3D printer wood projects

30 Best Wood 3D Prints That You Can Make Now (Free) – 3D Printerly

3D printing is unique in many ways and the possibilities it holds are limitless. Items printed to look like wood are remarkably identical to woods and have the same smell and feel.

In this article, I compiled a list of 30 cool things that you can 3D print from wood filaments with your 3D printer. Feel free to download these for free and get some awesome looking wood 3D prints.

The Frankenstein Light Switch Plate is a popular 3D print that would look great in wood filament. It has over 250,000 downloads and plenty of real examples that people have shown under the “Makes” tab on the Thingiverse page.

If you have a basement, this is a perfect replacement for your light switch.

Created by LoboCNC

Chess is one of the best classical games and nearly everyone would like to have one. You can create your own set of chess pieces by downloading this set of Chess pieces. You can get a lovely wooden finish.

If you want to go the extra mile, you can post-process your prints with a wood lacquer or polish to really make the pieces pop.

Created by TimEdwards

This is a mini castle tower for your small plants; cactus, aloes, etc. You can decide to put it on your desk in the office or in your home. 3D prints are great for decorations and can easily hold some of your favorite plants around the home.

Created by Qrome

The Collapsible Basket is a really innovative model that would look perfect in woof filament. It doesn’t require any supports to 3D print and can easily be collapsed. This model prints flat and extends into a functional basket.

Created by 3DPRINTINGWORLD

The Groot bust sculpture is a work reminiscent of the Guardian of the Galaxy movie. This has to be one of the best uses of wood filament if I had to choose. You can even choose to add some flicks of paint to add that natural wood and moss effect.

Created by Doodle_Monkey

Wargaming is more interesting with surrealistic creations. A fantasy Viking house is a good example of an item you can 3D print today. This model is pretty easy to 3D print and assemble.

A fantasy Viking house is a good example of an item you can 3D print today. This model is pretty easy to 3D print and assemble.

Created by Terrain4Print

As you can see in the picture, this Kumiko Shoji Style Lamp looks great with the wooden look. You can use glue to join the individual parts together.

Created by TanyaAkinora

Those who have tried this beautiful vase out have something good to say about it. The vase can be given a cool and unique look by printing it with a larger layer height like 0.3mm+. Vases printed with wooden filament creates an appealing look.

Created by virtox

Having a jewelry box is good, but what makes it feel better is making a jewelry box that is as beautiful as any you can get in the market. It has different removable dividers for the box that separate it into two or four parts.

The height of the dividers and inside the box is the same with thick padding for the floor made of velvet material to cushion whatever item is kept in the box.

Created by TheGreatMrBill

I singled this chest out of the catalog because it has a unique lock that allows me to keep my valuables safe.

Created by DrLex

Which of the spells in Harry Potter do you still remember? This wand would look perfect with a wooden filament with that grain finish. You can 3D print this to impress any friends or family that love the movie, or even as a Halloween prop.

Created by jakereeves

This lion is designed very nicely, representing one of the most magnificent beasts in the jungle.

One user in the video below sliced up this file and printed the top half of the model in gold silk PLA.

https://www.youtube.com/watch?v=BRjEoKFNqcI

Created by cncmodels4you

Hold my beer…Sometimes, you don’t want your hands moist from holding cold drinks, or you want to avoid the canned drink wetting a particular surface. A canned drink holder is an innovative solution to that problem.

It’s designed with an old school vikings look that many people will notice. You can also use it as a dice mug for gaming.

You can also use it as a dice mug for gaming.

Created by ArsMoriendi3D

Bees are gradually becoming endangered species. Acknowledging their importance and the contributions they make to the ecosystem can be done in many ways. One of them is a bee hotel. This is an artificial habitat for the bees to help them grow in number.

Those who have printed this have attested to the ease in printing and the effectiveness.

Created by mitrasmit

This is a smaller version of the Majoras mask. This version has an increased wall thickness and added an area at the back so it can be made into a keychain, lapel pin, or hang from a string.

Created by WeedMadSausage

This is an improved version of the previous bolt. This new bolt is reinforced with 100% infill, reduced contact sliding bar version to help with prints that seem to be fused together, improved support for the ball handle, etc.

This would usually go on a wooden door, so what better material to 3D print this than with wood filament.

Created by Sagittario

This is a fairly simple door handle that reminds people to keep the relevant place closed. Printing this with wood filament would look pretty good.

Created by andrewar

This planter is unique for many reasons, one of which is the design of the planter which allows air to enter the soil and the roots.

Created by cgpena

For the Steampunk fans out there, this is a really cool 3D print that you’ll love. It is a project that requires a little extra effort compared to other 3D prints, but I’m sure it will be worth it.

Created by out0fstep

This planter appeals to one’s aesthetic sense. The flower pot is designed with an organic double wall voronoi outside shell. There are two versions available, a small and a larger pot.

There are two versions available, a small and a larger pot.

You don’t have to be an Egyptologist to know and admire Egyptian arts. This hollow Nefertiti’s bust serves a dual purpose; a flower vase and a sculptural design.

Created by adafruit

I’ve been a game lover long enough to know that varieties of game pads are appreciated. This is the case for the Xbox One Face plate. The face plate comes with other features like the battery case.

Created by TheBearMethodst

The Tudor box is reminiscent of the era in England. It is characterized by its heavy wood carving effects which is common during the Tudor period. It is sliced into parts and should be conjoined when printing is completed.

Created by Ioubie

The appealing part of this sculptural work is the minimalist design. It works really well with a high quality wood filament, which can look even better by using wood stains.

It works really well with a high quality wood filament, which can look even better by using wood stains.

Created by MakePrintable

Hold my beer! The pack of six beer holders gives you the ability to transport your bottled beverage. This six Packer is constructed of 3/16″ thick laser-cut plywood and assembled with 4-40 1/2″ screws and nuts.

The bottle holes will accept anything from the run-of-the-mill long neck bottles to IBC Root Beer to short chubby craft beer bottles.

The 6 Packer was designed with OpenSCAD and it is parametric. You can change material thickness, bottle diameter, fastener size, hand grip size re-render, and cut out using your favorite laser cutter!

Created by timogiles

Baby Groot was inspired by Vol 2 of Guardians of Galaxy. To achieve a clearer detail, it is advised you use the high detail version to capture all the details that are put on it.

Though, if your slicer freezes/crashes, use the low detail version, as the high detail version has several million polygons and requires more RAM/computing power to be sliced.

Created by Byambaa

D&D lovers will appreciate this tray and carrying case. It is advisable to print the case upside-down to make sure your printing achieves the desired round edges.

Created by Aethernex

If you have an Apple Watch and want to give your charging process a little extra flare, you can 3D print this Baby Groot Apple Watch Holder out of some wood filament.

The design on this one is really cool, where it makes it look like Baby Groot is pushing on the screen of your watch. The designer recommends using an infill of around 40% and a layer height of around 0.15mm.

Created by Gazzie4

If you love wall accessories and stacking up your books on the shelf, this will appeal to you. It’s a modern design for your home that you can appreciate.

Created by comcom_atelier

This is a remodeled version of the original one with slight differences in some of the parts. 100% concentric infill is used for the horn and 20% rectilinear infill for the box.

You will only need support for the connector rings and will need to do some minor cleanup of them when finished.

Created by TheGreatMrBill

You made it to the end of the list! Hopefully you found it useful for your 3D printing journey.

If you want to check out other similar list posts I carefully put together, check out some of these:

- 51 Cool, Useful, Functional 3D Printed Objects That Actually Work

- 30 Cool Things to 3D Print for Gamers – Accessories & More

- 30 Cool Things to 3D Print for Dungeons & Dragons

- 35 Genius & Nerdy Things That You Can 3D Print Today

- 30 Holiday 3D Prints You Can Make – Valentines, Easter & More

- 31 Awesome 3D Printed Computer/Laptop Accessories to Make Now

- 30 Cool Phone Accessories That You Can 3D Print Today

3D Printing and Woodworking – A Perfect Combination

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

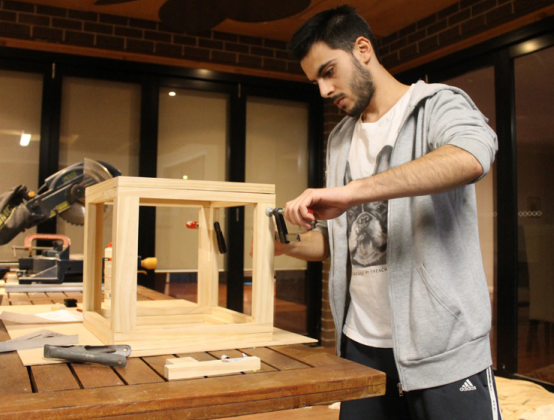

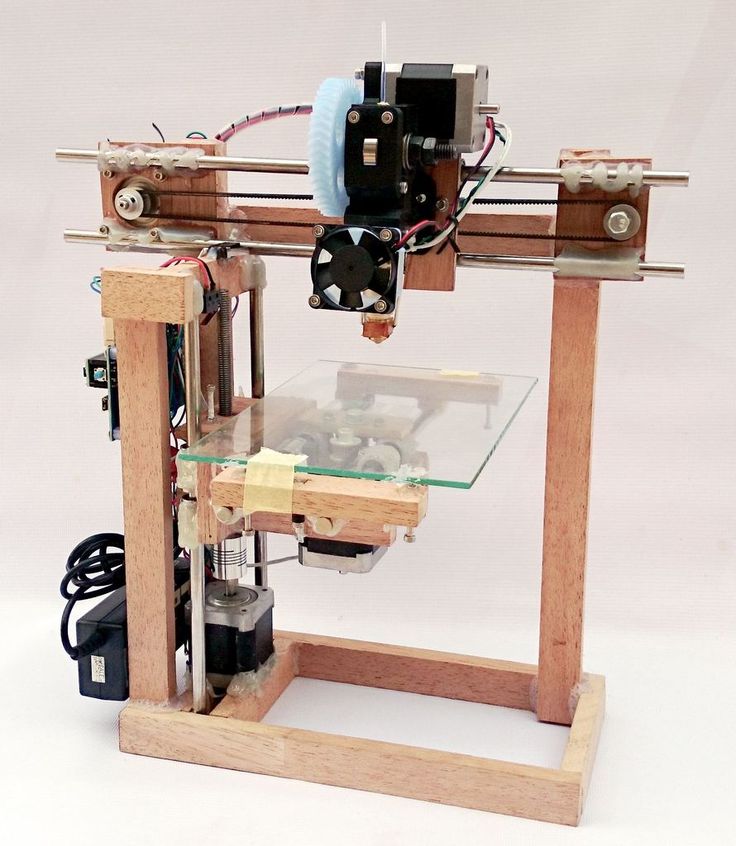

Before 3D printing, there was woodworking.

Woodworking has been one of the favorite hobbies of those who like to work with their hands. There was a certain fulfilling – perhaps even meditative – value to creating beautiful and useful things from planks of wood.

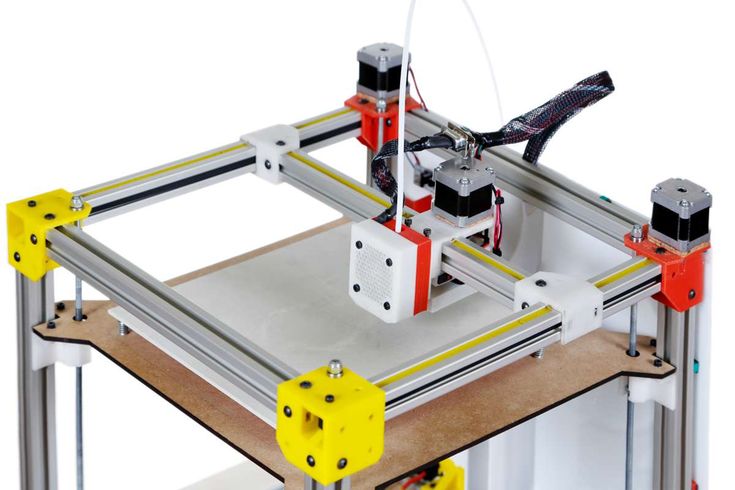

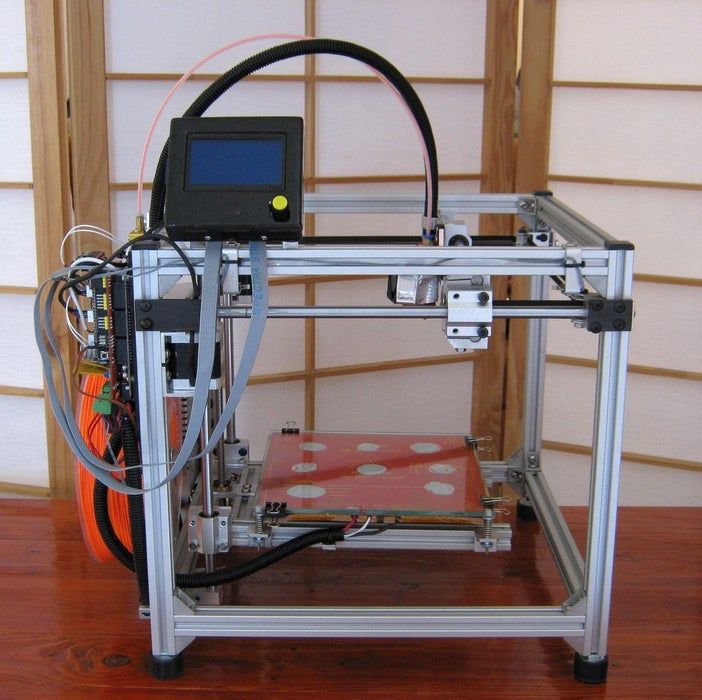

Some would describe 3D printing as the more modern version of woodworking. Although 3D printing demands different technical skills, the end goal is still to come up with something valuable out of raw materials.

If you’re interested in both, then there’s no need to pick just one. Woodworking and 3D printing are crafts that work incredibly well together.

3D printing vs. woodworking – key differences

Woodworking and 3D printing can be described as the two sides of the same coin. They are both manufacturing methods but go about using vastly different approaches.

Additive vs. subtractive

Woodworking is a classic example of subtractive manufacturing. This means that the final product is derived from a slab of raw material by chipping or cutting away the material that is not needed. This method inevitably generates more waste but produces finished parts that are mechanically stronger.

This method inevitably generates more waste but produces finished parts that are mechanically stronger.

3D printing is the very defining example of additive manufacturing. Instead of cutting away from a large block of material, a 3D printer product is built layer by layer. This method generates less waste but is also usually slower. An unfortunate consequence of 3D printing is that it is almost impossible to achieve the same mechanical integrity as a piece made via subtractive manufacturing.

Cost

In terms of the equipment, woodworking would likely require much greater capital. Between the various types of power tools and hand tools you will need, you will probably have to spend between $500 to $1000. It will be even more expensive if you’re getting a CNC machine like a lathe or mill.

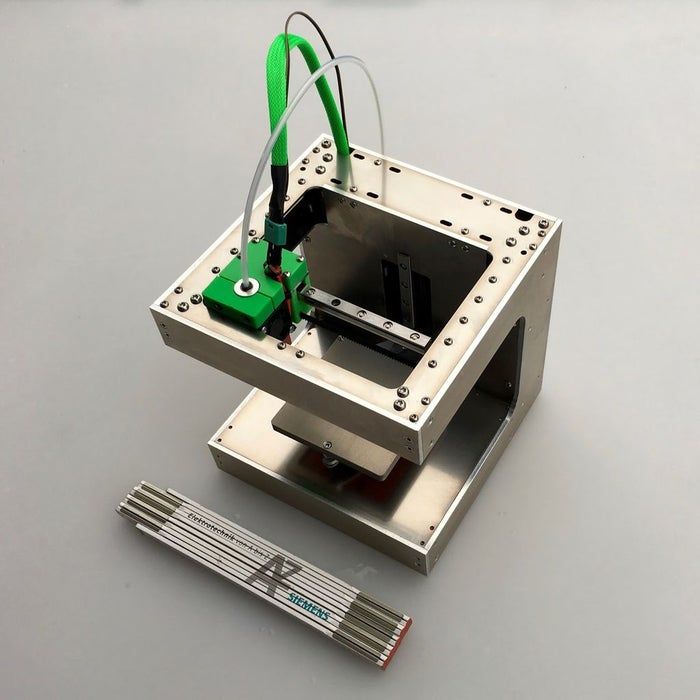

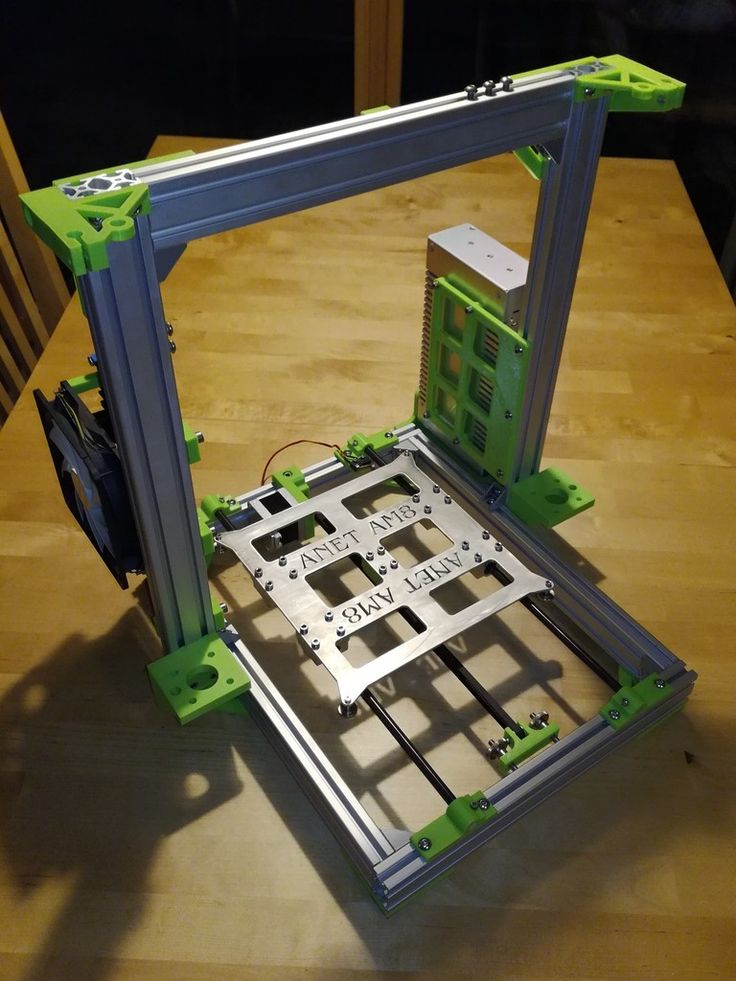

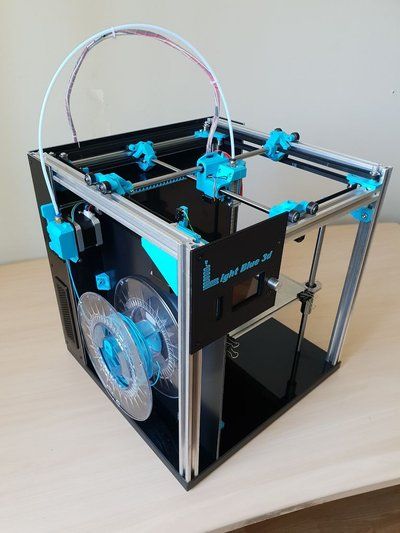

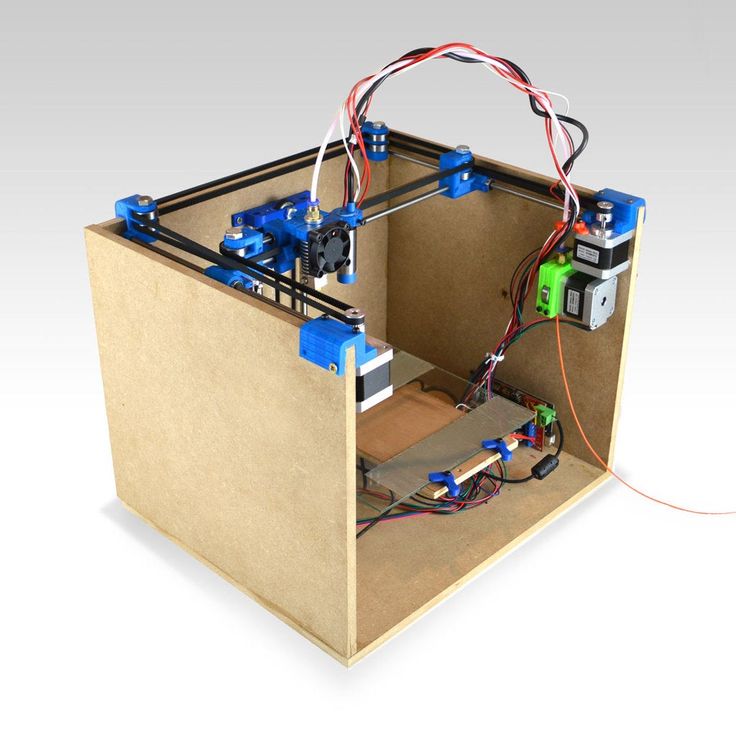

In contrast, 3D printing can be done with just a single 3D printer and a few basic hand tools. If you stick to entry-level 3D printers, you should not need to spend more than $500. 3D printers have gotten a lot less expensive in the last years, paving the way to the widespread use by hobbyists.

3D printers have gotten a lot less expensive in the last years, paving the way to the widespread use by hobbyists.

Skill level

Woodworking is an old-fashioned craft. This means that it requires substantial training or experience, especially if you’re working with lots of power tools. Someone who has never worked with these tools before isn’t likely to be able to create a good wooden desk over a single weekend.

3D printers are much more beginner-friendly. Although there are complex algorithms involves in running a 3D printer, most of these happen behind the scenes and do not need to be bothered with by average users. Most desktop-scale 3D printers are designed specifically so that even pure beginners can start printing in just a few minutes.

Those who do CNC woodworking can adjust much easier to 3D printing. CNC technology, after all, is also based on digital 3D models. As we shall see later on, 3D printing can have a unique case for those who use CNC machines for manufacturing.

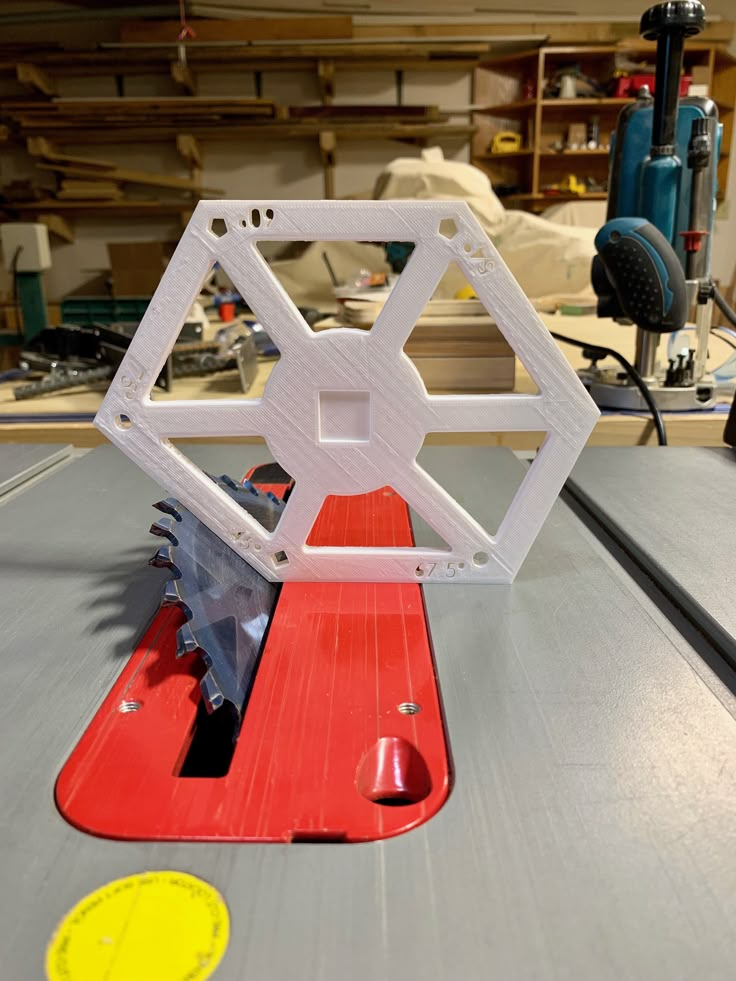

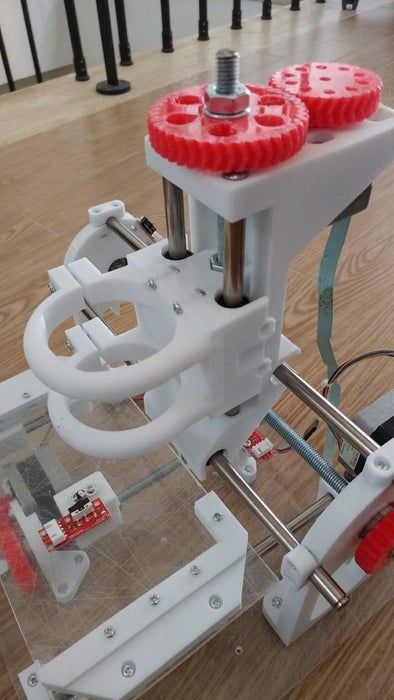

3D printed woodworking accessories

3D printing truly shines as a complementary craft to another hobby. This characteristic also applies to woodworking. You might have all the power tools set up, but there are so many ideas out there of “ad hoc” tools that are similarly useful. Here are some of the most popular:

Sanding sticks

Sanding tight spots in a wooden project can be challenging. You typically just wrap sandpaper around some arbitrary tool or just get your finger in there. This works eventually but is not very efficient.

These sanding sticks are designed to hold a strip of sandpaper in place with its clamps and thumbscrews. The sticks are available in various shapes and sizes, so you should not have a problem finding the one that you need. Although very simple, these sanding sticks can reduce the time and effort it takes to sand very small spaces.

Corner radius rounded corner template

Drawing the outline of a rounded corner on a wooden slab is easy. However, cutting away that rounded corner using a router takes considerably more skill.

However, cutting away that rounded corner using a router takes considerably more skill.

This rounder corner template is designed to fit into any sharp corner and serve as the template for the router. The STL file contains nine different templates with varying corner radius values. The corner template will very briefly come in contact with the router, so it’s best printed with a thermally stable plastic like ABS or Nylon.

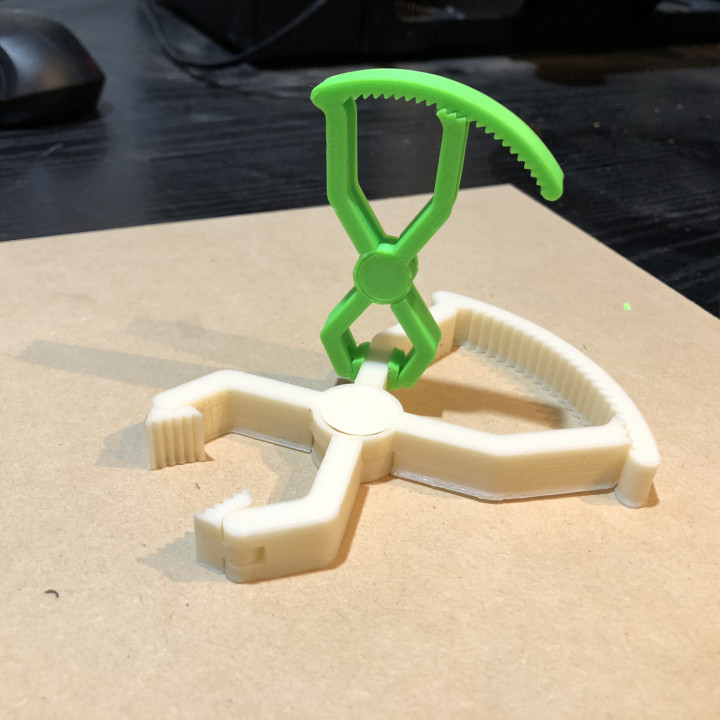

Universal clamping blocks

Putting together corners whether they are mitered or have wider or narrower angles is hard because they cannot simply be clamped together. The common solution to this problem is to glue temporary clamping blocks to the pieces that form the corner. This takes so much time and adds unnecessary work.

With these 3D-printed universal clamping blocks, you can say goodbye to all those creative solutions. These clamping blocks have circular levers that can be clamped tight, regardless of angle. It’s a very simple contraption that you might be left wondering why you did not have such a tool in the first place.

Vice jaws

This is another simple but useful idea – plastic jaws that you can affix to your vice so that it does not damage more fragile materials. This is best 3D printed with a plastic that is moderately flexible such as PLA. The vice jaws also work wonderfully with hard materials like wood as they can more effectively clamp the piece.

The vice jaws have small indentations on the bottom side. These are meant to house small magnets so that they can be attached and detached from your vice easily. They can also be glued onto the vice. There is really no disadvantage to just affixing these jaws to your vice permanently.

Universal center finder

Woodworking experts are also experts in finding the centerline of everything. A rectangular plank of wood is no problem, but those that have rounded corners require a bit more imagination. In any case, finding the centerline using old-fashioned methods takes a lot of time.

This universal center finder is a handy tool that you can 3D print quickly. The fence of the tool is specifically designed to fit both round and rectangular corners. There is also a small relief on the fence so that it can fit any piece that has burrs. A thin channel runs right down the middle so that you can mark the centerline with a pencil.

The fence of the tool is specifically designed to fit both round and rectangular corners. There is also a small relief on the fence so that it can fit any piece that has burrs. A thin channel runs right down the middle so that you can mark the centerline with a pencil.

Dust collection adapters

Dust collection is a crucial part of woodworking. Not only does wood dust get into your respiratory system, but it can also very easily cause a fire or dust explosion. Unfortunately, getting your dust collection hoses to fit with your vacuum units is an impossible task without adapters.

There is a whole slew of 3D printable dust collection adapters out there with different shapes and sizes. The model we are linking to here allows a Makita RT0070CX2J dust shroud to connect with smaller 36-mm hoses. If there’s a mismatch between any of your dust collection equipment, just do a quick search and you might just find the exact adapter you are looking for.

Parametric knobs

By far, this set of parametric knobs will likely be the most useful to any woodworking enthusiast. You can choose to integrate nut knobs for your finished product or use them as adjusters for jigs or create makeshift screwdrivers.

You can choose to integrate nut knobs for your finished product or use them as adjusters for jigs or create makeshift screwdrivers.

This STL file contains an array of nut knobs, wing nuts, and mini bits for hex and star screwdrivers. Yes, just about all of these parts can be purchased in your local hardware. However, that can get expensive after a while because these plastic nuts can break apart fairly easily. It’s much more prudent to 3D print a bunch of them so you can have one ready when you need it.

These plastic knobs can be made to fit snugly to any fixture by just heating them momentarily. You can also apply some glue for extra bond strength.

Cordless tool wall mount

When you start accumulating lots of power tools, getting them organized becomes more challenging. You will want to put them away but in a manner that still makes them accessible. How about wall mounting them?

This 3D printable bracket fits most of the Dewalt and Makita cordless tools. They can be screwed onto a wall or tacked into a secure pegboard. With a simple and elegant design, this wall mount can help you reclaim horizontal space in your workshop.

They can be screwed onto a wall or tacked into a secure pegboard. With a simple and elegant design, this wall mount can help you reclaim horizontal space in your workshop.

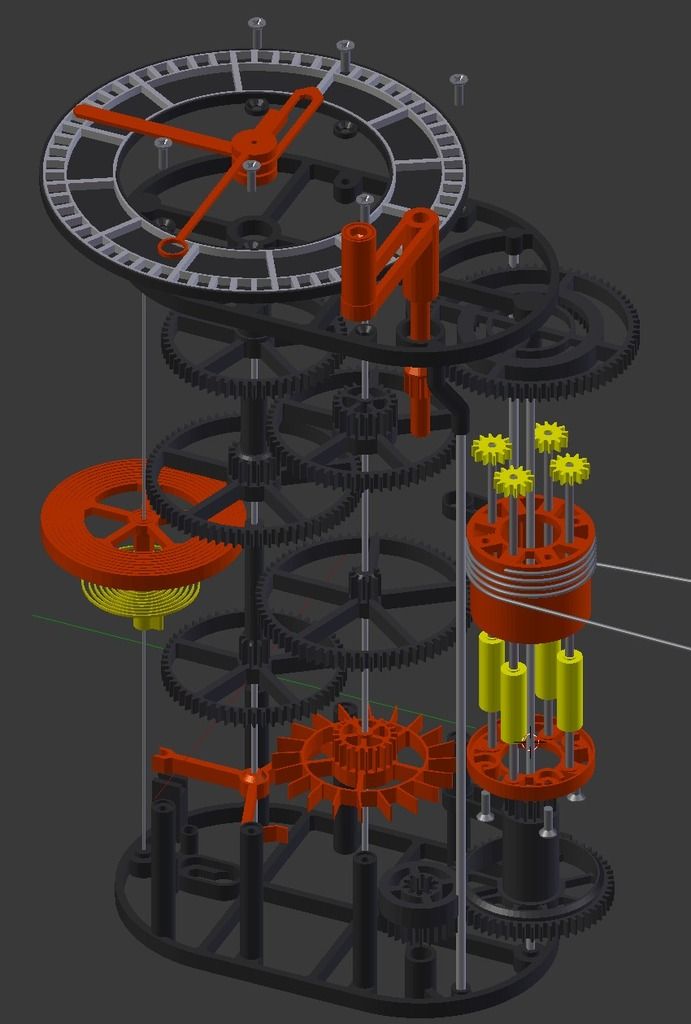

3D printed prototypes

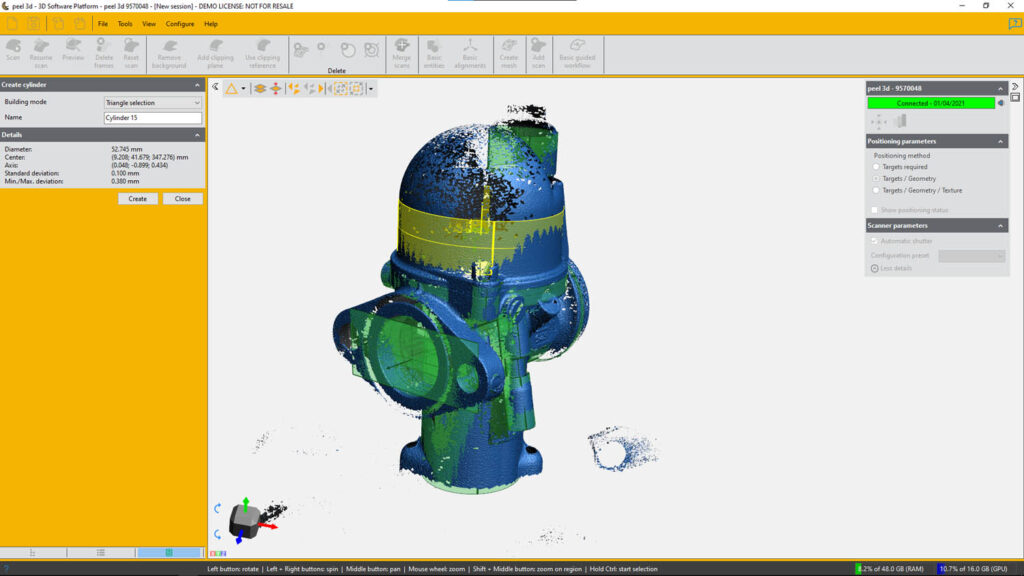

A subset of woodworking involves the use of CNC machines. These are typically mills or lathes that can run automatically based on an established algorithm. CNC woodworking is ideal for creating high-precision parts that require detailed etching.

A key characteristic of the CNC process is that it starts with a 3D model. This 3D model is processed in a CNC software platform to generate the code that the CNC machine will follow. This code or algorithm determines the exact movement of the machine’s cutting tools and other moving parts. Some in the industry call this “digital woodworking” and this technology has given way to some of the most impressive woodworking projects.

The beauty of combining CNC machining and 3D printing is that they can both be done using the same 3D model. For those who plan their builds in CAD platforms, 3D printing provides a way to quickly come up with prototypes. Do you want to test how a 4-foot sculpture will look before fully committing to it with wooden parts? Then print a small-scale replica of it over one afternoon.

For those who plan their builds in CAD platforms, 3D printing provides a way to quickly come up with prototypes. Do you want to test how a 4-foot sculpture will look before fully committing to it with wooden parts? Then print a small-scale replica of it over one afternoon.

Those who offer professional woodworking services can greatly benefit from 3D printed prototypes. A 3D printed copy is a great way to review a model with a client for approval or possible revision. Looking at a 3D model is a computer screen simply cannot compare to holding a physical copy in your hands.

More innovative woodworking enthusiasts have been trying to integrate 3D printing and woodworking in different ways. As 3D printers become more sophisticated, it’s not hard to imagine 3D printed projects going hand-in-hand with wood not just as prototypes but as finished parts. This seems to be the direction that the manufacturing industry is headed. Until then, 3D printing could remain the perfect complement to woodworking.

Final thoughts

Woodworking is a respectable craft. It has been around for centuries and has only been made better by modern equipment. Nowadays, wood craftsmen are capable of designs and products that would not have existed ten years ago.

With 3D printing on the rise, there is again an opportunity to advance the possibilities of woodworking. 3D printing is not a competitor or alternative to woodworking. In many cases, 3D printed parts can be very useful in creating new possibilities for woodworking. Combining both may just give way to a brand new craft.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

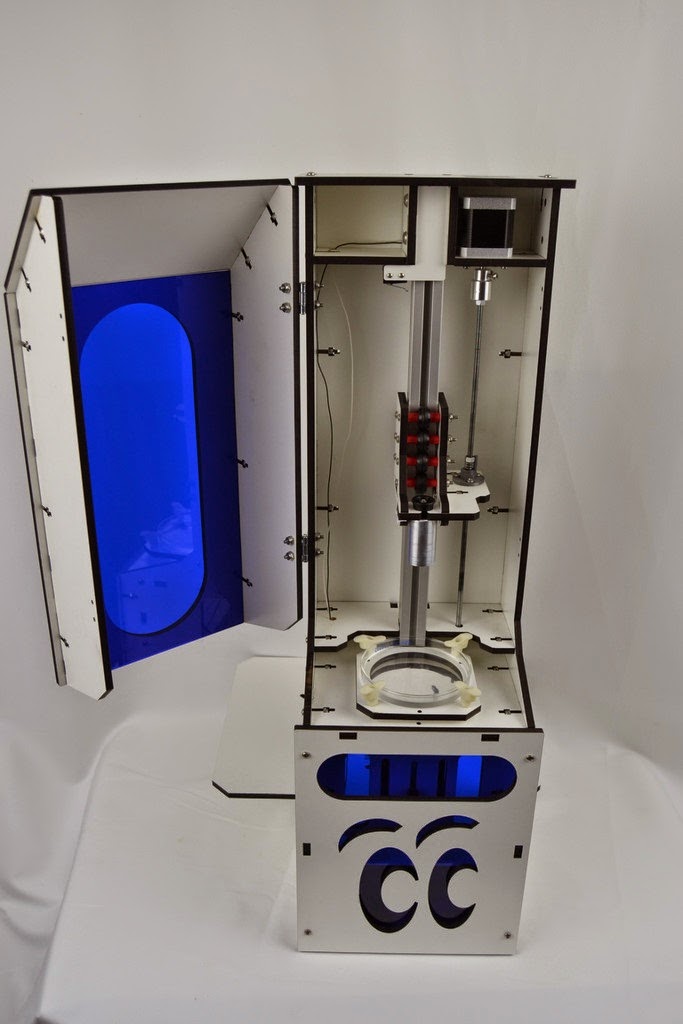

3D printing of wood-polymer composites from Desktop Metal

News

Under the new process called Forust, the inkjet-powder additive systems of its own production and the recently acquired company EnvisionTEC are being adapted.

Wastes from wood and paper production are used - sawdust and lignin (a family of natural wood biopolymers). The process is based on the technology of inkjet-powder 3D printing (Binder Jetting): the base material in a well-ground form is laid in a thin layer, then the inkjet heads form a pattern with a binder. Judging by the description, a printing stage has also been added to the Forust process to form textures on each layer. The process is repeated again and again until a finished product is obtained from a wood-polymer composite that is not inferior in mechanical properties to natural wood. The binder is epoxy bio-resin, so the process is as environmentally friendly as possible.

The process is based on the technology of inkjet-powder 3D printing (Binder Jetting): the base material in a well-ground form is laid in a thin layer, then the inkjet heads form a pattern with a binder. Judging by the description, a printing stage has also been added to the Forust process to form textures on each layer. The process is repeated again and again until a finished product is obtained from a wood-polymer composite that is not inferior in mechanical properties to natural wood. The binder is epoxy bio-resin, so the process is as environmentally friendly as possible.

The resulting composite material can reproduce various valuable wood species, such as ash, oak, walnut, ebony and mahogany, rosewood. Opportunities are not limited to imitators of natural wood: the technology allows you to reproduce a variety of textures specified through software, or materials without textures at all. 3D printed products lend themselves well to processing: drilling, sanding, polishing, varnishing, and so on - everything is just like with ordinary wood.

“Our process builds on extensive research into lumber hardwood over the past decade, which allows us to create complex and elegant finished structures. The combination of advanced computer-aided design software, proprietary materials, and inkjet-powder additive manufacturing platforms from Desktop Metal enables the production of beautiful, functional, and innovative wood products for architecture, interior design, and home improvement applications from recycled wood industry waste and by-products.” says Forust Project Manager Andrew Jeffrey.

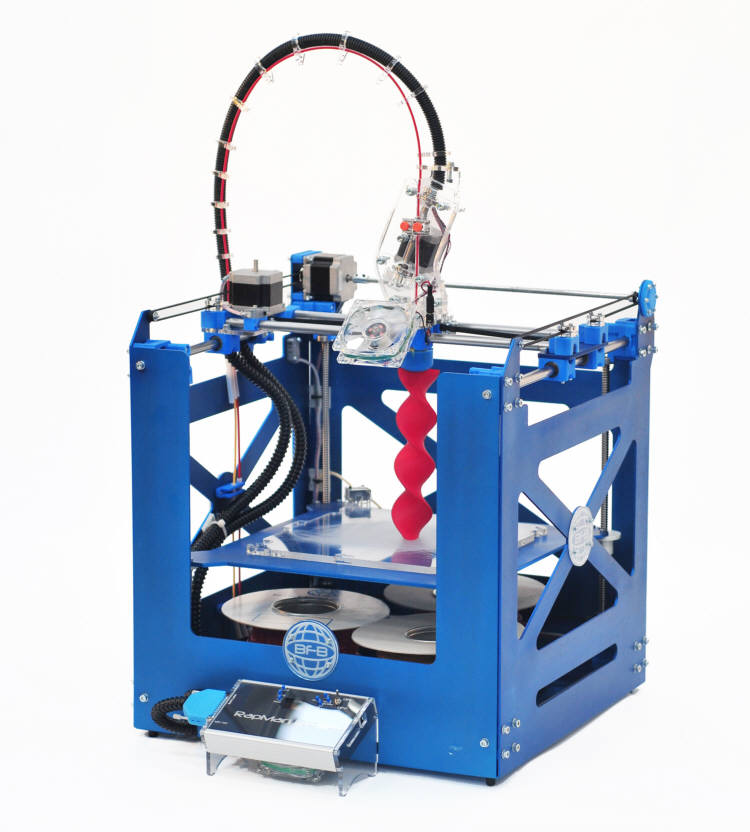

So far, two additive platforms have been adapted to the new process. The first of these is the Desktop Metal Shop inkjet-powder 3D printer with a working volume of up to sixteen liters, originally designed for 3D printing of metal blanks. The second is an additive system based on inkjet-powder 3D printing technology based on an industrial robotic arm, created by EnvisionTEC in 2017 together with the American engineering company Viridis3D. This equipment was originally intended for 3D printing of sand casting molds from quartz sand and furan resin binders.

This equipment was originally intended for 3D printing of sand casting molds from quartz sand and furan resin binders.

EnvisionTEC took over Desktop Metal in February of this year, but continues to operate under its own brand. Robotic additive systems from EnvisionTEC are available in different sizes, and the Forust project has been allocated the largest option - RAM 336. The numbers in the title indicate the size of the working area in feet along the corresponding axes, the productivity reaches one hundred liters per hour.

“We want designers to be free to experiment with geometry while using a material that has stood the test of time. On the other hand, we want users to have a choice at the end of the wood product life cycle – either toss the product to decompose over time like any other wood product, or to recycle it into new products through the Forust process. We are aiming for a truly closed production cycle,” explains Andrew Jeffery.

Additional information about the Forust project is available on the official website.

More interesting articles

5

Subscribe to the author

Subscribe

Don't want

In the village of Aisha, Zelenodolsk district of Tatarstan, work is underway to build thirty-four houses with the use of...

Read more

5

Follow author

Subscribe

Don't want

REC, one of the leading Russian manufacturers of consumables for FDM/FFF 3D printer...

Read more

59

Subscribe to the author

Subscribe

Don't want

The 3Dtoday portal, supported by Creality and Bestfilament, invites everyone to participate in. ..

..

Read more

17 real buildings printed on a 3D printer - the future vc.ru

3D printing technologies are developing at an extremely fast pace and are being used in various areas of human life.

41,796 views

Recently, much attention has been paid to the printing of buildings, and printed houses are increasingly appearing in recent years in different countries of the world - in the USA, Saudi Arabia, Mexico, France, Russia, the United Arab Emirates and others. I have prepared a list of existing 3D printed buildings for 2020.

What is a 3D printer for construction.

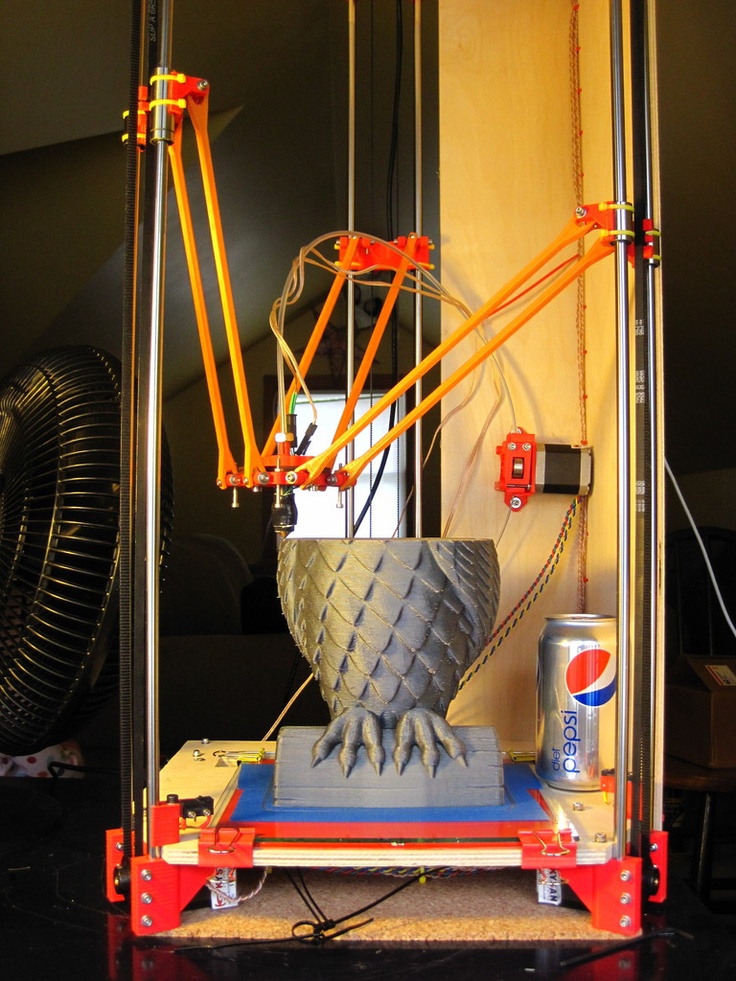

Today's 3D construction printers differ in designs and wall construction methods. The most common printers are portal construction, two- and four-support construction, based on a manipulator arm or a circular design. The equipment allows you to create small architectural forms and elements of structures for their subsequent assembly on site, or allow you to print the entire building on the construction site. The height and dimensions of the printed building depend on the specifications of the printer being used.

The height and dimensions of the printed building depend on the specifications of the printer being used.

How the printing process works.

The extruder extrudes a fast-hardening concrete mixture with various additives. Each subsequent layer is applied on top of the previous one, due to which a vertical structure is formed. The concrete layers below are thus compacted, thereby increasing their ability to withstand the next layers, and hence the entire weight of the structure. To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

Advantages of 3D printing over other construction methods.

3D printer fabrication opens up great opportunities for construction and related industries. Practical application has revealed the following advantages of additive manufacturing:

- It removes the limits from the imagination of designers and architects who design buildings, as it provides opportunities that are not available with the construction methods we are used to.

- High speed of construction of buildings and structures.

- Complete process automation.

- Low power equipment.

- Significant savings compared to conventional construction methods by reducing labor and energy costs and accelerating construction time.

- The formation of waste building materials is completely eliminated.

- Minimization of human intervention in the construction process not only allows building in places inaccessible to people, but also eliminates the human factor in ordinary areas and reduces the likelihood of error.

1. June 2014. China. China's Shanghai WinSun Decoration Design Engineering Co has unveiled 3D printed houses at an industrial park in China's Jiangsu province. A total of ten houses were created, each of which cost a little more than three thousand pounds sterling. Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors.

Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors.

2. August 2014. USA. Andrey Rudenko's company Totalkustom printed the lock. The printing took a total of 2 months. The machine's printing speed was 50 cm in 8 hours. The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

3. July 2015. China. Chinese company Zhuoda assembled a two-story house in record time. The modular home, made up of six 3D printed modules, was assembled on site in less than 3 hours. Of course actually about 90% of the work was carried out in the company's workshops, and on the site they were only assembled into a single building.

4. September 2015. Philippines. Andrey Rudenko's company Totalkustom built apartments on the territory of a hotel in the Philippines, 10. 5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5. May 2016. UAE. Chinese company Shanghai WinSun Decoration Design Engineering Co printed prefabricated structures for the subsequent assembly of an office building in Dubai. The area of a one-story building is about 250 square meters. m.

6. March 2017. Russia. Apis Cor unveiled the first 37 sq. m.. The printed house has an interesting shape, but as the participants themselves say: this is just to show the flexibility of printing technology, the shape of the buildings can also be the usual square. Compared to other construction 3D printers, this printer is very compact (4×1.6×1.5 m), weighs 2 tons, and can be easily transported to the construction site.

7. October 2017. Russia. In Yaroslavl, Spetsavia presented the first residential building in Europe and the CIS, built using construction 3D printing technology. Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

8. March 2018. France. Yhnova presented a five-room one-story house with an area of 95 square meters. For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

9. March 2018. USA. American Company Icon built a prototype home in Texas to prove the technology's performance. The area of the building was 32 sq.m., printing was performed by a portal type 3D printer moving along rails installed on the site.

10. July 2018. Spain. Be More 3D printed a 24 m2 concrete building. For the construction, a two-support 3D printer was used, the width of which is 7 meters and the height is 5 meters.

11. September 2018. Denmark. 3D Printhuset printed a 50 square meter office in Nordhavn. The 3D printer used for printing is of the portal type and has a size of 8 x 8 x 6 meters. Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

12. October 2018. Italy. Company Crane Wasp using a three-bearing construction 3D printer erected a building in ten days. The house uses passive solar heating technology and natural ventilation. The composition for printing was created on the basis of waste from rice cultivation (it was 25% local soil (clay and sand), 40% straw, another 25% - from rice husks and 10% - from hydraulic lime).

13. November 2018. Italy. Company Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

Italy. Company Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

November 14, 2018. Saudi Arabia. The Dutch company CyBe Construction has completed the construction of a building with an area of 80 sq.m. It took about a week to 3D print the necessary elements, and a little more than a day to assemble. The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.

15. August 2019. USA. S-Squared 3D Printers (SQ3D) has unveiled a prototype residential building that can be built from floor to roof in just twelve hours. The house has an area of 46 m2. During the printing process, a 3D printer of a two-support design was used.

16. October 2019. UAE. Apis Cor has announced the completion of the world's largest 3D printed building. Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

17. December 2019. Mexico. The American company Icon erected two residential buildings for the non-profit organization New Story, in southeastern Mexico. The imprinted buildings have a flat roof, curved walls and an area of 46.5 square meters

As can be seen from the impressive list of completed projects, progress in the field of construction 3D printing clearly does not stand still, new techniques are constantly being introduced, various materials are being created, including from recycled raw materials, and high-tech equipment is being developed. In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework.