Exone 3d printer price

ExOne and Rapidia launch Metal Designlab 3D printer and X1F furnace- technical specifications and pricing

0Shares

Binder jetting 3D printer manufacturer ExOne and Canadian metal 3D printing company Rapidia have launched the Metal Designlab system and X1F furnace.

As part of a new partnership between the firms, ExOne will exclusively market the machines, which feature Rapidia’s proprietary ‘two-step’ 3D printing technology. The technique is predicated on a water-based metal paste, that evaporates during printing, removing the need for any time-consuming polymer debinding steps.

The deal also gives ExOne first refusal over any future acquisition of its Vancouver-based partner, and sees Rapidia’s founder Dan Gelbart join as a ‘technical advisor.’ According to John Hartner, CEO of ExOne, the partnership will enable its clients in the industrial and education sectors to access an accelerated production workflow.

“We are delighted to partner with the visionary Dan Gelbart and the Rapidia team,” said Hartner. “Now researchers, educators, and industrial designers will be able to bypass days of waiting and produce high-quality parts without the limitations faced by parts that require traditional debinding.”

“This technology is a true time-saving innovation that complements ExOne’s portfolio.”

Rapidia’s ‘Two-step’ technology

Essentially, Rapidia’s proprietary two-step technology involves 3D printing directly onto a mildly-heated glass bed using a water-based metal or ceramic paste called ‘HydroFuse.’ The technique is advantageous because the resulting parts don’t require debinding before sintering, reducing what’s usually a ‘three-step’ process into a ‘two-step’ one.

Traditionally, three-step approaches have involved 3D printing objects with polymeric binders, but this causes shrinkage once they’ve been burnt off which sometimes limits their applications. By contrast, Rapidia’s pastes replace 98% of the binder with water which evaporates during printing, serving to lift any part thickness limitations and expedite the process.

Uniquely, Rapidia’s technology also allows for both 3D printed and machined parts to be moistened, stacked on top of one another and combined into a unified structure. By partnering with ExOne, Rapidia will effectively be able to utilize its reseller network, and market its two-step process to a wider audience.

For ExOne, meanwhile, the deal enables it to leverage the technology to broaden its existing metal 3D printing portfolio, as well as bolster its own capabilities. What’s more, given the interest in binder jetting technologies driven by Desktop Metal’s decision to go public, now could be the ideal time to market its new machines.

The Metal Designlab and X1F systems

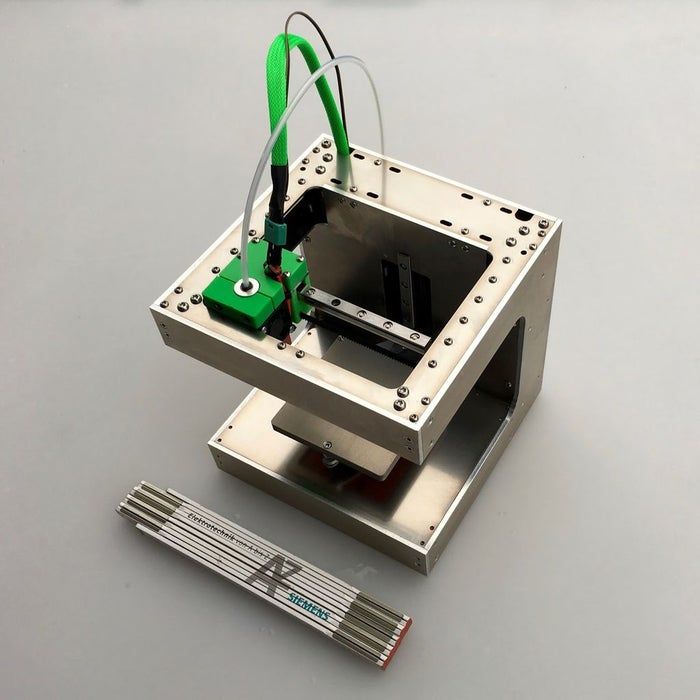

ExOne’s Metal Designlab 3D printer is based on the technology used within Rapidia’s earlier machines, and it functions using the same two 0.4mm or 0.6mm independent extruders. Similarly, with dimensions of 78 x 70 x 157 cm, the system remains relatively small, and its compatibility with water-soluble binders makes it somewhat ‘office-friendly.’

With regards to build volume, the Designlab is a little bigger than Rapidia’s initial machine at 200 x 280 x 150 mm, and requires 110-125 AC of power to run at a speed of 2.4 inches per hour. The overall system weighs in at 100kg, rising to 120kg once filled with cartridges, and the printer allows four of these to be loaded at one time.

In terms of materials, the Designlab is currently compatible with the 17-4PH and 316L stainless steels, with the promise of more new alloys and ceramics to come. Each refillable cartridge measures 7 cm x 35 cm, and contains 4-5 kg of ‘HydroFuse’ alloy, that’s designed to allow users to fabricate complex support-free metal parts.

Each refillable cartridge measures 7 cm x 35 cm, and contains 4-5 kg of ‘HydroFuse’ alloy, that’s designed to allow users to fabricate complex support-free metal parts.

Understandably, the X1F furnace system weighs a heavier 500kg, but it has the same 235mm x 400mm volume as Rapidia’s earlier machine. The furnace is also controlled by a similar 10-inch touch screen, and because it’s powered by a regular 220-240 AC socket, it doesn’t require any special installation by an engineer either.

Technical specifications and pricing

Below are the technical specifications for the Metal Designlab 3D printer and X1F furnace. Orders are now being accepted for both machines, with delivery available from Q2 2021 onwards. Readers interested in purchasing the systems can visit the ExOne website for a quote.

| Metal Designlab 3D printer | |

| Print Technology | Extrusion of water-based paste |

| Build Volume | 200 x 280 x 150 mm |

| Resolution | 0. 6mm and 0.4mm nozzles 6mm and 0.4mm nozzles |

| Print Speed | Over 40 cc (2.4 cubic inch) per hour |

| Print Sheet | Flexible stainless steel, reusable |

| Computer Interface | USB |

| Dimensions | 78 cm (W) x 70 cm (D) x 157 cm (H) |

| Weight | 100 kg, 120 kg with four full cartridges |

| X1F furnace | |

| Atmosphere | Forming gas (3% h3 in Ar) |

| Max Temperature | 1400 °C |

| Inside Dimensions | 235 mm (D) x 400 mm (L) |

| Outside Dimesions | 78 cm (W) x 105 cm (D) x 188 cm (H) |

| Weight | 500kg |

| Power | 220-240 VAC, 50/60 Hz |

| Ventilation | Single ½” plastic tubing vented to outside |

| Control | 10” touch screen |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

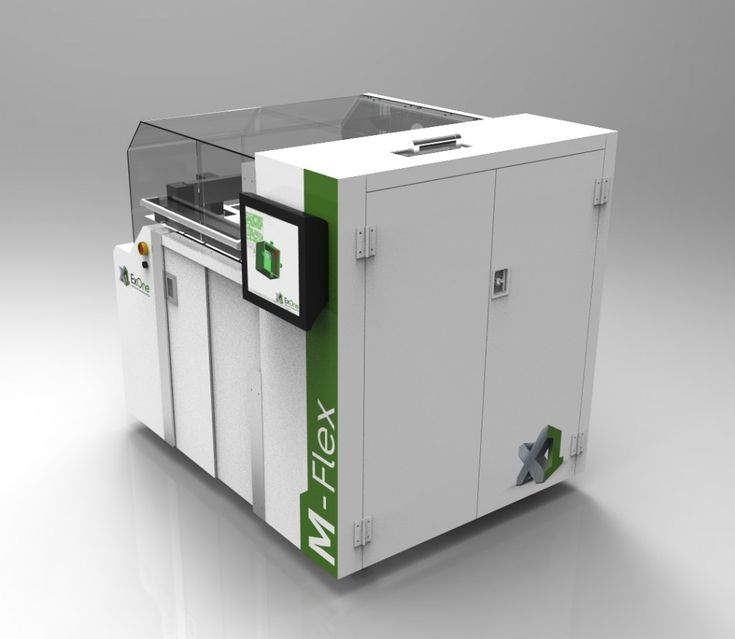

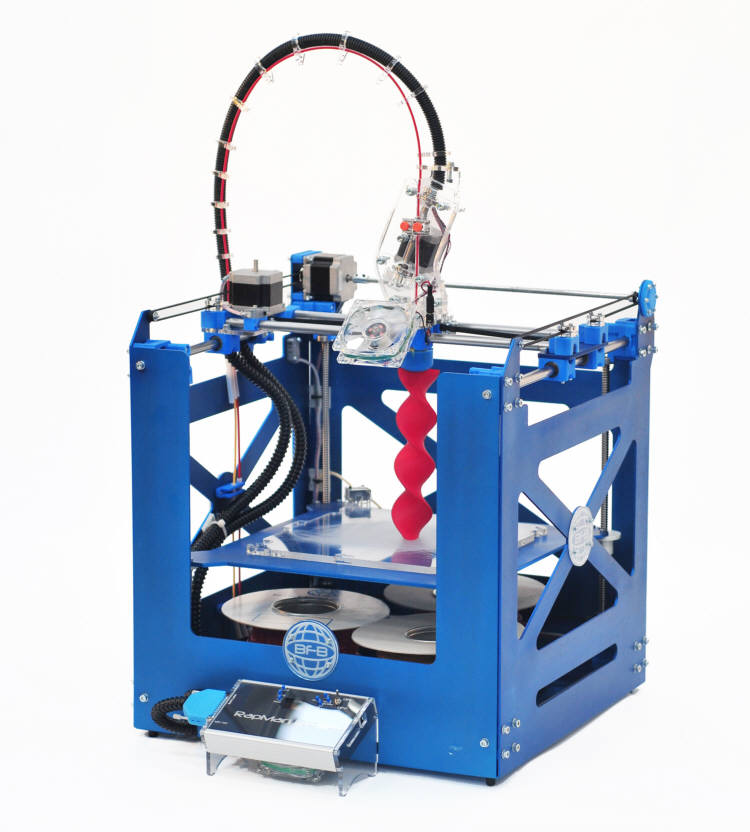

Featured image shows a concept image of ExOne’s new Designlab 3D printer and X1F furnace. Image via ExOne.

Tags Designlab 3D printer Desktop Metal Exone John Hartner Rapidia X1F furnace

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

New ExOne S-Max Flex sand binder jetting system to debut at CastExpo

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

The most affordable sand 3D printer ever offered by binder jetting pioneer ExOne, the all-new S-Max Flex, will debut at CastExpo 2022 in Columbus, Ohio, on April 23. The new machine has been designed from the ground up as a robotic 3D printing system that combines industry-leading binder jetting expertise from ExOne and Desktop Metal (and possibly ETEC Viridis as well). It features Single Pass Jetting technology and will enable more foundries than ever to enjoy the benefits of sand 3D printing technology.

It features Single Pass Jetting technology and will enable more foundries than ever to enjoy the benefits of sand 3D printing technology.

Targeted at the growing number of foundries and pattern shops looking to step into the next era of metal casting, the ExOne S-Max Flex is a simple and easy-to-use sand printing system with a quick payback. By pairing an industrial robot (similar to the one used by Viridis, also part of the Desktop Metal group now), with an all-new printhead and recoater design worthy of the trusted S-Max name, ExOne — in partnership with new owner Desktop Metal — created an Additive Manufacturing 2.0 system designed to democratize sand 3D printing for the foundry industry.

The combination of multiple sand binder jetting technologies into one company is “bound” to bring significant benefits in terms of leveraging best practices and more efficiently targeting the foundry segment. The benefits of sand binder jetting AM in large foundry core, patterns and mold production has been amply demonstrated as reported in 3dpbm Research’s report on the Ceramic AM market. The new system’s debut at CastExpo 2022 will help drive greater awareness.

The new system’s debut at CastExpo 2022 will help drive greater awareness.

With a giant build volume of 1900 x 1000 x 1000 mm (39.4 x 74.8 x 39.4 in), and build rate up to 115 l/h, this new turnkey system was developed to help smaller foundry businesses both survive and thrive into the future. The S-Max Flex allows its owners to offer quick turnaround times on high-quality sand molds and cores regardless of complexity – eliminating the need for traditional core production and assembly, and all the labor, scrap, and complication that comes with it. The S-Max Flex is intended to keep foundries competitive by enabling same-day castings of the complex cores becoming increasingly common as manufacturers consolidate and lightweight metal parts for electric cars and a new future. What’s more, this system enables foundries to operate more efficiently, despite labor shortages and supply chain challenges.

The system on display at CastExpo 2022 will also feature an all-new kinematic Single Pass Jetting printhead and recoater assembly designed by Desktop Metal and tested with input from ExOne’s experienced sand 3D printing team It will be combined with a proven industrial robot enabling a flexible layout and ease of access for routine service and maintenance. Desktop Metal’s easy-to-use Fabricate MFG integration will automatically nest parts within the job box for the highest accessibility.

Related Articles

Exone 3D printers

home

Manufacturers

ExOne

3D Printers

- 3D Printers

3D printer ExOne S-Print

Product not available for order

Working chamber

800x500x400 mm

Layer thickness from

240 microns

across the Russian Federation from 10 000

3D printer ExOne M-Print

Product not available for order

Working chamber

800 x 500 x 400 mm

Layer thickness from

150 µm

across the Russian Federation from 10 000

3D PrinterExOne X1 25Pro

Product not available for order

Working chamber

400x250x250 mm

Layer thickness from

30 µm

across the Russian Federation from 10 000

3D printer ExOne M-Flex

Not available for order

Working chamber

400 x 250 x 250 mm

Layer thickness from

100 µm

across the Russian Federation from 10 000

3D printer ExOne X1 160Pro

Product not available for order

Working chamber

800x500x400 mm

Layer thickness from

30 microns

across the Russian Federation from 10 000

ExOne Innovent+ 3D printer

Not available for order

Working chamber

160x65x65 mm

Layer thickness from

30 µm

across the Russian Federation from 10 000

3D printer ExOne Exerial

Product not available for order

Working chamber

2200 x 1200 x 600 mm

Layer thickness from

280 µm

across the Russian Federation from 10 000

3D printer ExOne S-Max +

Not available for order

Working chamber

1800 x 1000 x 600 mm

Layer thickness from

280 µm

across the Russian Federation from 10 000

3D printer ExOne S-Max

Product not available for order

Working chamber

1800x1000x700 mm

Layer thickness from

260 µm

across the Russian Federation from 10 000

3D printer ExOne S-Max Pro

Product not available for order

Working chamber

1800x1000x700 mm; 400H (With box-in-box system)

Layer thickness from

260 µm

across the Russian Federation from 10 000

3D Printers ExOne Company, LLC

Purpose

Purpose

Professional

Industrial

Personal

Commercial

3D printer type

3D printer type

Tabletop

Food

Professional

For home

Chocolate

Jewelry

Russian

Reprap

Dental

Full color

Industrial

Not expensive

Medical

For training

Material type

Material type

Plastic

606

Metal

50

Photopolymer

245

Other

144

Manufacturer

Manufacturer

3D Systems

84

PICASO 3D

8

Stratasys Ltd

38

Leapfrog BV

6

EnvisionTEC

51

Myriwell

4

3D Experts

3

PrintBox3D

4

FELIXrobotics

11

Solidoodle

8

WANHAO

32

ROKIT

5

SeeMeCNC

4

mUVe 3D LLC

1

RepRapPro

5

Formlabs

9

Afinia

1

Airwolf 3D

6

Type A Machines

2

iRapid

1

RoBo 3D Printer

3

Mixshop Inc.

4

IonCoreLtd

1

Old World Laboratories

1

XYZprinting

13

Panowin Technologies Co., Ltd.

2

MiiCraft

7

Portabee 3D Printer

2

Zeepro

1

Pirate 3D

1

Qualup SAS

2

BEETHEFIRST

3

Heacent

2

Robot Factory

2

Kuhling&Kuhling

1

3Dfactories

3

Tangible Engineering USA Corporation

1

DWS Lab

1

Sedgwick

2

3DJoy

4

Futura Elettronica

1

Makible Ltd

2

ALT Design

1

Active 3D

2

Trinitylabs

1

Sumpod Ltd.

4

Brahma3

1

Hyrel 3D

5

Omni3D

4

BCN3D Technologies

7

Boots Industries

2

ORD Solutions

2

Ironvault

1

2PrintBeta

3

Unique Design

3

Hot Proceed

1

3DD Plus

2

York3dPrinters

1

Code-P

4

Deezmaker

3

Ruian Maitian Network Technology Co

2

CB Printer

1

Print Technologies Pty Ltd.

5

MaukCC

1

Choc Edge Ltd

2

Shenzhen WeisTek Co.,Ltd

5

Delta Tower

2

Tegelbeckers Ltd

1

Deltaprinter

1

MindKits

1

Robot Co, Ltd

1

Romscraj

2

Fabmaker

1

Peerbhai Robotic

1

Sintermask GmbH

1

KL Services Group Inc

1

Fochif Mechatronics Technology Co. , Ltd

, Ltd

4

Teil3

1

Maker's Tool Works, LLC.

2

Gaminu

1

re:3D

1

inDimension3

4

Acuity Design

1

Essential Dynamics

1

Isis3D

1

Velleman

1

Kentstrapper

4

Blue Eagle Labs

1

Gubbels Engineering

2

Zortrax

8

3dBotic

1

MakerGear LLC

1

Jelwek

1

it is 3D

2

Cablysa Systems, S. L.

L.

3

Ac123Dc

1

E3D Online

1

Hydraraptor

1

MakerBot Industries, LLC

8

Delta Micro Factory Corporation

3

Ultimaker B.V.

11

Solidscape Inc.

8

MBot3D

4

B9 Creations

4

Jinhua Flashforge Technology Co., Ltd

26

Tinkerine Studio Ltd

3

Aleph Objects Inc.

4

DeltaMaker

1

Reprap Austria

3

IC3D LLC.

1

Ultibots, LLC.

2

Intelligent Machine Inc.

1

Metamaquina

1

Shenzhen Mootooh Engineering Co., Ltd.

1

Multitec GmbH

3

German RepRap GmbH

3

Sharebot

17

Nova 3D

1

QU-BD Inc.

4

RDMCU

1

Full Spectrum Laser LLC

1

Piece Maker Technologies

1

Printbot, Inc.

7

Terawatt Industries

1

botObjects

1

Lunavast

2

Maker Farm

3

NWRepRap

1

eMotion Tech

1

Printed Worlds

1

Reprapsource

1

Twelvepro Co

1

Replicator Warehouse

1

Stellamove Inc.

1

Make Mendel

6

Rapide 3D

2

Makealo

1

Crew Ltd.

1

Open cube

1

3D Kits

1

Coombes Solutions Ltd.

1

SHARK Limited Partnership

1

Smartfriendz

1

3DMonstr

1

Kikai Labs

2

THY3D

1

Tantillus

1

RepRap Diffusion

1

QSQM International Co.:quality(80)/images.vogel.de/vogelonline/bdb/649100/649117/original.jpg)

1

Tumaker

1

Makism 3D Corp.

3

3dBotZ

1

ZMorph 3d

1

Eckertech Inc.

1

Imec Proto

6

miniFactory Oy Ltd

1

printMATE 3D

1

CMET Inc.

5

Arcam AB

6

3Geometry Manufacturing Systems Pvt Ltd

8

Electro Optical Systems

15

Trump Precision Machinery Co. , Ltd.

, Ltd.

4

Wuhan Binhu Mechanical & Electrical Co., Ltd.

11

Optomec Inc.

1

Shaanxi Hengtong Intelligent Machine Co., Ltd.

9

Matsuura Machinery Corporation

1

ExOne Company, LLC

6

Concept Laser GmbH

9

Instrument Tech Co, Ltd

7

UnionTech

8

Renishaw plc

2

D-MEC Ltd.

3

Realizer GmbH

5

SLM Solutions GmbH

5

Fabriconic LLC

3

Mark Forged

8

Keyence Corporation

2

SYS+ENG

1

Lithoz GmbH

1

DWS s.r.l.

12

Beijing TierTime Technology Co. Ltd

17

Carima

3

Mcor Technologies Ltd.

3

Asiga

11

Rapid Shape GmbH

14

solido ltd.

1

Blueprinter ApS

1

Kevvox Pte Ltd.

2

JER Education Technology Co., Ltd

1

Azuma Engineering Machinery Inc.

2

Space Monkey

1

Trimaker

1

Most Fun

1

Iniciativas 3D

1

IdeaLab 3d

1

MendBot Labs

Bonsai Lab

2

MakerDreams

1

i3Dbot Co. , Ltd

, Ltd

2

Natural Machines

1

Cyrus3D

ITALYmaker

Something3D

Cagelli Distribution

E Crew Vis

BigRep GmbH

2

Voxeljet Technology GmbH

5

Sciaky Inc.

Mankati

4

F&B rapid production

3

3DQuality

17

Workshop Churyumov

2

Unimix

2

Center for Additive Technologies

3

ENNOVA

1

Exclusive Solutions

2

Magnum

5

SHEKLA

1

D-Force

3

BigRep

4

Roland

1

ABC 3D

2

MAKEX

1

3D Master Kit

7

Shining 3D

25

3NOVATICA

3

AVS Robotics

1

IMPRINTA

11

Createbot

5

AIO Robotics

1

RK-3D

1

SPETSAVIA

3

3DiY

14

Wonwall

1

Apium Additive Technologies

3

3DSUN

1

Cheap3D

1

3rd

1

EGL3D

1

Creality 3D

42

UNIMATECH

2

VolgoBot

3

ZVER 3D

3

Zenith

2

MicroFactory

1

Hewlett Packard

2

Shenzhen Anet Technology Co Ltd

15

MASS PORTAL SIA

11

Cyberon

2

PHOTOCENTRIC

2

TotalZ

11

3dcon

2

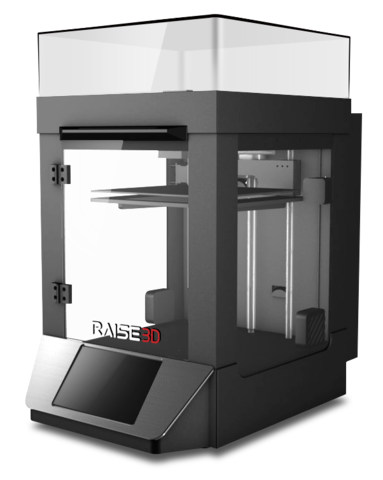

Raise3D

6

OOO RUSSIAN ENGINEER

1

Vortex-3D

5

Flying bear

11

Print3D

5

ROBOINO

1

SoloPrint

1

Fun Distribution

1

Alekmaker

2

Cronos

2

TEVO 3D

9

3D printers from China

2

ZAV 3D printer

4

Epo3d

1

FLSUN 3D

3

WINBO

19

PROTOTYPE

1

UNIZ TECHNOLOGY

2

W2P Engineering GmbH

4

MAESTRO

1

Pi 9 3D printer0003

1

Shenzhen Tronxy Technology Co

23

Kelandi

1

Geeetech

21

3DCeram

2

Omaker

1

Builder 3D Printers

6

Creatable Labs

1

ROBOZE

3

Desktop Metal

1

Sintratec

2

CreatBot

10

ANYCUBIC

29

3dlaboratorio

2

OOO SPC "Lasers and Equipment"

2

Prusa Research

6

Prismlab

3

ivilol

2

Geralkom-3D

7

EqMex

1

Tsar3D

2

Zhuhai CTC Electronic Co. , Ltd

, Ltd

3

Shenzhen Aurora Technology Co., Ltd

6

Monoprice

1

Shenzhen Salon Technologies Co., Ltd.

1

Shenzhen Sundystar Technology Co., Ltd

2

Shenzhen Easythreed Technology Co., Ltd

1

WOW Innovation Technology Co., Ltd.

2

Jinhua Xingzhe 3D Technology Co., Ltd

1

Shenzhen Zhongxin Microscience Software Co., Ltd.

1

Shenzhen Yaying Trading Co. , Ltd

, Ltd

5

Z Bolt Co.

2

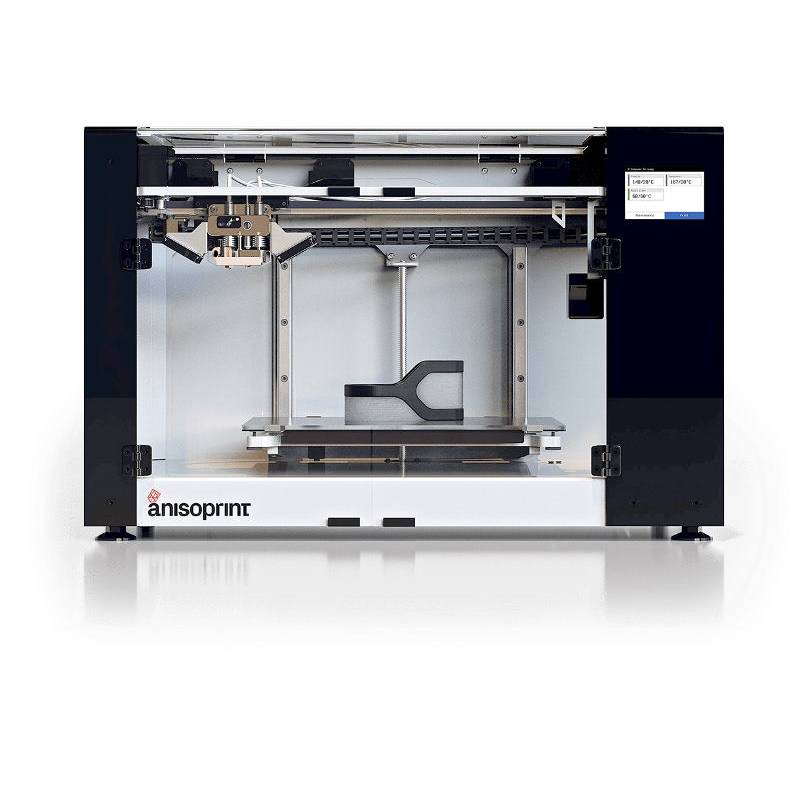

Anisoprint

1

Shanghai 3D ARTEL Science and Technology Co.

3

FABERANT 3D printers

1

Self-assembly 3D printers

4

ZRapid Tech

21

Zonestar

13

3DGence

3

BLB Industries

1

Hard Light

1

Stereotech

2

TPM3D

7

Artillery

4

Phrozen Tech Co.