3D printing service richmond va

3D Printing Service for Richmond, Virginia

CapabilitiesCustom Online 3D Printing ServiceVirginiaRichmond

High Quality Richmond, Virginia 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Richmond, Virginia 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

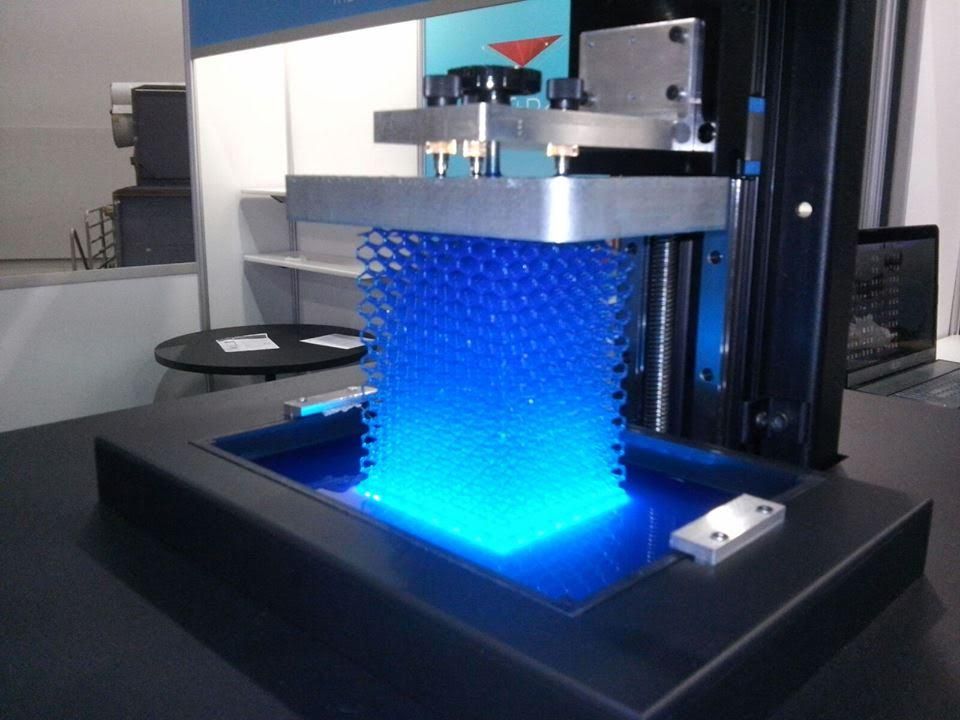

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Richmond, Virginia

Newport News

VirginiaCharlottesville

VirginiaNorfolk

VirginiaChesapeake

VirginiaAlexandria

VirginiaArlington

VirginiaVirginia Beach

VirginiaBethesda

MarylandSilver Spring

MarylandCollege Park

MarylandAnnapolis

MarylandBaltimore

MarylandDurham

North CarolinaRoanoke

VirginiaRaleigh

North CarolinaHagerstown

MarylandBlacksburg

VirginiaGreensboro

North CarolinaLancaster

PennsylvaniaWilmington

Delaware

Ready to start making custom 3D printed parts?

Home - 3D Print RVA

Celebrating 10 years in business!All meetings are by appointment only. We deal with a lot of confidential patent work and have client meetings on and off site

We deal with a lot of confidential patent work and have client meetings on and off site

Unfortunately, if you show up without an appointment, we won’t be able to see you.

SERVICES

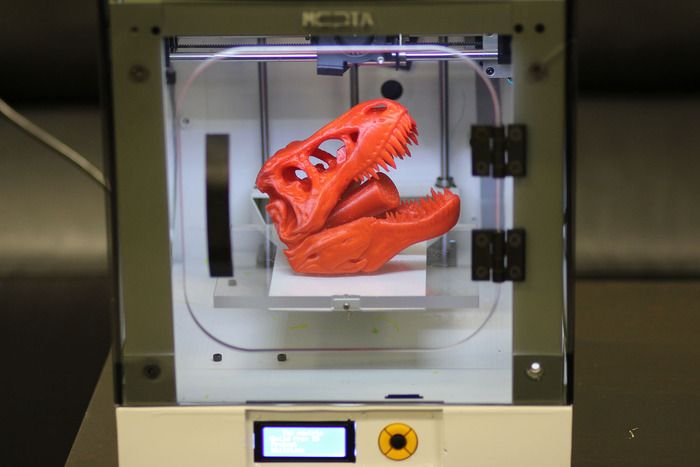

Since 2012, our primary focus has been prototyping new ideas, reverse engineering parts no longer being manufactured, and small scale manufacturing for businesses and residents. We can create 3D files for you, print your files on our industrial-grade 3d printers, scan tiny objects as small as jewelry, as large as cars, and people at high-resolution. We can also laser cut your project out of wood, acrylic, leather and other materials.

Concepts for prototypes, candy dispensers, cookie cutters, hard to find plastic replacement parts, replica movie props, toys, home decor, 3D puzzles, jewelry, and more! We can also convert most medical images to a 3D print.

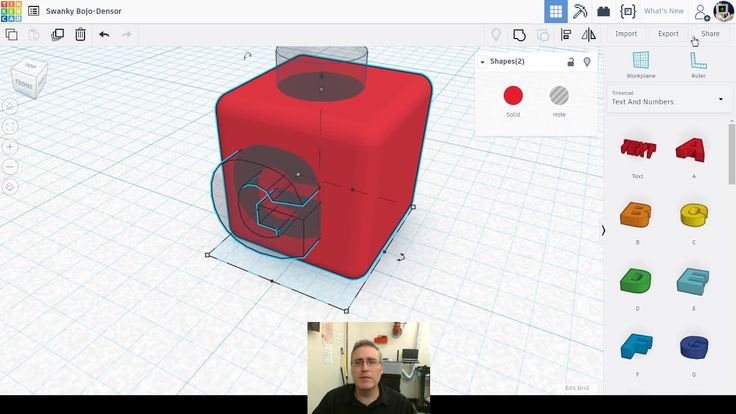

Computer-aided drafting (CAD) is the use of software to create, modify, analyze, or optimize a prototype or reverse engineered part. We charge $75/hour for CAD work.

We charge $75/hour for CAD work.

A 3D scanner is a device that collects data on an object’s shape and dimensions as a mesh file. With our high-resolution scanning equipment, we can scan objects as large as a house down to an object smaller than gaming miniatures. We also offer reverse engineering services which is used to convert a 3d scan into an editable CAD file. Read More

Our CO2 laser can cut and engrave, wood, acrylic, leather, paper, cardboard and more! We can also engrave or mark glass, tile and some metals. Our MOPA Fiber laser can engrave and mark most metals and mark in color on Titanium and Stainless Steel.

A waterjet uses water and an abrasive material to cut material with computer controlled precision. Materials cut include aluminum, steel, copper, glass, carbon fiber, and tile up to a half inch thick. Maximum size we can cut is 19″ x 13″

Vacuum Forming creates a form or mold from an object from a plastic sheet. The molds are food safe, so it’s a great way to make custom shaped edible treats as well as plaster molds. Maximum object size we can vacuum form is 6″ x 6″ x 6″.

Maximum object size we can vacuum form is 6″ x 6″ x 6″.

We can produce high-detailed 3d printed molds for injection molding! These molds can withstand temperatures necessary for LDPE, PP, TPE, PLA, ABS, HDPE, EVA and PS plastics. Max size of mold block is: 5.7″ x 5.7″ x 6.875″. Prices start at $500. Contact us for more details and design parameters.

Vacuum formed molds are a great for food items, silicone, plastics, plaster, wax, even concrete. Max. size of object to be molded is 6″ X 6″ X 4″.

We can produce high-detailed 3d printed molds for casting or print fine details in wax for lost wax casting. Max size of mold block is: 5.7″ x 5.7″ x 6.875″. Contact us for more details and design parameters.

OUR 3D PRINTING SERVICE FEATURES

We keep many colors in stock (see the colors section below for our many in-stock color options) but can special order other colors. Premium colors are more expensive and vary in price depending on pigments used.

The largest single part we can 3D print in plastic is 12″ X 12″ X 24″ (305mm X 305mm X 610mm). In resin, the largest we can 3D print is 5.7″ long x 5.7″ wide x 7.3″ high (145mm x 145mm x 185mm). For larger objects, we can 3D print in pieces and fuse the pieces together after printing is completed.

In resin, the largest we can 3D print is 5.7″ long x 5.7″ wide x 7.3″ high (145mm x 145mm x 185mm). For larger objects, we can 3D print in pieces and fuse the pieces together after printing is completed.

We can print any layer height between 0.05 mm and 0.64 mm in plastic filament and down to 0.025 mm in resin. (For reference, the width of a human hair is between 0.08 & 0.12mm) The big difference between these resolutions is time, detail and smoothness. A 0.1mm print can take up 6 times longer than a 0.3mm print, therefore costing more.

TYPES OF MATERIALS

Below are just a few materials we can print with and there are new materials being introduced every week. Contact us if you have a special request and will will try to accommodate you. For more details on select material properties click here.

PLA is the ‘default’ material for many 3D prints, with good reason – 3D prints retain higher details and is biodegradable. The downside is this biodegradable material is not ideal for high-heat environments.

A modified version of PLA that can withstand much higher temperatures, (similar to ABS) but requires treatment to handle higher temperatures.

ABS (Acrylonitrile Butadiene Styrene) is the same stuff Legos are made of. Best used for making durable parts that need to withstand higher temperatures. ABS plastic can shrink slightly when cool, so compensation in the part design is necessary.

Nylon is an incredibly strong, durable, and versatile 3D printing material. Flexible when thin, but with very high inter-layer adhesion, nylon lends itself well to things like living hinges and other functional parts.

PET (Polyethylene terephthalate) is an industrial-strength filament. It’s FDA approved for food containers and tools used for food consumption. PET is known for its clarity.

Thermoplastic Elastomer is a flexible material which feels and acts much like rubber. Used to make parts that can bend or must flex to fit their environment – stoppers, belts, springs, phone cases and more.

316L stainless steel, also known as A4 or marine grade stainless steel. These prints have a longer lead time as all prints need go through additional steps to produce the final part. Please contact us before designing your part so we can discuss limitations and workarounds.

A material that gives parts the look and feel of grey stone while retaining the resiliency of plastic, making it ideal for landscape and architectural designs. Anything made with this material can be painted and sanded. Texture options are smooth to a porous sandstone texture.

Bamboo, Coconut, pine and other wood fibers infused into PLA that gives 3D printed objects the look and feel of fiberboard. It also retains other wood-like attributes, such as the ability be cut, sanded and stained or painted.

Conductive Filament is a modified version of ABS filament and has a resistance of 1200 ohm/cm.

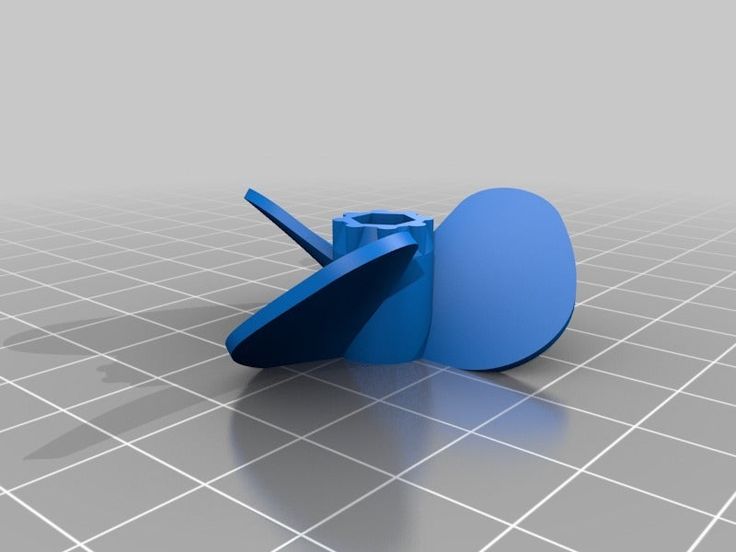

Carbon Fiber filament provides increased rigidity, therefore increased structural support built right in. It’s perfect for items that should not bend, such as: frames, supports, propellers, and tools. preferred by drone builders and RC Hobbyists.

It’s perfect for items that should not bend, such as: frames, supports, propellers, and tools. preferred by drone builders and RC Hobbyists.

Bronze, brass, copper, steel, iron and aluminum fibers are blended with PLA filament. 3D prints are heavier. Can be polished, tarnished or aged. Unpolished, the 3D print looks like cast metal. Ideal for printing jewlery, props, costumes, figurines.

This filament is best characterized as felt-like and is highly porous. This material is made from a rubber-elastomeric polymer. Is ideal for making filters, 3D membranes, and semipermeable membranes.

Polycarbonate (PC) is strong and very resistant to impact (used in bullet proof glass). Extremely tough, durable temperature resistant. This material is malleable while cold and bends without cracking.

Use MoldLay filament to 3D print objects that you want to make a mold of OR investment cast. Moldlay will easily melt out of negative impressions with very little residue. It is structurally sound with zero warping.

Polyetheretherketone offers offer the highest chemical resistance of any semi-crystalline plastic with excellent retention of mechanical properties up to 570°F (300°C). PEEK offers a combination of superlative properties that allows it to replace metal in some of the most severe end-use environments.

Ultem is a family of PEI products used in medical and chemical instrumentation due to their heat resistance, solvent resistance and flame resistance.

We can print other high temp, chemical resistant, and extreme strength plastics such as PSU, PEKK, PEI, PPSU, PPS, Nylons, CFPA6 and so much more!

A liquid that is hardened by focusing UV light in specific areas to create a desired shape. Extremely fine details up to 20 microns (0.02mm). Can be more durable than PLA and ABS. With proper post processing, the 3D print can be transparent.

Same as resin polymer, but a ceramic material version by Tethon 3D. 3D print can be painted, glazed and fired in a kiln, just like normal ceramics.

A resin polymer that is used for lost wax casting.

OTHER INFORMATION

We keep many colors in stock (see color options below of some in stock colors) but can special order other colors. Premium colors are slightly more expensive than the standard colors.

Please note: translucent filament is not transparent. It will allow light to pass through, like frosted glass or a lamp shade would. For transparency, your best option is a print in resin or to use a specialty filament such as PET.

We can currently 3D print any resolution between 0.05 mm and 0.3 mm in plastic filament (See photo for differences) and down to 0.02 mm in resin. (For reference, the width of a human hair is between 0.08 and 0.12mm) The big difference between these resolutions is time, detail and smoothness. a 0.1mm print can take up 6 times longer to print that a 0.3mm print, and uses more filament, therefore costing more. Even at 0.1mm, you can see and feel a fine texture in the object. Light sanding and some clean-up with a x-acto or utility knife may be necessary to achieve a perfectly smooth print for painting.

Light sanding and some clean-up with a x-acto or utility knife may be necessary to achieve a perfectly smooth print for painting.

Unlike the replicator in Star Trek, which produced an item in seconds, it can take anywhere between a couple of hours to a few days to print an object. Size, resolution, and how complicated a design is plays into the amount of time it takes to print.

The cost to print an object is determined by the amount of plastic used plus the amount of time to print. For our software to give an accurate printing estimate, We need

- a CAD-based or .STL file

- Resolution

- Durability

- Type of material you want the object printed in

- Color

WE CAN NOT GIVE YOU AN ACCURATE 3D PRINT ESTIMATE WITHOUT A CAD FILE, STL FILE, OR 3D SCAN OF YOUR ITEM. There are just too many variables to give you anything but a wide price range for a quote. If you do not have a digital file of your project, we can create one for you at a rate of $75/hour.

Due to operational costs, we have a minimum charge of $150.00. If your project is under $150, we can 3D print duplicates or 3D print additional items to give you $100 worth of printed product.

If you have a small project that you feel should be much less than $150.00, Richmond, Chesterfield, and Henrico public libraries offer 3d printing services at select locations for small projects. If you are outside of these areas, contact your public library to see if they offer 3d printing services.

If you are providing your own design file for 3D printing, we have compiled a few design recommendations. Click here for recommendations to help you create a file that should be cleaner, less troublesome for us and hopefully cheaper to print.

Contact us by email or call (804) 404-5380 for help, discuss your project or to arrange an appointment.

** Due to the sensitive nature of some projects all on-site client meetings are by appointment only.

**

**30 minute consultations are free. Any consultations over 30 minutes are charged in 15 minute increments at the rate of $75/hour.

Please be on time as we usually have meetings scheduled back-to back.

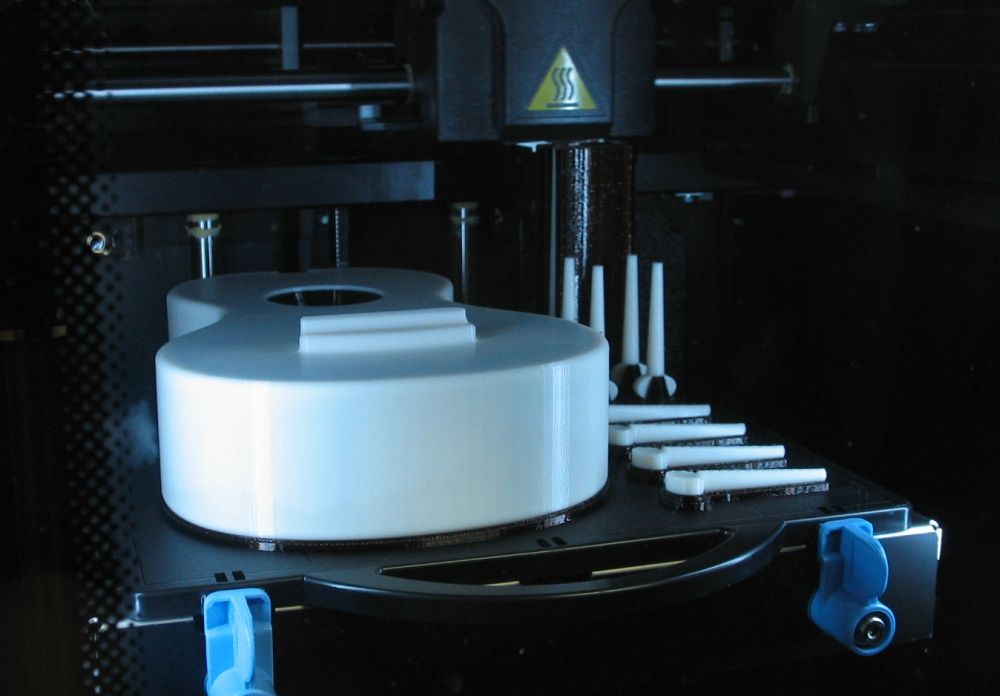

3D printing of Richmond rollers and wheels on Raise3D 3D printer

Richmond Wheels & Castor Co is a leader in the development of technical solutions for the elements of transportation. This includes: reinforced rollers, wheels, device components and other engineering work. Richmond manufactures products suitable for home use, offices and heavy industry.

Since 1961, the company has been manufacturing unloading and loading devices and today has 61 years of experience in the manufacturing industry in Australia, being the most popular manufacturer in the Australian market and the most sought after in the production of rims and pipeline rollers for the industry. Richmond is renowned for its quality, customized solutions and meets the needs of today's market. nine0003

nine0003

That is why this company has resorted to 3D printing, as it always strives for modern equipment and high production speed. Previously, production was established on milling and turning machines.

As a true expert in the development of polyurethane products and a recognized market leader in pipe roller bearings, 3D printing has been a natural progression for Richmond, who have always strived to be the first to innovate in their industry. Traditionally, the processing of products was carried out on CNC milling and turning machines. This includes polyurethane injection molds and final machining. nine0003

Why did you choose Raise3D?

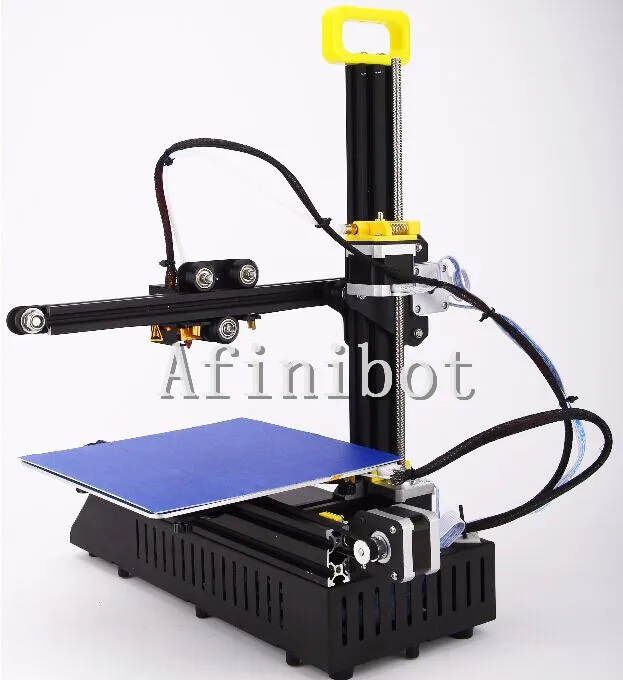

“Before introducing 3D printing, we attended seminars and trainings and were completely confused in the choice. After a huge amount of Internet research, we decided on the budget and the size of the print we needed. As a result, we got a high volume of printing at the best price and with excellent quality in Raise3D Pro2 Plus »

David Powell, QA Manager

Before purchasing 3D equipment, the company turned to experts from another company Bilby 3D with questions about the study of technology and the mechanical qualities of printing.

They investigated the temperature and pressure conditions faced by Richmond products, and based on the data obtained, they 3D printed a mold for Richmond Wheels, which was identical to the mold made by CNC milling, and then annealed the mold a mold with a diameter of about 30 cm for 11 hours at a temperature of 70 ° C. Then Richmond used a mold to cast a polyurethane wheel, which turned out to be a perfect shape. nine0003

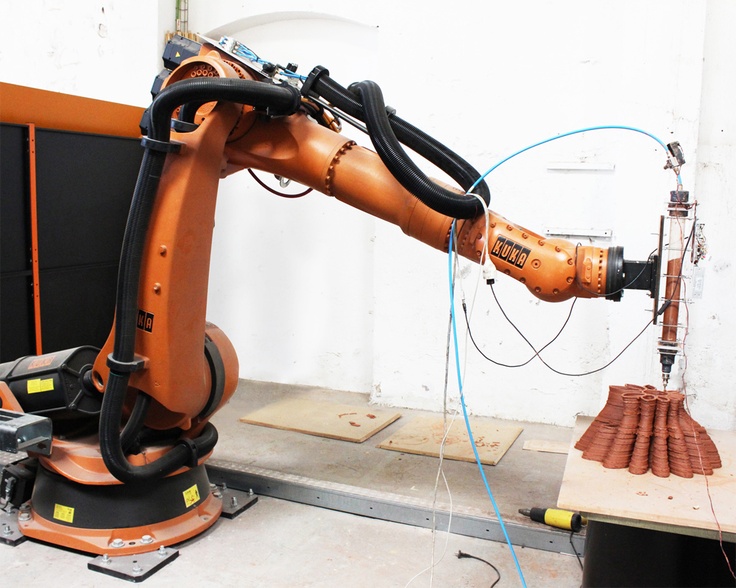

3D printing and custom fabrication on machines

Printing forms and CNC production take the same amount of time, but 3D printing allows you to reduce material consumption, production cost and the number of people involved in the workflow. Currently, Richmond is 3D printing a huge number of parts, such as:

- Rapid prototyping that promotes product promotion and final sale to customers. Creating a preliminary layout allows you to confirm the compliance of the forms with the requirements of the customer, then, based on the sample, a finished product with identical forms is produced.

This is a very useful and important stage for productive work. nine0035

This is a very useful and important stage for productive work. nine0035 - Manufacture of auxiliary tools, parts (small-scale production).

- Manufacture of polymer molds.

- Manufacture of CNC brackets, supports and screens, which are mainly supplied from abroad, thus reducing machine downtime. Also, their costs are significantly reduced.

“We have a lot of knowledge and 30 years of experience in the production and processing of products on traditional equipment. We realized that adapting to a new kind of manufacturing requires a new way of thinking, which brings great promise.” nine0014

David Powell, QA Manager

A very big plus for Richmond is that the range of materials suitable for printing on the Raise3D Pro2 Plus is huge, and a large selection helps to improve the production process.

Next on the agenda is research into carbon composites, which could open up new possibilities for printing. nine0003

nine0003

Join the vast international community of creative people who use Cliparto every day. to buy or sell images. nine0027 Or just buy individual images without registration.

| ◢ My Cliparto › Lightbox (0)

Do not remember your password / login? ◢ First time with us? Register ◢ Do you have an account at Vector-Images. | ||||||||||||||||

Images will be provided by Royalty-Free licenses . Our Terms of Service permit the use of images for a wide range of services, products and industries where images purchased through Cliparto will work for you.

Images will be provided by Royalty-Free licenses . Our Terms of Service permit the use of images for a wide range of services, products and industries where images purchased through Cliparto will work for you.  nine0003

nine0003