3D print tolerance test

▷ 3d printer tolerance test 【 STLFinder 】

3d printer tolerance test

thingiverse

3d printer tolerance test.

3D Printer Tolerance Test

thingiverse

Tolerance tests for a high res 3d printer, designed with features beyond machine resolution (~1500dpi) to demonstrate how your printer/material fails. Must be printed on a machine that uses some kind of support material. Includes thin walls and...

3D Printer Tolerance - Gap Test

myminifactory

. ..

I would print this test at a high quality setting if you want to know your printer's limitations, or if you want to know the tolerances for a given design, print the test at the same resolution and settings that you plan on printing your design.

3D Printer Tolerance - Gap Test

thingiverse

... I would print this test at a high quality setting if you want to know your printer's limitations, or if you want to know the tolerances for a given design, print the test at the same resolution and settings that you plan on printing your design.

3D Printer Tolerance - Gap Test

cults3d

. .. I would print this test at a high quality setting if you want to know your printer's limitations, or if you want to know the tolerances for a given design, print the test at the same resolution and settings that you plan on printing your design.

.. I would print this test at a high quality setting if you want to know your printer's limitations, or if you want to know the tolerances for a given design, print the test at the same resolution and settings that you plan on printing your design.

3D Printer Tolerance Test: Arial font

thingiverse

Customized version of http://www.thingiverse.com/thing:2318105 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=2318105

Tolerance Gauge Meter 3D Printer Accuracy Test

thingiverse

This is my version of the tolerance gauge meter for your 3D printer. Tolerances are between (0.2 up to 0.7 in the middle)

Tested on Anycubic I3 Mega and Mega S.

The design was inspired from Maker's Muse although i made it from scratch.

...

Tolerances are between (0.2 up to 0.7 in the middle)

Tested on Anycubic I3 Mega and Mega S.

The design was inspired from Maker's Muse although i made it from scratch.

...

Printer Tolerance Test 01

pinshape

This is a fast and easy model that I designed in order to test 3D model dimensions versus actual print dimensions on all 3 axes of my printer (daVinci 1.0 Pro). The overall print size is 6.0" x 6.0" x 0.75", but I've included several features to...

Printer Tolerance Test

thingiverse

6/10/19 Update: I went to print a test for my new printer and I was surprised by how much filament this used. The new model, "Small Test.stl" uses less filament and prints quicker. I got rid of the various chamfers and the text is now raised so it's...

The new model, "Small Test.stl" uses less filament and prints quicker. I got rid of the various chamfers and the text is now raised so it's...

Printer Tolerance Test

cults3d

6/10/19 Update: I went to print a test for my new printer and I was surprised by how much filament this used. The new model, "Small Test.stl" uses less filament and prints quicker. I got rid of the various chamfers and the text is now raised so it's...

Printer Tolerance Test

prusaprinters

I didn't label the chamfer on the bottom, but that one is 1.5mm.*6/10/19 Update: I went to print a test for my new printer and I was surprised by how much filament this used. The new model, "Small Test.stl" uses less filament and prints quicker. I...

The new model, "Small Test.stl" uses less filament and prints quicker. I...

Testing 3D printer tolerance

thingiverse

Do you know your 3D printer's tolerances? Did you know they vary depending on the materials and resolutions you use? Print these male/female models at various resolutions and with various materials to check your tolerances and make designing and...

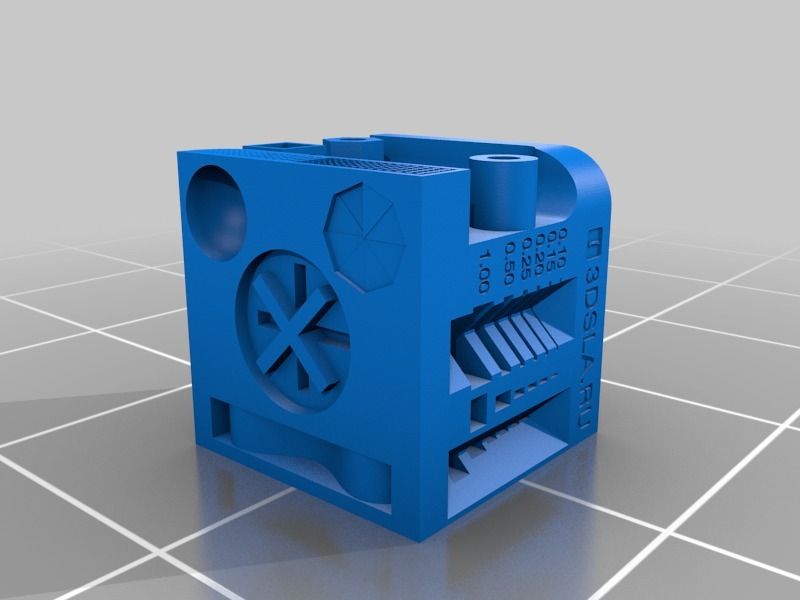

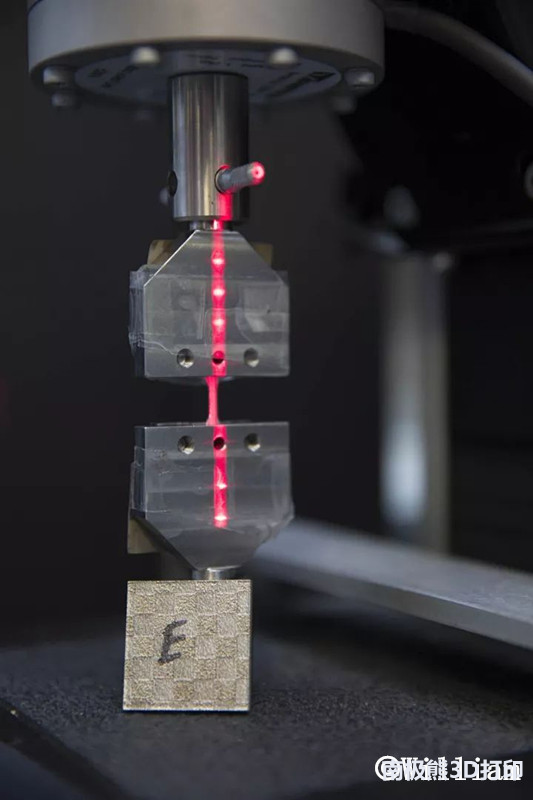

SLA printer accuracy/tolerance test

thingiverse

A 0.500" post with a set of slightly larger holes (0.510", 0.505", 0.502") to test your resin printer's accuracy.

The square and hexagon pieces are all 1. 000" across. ... The vertical heights of the pieces are all big round numbers: 0.500" (the...

000" across. ... The vertical heights of the pieces are all big round numbers: 0.500" (the...

Complete 3D Printer test all in one (stress test, bed level test, retraction test, calibration test, tolerance test, support test)

prusaprinters

The original file that I remixed is this, I have added new features to test.I added new things to test like stringing test and the write on the bottom. ...You can also test a lot of other things:bridgingbed levelstringingcalibration testoverhang...

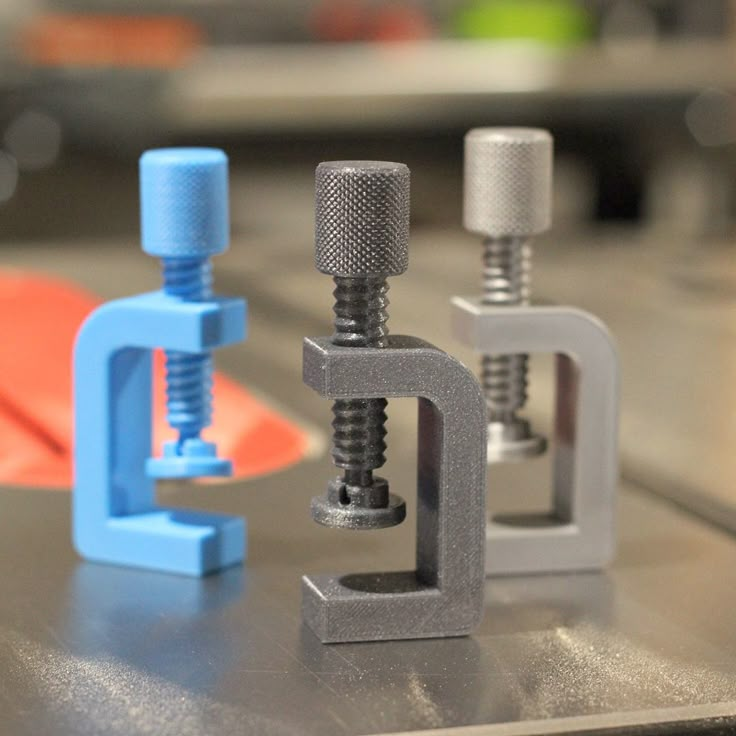

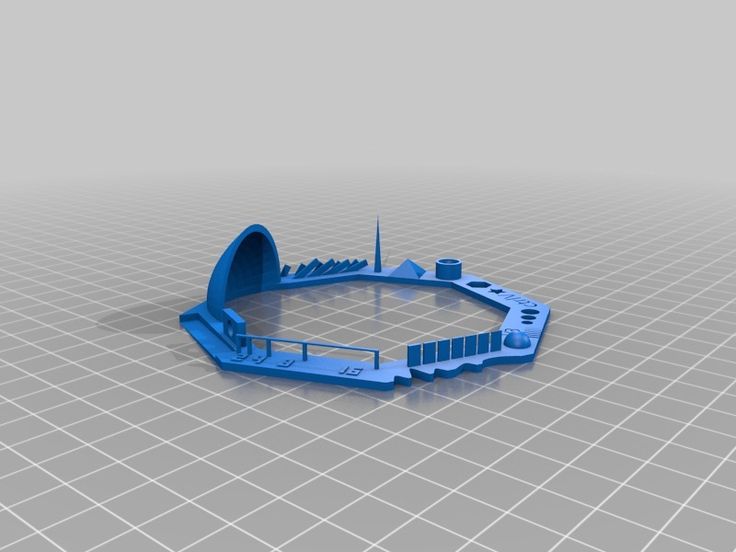

3D Printer Tolerance Block

cults3d

A 3D Printer Tolerance block to test out the precision and accuracy of your 3D Printer. Using arches and sharp lines this tolerance block tests the limits of your 3D printer letting you see exactly what your 3D Printer can do. You can also scale it...

Using arches and sharp lines this tolerance block tests the limits of your 3D printer letting you see exactly what your 3D Printer can do. You can also scale it...

3D Printer Tolerance Gauges

thingiverse

3.) Determine the closest fitting gauge 4.) Print the file with the closest matching gauge size: 3D Printer Tolerance Gauges Fine 20.## mm Advanced : If you have Fusion 360 you can edit the parameters for the "test pin" size and when you determine...

3D Printer Tolerance Testing Model

grabcad

This model is meant to help determine tolerances of mating and embedded 3D printed parts. There are 6 embedded parts (green) with tolerances from 0.15 - 0.40 mm at 0.05 mm steps. ...Similarly, there is are 6 slots for mating parts (blue) of the same...

There are 6 embedded parts (green) with tolerances from 0.15 - 0.40 mm at 0.05 mm steps. ...Similarly, there is are 6 slots for mating parts (blue) of the same...

Customizable 3D Tolerance Test

cults3d

Notes: * The model doesn't test tolerance of first layer which is typically more problematic due to 'squashing' it against the bed and always has ample clearance on the first layer. * The model has inside each cylinder an overhang of 45%. This is...

Customizable 3D Tolerance Test

thingiverse

Notes: * The model doesn't test tolerance of first layer which is typically more problematic due to 'squashing' it against the bed and always has ample clearance on the first layer. * The model has inside each cylinder an overhang of 45%. This is...

* The model has inside each cylinder an overhang of 45%. This is...

Tolerance Test 3D Print

cults3d

... with fusion 360, and print at the same time. ...With this test, you can find out what tolerance to put in your designs when you draw them. ... As always thanks for being here to look at my drawing, I hope it comes in handy, if you like leave a like.

3d-Printer Joint Tolerance Testpiece

cults3d

This allows you to test the fitting tolernaces of a given printer and material and see how well different tolerances it together and how movable they are. ...The whole articel can be scaled up or down to test finer sets of tolerances in different size. ..

..

3D printer test

cults3d

3D printer test

test you 3D printer

thingiverse

測試印表機準度 Test your 3D printer accuracy

Small Test 3D Printer

thingiverse

Rapid Test 3D Printer Retraction, Ghost, Flow... ...

3D Printer Test

thingiverse

3D Printer Test for Object Size. ...

...

dice 3D printer test

thingiverse

a simple 3d printer test nothing special

3D printer test

thingiverse

This is very simple 3D-printer test

3D Printer Test

thingiverse

A 3d printer test to do

3d printer height test

thingiverse

Just an easy test for 3d printer height

3D Printer Test

sketchfab

Just a quick Test for a new 3D Printer Design

Free STL file Customizable 3D Tolerance Test・3D print design to download・Cults

Customizable 3D printer support test

Free

Gecko (STL mesh cleaned up)

Free

Customizable Drawer Handles

Free

Customizable Torture Test

Free

Flashforge Creator Pro SD Card Grip

Free

Gecko Fridge Magnet

Free

Small bathroom sink drainer filter

Free

Personalize Your Bag Clips

Free

Best 3D printer files of the Tools category

Smurf - Papa smurf cookie cutter

€4

The Air Blower V2 for DeWalt, Makita & Milwaukee 18V-20V batteries

€3

LED mounts for bike light

Free

Lola Animatronic Driod

Free

Ball in a Box

Free

Faux Book Safe

Free

The geometric stand for MacBook Pro Retina

Free

Support for taking overhead shots

Free

Best sellers of the category Tools

3D Printer Tool Holder V3.

0

0€1.09

PRECISION CALIPER 3D PRINTING DIY

€3.08

FAST-PRINT STACKABLE STORAGE BOXES STACKABLE BINS

€1.50

SUPERBOX

€1.50

Ender 3 Briss fang Gen2, Red lizard, spider, nf crazy, dragonfly, etc.

€1.83

Phone holder

€2.57

The Business Card Embosser System

€3

BMG E3D V6 Direct Drive for Creality Ender 3 (Pro/V2) & CR-10

€4.49

Armadillo - Flex Wire Conduit

€1.84 -30% €1.29

Filament shield

€2.88

Fast-Print Paint Bottle Rack (6 Sizes)

€2.88

phone ring holder

€0.90

Scissor Paint Rack

€5. 47

47

PRECISION DIAL INDICATOR 3D PRINTING DIY

€1.88

Fast-Print Stackable Parts Bins / Storage Boxes

€2.88

well-engineered: Hemera fan duct

€2.50

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

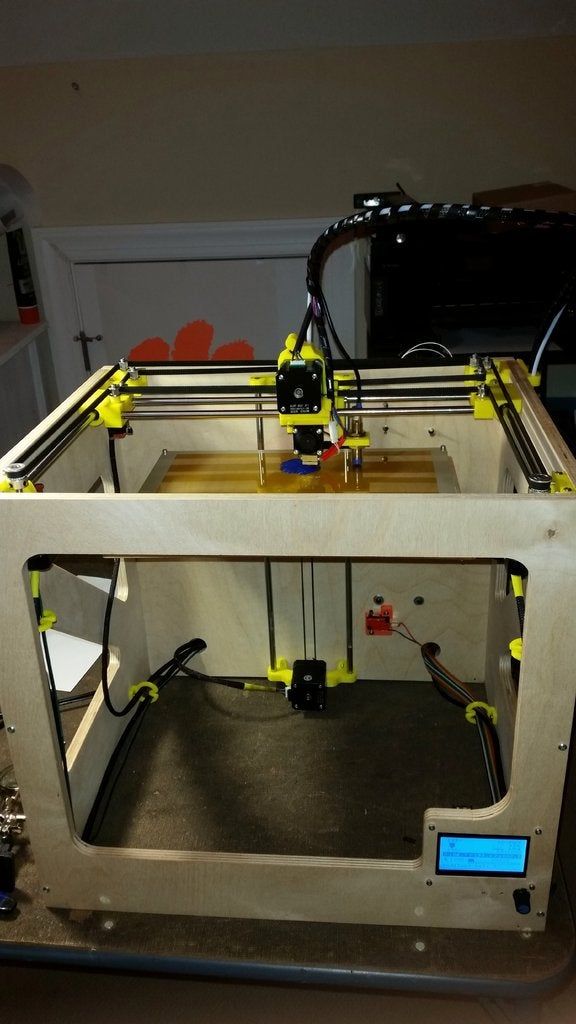

8 test print models

3D printer test models are required for:

- When you bought a new printer and need to test it on your favorite media

- When you have purchased new media and need to check the print specifications

- When you have been using a material for a long time but do not know its tensile strengths

We will talk about the 8 models most used for testing in 3D printing.

1 3D Benchy

3D Benchy is one of the most popular 3D printer test models. The boat figurine perfectly demonstrates the capabilities of FDM printers in any price category. Such a model will help you determine exactly the settings you need to set in order to get the perfect 3D print.

Printing 3D Benchy - will allow you to see how the printer copes with the "rendering" of curved surfaces, inclined planes, arcs, holes. The model is available in several versions, including multi-color. It takes approximately one hour to print a standard size 3D Benchy.

Download model on Thingiverse

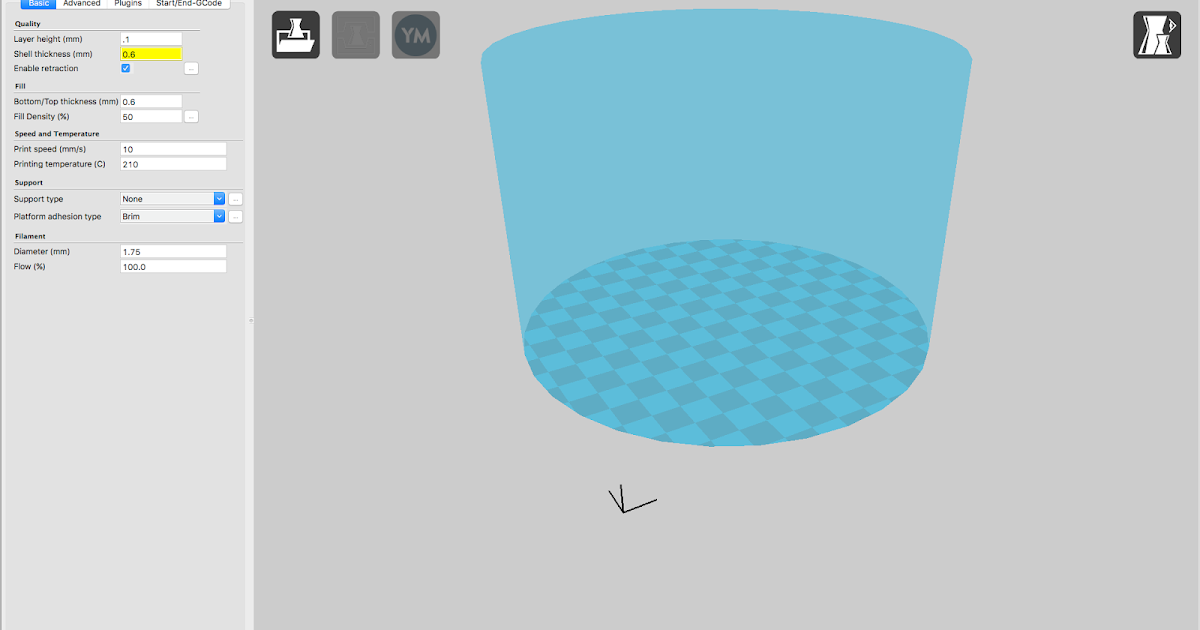

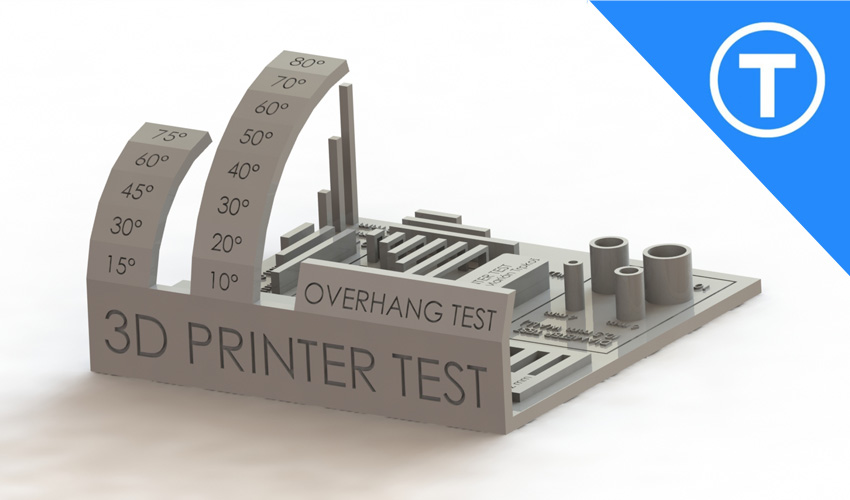

2. All-in-one 3D printer test

A comprehensive test model for a 3D printer will allow you to check the quality of printed overhangs, bridges, extrusion stability, the possibility of “snot” and the dependence of the result on temperature. An important advantage of this model is the instructions for it, which indicate potential solutions to various problems.

Quite a complex model in terms of setting all the parameters, but it's worth it, try it.

Download Thingiverse model

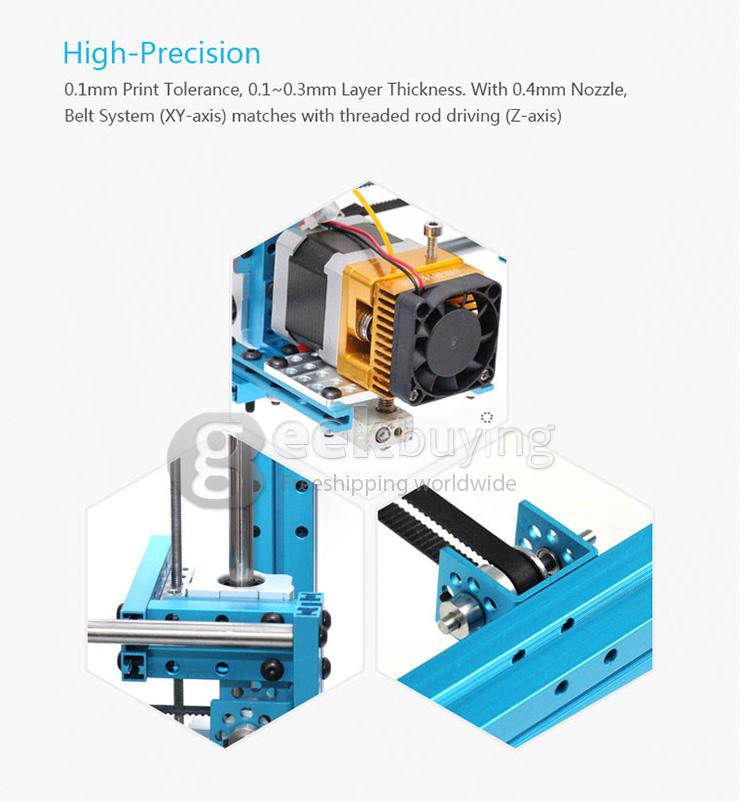

3. XYZ 20mm Calibration Cube

The main purpose of the XYZ 20 mm calibration cube is to establish the dependence of the movement of the extruder on the step of the motor. A test model for a 3D printer helps to make sure that 20 mm in the drawing corresponds to 20 mm of the printed product. At the same time, the calibration cube helps to establish the dependence of the degree of extrusion and print quality on the temperature of the extruder.

A test model for a 3D printer helps to make sure that 20 mm in the drawing corresponds to 20 mm of the printed product. At the same time, the calibration cube helps to establish the dependence of the degree of extrusion and print quality on the temperature of the extruder.

Download Thingiverse Model

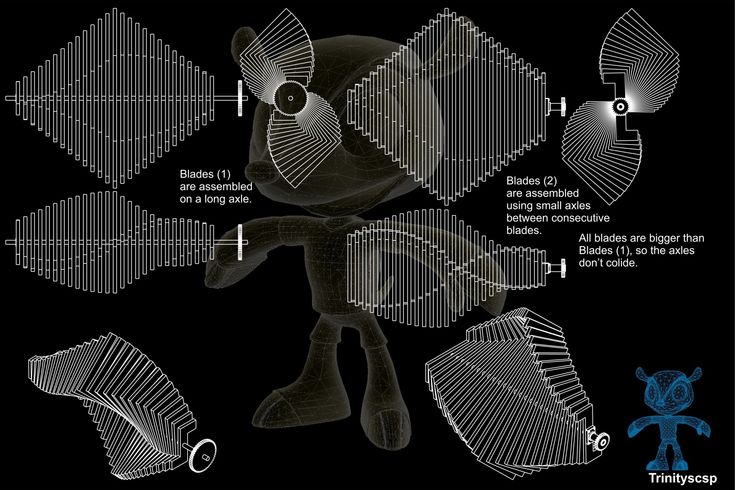

4. Matter Hackers' Mascot Phil A. Ment

This is a small astronaut figurine that has elements designed to test 3D printing.

These are small inserts, small relief details, overhangs, vertical and horizontal cylinders, fillets, chamfers, lintels and a perfectly domed helmet.

A feature of the model is the ability to obtain accurate data for different dimensions of the printed product.

Download model on Thingiverse

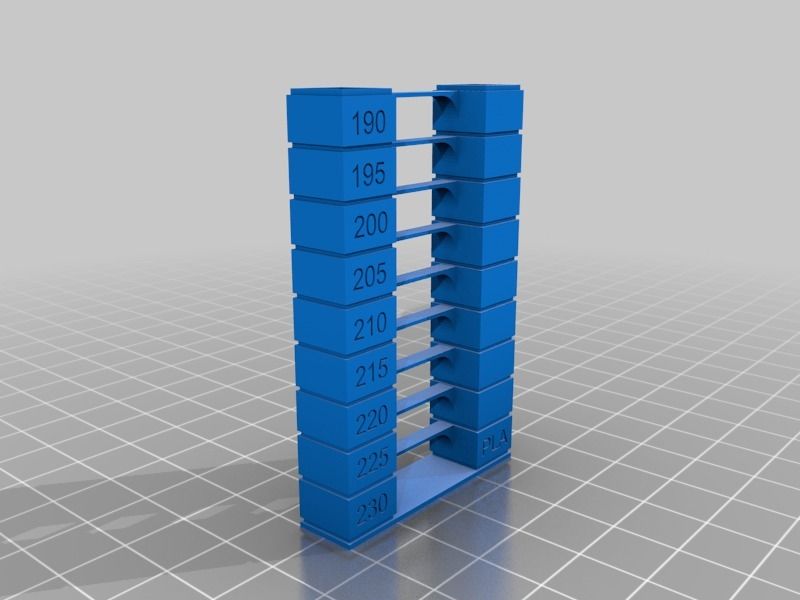

5. Smart compact temperature calibration tower

The calibration scale demonstrates the capabilities of the 3D printer when printing at different temperatures with one filament. The test model clearly shows the quality of overhangs, lintels, tensions, and the product can also be used to judge the ability of a 3D printer to print curved surfaces with a certain plastic.

A simple and intuitive tool allows you to find out the possibilities of materials that have not previously been used in work or printed with only one temperature.

It is important to consider that the print temperature setting for each signed element (floor) must be set in the slicer or manually in Gcode.

Download model on Thingiverse

6. Open-Source Printer Evaluation

This is a universal print model from Kickstarter and Autodesk. It was created taking into account the experience of using other models for testing. It contains bridges, overhangs, fine detailing and elements for assessing the spatial accuracy of 3D printing.

Download model on Github

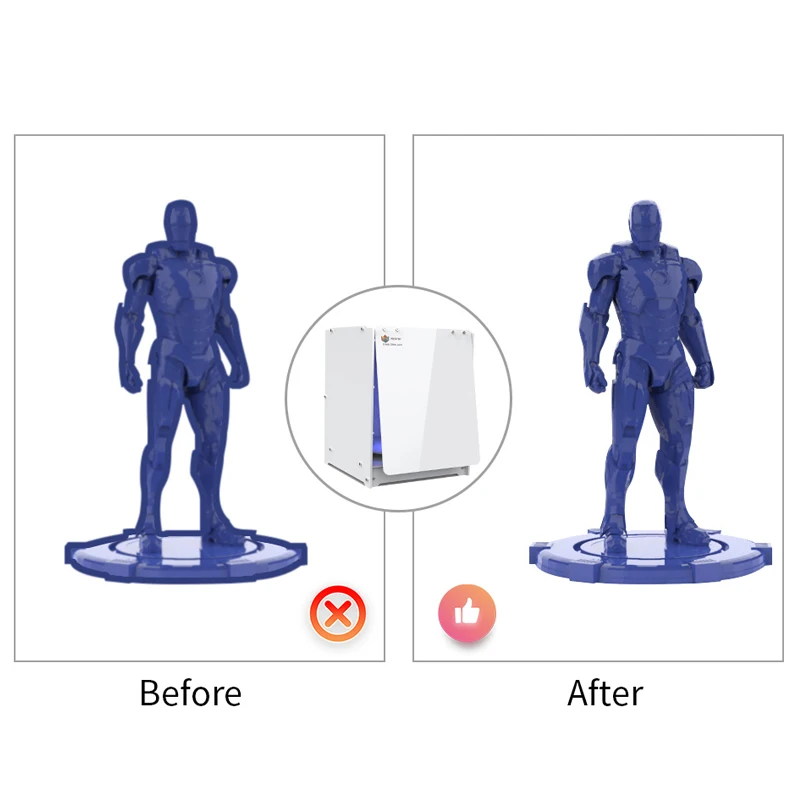

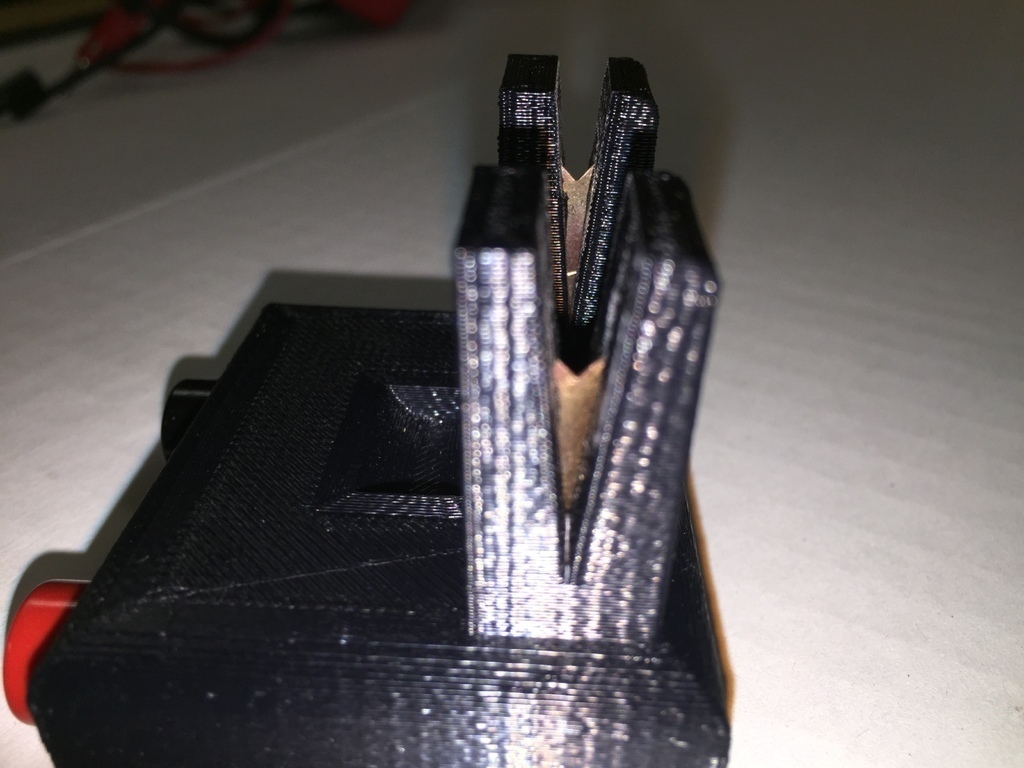

7. Economical Stringing Test

When printing complex-shaped objects, without knowing the capabilities of the filament and the printer, the user may encounter stringing (from string - string), and in Russian simply “snot” - when plastic reaches for the extruder, forming thin plastic fibers in the air. Such “snot” appears when the extruder is idle. To avoid this, the retract function is used - the retraction of the filament during idle movement. Correct setting of the retract level requires consideration of extruder speed, extruder temperature and filament properties.

Such “snot” appears when the extruder is idle. To avoid this, the retract function is used - the retraction of the filament during idle movement. Correct setting of the retract level requires consideration of extruder speed, extruder temperature and filament properties.

This test model is used to quickly check the correct setting of the 3D printer. If the strings between the vertical pyramids do not form, then the settings are correct. If horizontal plastic filaments appear, then some of the 3D printing parameters should be changed.

Download model on Thingiverse

8. PolyPearl Tower (Pearl Tower)

The design features of the model allow you to check the quality of jumpers, bends, protrusions, fix the appearance of “snot” and establish the strength of the model as a whole. This model can also be used as a stress test that determines the physical limits of a filament at a given temperature and print speed.

This model can also be used as a stress test that determines the physical limits of a filament at a given temperature and print speed.

Download model on Thingiverse

Conclusion

To improve your filament printing skills on your printer, we highly recommend doing a couple of test prints from this article. Thus, you will save more on plastic, because you will use the desired print settings.

Buy plastic for 3D printing at REC - get officially delivered products with warranty, service and technical support.

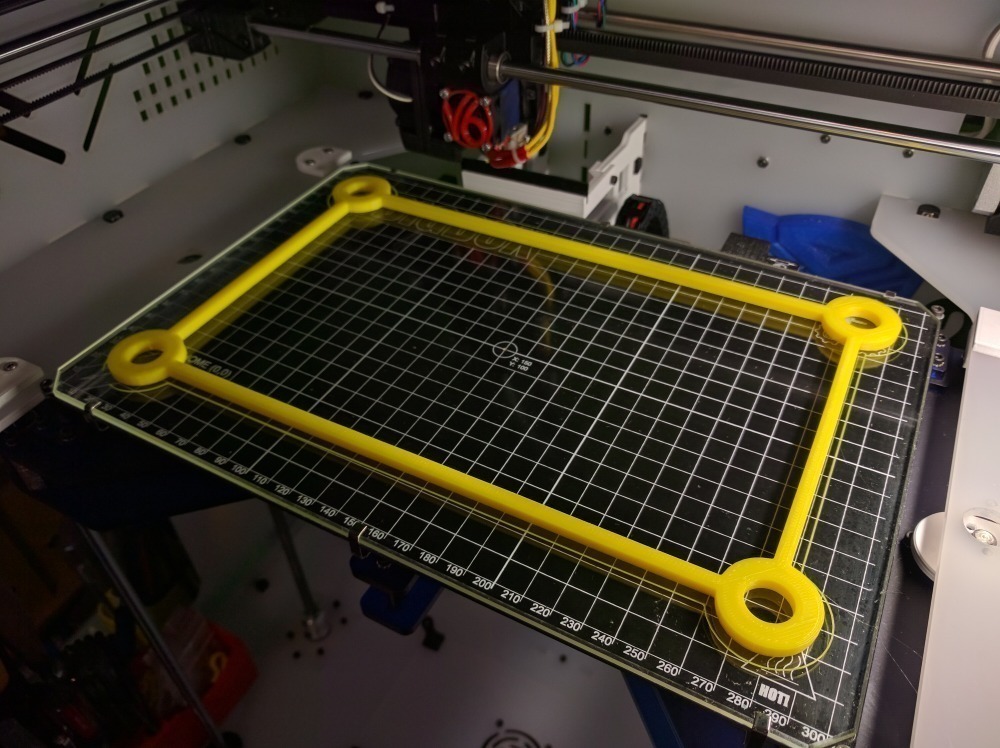

From classic to mystic. My print surface test.

Subjects:

1. Blue Male Scotch

2. Capton tape

3. Flon Lomond Self -adgesive Inkjet Film 1708411

4. Sitallic glass

5. Catalyst - beer - beer 'Velkopopovicky

Blue masking tape

Great for printing small PLA parts without heating the bed. With an increase in the area of \u200b\u200bthe part, the edges rise along with the adhesive tape.

Kapton scotch tape

I glue fresh scotch tape, smear 'Light Goat' beer on a table warmed up to 110 degrees.

The bottom surface of the part (ABS) turned out smooth, except for the corners, which were unpleasantly raised. It does not adhere very well to fresh beer and the beer itself remains a brown film on the bottom surface of the part. Beer is easily washed off with water. The part separates well from the table after cooling, but it cannot be left overnight. The plastic begins to pull the tape and air bubbles form under the tape.

Such a surface after a few days of printing

Left the part overnight and the kapton wrinkled.

The bottom surface is glossy, but bubble holes remain

Lomond film

I looked at this film for a long time, but the moment came when it was time to replace the Kapton and I decided to experiment. I cut the film into two equal sheets and glued one onto the washed surface of borosilicate glass.

I cut the film into two equal sheets and glued one onto the washed surface of borosilicate glass.

I completely forgot that the top layer of the film must be thoroughly washed off with water. At first, the ABS filament did not want to stick to the surface. After several calibrations of the nozzle relative to the table, the print still went. But the result did not satisfy me at all - the corners of the part were raised.

After the first print, there are air gaps under the film along the contour of the part.

I rubbed the surface of the film with my finger and remembered that the top layer needed to be washed off, which I did.

Sweat this bottom surface is obtained from ABS parts at Lomond. Minus one - it is very difficult to tear off the part from the film.

After a few days of printing, air bubbles begin to increase and appear on the underside of the part. But this film is much denser and stronger than Kapton tape, so you can print much more before the appearance of obscene-sized bubbles.

But this film is much denser and stronger than Kapton tape, so you can print much more before the appearance of obscene-sized bubbles.

Bubbles under the film.

Sitall glass

Let's move on to the mystical-cosmic material. So far, unexplored material that few people held in their hands.

Sitalls are crystalline materials obtained by introducing catalysts into molten glass, as a result of which crystallization centers appear in the volume of the material, on which crystals of the main phase grow. The term "sitalls" was proposed by the professor of Moscow Chemical Technology Institute. DI. Mendeleeva I.I. Kitaygorodsky and comes from the words "glass" and "crystal" . For the first time glass-ceramics were made in the 50s. 20th century Materials similar to sitalls are called pyroceram, devitroceram, glassceram abroad. Glass-ceramics have high strength, hardness, wear resistance, low thermal expansion , chemical and thermal resistance, gas and moisture resistance.

Packaging

Wipe thoroughly with 646 Thinner. Reconfigured the dimension along the Z axis. Started printing the gear from the Prusa i3 Rework kit. ABS 265 degrees, table 116 degrees.

The result disappointed me. At 76 degrees on the table, the part is removed by hand, as if it had just been placed on glass.

Added 2 degrees to the table.

Brim cannot be printed. At a table temperature of 85 degrees, the part can be removed from the glass.

Now I wonder how Brim works. I'm printing an extruder part from the Prusa i3 Rework kit. If Brim will hold parts with a large bottom area, then this will be ideal, but so far I have not noticed any advantages in adhesion.

Table 118 degrees.

Looks like Kapton without beer so far.

Table 122 degrees. Model cal.stl from the Mendel90 project. I lowered the nozzle along Z by 0. 1 mm.

1 mm.

Additional bubbles have appeared on the bottom surface of the part.

Tried to remove an underprinted part from a hot bed (119 degrees). Came off very easily.

I wiped the glass with alcohol - no effect.

Since the effect is like that of Kapton without beer, I decided to smear it with beer. The temperature of the table is 118 degrees.

This result is already acceptable. It shoots great.

A little tack on a large part, just like beer should be.

My findings

Blue tape. Great for small PLA parts. Does not require table heating.

Kapton tape. Good for medium sized ABS and PLA parts. It is obligatory to heat the table and apply a layer of beer. Brim is required. If you print infrequently, then enough for a long time.

Lomond film 1708411. PLA did not print with plastic.