3D scanner australia

Buy 3D Scanners in Australia

Default sortingSort by popularitySort by latestSort by price: low to highSort by price: high to low- View:

- 12

- 24

- All

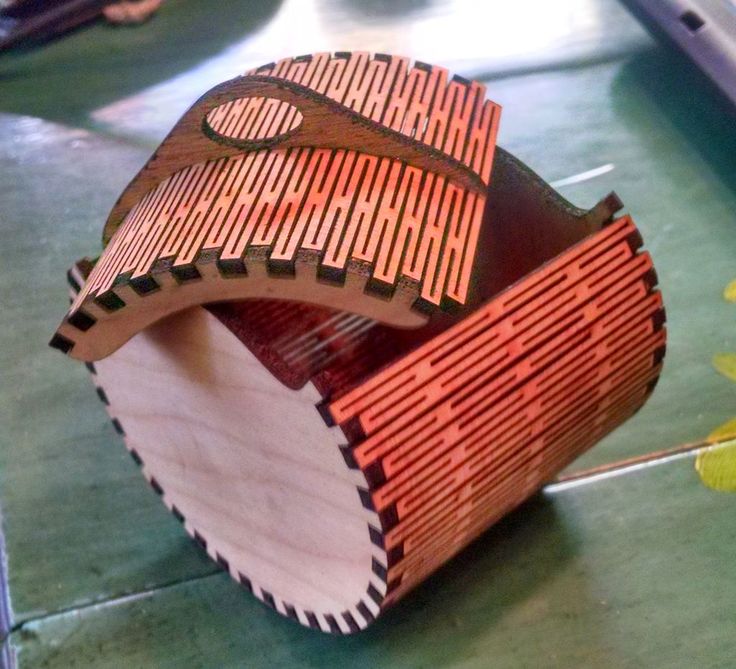

3D printing is impossible without files that tell the printer what to print. They represent 3D models of objects in a format understandable to a slicer, and when a file, a slicer, and a 3D printer come together, a printing miracle happens. One of the ways to create such files is 3D scanning, and in this article, we will explore 3D scanners and their capacities.

A Little Bit Of Science Behind 3D Scanning

Have you ever asked yourself a question: how does one scan a complex three-dimensional object, or an object too big to be put on a glass plate of an average scanner? The solution is as simple as it is brilliant: instead of pushing a flat object against a source of light behind the glass bed, light (or its substitute) is emitted towards the object from various positions, and sensor cameras record in the XYZ format the distance between the laser source and the object, shape of the laser ray, etc. Literally, the ray of laser or light probes the surface of an object, and the ‘brain’ of the scanner captures the gathered data in the form of a point cloud that is then translated into a polygonal model. The technology is called triangulation because there are always three working ‘points’: a source of laser/light of a scanner, a camera with sensors, and the actual light dot on the object.

Main Types of 3D Scanners to Know

The technology behind scanning is important because it directly impacts the accuracy of scanning. Accuracy stands for capturing small details, delivering the smooth surface, making replication as true-to-life as possible, and other aspects of 3D printing that depend on the quality of a 3D model file. The higher the accuracy, the better the printing outcome is. So, knowing about accuracy helps you make the ultimate decision about what 3D scanners to buy.

Structured light scanners

These scanners operate with the help of the source of light. This light is emitted in the form of a grid that covers the scanned area. This type of scanner is considered to provide better scanning quality, slightly superior to laser scanners because laser dots patterns create noise, which interferes with data acquisition by sensors. Yet, the structured light scanners will be on the more expensive side of the market.

This light is emitted in the form of a grid that covers the scanned area. This type of scanner is considered to provide better scanning quality, slightly superior to laser scanners because laser dots patterns create noise, which interferes with data acquisition by sensors. Yet, the structured light scanners will be on the more expensive side of the market.

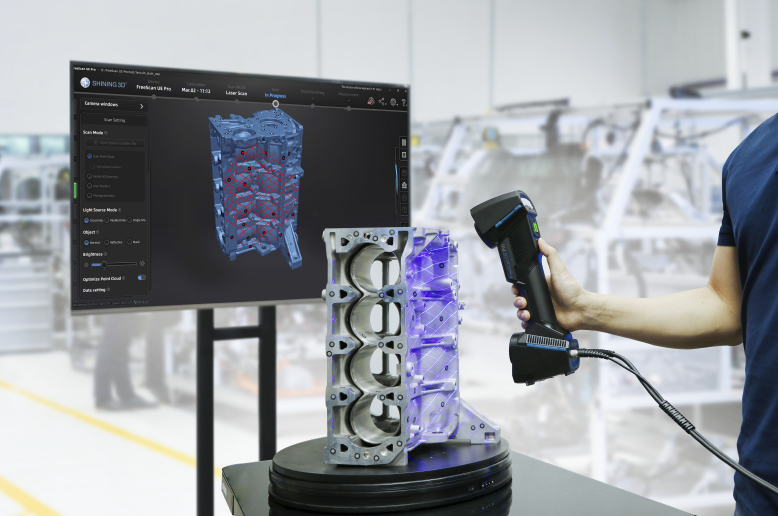

Laser 3D scanners

These scanners rely on laser rays to ‘map’ the surface and create XYZ descriptions of every point of the object. You’ve probably seen it in the movies: a red laser line moves along something and immediately, the digital model is reproduced on the computer screen. Now you can reenact this sci-fi scene right in your workshop with the advent of affordable laser scanners. The accuracy of these scanners is slightly lower than that of structured light devices, but for hobbies and some non-industrial tasks, they work fine. Besides, the costs of 3D scanners in this segment are lower than those for structured light devices.

Depth-sensing cameras

This feature has become a breakthrough in smartphone-based scanning, but its quality is far from what you would expect for 3D printing purposes. Cameras emit infrared light to create a network of dots on the object's surface. The resolution is usually more than 1mm, so minute details and edges are usually lost. Accuracy also declines as the distance to the object grows.

Essential Specifications of 3D Scanners To Check Before Buying

As you see, the best quality of 3D scanning is provided by structured light scanners (which are quite expensive). But what parameters should you look at if you try to buy a 3D scanner on a cheaper side?

Resolution is the distance between neighboring dots on the object. The lower the number denoting the resolution, the higher the resolution is. A resolution of 0.1mm is great for most printing purposes. Mind that the resolution higher than that will be 0.08mm (for example) and not 0. 2mm.

2mm.

Accuracy includes resolution, but it is more than that. Accuracy is in general the correspondence of a model to its real-life prototype. Accuracy usually fluctuates between 0.1 and 0.01mm (for portable scanners), and it is a good index.

Configuration of scanners

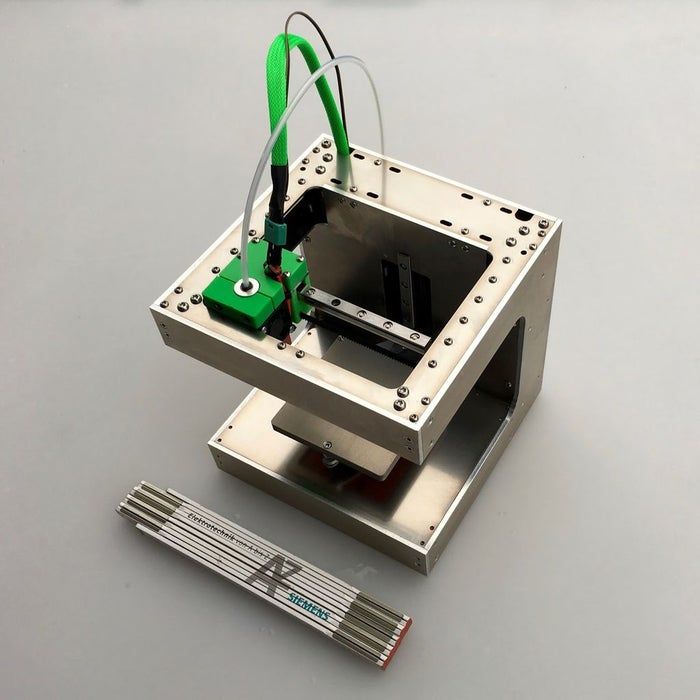

Handheld scanners can help you scan everything, from a human to a whole room. You carry the device around and perform scanning where you need it. More sophisticated models of portable scanners have a tripod in the box. When you need to scan an immovable object with great precision, just put the scanner on the tripod and go.

Turntable scanners are fixed devices directed at the rotating platform (turntable). Such scanners cannot scan something that does not fit on the rotating bed, but their fixed position accounts for greater accuracy of scanning. Since every area of an object needs to be captured by a scanner, some turntables can rotate along several different axes. In such a way, all sides of an object are properly scanned.

If you plan to scan objects in the distance, look for long-range scanners. They may be used as handheld or attached to tripods.

So if you ask yourself: which 3D scanner should I buy, think of the size and resolution of the objects to scan and see what type of scanner you can afford.

The Most Important Question: How To Pick A Right 3D Scanner

As you see, parameters to consider are diverse, and the point where the price and specs you need meet indicates the perfect scanner for you. If you think where to buy 3D scanner, here’s a tip.

Visit some 3D technology exhibitions and lay your hands on different scanners to understand the actual outcome of their work. If you cannot do it, decide on the resolution and accuracy you need, on the price you can pay, and look through the range of models in a given segment. Structured light devices are better; but for entry-level, some laser 3D scanners will be a solid solution in terms of pricing.

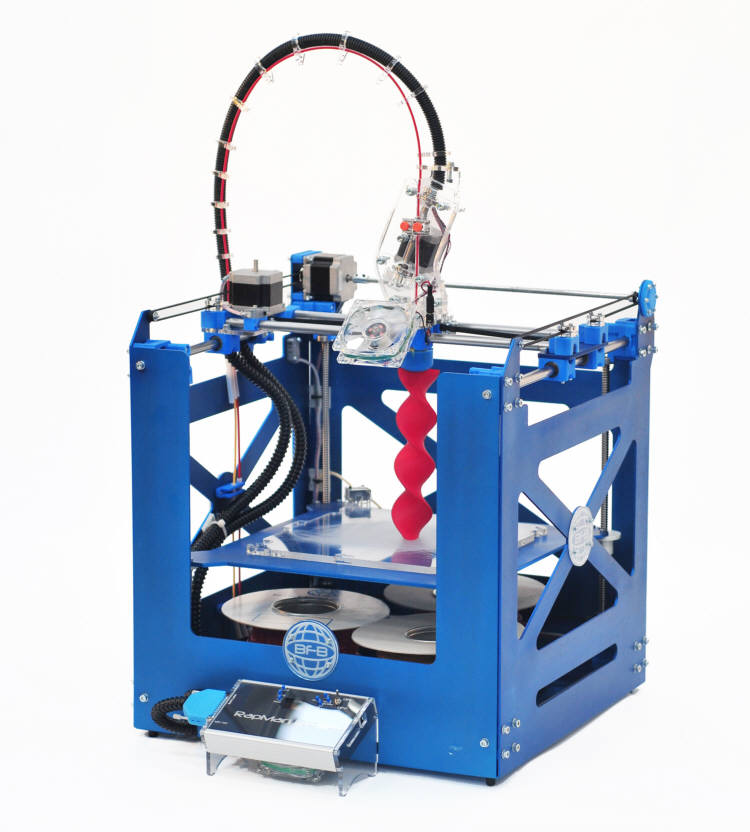

If you need brand names to start choosing a 3D scanner, look to Creality, Phiz, Matter and Form. They are the best in terms of price vs. quality combination for non-industrial purposes. On a more professional scale, look for Creaform, Shining EinScan, and Artec (the upscale kind of scanning device). You can easily order these 3D scanners in Perth, as well as in other big Australian cities.

They are the best in terms of price vs. quality combination for non-industrial purposes. On a more professional scale, look for Creaform, Shining EinScan, and Artec (the upscale kind of scanning device). You can easily order these 3D scanners in Perth, as well as in other big Australian cities.

Final Tips On How To Buy The Device Of Your Dreams

3D scanners are a pricey investment, so look for sellers who provide long-term warranty and service. It’s better to acquire from suppliers who have an office where you can go and ask for help directly if anything happens. So if you plan to buy 3D scanners in Melbourne, or order 3D scanners in Sydney, aim for local vendors. They will deliver the proper level of service and assistance, and it will support the national economy in general. So if you plan to purchase 3D scanners in Australia, go to trusted companies like Aurarum. You will get help in choosing and the excellent quality of the device you buy. Reliable and robust, like all things Australian.

3D Scanning | Services | Scan-Xpress Australia

Scan-Xpress provides cost effective, high-precision 3D scanning services using our dedicated, GOM 3D scanners in house. Our team will support you to ensure you get the best result possible for your project or application.

Request a 3D scanning quote

Applications

Obtaining accurate 3D scanning of a physical part has many potential applications. Here are some reasons you would use this service:

- Quality-control of a manufactured part

- Obtain accurate dimensions of a prototype

- Reverse engineering or competitor product analysis

- Recreate manufacturing data for an obsolete part

- Create 3D models and perform simulations or analyses

3D scanning process

1

Ship us your part

2

We discuss your project & needs

3

Our team performs 3D scan

4

Our team processes & sends your data

Request a 3D scanning quote

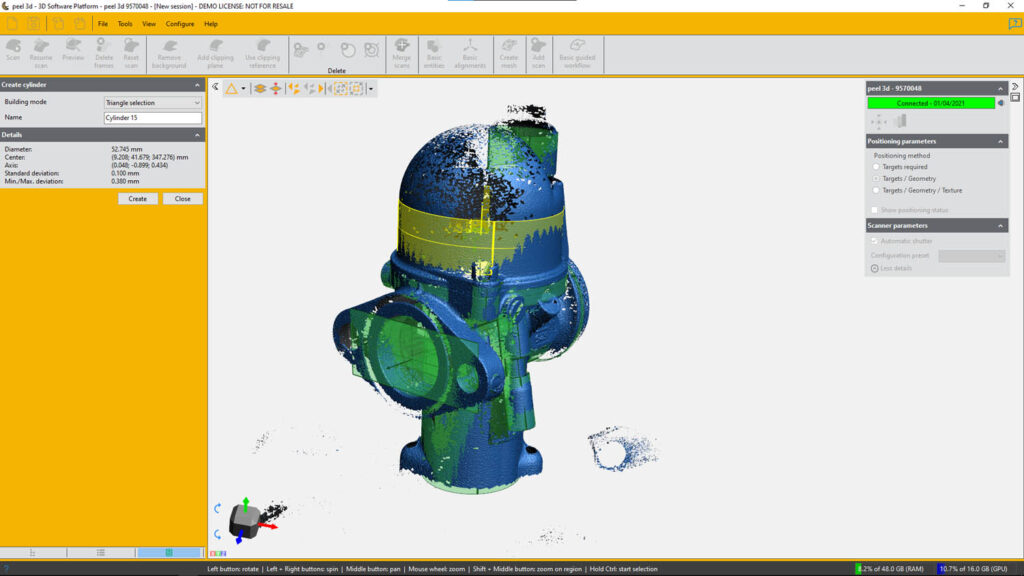

Our team is equipped with a number of optical metrology tools and 3D scanners in house to deliver you the best precision data for your part size and needs. Browse through our available systems below.

Browse through our available systems below.

GOM Scan 1

Small to medium size part scanner, 6 million points per scan resolution.

GOM SCAN 1

ATOS Core

High resolution blue light scanner for detailed small object scanning.

ATOS CORE

ATOS Q

Optical measurement system built for industrial applications.

ATOS Q

T-Scan Hawk

Handheld laser scanner with embedded photogrammetry for large volume scans.

T-SCAN HAWK

3D scanning Deliverable File Formats

The 3D scan data collected can be output in a mesh STL file format or as raw point could ASCI file format.

Alternatively, we offer comprehensive reverse engineering, inspection and analysis services for those looking to create working 3D CAD models or have our team perform specific analyses with the scan data.

3D scanning services: Notable Past Projects

Marine 3D scanning & Quality Inspection

One of our prospective customers was looking to use 3D scanning for quality control & reverse engineering of marine propellers. We used the ATOS Q to capture full field 3D data enabling us to compare to CAD and identify critical defects.

We used the ATOS Q to capture full field 3D data enabling us to compare to CAD and identify critical defects.

READ MORE

Consumer goods 3D scan & Reverse Engineer

Using the GOM Scan 1 and our WASP 3D printers, we performed a 3D scan, design and fast prototyping project for HopSkotch, a local Australian start-up. We delivered a minimal usable product in no time using these great modern tools.

READ MORE

Medical Device 3D scanning & quality inspection

MAXONIQ, a company specialising in the design and manufacture of medical devices and surgical implants, contracted Scan-Xpress to 3D scan and reverse engineer a series of small surgical screws.

READ MORE

Request a Quote

90,000 3D body scanners at Australian airports: what are they and how do they work? Sydney Airport has just started using 3D body CT scanners in its domestic Qantas terminal, T3. While CT scanners have been widely used in Australia's international terminals for many years and installed at Melbourne's T4 terminal, as well as at Gladstone and Canberra airports, many travelers are using the technology for the first time at a domestic airport. Saw

Saw

What are scanners and how do they work?

These are large tubes that passengers are asked to enter before raising their arms as the car spins around them. They use millimeter wave non-ionizing imaging to scan a person with what they wear under their clothes. They are able to detect metal and non-metal objects.

Airport security personnel are shown a simple cartoon outline of a person with areas of interest outlined in square boxes. Melbourne Airport states that no personal scans or personal information are stored or transmitted by the scanner.

CT scanners are also used to transport luggage.

Why are they brought?

In 2018, then-Secretary of the Interior Peter Dutton announced that airports would have to phase out the use of metal detectors when budgeting regional airports.

It happened in the year when two brothers planned to blow up a passenger plane with a bomb hidden in a meat grinder.

“We are concerned that various equipment is passing through the scanner that will not be detected at this time,” Dutton told Melbourne radio station 3AW in 2018. — We are worried about the gels. We're concerned about harmful gases, all kinds of things that are potentially not captured."

— We are worried about the gels. We're concerned about harmful gases, all kinds of things that are potentially not captured."

Dutton said the new scanners will be rolled out "in the next few years" but it took four years for a checkpoint at the terminal of Australia's busiest domestic airport to get the technology.

Guardian Australia is aware that other checkpoints at T3 in Sydney will be upgraded with the same technology by the end of the year.

How much does it cost?

The Australian Airports Association estimates the cost of the upgrade at $2 billion. The preliminary budget presented this year says the size, scope and scope of the upgrades, as well as the impact of the pandemic on the aviation industry, have further complicated the project for Australia's top 10 airports and the federal government. asked for money to cover expenses.

Will they move faster than airport security?

In principle, yes. CT scans mean passengers no longer have to remove laptops, aerosols and other items from their carry-on luggage at security checkpoints. But they will still need to take off their jackets and other outerwear.

But they will still need to take off their jackets and other outerwear.

ABC reporter Louise Milligan tweeted last week that she had to take off her fitted jacket. and said others have complained "Heavy Bulge" about safety.

Sign up to receive breaking news from Guardian Australia every morning

Sydney Airport declined to comment, but security contractor, Certis Security, told Guardian Australia that the removal of coats and jackets is a requirement and forwarded requests to the regulator, the Cyber Security Centre. and infrastructure security.

In practice, airports are still likely to be delayed given the current staff shortage, so scanners are unlikely to be closed for any length of time.

Can I refuse to go alone?

While exceptions are made for people who have a medical or physical disability that prevents them from going through a body scanner, airports will deny you access to the terminal if you do not comply.

Retrieved

Western Australia Museum Digitization | 3d daily

Architecture

Pelevin N. 0 comments 3d scanning, Autodesk, ReCap, Architecture, Hardware, Technology

0 comments 3d scanning, Autodesk, ReCap, Architecture, Hardware, Technology

Western Australia Museum is a major cultural organization. It was opened in 1891, and to the present time it already consists of five facilities located throughout the state. Reality Capture played a key role in the expansion by scanning the important historic facades of Perth's Old Gaol building.

The total cost of the expansion project was almost US$430 million, and the main objective was to integrate the new buildings with the old ones. This also included work on the conservation of the premises in order to maintain their integrity for many decades.

As all buildings will be mothballed for many years, accurate measurements are crucial. The government of Western Australia has opened a tender, in which it was necessary to create digital "fingerprints" of objects, which will be worked on by specialists from the museum.

In 2016, several companies came together to provide laser scanning services. FHM Consulting specialize in BIM scanning, 4D Delta provided technologies for visualizing the coordinate model. The specialists of both companies checked and modeled over 40,000 square meters, including three museum wings (Old Gaol, underground garage and redevelopment site). As part of the work, some street landscapes were also captured in order to maintain the structural integrity of all objects.

During the work, Faro and Leica 3d scanners were used, which made more than 600 images. The ReCap package was used as software, in which PTX files were processed. Fuller Hill (head of FHM Consulting) imported the data into Revit for more precise processing and creation of full-fledged models. At the last stages, 3Ds Max and Adobe Premiere software products were used, which made it possible to make the models as realistic as possible.

The grand opening of the new museum building is scheduled for 2020.