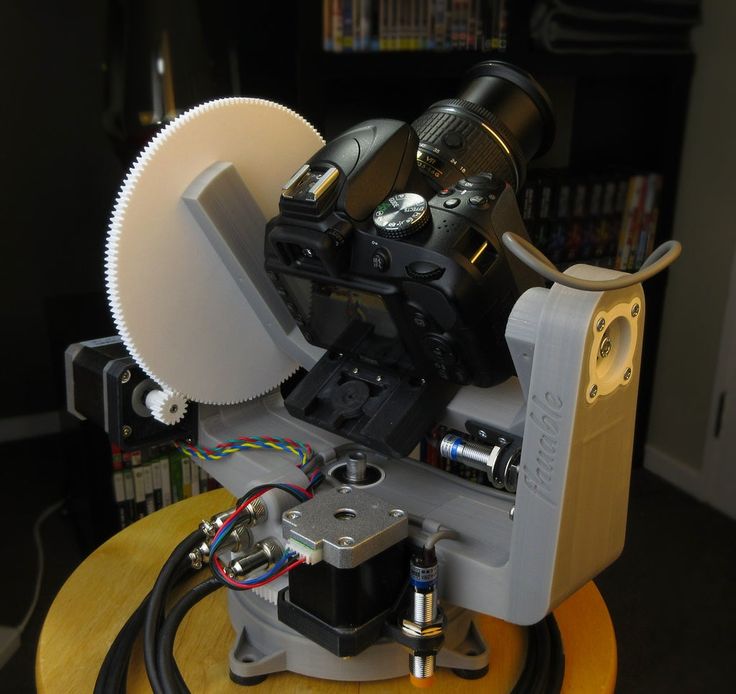

3D scanner camera

3D Scanners: What Are the Best Available Low-Cost Solutions?

Published on July 16, 2022 by Carlota V.

3D scanning is often used in the additive manufacturing (AM) sector to design a 3D model more easily than via modeling software. It captures data that is then transformed into a 3D model which can then be 3D printed. 3D scanners are based on two main technologies – laser triangulation and structured light – which will allow to obtain more or less precise details depending on the chosen device. Several affordable solutions, compared to professional scanners which are much more expensive, are available today to allow many users to bring their projects to life: whether you are a maker, a teacher or an industry leader, on of these low cost 3D scanners is bound to suit your needs! Easy to handle and transport, we have chosen some 3D scanners under $8,000 (€7,000), sorted by increasing price.

3D Scanner 2.0 from XYZprinting

Taiwanese manufacturer, XYZprinting, currently offers 5 scanners, though today we will focus on one of their more low-cost 3D scanners, the portable and high-resolution 3D Scanner 2. 0. With a wider scanning range than its younger sibling the 1.0 A, the scanner can scan objects that are 5 x 5 x 5 ~ 100 x 100 x 200 cm using an Intel® RealSense™ Camera. The scan resolution is also superior to the 1.0A, between 0.2 and 1.5 mm with an operating range ranging from 25 to 60 cm. The manufacturer also provides XYZScan Handy, a scanning and post-editing software to edit your models after scanning. The product is lightweight measuring 41 x 157 x 61 mm with a weight of 238 g. It is available from €199.

Structure Sensor from Occipital

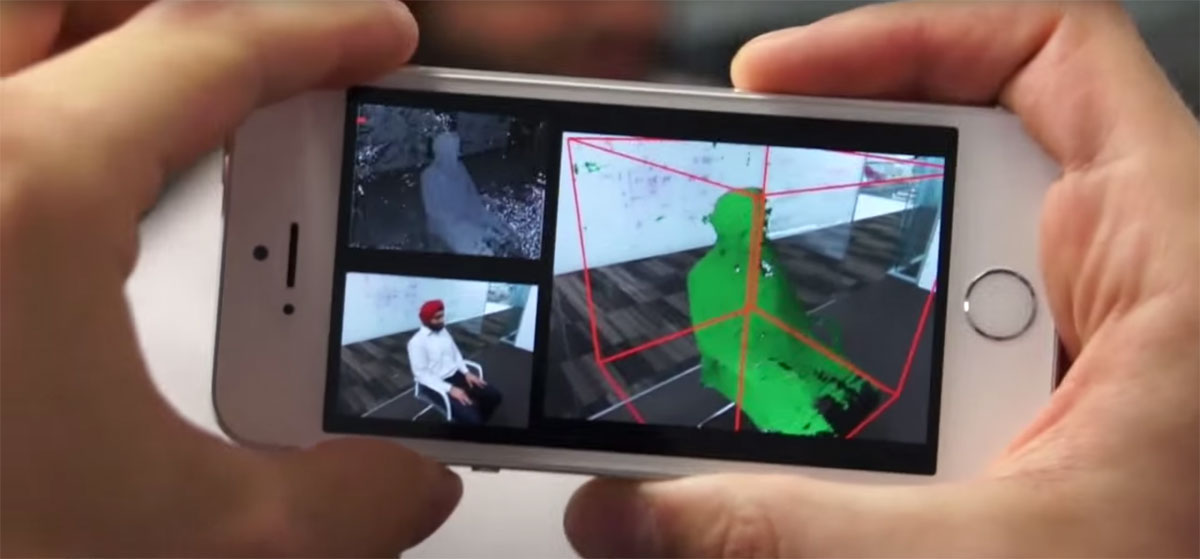

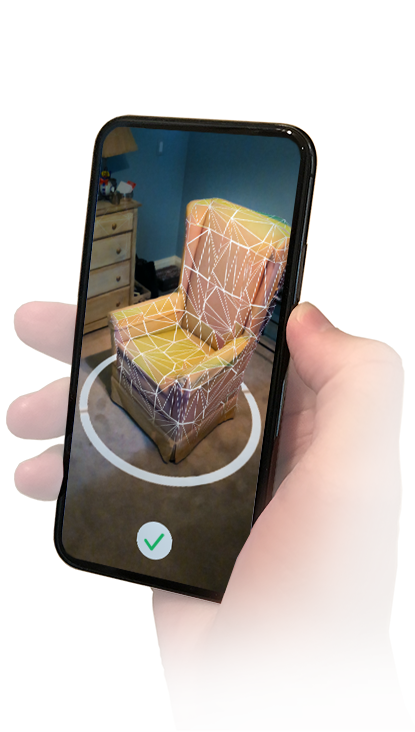

The Structure Sensor solution adds precise 3D vision to your mobile device, enabling 3D scanning among other features. The only equipment you will need for this 3D scanner to work is an iPad, then once you have downloaded the app Skanect Pro, it will work instantly.

The new version of this device is smaller than the last, 109mm x 18mm x 24mm, and weighs about 65 g. It is recommended to use it on a 0.3 m to 5m scanning range. Some other features on this device include indoor mapping and virtual reality gaming! The Structure Sensor retails for $527, making it a low-cost scanner when compared to many other options.

Some other features on this device include indoor mapping and virtual reality gaming! The Structure Sensor retails for $527, making it a low-cost scanner when compared to many other options.

POP 3D Scanner from Revopoint

The Revopoint POP is unique among 3D scanners as it has the distinction of being part of the highest crowdfunded campaign for a 3D scanner in Kickstarter, raising more than $2.28 million USD. It was developed by Revopoint, a company founded in 2014 by a group of young doctors and researchers from MIT, Kent University and other higher education institutions when they decided to focus on developing easy-to-use and cost-effective 3D scanners. It is safe to say that they certainly succeeded with their POP 3D scanner.

A binocular structured light 3D scanner that uses infrared as its light source, the Revopoint POP is a full-color scanner with an accuracy of up to 0.3mm, texture scan and an 8Fps scanning speed. It has a number of interesting features, including the fact that it is easy to use outdoors because of it’s portable and can be powered by a power bank. With a cost of the scanner of only $549 in USA and about $599 in Europe, it is one of the most affordable options on our list, all while still being an effective, precise, high-resolution scanner. Not to mention, it can be used by a variety of users, as it supports four OS platforms – Windows, Android, Mac and iOS.

With a cost of the scanner of only $549 in USA and about $599 in Europe, it is one of the most affordable options on our list, all while still being an effective, precise, high-resolution scanner. Not to mention, it can be used by a variety of users, as it supports four OS platforms – Windows, Android, Mac and iOS.

Creality CR-Scan 01

Known for its affordable desktop 3D printers, manufacturer Creality has also developed a low-cost 3D scanner, the CR-Scan 01. Weighing only 1.91 kilos, this portable scanner is easy to handle and offers a scanning area of 536 x 378 mm. You will be able to scan your objects with an accuracy of up to 0.1 mm and export them in stl or obj format. Several scanning modes are offered, either manual or on a turntable. It is currently available from 589 €.

SOL 3D Scanner from Scan Dimension

This scanner was developed by Scan Dimension, based in Denmark, and is essentially a hybrid solution. It uses a combination of laser triangulation and white light technology to 3D scan real-life objects. The SOL 3D scanner can provide a resolution of up to 0.1 mm. The 3D scanning process is automated and you can choose between a near and far scanning mode.

The SOL 3D scanner can provide a resolution of up to 0.1 mm. The 3D scanning process is automated and you can choose between a near and far scanning mode.

The SOL 3D scanner also includes software to simplify your entire workflow. In a few steps you will be sending your 3D model to your 3D printer. This is a solution meant for makers, hobbyists, educators and entrepreneurs who may not have the most experience with 3D scanners but still want to achieve great results with a relatively low cost. The SOL 3D scanner retails for $699.

V2 from Matter & Form

The Matter and Form 3D Scanner V2 is a desktop 3D scanning solution manufactured by Matter & Form, a company founded in 2013. This company has made it its mission to develop and distribute affordable, high-resolution 3D scanners. With the V2, it has achieved that mission: the 3D scanner is available from $750 and is capable of producing high-quality scans with an accuracy of up to 0.1 mm. It weighs 1.71 kilograms (3. 77 lbs) and has a height of 35.5 cm (13.5 in) and a width of 21 cm (8.25 in). The slim and foldable design allows the device to fit on small desks. The V2 allows scanning of objects with a maximum height of 25 cm (9.8 in) and a diameter of 18 cm (7.0 in). Windows and Mac scan files are supported, with multiple export options for 3D printing as well.

77 lbs) and has a height of 35.5 cm (13.5 in) and a width of 21 cm (8.25 in). The slim and foldable design allows the device to fit on small desks. The V2 allows scanning of objects with a maximum height of 25 cm (9.8 in) and a diameter of 18 cm (7.0 in). Windows and Mac scan files are supported, with multiple export options for 3D printing as well.

RangeVision NEO

The NEO 3D scanner from the manufacturer RangeVision is an entry-level device with two 2-megapixel cameras, which works using Structured Light Scanning (SLS) technology. With an automatic scan mode, the scanner is suitable for all those who have little experience in digitizing objects. The SLS-3D scanner can capture objects from 30mm to 1200mm with a precision of 0.05mm, with 3D scans created using RangeVision software. Also included is a turntable and tripod, which make scanning easier for the user. According to the manufacturer, the NEO’s scans are suitable for reverse engineering, 3D modeling, historic preservation and, of course, 3D printing. The RangeVision NEO is available from around €2,190, making it one of the few low cost desktop 3D scanners available.

The RangeVision NEO is available from around €2,190, making it one of the few low cost desktop 3D scanners available.

Calibry, the low-cost 3D scanner, from Thor3D

Thor3D is a Russian manufacturer that is behind the Calibry portable 3D scanner. Based on structured light technology, it integrates a touch screen so that the user can follow the points it captures in real time. It offers accuracy down to 0.1 mm and is capable of scanning objects from 30 cm to 10 meters long. Black and glossy surfaces can be easily scanned and exported in stl, obj, ply or WRML formats. Finally, the Calibry is fast and convenient, capable of scanning up to 3 million points per second and weighing only 900 grams. It is available from 4,990 euros.

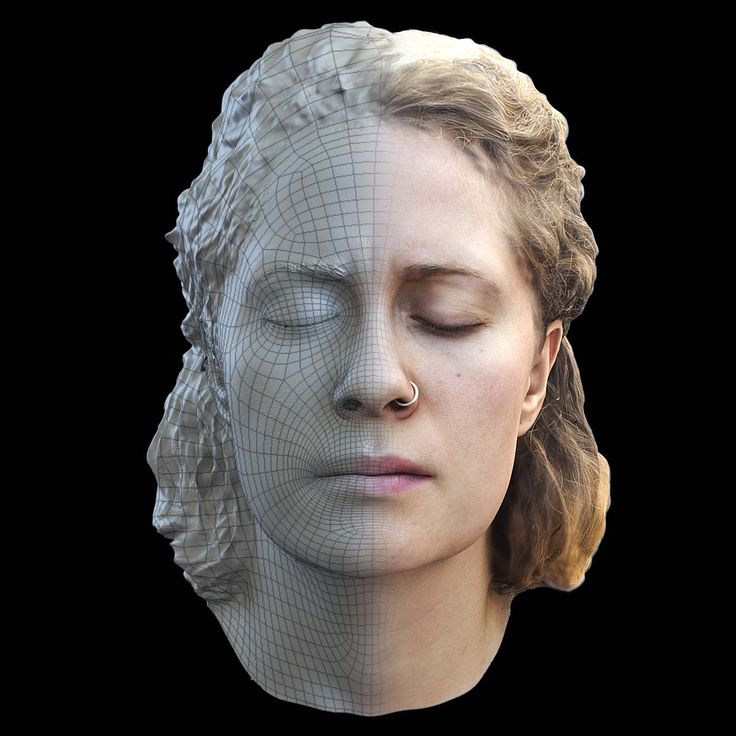

EINSCAN H from Shining 3D

The EinScan H is one of the most advanced versions of portable 3D scanners developed by the Chinese manufacturer Shining3D. Based on the hybrid structure light technology of LED and invisible infrared light, the EinScan H is able to perform human face scans more comfortably and without emitting strong light. It also incorporates a full-color camera and a large field of view for a truly impressive final quality of the models, ready for processing in just a few minutes. Its high resolution of 0.25 mm and data accuracy down to 0.05 mm make this a good choice in the market considering the price/performance ratio. In addition, it stands out for its light weight of almost 700g and intuitive user interface. The base price of this model is $5000 and you can get more information on the manufacturer’s website.

Based on the hybrid structure light technology of LED and invisible infrared light, the EinScan H is able to perform human face scans more comfortably and without emitting strong light. It also incorporates a full-color camera and a large field of view for a truly impressive final quality of the models, ready for processing in just a few minutes. Its high resolution of 0.25 mm and data accuracy down to 0.05 mm make this a good choice in the market considering the price/performance ratio. In addition, it stands out for its light weight of almost 700g and intuitive user interface. The base price of this model is $5000 and you can get more information on the manufacturer’s website.

Eva Lite from Artec 3D

Artec 3D, based in Luxembourg, offers the Eva Lite as its cheapest option for 3D scanning. This professional scanner is specialized in the digitization of complex geometries, such as the human body, and is therefore increasingly used in the medical field. It works on the basis of structured light technology and, although it does not have the ability to capture colours and textures like most scanners of the brand, it has an accuracy of 0.5 mm.

It works on the basis of structured light technology and, although it does not have the ability to capture colours and textures like most scanners of the brand, it has an accuracy of 0.5 mm.

This 3D scanner works with the software package Artec Studio. Artec Studio is a powerful tool for an optimized 3D scanning process. This software is able to perform, assemble and repair 3D scans. It is currently available at a price of $9,800. You can find more information HERE.

Any other low cost 3D printing scanners you think should be on this list? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox! For more 3Dnatives articles about 3D scanners, click HERE.

Professional 3D Scanners | Artec 3D

Handheld 3D scanners

Easily capture all angles of your object at speed

Leo

Our most comprehensive 3D scanner featuring wireless technology and an inbuilt touchscreen for instant data projection.

Space Spider

This new-generation metrological device is equipped with automatic temperature stabilization for high-precision scans.

Eva

Our most popular product, Eva is fast, versatile, and accurate.

Eva Lite

Entry-level structured light 3D scanner with geometry-only tracking and data capture.

Metrology-grade 3D scanning solutions

Capture both tiny and large objects or areas with the maximum precision. Ideal for quality assurance

Ray

Professional long-range laser 3D scanner with an inbuilt battery and sub-millimeter accuracy.

Micro

High-accuracy desktop 3D scanner for tiny parts, such as engine valves and connectors, jewelry, or dental components.

Artec Metrology Kit

A 2-micron measurement solution, ideal for inspection and reverse engineering.

Compare scanners

Find the 3D scanner best equipped for your industry or application.

How to 3D scan an object with a portable structured light scanner

When using a structured-light 3D scanner, there are certain rules and factors every professional should know.

How-Tos

Best 3D scanners — review by Artec 3D

After reviewing the top 3D scanner lists available on the Internet, we noticed that most don’t include information about the key parameters of the objects you need to scan. Important categories such as object size and the application(s) you’ll be using the scanner for are not covered. This review aims to fill this gap and help you find the best 3D solution for your project.

Reviews

How does 3D scanning technology work?

Starting out in the world of 3D scanning can be intimidating, but everything becomes clear once you take a moment to understand the technology behind it. From your own eyes (the original scanner!) to the latest 3D scanner on the market, here’s how it all works!

From your own eyes (the original scanner!) to the latest 3D scanner on the market, here’s how it all works!

Explainers

What is laser 3D scanning?

In this guide, we take a deeper look into one of the most popular 3D scanning technologies – laser 3D scanning. After reading it, you’ll be familiar with what types of scanners are referred to as “laser,” how they work, where they’re most useful, and what they are used for.

Explainers

Selecting the right 3D scanners for successful 3D printing

When it comes to 3D printing, software is often just as important as hardware. Here’s a look at which 3D scanners work best for 3D printing, and how you can get started.

Guides

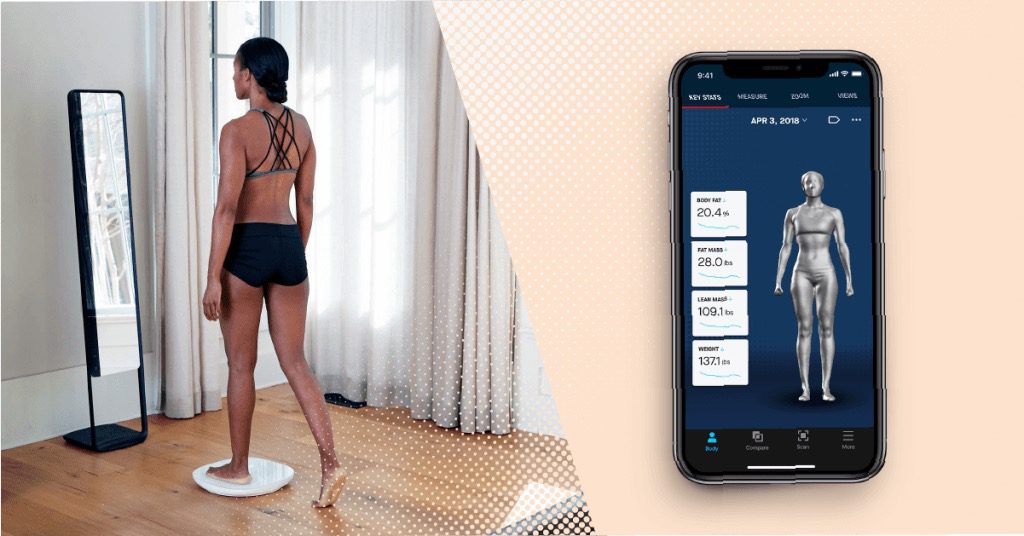

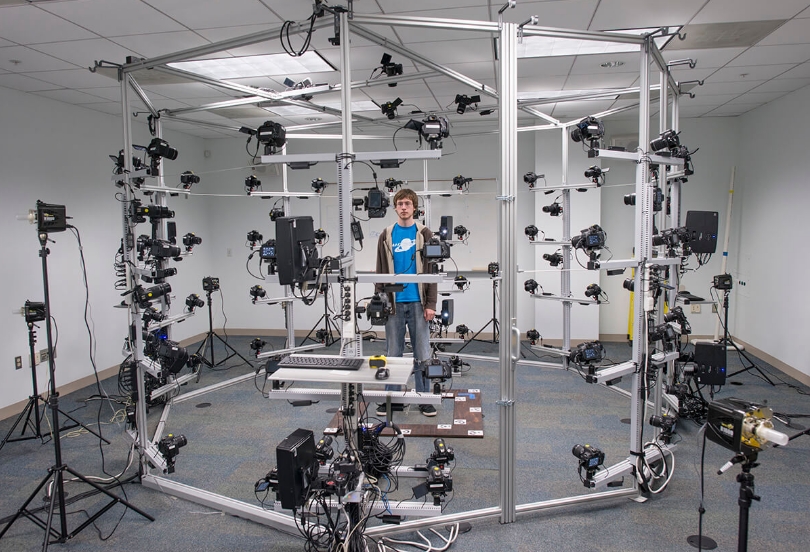

3D body scanning from A to Z

From custom prosthetics to perfectly fitted clothes, 3D printed figurines to realistic game avatars, 3D body scanners are becoming a key instrument for gaining valuable insight into the human body. In this article, we’ll cover the different types of body 3D scanners, the main challenges of capturing the human body, and look at how they are being used in medical, sports, clothing, and entertainment industries.

In this article, we’ll cover the different types of body 3D scanners, the main challenges of capturing the human body, and look at how they are being used in medical, sports, clothing, and entertainment industries.

Guides

See all materials

Case study

Building a Hellcat-powered ‘57 International Metro van with Artec Leo

Industrial design and manufacturing

Update

Artec 3D joins FEDIL association for fostering economic activity in Luxembourg

Dec. 09, 2022

09, 2022

Event

Meet Artec 3D and unbeatable 3D scanning solutions at Expo Manufactura

Feb. 07, 2023 | Cintermex (Monterrey, Nuevo León, Mexico)

Video

3D scanning a McDonnell-Douglas MD-902 helicopter with Artec Leo & Ray

Application

Overview and testing of the 3D scanner HP 3D Structured Light Scanner Pro S3 / Sudo Null IT News

Greetings.

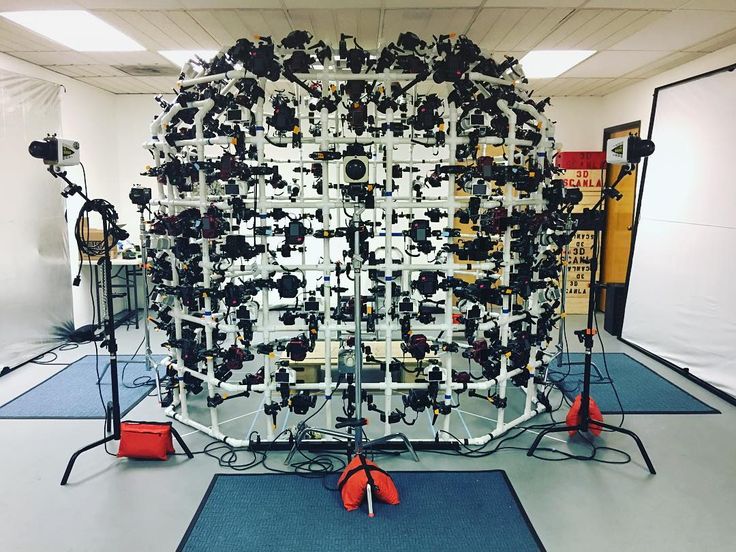

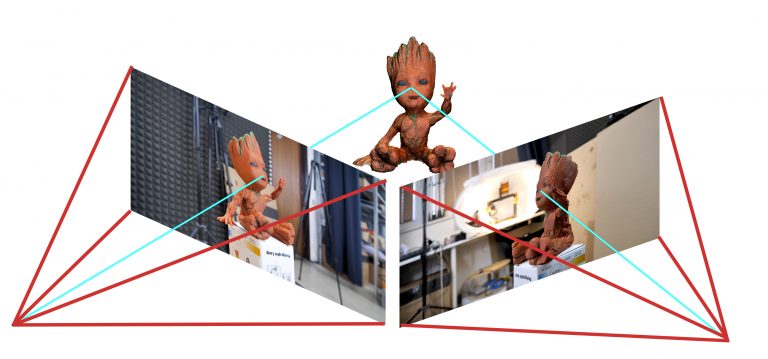

Recently, at work, I had a chance to test a 3D scanner from Hewlett Packard - HP 3D Structured Light Scanner Pro S3. Therefore, I decided to share with you my experience of using it. This scanner uses SLS structured light technology. The essence of the technology is that various template images are projected onto the scanned object using a conventional LED-DLP projector. A camera installed nearby captures the resulting distorted images. After that, a special program for these distortions evaluates the shape, depth, details of the object and recalculates all this data into a three-dimensional image. nine0005

Therefore, I decided to share with you my experience of using it. This scanner uses SLS structured light technology. The essence of the technology is that various template images are projected onto the scanned object using a conventional LED-DLP projector. A camera installed nearby captures the resulting distorted images. After that, a special program for these distortions evaluates the shape, depth, details of the object and recalculates all this data into a three-dimensional image. nine0005

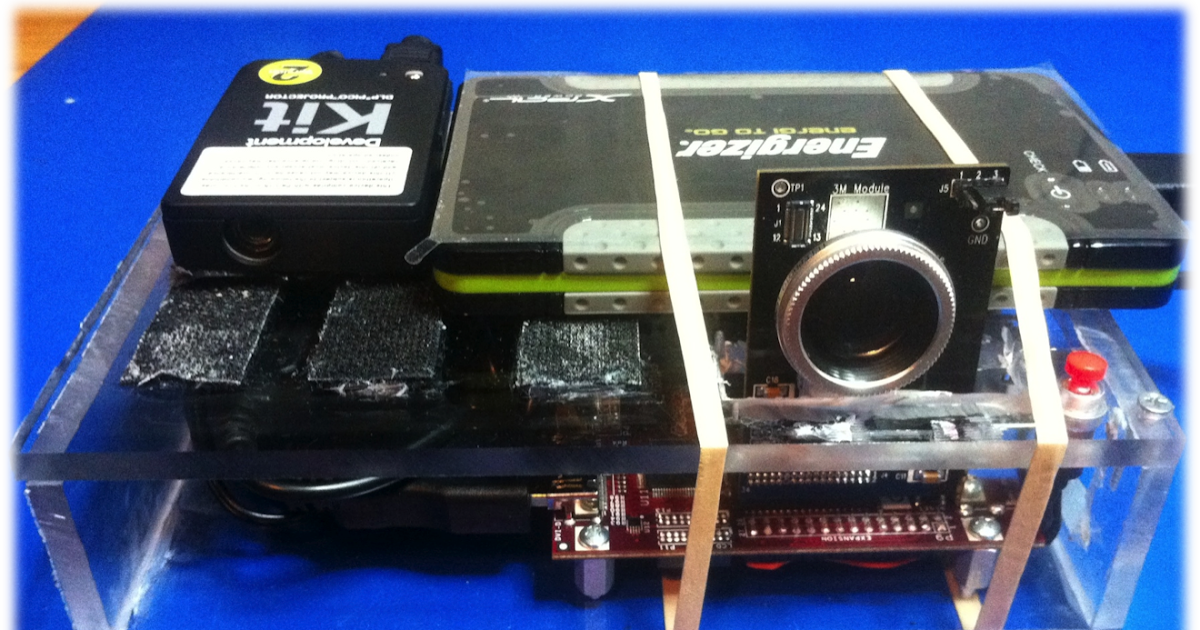

By and large, this scanner is not new and is a DAVID SLS-3 3D scanner.

Hewlett Packard bought DAVID with all their developments and now produces this scanner under its own brand. The device itself has not undergone almost any changes. The software has changed appearance, but all the main functionality remains the same.

The scanner consists of several components. The projector, oddly enough, is an Acer K132 with a resolution of 1280x800 and a brightness of 500 lumens. Camera – HP 3D HD Camera Pro 2.3MP. The camera and projector are mounted on a special slider rail. And the camera, in turn, is also fixed to a special swivel mount. A ruler is marked on the slider and there are holes for fixing the projector in different places. The degrees of rotation are marked on the swivel mount of the camera. The whole structure is mounted on a Hahnel triad 40 lite tripod. nine0003

Camera – HP 3D HD Camera Pro 2.3MP. The camera and projector are mounted on a special slider rail. And the camera, in turn, is also fixed to a special swivel mount. A ruler is marked on the slider and there are holes for fixing the projector in different places. The degrees of rotation are marked on the swivel mount of the camera. The whole structure is mounted on a Hahnel triad 40 lite tripod. nine0003

Also included in the kit are all the necessary wires for connection and a USB key-flash drive, it also contains the software. For calibration, two glass panels are used, with markers of different sizes applied to them on both sides. The panels are interconnected by flexible fasteners and are installed on special plastic corners. Additionally, for this scanner, you can buy another camera, there is also a turntable. But this instance is with one chamber and without a table. nine0003

The manufacturer promises scanning accuracy up to 50 microns (0.05% of the total object size), while the size of the model can be from 6 to 50 centimeters.

Let's move on to preparing the scanner for work. Out of the box, the camera and lens are already mounted on the rail. You just need to install all this on a tripod using a special mount. The camera is initially installed to the left of the projector. This option is suitable for scanning objects up to 350mm. In case you need to scan an object larger than 350mm, the camera must be installed to the right of the projector. To do this, unscrew the lamb of the projector mount and rotate it 180 degrees. After that, unscrew the restrictive bolt from the edge of the guide, unscrew the lamb of the camera mount, remove the camera from the guide, also turn it 180 degrees and fix everything back. The distance from the camera to the projector and the angle of its rotation depends on the size and type of the object being scanned, we will adjust them before calibration. nine0005 Next, you need to connect the projector to the power supply and to the computer using an HDMI cable. The camera is connected to a computer with a USB 3. 0 cable and is powered by it. We turn on the projector, in the operating system you need to configure it as a second monitor. After that, you need to install the software. You can do this from the USB flash drive that comes with the kit, or download from the HP website. With a full installation, all the necessary drivers will be installed automatically. The projector should display a table with horizontal and vertical lines. nine0003

0 cable and is powered by it. We turn on the projector, in the operating system you need to configure it as a second monitor. After that, you need to install the software. You can do this from the USB flash drive that comes with the kit, or download from the HP website. With a full installation, all the necessary drivers will be installed automatically. The projector should display a table with horizontal and vertical lines. nine0003

And so, we launch the installed HP 3D Scan program. The recommended system requirements for it are not very high: a dual-core 2GHz processor, 8GB of RAM and an Nvidia or AMD video card. But, of course, the more powerful the computer, the faster the processing will be.

In the first tab, Settings, you need to select the type of scanner, in our case it is HP 3D Structured Light Scanner Pro S3. Projector - Acer K132. And turn on the camera, we have it HP 3D 2.3MP Cam PRO. On the right there is an exposure setting (or rather shutter speed), as a rule, it should be set to 1/60 so that there is no flicker. And the brightness, it is better to always keep it at the maximum. nine0005 It is desirable to choose objects for scanning without transparent or reflective surfaces. It is also not desirable that the object be very dark or black. Black absorbs light, making the projected image very hard to see on the camera. If the object does not meet these conditions, it is necessary to cover it with a special matting spray. The background when scanning is vice versa, it is better to use black, then there will be no need to remove it. If this is not possible, the program can automatically remove the background, but more on that later. nine0003

And the brightness, it is better to always keep it at the maximum. nine0005 It is desirable to choose objects for scanning without transparent or reflective surfaces. It is also not desirable that the object be very dark or black. Black absorbs light, making the projected image very hard to see on the camera. If the object does not meet these conditions, it is necessary to cover it with a special matting spray. The background when scanning is vice versa, it is better to use black, then there will be no need to remove it. If this is not possible, the program can automatically remove the background, but more on that later. nine0003

For the first test, I chose a rather difficult object to scan, such an elephant. It has a difficult terrain in some places, protruding elements, and besides, it is quite dark, which makes scanning even more difficult.

The projector and camera need to be set up. We expose the projector in such a way that the image falls on the entire object and is slightly larger than it. Keep in mind that during the scanning process, the object will need to be rotated, and it is desirable that it be highlighted in any position. Now you need to focus the projector, this is done using the adjustment lever on the top of the projector. The point of intersection of the center lines of the projected image must be clearly focused on the object being scanned. nine0003

Keep in mind that during the scanning process, the object will need to be rotated, and it is desirable that it be highlighted in any position. Now you need to focus the projector, this is done using the adjustment lever on the top of the projector. The point of intersection of the center lines of the projected image must be clearly focused on the object being scanned. nine0003

Go to the camera. The angle of rotation is used from 20 to 30 degrees. As a rule, the optimal angle is considered to be 22 degrees. When scanning large objects or objects with deep holes, it may be necessary to decrease the angle, but distortion and noise may occur with an angle of less than 20 degrees. For flat objects, it is better to use an angle greater than 22 degrees, up to 30. In our case, the standard 22 degrees is fine. Now you need to set the camera relative to the projector. We loosen the lamb of its fastening and move it along the guide so that the projected image and the scanned object get into the lens. nine0003

nine0003

There are two adjustment rings on the camera lens. Closer to the edge is the focus ring, followed by aperture. Both rings have fixing bolts. The aperture should be set in such a way that the scanned object is neither overexposed nor too dark. So that the projected image can be seen on it.

The focus should be such that the intersection of the center lines is clear. For convenience, you can zoom in on the image in the program using the mouse wheel. The fixing bolts must be tightened so that the settings do not go astray. nine0003

The scanner can now be calibrated. There are 4 blocks of dots of different sizes on the calibration panels, three on one side and one largest on the other. You need to calibrate the scanner by the block that is slightly larger in size than the object being scanned. For example, for this elephant, the third block, penultimate in size, should fit. The second block is already too small for him, and the largest one is already too large.

Install the calibration panels so that the required block is folded inwards. nine0003

We install the scanner in front of them at a distance corresponding to the distance to the object being scanned, the picture from the projector and the image from the camera should be as clear as possible. The frame should contain from 15 to 70 points of the selected block. In the "calibration scaling" field, you need to specify the block size, it is indicated near the vertical line, next to each block. For the third block - this is 120mm. Click on the calibration button. The projector will display several patterns in turn. And if everything was set correctly, a checkered black and white picture like a chessboard will be shown. nine0003

After calibration, the entire structure can be moved and tilted, but the distance of the camera from the projector, its rotation angle and focus cannot be changed. The manufacturer claims that the aperture cannot be changed either. But empirically it turned out that when scanning dark objects, sometimes this has to be done. Since if the template is visible on the model, it will be overexposed on the calibration panels. Conversely, if everything is visible on the panels, the template will be too dark on the model. So this time, for this elephant, the aperture had to be slightly opened during scanning, after calibration. nine0003

Since if the template is visible on the model, it will be overexposed on the calibration panels. Conversely, if everything is visible on the panels, the template will be too dark on the model. So this time, for this elephant, the aperture had to be slightly opened during scanning, after calibration. nine0003

You can proceed to scanning. In the “template parameters” item, you can select the number of templates that will be projected onto the model in one scan, the more there are, the better the quality of the resulting scan will be.

There are 4 options: Quality, Default, Speed and Custom. There are quite a lot of folds and other small elements on the elephant, so we will choose “Quality” for it, these are 62 templates.

There are also 4 scanning modes. Single scan - can be useful if you are scanning an object from one side, for example, to obtain a relief. Manual scan sequence – scanning an object several times from different sides, turning it yourself. nine0003

nine0003

Automatic turntable – speaks for itself. And background scan - to use this function, you need to remove the object of scanning, scan only the background. Then, during further scanning, the program will be able to automatically remove it from all scans. We will rotate the elephant manually on a black background, therefore it is not necessary to scan the background, but we will choose the mode - manual sequence.

Next, you need to choose how the object moves. Free movement, horizontal rotations or manual turntable. For this and most situations, free movement is fine. nine0003

Automatically register texture - with this function the scanner will capture not only the relief, but also the colors of the object with textures. This way you will get a full color 3D model. This can be useful not only for beauty, but also will help the program in the future when comparing scans. But the scanning and processing time will increase slightly.

Below, in the "scan result" field, you can configure the smoothing parameters, checking the validity of fixed points, filtering and deleting parts that are smaller than the largest solid part. The manufacturer recommends not changing these parameters unless necessary. And then you can turn on the checkbox - Remove background. If the background was previously scanned, it will automatically be set. nine0003

The manufacturer recommends not changing these parameters unless necessary. And then you can turn on the checkbox - Remove background. If the background was previously scanned, it will automatically be set. nine0003

Let's proceed directly to scanning. You can manually click on the scan button (or hotkey F5), rotate the object, and then click the button again. Or you can check the "Auto next scan" box, then the program will count a few seconds before automatically making the next scan. Moreover, if you move the object at this moment, the counter will automatically reset. Thus, the next scan will be made only when the object is stationary. nine0003

For this elephant, we will not scan the textures and set the next scan to automatic, so that you do not have to press the button every time. We direct the projector at the object so that the template fully illuminates it. And press the scan button. After each scan, we rotate the model a little so that the scans have enough common elements for subsequent comparison. And so a full circle. The manufacturer recommends taking 6-8 shots, but the more shots there are, the easier it will be for the program to match the scans and the more details it will capture. nine0003

And so a full circle. The manufacturer recommends taking 6-8 shots, but the more shots there are, the easier it will be for the program to match the scans and the more details it will capture. nine0003

After one full circle, you can raise the scanner on a tripod, tilt it from top to bottom and scan the object from a different angle to capture horizontal planes that were not in the frame.

The same can be done from below. If it is not possible to raise the scanner high or low enough, the object can be turned over by itself.

When scans have been made in all possible positions, you can click on the “end sequence” button. The program will automatically try to match all scans with each other. In most cases, scans match well, provided they have enough common shapes. If any extra fixed elements get into the camera lens, they can interfere with the comparison. Then, before clicking the “complete sequence” button, you need to go to the “merge forms” tab. In the clearing block, you can choose the selection method. nine0003

nine0003

Select unnecessary objects and delete them by pressing the button with a cross in the same block, or by pressing the DEL hot key. And after that, return to the scanning tab and complete the sequence.

If automatic matching does not work properly, scans can be manually matched in pairs. To do this, in the "merge forms" tab in the "alignment" block, select "arbitrary".

Select two scans with common shapes, they will be matched automatically. In order not to display all the scans at once, you can click on the eye icon in the list of scans at the top. And click on the same icon next to the desired scans so that they are displayed. nine0005 If such a comparison did not work, you can check the "selection of a contact pair" checkbox.

This will allow you to manually mark the same elements on each scan, by which the program will navigate. You can enable "use texture" if the scan was done with textures. And also “use surface elements”, this will also improve the comparison, but also increase the processing time. Already aligned scans can be combined into groups, then when combined with the next scan, the program will use the group as one whole scan. nine0003

Already aligned scans can be combined into groups, then when combined with the next scan, the program will use the group as one whole scan. nine0003

After this manual matching, you need to select the "global high-precision matching" alignment. The program will neatly and accurately fit previously aligned scans. Before high-precision alignment, it is desirable to divide the scans combined into groups back.

If some areas of the scanned object are not visible on the scans, you can always make a few more scans from the desired sides.

As a result, about 30 scans were made for this elephant from different sides, top and bottom. But keep in mind that this object is quite complex and dark. The camera was far from always able to see and evenly fix the surfaces. But as a result, it turned out to assemble a whole elephant from scans. The scan took about 20 minutes. nine0003

At this stage, this is a point cloud. Now you can assemble it into a full-fledged 3D model - mesh. To do this, we will use the "merge" block. There are 3 settings, resolution, sharpness and close holes. Resolution marks the quality of the final model, increasing this parameter greatly affects the processing time and the use of computer resources. Sharpness is responsible for smoothing. Reducing this parameter will make the model blurry and hide flaws. An increase, on the contrary, will make a clear model, but the shortcomings will become more noticeable. nine0005 The closure of the holes speaks for itself.

To do this, we will use the "merge" block. There are 3 settings, resolution, sharpness and close holes. Resolution marks the quality of the final model, increasing this parameter greatly affects the processing time and the use of computer resources. Sharpness is responsible for smoothing. Reducing this parameter will make the model blurry and hide flaws. An increase, on the contrary, will make a clear model, but the shortcomings will become more noticeable. nine0005 The closure of the holes speaks for itself.

In most situations, the standard settings are sufficient. This is how the elephant ended up with the default settings. You can export the model in several formats - STL, OBJ, PLY and 3MF

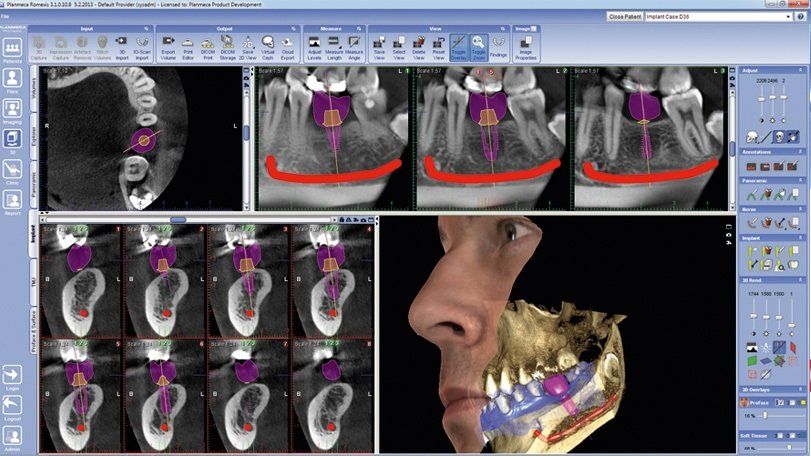

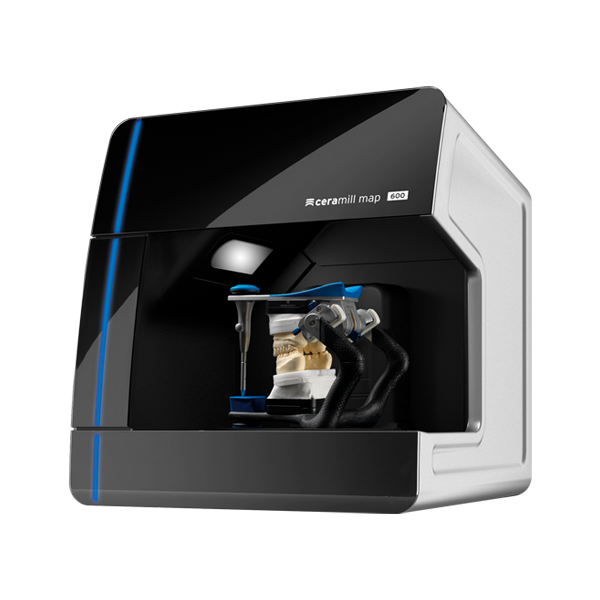

For the second test, I tried to scan a smaller object. Here is a dental impression printed on an SLA printer.

Dimensions are only 7.5x5x3 cm, which is almost the minimum for this scanner. nine0005 Of course, there is no special point in scanning what has already been printed, but for an example it will do. The result was a pleasant surprise, the quality was very good. Detailing is top notch. The scanner was able to see even the slightest transitions between layers, and printing flaws. Even though they are quite difficult to see with your eyes.

The result was a pleasant surprise, the quality was very good. Detailing is top notch. The scanner was able to see even the slightest transitions between layers, and printing flaws. Even though they are quite difficult to see with your eyes.

It is worth noting that the scanner perceives color changes on the scanned object as small changes in the relief. So, for example, there are several light scratches on these teeth. And on the final model, they look like protruding stripes. But all these shortcomings can be easily corrected with further post-processing, for example, in Meshmixer. Unfortunately, no 3D scanner gives a perfect result that does not require post-processing. nine0003

Only 10 scans were needed for this test, 8 from one angle, one a little higher and one a little lower.

When scanning, especially for such small objects, the scanner is very sensitive to vibrations. Roughly speaking, even a printing printer standing a meter away from it can create sufficient vibrations, due to which waves are obtained on scans. Walking near the scanner at the time of scanning is generally contraindicated. Despite the fact that the tripod seems to be strong and reliable, the heavy part with the projector and camera is very sensitive to any vibrations. Due to the fact that our specimen does not have a turntable, we had to turn these teeth very carefully during scanning, without making sudden movements and almost without breathing. nine0003

Walking near the scanner at the time of scanning is generally contraindicated. Despite the fact that the tripod seems to be strong and reliable, the heavy part with the projector and camera is very sensitive to any vibrations. Due to the fact that our specimen does not have a turntable, we had to turn these teeth very carefully during scanning, without making sudden movements and almost without breathing. nine0003

In any case, the result of this test is very good. Considering that it took very few scans, they were matched automatically without any problems. Glued into the model quickly. In total, this scan took no more than 10-15 minutes.

And the third test I did was with a larger part. This is a part of the intake manifold, also printed on an SLA printer, it was not possible to get a real part.

Its width is 34 centimeters, not the maximum for this scanner, but quite large. The detail is difficult to scan, has many thin elements, recesses and holes. It was really hard to scan it. Despite the fact that the turntable in this situation would not help. The part had to be twisted, turned over at different angles, and shown to the scanner from all sides. There was no black background of this size, so I had to scan on white. As we already mentioned, you can make the background automatically removed from the scans. To do this, you need to scan it without a model at the very beginning. The background is removed, but not always completely, small areas remain at a short distance from the model. They can be deleted without problems, but because of this time, the scan takes much longer. When scanning large objects, the accuracy is slightly reduced, since the projector and camera have to be placed at a greater distance and it is no longer possible to accurately fix small elements. But it turned out that after scanning the entire model and obtaining the general forms. You can always recalibrate the scanner with a smaller scale of the calibration panels pattern, scan individual areas closer and combine them with previously obtained scans.

Despite the fact that the turntable in this situation would not help. The part had to be twisted, turned over at different angles, and shown to the scanner from all sides. There was no black background of this size, so I had to scan on white. As we already mentioned, you can make the background automatically removed from the scans. To do this, you need to scan it without a model at the very beginning. The background is removed, but not always completely, small areas remain at a short distance from the model. They can be deleted without problems, but because of this time, the scan takes much longer. When scanning large objects, the accuracy is slightly reduced, since the projector and camera have to be placed at a greater distance and it is no longer possible to accurately fix small elements. But it turned out that after scanning the entire model and obtaining the general forms. You can always recalibrate the scanner with a smaller scale of the calibration panels pattern, scan individual areas closer and combine them with previously obtained scans. I was pleasantly surprised that even with such manipulations, all sizes are transmitted correctly and without distortion. The scans obtained after recalibration matched the original ones without any problems. nine0003

I was pleasantly surprised that even with such manipulations, all sizes are transmitted correctly and without distortion. The scans obtained after recalibration matched the original ones without any problems. nine0003

The result is, of course, not ideal. But worthy, given the complexity of the detail. In some places it was not possible to crawl with a scanner, their program finished drawing as best it could. It took a lot of time for scanning and processing, no matter how you lie, a total of 2-2.5 hours.

And finally, I scanned some more small objects with textures to show you how the scanner can capture colors and patterns. There is not much to tell about them, it was not difficult to scan them. So here are just a few photos. nine0003

What can be said in the end. The scanner can hardly be called easy to use. You need to understand the principles of its operation and the specifics of its use in different situations. Black, transparent and shiny objects need to be coated with a frosting spray, but this must be done with almost any 3D scanner. The software has great features and performs its functions quite well. But, as with the scanner itself, it requires certain skills, understanding of the capabilities and principles of operation. nine0003

Black, transparent and shiny objects need to be coated with a frosting spray, but this must be done with almost any 3D scanner. The software has great features and performs its functions quite well. But, as with the scanner itself, it requires certain skills, understanding of the capabilities and principles of operation. nine0003

I was pleasantly surprised by the quality when scanning small objects and the ability to additionally scan separate detailed areas for larger objects.

With proper skill, you can get very high quality 3D models with this scanner.

Wunder360 S1 Panoramic Camera with 3D Scanning Function

Wunder360 S1 is a multifunctional 360 degree camera with compact dimensions, user-friendly control system and automatic stitching. With all the benefits of a high-quality panoramic camera, Wunder360 S1 also offers a unique 3D scanning function in just a few clicks, which even a beginner in the field of VR content creation can master. Additional benefits are provided by advanced image stabilization technology and an intelligent frame tracking system, thanks to which the filmed movie will always be centered as the operator intended. In addition, the Wunder360 S1 comes with a waterproof housing for underwater shooting and is complemented by an advanced cloud service. nine0003

In addition, the Wunder360 S1 comes with a waterproof housing for underwater shooting and is complemented by an advanced cloud service. nine0003

Features

- 3D Scan

- Intelligent Object Tracking

- Super Smooth Stabilization

- IP68 watertight housing up to 30 meters

Specifications

| Number of lenses and angle of view | 2 spherical (360 by 360 degrees) |

| Diaphragm | f/2.4 |

| Sensor type | CMOS, 8MP |

| Photography resolution | 4096×2048 |

| Movie resolution | 3040×1520 at 30 fps 2176×1080 at 60 fps |

| Live function | Yes |

| Stabilization | Yes, 9-axle |

| Information display | Yes, 64×32 pixels |

| >Available settings | Exposure, white balance |

| Stitch type | Auto stitching in camera |

| Battery | 1200 mAh, autonomy - up to 2. 5 hours 5 hours |

| Memory | MicroSD cards |

Compact design

The Wunder360 S1 is a compact device that fits easily into a jacket pocket: at 74×50×35 mm, the camera weighs only 98 grams. The ergonomic body is devoid of sharp corners, and the optimal location of the control interface makes it easier to work with the device when you frequently turn on / off the shooting. The battery is installed in a tightly closed compartment, there is a small information display on the camera body, and the bottom edge is equipped with a standard connector for fixing the gadget on a tripod or any other mounting device. nine0003

Affordable 3D Scanner

3D is the content format of the future and S1 makes it accessible to everyone. Thanks to a convenient control system and ease of use of the 3D scanner function, Wunder360 S1 allows you to digitize not only interiors (like most competing cameras), but also individual objects, creating high-quality content for further viewing in VR headsets or processing in graphic editors. Great find for designers!

Great find for designers!

The Wunder360 S1 3D scanner uses a unique technology based on SLAM computer vision and AI deep learning algorithm. As a result, the S1 is able to create a depth map from just one 360-degree frame, which will then be processed by the 3D rendering engine embedded in the camera's graphics chip. After processing the data, the camera will generate ready-made 3D models or virtual tours for viewing in VR. nine0003

Original photo

Depth mapping

Intelligent Tracking System

Next Generation Image Stabilization

9-Axis Electronic Image Stabilization (EIS) is the highlight of the S1 under360. Videos have never looked so smooth and focused without the use of an external steadicam. The built-in EIS algorithm analyzes each captured frame in real time, forming the final image with the maximum level of stabilization for devices in the lower price range. nine0003

nine0003

Real-time stitching

The Wunder360 S1 is capable of shooting videos in two formats: 3K at 30 fps and 2K at 60 fps. In both cases, the camera stitches content automatically using the CEVA-XM4 processor, eliminating the need for mandatory post-production before exporting to Facebook or YouTube.

Phantom clips

How it works

Cloud service

Wunder360 S1 functionality offers access to its own cloud service with a convenient 3D content sharing system. With it you can:

- Create a complete virtual tour for VR headsets

- Create a high density 3D model for third-party export

- Convert 3D content to minecraft model