Diy full color 3d printer

Guide to Color 3D Printers

Are you looking to 3D print parts in color or to create vibrant, multi-color parts? Over the last few years, multiple new methods have emerged to 3D print in color, and newer 3D printers have become more accessible, empowering any designer, model maker, or hobbyist to create objects in a range of hues.

In this guide, we dive into the several techniques you can use to produce colored 3D printed parts, as well as the technologies and applications of color 3D printing.

There are several options to produce colored 3D printed parts, from color mixing to color matching, full color 3D printing, painting 3D printed parts, and hydrographics.

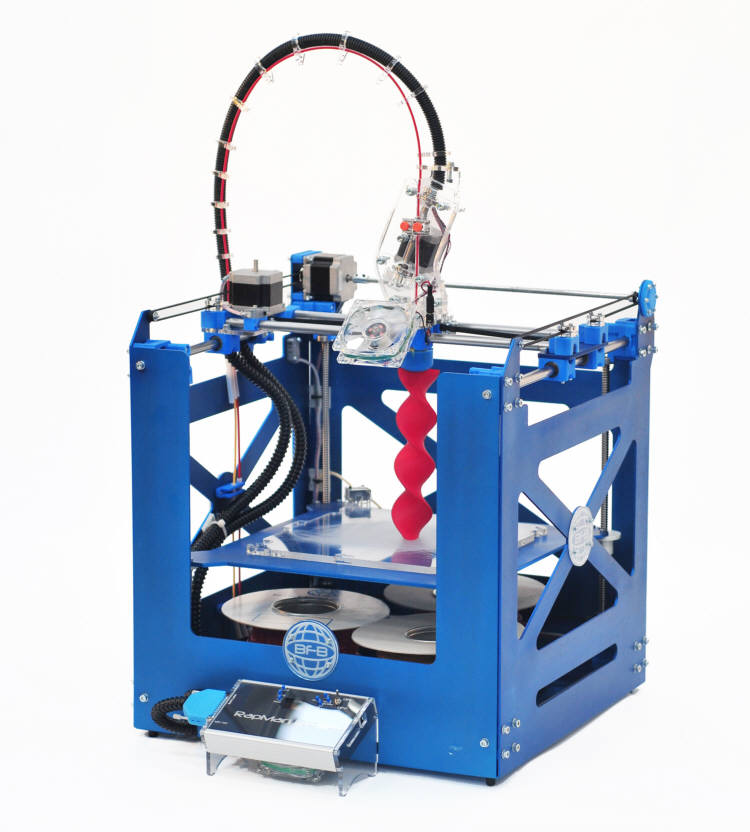

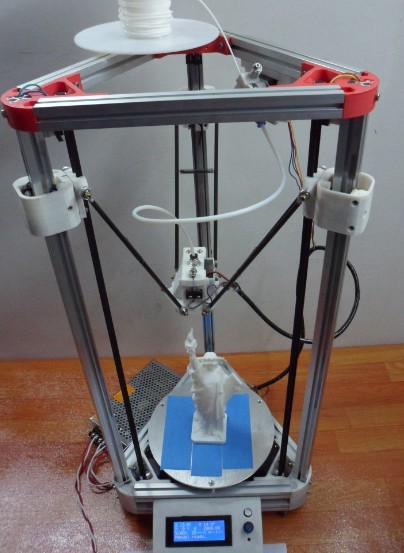

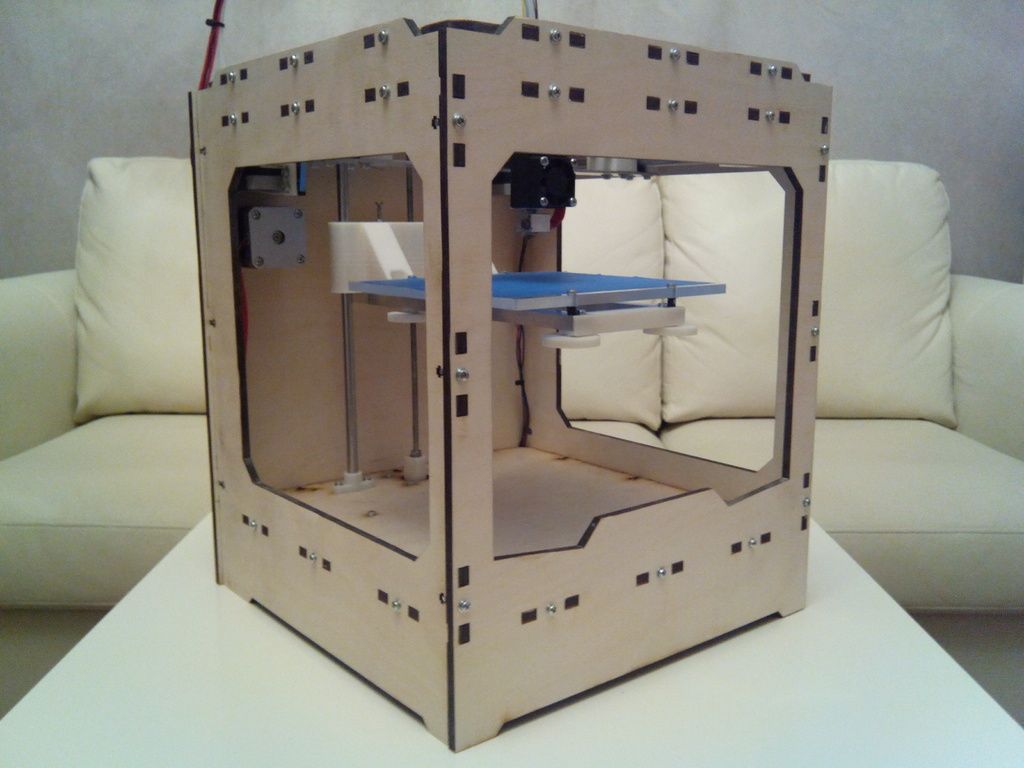

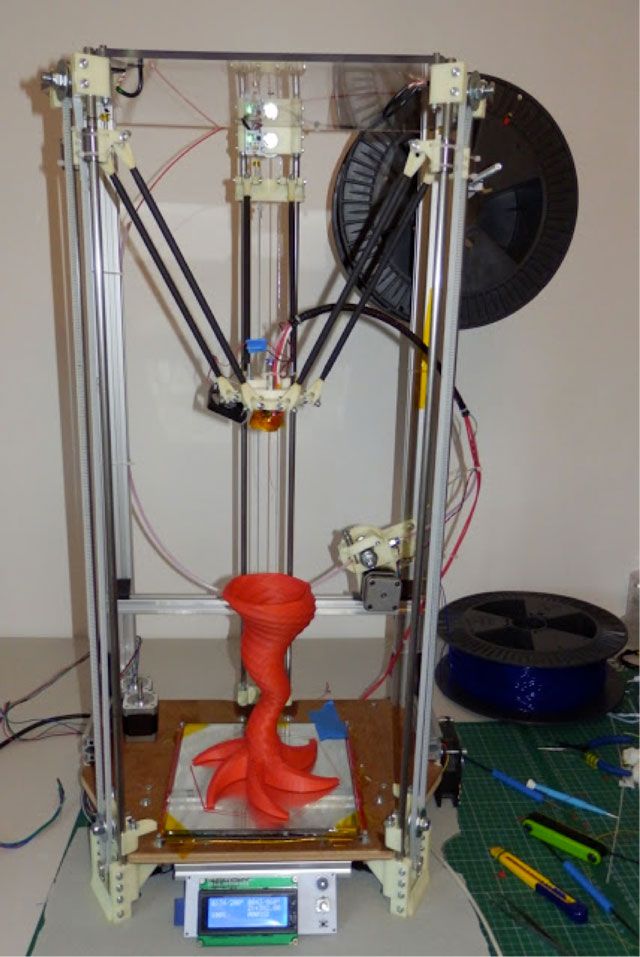

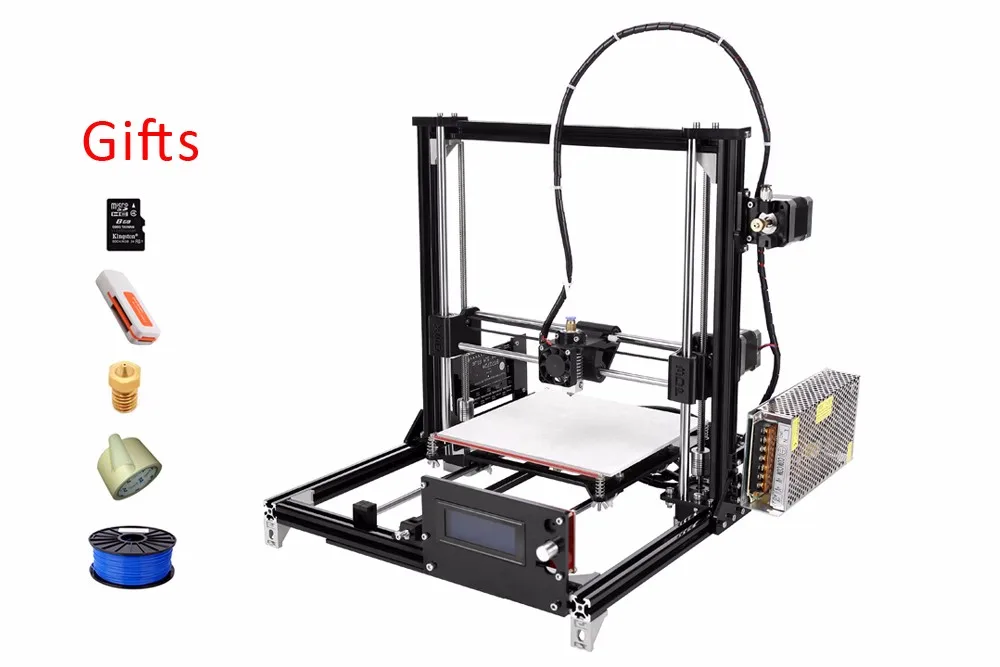

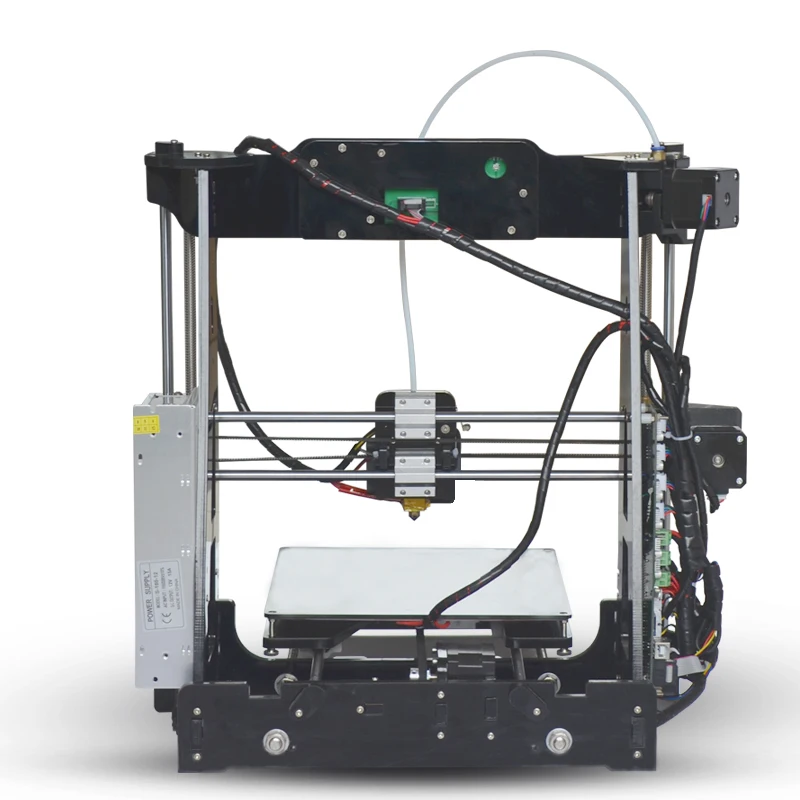

Direct color, also known as multicolor 3D printing is the most basic way to 3D print parts in multiple colors. It involves loading colored raw material into the printer. The most common way is using colored filaments with 3D printers that use fused deposition modeling (FDM) technology, which melts and deposits the filament onto the printer bed.

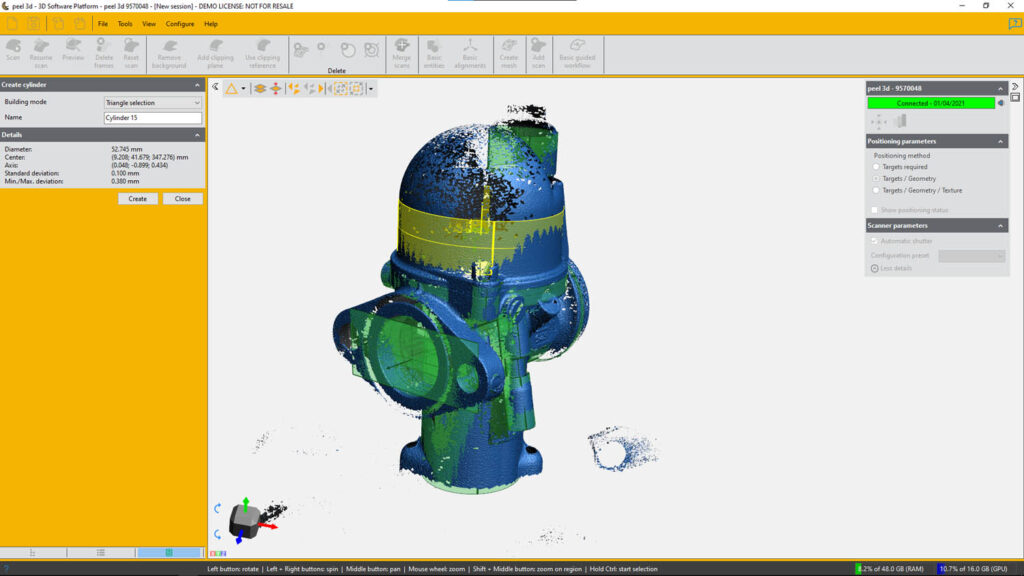

FDM 3D printing in color. (source: 3Dnatives)

FDM 3D printers can print in a single color, using colored filament, in two colors, using a dual extruder, or in multiple colors and gradients using color mixing, depending on how many filaments feed through the printer simultaneously.

The main advantage of these multicolor 3D printers is that they're easy to use and affordable. However, the disadvantages are that it’s not possible to achieve a specific color tone, and the final part will likely have visible layer lines. Also, the more extruders an FDM printer has, the bigger the chance of print errors.

While direct color printing only offers off-the-shelf color options, color matching allows you to create 3D printed parts in almost any custom color.

SLA 3D printed parts in various custom colors.

As the first integrated color-mixing solution for stereolithography (SLA) 3D printing, Formlabs Color Kit mixes color pigments into the base material to create a full cartridge of customized color resin. The SLA 3D printing process then uses a laser to solidify the colored resin and 3D print parts in vibrant colors with a smooth surface finish and almost imperceptible layer lines.

The SLA 3D printing process then uses a laser to solidify the colored resin and 3D print parts in vibrant colors with a smooth surface finish and almost imperceptible layer lines.

Color Kit, the first integrated color-mixing solution for SLA 3D printing.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

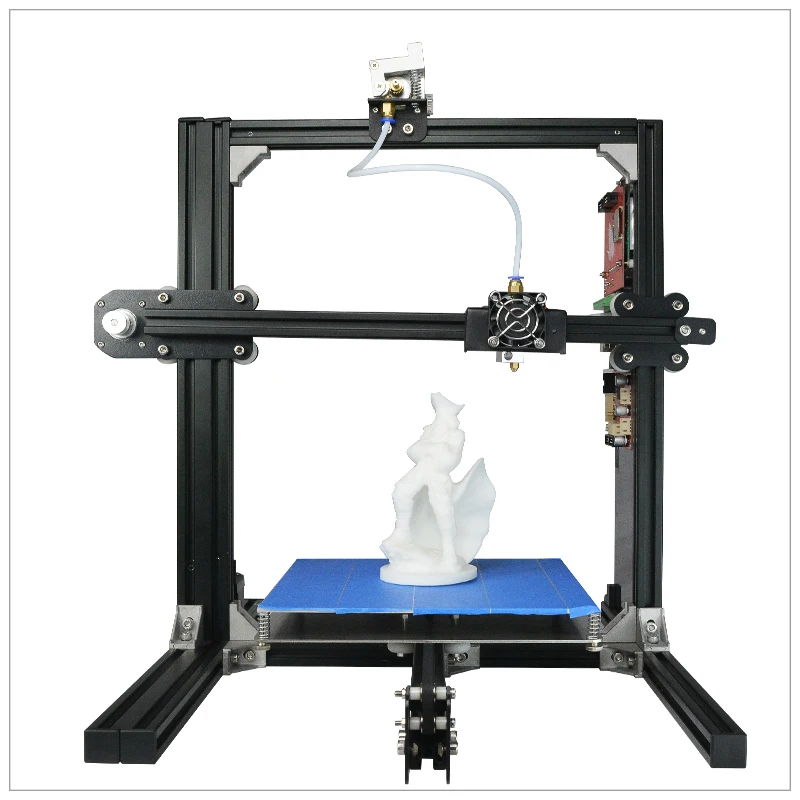

Full-color 3D printing is the most versatile color 3D printing method, as it produces objects in multiple colors at the same time, matching any tone and making realistic parts.

Unlike colored filaments or resin, the material used in full color printing is not pre-colored—the color is added to the base material during the printing process, similar to a color 2D printer.

Full-colored 3D printed part with binder jetting. (source: Hubs)

Technologies such as binder jetting and material jetting are able to produce full-color 3D prints. However, these processes have a high entry price, making them inaccessible to most users, while only one manufacturer offers a more affordable full color FDM 3D printer.

However, these processes have a high entry price, making them inaccessible to most users, while only one manufacturer offers a more affordable full color FDM 3D printer.

In certain cases, colored 3D prints may lack the detail or the vivid colors that an artist or designer aims for. Painting monochromatic 3D printed parts with acrylic, oil, or spray paint, while more time-consuming, offers an inexpensive and fully custom solution.

Side by side comparison on the before and after painting a dinosaur 3D printed SLA miniature.

Models that need a perfectly smooth finish or very fine features may require post-processing techniques, such as sanding, priming, or using a solvent prior to painting.

Sanding reduces imperfections in the surface, and primer fills in small cracks and holes. Additionally, some 3D printed parts may need an undercoat to diminish the neutral color of the primer before the paint application.

Watch or read our step-by-step guide on priming and painting 3D printed parts.

Hydrographics, also known as hydroprinting, water printing, or water transfer printing, is a common method for applying printed designs to three-dimensional surfaces. The process uses an inkjet printer to print an image on a polyvinyl alcohol film. The film gets submerged in water and receives an activator chemical spray. The color film then stretches over and adheres to the object as it’s slowly dipped through the floating film.

If you're interested in this process, read our guide about full color patterns to 3D prints with computational hydrographics.

The most used technologies in color printing are FDM, SLA, SLS/MJF, binder jetting, and material jetting. Let’s look at the pros and cons of each process.

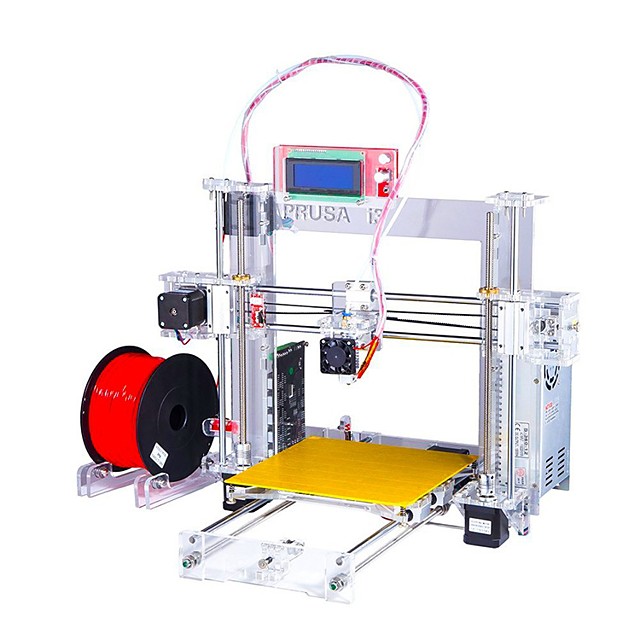

FDM, or fused deposition modeling, is one of the most common and least expensive technologies in consumer 3D printing. FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

Filaments for FDM printing in various colors. (source: All3DP.com)

FDM is mostly used for direct color printing, with single extruder printers, or for color mixing 3D printing, with dual or multiple extruder printers.

FDM can now also be used for full color 3D printing with the da Vinci Color 3D printer. With a colorless filament that is dyed using CMYK inkjet cartridges right before being extruded, it produces colored parts in a similar way to a color 2D printer.

SLA, or stereolithography 3D printing, uses a laser to cure liquid resin into hardened plastic in a process called photopolymerization. SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies.

Colored SLA parts, 3D printed with Formlabs Color Kit and Standard Resins.

SLA offers the possibility for color matching almost any custom color using Formlabs Color Kit, the first integrated color-mixing solution for SLA 3D printing. Thanks to their smooth surface finish, SLA printed parts can also easily be post-processed, painted, and used for applying hydrographics.

Thanks to their smooth surface finish, SLA printed parts can also easily be post-processed, painted, and used for applying hydrographics.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Selective laser sintering is the most common additive manufacturing technology for industrial applications, trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts.

Dyed SLS 3D printed parts. (source: Hubs)

SLS 3D printers use white, grey, or black nylon powder as a raw material. While the parts cannot be directly printed in color, they can be dyed or painted in post-processing.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

The binder jetting 3D printing technology is similar to SLS and MJF printing but uses a colored binding agent to bond powdered sandstone material instead of heat.

Parts produced with binder jetting have a porous surface and are very brittle, which means that this process is recommended only for static applications, such as creating full-color figurines and concept models.

Figurines printed with binder jetting. (source: Shapeways)

Material jetting 3D printers combine traditional inkjet printing with the use of photopolymer resins, by depositing droplets of the material on a build tray similar to 2D printers, which then gets hardened by UV light.

This process offers a myriad of color possibilities and can create photorealistic parts with vibrant colors. However, the parts have poor mechanical properties, are heat-sensitive, and the entry price for this technology is the highest of all color 3D printing options.

Color 3D printing with material jetting. (source: Hubs)

| FDM | SLA | SLS | Binder Jetting | Material Jetting | |

|---|---|---|---|---|---|

| Resolution | ★★☆☆☆ | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★★ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ | ★★★★★ |

| Surface Finish | ★★☆☆☆ | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★☆ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Description | The print head melts and extrudes thermoplastic filament | A laser solidifies liquid resin | A laser or light source sinters nylon powder | A binding agent bonds sandstone powder | An inkjet-like print head cures droplets of resin |

| Materials | Thermoplastic filaments | Varieties of liquid resin | Varieties of polymer powder | Sandstone | Varieties of liquid resin |

| Color 3D printing options | Direct color, color mixing, or full color | Color matching | None | Full color | Full color |

| Post-processing with colors | Painting (requires a lot of post-processing) Hydrographic printing | Painting Hydrographic printing | Dyeing Painting Hydrographic printing | Painting Hydrographic printing | Painting Hydrographic printing |

| Applications | Basic modelmaking | Rapid prototyping, miniatures and models, medical models | Rapid prototyping, end-use parts | Miniatures and models | Rapid prototyping, miniatures and models, medical models |

| Price | Budget printers and 3D printer kits start at a few hundred dollars. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. | Professional desktop printers start at $3,750, large-format benchtop printers at $11,000, and large-scale industrial machines are available from $80,000. | Professional benchtop printers start at $19,000. | Full color 3D printers start around $60,000. | Full color 3D printers start around $50,000 and large-scale machines are available from $100,000. |

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

Color 3D printing empowers engineers and designers to save money and time with looks-like prototypes, movie makers to turn digital models into props, model makers to create vibrant miniatures, medical professionals to produce accurate anatomical models, and more.

Rapid prototyping helps companies turn ideas into realistic proofs of concept, advances these concepts to high-fidelity prototypes that look and work like final products, and guides products through a series of validation stages toward mass production.

The development team at birdkids used SLA 3D printing to create prototypes in color.

Concept models in color can demonstrate an idea to stakeholders, create discussion, and drive acceptance or rejection using low-risk concept explorations.

At later stages, realistic looks-like prototypes in color can give a better idea of what an end product will look like and how the end-user will interact with it. Ergonomics, user interfaces, and overall user experience can be validated with 3D printed looks-like prototypes before spending significant design and engineering time to fully build out product features.

Color matching 3D printing or full color 3D printing also allows product development teams to experiment with different color options and run studies with customers before moving into production.

In the entertainment industry, 3D printed props and models are blurring the line between physical models and digital effects. Artists create realistic, detailed models using 3D modeling software and then bring them to life in a matter of hours using 3D printing. High-resolution 3D printing processes, like SLA, can reproduce even the most complex parameters of a design, such as skin texture.

A behind-the-scenes look at visual effects (VFX) and design studio Aaron Sims Creative’s process to design of Stranger Things’ Demogorgon.

Props masters, such as Russell Bobbitt for Marvel movies and Jaco Snyman for the Raised by Wolves series, as well as visual effects (VFX) and design studio Aaron Sims Creative for Stranger Things, have adopted the technology, as it significantly saves time in prop making and fuels creativity in the design process. The creation becomes more flexible and fluid, and props and models can be created in an efficient manner.

Without a doubt, 3D printing has revolutionized the creation of custom miniatures and figurines, whether for model making, tabletop games, collectibles, or other hobbies.

As full-color 3D printers are often out of budget for hobbyists and model makers traditionally hand-paint models anyway, the most popular way to create colorful models is to paint them after 3D printing.

For example, artists at Modern Life Workshop combine 3D modeling design with SLA 3D printing to create hyper-realistic celebrity portraits. The artists use the digital freehand sculpting software ZBrush to create detailed models on the computer. Then, they 3D print the designs on an SLA 3D printer and paint the parts by hand.

The artists from Modern Life Workshop create hyper-realistic sculptures with ZBrush and 3D printing.

In gaming, online communities have sprung up around tabletop games like Dungeons & Dragons, for which gamers use 3D printers to create one-of-a-kind D&D 3D printed miniatures, figurines, terrains, landscapes, and other board game accessories.

Professional model-making companies, like DM-Toys, also use 3D printing to accelerate prototyping and production cycles of custom models.

Global play and entertainment company Hasbro also uses the technology to create Hasbro Selfie Series figures—a groundbreaking endeavor to use 3D printing to manufacture personalized action figures at scale. For the first time, fans are now able to scan their face with a smart device and have a custom-made look-a-like action figure delivered to their door.

In healthcare, radiologists, surgeons, and biomedical professionals are increasingly turning to 3D printing to create accurate 3D models of anatomical features that can be used as reference tools for preoperative planning, intraoperative visualization, and education.

3D printing empowers medical professionals to create complex models with intricate details that would be impossible to produce with other technologies.

A fully colored pancreas model that was produced with SLA 3D printing and then painted with acrylic.

High-detailed color models are excellent in resident education programs, where each blood vessel or organ can be directly 3D printed or painted in different colors for easy classroom viewing.

Furthermore, patient-specific surgical models that are based on patient scan data are becoming increasingly useful tools in today’s practice of personalized, precision medicine.

Whether it is color matching to create 3D printed parts in almost any custom color, or printing high-resolution parts that can be painted to create hyper-realistic models, SLA 3D printing delivers incredible detail and seamless performance at an affordable price point.

Start 3D printing your own 3D printed parts on the Form 3 and bring your biggest ideas to life with the Form 3L.

See the Form 3See the Form 3L

The Top Full Color 3D Printers on the Market

Published on December 2, 2021 by Carlota V.

When it comes to choice of a 3D printer, several criteria must be taken into account: which applications it will be used for, the desired printing speed, the final quality of the parts, the quantity to be produced, among others. For some, a particularly essential aspect is the possibility to design parts in color. It is true that color integration is rarely the number one choice, but for some users, it is key. For example when creating a visual prototype that must look like a perfume bottle, or an anatomical model where blood vessels need to be distinguished from nerves and arteries. Enter full color 3D printers.

It is true that color integration is rarely the number one choice, but for some users, it is key. For example when creating a visual prototype that must look like a perfume bottle, or an anatomical model where blood vessels need to be distinguished from nerves and arteries. Enter full color 3D printers.

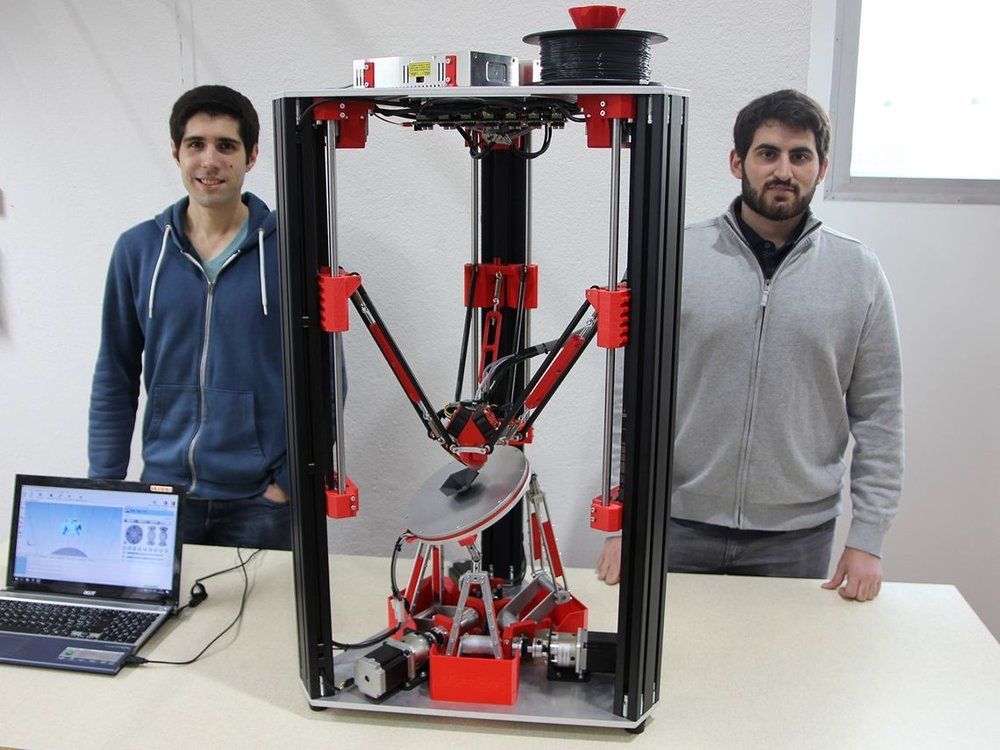

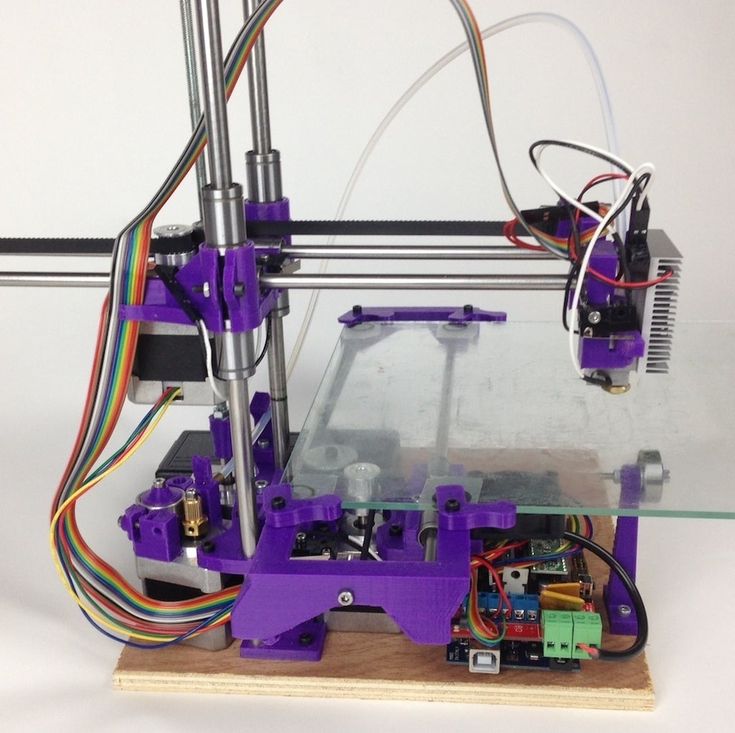

Integrating color into additive manufacturing is currently possible, whether through machines that are capable of offering a wide range of colors, accessories to be added to the printers, or post-processing solutions that offer options for dyeing, painting, varnishing, etc. In this listing, we focus on color 3D printers, i.e. machines that can produce a multi-color part at the end of the printing process. We have sorted them by printing process: extrusion, material jetting and powder binding.

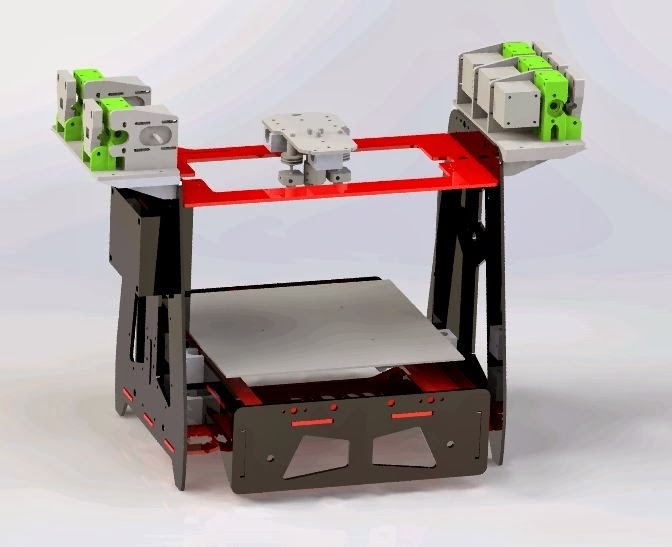

Fused Deposition Modeling

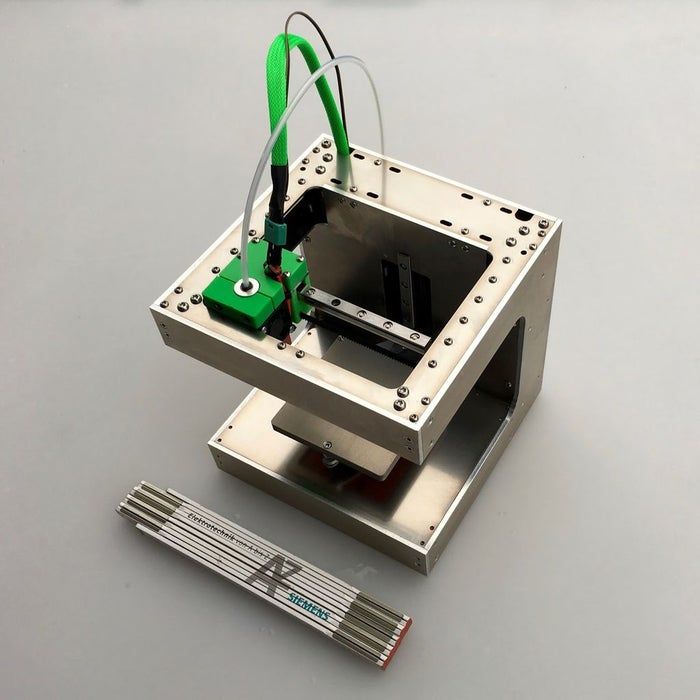

FDM technology offers several possibilities for creating coloured parts. For some color 3D printers, the presence of several extruders will allow the user to choose different filaments and combine them. Other manufacturers have developed a system that can color filaments directly inside the 3D printer: the machine releases color inks at the print head, resulting in a colored filament. Finally, there exist additional accessories available to mix different filaments together.

Other manufacturers have developed a system that can color filaments directly inside the 3D printer: the machine releases color inks at the print head, resulting in a colored filament. Finally, there exist additional accessories available to mix different filaments together.

Crane Quad

Known for launching the Micro 3D, a successful desktop 3D printer on Kickstarter in 2014, M3D continued to develop various FDM/FFF machines. Among its latest creations, the Crane Quad, a 3D printer capable of combining several filaments to create new combinations of colors or hybrid materials. In fact, the Crane Quad mixes 4 CMYK filaments to achieve more than 50,000 different colors. In addition, it offers a maximum manufacturing volume of 230 x 230 x 250 mm for a minimum layer height of 25 microns. It is marketed by M3D at a price of $999. You can find more information HERE.

da Vinci Color 3D printer and its mini

The da Vinci Color 3D printer combines FDM and Inkjet technologies, as it uses an absorbent, colorless PLA filament that can be mixed with different color inks. According to the manufacturer, CMYK ink cartridges can be used in an almost unlimited color gamut, up to 16 million shades. It has a print volume of 200 x 200 x 150 mm for a maximum print speed of 180 mm/s. In addition, XYZprinting also has a more compact version, the da Vinci Color Mini, with a smaller print volume of 130 x 130 x 130 x 130 mm. Features of this latest version include automatic calibration, wireless connectivity to connect to the printer remotely, and an optional laser engraving module for further customization of projects.

According to the manufacturer, CMYK ink cartridges can be used in an almost unlimited color gamut, up to 16 million shades. It has a print volume of 200 x 200 x 150 mm for a maximum print speed of 180 mm/s. In addition, XYZprinting also has a more compact version, the da Vinci Color Mini, with a smaller print volume of 130 x 130 x 130 x 130 mm. Features of this latest version include automatic calibration, wireless connectivity to connect to the printer remotely, and an optional laser engraving module for further customization of projects.

Element from Mosaic Manufacturing

The Element 3D printer was launched by the Canadian company Mosaïc Manufacturing. This professional machine makes it possible to achieve complex prints with different materials while obtaining realistic full-color and functional prints by combining flexible and rigid materials. It has a printing plate that reaches 120°C and a layer resolution of between 20 and 230 microns. With a maximum printing volume of 355 x 355 x 355 mm, the Element 3D printer has an all-metal gantry and a precision motion system. Other features include an internal camera for viewing the print, a touch screen control and connectivity via Wifi, LAN or USB. It is compatible with the Canva laminator, with which you can easily create, cut and manage any 3D printing project.

Other features include an internal camera for viewing the print, a touch screen control and connectivity via Wifi, LAN or USB. It is compatible with the Canva laminator, with which you can easily create, cut and manage any 3D printing project.

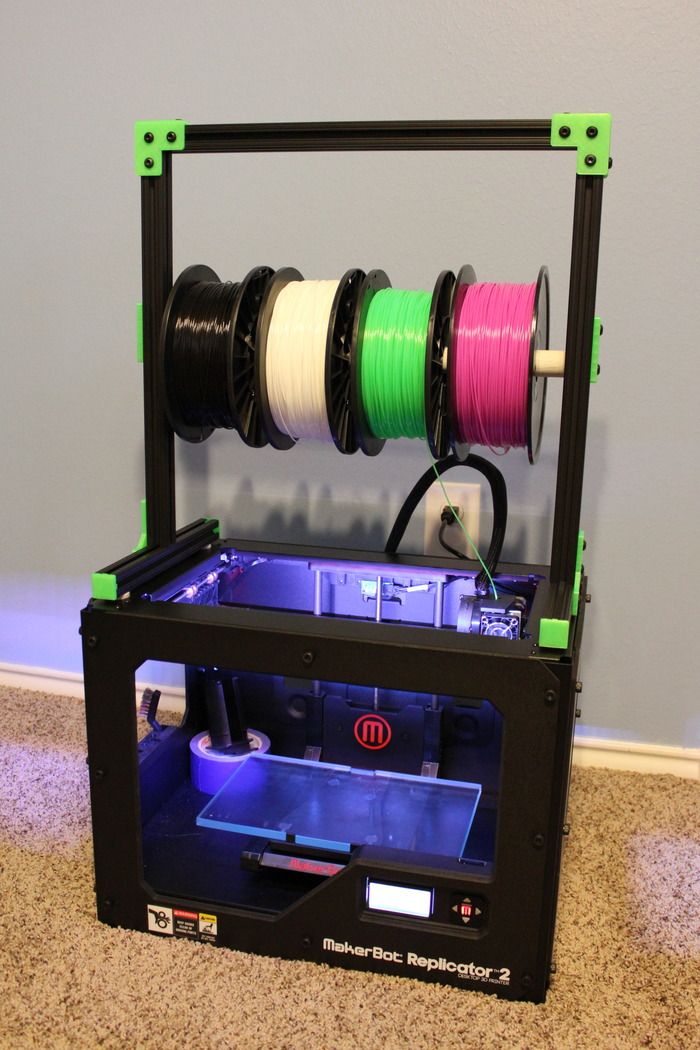

Palette 3

While the Palette 3 is not a 3D printer, it is probably one of the most accessible ways to design color parts. Developed by the Canadian company Mosaic Manufacturing, the machine should be connected to an extrusion 3D printer. It allows the combination of flexible and rigid materials, and users can not only create parts with complex shapes but also print in color in one go. A Pro version of the Palette 3 is also available, with advanced properties that allow users to print with technical materials and create durable, high-volume prints. Finally, the Palette 3 Pro features Splice Core Pro, a cooling system that makes filament bonding more reliable. The Palette 3 is available from €650 and the Palette 3 Pro from €850.

RoVa4D

The RoVa4D 3D printer grew out of a successful Kickstarter campaign by Canadian company ORD Solutions, which after its first Kickstarter campaign has dedicated itself to improving the capabilities of its 3D printer. This latest version supports 5 spools and a print head that allows printing with different materials and colors, from flexible materials to soluble materials. It has a printing volume of 120 x 120 x 180 mm. In order to be able to successfully achieve color printing, the machine has 5 different spools for CMYK colours (cyan, magenta, yellow, black and white), which are then mixed within the patented hotend to give the expected color as a result. The printer can currently be purchased at the manufacturer’s website for $7,500. You can find more information HERE.

XRIZE

The XRIZE is an industrial 3D printer that uses a hybrid process called Augmented Deposition to produce objects in multiple colors. This hybrid process combines extrusion-based 3D printing with a inkjet technology we know from 2D printers. While the part is created layer by layer with traditional colorless PLA, the 3D printer simultaneously releases CMYK inks (cyan, magenta, yellow, black) in the print head to add color. For example, text, images and QR codes can be printed on the part. Although the device can be described as a desktop machine, its build volume being 310 x 200 x 200 mm, the XRIZE with a price of $55,000 is less suitable for manufacturers and hobbyists but rather for industrial applications. You can find more information HERE.

This hybrid process combines extrusion-based 3D printing with a inkjet technology we know from 2D printers. While the part is created layer by layer with traditional colorless PLA, the 3D printer simultaneously releases CMYK inks (cyan, magenta, yellow, black) in the print head to add color. For example, text, images and QR codes can be printed on the part. Although the device can be described as a desktop machine, its build volume being 310 x 200 x 200 mm, the XRIZE with a price of $55,000 is less suitable for manufacturers and hobbyists but rather for industrial applications. You can find more information HERE.

Material Jetting

3DUJ-553 and 3DUJ-2207 from Mimaki

Japan’s Mimaki, a manufacturer of traditional 2D printers, was the first to make a UV-curable, colored material jet 3D printer. Its 3DUJ-553 solution was launched in 2017 and can create parts with more than 10 million colors. It uses a UV light curing process and is intended for the professional sector. During this process, a layer of material is applied and then covered with a UV-sensitive ink that light can solidify. The process is repeated until the final part is obtained.

During this process, a layer of material is applied and then covered with a UV-sensitive ink that light can solidify. The process is repeated until the final part is obtained.

More recently, Mimaki developed the 3DUJ-2207, a more compact 3D printer that offers the same color printing capabilities. It is more accessible and easier to use, unlocking a larger section of the current market. The 3DUJ-2207 is particularly suited to medical professionals, researchers and teachers, but also to designers and artists.

ActiveLab Digital Fabrication by Voxel8

The ActiveLab Digital Manufacturing System from Voxel8, acquired earlier this year by Kornit Digital, is another multi-material 3D printing solution using a technology based on material jetting. Its ActiveMix® technology consists of three possible elements, ActiveMix Extrusion, ActiveMix Spray and ActiveImage. The extrusion works to build 3D structures and thick films on any surface or texture with theologically tuned fluids while the spray rapidly covers large areas of a substrate with an elastomeric spray for textiles. Finally, the ActiveImage uses inkjet technology either through spray or extrusion, or both, to embed high-resolution graphics into elastomers. Users can expect full color graphics and the company points to its use especially in the creation of sporting goods, though it also has industrial and medical applications. You can find out more HERE.

Finally, the ActiveImage uses inkjet technology either through spray or extrusion, or both, to embed high-resolution graphics into elastomers. Users can expect full color graphics and the company points to its use especially in the creation of sporting goods, though it also has industrial and medical applications. You can find out more HERE.

Photo Credits: Voxel8

J55 Prime

One of the most well-known names in the world of full color 3D printers is of course Stratasys with their PolyJet technology, which has the distinction of enabling the mixing of colors, materials and even textures in one part. Though they have many different machines using Polyjet, we wanted to draw your attention to their J55 Prime which was released in 2020. This more compact solution still has the multi-material and multi-color capabilities of its larger predecessors but at a fraction of the price. It is able to print with 5 materials simultaneously meaning that users can create over 640,000 unique combinations, including Pantone Verified colors. As it has been designed for an office or studio it is also ultra-quiet, operating at the same level as a household refrigerator. Finally, it has a ProAero™ Air Extractor to capture and filter out fumes. You can find out more about the printer HERE.

As it has been designed for an office or studio it is also ultra-quiet, operating at the same level as a household refrigerator. Finally, it has a ProAero™ Air Extractor to capture and filter out fumes. You can find out more about the printer HERE.

ProJet CJP Series

The ProJet CJP 260Plus is 3D Systems’ most affordable and office friendly color 3D printing option. The ProJet CJP 260Plus creates photo-realistic parts in full CMY color with small feature details and the ability to use full texture/UV mapping to better evaluate the look, feel, and style of product designs. This 3D printer is based on 3D System’s ColorJet Printing technology, and has a maximum build volume of 236 x 185 x 127 mm.

3D Systems manufactures an entire range of color 3D printers, including the ProJet CJP 360, CJP 260 Plus, CJP 860Pro, CJP 660Pro, and the CJP 460Plus. They vary according to their build volume, the 860Pro being the largest solution, with a build volume of 508 × 381 × 229 mm. You can find more information HERE.

You can find more information HERE.

Binder Jetting

ComeTrue T10

Developed by Taiwanese manufacturer ComeTrue, the ComeTrue T10 3D printer is based on a Binder Jetting technology and coloured inks (CMYK). The advantage of such a process is the possibility of printing parts without printing supports as well as its speed, the T10 is indeed able to reach a printing speed of 20mm/h. The ComeTrue T10 allows the manufacture of parts with a maximum size of 200 x 160 x 150 mm with a resolution of 1200 x 556 DPI for a minimum layer height of 0.08 mm. The ComeTrue 3D printer requires a post-processing machine to remove the finished prints (Dry Vacuum Cleaner). The ComeTrue T10 is available for a price of about 25,000€. You can find more information HERE.

PartPro350 xBC from XYZprinting

Launched in 2018 by Chinese manufacturer XYZprinting, the PartPro350 xBC 3D printer uses Binder Jetting. It is compatible with standard thermoplastics, such as ABS and PLA and the machine has been designed for professionals. With a printing volume of 350 x 222 x 200 mm, the printer is, according to the manufacturer, 150% faster than machines using the same technology. Finally, the PartPro350 xBC has a removable tray so that users can easily remove parts after the printing process. According to some retailers, the price is between €25,500 and €35,000.

With a printing volume of 350 x 222 x 200 mm, the printer is, according to the manufacturer, 150% faster than machines using the same technology. Finally, the PartPro350 xBC has a removable tray so that users can easily remove parts after the printing process. According to some retailers, the price is between €25,500 and €35,000.

What did you think of our listing of full color 3D printers? Let us know in a comment below or on our Facebook and Twitter page! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

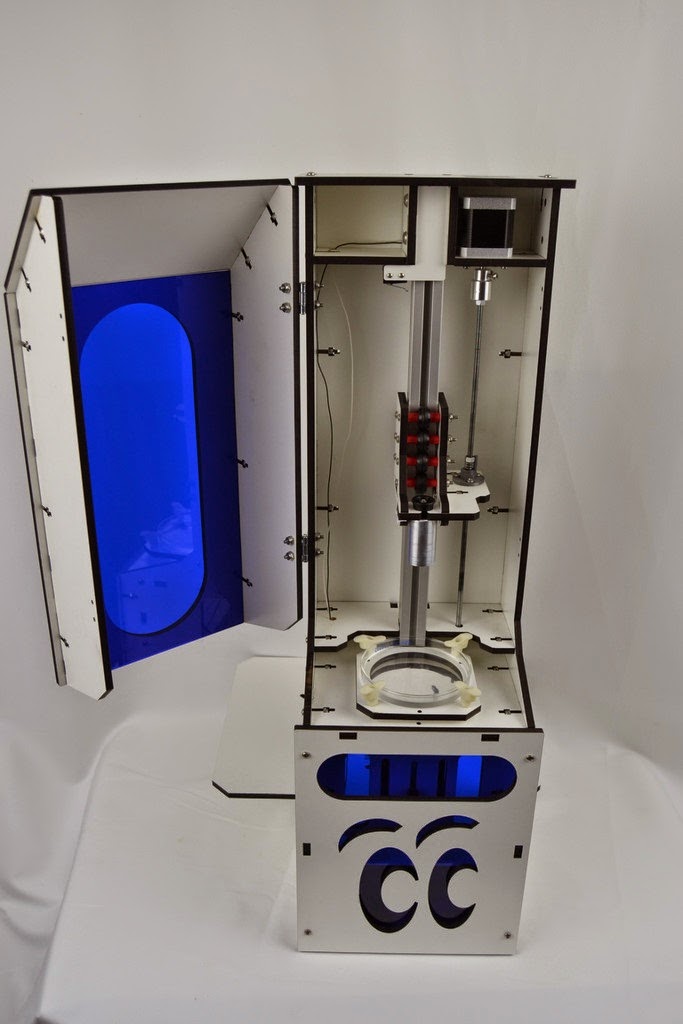

CJP do-it-yourself printer. Is it real?

I have been looking at such a printer for a long time, and there was a great desire to buy it, but alas, this is not an fmd that is in every 'house'.

In this regard, the thought arose, is it possible to assemble a similar printer, but in a more compact size than market printers, and use ordinary ink and plaster ...?

About half a year ago I googled a similar topic, and even found a video where a similar home-made printer works, but there was no more information. Now I came across an article on Geek, which describes the process of manufacturing a bioprinter. (For those who are interested, welcome: https://geektimes.ru/post/258136/). This article inspired even more enthusiasm and desire to create a printer =)

Get to the point. There are so many questions, the most important one is how to connect the 'printhead' part of the printer to the rest of the peripherals? Those. you need to somehow make friends with the print head, bypassing the printer circuitry. There is a similar project on kickstarter (https://www.kickstarter.com/projects/nicholasclewis/inkshield-an-open-source-inkjet-shield-for-arduino).

But, this head is not suitable, because full-color printing is needed. ..

..

Also one of the main issues is software, there are specialized programs for 'powder printing'.

By the way, industrial printers seem to use HP heads, but since it is not suitable for such purposes, after a certain number of layers the head leaves to wash...

The second important issue is the printing technology itself. To be honest, I didn’t really understand how gypsum is glued together, but most likely, the hardener is added to the ink itself ... How much additional 'pain' appears here? what? what is the setting time? In theory, since the printer is planned to be used at home, one might think in the direction of UV 'setting' of the plaster. That is, add some kind of hardener that sets under the influence of UV. The topic is quite interesting and there are also many options.

While writing, I found a couple of videos on this topic.

https://www.youtube.com/watch?v=HIAddQmqlgEhttps://www.youtube.com/watch?v=08gOblOETlU In general, I want to ask what anyone thinks about this topic, what are the options for execution, in which way should i think?

The topic is quite interesting, and I think that sooner or later someone would write about it. So, we can say that a start has been made)

So, we can say that a start has been made)

Please do not criticize much, so that the post was written purely in order to ask who thinks what and how he sees the continuation of this topic.

FAQ

Hello, friends!

I got a PETG adapter spool from Bestfilament. In addition, they said, no matter what they print, everything breaks ...

Read more

serz55

Loading

03.10.2022

436

hello to honest people. Guys help who knows what)))) I finally decided to put the SKR 1.4 Turbo board on my cube with Anki8. there was a stock one (on ...

Read more

mlizart

Loading

03/15/2018

24468

Several times already I turned to the respected community with a question on the topic - why do they say '3D printing', '3D printers' and other interpretations, like. ..

..

Read more

3D printing of objects of any complexity in Lipetsk

The Concept company provides 3D printing services for objects in Lipetsk, as well as with delivery to other cities of the Russian Federation. We have favorable prices and the ability to use all technologies (FDM, CJP, SLA, DLP, MJM , POLYJET, SLS, DMLS, DMLM, LOM) and any 3D printing materials:

- ABS, PLA, Flex, Nylon,

- Laywoo-D3,

- Laybrick,

- Bronzefill

- other plastics composites,

- Technical photopolymers (rigid and elastic),

- Jewelery and Dental Burnout and Lost Resins,

- Full color plastic,

- Full color plaster,

- Metal (steel, cobalt chrome).

- Polyamide.

Affordable, high-quality, high-precision 3D printing

Relatively new 3D printing technology is gaining popularity. In this way, you can quickly make both a simple pencil holder for home use, and complex mechanisms, from a variety of moving parts, the creation of which requires high precision and maximum adjustment of individual elements to each other.

The prospects for using 3D printing technology are extensive. Scientists predict that in the near future 3D printers will become a fairly common phenomenon, in demand both in household use and in construction or industry.

The ease of use of the device makes the technology available for use even by schoolchildren. Therefore, the printer can be a great gift for a child who likes to make something with his own hands or for people who are fond of technology, needlework, and creativity. It is enough to choose a model that is suitable for functions, price and software.

Just a few years ago, buying a simple 3D printer was only available to large companies or people with really high incomes. Today, such devices with functions suitable for home use are available at the best price. If you do not need a highly specialized device, for example, for growing human joints, then it is quite possible to purchase it for home use for reasonable money.

Order 3D printing of any complexity in our company

Although the devices are quite affordable, it is not always advisable to buy a 3D printer for making 1-2 parts. After all, you will then have to store it somewhere, and it will take a lot of time to master the work with new software. Therefore, having ordered the manufacture of a part from our specialists, you can get the desired result in the shortest possible time. These can be souvenirs, models of well-known buildings or monuments, decorations or parts for products and mechanisms.

After all, you will then have to store it somewhere, and it will take a lot of time to master the work with new software. Therefore, having ordered the manufacture of a part from our specialists, you can get the desired result in the shortest possible time. These can be souvenirs, models of well-known buildings or monuments, decorations or parts for products and mechanisms.

It can be a unique gift that will surprise your family and friends, a single item for an exclusive craft or a small batch for your business.

Ordering 3D printing will save you a lot of time and money. We not only provide printing services from a finished sketch, but also create drawings according to your verbal description. You can order from us the printing of products of any complexity, with the smallest details, and be sure of the reliability and accuracy of manufacturing to the smallest detail. You will receive significant discounts for sufficiently large batches of products according to one template.

3D printer services

More recently, the only way to replace a failed part of any mechanism was to buy it in a store, which in itself is a considerable difficulty, since the necessary elements are not sold everywhere. With the advent of the 3D printer, things have become much easier. It is possible to print an element of any complexity from metal or other material by spending several hours or even minutes on it.

However, the relatively high cost of the unit makes it inexpedient to purchase it for the sake of manufacturing just one part or element. If you need only one part or a small batch, use the services of a 3D printer in Lipetsk. We will produce the necessary items for you in the shortest possible time.

Technology allows you to create things that match the drawings as closely as possible. The cost of time and material is minimal. Among the products that the printer creates:

- souvenirs;

- chess;

- interior items and utensils;

- parts for complex mechanisms.

Learn more