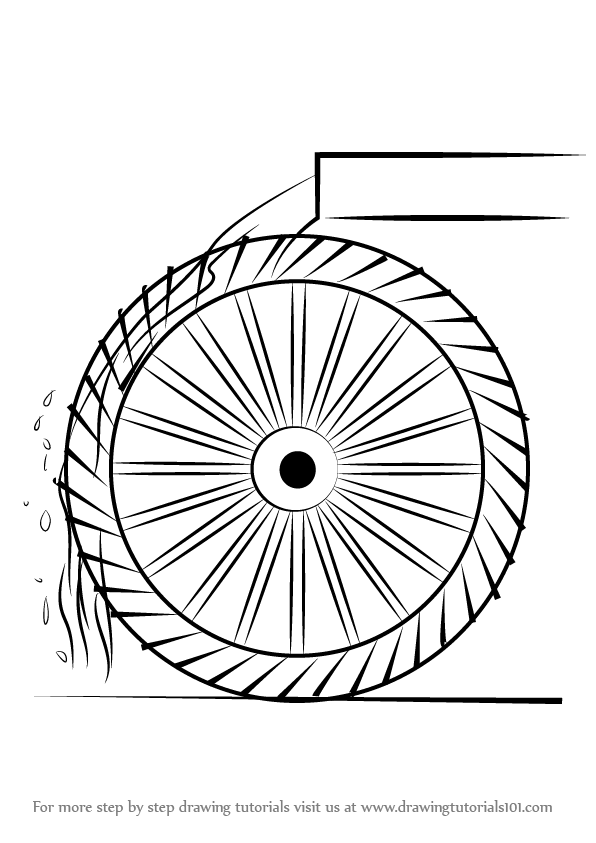

3D printed water wheel

Free STL file Waterwheel・3D printer design to download・Cults

Doors and windows

Free

Train Signal (G gage)

Free

F4 Phantom

Free

Lionel telephone poles

Free

Wood storage box

Free

Mexican Train Engine

Free

f35

Free

Church windows and double door for G gage layout

Free

Best 3D printer files of the Architecture category

Maiden's Tower -Azerbaijan-

Free

Pyramids of Meroe ‐Sudan‐

Free

2-track HO locomotive shed

€3

Column Egypt to paint -Column paintable Egypt

Free

Eiffel Tower HD

Free

Krusty Krab

€6. 14

My Muhammad Ali Mosque(1:1000)

Free

Winterfell

Free

Best sellers of the category Architecture

Diorama Garage | Diecast Garage | 1:64 1/64 |

€10 -60% €4

Tower Of Terror Disneyland Paris

€3.50

Cinderella Castle

€5

NEW YORK CITY - EMPIRE STATE BUILDING - MANHATTAN

€1.74

EMPIRE STATE BUILDING - NEW YORK CITY

€3.99

Grain Bin

€1.72

Disneyland Paris Cinderella Castle

€3. 50

50

Elbphilharmonie Hamburg

€5.90

[Japanese Capsule Toy Machine]EduColon(Rich Design Set)

€4.57

The Space Launch System (SLS): NASA’s Artemis I Moon Rocket with platform. File STL-OBJ for 3D Printer

€2.95

Orthanc Tower - Isengard - Lord of the Rings 3D print model

€1

Kandarian Dagger ,evil dead

€2.60

Godzilla in New York City - Manhattan

€3.60

Giant wheel / ferris wheel / grande roue / 1 meter

€8

Cessna 172 Skyhawk 1:72

€2

Scale maritime container for desktops ASSEMBLY

€6.15

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

▷ mill with water wheel 3d models 【 STLFinder 】

water mill wheel

grabcad

sheet metal water mill wheelASM file can be opened with solidworks 2016 or latest, with "large design review" optionThe is also an 3D PDF file that can be opened with Adobe Reader

Working Water Wheel & Mill

thingiverse

A 9-volt works but may send too much water) - 5. 5mm inner diameter (ID) flexable tubing, approx 6" (Needs to fit over nozzle ends) - 3.8mm diameter x ~32mm long metal pin for wheel axle. - Washer to fit on pin between wheel and building - Some thick...

5mm inner diameter (ID) flexable tubing, approx 6" (Needs to fit over nozzle ends) - 3.8mm diameter x ~32mm long metal pin for wheel axle. - Washer to fit on pin between wheel and building - Some thick...

Wooden toy water mill wheel 3D model

cgtrader

Wooden toy water mill wheel

water wheel mill and bakery - terrain

thingiverse

water wheel mill and bakery - terrain

OpenForge - Open-air Water Wheel Mill

thingiverse

Today we bring you an open-air water wheel mill, perfect for all your local villagers to grind their grains into flour. The water wheel extends over a small river embankment into the running water, which turns the grind stone via a geared shaft.

...

The water wheel extends over a small river embankment into the running water, which turns the grind stone via a geared shaft.

...

Water Mill

thingiverse

Water mill

Water Mill

grabcad

Water Mill

Water mill

pinshape

Mini water mill

Water mill

pinshape

Water mill Molino de agua

Water Wheel with Tower

thingiverse

Created with Design Spark Mechanical. http://www.rs-online.com/designspark/electronics/eng/page/mechanical Have a great day! ...:-) Robert KB3LNN

http://www.rs-online.com/designspark/electronics/eng/page/mechanical Have a great day! ...:-) Robert KB3LNN

Water Mill

sketchfab

Low poly hand painted water mill Based on a painting by Citetanoi Sceppass

Water mill

grabcad

Old scool look water mill Recommendation for connection - use secondary adhesive. ... STL files are marked with x2, x8 are paired parts to be produced in a number of the x

Water Mill

sketchfab

Model for a University assignment where we were asked to make a toony Medieval RTS-style building. ...For this I decided to create a water-mill.

...For this I decided to create a water-mill.

water mill

thingiverse

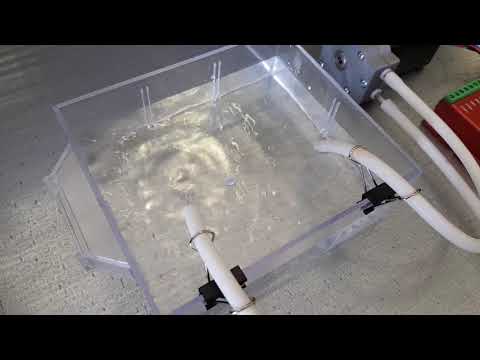

put water in the top and it spins the wheel, put the tab in place and it goes down the other path.

Mill-wheel

thingiverse

Mill wheel. ...The model can be printed at once without gluing (tested on Prusa i3)

Mill-wheel

cults3d

Mill wheel. ...The model can be printed at once without gluing (tested on Prusa i3)

medieval house with a water mill Low-poly 3D model

cgtrader

medieval house with a water mill vertex 15 999 polygon 13 913

Mill wheel decorative wheel

sketchfab

by ArtistJodi ©2020 mill wheel decrative wheel garden accessories wall deco

water mill 3D model

cgtrader

water mill

Water mill (Inventor 2015)

grabcad

Water mill (Inventor 2015)

Water mill - mini

grabcad

Mini water mill for laser cutting

water mill(su değirmeni)

grabcad

autocad 3d water mill(su değirmeni)

Medieval Water Mill

thingiverse

This Water Mill was designed in Sketchup by a student Print Settings Printer Brand: Ultimaker Printer: Ultimaker 2 Rafts: No Supports: Yes Resolution: 100 Microns Infill: 15% Notes: Printed with Brim Supports at 30mm/s Post-Printing

Decorative Pond with Water Wheel 3D model

cgtrader

Decorative pond with a water wheel.

WATER MILL - OO

thingiverse

FILES - MK1_Mill - The basic 2-storey mill with sluice and motor mount. - Mk3_Mill - 2-storey mill with rear steps & retaining wall. No motor mount. - Mk4_Mill - 3-storey mill with rear steps, retaining wall & motor mount. (Note. This file has a...

Classicism - Wind&Water Mill

sketchfab

A mill that creates power from both wind and water made in the style “Classicism” Classicism is the 18th century “French” version of ancient roman/greek architecture

Monjolo: Primitive water mill

thingiverse

Project Project name Monjolo: Primitive water mill Overview & Background You will learn how torque works on a pivotal, free moving, seesaw-like machine. You don't need any background to built this project. You can go deep about into the relation...

You don't need any background to built this project. You can go deep about into the relation...

Spout Water Mill

thingiverse

Clips on to the end of the gutter spout and spins when it's raining. ...Fits roughly 100mm spouting. Use two M5 bolts to attach wheel to clip.

Cartoon water mill

3docean

Preview rendered with V-Ray File Formats: 3ds Max 2012, FBX, OBJ

Water wheel with drink can water supply tank

myminifactory

The camshaft here is driven by an overshot-style water wheel, with water gravity-fed from a raised tank (in our case a standard slim 250 mL drink can, e. g. RedBull). Print the provided files and assemble (with super glue) to create your own. ...

g. RedBull). Print the provided files and assemble (with super glue) to create your own. ...

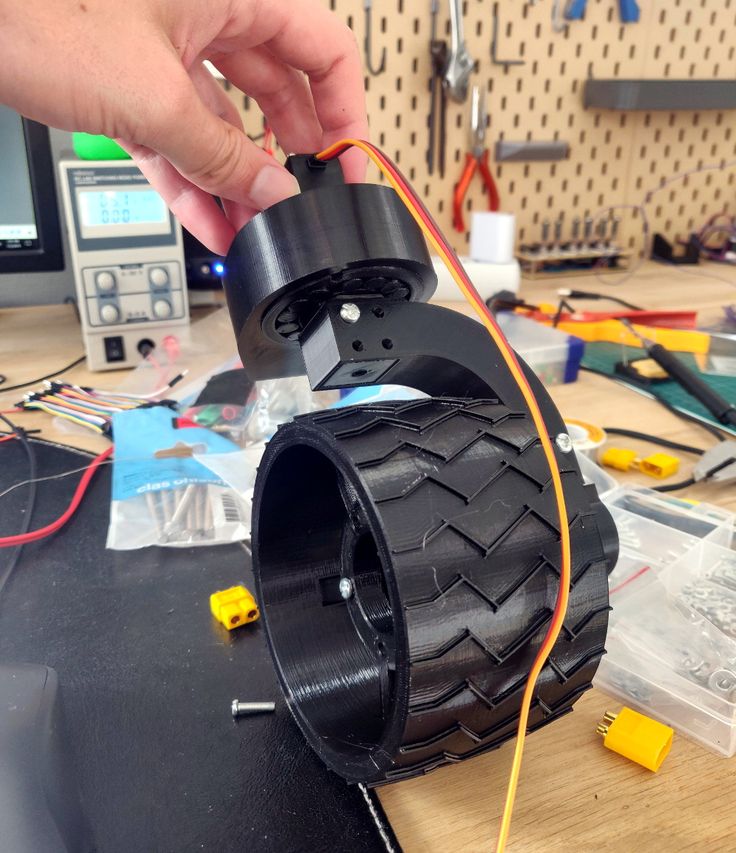

13 notes about 3D printing, after 3 years of owning a 3D printer / Habr

This article will be, first of all, of interest both to those who have directly dealt with 3D printing, that is, who owns a 3D printer, but also to those who are just about to join the ranks of 3D printers and are thinking about buying their own printer.

In the framework of this article, I want to present my observations, as a direct owner of a 3D printer, for more than 3 years.

Despite the fact that 3D printers have been known for a long time and, in my memory, have become widely used, judging by the information on various resources, starting around 2010 (I may be wrong, these are my subjective observations), for a long time I ignored this area, it’s hard to say why…

Probably thought it was some kind of "childish pampering", another hype topic for which there is simply not enough time. ..

..

The turning point happened when one of the wheels on my travel suitcase wore out. You know, a big plastic suitcase, with four spinning wheels on the bottom. Unfortunately, it is a “rather disposable thing”, due to the lack of bearings on the wheels, which is why the wear of the friction point of the axle and wheel allows the suitcase to last no more than one or two seasons. nine0003

And it’s like “lightning flashed in the middle of the day: 3D printer!” It is with his help that I can fix this problem! Looking ahead, I’ll say that I didn’t succeed in fixing the suitcase in this way, so I had to use a different approach ...

As a result, I “upped” it - installing wheels from unnecessary roller skates. Thanks to this “up”, the suitcase has become a real all-terrain vehicle and, even being very loaded, it rides easily - pushed forward even with “one finger”. And even in the snow, 5-6 cm thick. A tank, not a suitcase turned out! By the way - I took spinning wheeled "units" in Leroy. Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

But this thought itself became a kind of trigger that allowed me to finally join the world of printers and buy my first 3D printer.

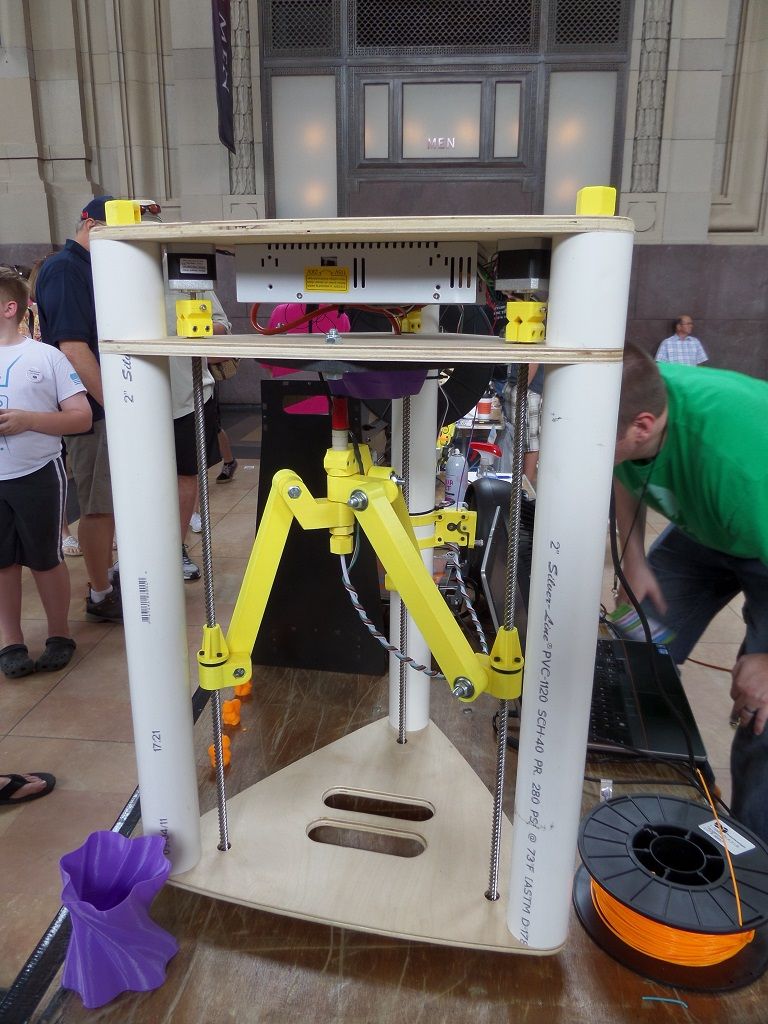

Like many, before buying it, I studied various forums and sites for a long time, delving into all the subtleties. And for some reason, I immediately liked the type of printer called the delta printer. Probably because during operation it looks like some kind of "alien device".

If at your leisure you like to sit “looking into the carpet”, then with the advent of such a printer you will have a much more interesting activity, even hypnotizing, one might say :-))

And this, in fact, is my delta (if anyone is interested), which went through, let's say, the "ultimate up": all the electronics are placed upstairs, on a self-made welded frame, covered with polyethylene and a magnetic door is made. The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

Well, yes, I won’t argue for a long time, let’s start reviewing the main facts that I have accumulated as a result of owning this car ... The facts are purely subjective and may differ from your vision. In any case, I will be glad to comments, clarifications, etc. nine0003

▍ NOTE 1. Delta is good, but...

Here I should give a number of my observations regarding the delta printer:

- It contains a completely finished frame of the future box, which makes it easy to form a heat chamber. I understand that many printers are made in the form factor of a “certain box” (but this point cannot be ignored), which greatly facilitates the process of wrapping this box with heat-insulating material.

In my case, as such a material, I used a plastic film. nine0032

In my case, as such a material, I used a plastic film. nine0032 - Already thanks to its design, delta allows you to work at much higher speeds than XY printers. By the way, it is on the delta principle that many modern high-speed industrial robots are built to sort various parts directly on the conveyor belt:

However, this plus does not allow to fully realize the occurrence of parasitic vibrations, even despite their suppressors:

Thus, accurate printing is possible, only at speeds (at least that was the case for me), no more than 60 mm per second. A complex procedure for aligning the movement of the head parallel to the table, which is why, for many, the so-called "lens" appears. People struggle with it with varying degrees of success, but I have not encountered this on my printer and for me, therefore, the “lens” has never been a problem. At the same point, it is worth noting the calibration of the table, which was initially absent on the first deltas, and I had to use an external third-party solution from one American do-it-yourselfer called EZBED. This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

▍ NOTE 2. "Size doesn't matter..." :-)

When I got the printer, I was impressed by the possibility of huge printouts, a la the handguards of some futuristic rifles, huge body parts, etc.

However, if you try to analyze the results of your many years of practice, it turns out that in most cases, rather small objects were printed that easily fit in the palm of your hand, a maximum of two palms. Despite such a seemingly small size, the printing of these details took a significant amount of time. Of course, this very much depends on which nozzle you print with. But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size. nine0003

But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size. nine0003

Therefore, to be honest, the need for a printer that allows you to print "Venus de Milo in life size" is not obvious.

Of course, you can object to me that “I’m going to buy a printer, I’ll get used to it a little and I’ll get started!!!”

One simple point must be taken into account here: there are no universal things. And in order to understand how much 3D printing in general and your printer, in particular, you will need to solve your problems, and how much it will be able to solve such problems, you just need to first try the 3D printing method personally and then a lot will become clear to you . nine0003

Therefore, for a beginner, I recommend taking a small printer that allows you to print extremely small items that fit in the palm of two. With such a device, you will definitely never lose, as it will always be needed. In addition, with its help you will be able to get used to the printing process and, if necessary, purchase a larger device, already clearly understanding its capabilities and ability to solve your set of tasks.

In addition, with its help you will be able to get used to the printing process and, if necessary, purchase a larger device, already clearly understanding its capabilities and ability to solve your set of tasks.

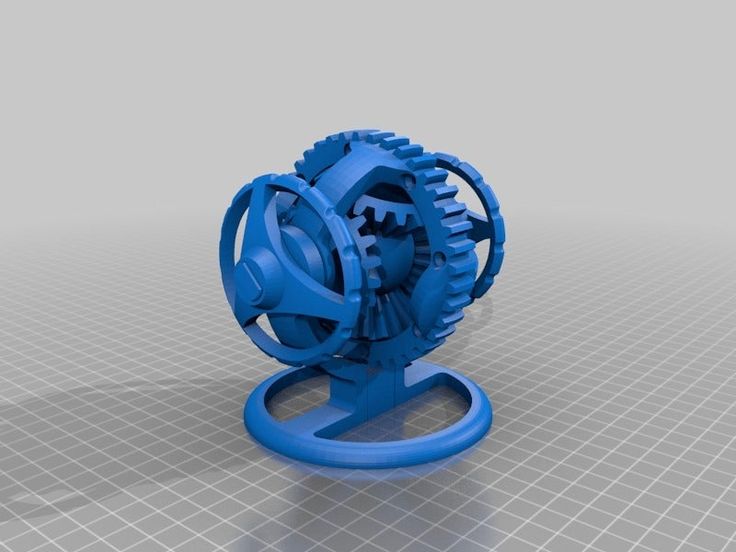

▍ NOTE 3. "What type of printer to get." nine0027

Based on the foregoing, I do not recommend taking a delta printer and this can be said right away.

Not because it is bad, in fact, it prints quite accurately, its main problem (in my opinion) is the inability to print rectangular flat, fairly large case components, as well as the inability to fully realize high-speed work, since the quality drops critically. Here it turns out to be a rather offensive situation - the printer can work quickly, but this cannot be done, since the quality will be “nothing”. nine0003

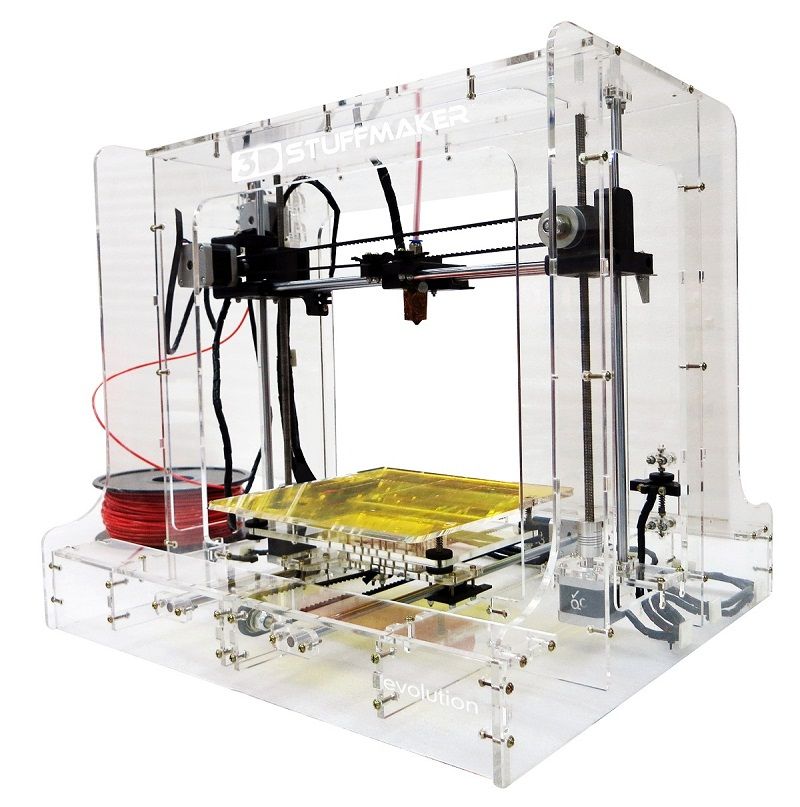

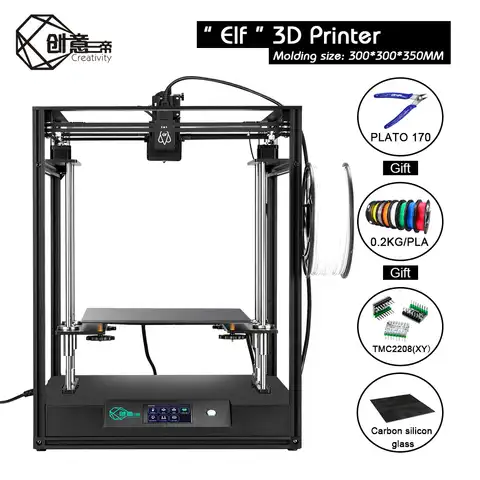

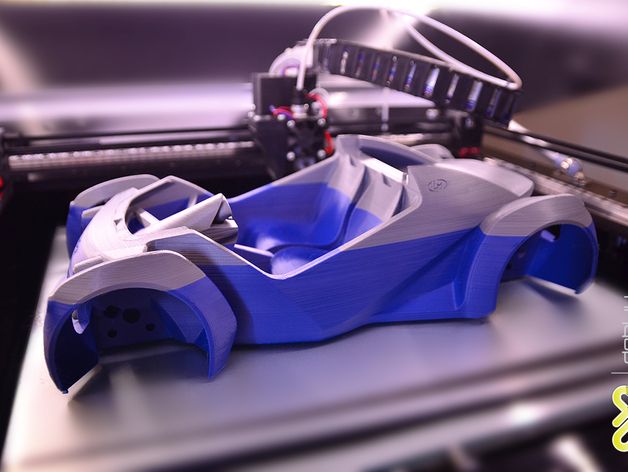

And then what kind to take? Depending on the budget and capabilities, I recommend taking any cube printer, for example, the same Core XY (the head moves, and the table goes down as the model “grows”, from top to bottom):

Image source: thingiverse. com

com

Such a printer allows you to easily print fairly large flat parts of cases, has good speed and accuracy. In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling. nine0003

However, the advantages of this printer will not be fully revealed if it has a direct extruder. On the one hand, it will allow printing with rubber-like materials, on the other -

large inertia and head weight. And these are parasitic vibrations, wear of the fur. parts, etc. (like everything in life, “we treat one thing and cripple another” :-))

At the initial stages, this may not be necessary, but in the future it may be necessary to print, for example, tires for your homemade car. And with this, the Bowden extruder has obvious problems. Although, in fairness, printing with such a rubber-like material is far from a daily need. However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so. nine0003

However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so. nine0003

By the way, there are printers of a cheaper type, the so-called "drygostol", printing by moving the table and head:

They are inexpensive, moderately accurate, but they require a sufficiently high-quality gluing of the printed model to the table, because the table moves, and the model can come off when the table is jerked sharply. When printing large models, this can be a problem.

▍ NOTE 4. What to print with?

It's only a matter of taste and purpose. That is, if your printout will only stand on a shelf and should differ in some kind of aesthetic appearance, these are some requirements, if the printout is an engineering part that will be operated under conditions of increased mechanical load, these are different requirements. That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties. nine0003

That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties. nine0003

For engineering parts, for example, I only use ABS. It combines high hardness, strength and low price. Although I understand that now this last statement will cause a storm of comments in the style of “no! - there is even stronger, even better, the same PETG, etc. ":-)

Just here I wanted to say that thanks to the low price and the practical experiments that I conducted with ABS plastic, I realized that it is completely meets all my requirements. nine0003

However, the fact that ABS plastic releases carcinogenic substances when heated is quite annoying and forces you to take measures to prevent poisoning. For this, my printer prints completely closed and on an open balcony. After printing, the printer chamber opens, and it remains open in this form until it is completely ventilated and cools down.

▍ NOTE 5. "ABS is difficult to type on, it flakes, peels off the table, etc.

.."

.." With a properly configured printer (in my case, at a print temperature of 205 degrees, a thermal chamber and a desktop temperature of 100 degrees), the use of auxiliary techniques, for example, among which, one can name the so-called ABS juice (which is ABS- plastic dissolved in acetone), you can create wear-resistant and durable things, without any hypothetical problems. nine0003

For example, my printer has been printing for many hours at temperatures well below freezing. And this happened more than once, not twice, not three! And the print quality was excellent:

12-hour ABS printing at -4 C

▍ NOTE 6. Acetone for post-processing and ABS juicing

At one time, I wrote a fairly detailed article on this topic and I will try to give the main excerpts from it. The essence of the issue here is as follows: due to the fact that different GOSTs are used for the production of acetone, acetone differs in quality. Despite the fact that it would seem that “acetone is also acetone in Africa,” nevertheless, one type of acetone can differ significantly from each other. For example, ordinary acetone, which can be bought at any hardware store, such as "1000 little things", "store near the house" and the like, is very low quality acetone, smells disgusting (although someone like it, maybe someone likes its pleasant building aroma and "aftertaste" :-))). nine0003

Despite the fact that it would seem that “acetone is also acetone in Africa,” nevertheless, one type of acetone can differ significantly from each other. For example, ordinary acetone, which can be bought at any hardware store, such as "1000 little things", "store near the house" and the like, is very low quality acetone, smells disgusting (although someone like it, maybe someone likes its pleasant building aroma and "aftertaste" :-))). nine0003

In contrast to it, there is a much higher quality acetone, which, however, is not found at all in any household stores, even large chain stores, such as Auchan or Leroy Merlin.

This type of acetone is found exclusively in shops that sell varnishes and paints for automotive work, i.e. these are highly specialized shops for car workshops:

Acetone, which can be purchased there, is of excellent quality, smells almost like alcohol, quickly disappears,

:-) - this is a joke, of course, don't even try it.

However, its main advantage, compared to household type acetone, is that it perfectly dissolves ABS plastic and does not allow it to precipitate. For me personally, it was a very surprising observation when the same ABS plastic was perfectly dissolved with acetone from an auto shop, and completely precipitated when I tried to use household acetone (I just ran out of good acetone, and I had to use "what is "). nine0003

Therefore, if you want your results to always be excellent, then here is the right acetone. It should be labeled "for professional use":

▍ NOTE 7. What about ABS juice?

"ABS juice" is what printers call a mixture of acetone and pieces of ABS plastic dissolved in it. This mixture is smeared on the surface of the desktop before printing and allowed to dry. Thanks to this spread, the model easily sticks to the desktop and does not peel off during the printing process. After printing is completed and the platen has cooled down, the model can be easily separated. nine0003

nine0003

All that needs to be said here is that, after trying different approaches over time, I settled on using flexible metal spatulas, also called "Japanese type spatulas":

According to the results of many tests, this method of spreading turned out to be one of the most convenient options, such spatulas can be cleaned very quickly and easily after work. In other words, highly recommended!

▍ NOTE 8. "Yes, nothing sensible can be done on it, I indulged a little and decided to sell it - you can't use it for anything good anyway"

I absolutely disagree with the statement above, which is periodically heard from newcomers to 3D printing. You can even say more: at the moment I can’t even imagine how I used to live without a 3D printer! Since it is he who makes it possible for any do-it-yourselfer to significantly expand their capabilities and make piece products, almost of factory quality! Of course, for this, appropriate hands must be applied to the 3D printer, but that’s another question… and take on things that I would never have thought to take on before! nine0003

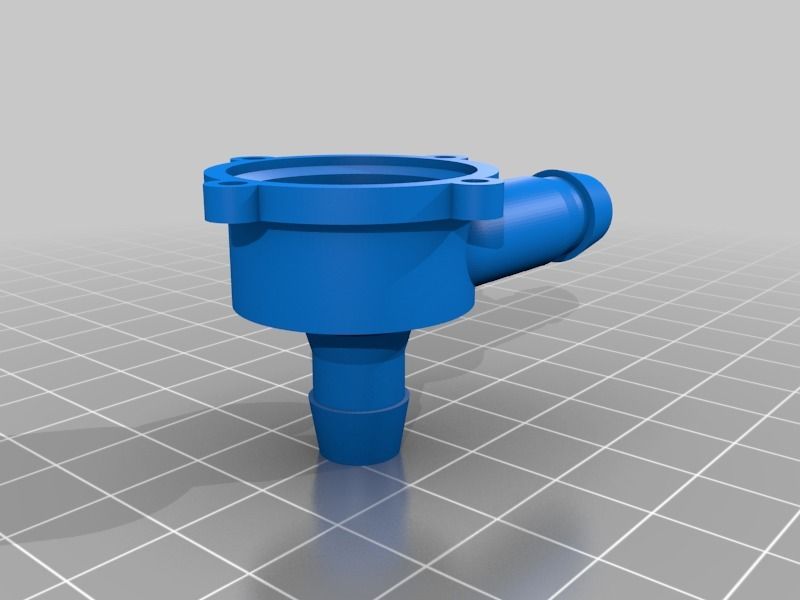

For example, among my homemade products, the following can be listed:

- Heated sole for boots, which is a hose integrated into the insole (and filled with household silicone from a household store), through which water flows, heated with a catalytic type hand warmer.

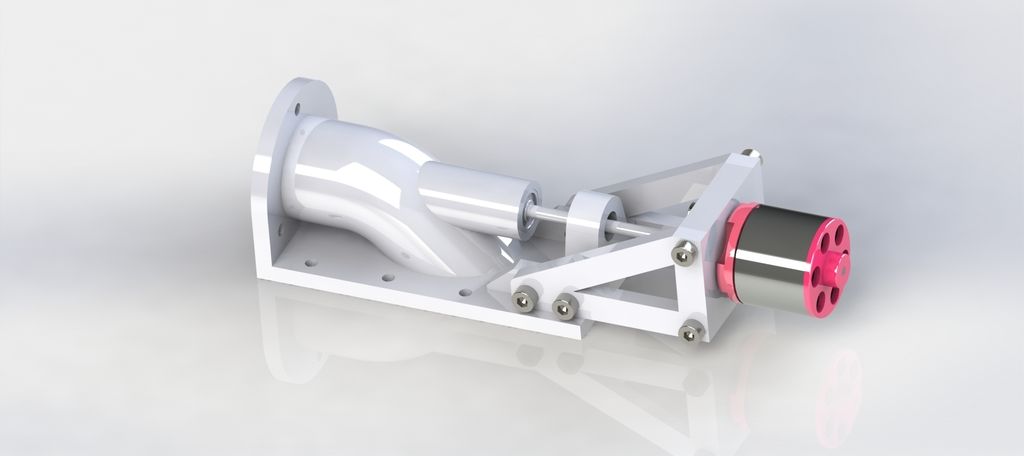

Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater. The project is currently in progress. nine0032

Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater. The project is currently in progress. nine0032

- Centrifugal water pump mounted on the shaft of an internal combustion engine that drives a high pressure wearable air compressor with a pressure of 500 bar. The pump pumps coolant through the casing of the high pressure pump, or rather its second stage. Despite the fact that the pump is 3D printed and runs at over 6000 rpm, nothing “fell apart, fell apart, didn’t break.” As you can see in the photo, the pump is installed instead of the “starter”, that is, the armstarter. The compressor scheme as a whole is as follows: 2 engines. Connected by clutch. One is heavy duty. The second is modified and turned into a high pressure compressor:

Yes, before assembling this, I also did not believe that this was possible. Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

- I printed a number of Rank-Hilsch test tubes, the essence of which I have described in detail in this article.

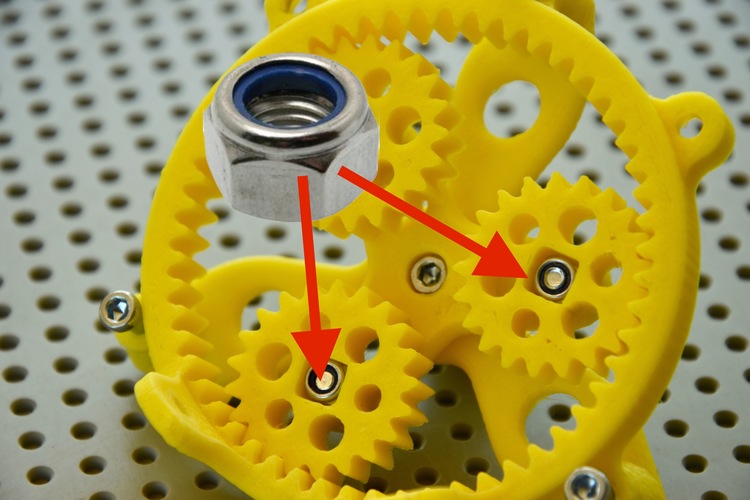

- Printed mass of parts, more than 100 pieces, to create 10 web-controlled robots. There was also a detailed article about this here.

Well, and a bunch of all sorts of useful and not very crafts. As you can see from my crafts above, I have a special passion for creating some useful things, a utilitarian direction. That is, so that the printout is useful, and does not belong to the type “yyy breathe, Mikola, what am I doing here” :-), and then put it on the shelf and that's it. Although, engineers are also not alien to beauties, and this will be my next fact below. nine0003

▍ NOTE 9 Proper placement of the model when printing is half the battle

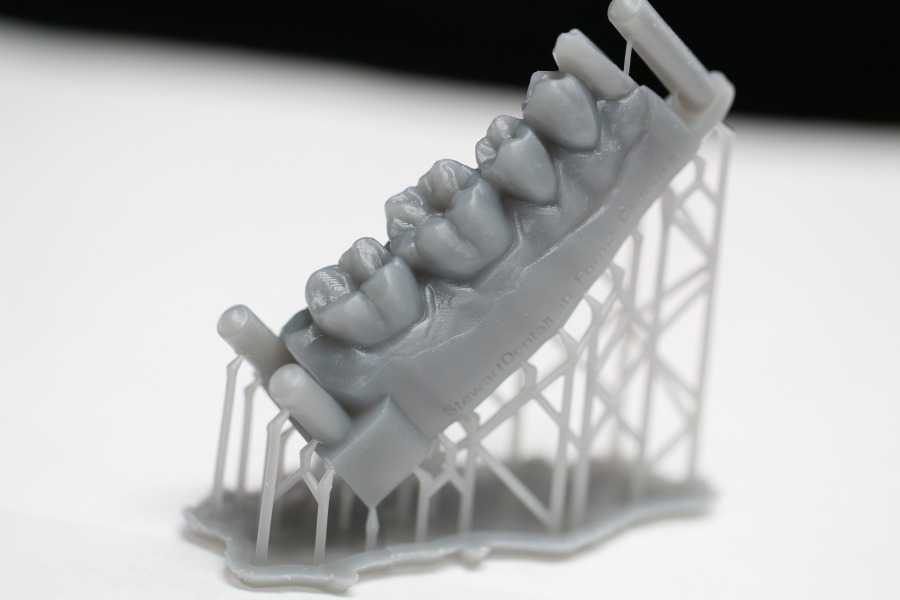

It would seem an obvious fact, but many underestimate it. Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

This allows the layers in the printout to run at an angle of approximately 45-50 degrees to the model. The result of this is that the printed model is almost completely invisible layers and the model looks like it has been post-processed, but at the same time retains a deep matte color, which, to my personal taste, is more like a marble than a glossy result of processing in an acetone bath : nine0003

An additional advantage of this method is that the layers going at an angle of 45-50 ° to the model give it additional strength. This is especially true for printing statues, which contain many thin elements that are easily chipped when the statue is accidentally dropped from a table or shelf (learned from bitter experience, this happened to me many times, and ruined some fairly decent prints).

That is, the layers going across the model, if the model has a large length in height, does not allow it to maintain sufficient strength. For better understanding, I tried to illustrate this point in the figures below:

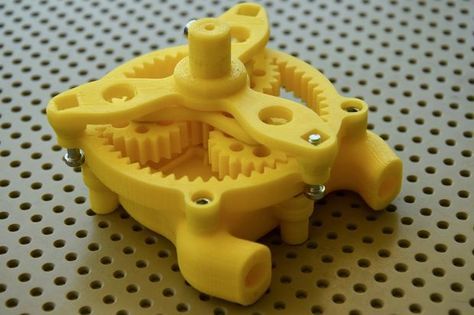

▍ NOTE 10. Bleeding must be taken into account when printing, especially if the model is composed of separate parts and must be assembled by joining these parts to each other, entering into each other, etc.

I tried to illustrate this point in the figures below. The implication here is that if you're printing a composite model, you need to correct for the amount of bleed on the plastic (I'm not sure what it's called, but at least I tried to convey what I mean). If this is not taken into account, then the model will not fit. nine0003

For example, in my case this correction is 0.2 mm per diameter - if I want the model to fit more tightly; if I need a free joint, without excessive density, then 0.3 mm per diameter:

That is, suppose that the blue part has a size of 10x10mm. So it must be modeled in a CAD program as 9.8x9.8 mm (if we want it to sit tight) or 9.7x9.7 mm (to sit freely). Well, or expand the hole in the green part, and leave the blue one as it is. nine0005 This is often a problem when you download a prefabricated model from the Internet - but it is not going to, even if you crack! And because no amendments have been made…

So it must be modeled in a CAD program as 9.8x9.8 mm (if we want it to sit tight) or 9.7x9.7 mm (to sit freely). Well, or expand the hole in the green part, and leave the blue one as it is. nine0005 This is often a problem when you download a prefabricated model from the Internet - but it is not going to, even if you crack! And because no amendments have been made…

For your particular case, the amendments may be different.

▍ NOTE 11. What if...

In fact, this note complements note number 8. Using a 3D printer allows you to create metal parts using a printed 3D model. For this, the casting method is used according to the lost wax or burnt model. In our case, we will deal mainly with metal casting on a burnt model. nine0003

Briefly, it looks like this: printing a 3D model (using PLA plastic) → pouring it with plaster → burning PLA plastic, simultaneously with burning the mold, in a conventional stove oven → pouring the resulting mold with molten metal (melted in a conventional microwave) .

Image source: 3dtopo.com

I told about a simple method of melting metals in a home microwave oven here.

There was even a good article about casting on Habré. nine0003

▍ NOTE 12. Durability?

Despite the fact that ABS plastic is called exposed to ultraviolet radiation and, accordingly, burns out, losing its strength in the sun, in my practice, even printouts that are constantly exposed to the sun have not lost their strength and color at all, continuing to be successfully used and Currently.

It should also be added here that printouts are constantly exposed not only to the rays of the sun, but also work continuously in damp conditions! nine0003

As such printouts, I can give an example of winglets for technical cranes, which I printed out, but, unfortunately, did not photograph this process; as well as fasteners on shoes that I use “both in the snow, and in the heat and in the pouring rain, and in general are always with me”:

▍ NOTE 13.

And what about the thread?

And what about the thread? Periodically, there is a need to print parts containing a particular thread. Modeling such products requires a good understanding of what a thread is in general, as well as what corrections need to be made in your particular case, which I have already described above. nine0003

But since I've owned a metal lathe for a long time, I'm not at all happy with the 3D printed carving that looks like "something very carving-like".

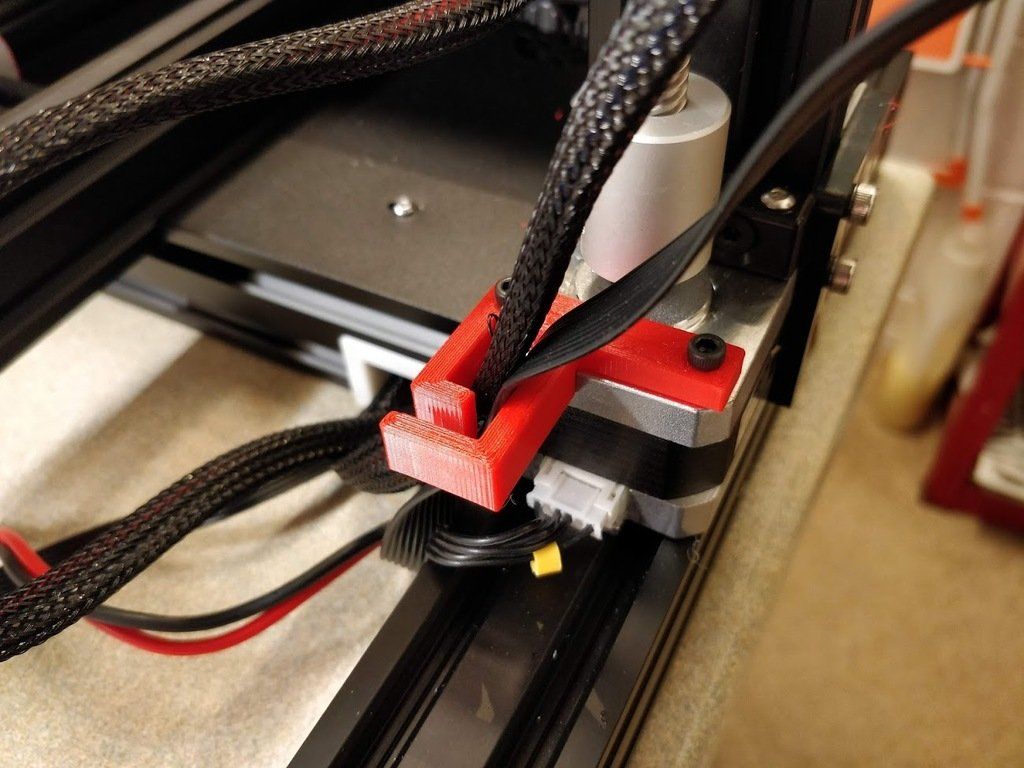

I am satisfied with an exceptionally perfect carving. Therefore, I keep in stock a large set of various taps and dies, with which I cut all my threads in plastic printouts:

I posted a photo of dies and taps not to brag, but to make the reader understand that serious carving requires a serious approach (unfortunately). And considerable costs for all this thread-cutting iron ...

To create your own threads (both threaded channels and threaded pins), I recommend the following reference materials: for holes, for pins.

Well, that's where I want to end my story and note that he does not claim to be exceptionally accurate and exhaustive. Nevertheless, I tried to state a number of my observations. It will be interesting to read yours, in the comments!

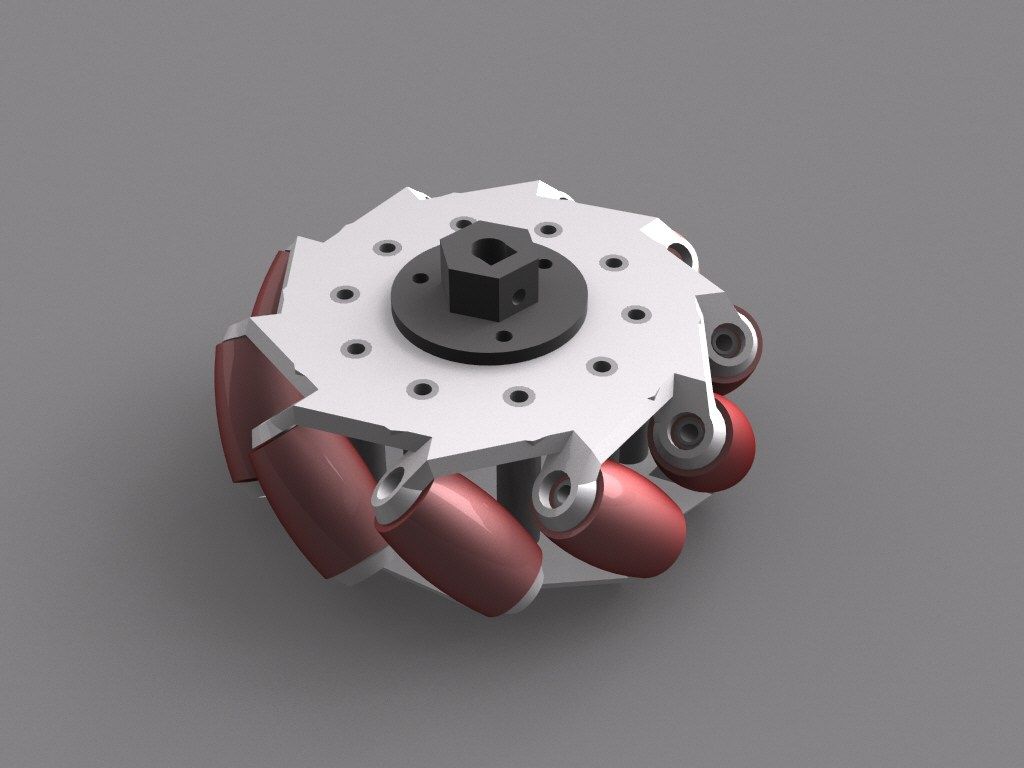

Water wheel STL file・Model for download and 3D printing・Cults

box

1 €

Renault logo

2 €

Best 3D Printer Files in Architecture Category

Deactivated

1900 level crossing with rail crossing

6.50 €

nine0216 Chair CH07 Hans Wegner1,50 €

Wat Phra Kaeo in Thailand

Free

Wall nerve clip

1 €

Eiffel Tower HD

Free

Leon Cathedral

Free

Bestsellers in the category Architecture

House Toretto v2

4. 98 €

98 €

Space Launch System (SLS): NASA Artemis I Lunar Rocket with Platform. STL-OBJ file for 3D printer

2.95 €

Kandarian dagger, evil dead

2.60 €

nine0216 1/64 Generic Showroom1 €

NEW YORK - EMPIRE STATE BUILDING - MANHATTAN

1.74 €

Cinderella's Parisian castle at Disneyland

3.50 €

Table top scale shipping container ASSEMBLY

6.15 €

Diorama Garage | Diecast Garage | 1:64 | 1/64 | nine0217

10€ -60% 4 €

Birdhouse -3 pieces

3,80 €

Garage equipment and furniture

1 €

Grain tank

1. 72 €

72 €

EMPIRE STATE BUILDING - NEW YORK

€3.99

1-100th scale furniture Architecture

0,74 €

Elbphilharmonie Hamburg

5,90 €

Lusail Stadium

5.11 €

Fence v2 - 1:35

0.50 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

-

AD: Disable AdBlock banner blocker and click on our banner ads.