3D printer rank

Prusa MK3S+ 3D Printer Review: The Heavyweight Champ Continues to Dominate

Tom's Hardware Verdict

The Prusa MK3S+ continues to hold its own in a market saturated with low-cost competitors.

Pros

- +

+ PrusaSlicer provides best-in-class model slicing

- +

+ Flexible build platform sets the standard

- +

+ Automatic bed leveling

- +

+ Stealth Mode enables a nearly silent printing experience

Why you can trust Tom's Hardware Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

There are few 3D printers with as many industry accolades as the Prusa i3 MK3S+, and after spending some time with this printer, it’s easy to see why it’s one of the best 3D printers currently on the market. With a price tag of $999 for an assembled machine or $750 for a DIY kit, the price point of the MK3S+ is towards the high end for an open format consumer 3D printer, but the features of this machine and the ecosystem created by Prusa (they make their own hardware, software, filament, and more) have made the MK3S+ a formidable machine for anyone interested in taking their 3D printing game to the next level.

The features of the MK3S+ (silent stepper drivers, power-panic, etc.), noteworthy when originally launched, have largely become standard on lower-cost machines and may not seem particularly impressive on a spec sheet. However, clever software implementation and well-written documentation have created a machine that provides a best-in-class printing experience. For instance, the auto-leveling SuperPINDA probe of the MK3S+ maps the build platform for surface distortions, but the printer firmware is capable of storing multiple Z-offsets so you can switch build platforms without having to recalibrate every time.

The MK3S+ is a visually distinct machine; and the Prusa team has kept their black and orange color scheme for their smaller printer, the Prusa Mini+. The bright orange printed parts on the MK3S+ have created instant brand-recognition for the Prusa line of printers, and Prusa has doubled down on this by reinforcing their branding across their machine. In fact, you can find the word ‘Prusa’ printed, engraved, or etched into the MK3S+ in 25 places, 29 if you’re using a spool of their Prusa Polymers Prusament PLA material.

Specifications

Swipe to scroll horizontally

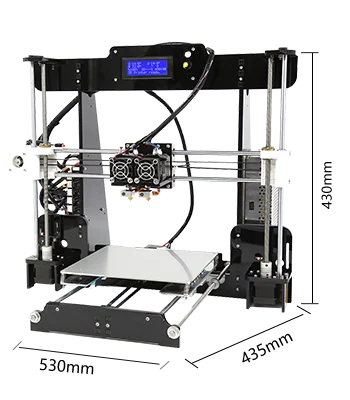

| Machine Footprint | 16.5 x 16.5 x 15 inches (42.0cm x 42.0cm x 38.0cm) |

| Build Volume | 9.84 x 8.3 x 8.3 inches (250mm x 210mm x 210mm) |

| Material | 1.75mm PLA, ABS, ASA, PETG |

| Extruder Type | Direct Drive |

| Nozzle | .4mm |

| Build Platform | Magnetic Heatbed with removable PEI spring steel sheets |

| Power Supply | 240 Watts |

| Connectivity | USB, SD Card |

| Interface | 3.4-inch Mono LCD and click wheel |

| Filament Run-Out Sensor | Yes |

Included with Prusa MK3S+

The fully assembled Prusa MK3S+ ships with all of the accessories required to make your first print, and also includes enough spare parts to replace almost every fastener on the machine. The fully assembled MK3S+ also includes a bag of Haribo Goldbears, a signature addition from the Prusa team.

The fully assembled MK3S+ also includes a bag of Haribo Goldbears, a signature addition from the Prusa team.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Prusa MK3S+ includes a full spool of silver PLA material, screwdriver, a metal part scraper, a glue stick (for adhesion), an isopropyl alcohol wipe, lubricant for the linear rails, power and USB cables, a sheet of stickers, a printed handbook, and a diagnostic printout that confirms the functionality of the mechanical and electrical systems.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The usefulness of the handbook is hard to overstate. When you’re starting out with your first 3D printer, it can be difficult to pinpoint the cause of problems such as loss-of-extrusion, poor layer adhesion, or a clogged extruder. The included handbook is full of detailed photographs, troubleshooting workflows, and solutions to common problems. This is an invaluable resource for beginners, amateurs, and experts alike, and it’s clear to me that Prusa has set the standard for technical documentation.

Setting up the Prusa MK3S+

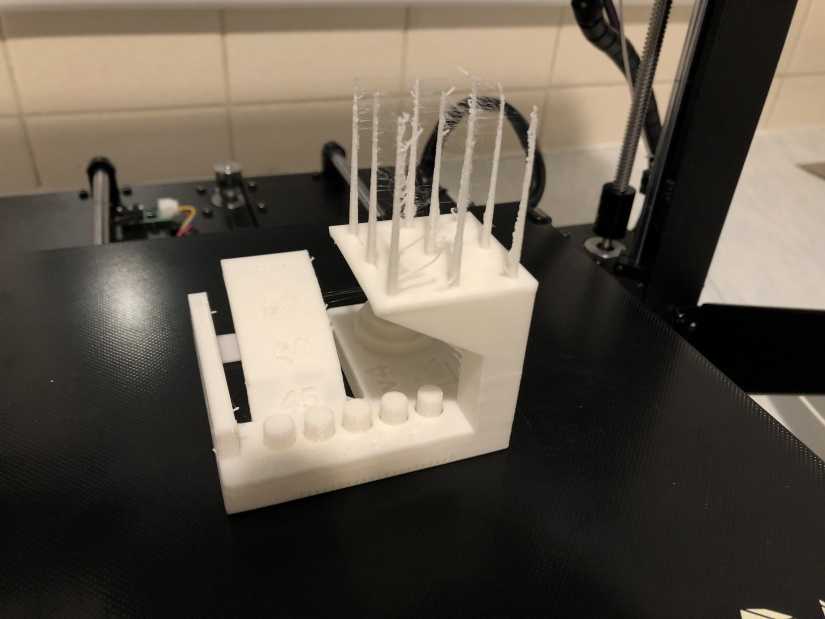

(Image credit: Tom's Hardware)The Prusa MK3S+ ships with a completed print attached to the build platform. This print features a serpentine line with 90 degree angles, curves, and a solid block in the center with the Prusa logo facing upwards. This print serves to confirm that the printer is functional and has been properly assembled and calibrated. I was able to easily remove the print from the build platform by bending the steel sheet and carefully removing it.

(Image credit: Tom's Hardware)After powering on, the printer automatically runs through an initial setup process. This process involves calibrating the Z axis by running it all the way to the top of the printer, running the mesh bed leveling process to set the Z offsets, and loading the filament. This entire process only took me a few minutes, and the high level of automation involved means that the only thing I needed to do was insert the filament into the extruder after it had heated up.

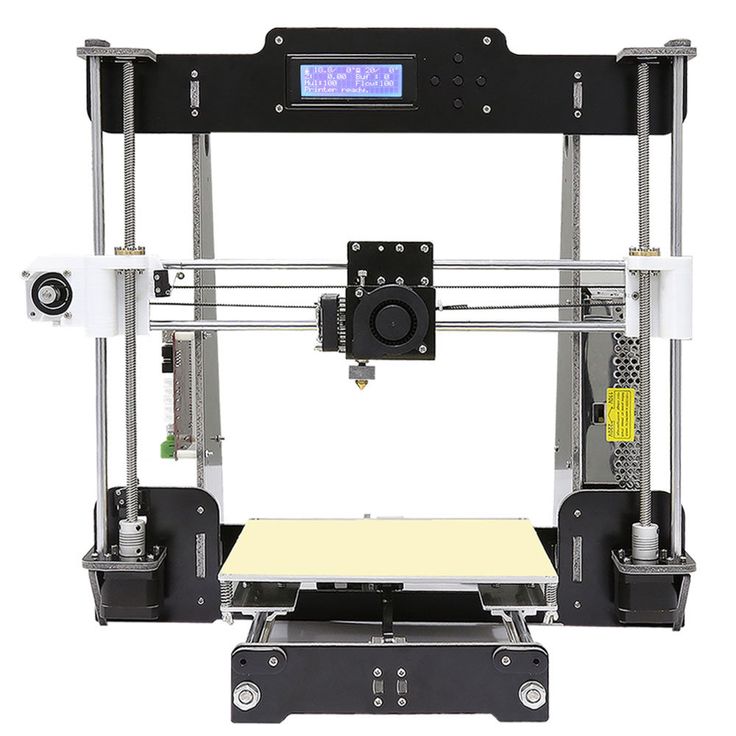

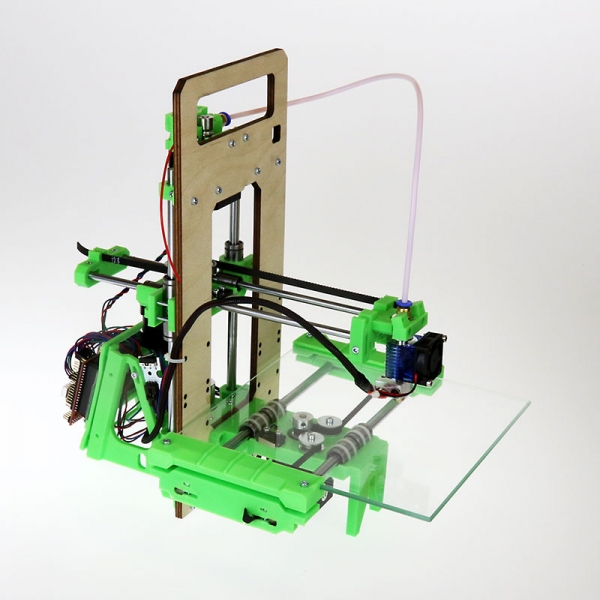

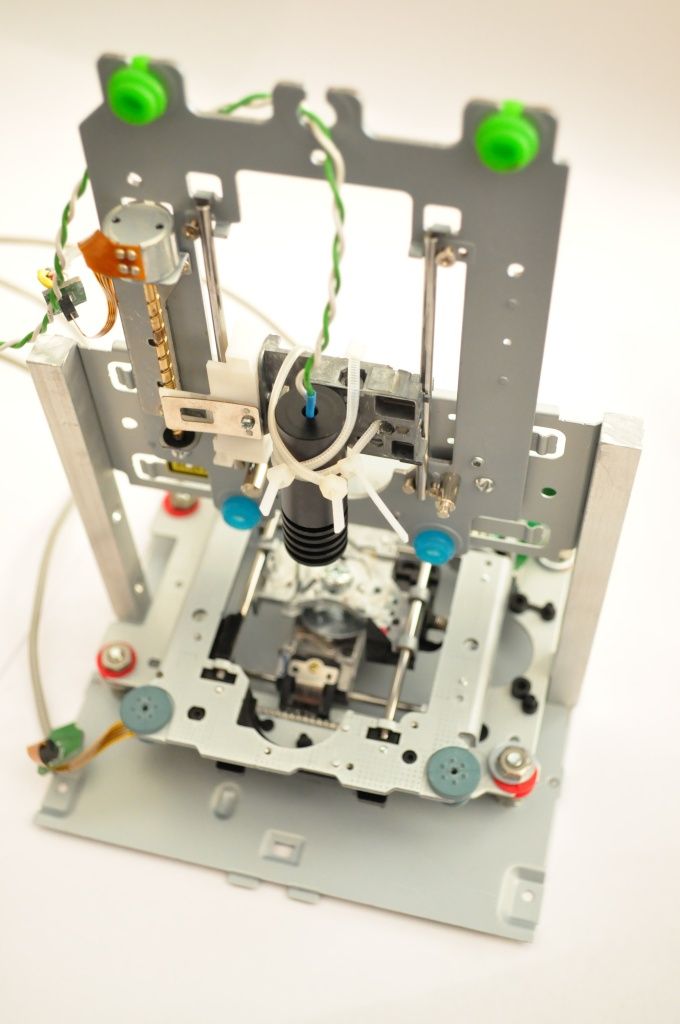

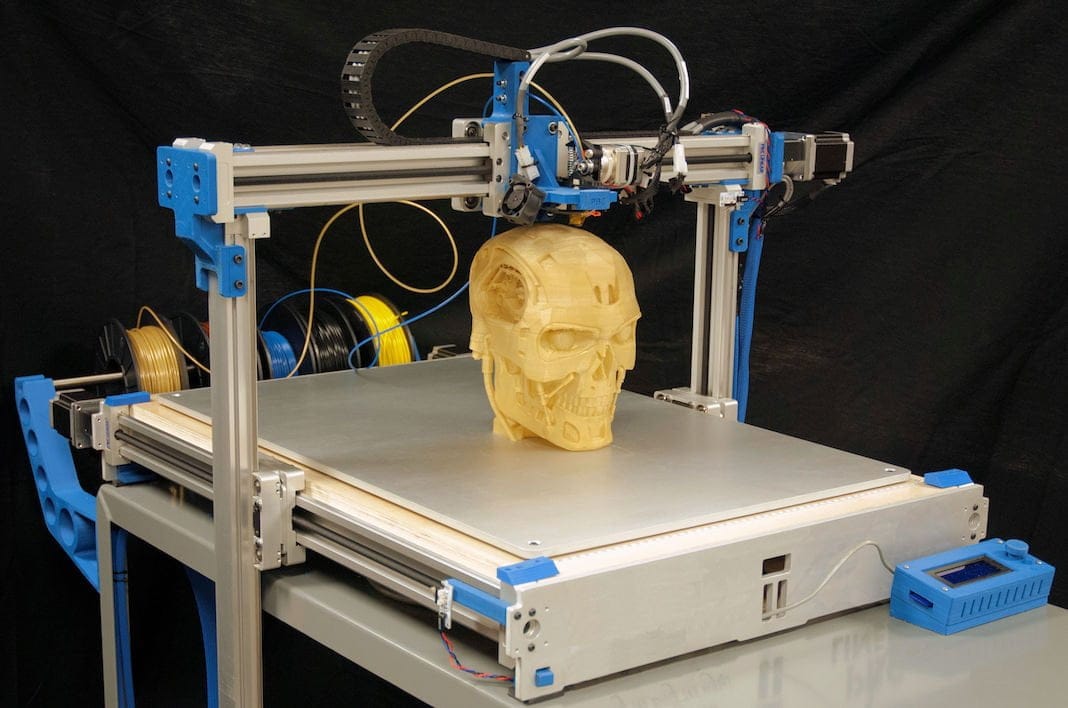

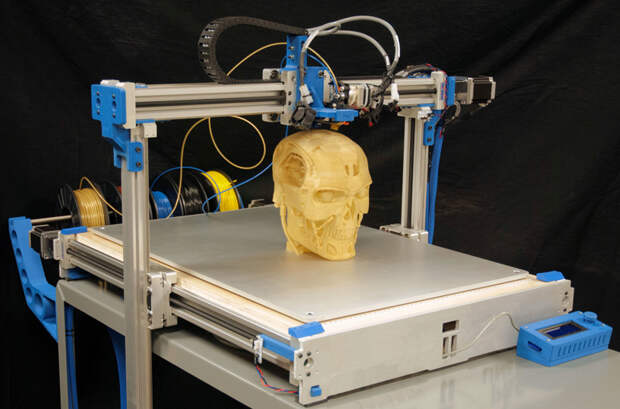

You might be surprised to find that the Prusa MK3S+ is based on the RepRap i3 (third iteration) frame, originally released in September of 2012. Despite this nearly decade-old release date, the MK3S+ is full of modern advancements and enough innovative features to still be a top contender in the prosumer 3D printer market.

Image 1 of 2

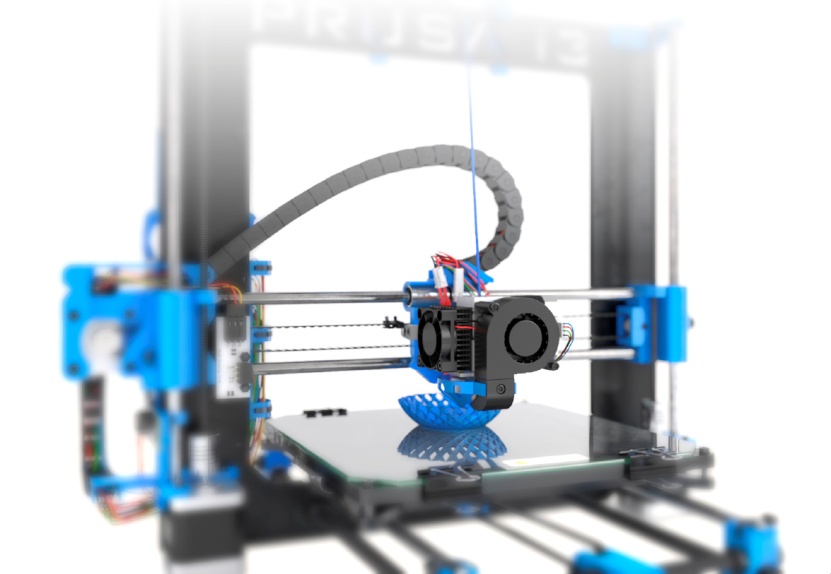

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The bright orange color makes the 3D printed parts on the MK3S+ easy to spot. The brackets mounted to the printer are printed in-house by Prusa using their own Prusament PETG filament. These brackets are robust and sturdy, and the uniform appearance between the printed parts give the printer a professional appearance. This version of the MK3S+ shipped with orange printed brackets, but the printer is also available in an all-black variant. A large selling point of the MK3S+ is the open-source nature of the machine, which means the printed parts are all available to download if you want to download, modify, or print them out yourself.

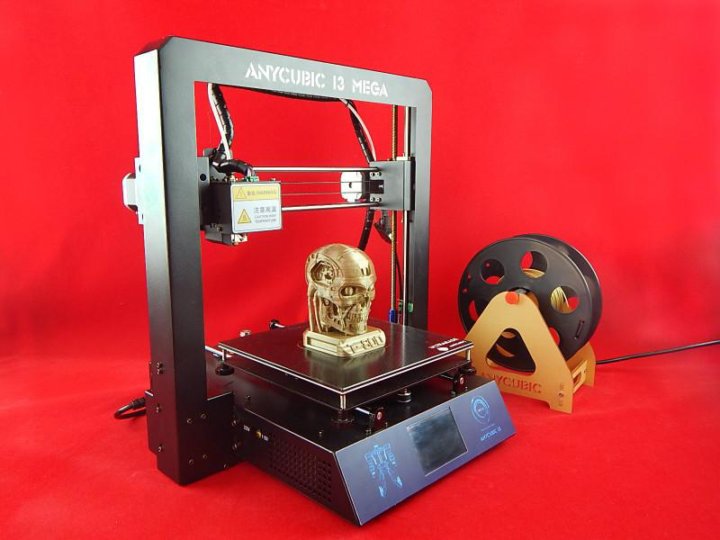

The monochrome LCD interface and click-wheel on the MK3S+ is one of the few less-than-impressive features on this machine; it feels dated and the UI navigation can be a little clunky. This stands in contrast with printers like the Anycubic Vyper, a sub-$400 machine that features a bright and responsive color touchscreen that shows detailed print statistics during printing. This monochrome display was industry standard when the original 8-bit i3-style of printers was introduced, but it feels outdated when compared to recent printers with color touchscreens.

(Image credit: Tom's Hardware)The MK3S+ uses a filament spool holder that mounts directly to the frame of the printer. The T-shaped holder is able to hold two spools simultaneously, which is ideal if you plan on swapping between multiple colors to produce a multicolor 3D print. The direct-drive extruder on the MK3S+ feeds filament straight down into the hot end, so mounting the filament directly above the extruder gives the filament a straight path between the spool and the extruder.

At the heart of the MK3S+ is the 8-bit Einsy RAMBo board, housed in a 3D printed enclosure mounted to the frame of the machine. This board is equipped with Trinamic 2130 silent stepper drivers, user-replaceable fuses, and the cable management is clean and professional.

The features made possible by this board (power-panic, live-Z adjust, silent steppers) were all major leaps when originally introduced, but many of these features have made their way down to less expensive FDM 3D printers like the Elegoo Neptune 2. The interface feels sorely in need of an update, and the addition of a color touchscreen and a 32-bit board (such as the one equipped on the Prusa Mini+) would refresh this platform.

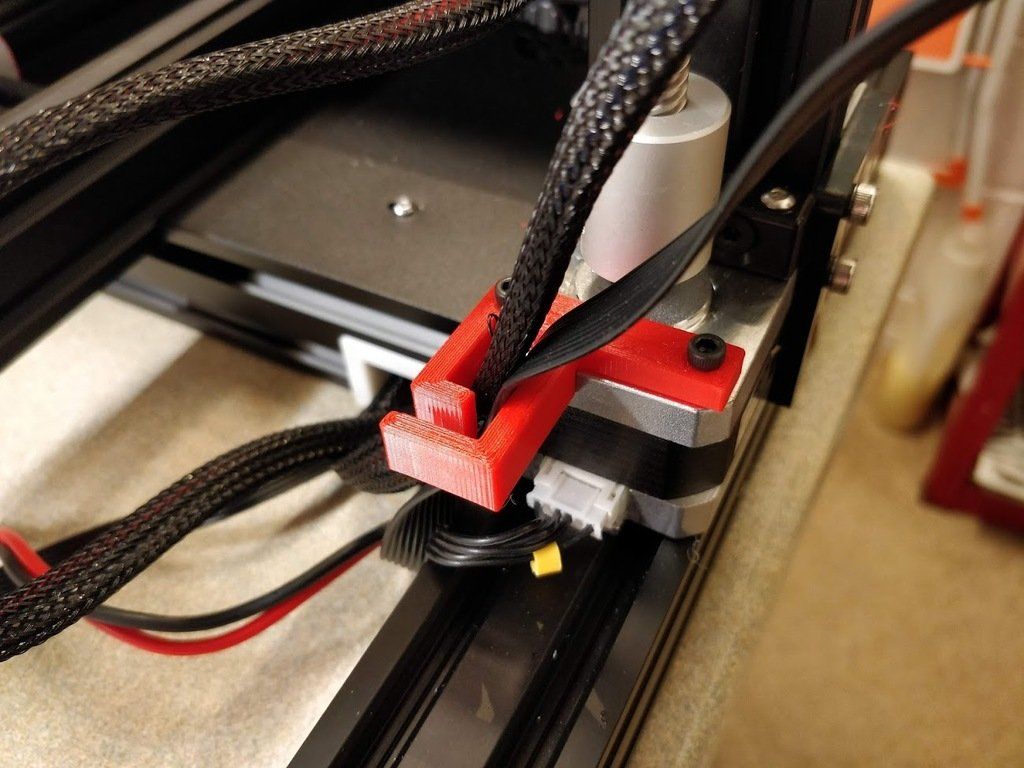

(Image credit: Tom's Hardware)The attention to detail on the Prusa MK3S+ is clear, and a perfect example of this is the wire management across the machine. Current-carrying wires are attached to the extruder module with zip ties that act as a strain-relief to prevent the wires from fatiguing and separating. The wires from the power supply are tucked neatly under the frame of the machine, out of sight and reach from users to prevent accidentally unplugging them during printing.

The wires from the power supply are tucked neatly under the frame of the machine, out of sight and reach from users to prevent accidentally unplugging them during printing.

What Makes the Prusa MK3S+ Different?

It can be hard to understand why the Prusa MK3S+ costs so much more than a printer like the Creality Ender 3 Pro, which seems to have similar specs on paper. To understand why this machine is so much more expensive, we need to take a closer look at the individual components of the MK3S+.

(Image credit: Tom's Hardware)Critical to the success of the MK3S+ is its custom-made Delta 240 Watt power supply, mounted to the frame of the machine. This unit supplies 24V power to the bed with a max current of 10 Amps, which provides fast and reliable heating for printing high temperature materials like PETG and ASA. Less expensive machines typically use lower wattage power supplies, such as the 150W power supply used by the Flashforge Adventurer 3 Lite, which take longer to heat and can have difficulty maintaining a higher temperature.

The 24V heated bed is able to reliably hit 100C, which is more than enough to allow high temperature materials like PETG and ASA to adhere to the build platform without delaminating. The magnetic build platform is firmly held in place without any clips or latches and can easily be removed once it cools to room temperature. PETG in particular is easy to remove from the textured surface of the textured spring steel sheet, and the MK3S+ build platform is best-in-class for high-temperature adhesion.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The MK3S+ is equipped with a genuine E3D hot end, and it has the holographic sticker to prove it (seriously). E3D manufactures every component in the hot end from the nozzle to the heatbreak which means you are very unlikely to run into the type of manufacturing defects that occasionally pop up on less expensive printers (incorrectly drilled nozzles, degraded PTFE tube liner, etc. ) In addition, this nozzle is rated for a max temperature of 300C (572F), which is easily hot enough to extrude most common thermoplastics and even some higher-temperature engineering-grade materials like Nylon and Polycarbonate.

) In addition, this nozzle is rated for a max temperature of 300C (572F), which is easily hot enough to extrude most common thermoplastics and even some higher-temperature engineering-grade materials like Nylon and Polycarbonate.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The printed parts on the MK3S+ are a perfect example of a company applying its in-depth knowledge of a subject to its product. The printed brackets found on the MK3S+ have been printed in PETG, and the outward-facing textured surface shows the level of quality you can expect from using a textured sheet.

In addition, I appreciate that Prusa has applied DFAM (Design for Additive Manufacturing) principles to these parts. These DFAM principles include concepts like printing hexagons instead of circles for relief holes, which print without requiring support material, and printing brackets perpendicular to their intended load to create mechanically tough parts.

(Image credit: Tom's Hardware)The Prusa MK3S+ comes equipped with a SuperPINDA probe which is used for hands-free leveling of the build platform. The SuperPINDA (which stands for Super Prusa INDuction Autoleveling sensor) operates by detecting the proximity of the probe to the build platform and storing that information in firmware. The MK3S+ isn’t the first printer to use a probe for bed leveling, but the software implementation in PrusaSlicer means that after the printer has been set up, you can print without spending much time thinking about calibration.

The SuperPINDA (which stands for Super Prusa INDuction Autoleveling sensor) operates by detecting the proximity of the probe to the build platform and storing that information in firmware. The MK3S+ isn’t the first printer to use a probe for bed leveling, but the software implementation in PrusaSlicer means that after the printer has been set up, you can print without spending much time thinking about calibration.

Compared to the manual bed leveling process of a printer like the Creality Ender 3 Pro, the MK3S+ is faster, easier to use, and requires less trial and error. PrusaSlicer includes a “G80” command in the start G-code (the instructions the printer reads when making a part), and this command performs a ‘Mesh Bed Leveling’ which probes the bed in a 3x3 grid to create a mesh surface that is used for calibration. This mesh surface causes the Z-axis motors to undulate over uneven areas while the print head remains perpendicular in the X/Y axis. During my testing, I didn’t need to run a single non-print calibration on the printer after the initial mesh bed leveling.

During my testing, I didn’t need to run a single non-print calibration on the printer after the initial mesh bed leveling.

Build Platforms on Prusa MK3S+

(Image credit: Tom's Hardware)Removing a printed part from the build platform of a 3D printer can be a challenging experience if the printer isn’t calibrated correctly. The Prusa MK3S+ attempts to solve this problem by using a removable build platform that is held in place magnetically and can be flexed to remove parts after the platform has cooled. I’ve tried many different types of build surfaces, and the smooth PEI sheet used by Prusa is by far one of the easiest to print on, remove parts from, and clean.

(Image credit: Tom's Hardware)Prusa also offers a textured steel build platform for the MK3S+ that has a gritty surface which can give printed parts a more uniform appearance. In fact, the signature textured look of the printed parts on the MK3S+ come from this build platform.

Parts printed on a smooth build platform will have a smooth bottom surface, which looks visually distinct from the striations on the sides of the part. By using a textured sheet, I was able to make prints that have a textured appearance on the bottom as well as the sides. This sheet is ideal for printing with PETG; the high print temperature of the material requires a textured surface to stick to, but also needs a surface that it can easily detach from.

By using a textured sheet, I was able to make prints that have a textured appearance on the bottom as well as the sides. This sheet is ideal for printing with PETG; the high print temperature of the material requires a textured surface to stick to, but also needs a surface that it can easily detach from.

Printing on the Prusa MK3S+

(Image credit: Tom's Hardware)The sample prints on the included SD card with the Prusa MK3S+ are a refreshing change from the sample parts that are typically included with low-cost 3D printers. The MK3S+ includes 16 pre-sliced parts that have been prepared for PLA with the total print time included in the file name. The sample prints vary in time from 23 minutes (a simple block with the word PRUSA on it) to almost 14 hours (a castle printed at .1mm layer height), and have all been prepared using sensible settings for the machine and highlight various features (variable layer height, multicolor printing, and fine .1mm layer resolution).

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)One of my favorite sample parts is the planetary gear bearing that prints in a single print. I printed this model using the Prusament Jet Black PLA material, and after removing it from the build platform I was able to easily spin the gear freely. This part really highlights the ability of the MK3S+ to produce parts with functional strength and purpose in addition to parts designed with aesthetics in mind.

(Image credit: Tom's Hardware)Another stand-out sample print included with the MK3S+ is the dragon model titled Adalinda the Singing Serpent by Loubie3D. This model takes a little longer to print (about 8 hours), but the final print is another favorite of mine. Because this model was sliced by Prusa for the MK3S+ printer, the sample print comes out with a high level of detail and no unexpected settings that can cause problems (too many exterior shells, no retraction, etc. ) like the sample prints included with other FDM 3D printers.

) like the sample prints included with other FDM 3D printers.

Printing with PrusaSlicer on the Prusa MK3S+

(Image credit: Prusa)Prusa has developed its own in-house slicer for the Prusa MK3S+, called PrusaSlicer. PrusaSlicer is a fork of the confusing-to-pronounce Slic3r app, which is also a free and open-source app. Prusa has invested a considerable amount of time and effort in PrusaSlicer, and this has translated into one of the most powerful 3D printing slicer apps available for desktop 3D printers on the market.

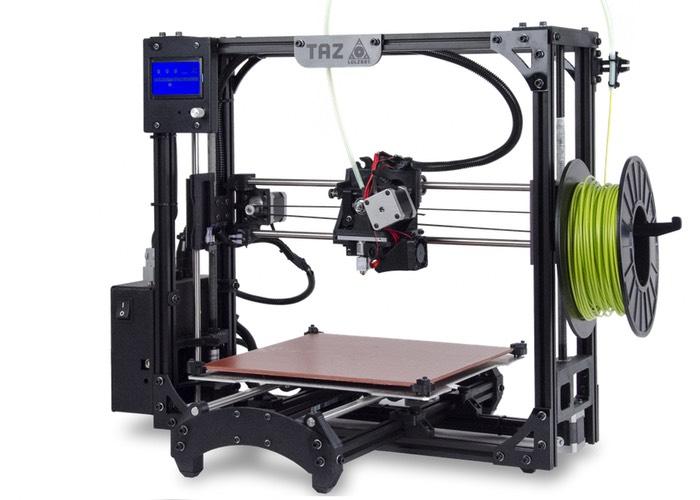

(Image credit: Prusa)The current version of PrusaSlicer (2.3.3) includes profiles for printers by Prusa, Creality, Lulzbot, and more, and also includes a library of material profiles. In addition to these profiles, PrusaSlicer also includes multiple print setting profiles, which range from ultra-high detail at 0.05mm layer height to a draft mode which offers .3mm layers fast print speed at the expense of reduced quality.

Slicing Models in PrusaSlicer for the Prusa MK3S+

(Image credit: Prusa)PrusaSlicer is a feature-rich program with a simplified interface that is accessible to beginners, experts, and everyone in between. I’ve spent a lot of time in the PrusaSlicer settings, and I appreciate how much work Prusa has put into making almost every parameter of the printing process addressable without creating an overwhelming interface.

The settings are broken down into three primary categories: Print Settings, Filament Settings, and Printer Settings. Print Settings generally focuses on the speed / quality of the print, Filament Settings is used to determine temperature and extrusion parameters, and Printer Settings is used for global parameters and determining start / stop instructions.

(Image credit: Prusa)The primary interface offers three settings: Simple, Advanced, and Expert. Simple offers a stripped-down experience with only a few parameters able to be adjusted, while Advanced and Expert allow you to adjust the print on a more granular level.

PrusaSlicer Quality Settings for the Prusa MK3S+ / PLA

(Image credit: Prusa)Swipe to scroll horizontally

| Material | Prusa Basic PLA, Silver |

| Layer Height | 0.20 mm |

| Infill Percentage | 15%, Gyroid |

| Print Speed | 45mm/second |

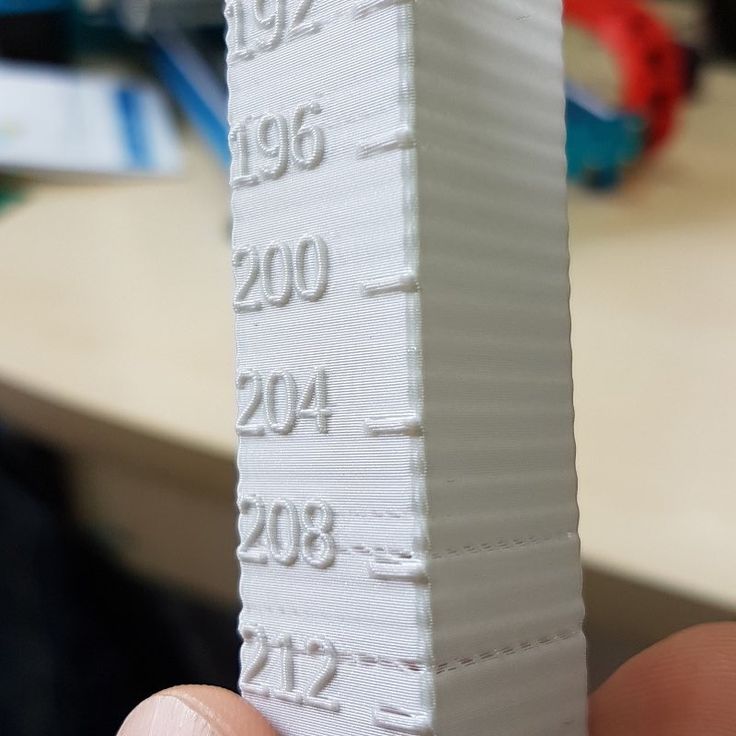

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 1 Hour, 34 Minutes |

There are few prints that are better at testing out a printer than the 3DBenchy, so I used the included spool of silver Prusa PLA to print this model out using the default . 2mm Quality PrusaSlicer settings. I was impressed with the overall quality of the Benchy, and even with a highly-reflective material like a silver PLA which can highlight defects from uneven layers, the layers looked even and consistent throughout.

2mm Quality PrusaSlicer settings. I was impressed with the overall quality of the Benchy, and even with a highly-reflective material like a silver PLA which can highlight defects from uneven layers, the layers looked even and consistent throughout.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Benchy boat model is designed to highlight various features of a printer (such as the ability to print steep overhangs, small features, etc.), and a quick examination of the model shows that the MK3S+ performed very well and didn’t have any of the common defects typically seen on this model.

PrusaSlicer Spiral Vase Settings for the Prusa MK3S+ / PLA

(Image credit: Prusa)Swipe to scroll horizontally

| Material | Prusament PLA, Galaxy Purple |

| Layer Height | 0.20mm |

| Infill Percentage | 0% |

| Print Speed | 60mm/second |

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 3 Hours, 9 Minutes |

Slicing a model using the ‘Spiral Vase’ mode in PrusaSlicer will automatically create a model that is composed of a single continuously rising helical contour, which allows models to be printed a fraction of the time it would normally take to print using multiple layers. This mode is ideal for printing objects like vases or enclosures that only require a single contour as opposed to multiple contours and an infill structure. I printed the Curved Honeycomb Vase by eggnot to highlight this printing mode.

This mode is ideal for printing objects like vases or enclosures that only require a single contour as opposed to multiple contours and an infill structure. I printed the Curved Honeycomb Vase by eggnot to highlight this printing mode.

The Prusament Galaxy Purple is a favorite color of mine due to the glitter additive in the filament. This additive creates layer lines that are evenly blended and have a textured appearance. Combining this material with the Spiral Vase mode produces parts that look almost conventionally manufactured, with layer lines that are difficult to see. This model printed in just over 3 hours in Spiral Vase mode, as opposed to over 13 hours if it had been printed using conventional settings.

PrusaSlicer Speed Settings for the Prusa MK3S+ / PETG

(Image credit: Prusa)Swipe to scroll horizontally

| Material | Prusament PETG, Chalky Blue |

| Layer Height | 0. 2mm 2mm |

| Infill Percentage | 15%, Grid |

| Print Speed | 60mm/second |

| Extruder Temperature | 250 degrees Celsius (482 degrees Fahrenheit) |

| Heated Bed Temp | 90 degrees Celsius (194 degrees Fahrenheit) |

| Print Time | 4 Hours, 5 Minutes |

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)PETG is a material that offers increased mechanical toughness, heat resistance, and flexibility when compared with parts printed with PLA. Prusa has taken advantage of these material properties by printing many of the components on the MK3S+ with PETG, which creates a rigid part that is able to withstand mechanical stress. PETG is also notoriously difficult to print with due to the high level of stringing that can occur when printing multiple parts simultaneously, but I didn’t have any issues when printing with the Prusament PETG material on the MK3S+.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)I used the default settings in PrusaSlicer to print the clamp model provided by Prusa that was designed specifically for PETG. This model features a functional thread, a flexible ball-and-socket joint, and can be tensioned without snapping the body of the clamp. The part printed in multiple pieces without stringing, and I was able to easily assemble it and verify functionality without damaging the clamp. If printed in a more brittle material (like PLA), I would expect the clamp to crack at a transition point on the body, but the PETG was able to hold tension without deforming or breaking.

PrusaSlicer 3MF Import for the Prusa MK3S+ / PLA

(Image credit: Prusa)Swipe to scroll horizontally

| Material | Prusa Basic PLA, Silver |

| Layer Height | 0. 20mm 20mm |

| Infill Percentage | 15%, Grid |

| Print Speed | 60mm/second |

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 2 Hours, 17 Minutes |

PrusaPrinters (the online file repository created and maintained by Prusa) offers the unique ability to share 3D printable files that have been pre-sliced and prepared for the MK3S+ with detailed print statistics available from the site. A perfect example of this is the Bag Clip by Andrei; a cam-driven bag clip that highlights the type of design freedom offered by a 3D printer.

This model has been uploaded as a .3MF file that contains all of the information required to print, such as slicer settings, nozzle and bed temperature, and custom support structures (visibile in the screenshot above. ) 3MF is an increasingly popular alternative to the STL file, which doesn’t contain much information aside from the raw geometry of a model.

) 3MF is an increasingly popular alternative to the STL file, which doesn’t contain much information aside from the raw geometry of a model.

This part printed flawlessly on the first try, and the provided .3MF (or .gcode) allows a user to send this file to anyone else with the same printer and material and feel confident that the part will be indistinguishable in appearance and performance. I’ve always thought of a 3D printer as the replicator from the Michael Crichton novel Timeline, which is able to produce identical objects at various locations by converting them into digital information. However, the success of a part is frequently beholden to the settings selected by a user for fabrication, so the ability to share the fabrication plans is one step closer to being able to send a physical product as a form of digital data.

(Image credit: Tom's Hardware)At a price-point of $999 for an assembled printer (or $749 for a kit), the Prusa MK3S+ is a machine that doesn’t compromise on user experience and is absolutely one of the best 3D printers currently on the market. The MK3S+ has a professional and neat appearance, but the 8-bit monochrome LCD user interface might be a challenge for some users to get past, given the steep price. Interface aside, the prosumer features of the MK3S+ make it a stand-out machine for anyone who is looking for a reliable machine to produce functional parts without worrying about spending a lot of time tinkering.

The MK3S+ has a professional and neat appearance, but the 8-bit monochrome LCD user interface might be a challenge for some users to get past, given the steep price. Interface aside, the prosumer features of the MK3S+ make it a stand-out machine for anyone who is looking for a reliable machine to produce functional parts without worrying about spending a lot of time tinkering.

If you are looking for a less expensive machine outside of the Prusa ecosystem, the Elegoo Neptune 2 (currently on Amazon for $180) offers similar printing size and features (with the notable exception of automatic bed leveling) at a fraction of the price but without the same level of robust support and documentation provided by the MK3S+ or any of the name-brand components like the E3D hotend. If you want the Prusa experience but are looking to spend a little less money, the Prusa Mini+ (available from Prusa for $399 assembled, $349 for a kit) is an excellent place to start.

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

Best 3D Printers Of 2023

Our list of the best 3D printers contains clear and concise information on all kinds of 3D printers. (Image credit: Future)The best 3D printers have become more affordable, and the 3D printer market is growing at an explosive rate, with new brands and styles of printing making an appearance each year. Where many 3D printers used to be huge, expensive machines, developments in technology and production now mean that many of the best options you can buy are increasingly affordable and can sit on a desk in your home without needing workshop space.

Naturally, this means there's now a massive choice of 3D printers that cater to all sorts of user needs and budgets. While this choice is excellent, picking the best 3D printer for your specific needs can be difficult. However, this guide can help, as we pick some brilliant 3D printers for all uses and budgets, with clear buying advice to help you determine which one you should buy.

While this choice is excellent, picking the best 3D printer for your specific needs can be difficult. However, this guide can help, as we pick some brilliant 3D printers for all uses and budgets, with clear buying advice to help you determine which one you should buy.

Printing hardware has taken off in recent years, so while a handful of filament printers (otherwise known as FDM printers) were all that was once available, there's now a wide variety of different styles to suit your needs across a range of budgets.

Unlike office-style printers that just print ink onto paper, 3D printers turn digital models into real-world objects made from plastic, metal, and wood. FDM printers now come in all shapes and sizes and are well-suited to prototyping and crafting larger objects. At the same time, resin-based (SLA, MSLA, and DLP) allow for much greater detail, typically at a smaller scale, making them a fantastic buy for anyone looking to design jewelry or create tabletop miniatures.

You can use 3D printers to build complete products, make spare parts, or simply create things you’ll find helpful for your home, office, and workshop. And, since 3D printing technology is within the grasp of just about anyone, you don’t have to utilize one to your advantage.

Whether you’re just getting your feet wet or are an expert, here are the best 3D printers ranges to consider. We've compared these printers across size, functionality, and use case, so there should be something for you, whatever it is you’re looking for. We also looked at their print resolution, build platform, filament type, and pricing.

Remember that the more expensive choices are better suited for professionals, while the best cheap 3D printers are ideal for those just starting.

The best 3D printers of 2023 in full:

Why you can trust TechRadar Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

The best 3D printers

Original Prusa MINI (Image credit: Prusa)1. Original Prusa MINI+

Small, affordable, and remarkable 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build Area: 18 x 18 x 18cm

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 33 x 33 x 38cm

Weight: 4.5kg

Today's Best Deals

Reasons to buy

+

Great value for an FDM printer

+

Easy to use

+

Supports a variety of filament types

Reasons to avoid

-

Reel sits separately

-

Imperfect print quality

-

Calibration can be tricky

This affordable open-frame 3D printer is small enough to sit on your desk and easy enough to assemble yourself without expertise. It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS, and Flex into accurate printed products.

It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS, and Flex into accurate printed products.

There’s a Network LAN and USB port for simple connectivity and a user-friendly interface. The 2.8-inch 65k colour screen makes navigating the options and settings easy, and on first starting the machine, it takes you step by step through the set-up process. This entry-level printer should be the first choice for crafters, modelers, and engineering enthusiasts.

The Original Prusa MINI+ is a replacement for the Original Prusa MINI (minus the plus), the key advantage being that it now comes with a superPINDA sensor, which is not temperature dependent allowing the first layer calibration to be faster and more reliable.

Read the full review: Original Prusa MINI.

CEL-UK RoboxPro (Image credit: CEL-UK)2. CEL-UK RoboxPro

Best 3D printer for commercial printing

Specifications

Print technology: Fused Deposition Modeling

Build Area: 210 x 300 x 400mm

Minimum layer resolution: 50 microns

Maximum layer resolution: 500 microns

Dimensions: 513 x 508 x 605mm

Weight: 26kg

Today's Best Deals

Reasons to buy

+

Swappable print heads

+

Dual Extruder and auto bed leveling

+

Network ready, no wired needed

Reasons to avoid

-

Large scale printer, not ideal for home use

-

Can be difficult to load filament

CEL-UK is a leader in 3D Printer innovation, with the original Robox printers introducing many new features to the world of FDM 3D printers. The RoboxPro is Robox on a large scale with a feature set that reads like a 3D print wish list; auto filament loading, auto bed leveling, Wi-Fi, network printing, and swappable tool heads.

The RoboxPro is Robox on a large scale with a feature set that reads like a 3D print wish list; auto filament loading, auto bed leveling, Wi-Fi, network printing, and swappable tool heads.

The main focus of the machine is quality and reliability, designed for anyone wanting a printer that can realize product ideas and get them to market. The enclosed design makes it an ideal choice for commercial and educational use.

There's a sizable touchscreen panel built into the front of the machine. It displays the current materials and can be used to navigate settings and print directly from USB or other external drives.

Read the full CEL-UK RoboxPro review.

(Image credit: Creality)3. Creality Ender-5 S1

An ideal 3D printer for any 3D print enthusiast or small business on a budget

Specifications

Print Technology: Fused Deposition Modeling

Build Area: 220 x 220 x 280mm

Minimum Layer Resolution: 0. 05mm

05mm

Maximum Layer Resolution: 0.35mm

Dimensions: 425 x 460 x 570mm

Weight: 12.1kg

Today's Best Deals

Reasons to buy

+

Incredible value

+

Robust design

+

High-quality tool head

Reasons to avoid

-

Not a true CORE XY printer

-

Large footprint

-

No enclosure for enhanced materials (Optional extra)

Having a predecessor with a decent reputation instantly puts pressure on the new model to perform. From the small amount of initial construction needed to build the printer to the outstanding bed leveling technology, the Ender-5 S1 proves to be a decent upgrade and on a completely different level of quality to the original Ender-5.

The cubed design might not be a true CORE XY printer, but the robust frame and tool head design's and precision enables a print quality that pits this printer against models that are at least twice the price.

The design is refined, the tool head completely overhauled, and with upgrade options such as an enclosure and laser head, there is plenty of scopes to expand your creativity. This is a printer designed for both enthusiasts and small business users.

Read our full Creality-5 S1 review.

(Image credit: TRILAB)4. TRILAB DeltiQ 2

Distinctive delta design for professional 3D printing

Specifications

Print technology: Fused Deposition Modeling (FMD)

Build area: 25 x 25 x 30cm

Minimum layer resolution: 50 microns

Maximum layer resolution: Variable

Dimensions: 41 x 50 x 81cm

Weight: 10kg

Today's Best Deals

Reasons to buy

+

Elegant design

+

Easy expansion

Reasons to avoid

-

Not suitable for all materials

-

Fully open design

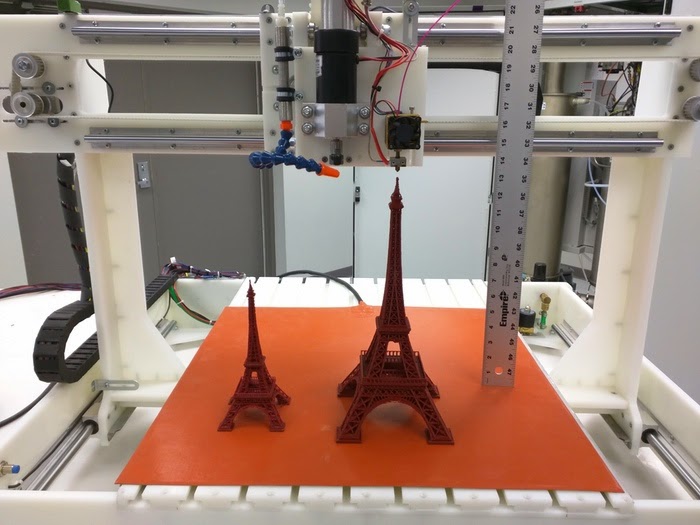

This elegant delta design should get your attention if you’re looking for a professional 3D printer for fairly large and complex projects. It uses FDM technology to build 3D models from rolls of filament. Still, instead of the more common cartesian printers, the TRILAB DeltiQ 2 has a fixed round build plate with the extruder suspended between three arms that move the print head along three axes. It gives this model a fairly small footprint, while its high tower design ensures it can print some quite large pieces.

It uses FDM technology to build 3D models from rolls of filament. Still, instead of the more common cartesian printers, the TRILAB DeltiQ 2 has a fixed round build plate with the extruder suspended between three arms that move the print head along three axes. It gives this model a fairly small footprint, while its high tower design ensures it can print some quite large pieces.

And unlike most 3D printers, it has two extruder options, one for standard PLA and PETG and the other for flexibles. It just requires a little retooling to swap between them. The TRILAB DeltiQ 2 uses some of the best components available in its construction, and the interface is a smartphone running a dedicated app. This handsome, high-end workshop printer would sit well in any laboratory, studio or classroom.

Read our full TRILAB DeltiQ 2 review.

Original PRUSA SL1 (Image credit: PRUSA)5. Original PRUSA SL1S SPEED

The best MSLA printer just got better

Specifications

Print technology: Stereolithography

Build area: 320 x 450 x 500mm

Minimum layer resolution: 25 microns

Maximum layer resolution: 100 microns

Dimensions: 400 x 237 x 225 mm

Weight: 4. 5kg

5kg

Today's Best Deals

Reasons to buy

+

Rapid printing

+

Great build quality

Reasons to avoid

-

High maintenance

-

Limited build volume

Prusa Research revolutionized the FDM 3D printer market, and this model looks set to do the same for SLA printers. While this printer uses stereolithography technology, it's a slight variant known as MSLA.

This uses a monochrome LCD and UV LED to expose the resin, which is cheaper than precision lasers but just as accurate. The SL1S SPEED replaces the outgoing SL1, and as you might have guessed from that model name, it’s faster – around ten times faster and with a vastly improved print quality.

The SL1S's design hasn't physically changed a great deal over the SL1. It features the same touchscreen LCD on the front, which is again good and responsive.

The speedy new model looks set to lead the SLA market with support from the excellent PrusaSlicer software and a huge open-source community.

Read our full Original Prusa SL1S 3D printer review.

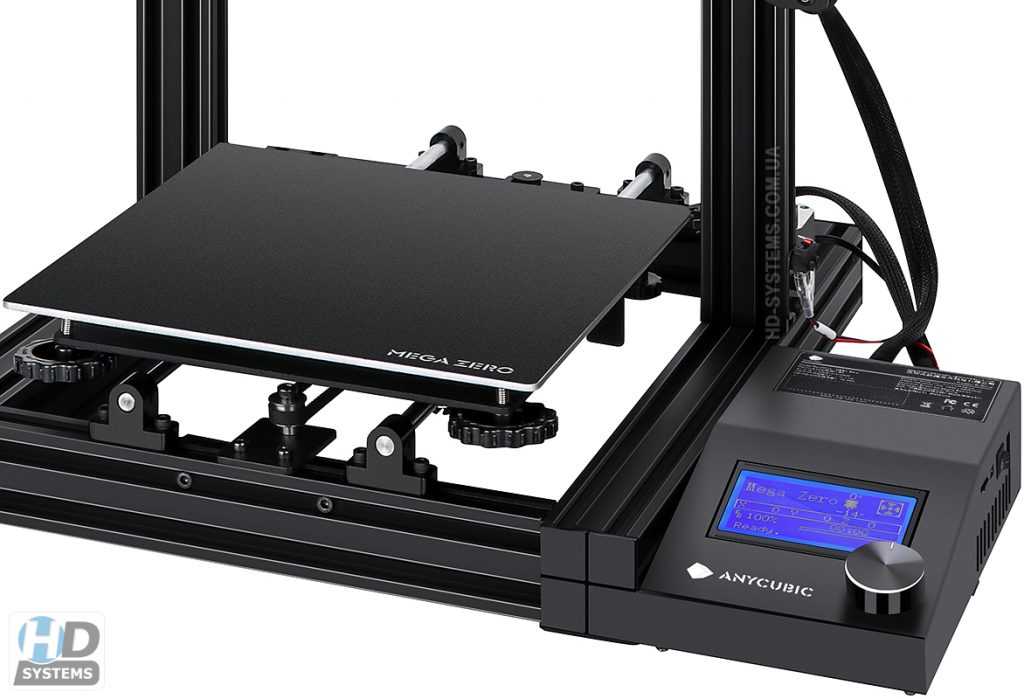

Anycubic Vyper (Image credit: Anycubic)6. AnyCubic Vyper

The best beginner friendly FDM 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 245 x 245 x 260mm

Dimensions: 508 × 457 × 516mm

Weight: 10kg

Colour

Black

Condition

New

Today's Best Deals

Reasons to buy

+

Built-in accessories drawer

+

Reliable automatic bed-leveling

+

Great value for the features you get

Reasons to avoid

-

Excessive initial stringing

-

Questionable build quality in places

-

Cura profile needs fine-tuning

If the world of 3D printing ever seemed too intimidating for you, look no further than the AnyCubic Vyper. While perfect for beginners with its auto-leveling feature and minimal assembly, seasoned printing hobbyists will also appreciate what it can offer, albeit with a few adjustments.

While perfect for beginners with its auto-leveling feature and minimal assembly, seasoned printing hobbyists will also appreciate what it can offer, albeit with a few adjustments.

As the 'automatic leveling' might imply, the AnyCubic Vyper removes the need to align your build plate manually should you want to move the machine to a different location. It's fast and accurate, saving time when setting up your first print, which makes setting up and getting started a breeze.

The touchscreen control panel is satisfyingly fast and easy to use, but we found that the estimated print completion time was consistently incorrect. Once the printer is properly optimized, you'll enjoy impressive print quality.

Read our full AnyCubic Vyper review.

Raise3D E2 (Image credit: Raise3D)7. Raise3D E2

The best workhorse 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 330 x 240 x 240mm

Minimum layer resolution: 20 microns

Maximum layer resolution: 250 microns

Dimensions: 607 x 596 x 465mm

Weight: 35kg

Colour

Black

Condition

New

Today's Best Deals

Reasons to buy

+

High-resolution print capability

+

Innovative ouch screen interface

+

Dual Extruder system can work independently

Reasons to avoid

-

Huge and heavy, not ideal for home use

-

Careful placement of bed required

-

Needs manual assistance for filament loading

3D printing has come of age, and machines like the Raise3D E2 bring high-end FFF printing to the home, education, and business. This dual extrusion printer goes head-to-head with the RoboxPro and will fulfill most companies' design and development needs with slick business and network integration.

This dual extrusion printer goes head-to-head with the RoboxPro and will fulfill most companies' design and development needs with slick business and network integration.

The printer display is vast and detailed, and you can swiftly access all the printer settings through the fast and responsive touchscreen interface. You can print directly from a USB key, wired connection, network, or Wi-Fi, making it ideal if several people are utilizing the printer. You will also find many step-by-step videos for many of the printer's features.

Home and educational users will benefit from a simple interface and near-faultless reliability. The only drawback of this machine is its size and weight.

Read the full Raise3D E review.

(Image credit: Anycubic)8. Anycubic Photon M3

Detailed 3D modelling for beginners

Specifications

Print technology: Stereolithography (SLA)

Build area: 18 x 18 x 18cm

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 18 x 16. 4 x 10cm

4 x 10cm

Weight: 7kg

Colour

Yellow

Condition

New

Today's Best Deals

Reasons to buy

+

Good value

+

Detailed models

Reasons to avoid

-

Print size is small

-

Poorly placed USB port

The Anycubic Photon M3 is the ideal entry-level resin printer to introduce you to 3D printing. It’s relatively easy to set up and operate, and the box includes everything you need to get started except for the UV resin. This compact model will fit easily on your desk in a well-ventilated room, though the build volume is somewhat limited at 180 x 163.9 x 102.4mm or 7 x 6.5 x 4-inches.

This modest machine can turn out surprisingly detailed models for printing small plastic parts or artistic pieces. The interface is a 7.6-inch panel, and the software will help you print your project and slice it. If you want to make larger models, you should consider one of Anycubic’s larger 3D printers, but this is a great place to start for $299 (about £275 / AU$480).

If you want to make larger models, you should consider one of Anycubic’s larger 3D printers, but this is a great place to start for $299 (about £275 / AU$480).

Read our full Anycubic Photon M3 review.

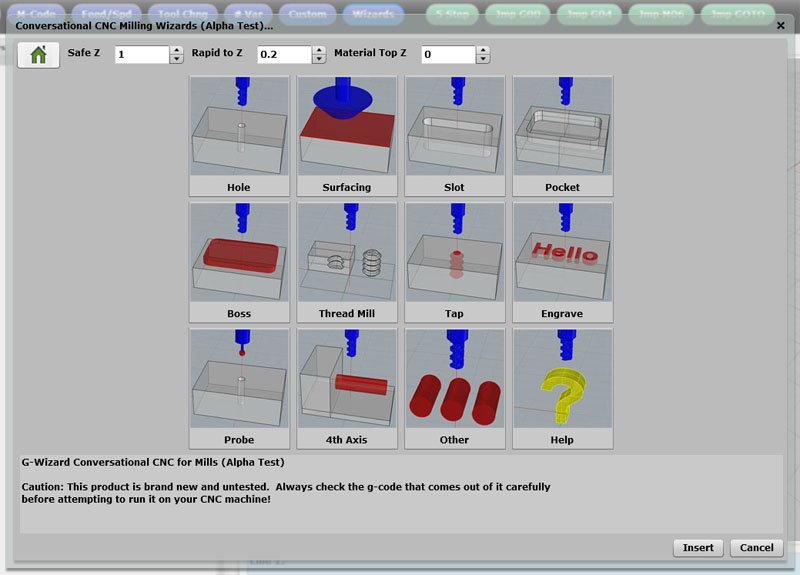

Snapmaker 2.0 A350 (Image credit: Snapmaker)9. Snapmaker 2.0 A350

Best 3-in-1 3D printer

Specifications

Print technology: Fused Filament Fabrication, CNC, Laser

Build area: 350 x 350 x 350mm

Minimum layer resolution: 50 microns

Maximum layer resolution: 300 microns

Dimensions: 645 x 480 x 580mm

Weight: 29kg

Today's Best Deals

Reasons to buy

+

3D printer, CNC, and Laser cutter in one

+

Solid design and build quality

+

Easy to understand software

Reasons to avoid

-

Switching between uses takes time

-

Enclosure purchased separately

-

Very noisy when printing

A true 3-in-1 machine makes sense because 3D printers, CNC, and Laser cutters all use the same basic mechanics and technology. The original Snapmaker has a dedicated following, so it is no surprise that Snapmaker 2.0 builds on its predecessor's reputation and features.

The original Snapmaker has a dedicated following, so it is no surprise that Snapmaker 2.0 builds on its predecessor's reputation and features.

The SnapMaker boasts excellent build quality and comes with clear assembly instructions. The assembly takes around 20 minutes. There's a 5-inch (720x1280px) touchscreen on the machine that can be used to select options, preview models, calibrate and open stored files. The touch screen is a powerful addition to the usability of the machine — it runs on Android OS and features a Quad-Core A7 CPU @1.1GHz.

The A350 is the largest of three models and proves proficient in all disciplines. Swapping between the three heads and beds does take time to reconfigure and calibrate, but for the price and features, it's worth it.

Read the full Snapmaker 2.0 A350 review.

- We've also featured the best printers and the best laptops for graphic design.

What is a 3D printer?

A 3D printer is a machine that creates three-dimensional objects using computer-created designs (like a digital 3D or CAD model).

These machines rely on an additive manufacturing process to build objects layer by layer.

How to choose the best 3D printers for you?

To select the best 3D printer, you'll need to consider what you're going to do with it. If you're going to be printing small objects, then a small-size printer is apt, but a large printer is naturally the best option for bigger creations.

For printing high-quality objects with fine details, you'll need a high resolution printer, but these prints will cost more and take more time to get ready.

Look out for the printer's interface and the overall ease of use, along with other aspects like the kind of software it uses, the type of filament, build platform, and pricing.

The best 3D printers: How we test

3D printers are tested using a collection of bespoke benchmarks that help show the strengths and weaknesses of each model that, after time, can be compared against other products. These will differ depending on printer type, but a filament printer will be tested for stringing, bridging, and speed, as well as additional commentary on detail, achieved, and noise levels.

This will be done fairly, with dues given to different materials and printer types, with resin printers being subject to smaller, more detailed models to replace the stringing test. Design, price, and performance will also be explored as sections within the reviews.

All our tests are conducted from the perspective of the printers target market where possible, so expect to see a lot of tabletop miniatures and figurines alongside the usual 'benches' (test models that are also dubbed as 'torture tests' to see where a printer needs to be better optimized for future prints).

Round up of today's best deals

Creality Ender-5 S1

$89.99

View

See all prices

Reduced Price

Anycubic Vyper

$499

$429. 99

99

View

See all prices

Raise3D E2

$3,499

View

See all prices

Anycubic Photon M3

$319.99

View

See all prices

powered by

Sign up to theTechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

Contact me with news and offers from other Future brandsReceive email from us on behalf of our trusted partners or sponsorsCollin is the B2B Hardware Editor for TechRadar Pro. He has been in journalism for years with experience in both small and large markets including Gearadical, DailyBeast, FutureNet and more.

3D File All Ranks - BrawlStars・3D Printer Design Download・Cults

Fortnite Heavy Sniper for LEGO

0.65 €

Yoshi cookie cutter 🍪

0,50 €

Keychain BrawlStars

0.99 €

Gear lever system - key fob

1.99 €

COOKIE CUTTER MARIO 🍪

0,50 €

remote control box

1,50 €

BrawlStars shuriken pack

0.50 €

Dennerle LED lamp holder

4 €

Best 3D Printer Files in Home Category nine0037

Key holder "Exploding boar head"

2,84 €

Polygonal pot Typical V1

Free

Linear Abstract Vase

1. 38 €

38 €

Instax Wave Fujifilm Box

Free

TRIO'PICAL

2.50 €

Recycled bottle Watering can

Free

Chinese dragon door knock

2 €

H.A.V.O.C. Vase Collection

2,50 €

Bestsellers in the Home category

Modular, stackable boxes

€3.20

Box / Travel bag

2.60 €

Bear wine holder

2.31 €

Cable holder for rabbit

1.34 €

Clothes hanger "Wolf"

2. 17 €

17 €

Wall shelf "Mushroom Amanita"

2.40 €

Another quick-change toilet roll holder

1 €

Prepaid Gift Card Holder v2.0

1.89 €

Crystal corner decor - printing on site

1.52 €

Hanging cat - print-in-place

1.45 €

Modular storage drawer system with quick print

5.64 €

HAIRY FLEXIBLE GNOME FOR ON-SITE PRINTING

2.31 €

Candlestick - Arbre de vie

1,20 €

Wall shelf "Oyster mushroom"

2,40 €

nine0003 Another quick-change paper towel holder1 €

Wallet card holder (universal package)

1. 26 €

26 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in maintaining activities and making future designs of is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories.