3D printing services california

3D Printing Service for Los Angeles, California

CapabilitiesCustom Online 3D Printing ServiceCaliforniaLos Angeles

High Quality Los Angeles, California 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Guaranteed Quality

We back every part we ship with the Xometry Quality Guarantee. Our number one job at Xometry is making your custom parts to your specifications.

Your Los Angeles, California 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Los Angeles 3D Printing - Industries and Applications

3D printing, a form of additive manufacturing, is a tremendous manufacturing asset to businesses and organizations in Los Angeles, California. If you're looking to better understand how 3D printing could add value to your project or industry, Xometry can assist you with your goals.

According to Thomasnet.com®'s 2022 sourcing data, the top six most popular manufacturing industries in Los Angeles are Software & Technology, General Manufacturing, Aerospace & Defense, Food & Beverage, Electronics, and Automotive. Here's how 3D printing can support local manufacturing in Los Angeles in some of these popular sectors:

- General manufacturing: Considered a necessary utility tool that the majority of manufacturing companies are employing, 3D printing is a low-cost and invaluable manufacturing solution used in many avenues, from parts of the production line and making jigs and fixtures to creating custom tooling for laser marking. It also allows for rapid prototyping to test design concepts ahead of production runs, thus reducing risk and eliminating costly design flaws. Top automotive companies are eager to leverage this technology, i.e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs.

One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining.

One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining. - Aerospace and defense: 3D printing is already being utilized in aerospace and, though not yet heavily adopted in defense, has the potential to provide enormous value in the sector. 3D printing applications in aerospace mainly revolve around reducing foreign object debris (FOD) by consolidating part count, while also reducing the weight of components thereby significantly reducing costs. Freeform aerospace designs via additive can also benefit through topology optimization, a method utilizing mathematical tools to augment the distribution of the designs’ material.

For defense, 3D printing can simplify the life cycle support of any product, specifically for low-volume repairs or replacements of highly custom legacy products that are no longer manufactured. In addition to using this technology for the creation of advanced weapon systems like drones and weaponry, additive manufacturing can reduce the downtime from repairs through rapid response, with the potential for real-time 3D printing base replacement units for the military. Though there is still a lot of discovery yet to take place in relation to legacy parts, it is an interesting avenue with a lot of potential for the defense sector.

For defense, 3D printing can simplify the life cycle support of any product, specifically for low-volume repairs or replacements of highly custom legacy products that are no longer manufactured. In addition to using this technology for the creation of advanced weapon systems like drones and weaponry, additive manufacturing can reduce the downtime from repairs through rapid response, with the potential for real-time 3D printing base replacement units for the military. Though there is still a lot of discovery yet to take place in relation to legacy parts, it is an interesting avenue with a lot of potential for the defense sector. - Food and beverage: On the manufacturing side of food and beverage, 3D printing is gaining traction as a valuable utility, with the potential to become so much more. Though general mass-market kitchenware isn’t 3D printed, the prototypes for these products very likely are, as well as other essential items in the sector such as food packaging, utensils, or spare parts for food production lines.

3D printed foods have long been the topic of fervent interest, with advancements such as the first commercial 3D chocolate printer that is set to change the game for bakeries and chocolatiers everywhere. But there are a few limitations, the main one being cleanability as a 3D printed surface with micropores is not smooth enough to be considered food-grade. The addition of chemical vapor smoothing for the post-processing of 3D printed products has, however, made it possible to get closer to food processing with 3D printing than ever before.

3D printed foods have long been the topic of fervent interest, with advancements such as the first commercial 3D chocolate printer that is set to change the game for bakeries and chocolatiers everywhere. But there are a few limitations, the main one being cleanability as a 3D printed surface with micropores is not smooth enough to be considered food-grade. The addition of chemical vapor smoothing for the post-processing of 3D printed products has, however, made it possible to get closer to food processing with 3D printing than ever before. - Electronics: Additive manufacturing in this sector largely focuses on the 3D printing of plastics to produce custom enclosures with bespoke individual functions. IoT devices and wire routings that would be difficult and cumbersome to traditionally manufacture with standard tooling can be directly printed with metal or even substituted with a high-performance polymer in a short amount of time. Manufacturers of customized electronics and other products, from wearables to bridge- and high-fidelity tooling, are also turning to this technology.

- Automotive: Additive manufacturing has been used in the automotive industry for decades with manufacturers choosing to 3D print automotive prototypes for early-stage research and testing. Today, major automakers — Ford, BMW, GM, and many more — have adopted 3D printing within their manufacturing operations for the rapid creation of purpose-built components such as handheld jigs, grips, custom fixtures, thermoforming tools, and molds. In some cases, additive manufacturing has been used within automotive for installed components, especially when mass configuration or personalization is desired, as this allows companies to keep costs low and avoid future losses by printing only samples and low volumes.

The additive manufacturing and material market is rampantly growing and is estimated to reach US$61.1 Billion by the year 2027. With the technology being so prolific, providing endless options, and the opportunity to greatly add to and advance your business, let Xometry cater to all your industrial-grade 3D printing needs.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

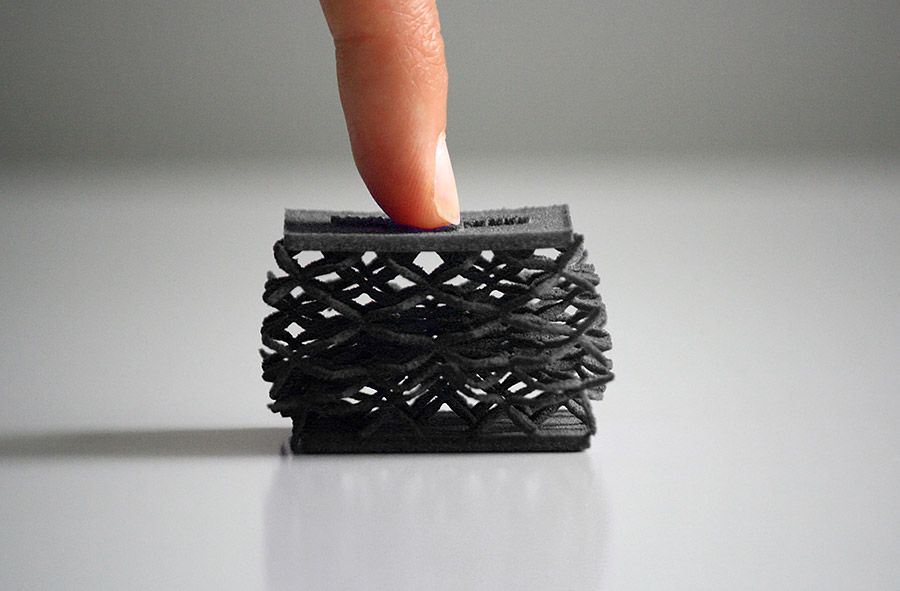

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

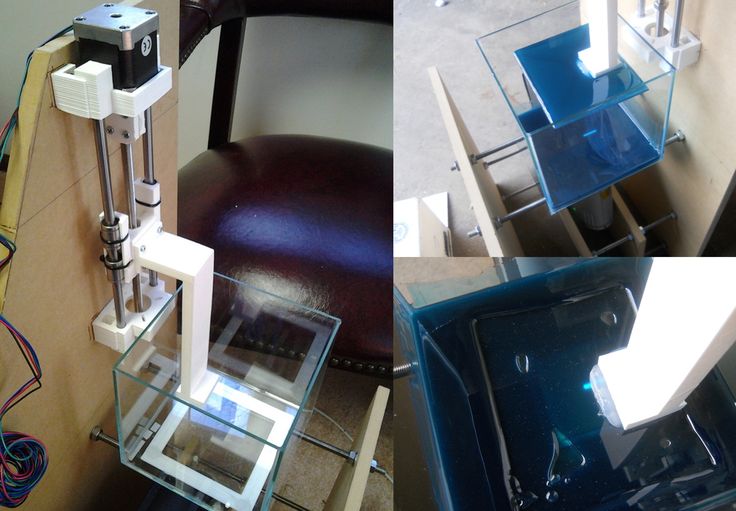

Stereolithography (SLA)

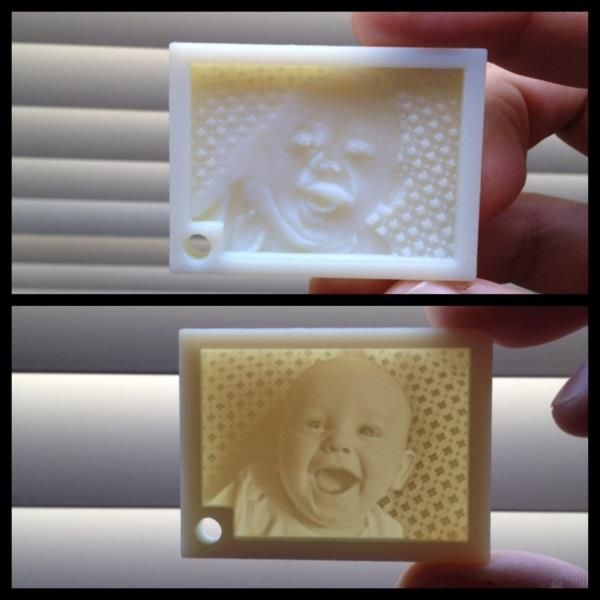

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

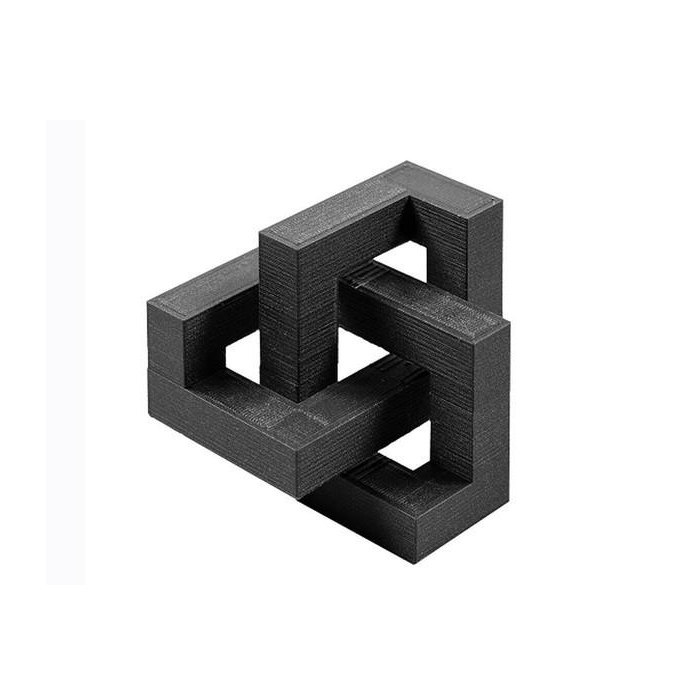

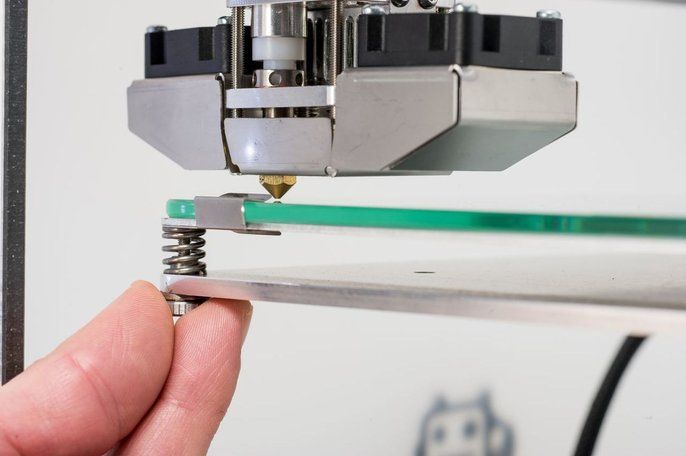

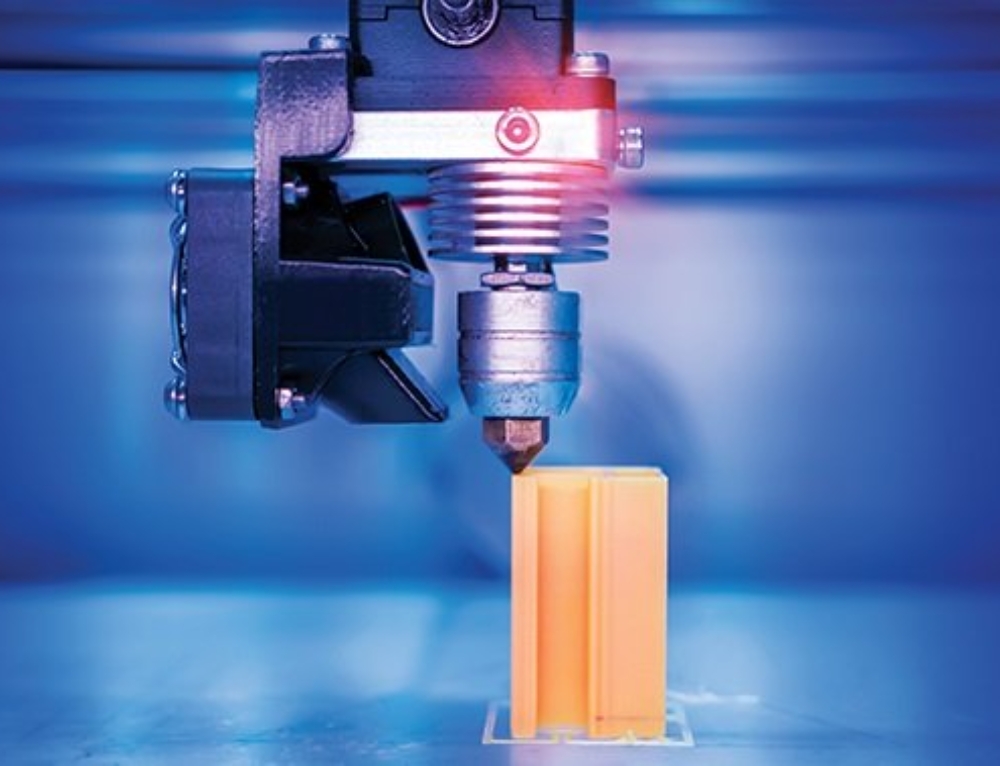

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Ready to start making custom 3D printed parts?

Top 10 3D Printing Companies in California

Undeniably, 3D printing companies have been one of the key factors that revolutionized the manufacturing industry. In recent years, technological advancements, evolving supply chain, and rapid pace of innovation have fueled 3D printing to become a mainstream manufacturing process around the world. While the world is leveraging the potentials of 3D printing, the U.S. has also witnessed tremendous growth in the 3D printing industry in recent years.

While the world is leveraging the potentials of 3D printing, the U.S. has also witnessed tremendous growth in the 3D printing industry in recent years.

Rapid industrial growth in the sectors like defense, healthcare, automobile, aerospace, etc. has been accelerating the prominence of 3D printing in the country. California, in particular, has emerged as a hub for 3D printing companies. Numerous 3D printing projects, like The world’s first 3D-printed zero net energy homes community are being built in California. Seeing the plethora of growth opportunities, it’s a no-brainer that numerous 3D printing companies are emerging in California.

Here is the list of the Top 10 3D printing companies in California that are leading the market with their cutting-edge products and services.

1.

Mighty BuildingsMighty Buildings is an Oakland-based company that recently made headlines for building the world’s first 3D-printed zero net energy homes community. It is a revolutionary housing solution of the future that is not only hoping to tackle housing affordability but is also taking into account sustainable and safe living. Mighty Buildings is the world’s first 3D printing company to receive approval under California’s Factory Built Housing program for a residential unit incorporating 3D printing. For its exemplary offerings, the company was recently published in Mirror Review’s “The 10 Compelling 3D Printing Companies, 2021”.

It is a revolutionary housing solution of the future that is not only hoping to tackle housing affordability but is also taking into account sustainable and safe living. Mighty Buildings is the world’s first 3D printing company to receive approval under California’s Factory Built Housing program for a residential unit incorporating 3D printing. For its exemplary offerings, the company was recently published in Mirror Review’s “The 10 Compelling 3D Printing Companies, 2021”.

2.

Velo 3DHeadquartered in Campbell, California, Velo 3D is one of the best 3D printing companies in the region. The company specializes in providing end-to-end metal 3D printing solutions for important parts used in space exploration. These solutions aid in boosting transportation efficiency and producing cleaner energy. The solutions are used by innovators in supersonic and hypersonic flight, space travel, advanced power production, and renewable energy. Velo3D empowers innovators to imagine and build the technologies for the future.

Velo3D empowers innovators to imagine and build the technologies for the future.

3.

MantleMantle is a 3D printing company committed to bringing high-volume products to life faster, cheaper, and more easily than ever before. The San-Francisco-based company aims to change the face of manufacturing by enabling new levels of speed and productivity. Mantle’s patented Trueshape technology produces precision metal parts with accurate dimensional tolerances and a sleek surface finish. The parts manufactured by this technology do not require any post-processing, which makes the process less time-consuming.

4.

ArevoArevo develops technology to enable the direct digital additive manufacturing of lightweight and strong composite parts for end-use applications. Moving beyond prototypes, Arevo is enabling the design and fabrication of large, mass-produced parts. The company provides designers and manufacturers with the freedom to leverage the immense potential of composite materials for a plethora of industrial and consumer products. Focusing on sectors like defense, aerospace, transportation, consumer electronics, etc., Arevo is optimizing additive manufacturing solutions for Original Equipment manufacturers around the world.

Focusing on sectors like defense, aerospace, transportation, consumer electronics, etc., Arevo is optimizing additive manufacturing solutions for Original Equipment manufacturers around the world.

5.

Fabric8 LabsFabric8 Labs is transforming the additive manufacturing of metals with its cutting-edge technologies. Based in San Diego, the company is leveraging advanced manufacturing to commercialize breakthroughs in material processing and material science. Its technology helps in lowering manufacturing costs and supports the increasing improvements in manufacturing capabilities and material quality. Fabric8 Labs is working to expand the opportunities for metal 3D printing across the market.

6.

3D Accuracy3D Accuracy provides in-house 3D design and 3D printing services to aid its clients in launching their products quickly and affordably. Regardless of the number of parts required, the company is committed to getting the parts manufactured rapidly. The Riverside, California-based company leverages its 30 years of experience to assist its clients in realizing their market share and profitability goals. 3D Accuracy aims to streamline the transition from low-volume to high-volume production quantities.

The Riverside, California-based company leverages its 30 years of experience to assist its clients in realizing their market share and profitability goals. 3D Accuracy aims to streamline the transition from low-volume to high-volume production quantities.

7.

3D Grounds3D Grounds is one of the leading 3D printing companies in California that provides top-notch 3D scanning and 3D printing services. Its studio provides high-definition full-body, head, and object scanning for digital purposes. Moreover, the company provides high-resolution 3D prints out of ABS-like plastic and Sand Stone materials. 3D Grounds has been working with premier clients like Autodesk, Redgate, Turo, Qualcomm, Sony Music, VMware, etc.

8.

3D Printed MicroTECIncepted in 2017, 3D Printed MicroTEC is one of the market leaders for 3D printed microfluidics and packaging of 3D microsystems for industrial applications. The company leverages proprietary additive manufacturing technology to produce large volumes of highly-precise 3D structures. 3D Printed MicroTEC exclusively partners with MicroTEC Gesellschaft fuer Mikrotechnologie mbH—a German 3D printing company—to offer its distinguished services and solutions.

3D Printed MicroTEC exclusively partners with MicroTEC Gesellschaft fuer Mikrotechnologie mbH—a German 3D printing company—to offer its distinguished services and solutions.

9.

Baked 3DBaked 3D produces durable prototypes and end-use production parts by additive manufacturing or 3D printing services. The company specializes in printing 3D parts or functioning prototypes with high detail and durability. Baker3D profusely invests in the clients’ innovative ideas and has leveraged its experience to make great innovations in production. While carrying out the production process, the company takes into consideration various factors like quality, speed, functionality, etc.

10.

CarbonCarbon is a leading 3D printing company that helps businesses develop better products and bring them to market in less time. Headquartered in Redwood City, California, Carbon is a venture-backed company that has its clientele in 17 countries around the world. The company’s “The Carbon Digital Light Synthesis” process enables the development of functional prototypes and end-use parts on a single machine.

The company’s “The Carbon Digital Light Synthesis” process enables the development of functional prototypes and end-use parts on a single machine.

To know more about 3D printing companies, please check out our magazine issue, “The 10 Compelling 3D Printing Companies, 2021”.

The Masters Movement, IP Litigation and Law Reform

October 2019

Author: ), Brisbane, Australia

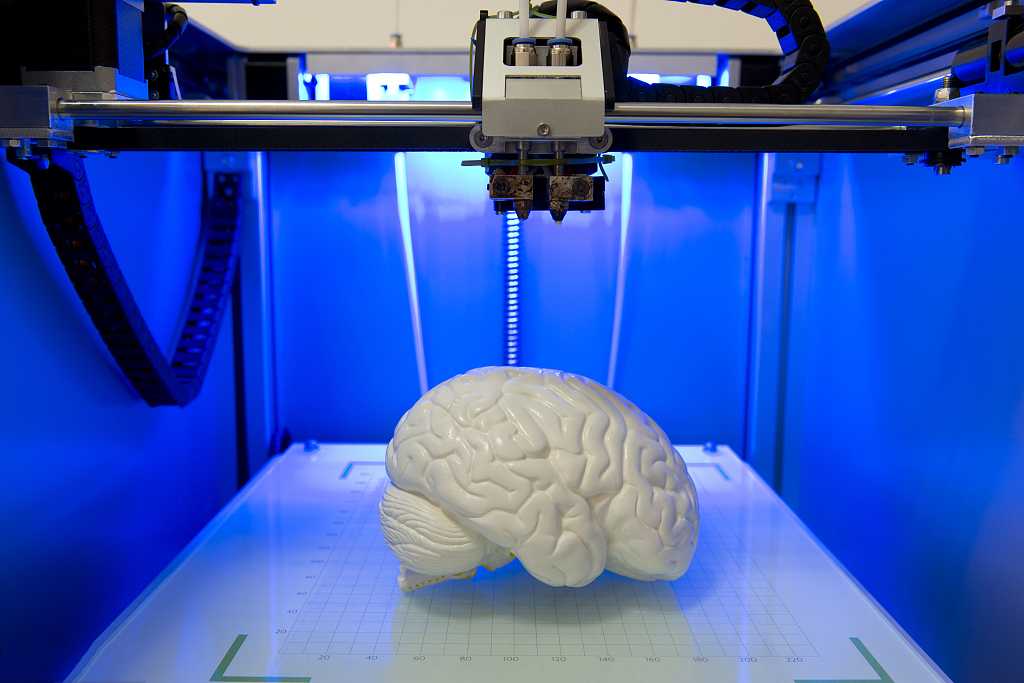

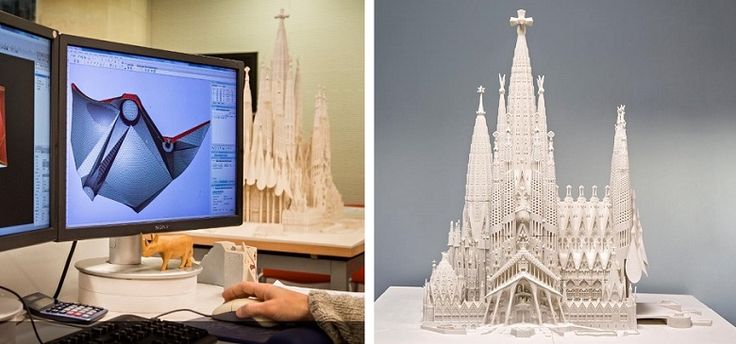

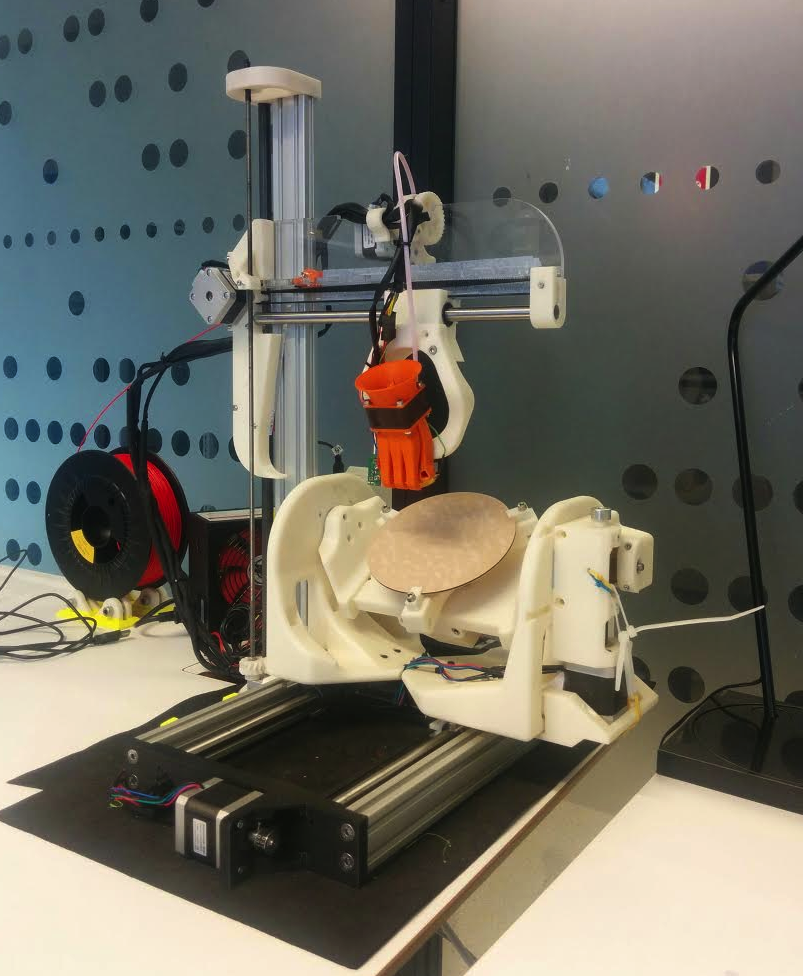

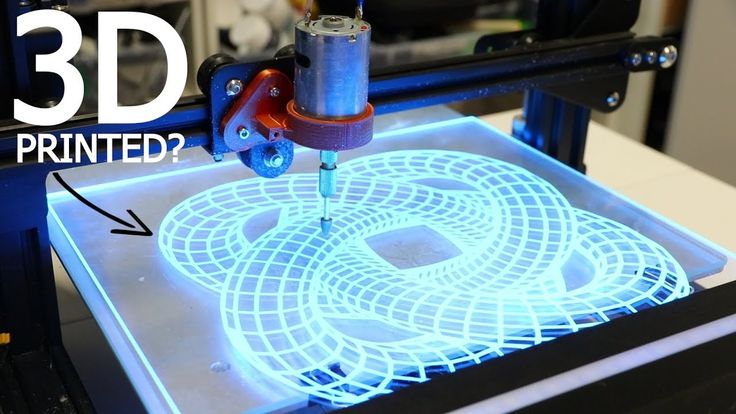

3D printing is an industry based on the principle of additive manufacturing (as opposed to the subtractive manufacturing principle that underlies the traditional manufacturing industry). 3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them. nine0003 Currently, the development of 3D printing is in a transitional phase. While the consumer “3D printing revolution” has failed, other varieties and categories of 3D printing have seen growth. (Photo courtesy of Queensland University of Technology)

(Photo courtesy of Queensland University of Technology)

3D printing is currently in transition. The consumer "3D printing revolution", which aimed to have a 3D printer in every home, has failed. MakerBot, a pioneer in 3D printing, is having trouble with its changing approach to intellectual property (IP) issues, disrupting its ties to the open source software community, and the user audience turned away from it. As former MakerBot CEO Bre Pettis said in an interview, "The open source community has kicked us out of their paradise." As a result, MakerBot was acquired by Stratasys, a leader in the 3D printing industry, which restructured and repurposed it. nine0003

Some other key players also went bankrupt. In particular, TechShop, a membership-funded and open-to-all network of studio-workshops for home craftsmen, went bankrupt. Maker Media, which publishes Make magazine and hosts craft festivals in the United States, has gone under external control. Make magazine founder Dale Doherty is trying to revitalize his project with a new structure he created called Make Community LLC. nine0003

nine0003

Industrial 3D printing continues to grow

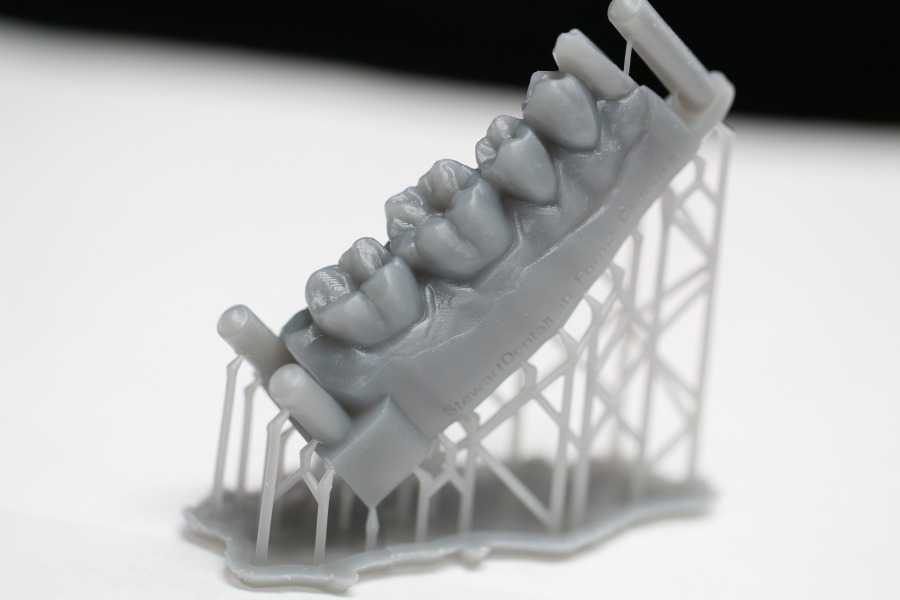

Although personal 3D printing has not developed as expected, there has been growth in a number of other forms and categories of 3D printing. Along with robotics and big data, 3D printing has become one of the promising technologies in the manufacturing industry. Companies specializing in information technology and design are working to improve the way 3D printing is used. Significant investments, especially from transport companies, have been attracted by the technology of 3D printing of metal products. In addition, there have been large-scale experiments related to the application of 3D printing in the healthcare sector, including 3D printing in dentistry, 3D printing in medicine, and bioprinting. nine0003

As technology improves and develops, there have been several cases of lawsuits being filed in the courts, as well as certain political developments regarding the regulation of the 3D printing industry. Our recently published book 3D Printing and Beyond explores some of the major developments in IC and 3D printing. In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing. nine0003

In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing. nine0003

3D printing and copyright law

A few years ago, there was a panic that the widespread use of 3D printing would lead to a wave of large-scale infringements of authors' rights, similar to the situation that arose with the advent of the Napster file-sharing network . Although such fears have not yet materialized, there have been various conflicts related to copyright and 3D printing. For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist. nine0003 “There have been large-scale experiments with 3D printing applications in healthcare, including 3D printing in dentistry, 3D printing in medicine, and bioprinting,” says Rimmer. (Photo credit: Stratasys)

United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist. nine0003 “There have been large-scale experiments with 3D printing applications in healthcare, including 3D printing in dentistry, 3D printing in medicine, and bioprinting,” says Rimmer. (Photo credit: Stratasys)

3D printing was also subject to the on-demand removal of content under the Digital Millennium Copyright Act (USA). Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries. nine0003

In addition, discussions took place on issues related to the use of technical protection measures in the context of copyright law and 3D printing. For example, the US Copyright Office has confirmed a limited technical protection exception for 3D printing stocks.

For example, the US Copyright Office has confirmed a limited technical protection exception for 3D printing stocks.

3D printing and design law

Developments in 3D printing have also raised the issue of product repair rights. nine0003

Efforts have been made across the European Union to recognize the right to repair in order to support consumer rights and develop a circular economy. In this regard, one of the important factors in achieving changes in the behavior of companies and consumers has become the European Greening Directive (Directive 2009/125/EC).

In July 2019, the United States Federal Trade Commission held a Hearing on "Can't be Repaired: A Workshop on Product Repair Restrictions." Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States. nine0003

nine0003

Significant and first-of-its-kind litigation in Australia regarding right to repair under Design Law ( GM Global Technology Operations LLC v S . . - S - Auto Parts Pty Ltd [2019] FCA 97). The Australian Treasury is considering policy options regarding the practice of sharing vehicle repair information. nine0003

Australian Capital Territory (ACT) Consumer Affairs Minister Shane Rettenbury called for recognition of the right to repair from the rostrum of the Consumer Affairs Forum, which includes ministers from both Australia and New Zealand. Federal Minister Michael Succar asked the Australian Productivity Commission to look into the matter.

Calls for right-to-repair laws, both at the provincial and federal levels, are also being heard in Canada. As Laura Tribe, Executive Director of Open Media, noted in this regard, “We are committed to ensuring that people have the opportunity to be the real owners of the products they own. ” nine0003

” nine0003

3D printing and trademark law

3D printing also brings uncertainty to trademark law and related legal regimes, including product substitution, identity rights, commercial use of characters, and trade dress. The legal conflict surrounding Katy Perry's trademark application for the "shark on the left" image provides some insight into some of the issues that arise in this regard. nine0003

Regarding bioprinting, Advanced Solutions Life Sciences sued Biobots Inc. Due to the alleged violation of its trademark rights ( Advanced Solutions Life Sciences , LLC V BIOBIOTS Inc 15 May 201111111111111. Advanced Solutions Life Sciences owns and uses the registered trademark Bioassemblybot for 3D bioprinting and tissue growth. nine0003

3D Printing and Patent Law

According to the 2015 WIPO Global Intellectual Property Report, Revolutionary Innovation and Economic Growth, 3D printing patent applications are on the rise. Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry. nine0003

Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry. nine0003

With the growing commercial importance of 3D printing in the manufacturing industry, there have been a significant number of litigations related to 3D printing of metal products. In July 2018, as part of the “Desktop Metal Inc.” v. Markforged, Inc. and Matiu Parangi (2018 Case No. 1:18-CV-10524), a federal jury found that Markforged Inc. did not infringe two patents owned by rival Desktop Metal Inc. (See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. . ” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs." For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs." For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

In 2018 (after the above verdict) Desktop Metal Inc. and Markforged Inc. entered into a confidential financial agreement that settled all other litigation between them. However, in 2019 Markforged Inc. filed another lawsuit against Desktop Metal Inc. due to the fact that, according to her, the latter violated that part of the agreement, which concerned non-disclosure of negative information.

3D printing and trade secrets

In addition, the first litigation regarding 3D printing and trade secret legislation took place. In 2016, Florida-based 3D printing startup Magic Leap filed a lawsuit in federal court for the Northern District of California against two of its former employees for misappropriation of trade secret information within the meaning of Trade Secret Protection Act (“ Magic Leap Inc ." v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

In 2016, Florida-based 3D printing startup Magic Leap filed a lawsuit in federal court for the Northern District of California against two of its former employees for misappropriation of trade secret information within the meaning of Trade Secret Protection Act (“ Magic Leap Inc ." v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

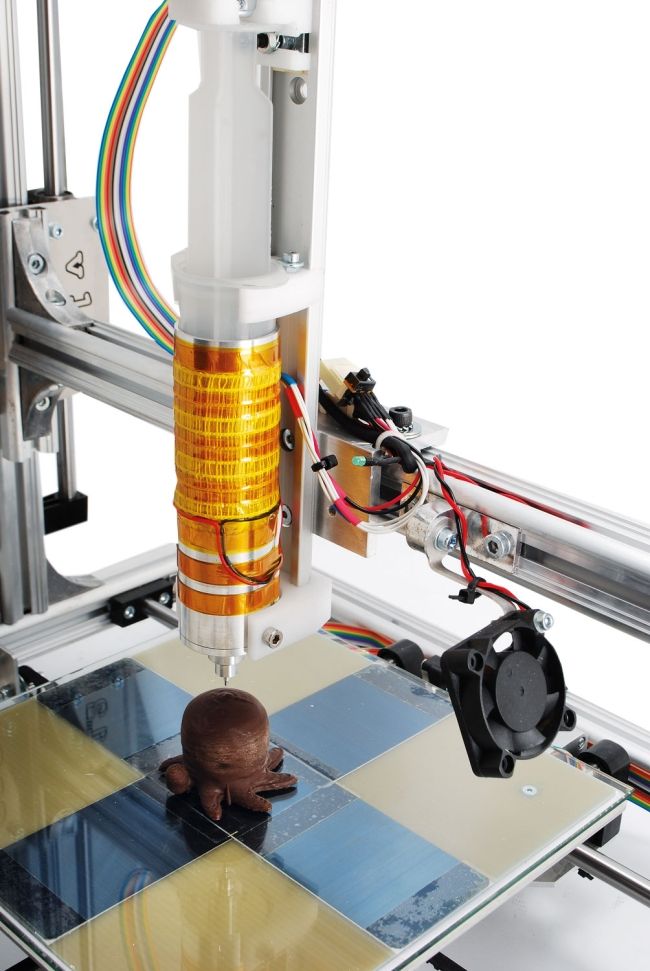

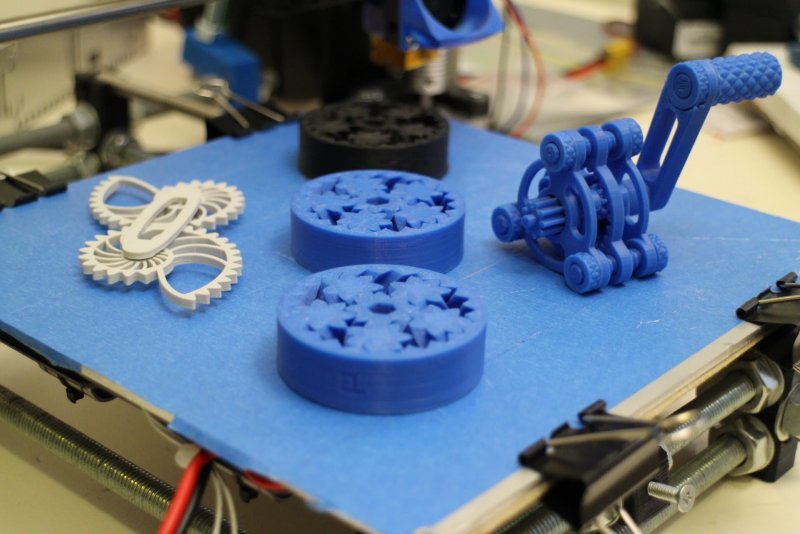

(Photo courtesy of Stratasys)

(Photo courtesy of Stratasys) 3D printing and open licensing

In addition to proprietary IP protections, 3D printing has a widespread practice of open licensing. Companies with a free distribution philosophy include Prusa Research (Czech Republic), Shapeways (Netherlands-US) and Ultimaker (Netherlands). Members of the Craft Movement used open licensing mechanisms to share and distribute 3D printing files. As noted in The State of the Commons 2017, the Thingiverse platform was one of the most popular platforms using Creative Commons licenses. nine0003

Other issues arising from the development of 3D printing

In addition to IP issues, the development of 3D printing also raises a number of other legal, ethical and regulatory issues. In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing. nine0003

The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing. nine0003

Litigation regarding 3D printing of firearms is also ongoing in the United States. Several state attorneys general have sued the current administration to obstruct an agreement between the federal government and Defense Distributed. Several criminal cases have been filed in Australia, the United Kingdom, the United States and Japan in connection with attempts to 3D print firearms. Legislators are debating the feasibility of criminalizing crimes related to possession of digital blueprints for 3D printed firearms. nine0003

Footnotes

* Dr. Matthew Rimmer is Head of the KTU Research Program on Intellectual Property Law and Innovation and is involved in the KTU Research Center for Electronic Media, the KTU Australian Health Law Research Center and the KTU Research Program in International Law and global governance. In addition, he is a Senior Research Fellow at the Australian IP and 3D Printing Research Council Innovation Project. Dr. Rimmer is the author of numerous publications on copyright and information technology, patent law and biotechnology, access to medicines, anonymous packaging of tobacco products, IP and climate change, and IP of indigenous peoples. His current research interests include IP, Creative Industries and 3D Printing; IP and Public Health; and IP and Trade, including the Trans-Pacific Partnership, the Transatlantic Trade and Investment Partnership and the Agreement on Trade in Services. His work is held in the SSRN Abstracts and Bepress Selected Works archives and funded by the Australian Research Council. nine0012

Dr. Rimmer is the author of numerous publications on copyright and information technology, patent law and biotechnology, access to medicines, anonymous packaging of tobacco products, IP and climate change, and IP of indigenous peoples. His current research interests include IP, Creative Industries and 3D Printing; IP and Public Health; and IP and Trade, including the Trans-Pacific Partnership, the Transatlantic Trade and Investment Partnership and the Agreement on Trade in Services. His work is held in the SSRN Abstracts and Bepress Selected Works archives and funded by the Australian Research Council. nine0012

Related Links

- Read more about 3D printing and IP Litigation

How are 3D printers changing the real estate market right now?

LonGrad

Your next home can be printed

Several new homes across California are selling unusually fast. In the last two months, 82 houses have been sold out, and another 1,000 are on the waiting list. However, the wait doesn't have to be long: while a typical brick home can take weeks to build, Palari Homes and Mighty Buildings can build one in less than 24 hours. This is due to the fact that their objects are assembled from pre-assembled components at the factory. The idea itself is not new, but in this case the components are obtained in an unusual way: they are printed. nine0155

However, the wait doesn't have to be long: while a typical brick home can take weeks to build, Palari Homes and Mighty Buildings can build one in less than 24 hours. This is due to the fact that their objects are assembled from pre-assembled components at the factory. The idea itself is not new, but in this case the components are obtained in an unusual way: they are printed. nine0155

Plan of a five-acre 3D printed neighborhood in Rancho Mirage, California.

3D printing has been around since the early 1980s but is now gaining momentum. It is already being used to make everything from orthopedic implants to aircraft components.

Details vary between products and processes, but the basic principle remains the same: a layer of material is laid and fixed, another one is placed on top of it, and then another and another. By changing the shape and sometimes the composition of each layer, it is possible to create objects that would be difficult or impossible to make with more traditional methods. In addition, unlike traditional manufacturing processes, there is no waste of materials. nine0003

In addition, unlike traditional manufacturing processes, there is no waste of materials. nine0003

3D printing houses is the greenest way to build

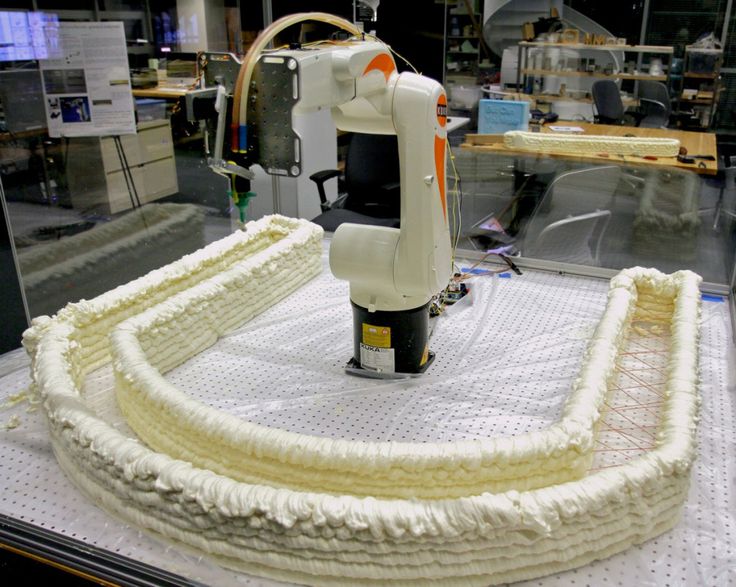

In the case of Palari Homes and Mighty Buildings, the printers are much larger than those required for artificial knees and airplane wings, and the materials are somewhat rougher. But the principle remains the same. The nozzles extrude a paste (in this case, composite), which then hardens under the influence of ultraviolet light. This allows Mighty Buildings to print details such as cornices and ceilings without the use of reference forms - as well as simpler things like walls. They are then assembled on site and attached to a permanent foundation by the builders of Palari Homes. nine0003

Not only does 3D printing provide versatility and faster construction, it also promises a lower cost and more sustainable approach than traditional construction methods currently offer. This could be the answer to two of the problems the world is currently facing: housing shortages and climate change. About 1.6 billion people - more than 20% of the world's population - do not have adequate housing. And the construction industry accounts for 11% of global anthropogenic carbon dioxide emissions. At the same time, the industry does not show success in reducing its carbon footprint. nine0003

This could be the answer to two of the problems the world is currently facing: housing shortages and climate change. About 1.6 billion people - more than 20% of the world's population - do not have adequate housing. And the construction industry accounts for 11% of global anthropogenic carbon dioxide emissions. At the same time, the industry does not show success in reducing its carbon footprint. nine0003

Automation brings huge cost savings. Mighty Buildings says computerizing 80% of the printing process means the firm only needs 5% of the workforce it would otherwise have. It also doubles the rate of production. This is good news for the construction industry, which has struggled for years to increase its productivity. According to the McKinsey consulting firm, over the past two decades, the industry has grown by only a third of the overall level of productivity in the global economy as a whole. Digitization is slower than almost any other industry. In many places, the industry also suffers from a shortage of skilled labor. And it is expected that the situation will not improve further. In America, for example, about 40% of construction workers are expected to retire within the next decade. nine0155

And it is expected that the situation will not improve further. In America, for example, about 40% of construction workers are expected to retire within the next decade. nine0155

3D printer at Mighty Buildings headquarters.

The environmental benefits come in many ways, but the important thing is that you don't have to move a lot of heavy objects. For example, Palari Homes estimates that assembling its products reduces the number of truck rides needed to build a home by as much as two tons of carbon dioxide emissions per home are reduced.

Palari Homes and Mighty Buildings are not alone in their endeavors: similar projects are being launched everywhere. The vast majority of structures are printed using concrete. 14Trees, a joint venture between Holcim (the world's largest cement producer) and CDC Group, the UK government's development finance organization, operates in Malawi. Its representatives claim that it is possible to print a house in just 12 hours for less than $10,000. 14Trees notes that this process is not only cheap and fast, but also environmentally friendly. Holcim says that by applying the exact amount of cement needed and thus reducing waste, 3D printing generates only 30% of the carbon dioxide produced by fired clay bricks. nine0003

14Trees notes that this process is not only cheap and fast, but also environmentally friendly. Holcim says that by applying the exact amount of cement needed and thus reducing waste, 3D printing generates only 30% of the carbon dioxide produced by fired clay bricks. nine0003

Meanwhile, in Mexico, the homeless charity New Story partnered with 3D printing firm ICON to build ten 46-square-meter houses. Each of these houses was printed in about 24 hours (although those hours were spread over several days), with the final elements collected by Échale, another local charity. In Europe, the first 3D-printed house on the continent was built in Eindhoven, the Netherlands - the keys to it were handed over to tenants on July 30. nine0155

First 3D printed house in Europe. Based in Eindhoven, The Netherlands.

Layer cake

The house in question, the first of five detached two-bedroom houses in a project coordinated by the Eindhoven municipal government and the City University of Technology, is the result of a collaboration between several firms. The Dutch division of the French building materials company Saint-Gobain developed the required concrete mortar. Construction firm Van Wijnen erected the structure, while consultant Witteveen + Bos was in charge of the design. The building is leased by its owner Vesteda, a Dutch residential property investor. nine0155

The Dutch division of the French building materials company Saint-Gobain developed the required concrete mortar. Construction firm Van Wijnen erected the structure, while consultant Witteveen + Bos was in charge of the design. The building is leased by its owner Vesteda, a Dutch residential property investor. nine0155

3D printed house project in Eindhoven, The Netherlands

However, using cement in these projects is not an environmentally friendly process. It converts calcium carbonate in the form of limestone to calcium oxide and carbon dioxide, and this process is believed to account for about 8% of anthropogenic emissions of this gas. So a group at Texas A&M University, led by Sarbajit Banerjee, developed a way to do without cement.

Dr. Banerjee's new building material was inspired by a project he initiated years ago. It was a program to build access roads to remote areas of the Canadian province of Alberta using materials at hand. The crushed stone he invented combined local soil with wood fiber mulch and was held together with liquid or water-soluble silicates, which then hardened and acted like cement. To build houses, he uses clay and stone debris that lie under the top layer of soil near the construction site, grinds them into powder and mixes with silicates. The resulting mixture can be squeezed out through a nozzle, after which it will quickly harden and gain strength to maintain its shape and withstand the weight of the next layer. This makes the process doubly "green": it eliminates both the cement and the need to transport to the construction site, often over long distances, the sand and aggregates used in conventional concrete. nine0155

The crushed stone he invented combined local soil with wood fiber mulch and was held together with liquid or water-soluble silicates, which then hardened and acted like cement. To build houses, he uses clay and stone debris that lie under the top layer of soil near the construction site, grinds them into powder and mixes with silicates. The resulting mixture can be squeezed out through a nozzle, after which it will quickly harden and gain strength to maintain its shape and withstand the weight of the next layer. This makes the process doubly "green": it eliminates both the cement and the need to transport to the construction site, often over long distances, the sand and aggregates used in conventional concrete. nine0155

Benefits of cement

There are limits to building 3D printed houses. To begin with, it is necessary to create a legislative framework for the construction of such houses. To this end, UL, one of America's largest certification agencies, collaborated with Mighty Buildings to develop the first 3D printing standard. Its principles will be incorporated into the new International Housing Code, which is in use or has been adopted by every US state except Wisconsin. While this is a welcome move for a young industry, most governments have yet to develop country-specific standards. There are also questions about the quality and finish of houses built on 3D printers. nine0003

Its principles will be incorporated into the new International Housing Code, which is in use or has been adopted by every US state except Wisconsin. While this is a welcome move for a young industry, most governments have yet to develop country-specific standards. There are also questions about the quality and finish of houses built on 3D printers. nine0003

Nevertheless, the prospects look promising. Last year, Germany approved plans to 3D print an apartment building. The three-story structure of the German construction company Peri is assembled from parts made using printers developed by the Danish company Cobod. This building will have five apartments. The use of the technology is also expanding in the Middle East and Asia. The Dubai government wants a quarter of the country's new buildings to be 3D printed by 2030 and is dedicating an entire area on the outskirts of the capital to house 3D printing companies and their warehouses. Saudi Arabia plans to use 3D printing to build 1. 5 million homes over the next decade. India's Ministry of Housing and Urban Development wants to use 3D printing to solve the country's housing shortage. nine0003

5 million homes over the next decade. India's Ministry of Housing and Urban Development wants to use 3D printing to solve the country's housing shortage. nine0003

If successful, 3D printed construction could expand beyond the residential sector: warehouses, offices and other commercial buildings have good prospects. The US space agency NASA is exploring the use of 3D printing to build landing sites, living quarters and roads on Mars and the Moon. There is no soil on these two celestial bodies, only crushed rock called regolith. Dr. Banerjee's group, which works with NASA, says their 3D printing approach also works well with this material. “Ultimately we would like to have real estate on Mars and the Moon, but we won't be able to carry concrete with us there,” says Dr. Banerjee. "We'll have to work with the regolith." nine0155

If you are interested in options for alternative construction methods in order to increase the return on investment, then contact us! Longrad has been actively working with developers who build prefabricated houses for several years.

Learn more