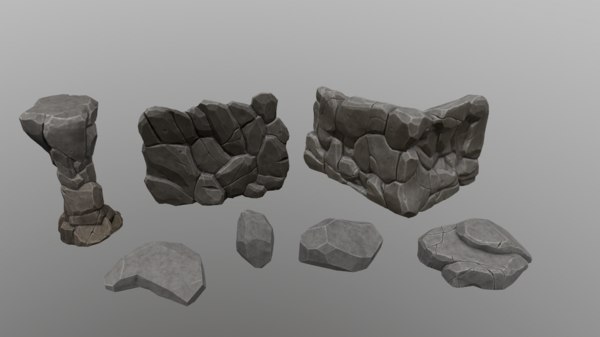

3D printing stone

3D Printing Services using stone, marble, minerals, in large scale

PreviousNext

1234

3D Printing Service

3D Printing Service of Minerals in large scale

We give everyone the opportunity to realize great ideas, using the infinite possibilities of the Additive Manufacturing (3D Printing).

With our innovative technologies, creativity and imagination no longer know the limits of realization, both in shape and size.

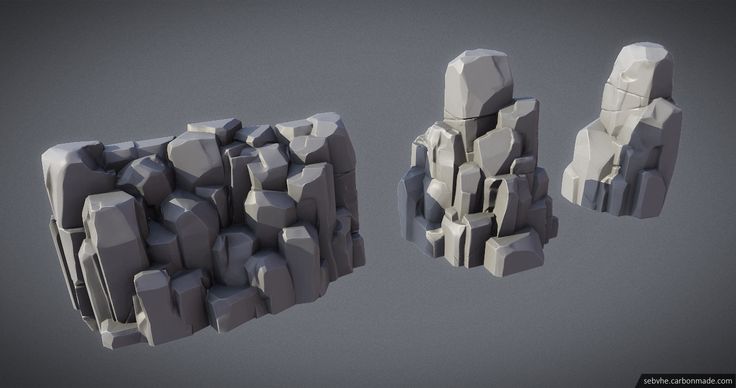

ANY GEOMETRIC FORM

With 3D printing it is easy to create complex shapes.

Empty areas, undercuts, curves, corners and cantilevered items; it is even possible to develop parts inside the object.

No more construction difficulties.

LARGE SIZE

Technology, speed and print resolution are optimized for making objects in large size, starting from about half a meter per side up to much more important formats: just think that today we print objects 50 cm high in an hour!

NATURAL MATERIALS

Our technology does not produce processing waste, on the contrary: it allows to reuse the “waste” of stone, marble, sand, …

Valuable materials that are considered quarry waste due to their size are transformed into our raw material.

How does it work?

Imagine without limits

Create a digital file in .stl format:

model your idea or scan the object to be reproduced

.

We print it

We put at your disposal all our skills, tools and professionalism to print and post-produce your idea.

Receive it all over the world

From project to reality:

we bet you can’t wait to touch it!

You have the possibility to go beyond the current limits

Complex shapes, production costs, speed of realization, unique pieces are no longer a problem for your creativity.

INNOVATIVE MATERIALS

Innovation is not just using rock as a printing material, but also using locally sourced materials and natural and environmentally friendly, non-polluting binders.

Marbles, stones, sands, aggregates in granules consolidate thanks to our formulation, of which we have registered the patent, which includes only natural inorganic materials and which can replace the use of Portland cements.

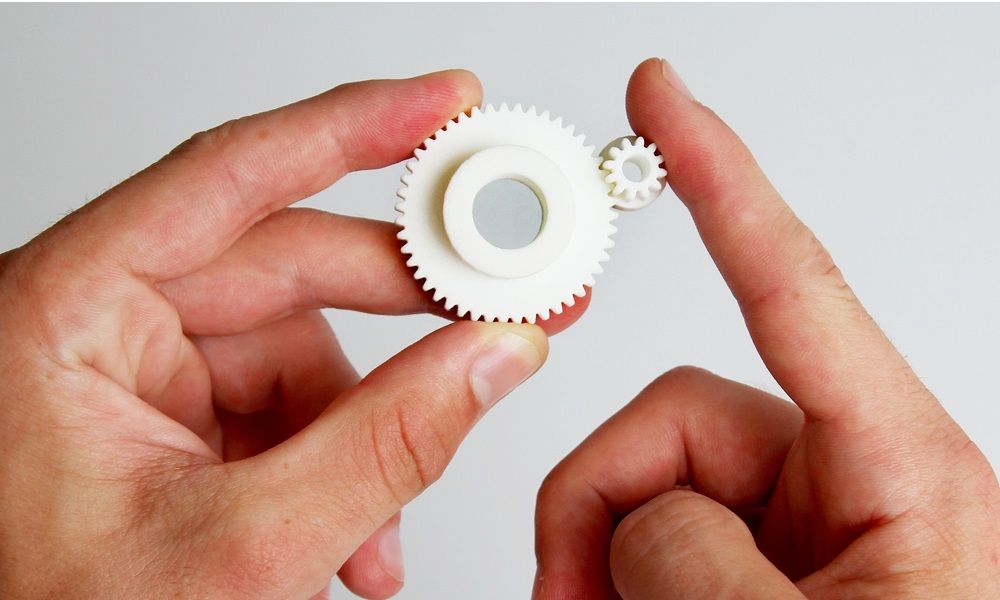

QUICK PROTOTYPING

Switching from the digital model to the real prototype is extremely simple, fast and convenient. It is one of the great advantages of additive manufacturing that allows the creation of objects in scale or in natural dimensions.

Using our technology means having the product in your hands quickly and being able to touch, test and verify.

PRODUCTION OF LIMITED SERIES

We have succeeded in industrializing customization, from today the craftsmanship has the same cost as mass production.

It is no longer necessary to produce large quantities of stocks to implement economies of scale and immobilize capital in warehouses. With our printing technology it is possible to make single objects, small series or large productions and, if required, differentiate the details of individual products without additional costs.

With our printing technology it is possible to make single objects, small series or large productions and, if required, differentiate the details of individual products without additional costs.

REVERSE ENGINEERING

A digital model suitable for printing can also be obtained through a 3D digital scan: artworks, cultural heritage, archaeological sites, architectural or design elements.

Reproduction is the same as the original in both form and size, useful for replacing damaged pieces and for duplicating, protecting and making more accessible valuable original items.

We can print everything

Our technology has found application in many sectors … and they are constantly increasing!

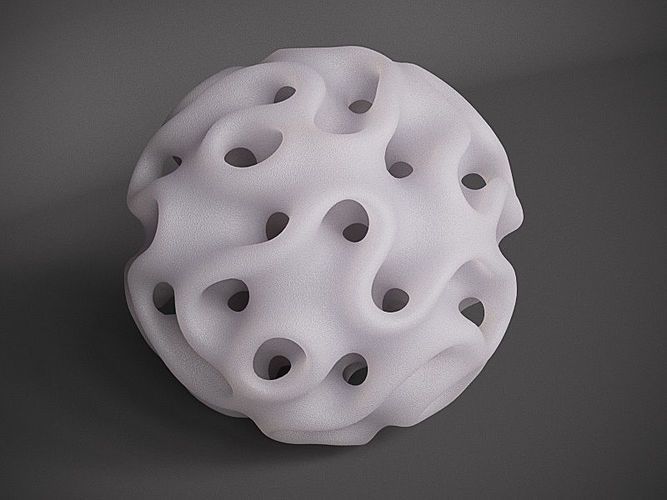

CORAL REEFS AND BANKS

Reconstructing reefs and local environments for fauna using environmental marine data and specific hydrodynamic processes of the place to protect. The natural materials used and the 3D printing process are highly suitable to shape appropriate forms for fish restocking.

The natural materials used and the 3D printing process are highly suitable to shape appropriate forms for fish restocking.

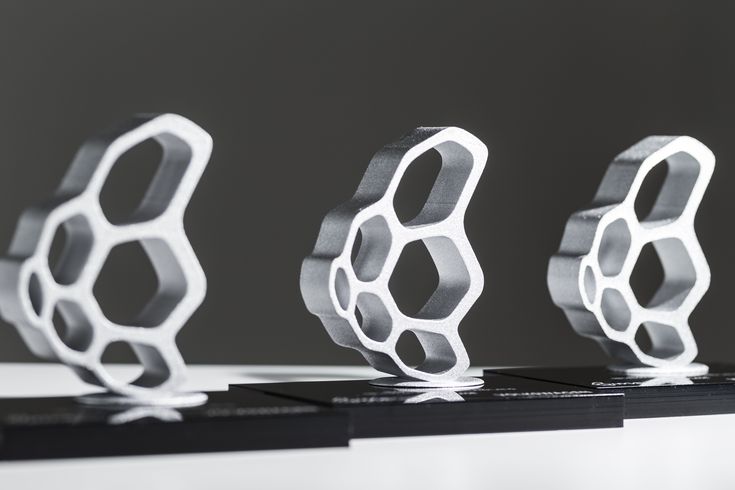

QUANTITIES AND VARIATIONS IN THE SERIES

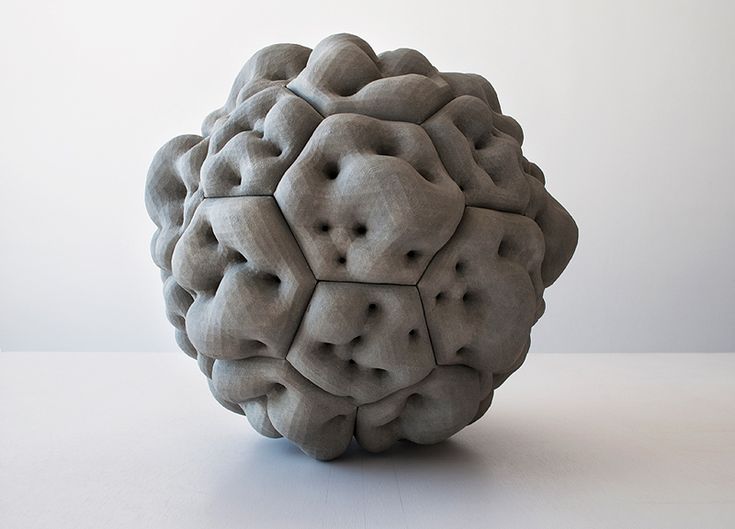

Thanks to the 3D stone printing process, which begins with a digital design, it is now possible to create series of revolutionary features. Contrary to the molds, the unit cost is no longer affected by the amount of pieces. The prints can have small variations and even be in scale, like these geometric models of Stereographic Projections.

SHOWCASES THAT CAPTURE

The elegance of marble, the naturalness of the stone and the evolution of shapes never seen before capture the attention of people. So 3D printing of stone and customized surface finishes enter the business spaces as a design element and, why not, as the art of setting up shop windows: an example is the design by Architect Andrea Tognon for Jil Sander, in Berlin.

Discover what additive manufacturing can do for you.

Did we arouse your curiosity?

Please, read the answers to frequently asked questions about 3D mineral printing.

Do you also want to ask us a question?

Request a free consultation on the incredible world of additive manufacturing for Minerals.

When you conceive new projects, free your imagination from production constraints.

This is precisely what many professionals already did:

© Copyright - Desamanera S.r.l. - P.IVA 01498800299 - made @ rrWeb.it

3D Printers for minerals, marble, stone, in large scale

Superior freedom in terms of shapes and dimensions

In this production technology, the powder bed contains and supports the shapes and in this way it allows to easily create very wide and complex objects.

Custom-made 3D printers

We do not produce standard 3D printers: we offer the market custom-designed machines, depending on the size and the specific sector in which they have to operate.

Our standard is technology, at the highest level currently developed.

Greater efficiency in production

The production process becomes faster, more fluid and more versatile. You can produce different objects, simultaneously; copies of the same object, or parts of it, even after some time; serial objects that differ only in small details.

All this without cost differences, with greater rapidity and a considerable reduction in the waste.

Certifications and security

All our machines are designed according to CEI – EN standards and guarantee the highest quality and safety in all use phases.

User-friendliness

The main operational operative features of Desamanera systems and printers meet practical and daily needs: ease of use, maximum reliability, simple and intuitive control and maintenance.

New business opportunities

Own production system innovation determines important competitive advantages: it offers the opportunity to improve its own value proposition (services and products) and, consequently, to innovate the reference market and penetrate new sectors.

Additive Manufacturing was born more than 30 years ago as a rapid prototyping technology. Step by step it consolidated processes, technologies, models and paradigms.

AM is grown and consolidated as a customized-production technology and every day it opens up new revenue areas, sector by sector.

We have the fourth industrial revolution in front of us, and we are just getting started:

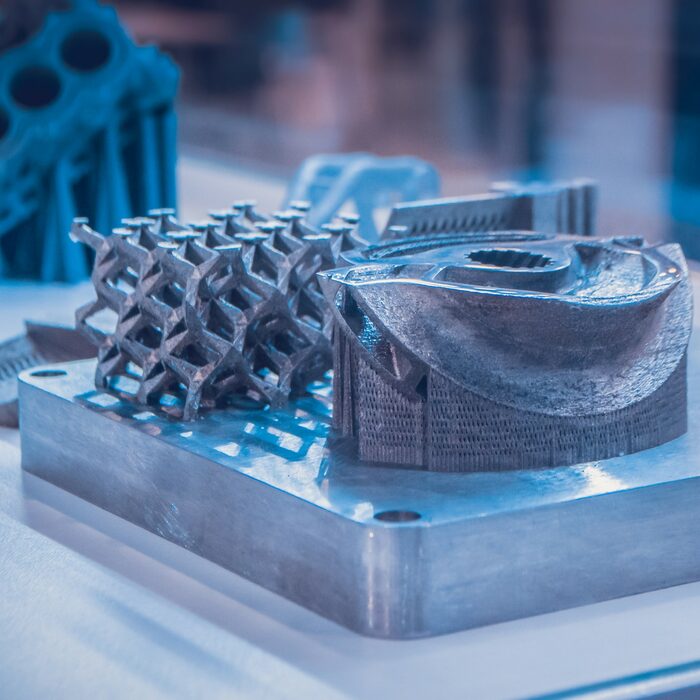

RAPID PROTOTYPING

Every product goes through the prototyping phase, a product design key moment that highlights strengths and weaknesses. Thanks to the prototype the imagined object output is evaluated in concrete and allows all the necessary optimizations: production process and time, product performance and appearance, tests and market analysis, marketing activities and product launch out, both cost and revenue economic evaluations.

Thanks to its flexibility and cost-efficiency, Desamanera 3D printing is the ideal technology to produce prototypes in the most effective and fastest way and to produce many more, in particular for medium-large objects with ceramic, stone, marble, …

INDUSTRIAL PRODUCTION

The 3D printing technology starts to be specifically optimized and adopted in mass production. It may seem a paradox, but it is not: it is the paradigm of mass customization, where production processes and technologies offer the mass production affordability and, at the same time, guarantee customization opportunities reserved, so far, to the customers of most high-end artisans and to the luxury market.

It may seem a paradox, but it is not: it is the paradigm of mass customization, where production processes and technologies offer the mass production affordability and, at the same time, guarantee customization opportunities reserved, so far, to the customers of most high-end artisans and to the luxury market.

Industrial production 3D printing is already consolidated in some sectors, such as Dental, Automotive, Aeronautics and Space. With the aim of reducing costs and increasing efficiency, many other manufacturing industries are intensively investing to acquire a very important competitive advantage that widens the range of potentially achievable merchandise sectorscommodities sectors and markets and introduces innovation even in mature commodities sectors.

RESEARCH & DEVELOPMENT

Universities and Research Centers, as well as internal corporate R&D departments, share the desire to discover, study, test and optimize new technologies and new materials.

The goal is to improve human well-being and quality of life, to the benefit of all. Even in ways that Desamanera haven’t thought yet:

- materials development and optimization according to specific aesthetic and technical characteristics,

- accessibility to design and development of products with completely new dimensions, shapes and performances,

- the implementation of new machinery and new processes that have the power to trasform the business model.

3D PRINTING SERVICE

When the need comes in one time, the absence of familiarity with the technology and the resources required can be overcome only with a professional 3D printing service and expert and competent assistance. The companies that offer 3D printing services are more and more numerousconstantly incresed, precisely because the demand for this service is always greater.

The catchment area expands much more, since there are no direct competitors as much effective in terms of time, shape, size and complexity; there are no competitors that serve selected mineral and environmentally friendly materials.![]()

These reflections are the result of in-depth research and dialogues with professionals in many sectors. The technology, the processes and the materials we have developed, because of their relative youthlimited age, nowadays have found solid application only in a small percentage of the areas that can be potentially revolutionized.

The next one could be yours.

It is Additive Manufacturing

It creates objects from minerals powder: add material and minimize waste production.

This differs from subtractive production methods such as sculpture and CNC machines, which do not allow specific shape complexity and do produce a large amount of waste material.

It is an indirect powder-based 3D printing technology

Direct 3D printing (for example extrusion technology) freely deposits the material: supports are needed for particular shapes and overhang, a precise production speed must be respected according to the characteristics of the material used, the change of material during printing may be the cause of slowdowns and inefficiencies.

Indirect additive manufacturing, instead, uses a process that first distributes the material and after deposits selectively the binder to consolidate only a part, depending on shape and useful thicknesses.

The powder bed created contains and supports shapes and sizes of all kinds, with stability and without time constraints.

It’s Desamanera, one of a kind

The traditional manufacturing methods of materials such as minerals, stone, marble, … are based on expensive and bulky equipment, resins and chemicals, molds, complex production processes.

Quite the opposite, Desamanera technology has been purposely designed for:

- the respect of Environment and the enhancement of Nature, thanks to the use of natural binders.

- daily using, thanks to fluid and simple production processes.

- versatility and specific needs adaptation, because every printer is customized.

R&D is fundamental for us. We chose how to design every element of the system, from mechanics to electronics, from fluid dynamics to ICT, and we personally experience every production process phase.

Each component is subject to test and research and reaches cutting-edge performance also thanks to the collaboration with Universities and Research Centers and the participation in national and international projects. Among the many, we proudly mention the University of Padua, the German Federal Institute BAM, the ADMIN4D project and the h3020 RISE-AMITIE project.

Desamanera 3D printing technology is designed for inert materials use, in very fine particle size. The production consolidates the powder through a chemical reaction and the printed material appears as a stone.

For us, the environment respect is fundamental: the aggregates we use most are marbles, dolomites, stones, sands coming from the other processes waste; the binder is an our patented formulation which includes only natural inorganic materials and which can replace Portland cements use.

However, the technology allows the choice of other materials according to the chemical, physical and performance characteristics, required for specific uses.

Inert material with 0.5 – 2 mm particle size. It can be stones, marbles, sands, pure or mixed together, also coming from other processes waste.

NATURAL BINDERThe binder we developed in collaboration with the University of Padua is natural, inorganic, environmentally-friendly and composed by readily available raw materials.

It is patented, and according to our current knowledge it is the only one in the world activated exclusively by water.

Desamanera technologies also allow the use of other binders without particular design changes, depending on the production requirements.

Please consider alternatives to the Portland cement use, if possible: it is one of the major CO2 emissions cause in the atmosphere.

The technical characteristics and mechanical properties of the printed material change depending on the used aggregates and binders combination. However, our natural binder makes printed parts particularly suitable for outdoor use, stable to atmospheric agents and functional even in underwater environments.

However, our natural binder makes printed parts particularly suitable for outdoor use, stable to atmospheric agents and functional even in underwater environments.

Contact us to request the technical sheet.

Printer dimensions and technical characteristics are personalized, custom designed to meet specific needs and requirements of the application area, of the printed products and of the setted goals.

We kwon well We are well aware that every sector requires professionalism and specific skills, as well as every market has specific performance, quality and material requirements. For this reason, every printers has diversified technical specifications.

The features always present in our printers are summarized below.

Desa1 150.150, the first printer we designed and we still use to develop upgrade and offer printing services.

Desa1 60.60 (Pa.Sta), customized printer for the laboratory of the University of Padua, Industrial Engineering Department.

| Printing Technology | Powder-based Waterjet |

|---|---|

| Printing envelope dimensions (X, Y, Z) | Starting from 550 x 550 x 550 mm |

| Layer resolution | Starting from 2 mm |

| Voxel Dimension (X, Y, Z) | Starting from 2 mm side, programmable |

| Average Printing Speed | Depends on the height of the layer. For 3 mm high layers, 60 cm/h in height. |

| Number of nozzles | From 190 to over 1000. |

| Positioning repeatability | +/- 0.1 mm |

| Powder bed Deposition | Recoater system – programmable |

| Liquid Deposition | Adjustable flow |

| Liquid Viscosity | Water: 1 cP +/- 50% |

| Liquid PH | Variable from 6.5 to 9.5 |

| System operative Life | Up to 10,000 operating hours |

| Certifications | CEI – EN |

| Average Required Power | From 2. 5 to 3 kW (engine and electro-valves) 5 to 3 kW (engine and electro-valves) |

| Environmental Operative Conditions | Temperature: from 0 ° C to + 35 ° C Humidity: up to 95% |

Formfutura's new 3D printing materials imitate stone and ceramics

News

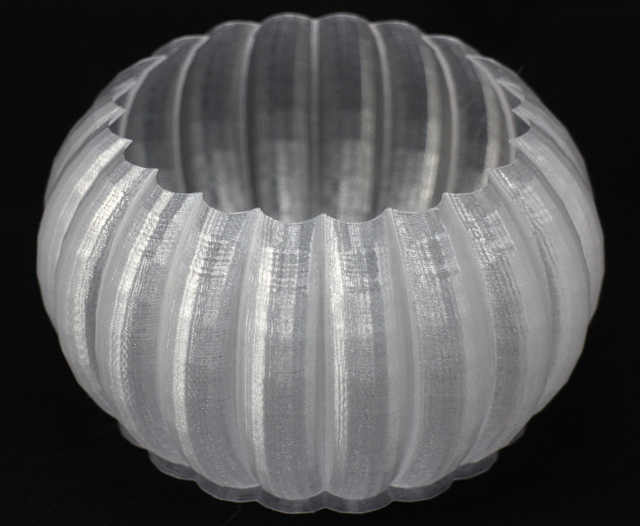

The Dutch company Formfutura launches sales of the StoneFil line, its own version of filaments that imitate stone and ceramics.

Like most similar composites, the material is based on environmentally friendly, biodegradable PLA filled with a target material, in this case crushed stone. The developers offer several versions of StoneFil at once, stylized as pottery clay, cement, granite and terracotta. As expected, products made from new materials have rough, matte surfaces.

Filling of the composite with additives reaches 50% by volume, resulting in a specific gravity of the filament about 37% higher than that of pure polylactide. The recommended extrusion temperature range is 190-240°C. Since the material is based on polylactide, "stone" models will be more decorative than functional. Thus, the Vicat softening temperature is 57°C, and the tensile strength does not exceed 38 MPa. When using a new filament, it is worth remembering its high abrasiveness. On the other hand, the material retains the main positive quality of PLA plastic - ease of printing, and also does not use any toxic additives. Detailed information on the characteristics of StoneFil can be viewed at this link.

The recommended extrusion temperature range is 190-240°C. Since the material is based on polylactide, "stone" models will be more decorative than functional. Thus, the Vicat softening temperature is 57°C, and the tensile strength does not exceed 38 MPa. When using a new filament, it is worth remembering its high abrasiveness. On the other hand, the material retains the main positive quality of PLA plastic - ease of printing, and also does not use any toxic additives. Detailed information on the characteristics of StoneFil can be viewed at this link.

Each StoneFil is available in 1, 75 and 2.85 mm diameters. The price of one spool weighing 500 g, excluding taxes and shipping costs, is €27.23. Additional information is available on the manufacturer's website.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Follow author

Follow

Don't want to

2

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want

On October 21, the solemn opening of the production site for the production of so-called. ..

..

Read more

eight

Subscribe to the author

Subscribe

Don’t want

Skat 3D prototyping and 3D printing center specialists launched additive manufacturing of orthopedic...

Read more

59

Subscribe to the author

Subscribe

Don't want

The 3Dtoday portal, with the support of Creality and Bestfilament, invites everyone to participate in...

Read more advantages of 3D printers using FDM technology. However, does a happy buyer really become the owner of a “magic box” capable of reproducing any plastic part, or is it still a DIY tool, like an engraver or a burning device, and will not be useful to everyone?

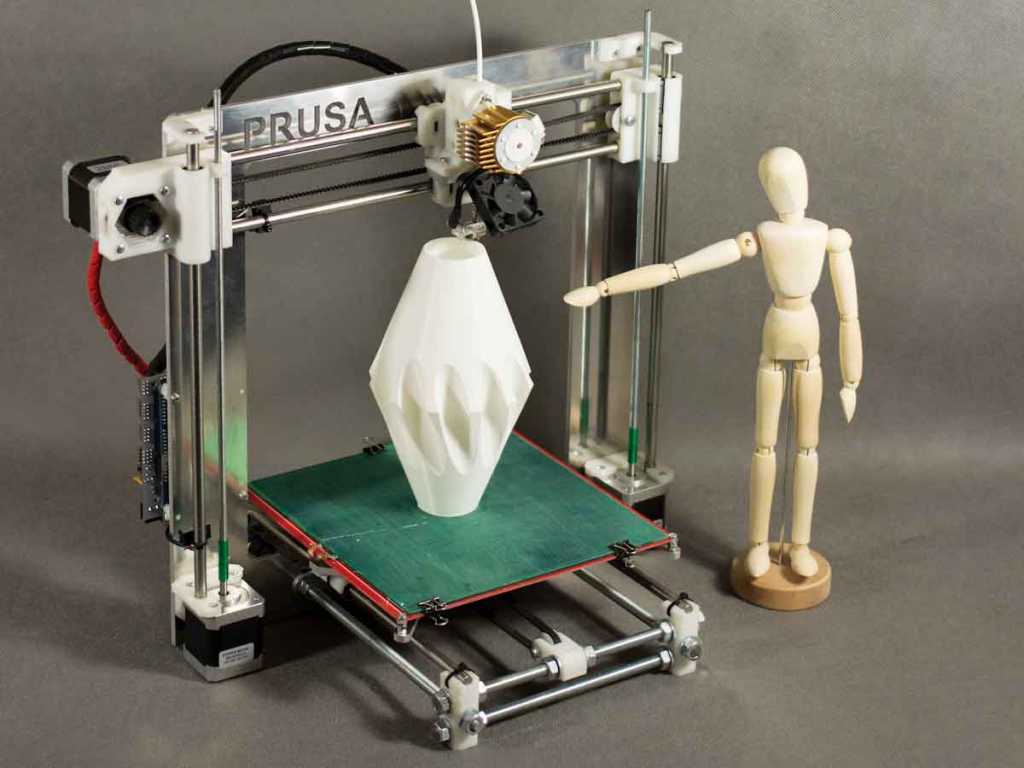

FDM or Fused deposition modeling (also FFF or Fused Filament Fabrication) is a method of additive "growing" of objects, on the basis of which almost all modern "household" 3D printers are built. The technique involves the layer-by-layer "growing" of an object from molten plastic, which is fed in the form of a rod.

The technique involves the layer-by-layer "growing" of an object from molten plastic, which is fed in the form of a rod.

The idea was originally patented, but the patent expired, and after that, inexpensive 3D printers from a variety of manufacturers flooded the market - from eminent Americans to unnamed Chinese - for every taste and budget. Someone chooses by brand - however, if you have knowledge in electronics and a desire to solve emerging problems on your own (without technical support from the manufacturer), you can save money by purchasing a kit kit or even assembling a printer from scratch according to one of the hundreds of published models.

Barrel of honey

FDM technology is really impressive. Today, it's no longer just a rapid prototyping tool for designers and architects. In fact, having a three-dimensional model of an object, we can reproduce it at home, if necessary, changing the scale or modifying it a little in the editor. For example, you can download a car mount model for a phone and scale it to fit your own device. Or, from scratch, draw any household detail - from a lamp shade to a door handle, not to mention all sorts of little things like homemade GoPro mounts, elements of children's designers, etc.

For example, you can download a car mount model for a phone and scale it to fit your own device. Or, from scratch, draw any household detail - from a lamp shade to a door handle, not to mention all sorts of little things like homemade GoPro mounts, elements of children's designers, etc.

Of course, 3D printing cannot replace a conveyor with mass production - the speed of layer-by-layer formation of plastic parts is low, so one "typical" printer can serve only the requests of its owner at best. But the task of jumping over existing production technologies is not worth it. 3D printing rules where maximum customization is needed and mass production would be categorically unprofitable. Therefore, it is very fond of DIY fans in various fields, etc. Basically, a 3D printer is a DIY tool.

Consumer 3D printing is now experiencing explosive growth. FDM technology is quite simple, and the enthusiast community has already developed several typical designs of such printers that differ in bar feeding methods and kinematics. On the basis of these typical designs, both branded printers and dozens, if not hundreds of homemade products, individual parts or even complete kits for which you can buy on Ebay or AliExpress are created.

On the basis of these typical designs, both branded printers and dozens, if not hundreds of homemade products, individual parts or even complete kits for which you can buy on Ebay or AliExpress are created.

Tar... also a barrel?

It would seem that the technology is running in, getting cheaper, while there is already a serious demand for it. Isn't this the key to an early huge success in the mass market (as it already happened with mobile phones, digital cameras, and a little earlier - computers)? Isn't it time to buy?

It seems to us that there is no need to rush. FDM technology is quite capricious, and so far it is far from being a kind of "digital camera" or "washing machine" in the hands of an ignorant user. Almost every corner here has to apply engineering thought. In fairness, it should be noted that if you are good at engineering, then the possibilities of 3D printing are really huge. But it’s better to know in advance what you are “subscribing to”.

Table and model processing

Layering something requires special preparation of models and the surface on which printing is carried out, plus post-processing of parts will be needed.

The printer comes with a glass or metal table - not any material will stick to them without additional tricks (and not any will then come off without violating the geometry of the model). PLA can be printed on an unheated tabletop using blue tape, 3M's extra strong masking tape that has now been reclassified as "3D printing tape" by enterprising users. The vast majority of thermoplastics need at least table heating, and sometimes additional adhesive coatings (varnish, glue, beer, acetone syrup, etc. - there are a lot of options tested by users). Finding the right coating for this particular printer (and plastic) is a path of experimentation and error. You will have to spoil more than one model before you find the very best option.

But the problem is not limited to printing the first layer. A thread of melted plastic cannot hang in the air, therefore, on strongly protruding parts (for example, parts with a reverse slope), supports are needed, which will need to be cut off at the end of printing, somehow processing the cut so that there are no sharp edges. It should be noted that even the most ordinary vertical wall after a 3D printer will not be perfectly smooth (at least the layer boundaries will be noticeable, and maybe other defects). So post-processing will be required for almost all parts for which surface quality is important.

Not all plastics lend themselves well to post-processing. Those who print a lot and with different materials will have to bring a whole set of solvents, hand tools, etc. at home. (as well as those who actively have fun DIY). By the way, at the same time, some plastics are also toxic when printed - so closed cases, hoods, etc. are needed.

Features of consumables

Characteristics of the result strongly depend on consumables ). If such plastic is not stored in tightly sealed bags with silica gel, the rod becomes brittle, may break when fed, make strange sounds when printing, do not fit well on the model, etc.

If such plastic is not stored in tightly sealed bags with silica gel, the rod becomes brittle, may break when fed, make strange sounds when printing, do not fit well on the model, etc.

In general, even if the quality of the material is at its best (no obvious problems), not every model is suitable for printing with certain plastics. Some materials are brittle and do not allow printing thin walls, while others, on the contrary, are well stratified in volume.

Each plastic has its own optimum printing temperature. When it is exceeded, detailing deteriorates and surface defects appear. In the reverse situation, the layers are badly sintered. In the same way, there are optimal layer thickness, retract parameters (reverse thread movement) and other similar parameters.

Many printing errors can be "compensated" by reducing the speed. But it is rightly said that the main problem is not to print the object, but to do it in a reasonable time. Therefore, for objects larger than a matchbox, you will have to deal with the optimal settings for each plastic.

Difficulties are added by the fact that “colleagues” on the forum will not tell you the detailed settings - the optimal parameters are largely determined by the printer itself: how well its temperature sensor is calibrated; whether remote thread feed is used, etc. Plus, the final numbers may differ for the same plastic from different manufacturers, as well as for coils of different colors from the same manufacturer.

Printer tricks

The printer itself can also be capricious. Each of the existing designs on the market has its drawbacks. Somewhere the motors, which should be perfectly synchronized, work a little differently; somewhere - the table oscillates while printing at high speed; somewhere too large a contribution comes from the weight of the print head. In the same way, there are “sore spots” that will come out regardless of whether it is a self-assembled printer, a whale printer or bought in the form of a “black box from the manufacturer”. In the first two cases, the probability of getting glitches is somewhat higher, but the proprietary origin does not save the device from "typical" diseases.

In the first two cases, the probability of getting glitches is somewhat higher, but the proprietary origin does not save the device from "typical" diseases.

The average 3D printer has a lot of moving parts, and the mechanics have their own lifespan. In some devices, plastic gears wear out, in others, a Teflon tube is gradually bitten by a fitting, etc. Sooner or later, such small flaws begin to affect the result of printing. Alas, there is no universal FAQ that helps to catch the problem by the final result. Here, as in old cars - you need to look for colleagues in misfortune, study the forums and hope that someone has already encountered this problem. Or - as an option - find out which of the nodes is to blame for the problem, and completely shake it up. But this is more like building your own printer from scratch.

Software errors

Before tens of meters of a bar turn into a viable object, the model must go through the slicing procedure - cutting into layers, taking into account the technical characteristics of the printer - nozzle size, layer thickness, etc. A slicer can "break wood" if the original model is not closed (it happens that holes are obtained on the simplest model - in the most direct sense). To “treat” models, there are online services and tools in specialized software, but they do not always cope with the task. At the same time, they themselves may well “lose” some details.

A slicer can "break wood" if the original model is not closed (it happens that holes are obtained on the simplest model - in the most direct sense). To “treat” models, there are online services and tools in specialized software, but they do not always cope with the task. At the same time, they themselves may well “lose” some details.

Frankly, the slicer can make a mistake even if the model is perfectly normal, and rounding is to blame. If the shaft thread pitch along some axis is not proportional to the layer thickness, the rounding error will accumulate during slicing, which manifests itself in the form of a corrugated surface on the model.

Speaking more globally, the main problem of consumer 3D printing in the current version is the lack of feedback when growing a model: the printer simply does not see what it is printing. There are temperature sensors, thread jams and other tools, but the appearance of the model is not evaluated in any way. The only feedback comes through the user, who interprets what is happening in his own way.

As a result, a 3D printer today is not exactly household appliances. It cannot be compared with an ordinary printer, let alone a washing machine. Can you imagine if, in order to successfully wash clothes, you had to select the speed of the drum of the machine during the experiments, changing it through the firmware? Yes, for some it was really interesting, but hardly for the majority.

3D printer closest to a power tool. This is a great tool for creating objects, but you need to know how to use it. Unfortunately, at the moment, this idea is not entirely clear in the advertising of some 3D printers - as a result, there is a quite noticeable proportion of disillusioned buyers who expected miracles from science fiction, but received an unused junk rack at home.

Future

In my opinion, in the future, 3D printing technology still has a chance to become truly household. Firstly, FDM is developing rapidly: firmware is being improved, new sensors are being added, etc.