3D printing watch

Free-D, a 3D Printed Watch With a Unique Design

3D printing news News Free-D, a Dynamic 3D Printed Watch Combining Traditional and Innovative Technologies

Published on April 6, 2022 by Clemens M.

SevenFriday, a company based in Zurich, offers lifestyle accessories such as watches and eyewear. From its beginnings, the company’s main objective has been to offer unique designs inspired by the industrial world. For 10th anniversary, SevenFriday certainly did not to disappoint on this. The brand recently unveiled a new watch called Free-D with an impressive and unique design. The accessory integrates many 3D printed elements and wants to give a futuristic impression by its design and its “architecture”.

This is not the first time that additive manufacturing has been used to design watches. Several companies have already adapted the technology to manufacture unconventional timepieces. One example is the French startup Kairod. The young company has developed a watch uses laser powder bed fusion processes, enabling them to combine tradition and innovation. Similarly, Zigante, another startup, uses FDM technology to design custom-made and ecological watches. As you can imagine, 3D technologies allow watch manufacturers to use less materials as well as minimize waste, allowing for more sustainable production.

Photo Credits: SevenFriday

A Closer Look at the FREE-D

The watch, which is extra large, mixes both conventional manufacturing methods and innovations. While the inner titanium case is machined using traditional manufacturing, the outer lining is 3D printed from PA11. Thanks to this material, the company is able to design organic, lightweight and durable parts. And the company certainly seems pleased with the results, “The latest version challenges everything you’d expect from an ordinary watch. Reminiscent of space travel, both in shape and feel, the FREE-D is the fantasy of every back-to-the-future fanatic.”

For those who would like to purchase the Free-D, the watch will be available for €3420, which places it among the most expensive products marketed by SevenFriday. In addition, the Free-D comes with a digital image of itself and a certificate in the form of a NFT, accessible through a NFC chip that’s embedded in the back of the case. Currently, the watch is not actually available for sale on SevenFriday’s website, but the company has officially announced the launch of the product, as you can see in the video below.

In addition, the Free-D comes with a digital image of itself and a certificate in the form of a NFT, accessible through a NFC chip that’s embedded in the back of the case. Currently, the watch is not actually available for sale on SevenFriday’s website, but the company has officially announced the launch of the product, as you can see in the video below.

What do you think of the Free-D, the watch developed by Seven Friday to celebrate its 10th anniversary? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: SevenFriday

Is It Now Possible To 3D-Print A Mechanical Watch Movement?

Written by Ashley Sandeman and edited by Ariel Adams

The first time I saw a Star Trek replicator, I knew I had to have one. And high on the list of objects I’d like to print at home is my own mechanical watch.

And high on the list of objects I’d like to print at home is my own mechanical watch.

Advertising Message

But despite all the promises of 3D printing technology, miniaturizing metallic parts at a watchmaking scale has remained elusive. Hopes, however, remain high as the technology in question is evolving rapidly. Cracking the shell of the 3D-printed metal mechanical watch movement could forever change the economics and power bases of today’s luxury wristwatch industry.

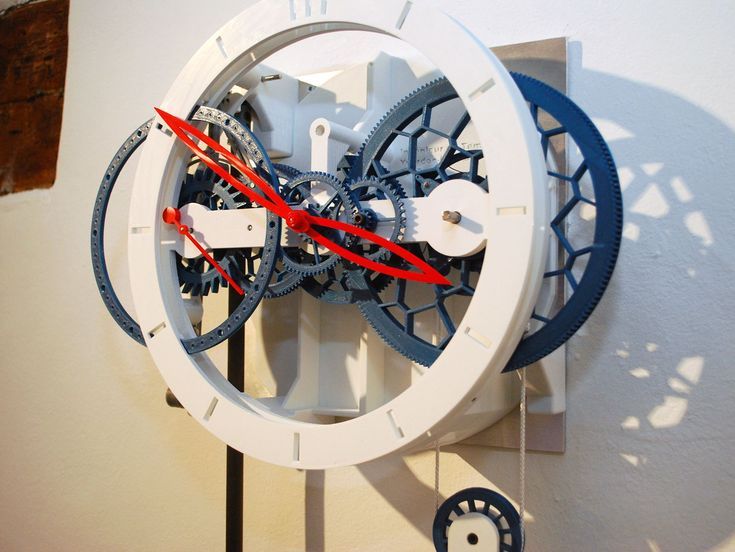

Photo Credit: SSPopov

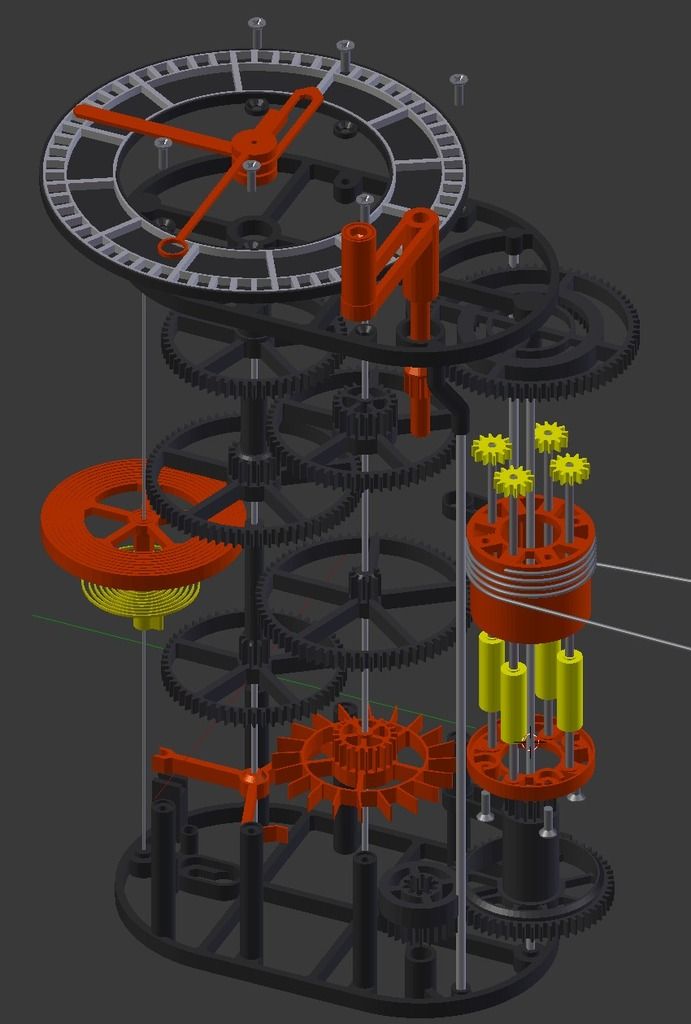

Back in 2014, I became excited by the work of watchmaker and software engineer Nicholas Manousos, who 3D-printed the Tourbillon 1000%. Printed in PLA (Polylactic acid) plastic at a ten-fold size increase of a normal tourbillon, this was part of a larger project to produce a fully functioning movement. It was later abandoned due to technical challenges.

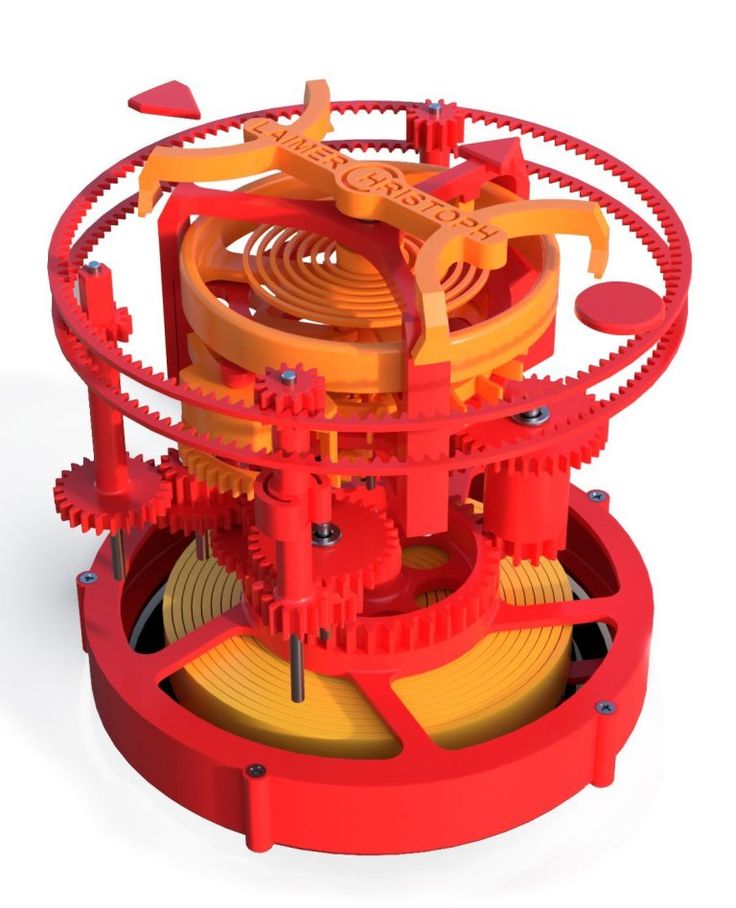

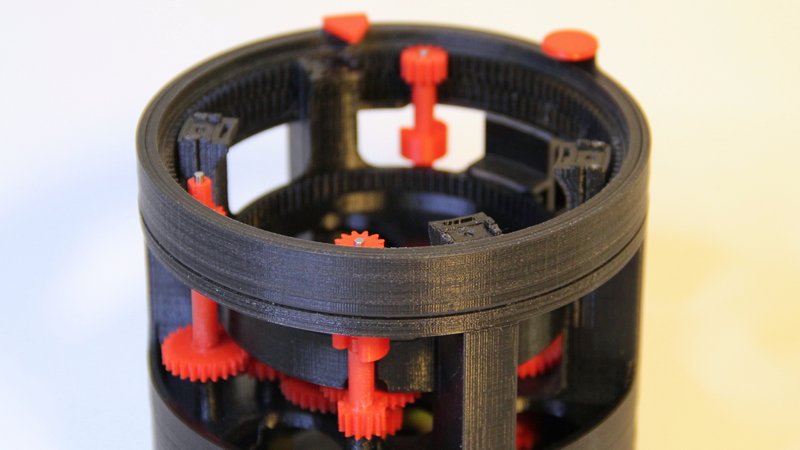

In 2016, Christoph Laimer gave us further hope. He 3D-printed a tourbillon pocket watch at 98mm in diameter that ran for about 30 minutes using a consumer-grade printer.

Advertising Message

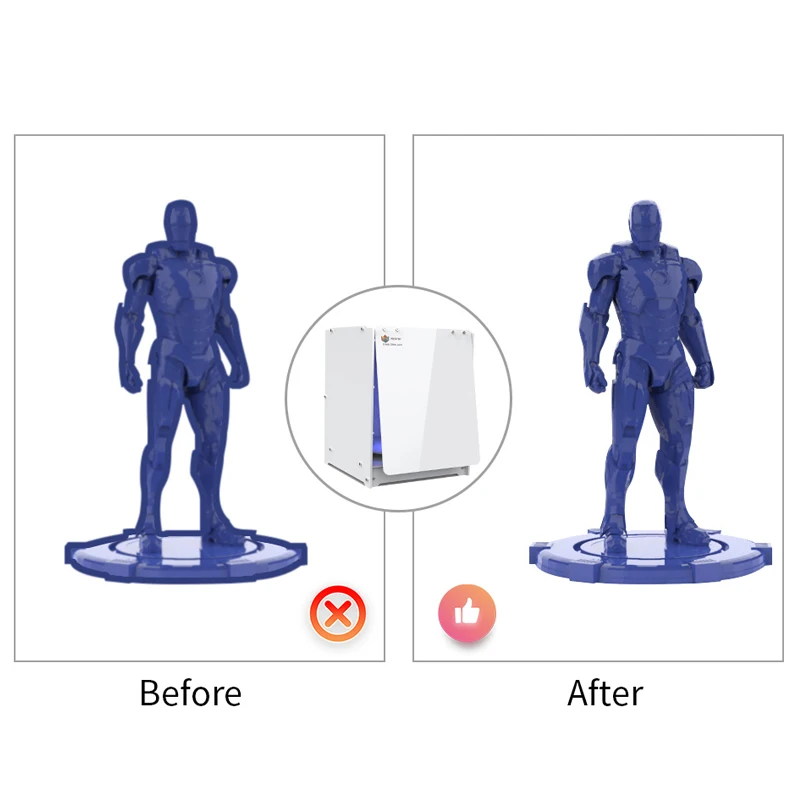

More recently, Panerai used the 3D printing technique DMLS (Direct Metal Laser Sintering) on the case of the Luminor Marina – 44mm (PAM01662). This makes Panerai one of the few companies to take 3D printing to production. Elsewhere, we’ve seen 3D Printing used for rapid prototyping in R&D departments at IWC, A. Lange & Söhne, Parmigiani, and the R&D Q-Lab at Roger Dubuis. Admittedly, these uses are not related to internal watch movements or mechanisms. Rather, they are mostly decorative or helpful in the context of testing new product designs.

Over the same recent timeframe, the most visible miniaturization of consumer technology means smartphones can now replace laptops. And your smartwatch can replace some functionality of your phone. So, with all these advancements, why isn’t anyone able to solve the challenge of 3D printing a fully metallic watch? The answer comes down (ironically) to accuracy and precision.

And your smartwatch can replace some functionality of your phone. So, with all these advancements, why isn’t anyone able to solve the challenge of 3D printing a fully metallic watch? The answer comes down (ironically) to accuracy and precision.

The layperson might think 3D printing a watch is straightforward. You take a CAD model of the watch, feed it into a machine, and out pops your product. No more Rolex shortages, right? But while we can print basic parts at home in rough plastic, it’s more complicated when it comes to precise metal parts. And with regard to 3D printing, the frontier has moved beyond plastic. Certain forms of metal can now be 3D-printed, as well — which is where real watchmaking comes in.

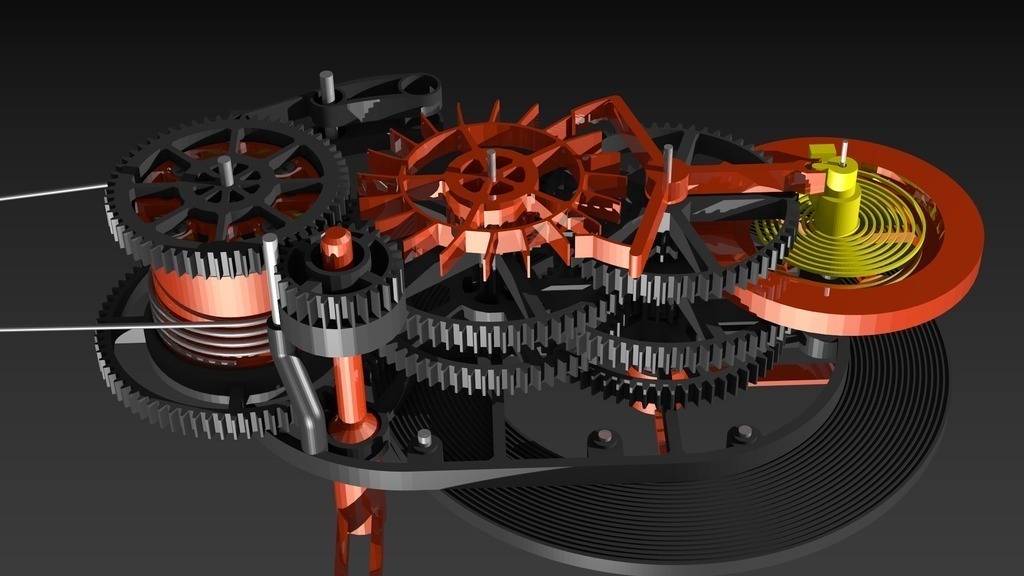

Timepiece aficionados often forget that beneath the dial, a movement’s components make up the majority of parts in a watch — which typically number in the hundreds of — if not several hundred — parts). Precision intolerance is one of the major reasons we haven’t seen printed movements yet. The current landscape of commercial and industrial 3D printing machines simply aren’t suited for the tiny sizes and near-perfect tolerances even the most basic of mechanical watch movements require. In many ways, the industrial machine that the traditional watch industry built to mass-produce precision parts is a key component in its longevity. Much of the know-how remains tightly guarded at companies in Switzerland. For example, there are only a handful of companies that can produce their own regulation system balance springs. The Swatch Group’s Nivarox is among the few companies that can mass-produce them — and they still don’t have very many competitors.

The current landscape of commercial and industrial 3D printing machines simply aren’t suited for the tiny sizes and near-perfect tolerances even the most basic of mechanical watch movements require. In many ways, the industrial machine that the traditional watch industry built to mass-produce precision parts is a key component in its longevity. Much of the know-how remains tightly guarded at companies in Switzerland. For example, there are only a handful of companies that can produce their own regulation system balance springs. The Swatch Group’s Nivarox is among the few companies that can mass-produce them — and they still don’t have very many competitors.

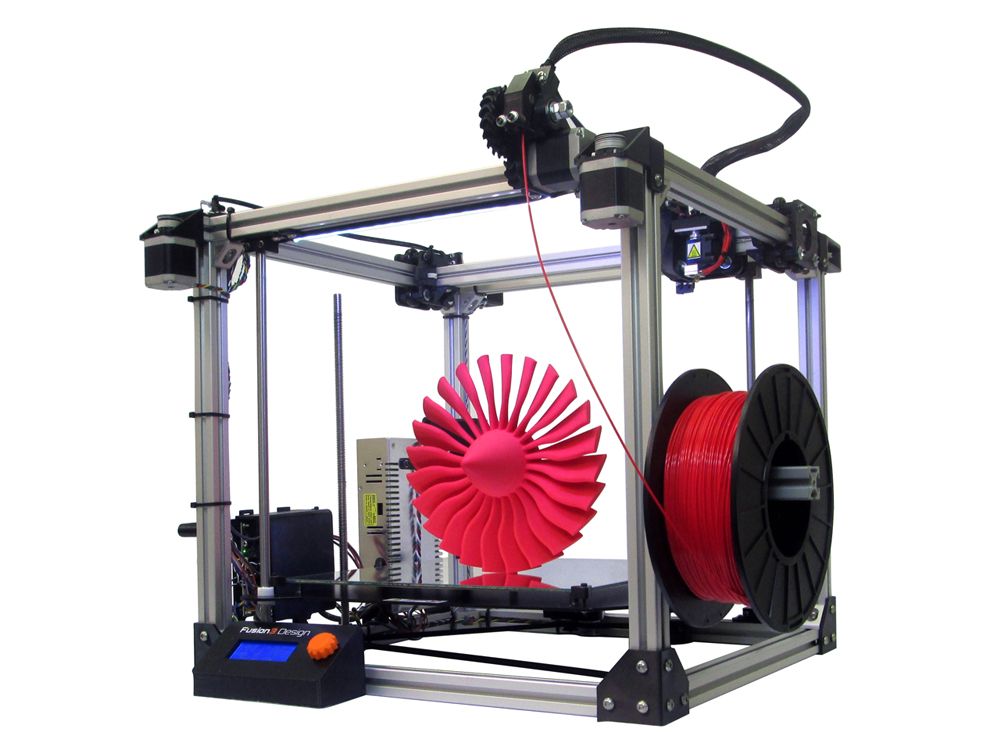

To help understand the 3D printing precision gap, I sat down with British watch designer, aerospace engineer, and expert in 3D printing, Gregg Cowell. Cowell has undertaken this challenge over the past three years and answered using his pictured prototype watch to illustrate. The watch was produced using production-level manufacturing equipment across four different locations in the UK.

His watch (pictured within this article) demonstrates what different 3D printing techniques can achieve (and not necessarily mainstream tastes). The case is produced under high-resolution laser titanium melting. Cowell has taken his prototype further, printing a single interlinked bracelet using a coarser powder mixture under a standard resolution titanium laser method. Meanwhile, the bracelet clasp is produced in steel using binder jetting, as printing titanium is prohibitively difficult at the scale of the clasp. Finally, the high-finish rhodium dial is produced using a mixture of old and new technology called lost wax casting.

The different techniques are important, maximizing the product definition of each part. For example, Lost wax casting was used on the dial of Gregg’s watch because it produces a better finish than laser sintering. Similarly, the DMLS process used to produce the Luminor Marina case isn’t suitable for the precision parts of movement manufacture because where laser melting is used, it produces tiny surface bubbles that must be removed after printing. The difficulty comes in manufacturing highly finished parts small enough and strong enough to withstand the forces generated by the movement. There are new and experimental miniaturizing processes, such as MICA Freeform, but this focuses on sizes too small to replicate traditional escapements. Cowell has produced a metallic escapement fork but has been unable to achieve a tolerance for it to operate in a working movement.

The difficulty comes in manufacturing highly finished parts small enough and strong enough to withstand the forces generated by the movement. There are new and experimental miniaturizing processes, such as MICA Freeform, but this focuses on sizes too small to replicate traditional escapements. Cowell has produced a metallic escapement fork but has been unable to achieve a tolerance for it to operate in a working movement.

An easy way to improve 3D printing precision is to simply make a finer writing instrument. In 2014 the hefty size of the Manousos Tourbillon 1000% was dictated in part by the nozzle width-limitations of the printer and the tolerances required to make it function without ripping off gear teeth. Manousos wasn’t able to achieve the needed tolerance precision with 3D-printed plastic until working at 1000% of the original metal movement’s size. Cowell likewise believes traditional escapement designs are ill-suited to manufacture given the current limitations and capabilities of current printing technology.

Photo credit: Marina Grigorivna

As watch lovers, we can only speculate that applicable 3D printing experts over at the larger watch brands have all come to similar conclusions about how 3D printing currently can’t do much for them. Today, 3D printing technology isn’t well-suited to the lilliputian part size-needs of traditionally manufactured watches. That said, the tolerance of 3D-printed metal (in combination with some finishing processes) might be a welcome addition to the construction of watch cases and other structural elements.

I asked Alessandro Ficarelli — Product Development Director at Panerai — why the brand chose a 3D-printed component for a case construction part for the PAM01662, and also what developments we can expect to see next from the Panerai Laboratorio di Idee. Here is what he said [edited]:

“3D printing technologies are often used for prototyping since the quality level normally reached by the printed material is not sufficient for production parts. “Panerai, after a long development phase … started with the improvement of the powders used as raw material and ended with the configuration of the entire 3D printing process. [Panerai] managed to achieve a quality of the printed material without equal. This material has no porosity; its behavior is perfect through all the printed part and makes it possible to produce technically and aesthetically perfect components, meeting the very high standards of Panerai. Looking at the future, we will further explore the universe of more durable, eco-friendly materials to ride the new sustainable challenges of tomorrow.”

“Panerai, after a long development phase … started with the improvement of the powders used as raw material and ended with the configuration of the entire 3D printing process. [Panerai] managed to achieve a quality of the printed material without equal. This material has no porosity; its behavior is perfect through all the printed part and makes it possible to produce technically and aesthetically perfect components, meeting the very high standards of Panerai. Looking at the future, we will further explore the universe of more durable, eco-friendly materials to ride the new sustainable challenges of tomorrow.”

This final statement refers to Panerai’s 2020 developments of the eco-sustainable basalt-fiber composite material Fibratech™ and the new EcoPangaea™ composite. It points toward another change we’ve seen since 2014: the rise of company eco-credentials and the environmental awareness of consumers that are driving innovation and sales. But that is another story altogether that aBlogtoWatch has also been covering.

In 2018, Roger Dubuis CEO Jean-Marc Pontroué was quoted in the South China Morning Post as saying there was a “high likelihood” we would see 3D printed movement parts in its watches by 2019. That date has passed, and Pontroué is now CEO of Panerai. I asked current Roger Dubuis CEO Nicola Andreatta if he could expand on the comments of his predecessor, but for now, Roger Dubuis is making no comment.

Photo credit: Moreno Soppelsa

Unless that comment comes in the form of a product, it looks unlikely we’re on the verge of a 3D printing revolution in the mechanical watchmaking world. Like many industries, material developments in watchmaking are increasingly used to highlight environmental awareness. 3D printing is not as cool these days as saving the planet. But it is probably technology we need if we are ever going to get off this planet.

Relatively modest consumer demand for luxury 3D printed products makes it unlikely that many brands will invest in vanity 3D-printed watch case materials today. Consumers will spend a premium on products that apparently have some connection with earth-friendly sustainability — even if there is no direct evidence those products actually result in net gains for ecological impact reduction.

Consumers will spend a premium on products that apparently have some connection with earth-friendly sustainability — even if there is no direct evidence those products actually result in net gains for ecological impact reduction.

Photo credit: Marina Grigorivna

The current nerdy unsexy view on 3D printed components, from a pop culture perspective, makes it hard to imagine that established luxury watchmakers will be striving to press the boundaries of 3D printing technology, especially when the security of machined movements is under no threat from the market or driven forward by consumer pressure.

Watchmakers all seem to agree that if one could 3D-print metal watch parts it would be a game-changer — not merely in being able to mass-produce parts in a new way but also to solve some old problems while answering new ones. The vintage and restoration market will fundamentally change when brand new parts (that have the potential to again ask the question of what is “vintage”) for old watches can be produced out of relative thin air, and then simply polished to perfection. Creatives would also love the new level of design freedom afforded by an ever-expanded set of structural part opportunities. A 3D-printed part could easily befuddle even the most complicated of computer-controlled cutting (CNC) machines. What the CNC machine has on 3D printing today is, again, precision. Given the incredible promise to the watch industry afforded with the eventual availability of precision 3D-printed parts, the technology’s advent is worth watching out for.

Creatives would also love the new level of design freedom afforded by an ever-expanded set of structural part opportunities. A 3D-printed part could easily befuddle even the most complicated of computer-controlled cutting (CNC) machines. What the CNC machine has on 3D printing today is, again, precision. Given the incredible promise to the watch industry afforded with the eventual availability of precision 3D-printed parts, the technology’s advent is worth watching out for.

Ashley Sandeman has loved watches since getting a Casio TS-100 at age six. Now a little older, he helps businesses deliver strategy and writes about watches, lifestyle, and fiction. He sometimes still wears the TS-100, and anything else he can. Connect with Ashley on LinkedIn.

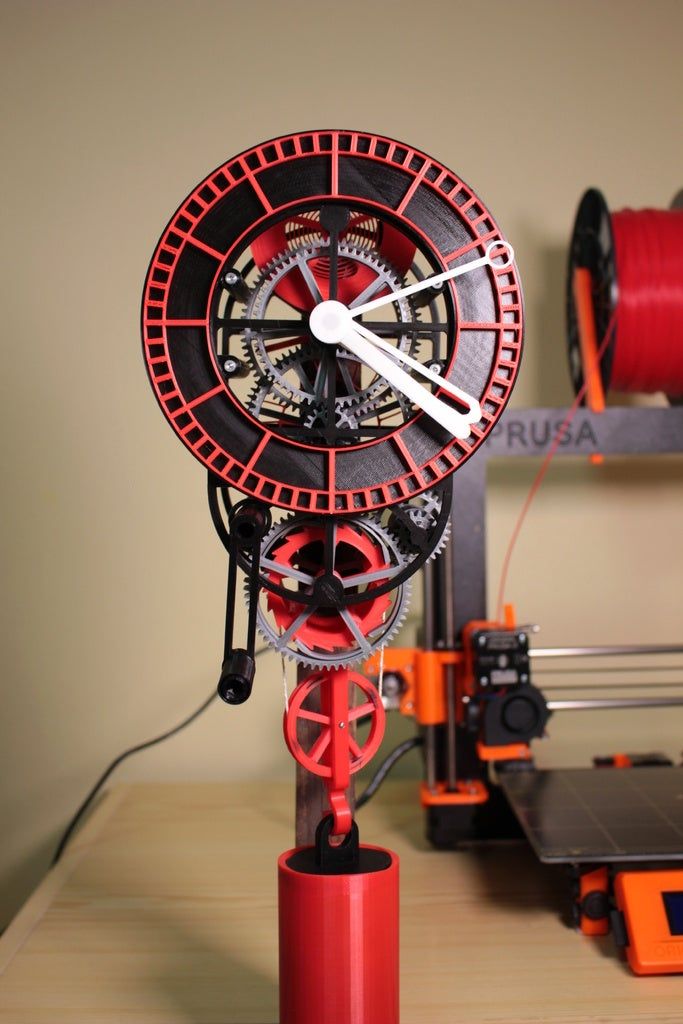

3D Printed Illuminated Wall Clock

You Are Here

Home

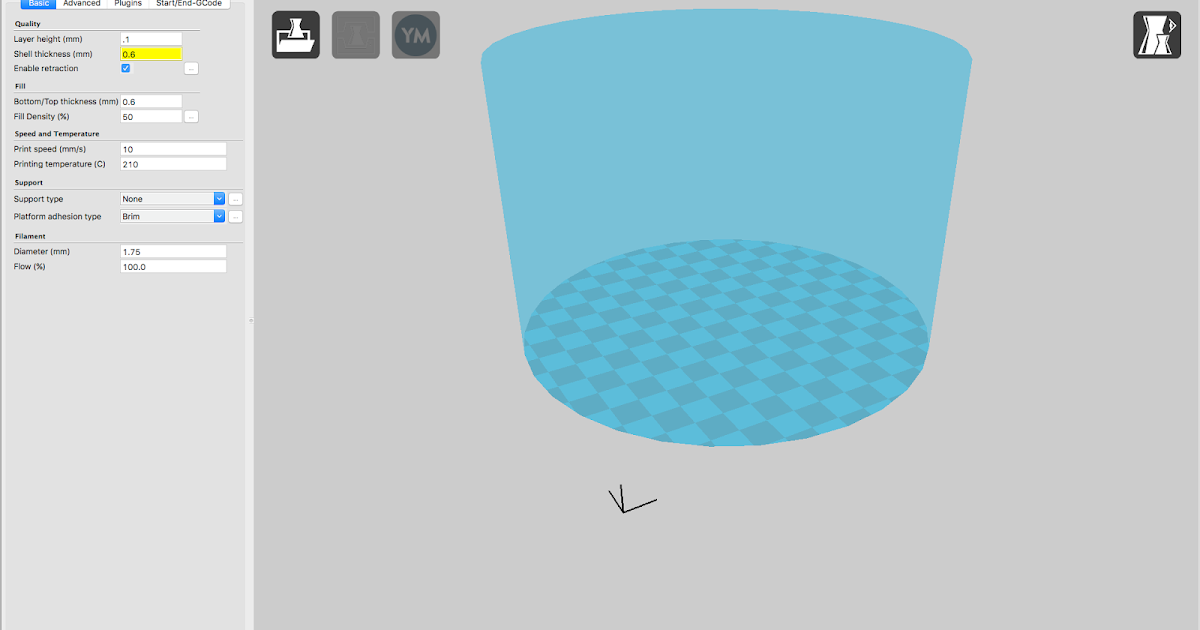

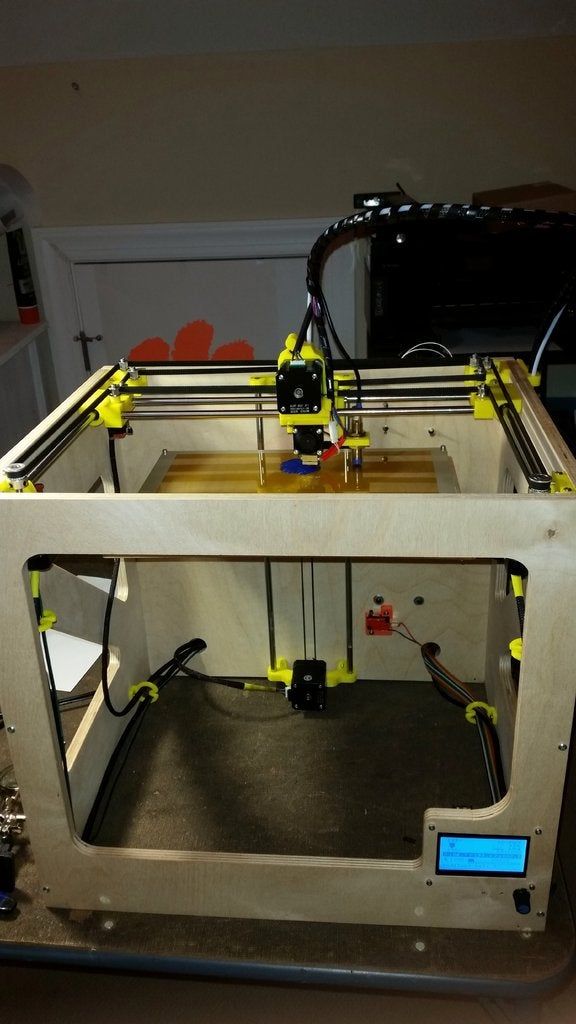

One of the problems with 3D printing is the large amount of plastic waste. Let's face it, all makers fill their trash cans with failed prints and empty spools. This is a real huge graveyard of worn plastic.

Let's face it, all makers fill their trash cans with failed prints and empty spools. This is a real huge graveyard of worn plastic.

Original clock + light: 2 in 1

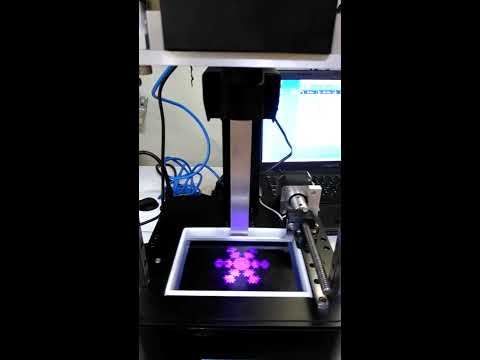

There are many ways to get creative and recycle plastic waste. Here we will consider the possibility of reusing spools for plastic threads. This idea belongs to the maker under the nickname dominofreak. We found it on Thingiverse. It consists in making a wall clock out of a used coil.

This is a relatively simple project that uses 3D printing and LED lighting. Stop throwing plastic spools in the bin and turn them into color changing wall clocks.

In addition to the blank spool, you will need to print some watch parts. For example, it will be necessary to make a diffuser and a clockwork using a 3D printer. We suggest downloading the STL files necessary for this on Thingiverse.

What do you need to know to implement the project?

Before jumping into this idea, it's important to understand that not all filament spools are the same physical size. You may need to measure the coil and adjust the 3D model settings accordingly. The author of the project used a plastic spool from the German manufacturer of 3D printing filament Janbex (the exact dimensions of this spool can be found on Thingiverse).

You may need to measure the coil and adjust the 3D model settings accordingly. The author of the project used a plastic spool from the German manufacturer of 3D printing filament Janbex (the exact dimensions of this spool can be found on Thingiverse).

In addition to the coil and 3D printed parts, you will need an LED strip and a clockwork. According to dominofreak, the 3D model is meant to be printed with support structures. To ensure that the light emits properly through the clock panel, the designer used white PLA to print a thin wall (only one layer thick).

Now a question about the LED strip. The author suggests using a battery power supply so as not to mess around with cables and wires. The battery compartment is safely hidden in the inside of the coil.

Source

Other materials:

- Fillamentum offers material for FDM 3D printers based on PVC

- Space meatballs: 3D Bioprinting Solutions will conduct experiments on 3D printing of meat in orbit

- Scientists have developed a SEAM system for accelerated 3D printing of plastic

- New methods of analysis will help improve metal laser 3D printing

- Autodesk opens generative design lab in Chicago

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

Pendulum Clock 3D File・3D Printing Idea for Download・Cults

Bench Vise - Forming Lathe

Free

Print_In_Place - Adjustable Stand for Mobile, Tablet and Game Control

Free

Speed reducer

Free

Coffee cup - home office

Free

Adjustable Shim

Free

Speed reducer - new version

Free

Support for hose - Ebox of Esun

Free

The best files for 3D printers in the Tools category

Miter Box

Free

High-low suction suction ejector / dental turbine

0. 64 €

64 €

3D Digital Clock

Free

cherry and plum picker

free

DIY 3D Printed Dremel CNC

Free

Grinder Rick and Morty

2,50 €

Little MasterSpool Roller V2.0

Free

strong and compact Face-Shield Covid 19/ NAPA DYNAMICS

Free

Bestsellers in the Tools category

BMG E3D V6 direct drive for Creality Ender 3 (Pro/V2) & CR-10

€4.49

Armadillo - flexible wire conduit

€1.84 -thirty% 1.29 €

ENDER 3 S1/PRO SPRITE, 4020 FAN CR TOUCH NO Y OFFSET

1,91 €

Phone holder

2. 57 €

57 €

PRECISION CALIPER 3D PRINT DIY

3.08 €

GEAR AND DRIVE

3.47 €

PET-Machine, make your own plastic bottle filament at home!

50 € -80% 10 €

Fire hydrant storage container

1.98 €

Printer boxes for Ikea Lack Table

1.99 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 PRO

2,97 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

1.83 €

Quick print stackable parts containers / storage boxes

2.88 €

Case for Chill Buddy 9 Lighter0066

0.98 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.