Houston 3d printing services

3D Printing Service for Houston, Texas

CapabilitiesCustom Online 3D Printing ServiceTexasHouston

High Quality Houston, Texas 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Guaranteed Quality

We back every part we ship with the Xometry Quality Guarantee. Our number one job at Xometry is making your custom parts to your specifications.

Your Houston, Texas 3D Printing Service: 3D Prototypes and Production Parts

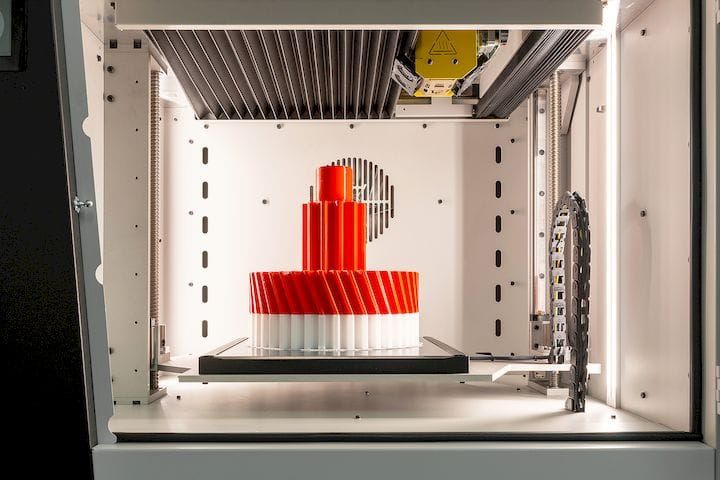

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

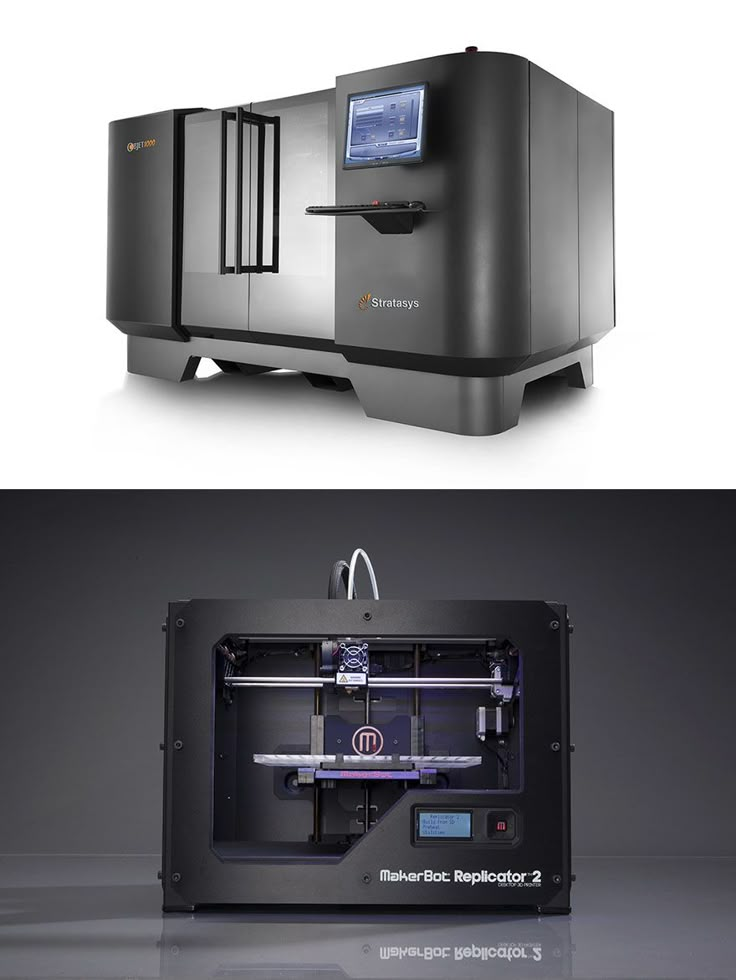

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Houston 3D Printing - Industries and Applications

3D printing, a form of additive manufacturing, is a tremendous manufacturing asset to businesses and organizations in Houston, Texas. If you're looking to better understand how 3D printing could add value to your project or industry, Xometry can assist you with your goals.

According to Thomasnet. com®'s 2022 sourcing data, the top six most popular manufacturing industries in Houston are Chemicals, Education, Transportation and Logistics, General Manufacturing, Metals, and Energy and Utilities. Here's how 3D printing can support local manufacturing in Houston in some of these popular sectors:

com®'s 2022 sourcing data, the top six most popular manufacturing industries in Houston are Chemicals, Education, Transportation and Logistics, General Manufacturing, Metals, and Energy and Utilities. Here's how 3D printing can support local manufacturing in Houston in some of these popular sectors:

- Chemicals: 3D printers can produce necessary complex multi-component chemical equipment within a laboratory, expediting chemical research and making it an invaluable resource for research and development in the chemical industry. Additive manufacturing also allows engineers to make custom sampling, holding, and compounding laboratory equipment and prototypes. Though only a fraction of the materials that are commonly used in conventional component manufacturing can be used for 3D printing, this avenue is being thoroughly explored.

- Education: 3D printing technologies play an increasingly important role in STEM education.

With greater access to CAD, 3D printers in education enable educators to teach students how to create tangible products and tools with a very low barrier to entry. Scientific concepts and deep theoretical constructs can be taught more efficiently with accurate physical 3D printed prototypes to hand. Integrated into classroom environments from elementary school to university, 3D printers are not only a useful hands-on learning tool for students but also a powerful research resource for teachers.

With greater access to CAD, 3D printers in education enable educators to teach students how to create tangible products and tools with a very low barrier to entry. Scientific concepts and deep theoretical constructs can be taught more efficiently with accurate physical 3D printed prototypes to hand. Integrated into classroom environments from elementary school to university, 3D printers are not only a useful hands-on learning tool for students but also a powerful research resource for teachers. - General manufacturing: Considered a necessary utility tool that the majority of manufacturing companies are employing, 3D printing is a low-cost and invaluable manufacturing solution used in many avenues, from parts of the production line and making jigs and fixtures to creating custom tooling for laser marking. It also allows for rapid prototyping to test design concepts ahead of production runs, thus reducing risk and eliminating costly design flaws. Top automotive companies are eager to leverage this technology, i.

e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs. One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining.

e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs. One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining. - Metals (raw, formed, fabricated): Though most commonly associated with plastic, 3D printing is seeing a rapid rise in the use of metal and the creation of tools to form metal in areas like sheet fabrication, rigid tooling, and even powder metallurgy. In metal injection molding and die casting processes, rigid tooling using extremely tough yet ductile maraging steel is being created with additive manufacturing without the need for a CNC machine.

Even jewelers are digitally creating custom 3D printed prototypes using a master wax pattern. With the ability to create custom products that can be ordered to have the exact features and even bend desired, 3D printing is being used more and more in the metals industry.

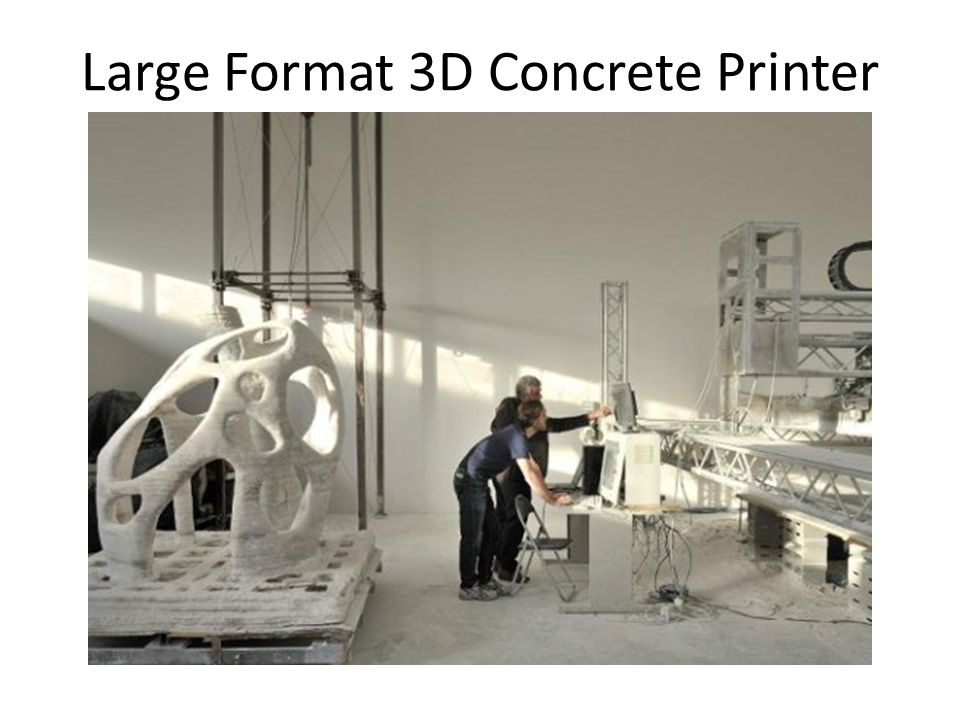

Even jewelers are digitally creating custom 3D printed prototypes using a master wax pattern. With the ability to create custom products that can be ordered to have the exact features and even bend desired, 3D printing is being used more and more in the metals industry. - Energy and utilities: Thanks to its quick turnaround time compared to traditional tooling, 3D printing is also being explored for energy and utilities. Parts which are typically cast can be directly printed out of metal or a high-performance polymer substitute quickly and in fewer numbers. There are also many opportunities for large-format industrial printing in the fields of renewable energy and oil & gas. Bespoke, hard-to-transport parts such as metal tubular designs for drilling with internal features to cater to camera monitoring, circuit boards, and sensors can be 3D printed. In these industries, additive manufacturing is more than just engineering a machine component; with the ability to create state-of-the-art groundbreaking mechanisms with endless capabilities, 3D printing can significantly transform and modernize these sectors.

The additive manufacturing and material market is rampantly growing and is estimated to reach US$61.1 Billion by the year 2027. With the technology being so prolific, providing endless options, and the opportunity to greatly add to and advance your business, let Xometry cater to all your industrial-grade 3D printing needs.

Xometry's High Quality 3D Printing Services

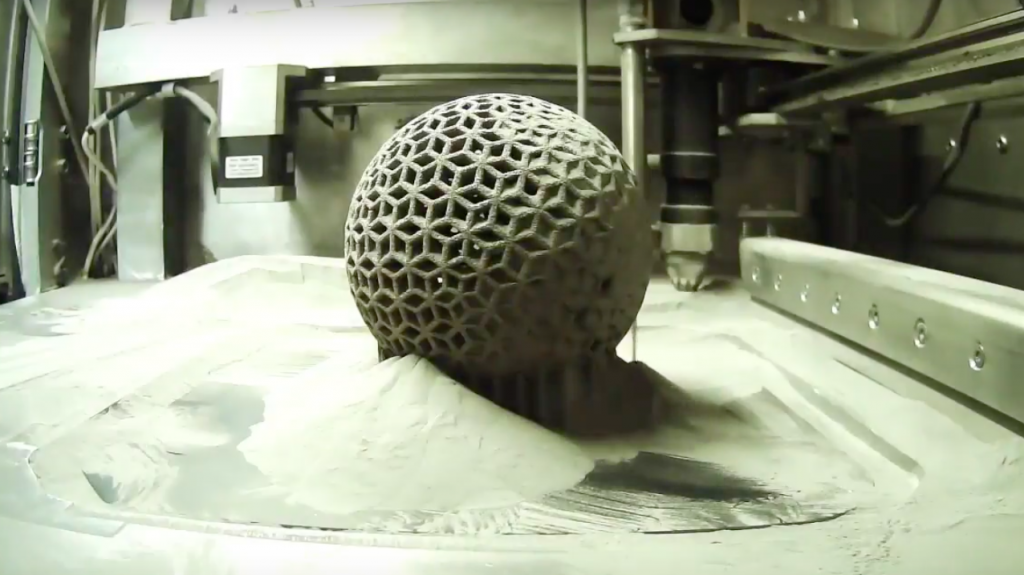

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

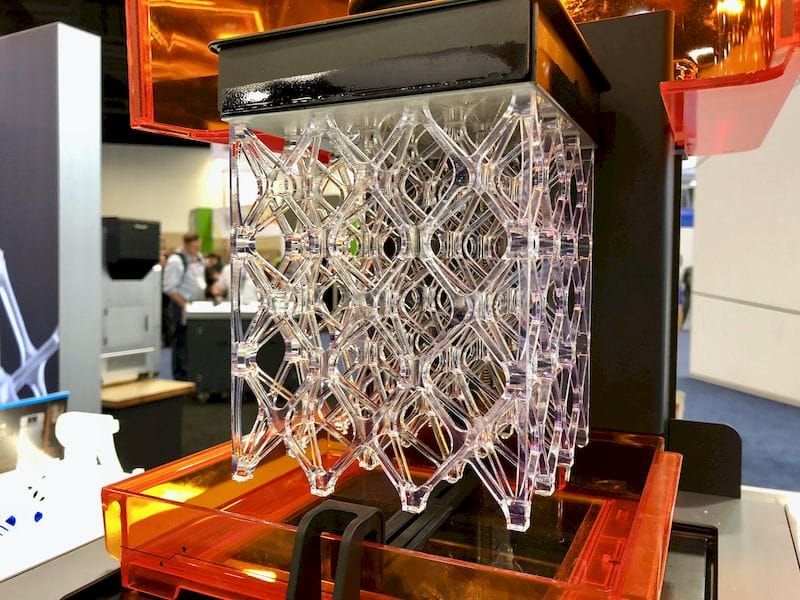

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

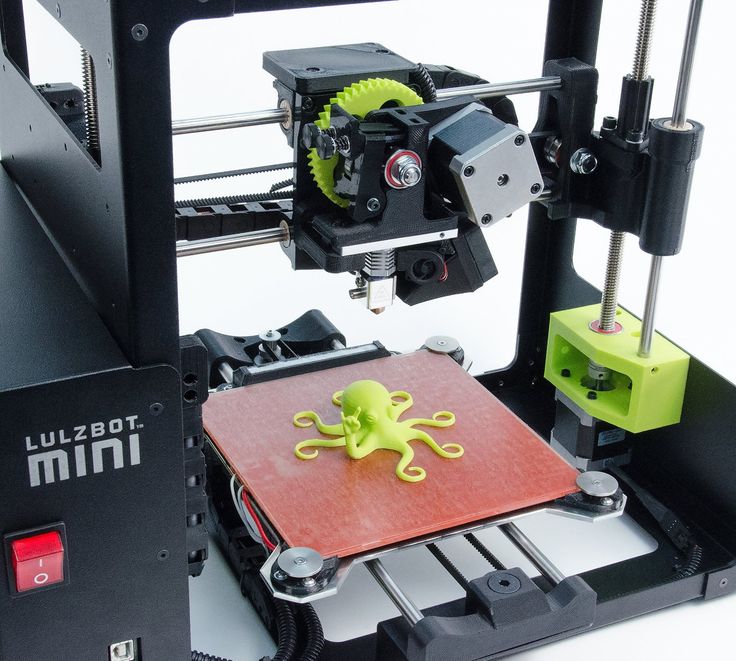

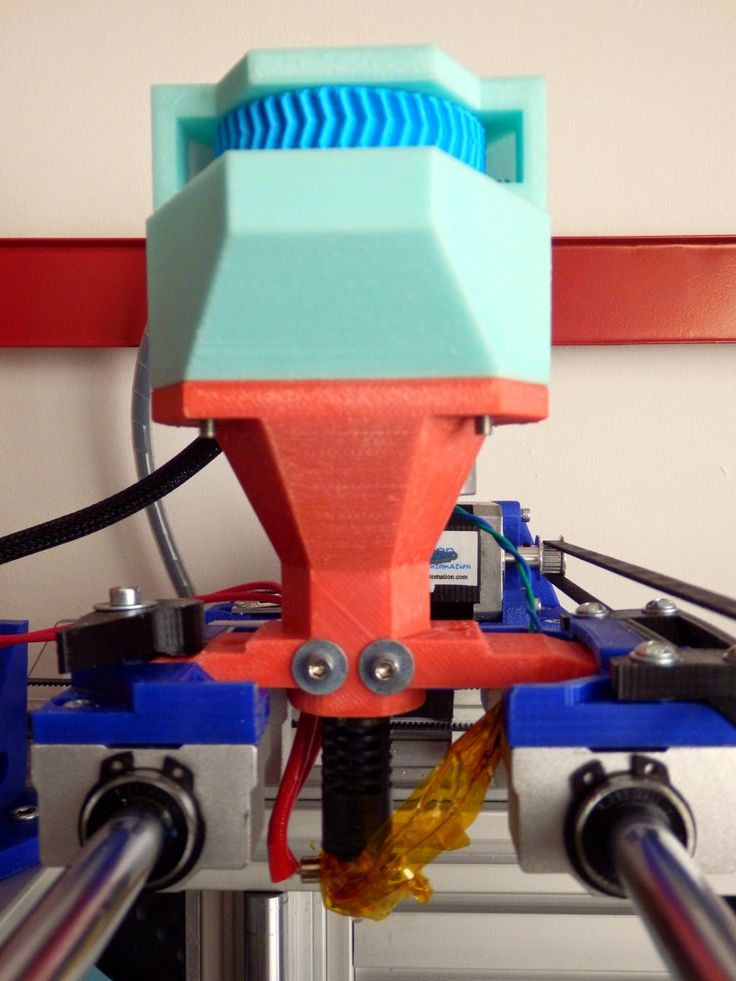

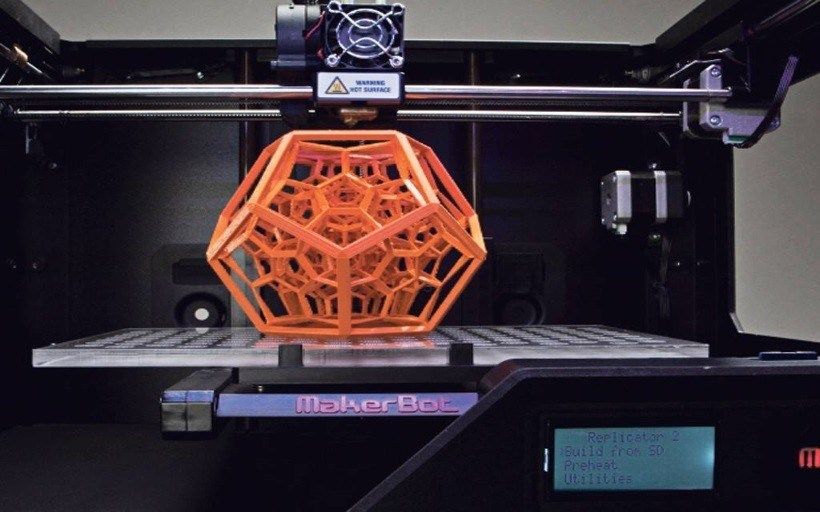

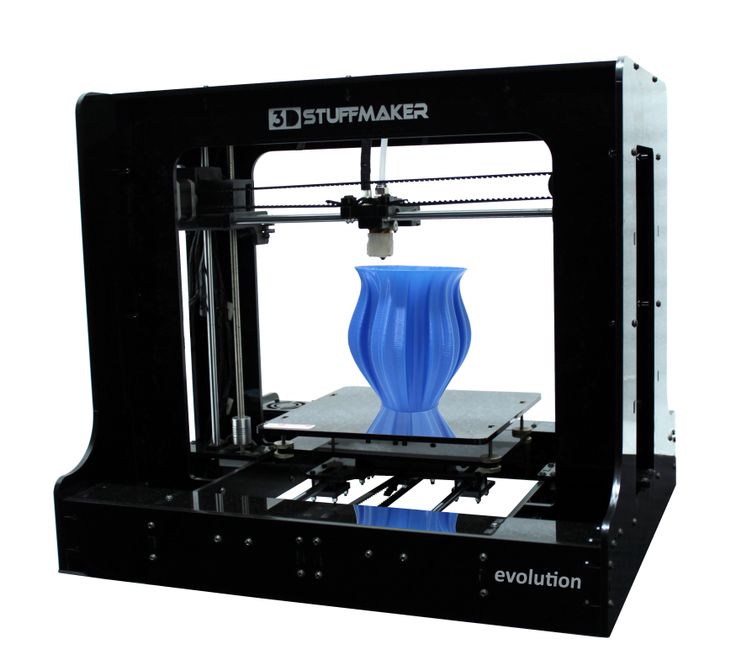

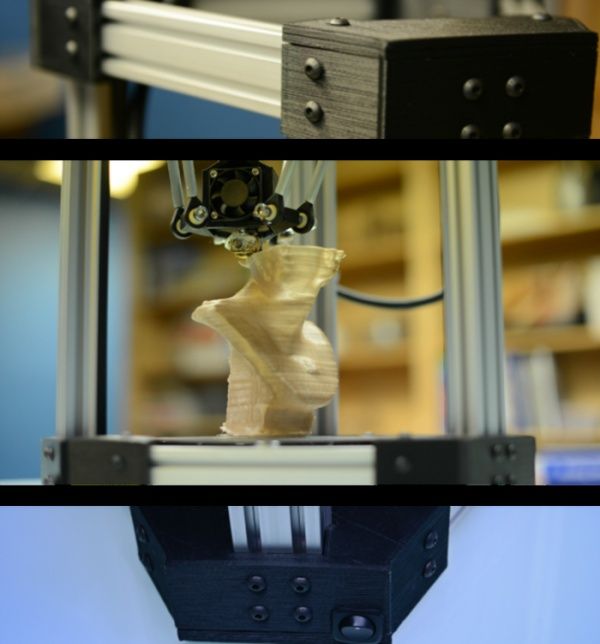

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

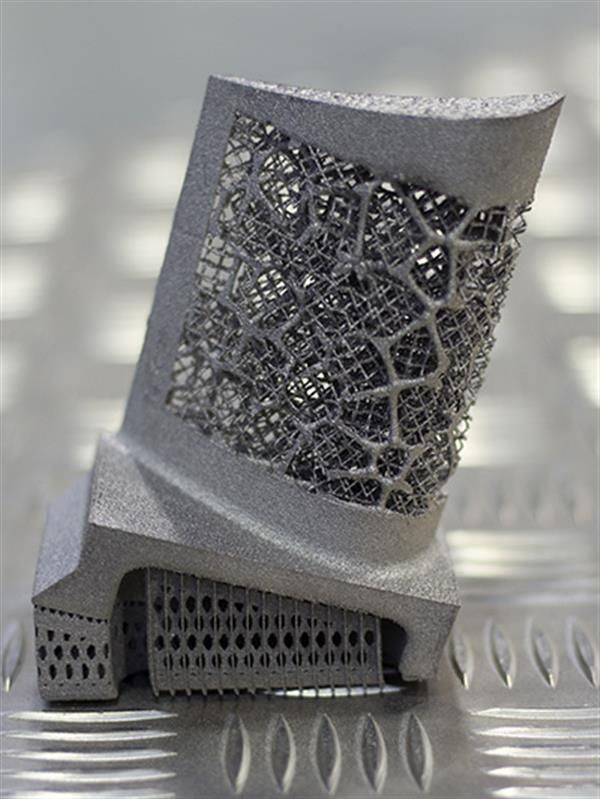

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Ready to start making custom 3D printed parts?

3D Printing Service Houston, TX | Instant Quotes Online

Our 3D printing capabilities

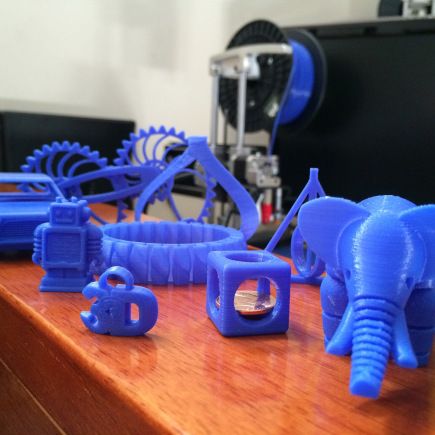

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

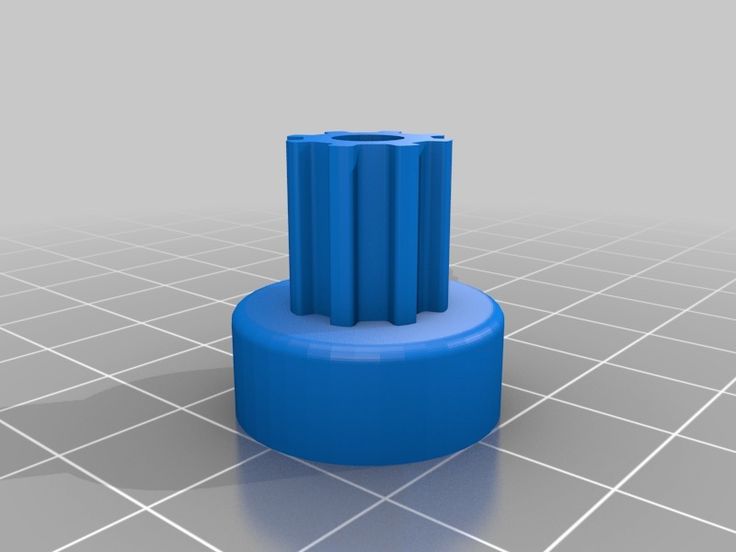

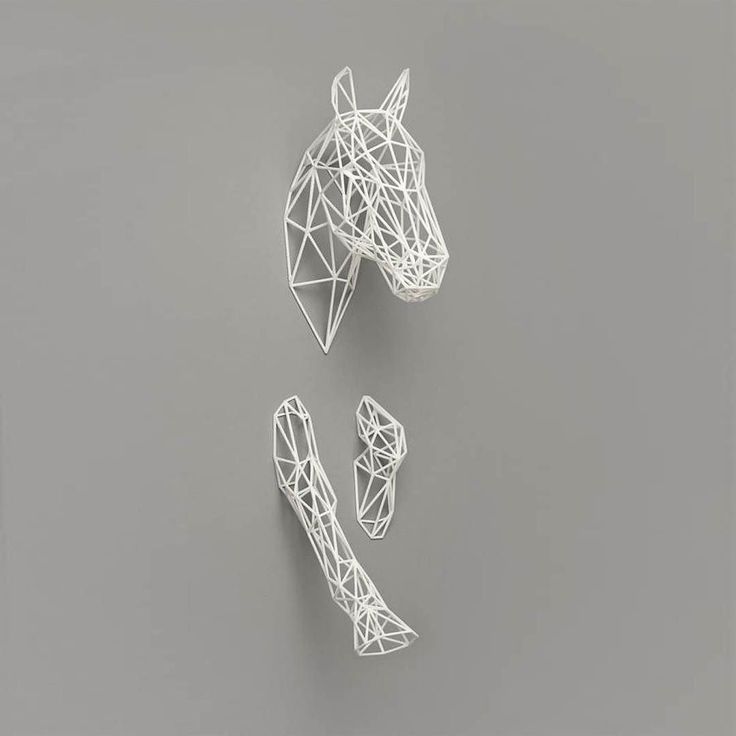

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 202 customers are satisfied with our 3D printing service.

“excellent work will, definitely order again.”

“Great communication, perfect print, and even helped choose the material best suited for the print.”

“Both the details and sizes are nicely printed.”

“Parts were shipped very fast! My parts came out much better than expected. ”

“Super fast and great communication! Highly recommended”

“A+ job! Prints look fantastic and they arrived 4 days before the deadline to ship! Awesome service! ”

“Good service. The print was almost exactly what I expected. Any mistake was completely my fault.”

“Great as always, parts are amazing quality.”

“This is is really wonderful service. The parts were perfect, mirror clean. No polishing necessary. 10 star.”

“First experience with 3D printing. Came out great, thank you!”

“great job fast turn-around, thank you so much.”

“Excellent and consistent service/quality!”

“Printed fast and communicated well, thanks!”

“This part is just what I needed and it fits perfectly. Thanks,

Ric”

Thanks,

Ric”

“Parts look great and communication was good. Will do business again.”

“Great parts, fast service and excellent communication. ”

“Parts turned out great and were on time. ”

“Perfect prints arrived sooner than expected.”

“Unbelievably satisfied with the job performed. Great quality. Great communication. Fast shipping. Thank you!”

“I am a repeat customer, always great service, Jarod is very knowledgeable. ”

“Good parts, stayed up to date with every step”

“Great service. Prompt, no problems with communications and exactly what I requested.”

“The print quality for all of my parts was excellent parts arrived quicker than quoted time. Great communications.”

“Thanks for your excellent product support and manufacturabilty advice”

“Great communication and service. Real pleasure to do business with. Fast shipping too. The parts came out better than I had hoped. Excellent Job!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Houston, TX

Atascocita, TX Baytown, TX Pasadena, TX

Spring, TX Houston, TX League City, TX

The Woodlands, TX Pearland, TX Conroe, TX

Texas City, TX

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

3D printers for creating equipment for underwater work

Mechanical engineering

Implementation stories

Author: Olga Gorobets

Author: Olga Gorobets

3D printing high quality illustrative models | Why selective laser sintering? | 3D printer at the service of innovation

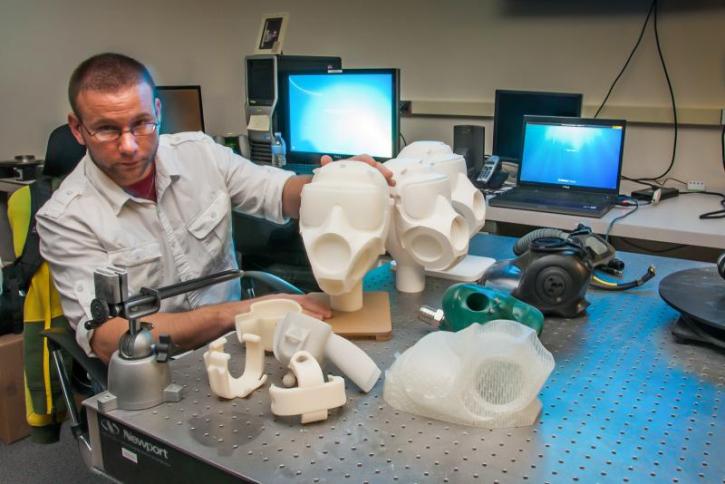

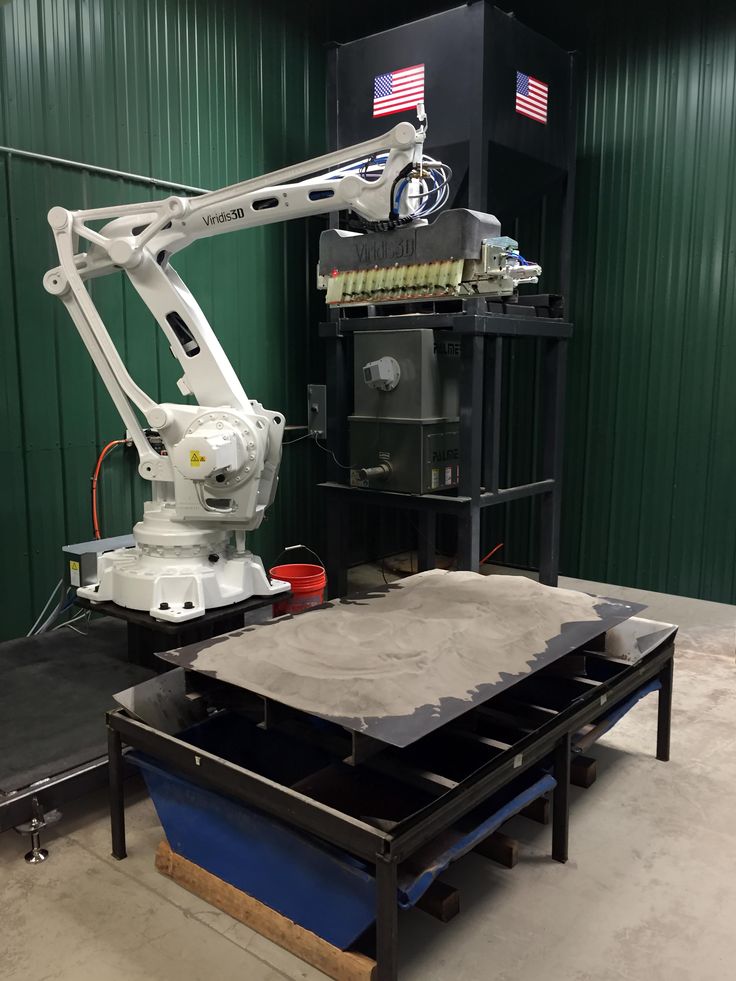

Selective laser sintering has produced high-quality illustrative models of underwater equipment manufactured by the Dutch company Seatools.

No matter how deep below the surface of the ocean your target may be, Seatools is here to design, manufacture and test specialized subsea equipment. Seatools, based in the Netherlands, is a global provider of customized solutions for offshore oil and gas, aquaculture and marine renewable energy. Given its vast and diverse industry, Seatools was faced with the challenge of presenting its portfolio of solutions quickly and efficiently at the prestigious Offshore Technology Conference (OTC) in Houston, Texas.

It is the world's largest oil and gas event with over 2,300 exhibitors. Seatools knew it needed to get creative with its display to recoup its investment in development, capture industry attention, and explore new directions.

Using 3D Systems' On Demand Manufacturing services, Seatools created a unique underwater landscape to showcase seven 3D printed illustrative models of various underwater equipment. 3D Systems' On-Demand Manufacturing division offers a wide range of prototyping and manufacturing services for the full cycle of product development and can quickly produce high-quality products - from rapid prototyping and advanced designs to printing visual models and small-scale products.

3D print high quality visual models

To explore different options for obtaining scaled equipment models, Seatools first defined the desired result. In general, high quality, detailed models were needed that would showcase the level of the company and withstand sea transportation.

“It was very important to me that the models arrived in Houston intact,” said Johan Saul, Seatools Supervisory Board Member and Head of Marketing and Business Development. “We sell sophisticated high-quality equipment, so if we showed damaged models at the exhibition, it would go against the quality we declare.” Seven models were selected for the demonstration, and given the limited time remaining before the opening of the exhibition, the speed of production was of great importance.

Given the long time and high cost of manually producing scaled models, traditional technologies had to be abandoned in favor of 3D printing. Thus, it was only a question of choosing a specific technology, and a comparative analysis undertaken by Seatools pointed to selective laser sintering (SLS).

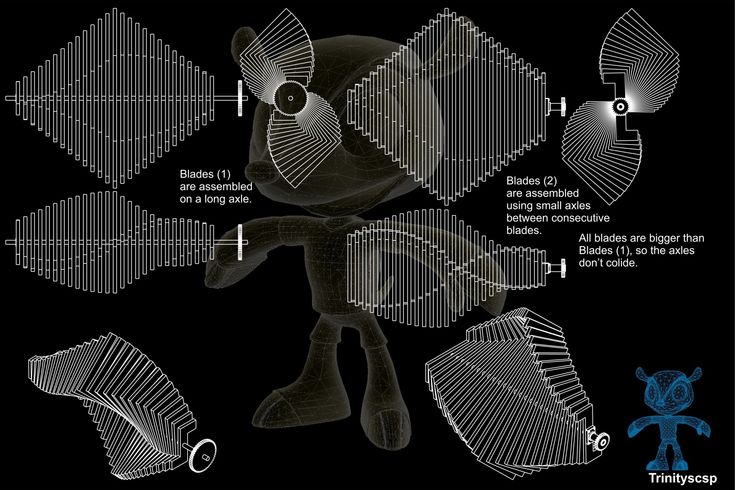

“The 3D models had to be transported by trucks, and we knew from experience with other projects that scaled models can withstand high impact loads,” said Johan Sol. After discussions with 3D Systems On Demand Manufacturing in the Netherlands, Seatools selected high-strength nylon models produced on SLS printers from DuraForm PA. After 3D printing, the scaled models were post-processed, painted and assembled by 3D Systems specialists and handed over to the customer - all in strict accordance with the specifications.

Reduced models of devices for underwater work were printed on the SLS printer. The presence of working hinges allows you to demonstrate the capabilities of complex large-sized equipment

Why selective laser sintering?

The choice of SLS technology proved to be the right one both in terms of durability and visual appeal. Due to the properties of materials, selective laser sintering is widely used for the fabrication of functional parts assembled on snaps and flexible hinges, which proved to be extremely relevant for this project. To help Seatools produce 3D visual models that meet the company's quality standards, On Demand Manufacturing has developed components for each model of equipment to be painted and assembled.

To help Seatools produce 3D visual models that meet the company's quality standards, On Demand Manufacturing has developed components for each model of equipment to be painted and assembled.

According to Johan Sol, the results exceeded all expectations. Scaled models of various fixtures, printed on an SLS printer, perfectly carried the journey from the Netherlands to Houston and were shown at the exhibition as accurate full-size mock-ups of innovative equipment. Due to the properties of SLS materials and the high strength of thin walls, Seatools was eventually able to use more high-quality parts in models compared to alternative 3D printing technologies. Visitors to the show appreciated the variety of solutions offered by Seatools, and in addition, the models showed the level of attention and quality that Seatools customers can expect when working with the company.

The 3D models did an excellent job of helping Seatools stand out from the crowd of other exhibitors and played an important role in the design of the company's booth. The experience of Johan Sol shows that the exhibitor has only a few seconds to interest the visitor. Models not only helped Seatools attract visitors to its stand, but also allowed the company's specialists to make the sales process more efficient and interactive. “Our team was able to place the models in the context of the underwater world and present the company by demonstrating the various capabilities of Seatools,” Saul said.

The experience of Johan Sol shows that the exhibitor has only a few seconds to interest the visitor. Models not only helped Seatools attract visitors to its stand, but also allowed the company's specialists to make the sales process more efficient and interactive. “Our team was able to place the models in the context of the underwater world and present the company by demonstrating the various capabilities of Seatools,” Saul said.

3D printer at the service of innovation

As one of the leaders in its field, Seatools is constantly innovating to meet unique challenges. The company is no less meticulous in its participation in trade fairs and has made every effort to demonstrate the complexity of the tasks it solves in the interests of its customers around the world. Seatools not only successfully and creatively showed what tasks it can perform, but also, thanks to the underwater landscape created by it on a 3D printer, helped the guests of the booth to understand what Seatools is doing.

“The underwater landscape was the highlight of the program,” Saul says. “He attracted visitors and helped us establish contacts and start relationships with new partners.”

Translation from English. The original of this material on the site 3D Systems

Article published on 03/19/2018, updated on 05/14/2021

3D printing services on a 3D printer prices from 6 rubles / g. The fastest 3D printing terms in Moscow and the Moscow region.

Order

Technologies do not stand still, and what used to be found only in science fiction books is already becoming a reality. One of the actively developing areas today is 3D printing with polymeric materials.

Interest in 3D printing is not surprising, because the horizons that it opens up are endless. Printing plastic manufacturers are constantly working on creating new structures by imparting different properties to polymers. Now you can find plastics that give odds to metal in terms of strength, elastane, which allows you to create flexible structures, and protective polymers that fly into space.

Now you can find plastics that give odds to metal in terms of strength, elastane, which allows you to create flexible structures, and protective polymers that fly into space.

Ordering 3d printing will not be difficult. You do not have to understand the molecular formulas and chemical properties of raw materials. It is enough to tell in detail about where and how the finished product will be used, and our specialists will select the optimal polymer.

How do we work?

3D Printing in 3 Easy Steps

Layout

Do you have a great idea but don't have a printable layout? For us, this is not a problem. Experienced specialists will digitize your sketches

our staff of technicians is equipped with modern high-speed machines that work with various types of polymers

Processing

Careful manual post-processing allows the product to get a presentable appearance. Our masters approach this task responsibly

Example of printing parameters

| Scope of application | Implementation in % |

| Electrical equipment, decorative products | 21. 8% 8% |

| Printing for automotive | 18.6% |

| Medicine, traumatology, orthopedics | 16.4% |

| Industry, machine building, machine building | 9009|

| Aviation, Cosmos | 10.2 |

| Science | 6.8 | Architecture, Construction | 3.2% |

Our park of 3d equipment allows us to fulfill any orders in the shortest possible time. Regardless of what you have to work with with a sample or a layout on paper, we will independently prepare and process the future layout and send it to you for approval. Only experienced craftsmen work in our staff, which means that you can order a print of any degree of complexity without fear for the quality of the finished product.

PMK3D works with leading plastic manufacturers and always follows the latest news and market trends. If you need 3D printing from specific polymers, for example, increased strength, non-flammable, or visually similar to glass and ceramics, then choosing our contractor is the best solution.