3D printer house building video

3D-Printed Houses - The Future Of Construction? (Video)

The 1,200-square-foot home has three bedrooms, two full bathrooms, and a covered front porch. Yet it took just 28 hours to erect the home’s concrete walls — that’s because they’re printed, reducing the standard construction schedule by at least 4 weeks. Using automated computer technology and a patented concrete mix, Habitat for Humanity recently completed the first of many planned 3D-printed houses in Williamsburg, Virginia and elsewhere.

The new owner, April Stringfield, and her 13-year-old son, are happy to know that the home will be theirs. Ms. Stringfield has worked as a laundry facilities supervisor for 5 years at a local hotel, however, her income totals less than 80% of the area median income. Needless to say, becoming a homeowner seemed out of reach — until being accepted for one of the Habitat for Humanity 3D-printed houses. “My son and I are so thankful,” she said at the home’s dedication. “I always wanted to be a homeowner. It’s a dream come true.”

Habitat for Humanity has constructed hundreds of thousands of affordable homes for people who need them.

Habitat for Humanity 3D-printed house groundbreaking July 12, 2021.

3D printing is a fairly new technique in the construction sector, with the aim to improve the economics and alleviate environmental impacts. It is an innovative area that combines the knowledge of traditional construction with digital fabrication. The elimination of formwork plus several other major benefits has great potential and has caught the attention of the construction industry.

Why 3D printing?

- It saves up to 15% per square foot in building costs for contractors.

- It offers better retains temperature, reducing heating and cooling costs for homeowners.

- It is resistant to tornado and hurricane damage.

3D-printed houses are already being built and sold to the general public.

How 3D-Printed Houses are Constructed

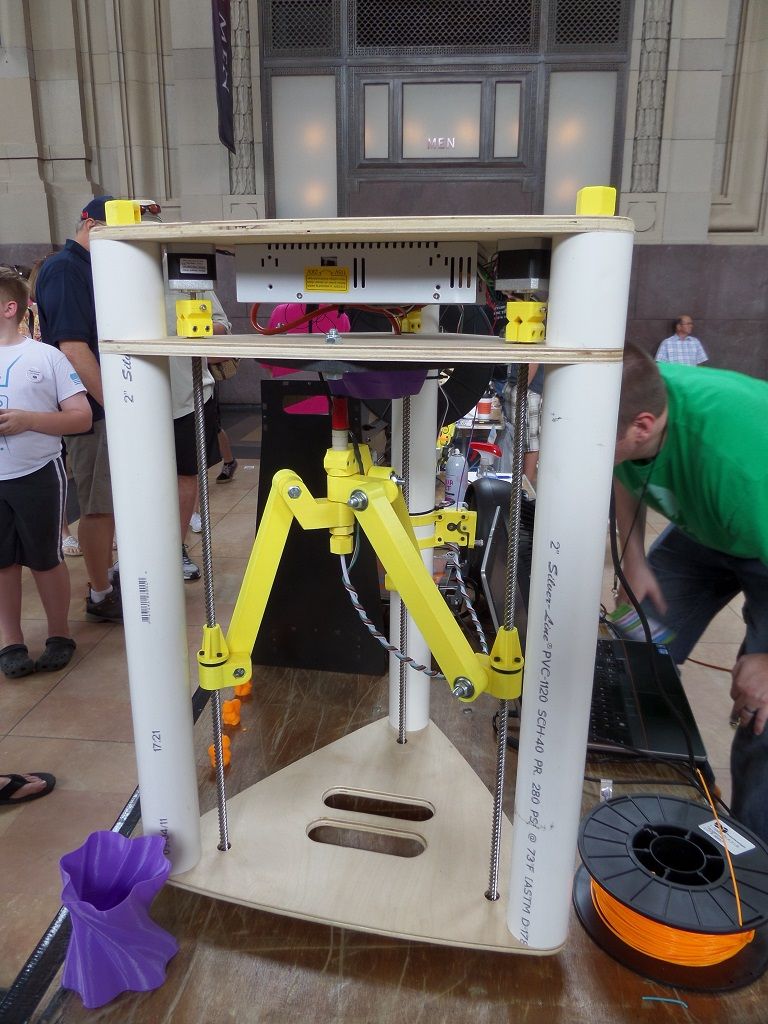

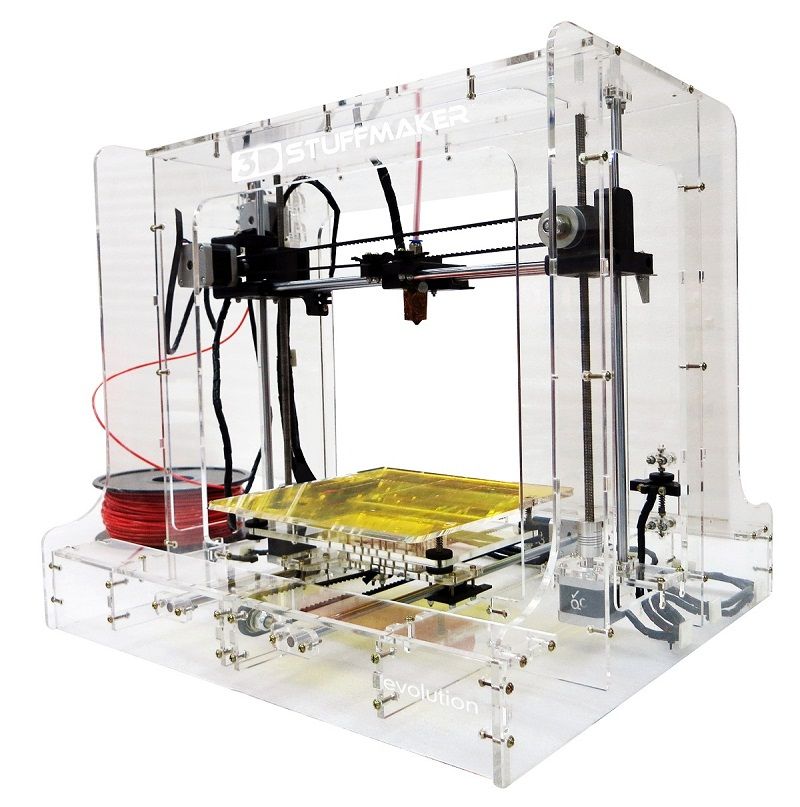

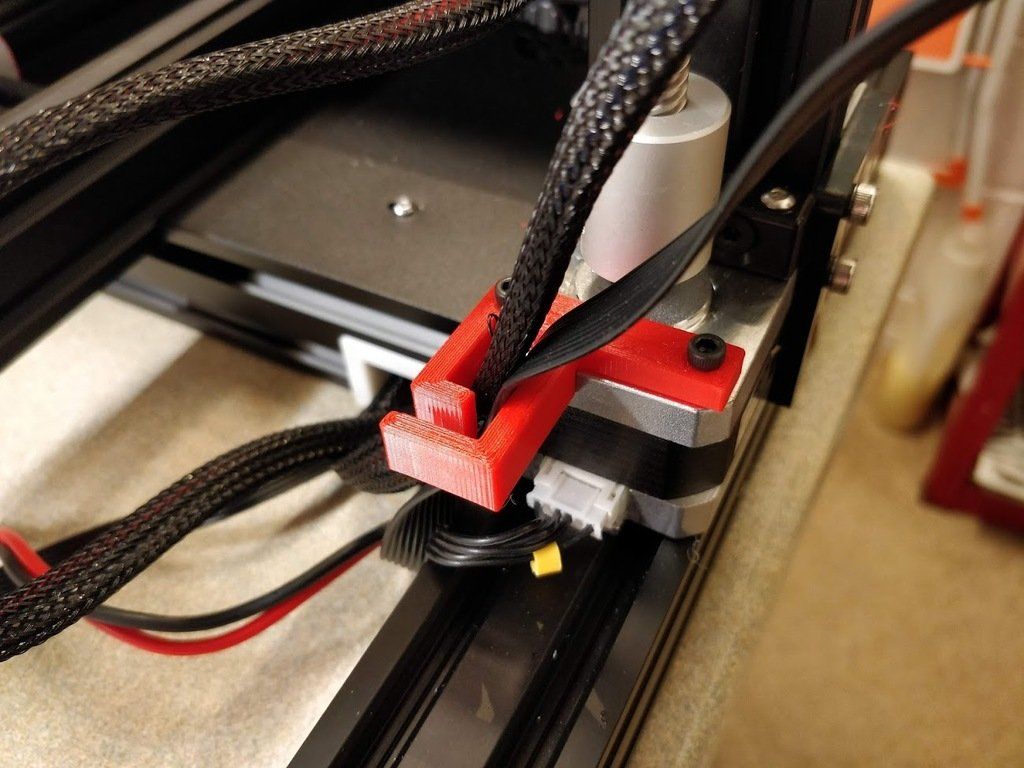

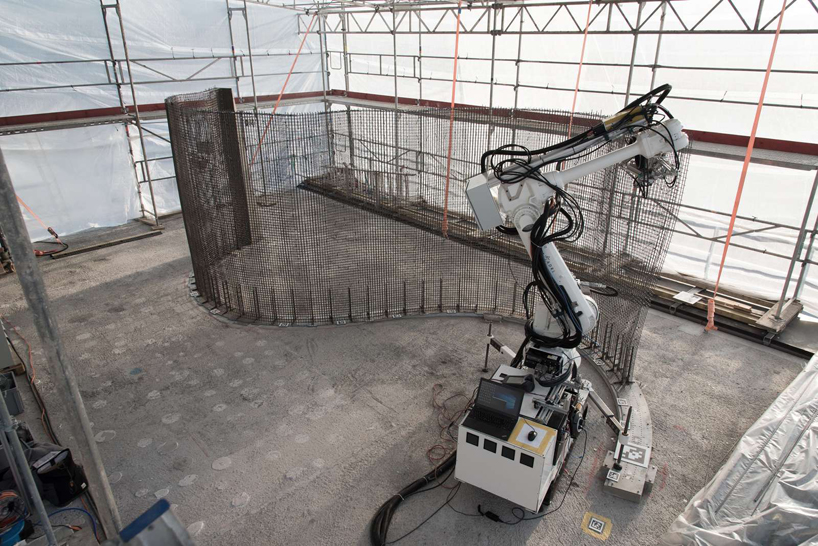

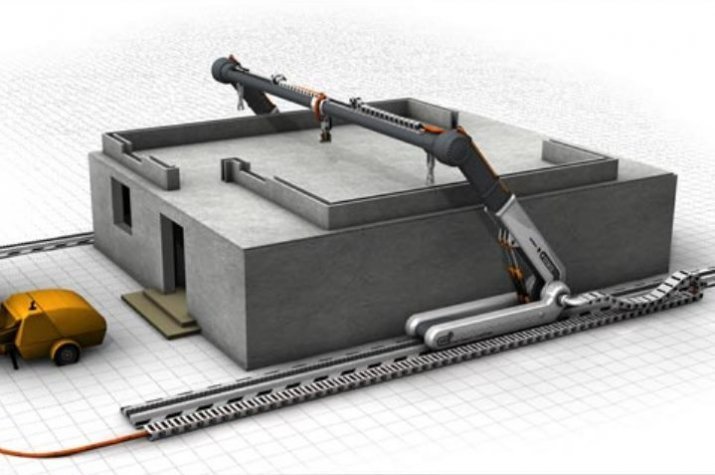

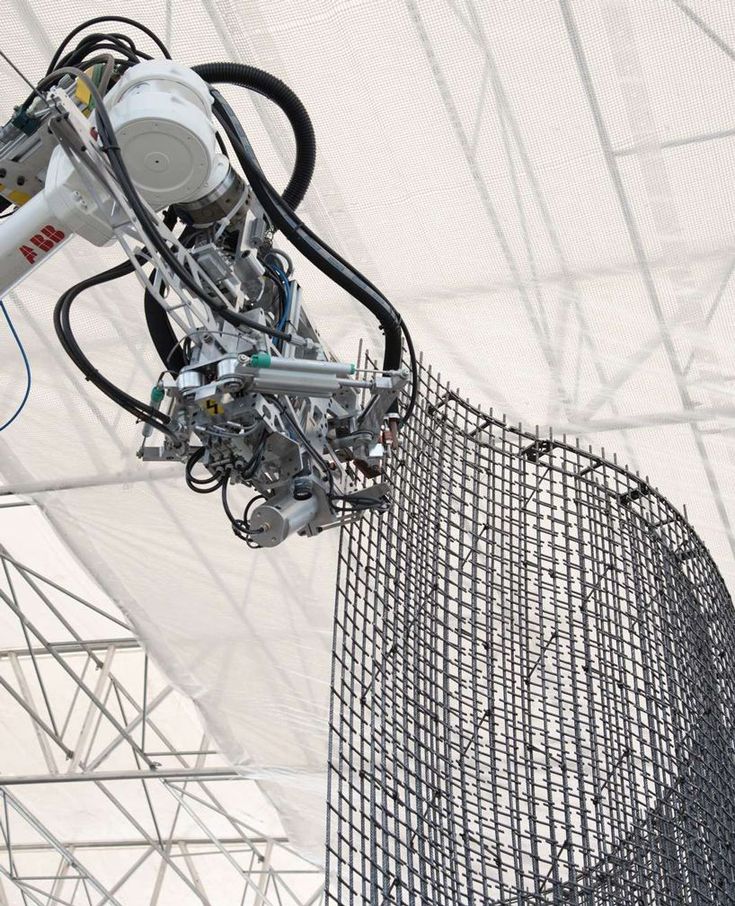

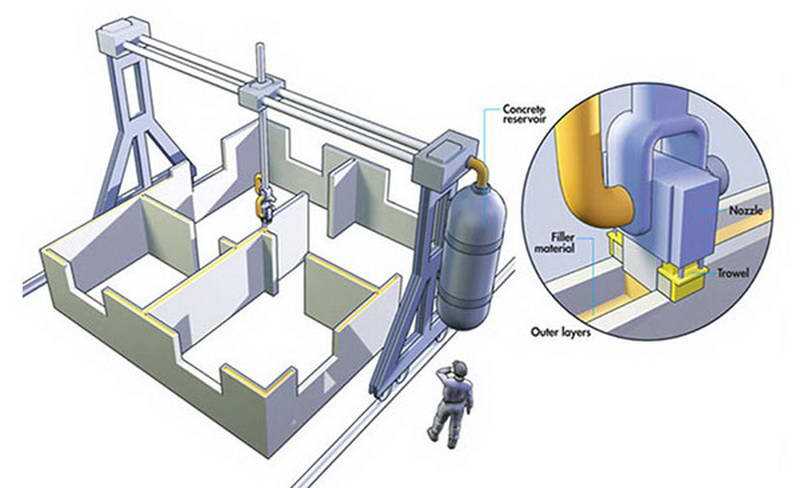

The concept of additive manufacturing — the more technical term for 3D printing — dates back to the 1980s, but has become much more popular in the last decade. 3D printing begins with a digital file of a house design. Large robotic arms on a swivel produce fully functional houses as, layer by layer, they deposit material to build up the house in three dimensions, one layer at a time.

3D printing begins with a digital file of a house design. Large robotic arms on a swivel produce fully functional houses as, layer by layer, they deposit material to build up the house in three dimensions, one layer at a time.

For Ms. Stringfield’s Habitat for Humanity home, Alquist used a patented concrete mix and extrusion machine to print exterior and interior walls, which were reinforced with steel during the printing process. Afterward, the exterior walls were sealed with a clear or tinted coating that keeps moisture from transferring through the concrete. The contractor incorporated traditional siding on the roof gables and used standard bricks on the porch pillars.

Homeowners can choose a standard gray concrete color or select from a range of attractive earth tone hues to give the home a custom look.

After Alquist finished printing the walls, traditional builders constructed the roof, ran plumbing and wiring, and installed interior flooring and other finishes. Through the Williamsburg chapter of Habitat, contractors, subcontractors, and other volunteers donated their time to complete the remaining parts of the house.

Life-Cycle Assessment of 3D-Printed Houses

The life-cycle assessment (LCA) framework is utilized to quantify the environmental loads of raw materials extraction and manufacturing, as well as energy consumption during construction and operation phases. Want the stats? A study conducted in the United Arab Emirates looked at the construction process of a single-story 3D-printed house to conduct the comparative assessment against traditional concrete construction.

The economics of the selected structural systems were investigated through life-cycle costing analysis (LCCA), that included mainly the construction costs and energy savings. An eco-efficiency analysis was employed to aggregate the results of the LCA and LCCA into a single framework to aid in decision making by selecting the optimum and most eco-efficient alternative.

The findings revealed that houses built using additive manufacturing and 3D-printed materials were more environmentally favorable. The conventional construction method had higher impacts when compared to the 3D-printing method with global warming potential of 1154. 20 and 608.55 kg CO2 eq, non-carcinogenic toxicity 675.10 and 11.9 kg 1,4-DCB, and water consumption 233.35 and 183.95 m3, respectively.

20 and 608.55 kg CO2 eq, non-carcinogenic toxicity 675.10 and 11.9 kg 1,4-DCB, and water consumption 233.35 and 183.95 m3, respectively.

The 3D-printed house was also found to be an economically viable option, with 78% reduction in the overall capital costs when compared to conventional construction methods. The combined environmental and economic results revealed that the overall process of the 3D-printed house had higher eco-efficiency compared to concrete-based construction. The main results of the sensitivity analysis revealed that up to 90% of the environmental impacts in 3D-printing mortars can be mitigated with decreasing cement ratios.

Environmental Impact of 3D-Printed Houses

Alquist — the company behind the Habitat for Humanity 3D-printing — uses the technology to create designs while lowering the cost of housing and infrastructure in economically distressed and under-served communities. Each Alquist home comes equipped with Virginia Tech’s proprietary Raspberry Pi-based monitoring system, which monitors the indoor environment, provides security and emergency management, optimizes energy consumption, and analyzes occupant comfort and space utilization.

Alquist also installs a 3D printer in the kitchen of every home it builds. The homeowner receives a downloadable computer file that will allow them to print knobs, light switch covers, and other replaceable parts.

While 3D-printed houses are still uncommon, the Williamsburg house symbolized the potential of affordable homes that limit the use of natural resources like trees. Every new home built by Habitat for Humanity Peninsula and Greater Williamsburg is EarthCraft certified. EarthCraft is a voluntary green building program that serves as a blueprint for healthy, comfortable homes and works to both reduce utility bills and minimize environmental impacts.

Final Thoughts

Construction of each home built by Habitat for Humanity Peninsula and Greater Williamsburg is a cooperative effort between volunteers, house sponsors, and the buyers of the home. Participating families provide at least 300 hours of work toward building their own and other families’ homes, called sweat equity. Habitat’s homebuyer program resulted in monthly mortgage payments of no more than 30% of Ms. Stringfield’s income, including her real estate taxes and homeowner’s insurance.

Habitat’s homebuyer program resulted in monthly mortgage payments of no more than 30% of Ms. Stringfield’s income, including her real estate taxes and homeowner’s insurance.

3D-printed houses are inherently resilient, cost-effective, and have sturdy construction. They can help make homes more affordable and are likely to become another tool in the toolkits to fight against homelessness and the effects of the climate crisis.

Interested in learning more about the possibilities of 3D printing? Check out these articles: water power prototypes, EV parts, and carbon fiber bikes.

Appreciate CleanTechnica’s originality and cleantech news coverage? Consider becoming a CleanTechnica Member, Supporter, Technician, or Ambassador — or a patron on Patreon.

Don't want to miss a cleantech story? Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Have a tip for CleanTechnica, want to advertise, or want to suggest a guest for our CleanTech Talk podcast? Contact us here.

In this article:3d printing, Habitat for Humanity

Carolyn Fortuna (they, them), Ph.D., is a writer, researcher, and educator with a lifelong dedication to ecojustice. Carolyn has won awards from the Anti-Defamation League, The International Literacy Association, and The Leavy Foundation. Carolyn is a small-time investor in Tesla. Please follow Carolyn on Twitter and Facebook.

Timelapse video shows construction of 3D-printed home

Timelapse video shows construction of 3D-printed home

01:31

Now playing

- Source: WTKR

'Glass Onion' actress talks about the challenge of her role

02:38

Now playing

- Source: CNN

'You're just a hamster spinning on a wheel': Restaurant owner struggles to stay open

02:39

Now playing

- Source: CNN

An iconic French food is under threat. Hear why one baker is speaking out

Hear why one baker is speaking out

02:20

Now playing

- Source: CNN

The debt ceiling drama, explained in 2 minutes

This horror film doll is dancing her way into viral fame

01:00

Now playing

- Source: CNN Business

Your questions about a possible gas stove ban, answered

03:03

Now playing

- Source: CNN Business

See huge former NBA player win small car on game show

02:10

Now playing

- Source: CNN

This 82-year-old couldn't afford to retire. Then a TikTok user stepped in

Then a TikTok user stepped in

01:53

Now playing

- Source: CNN

'Shamefully good': Stephen Colbert reacts to Tom Hanks' new cocktail creation

01:17

Now playing

- Source: CNN Business

See CES 2023's weirdest new technologies

02:25

Now playing

- Source: CNN

New study shows walking this way burns just as much energy as jogging

02:34

Now playing

- Source: CNN

Ellen DeGeneres posts video of flash flood near Montecito home

01:16

Now playing

- Source: CNN

401(k) rules just got better. Here are the important changes

Here are the important changes

01:54

Now playing

- Source: CNN Business

Watch: Late night hosts react to Prince Harry's memoir

'This could be bad for you': WSJ reporter handcuffed while on assignment

05:34

Now playing

- Source: CNN Business

home construction printers, the most important technology news

World's largest 3D printed housing development to be built in Texas

After completing four buildings in collaboration with Lake|Flato Architects in Texas, the company has teamed up with real estate developer Lennar for an even more ambitious project of 100 3D-printed residential buildings designed in conjunction with Bjarke Ingels Group (BIG). nine0006

nine0006

Project described by

...3D technology Diamond Age will increase the speed of building houses nine times

Tech startup Diamond Age has received its first $8 million in venture capital investment to bring its construction robots to industrial scale production. A California-based company has developed a residential printing system on massive 3D printers and promises to show it in practice in the near future on the construction of a private house with an area of 335 square meters. meters. nine0006

...Founder and

3D printed Fibonacci house for rent

The Fibonacci sequence found in nature has already been used in the creation of cars, yachts and buildings. Now this row, each number of which is the result of adding the previous two, has been used by Twente Additive Manufacturing (TAM) to design "Canada's first 3D printed house. " The project is a stationary concrete building,

" The project is a stationary concrete building,

Mighty Buildings received $22 million to create cheap 3D-printed eco-houses

US startup Mighty Buildings, which developed the unique 3D printed construction method , has announced that it has raised $22 million in Series B funding. With this amount, the amount of capital raised since the company was founded in 2017 has reached 100 million.

Mighty Building declares its mission to create "beautiful, sustainable and

...The world's first 3D printed steel bridge goes into operation

MX3D has completed its ambitious plan to install a 3D printed metal footbridge across a canal in Amsterdam. The official opening of the facility took place with the personal participation of the Queen of the Netherlands .

Designed by Joris Laarman Lab and engineered by Arup with ABB, Lenovo,

...Icon launches next generation 3D printing at home

While 3D printed construction is in its infancy, Icon has already printed both budget housing in Mexico and luxury cottages in the US . Now she has teamed up with the prestigious design studio

Now she has teamed up with the prestigious design studio

TECLA's first 3D-printed clay house is ready

Italian 3D printing company WASP and its partner, Mario Cucinella Architects, have successfully completed the first building of the TECLA project, which was unveiled last year. Innovative hornet's nest home built close to

...3D-printed house can already be bought in the US

Kirk Andersen, CEO of New York-based SQ4D, announced the creation of a home that will be the first 3D-printed building in the US to go public. Andersen's company has already proved the capabilities of its 3D construction printing technologies by erecting a demonstration

...The largest construction 3D printer printed a two-story concrete house (video)

Belgium-based Kamp C, a provincial center for sustainable development and building innovation, recently used Europe's largest concrete 3D printer to create the world's first two-story house 3D printed in one piece.

Lunar base buildings to be 3D printed - Project Olympus

NASA has teamed up with architecture firm Bjarke Ingels Group, developer of advanced building technologies ICON, and SEArch+, an innovative design firm for human life beyond Earth, to create Project Olympus, the space building system that will be needed to explore the moon. nine0006

The joint work is carried out as part of the plan for the study of the natural satellite of the Earth, adopted by NASA in 2020

...TECLA - clay house created on a 3D printer based on the principle of a hornet's nest

3D printing will soon become the most important tool in the construction industry around the world, so architects and designers are creating new housing projects that can be simply reproduced on a printer. nine0006

nine0006

...

DFAB House is a robot-built house that is revolutionizing the industry (video)

Construction is one of the most harmful to nature and inefficient areas of human activity. According to a UN study, the construction industry is responsible for 40% of the world's carbon dioxide emissions. In Switzerland, robotics and digital technologies were proposed to solve this problem, and a house called

...3D Printed 'Sun Palm Concrete Forest' Could Be Dubai Pavilion at Expo 2020

MEAN (Middle East Architecture Network) from the UAE proposed an original design solution for the Dubai Pavilion (Boulevard Roundabout Pavilion) at the international exhibition Expo-2020.

Imprinted from concrete on

... nine0013The first 3D-printed houses in Mexico are inhabited (video)

We previously wrote about New Story, a non-profit organization that has developed 3D housing technology for the homeless and underprivileged in Latin America. Recently, an ambitious plan has been successfully implemented.

Recently, an ambitious plan has been successfully implemented.

The first stage of the project, in which

... nine0013World's largest 3D printed building opens in Dubai (video)

A new building 9.5 meters high with an area of 640 square meters has been opened in Dubai's Warsan district. It became a record in size among structures created using the 3D printer. The house serves as a clear illustration of the advantages of using such technologies in construction. The authorities are confident that with their help it will be possible to make a revolution in

...3D printer will build a whole village of houses for the homeless

3D printing technology has great potential in many areas - from space to medicine , but the benefits of its practical

...New construction 3D printer can print a house in 12 hours nine0004

The widespread use of 3D printers in the construction industry is a matter of the near future, and the creators of advanced equipment demonstrate not only houses and military barracks, but even entire microdistricts ,

. ..

.. ICON construction 3D printers will build low-income low-income housing in Latin America

nine0005The housing problem can be solved with the help of three-dimensional printing, engineers are sure. Modern technologies 3D-construction allow you to build budget houses, which is especially important for Latin American countries, where many families live on less than $ 200 a month. In the future, such an experience of cheap and fast construction of buildings may become the world's

...3D printing of budget housing has accelerated by 2 times with the new ICON Vulcun II printer nine0004

An Austin-based tech company unveiled the Vulcan II 3D printer, which can print a house up to 180 square meters. m. with the cost of production is two times lower than the traditional method of construction.

"Vulcan II is four times bigger and twice as fast as the previous version, and we are ready to start delivering it to customers in the near future," said ICON CEO and co-founder Jason

. .. nine0013

.. nine0013 India plans to launch mass 3D house construction

Indian company Tvasta Manufacturing Solutions announced its intention to build houses from foundation to finish using 3D printing .

Entirely 3D printed houses could appear in India within a year. The basis for such optimistic forecasts is the success of the Indian Institute of Technology Madras (ITT Madras) team, state

...Construction robot creates pavilion from gravel and rope (video)

In front of the museum in the historic center of the Swiss city of Winterthur stands one of the strangest buildings ever built - the Rock Print Pavilion. At first glance it seems that its columns are made of rough reinforced concrete or gabions, so popular among architects today. However, neither cement nor iron fittings were involved in its creation - in fact, it is made of small loose stones,

...Crane Wasp construction 3D printer can print eco-house for $1000 (video)

Soil construction is one of the oldest techniques that goes well with modern digital technologies. A few years ago, Italian engineers decided to use it in conjunction with 3D printed to build a low-budget sustainable

A few years ago, Italian engineers decided to use it in conjunction with 3D printed to build a low-budget sustainable

New cement mortar for 3D printing will be stronger under load (video)

Engineers figured out how to turn cement mortar's vulnerabilities into strengths in the extreme conditions of fires and earthquakes.

Purdue University researchers have developed a cement paste for 3D printers that could be a key ingredient in concrete or other mixtures used in the construction of complex architectural structures. The new material has an innovative

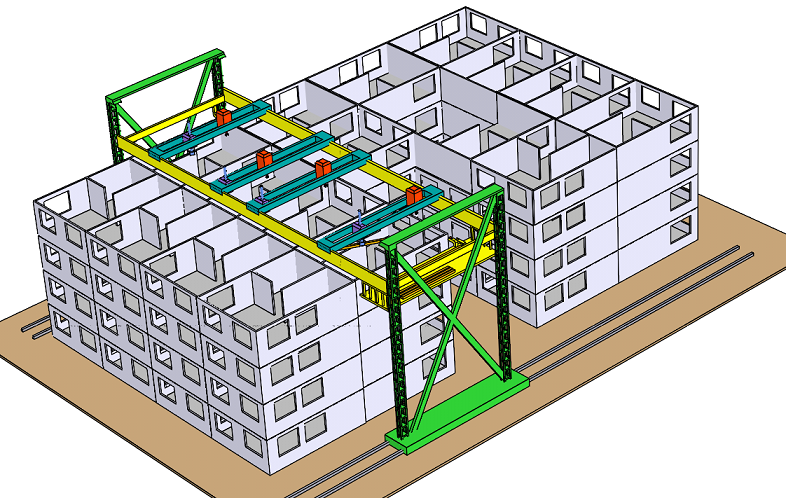

...Mobile building printing robots will make 3D construction more efficient

3D printers are capable of printing very large things, but the amount of work they have to do is often limited. There are manipulators that print anywhere they can get, and portal building printers that create structures such as buildings, as long as the structures are a bit smaller than they are. nine0006

nine0006

To avoid such restrictions, it is necessary to ...

Video: what will be 3D-printed houses on Mars - versions of NASA and participants in the 3D Printed Habitat Challenge

Although it may be a long time before the colonization of Mars , back in 2015 NASA announced a competition for the design of housing for astronauts on the Red Planet - maybe temporary, or maybe permanent. The contest is called... nine0006

In Holland, a whole microdistrict will be created from 3D-printed houses (video)

The Dutch city of Eindhoven will see the first of five designed 3D printed concrete houses this year; It will be put into operation at the beginning of 2019. The partners of Project Milestone are Eindhoven City Hall, the local university of technology, contractor Van Wijnen, building materials supplier Saint Gobain-Weber Beamix and engineering firm Witteveen+Bos. All five

...Span of a metal bridge printed on a 3D printer (video)

The Dutch company MX3D has printed the complete span of the pedestrian steel bridge, which is planned to be installed over the Oudesijs Achterburgwal in Amsterdam. According to post on the company's website, from the beginning of the design of the bridge to the creation of

According to post on the company's website, from the beginning of the design of the bridge to the creation of

"The first 3D printed house in Europe" will be built by Arup and CLS Architetti

Looks like 3D building is going mainstream. This is facilitated by engineering companies Arup and CLS Architetti, who are working together on the "first 3D printed house in the EU". The project is named 3D Housing 05 and its goal is to demonstrate the effectiveness of new additive technologies in

... nine00133D house building with polyurethane foam: French experience (video)

Over the last couple of weeks, the 3D building industry has been aware of several exciting new projects, including the $4,000 print house from startup New Story and "the first European

...A new house printed on a 3D printer will cost $4,000 nine0004

About a billion people on the planet still do not have any housing similar to a normal house. American companies ICON and New Story hope to correct this situation. They learned how to create houses on a 3D printer from local building materials. A printed house with an area of 55 to 75 square meters. m costs about 4 thousand dollars, and its construction takes only one day.

American companies ICON and New Story hope to correct this situation. They learned how to create houses on a 3D printer from local building materials. A printed house with an area of 55 to 75 square meters. m costs about 4 thousand dollars, and its construction takes only one day.

...

Creative agency Framlab has unveiled a new type of parasitic architecture to accommodate the growing number of homeless people in New York City. The concept is called Homed and is a temporary housing consisting of printed on ...

The world's first 3D printed reinforced concrete bridge is being built in Holland nine0004

Engineers from the Faculty of Civil Engineering of the Technical University of Eindhoven (TU/e) have begun to build a concrete bridge on a 3D printer using a new technology. The bike crossing will be part of a new section of the ring road around Gemert, where the construction company BAM Infra will also apply its innovative technologies. It is worth noting that 3D printed bridges have been created before

It is worth noting that 3D printed bridges have been created before

Standalone construction 3D printer to quickly print buildings on other planets created by MIT scientists

Researchers at the Massachusetts Institute of Technology have created a robot that can print an entire building. An innovative 3D construction printer could herald entirely new methods of building structures, significantly reducing the cost and speed of the process.

Using new technology, builders

...For the first time in the world, Cazza will print a skyscraper on a 3D printer

Dubai-based construction firm Cazza has announced plans to build the world's first 3D printed skyscraper. The high-rise building will be built using a technology the company calls "crane printing." For this

...PassiveDom: "smart" eco-house, printed on a 3D printer, developed in Ukraine

Ukrainian startup PassivDom intends to revolutionize the construction industry by offering its 3D printing technology that creates completely ready-to-live . ..

..

Apis Cor: how to print a house on a 3D printer for $10,000 in a day (video) nine0004

It usually takes months or even years to build a residential building. These deadlines exacerbate the housing crisis that is constantly inherent in large cities. Apis Cor decided to overcome this problem with by creating

...At the InnoTech Ukraine forum Maksim Gerbut rozpovist, how to encourage the booths for help from a 3D printer

nine0005 7–9 April at InnoTech Ukraine 2017 speak at the conference as CEO of the project PassivDom Maxim Gerbut.

Topic of the yoga update: “Energy-efficient technologies and mobile life: how 3D-technologies improve efficiency”.

...

World's first 3D printed bridge opened for public use in Spain

For the first time in the world, a 3D printed footbridge has been opened for public use in Alcobendas, south of Madrid. The length of the structure is more than 12 meters. nine0006

The length of the structure is more than 12 meters. nine0006

The grand opening of the printed bridge took place on December 14 in the Castilla-La Mancha Park in Alcobendas. It consists of 8 parts and is made of

...Arconic created the concept of an eco-skyscraper 5 km high (video)

American engineering company Arconic has developed a concept for the city of the future, including 3D-printed kilometer-high skyscrapers, unmanned aerial vehicles, teleportation, and ubiquitous augmented reality. The developers drew inspiration not only from modern achievements and trends in science and technology, but also from

...Cazza will open a way to quickly 3D print houses and entire cities

American startup Cazza plans to automate the entire process of building houses. At the same time, the new method will be environmentally friendly due to 3D printing of buildings using a special technology and proprietary materials developed by the company itself. According to its creator, you can build a house with an area of 100 square meters in

According to its creator, you can build a house with an area of 100 square meters in

A house that will 3D print itself and grow food for its residents

British researchers at the University of Sheffield have come up with a concept for houses of the future that will build themselves using 3D printing and produce food for their owners. The development was called Aquaponic Future Housing (Aquaponic houses of the future). nine0006

These are two or three story buildings printed with ...

Australians built a robot mason (video)

Australian startup Fastbrick Robotics has developed a technology for automatic bricklaying. Created by the company's engineers, the robot named Hadrian 105 is absolutely capable of laying 225 bricks per hour, which is 4 times faster than

...The warmest non-volatile house in the world will be shown in Ukraine

August 16, 2016 in the shopping center "Domosfera" (Kyiv, Stolichnoe shosse, 101) will host a conference-presentation dedicated to the latest achievements in the field of energy-saving technologies and energy efficiency. The Ukrainian technology startup PassivDom will present to the public its latest technology for the production of a modular prefabricated house, which

The Ukrainian technology startup PassivDom will present to the public its latest technology for the production of a modular prefabricated house, which

3D printed houses and modern green building trends at FabCity

The 3D-printed waterproof cardboard houses are one of the most interesting ideas on display at the special exhibition in Amsterdam.

On campus FabCity on island

...ESA plans to build a permanent base on the moon (video)

How realistic is it to build a permanent base on the Moon and what will be required for this? This question includes a wide variety of problems that go beyond the space disciplines. They go far beyond the field of science and technology - two areas that are considered key to space exploration, but additionally include in

... nine0013Construction 3D printer Apis Cor is a mobile robot builder that builds 190 m2 of housing per day

3D construction of houses or contour construction - a technique that has been known since at least 2005. But despite its relative youth, the technology is already

But despite its relative youth, the technology is already

Fake: “3D printers were already printing houses in the 1930s”

nine0492 Fake News07/22/2022 10:22

A message appeared on social networks that already in the 1930s people were able to print residential buildings on a 3D printer. According to the author of the idea, now this technology is being hidden, since such houses would be very cheap, which would allegedly harm the market economy. The mailing is accompanied by a video in which concrete walls are erected using an unusual device. We tell you what is actually shown in the video and why this is not a 3D printer. nine0009

The video being distributed was indeed filmed in the late 1930s in the United States. The footage shows the construction of the building according to the method, which was patented in 1941 by William E. Earschel.

The method itself was to use a special device that was able to erect and immediately smooth concrete walls. However, it is difficult to call it a 3D printer, since the construction process is still not fully automated. On the videos that can be found on the Web, it can be seen that workers manually load concrete already mixed in advance into the machine, and the device itself lays it out only in a circle and nothing else. nine0006

The patent filed by the inventor states that the device can be set up to place concrete in conical or hyperbolic shapes, however this setting must be done by hand. The patent itself was valid for 20 years. It expired in January 1961. Nevertheless, the description and drawings are still kept in the public domain. Therefore, this technology is not secret and anyone can access it.

William E. Ershel's technology differs from today's 3D printers in many ways. 3D printers are programmed in such a way as to lay out the material in certain forms in advance, while the forms can be of absolutely any complexity. The printing process is almost completely automated and does not require heavy physical labor of people. nine0006

The theory that 3D printing at home is currently unprofitable is a lie. In fact, such projects are being developed and are considered very promising. The problem today lies only in the fact that not all buildings constructed in this way meet the safety and quality requirements put forward by the authorities of the states. However, in some countries this issue is already being addressed. For example, 3D-printed houses already exist in Denmark, India and Germany. According to the World Economic Forum, it is this technology that in the future may be the key to solving the problem of providing people with affordable and high-quality housing.