3D printing for the blind

3D printing for people who are blind or have low vision – overview

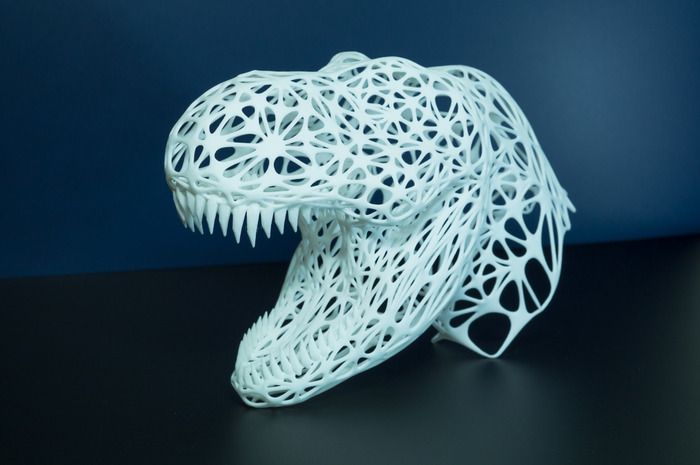

3D printers operate by printing one thin layer on top of another to create a 3-dimensional object. There are many types of printers and materials, but the most common and affordable use a heated nozzle to print with plastic.

Guidelines for 3D printing for touch readers

ANZAGG is in the process of creating guidelines for 3D printing for touch readers. This work is being done in collaboration with an ARC Linkage Project being led by Monash University to investigate 3D printing for access to graphics by people who are blind or have low vision.

The first nine sections of these guidelines are complete and available online here:

- When to use 3D printing for touch readers

- Where to find pre-existing 3D models for printing

- 3D printing design software

- 3D printing by people who are blind or have low vision

- Other methods for creating 3D models

- Labelling 3D models

- Finishing – Preparing 3D prints for touch readers

- Understanding 3D models through touch

- 3D printing on paper to create tactile graphics

ANZAGG 3D printing group

The Australia and New Zealand Accessible Graphics Group has a working group for professionals involved in 3D printing for touch readers in Australia and New Zealand. We meet monthly by Zoom and share resources, ideas and progress through Microsoft Teams. If you are interested in joining, please contact [email protected].

When to use 3D printed models

3D printed models have several advantages over other formats for accessible graphics provision:

- 3D models are often easier to understand than 2.5D tactile graphics

- 3D printed models can be cheaper or easier to obtain than other models

- 3D models can provide touch access to objects that are otherwise too small, too large, too dangerous, too precious or too rare to be touched

- 3D models can also be valuable for sighted peers in an integrated classroom setting

However, there are also some limitations to 3D printing that should be kept in mind:

- 3D printed models can take up to a day to print

- size is limited on most 3D printers

- labelling is difficult on 3D models, meaning that objects usually require accompanying explanations

Refer also to our more in-depth exploration of when to use 3D printing for touch access.

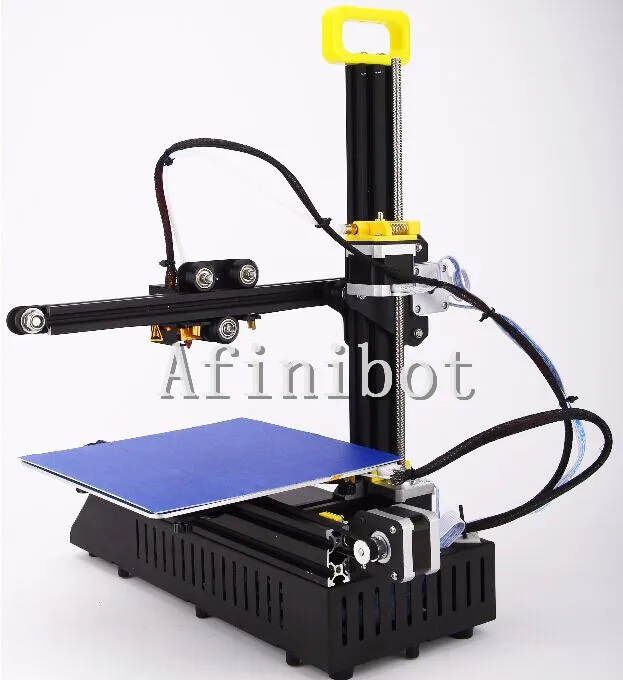

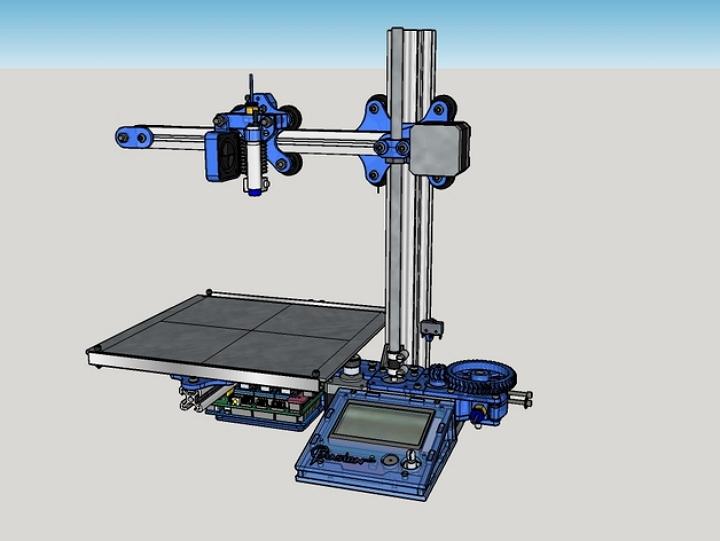

3D printers

3D printers are available for use in some universities, schools and public libraries. A moderate level of technical expertise is required to use and maintain a 3D printer.

We recommend FDM printers, which use plastic filament on a reel, as these are affordable and should meet most of your needs. A heated print bed is highly recommended for FDM printers to assist with adhesion. FDM printers can range in price from around $500 to $5000, depending on build size, output quality and ability to be modified.

3D printing services

There are many options for 3D printing if you do not have your own printer.

- CraftCloud provides quotes from a global network of providers.

- PrusaPrinters has a community website for 3D printer users around the world. It allows you to connect with individuals who can provide a print-on-demand service. Registration is required.

- NextSense are able to provide 3D prints for touch readers. They are a registered NDIS provider.

- See3D is a not-for-profit organisation providing volunteer 3D printing for touch readers. They are based in the US but can expand internationally.

- Some public libraries have 3D printers available for public use, charging by the hour. Check your local council website.

- Many schools have 3D printers. It may even be possible to request student designs.

Designing your own 3D models

Map of Melbourne’s CBD, created using Touch Mapper

Designing your own models for 3D printing can take anywhere from 5 minutes to a week, depending on complexity. Always look for a pre-existing model first!

Refer to our guidelines on 3D printing software for information on the different approaches to designing 3D models and what software to use.

A free braille font is available at http://www.thingiverse.com/thing:74358 and can be used to create custom text via free OpenSCAD software.

Some things to keep in mind when designing a 3D model:

- Vertical heights should usually be reduced so that fingers can easily reach the base of a model.

Around 5mm is sufficient for walls on a 3D floorplan.

Around 5mm is sufficient for walls on a 3D floorplan. - Pathways and gaps between objects should be large enough to allow exploration by the fingers. Around 5mm is a sufficient width for an indented road or pathway. A gap of at least 15mm is recommended for doorways.

- Braille prints much more smoothly on the side of objects.

- After printing, it is possible to add texture (for tactile distinction) or colour (for high contrast for people with low vision). Refer to our guidelines on finishing for suggested techniques.

3D map of a park, designed using Tinkercad

Further resources

- 3D printing for Education for students with a vision impairment, by DIAGRAM Center

Return to ANZAGG main page

With thanks to Monash University and the Australian Government Office for Learning and Teaching for assistance in development of this page.

Last updated: November 23, 2022 at 17:44 pm

3D model selection, design and printing by people who are blind or have low vision

Most 3D printing software and equipment has been designed without accessibility in mind. However, there are some options for people who are blind or have low vision and who want to print or create their own 3D models.

However, there are some options for people who are blind or have low vision and who want to print or create their own 3D models.

Selecting a 3D model

When selecting existing models to print, databases of 3D models specifically for touch readers such as BTactile are the best place to search. Another option is to use communities like Thingiverse and determine suitability of the model by reading the comments from the maker and people who have printed the model.

Refer to Where to find 3D printing designs for further sources.

3D design by people with low vision

The South Australia School for Vision Impaired (SASVI) have successfully run a 3D design program with low vision students using Makers Empire. Text-to-speech has now been incorporated into the app. It also includes a limited braille font.

3D design by people who are blind

OpenSCAD is a free open source online software for creating 3D designs. It is accessible because it is script-based, however this also means that some basic programming knowledge is required for its use. NVDA is the best screen reading software to use with OpenSCAD.

NVDA is the best screen reading software to use with OpenSCAD.

OpenSCAD

ShapeShift is a dynamic pin display that can be paired with OpenSCAD to preview models as they are being created, allowing blind users to check and modify their designs before printing. The specifications and instructions to make your own ShapeShift are available at https://github.com/ShapeLab/shapeShift. Further, a VSC extension was used to modify OpenSCAD to overcome some of its accessibility issues. This is available from https://github.com/alexasiu/shapeCAD-Extension.

OpenJSCAD is essentially the same as OpenSCAD but it used JavaScript programming syntax. Furthermore, OpenJSCAD can be used online. Researchers at the University of Marburg have developed open source software which is paired with OpenJSCAD and a Falcon Haptic Device to provide audio and haptic feedback for blind 3D modelers. Software downloads and instructions are provided at https://www.uni-marburg.de/en/fb12/research-groups/grafikmultimedia/research/haptic_mesh_inspection.

Another option is to convert from drawings or models created by a blind person into a 3D computer model that can be 3D printed at any size and with durable materials.

At the Royal Dutch Visio school, students draw the object from four sides and a sighted person converts this to a 3D model by hand.

Software such as www.df3d.com/extrude can be used to convert any greyscale picture to 3D by extruding darker areas at a higher point.

3D scanning is a more complex process. Begin with a physical sculpture created by the blind person using modelling clay, blocks or similar. Smartphone apps are available to take a series of images of the sculpture from all angles. This is best done in even light, keeping the camera an equal distance from the object and making sure that the whole object fits in the frame. Note that the resultant 3D file may need further editing before it is able to be 3D printed.

Using a 3D printer

Most 3D printers use an LCD display for operation, however some allow remote printing, making them more accessible for blind users.

Simplify3d (paid) or Slic3r (free) recommended for preparing the model for printing as more functions are accessible using a screen reader, including orienting the 3D model on the print bed.

Octoprint is an Open Source web interface that can be used with most 3D printers. It can be used as a slicer; to monitor, start, pause and stop prints; and to control other printer functions such as temperature, changing filaments, levelling the bed, etc.

Prusa 3D printers have a sound assist mode that plays a beep when you land on an item and when you reach the top/bottom of a menu as you turn a physical click knob. It is possible to memorize the menu items (or list them beside the printer) and then count to select the desired item using the physical click knob.

>Prints in progress can be supervised non-visually by sound or touch:

- Loose filament tends to move around on the plate, making a high-pitched ticking sound;

- Raised corners due to adhesion problems cause a scraping sound when the nozzle passes over that area;

- Depending on your printer, you may be able to hear the the filament spool moving to confirm that there is no blockage;

- Touch the filament as it enters the feed tube to check that it is moving;

- During the FDM printing process it is best not to touch the printing area as the nozzle is extremely hot, the printing head can be easily moved and oils on the skin can interfere with adhesion.

It is safe to pause the print and touch the partially completed model. If well familiarised with the printer, adults may check a print in progress by using one hand to track where the print head is working and the other hand to gently touch a part of the model that is not currently being printed.

It is safe to pause the print and touch the partially completed model. If well familiarised with the printer, adults may check a print in progress by using one hand to track where the print head is working and the other hand to gently touch a part of the model that is not currently being printed.

Last updated: June 12, 2022 at 9:42 am

3D printing will help the blind and visually impaired to get acquainted with the sights of the Kremlin

News

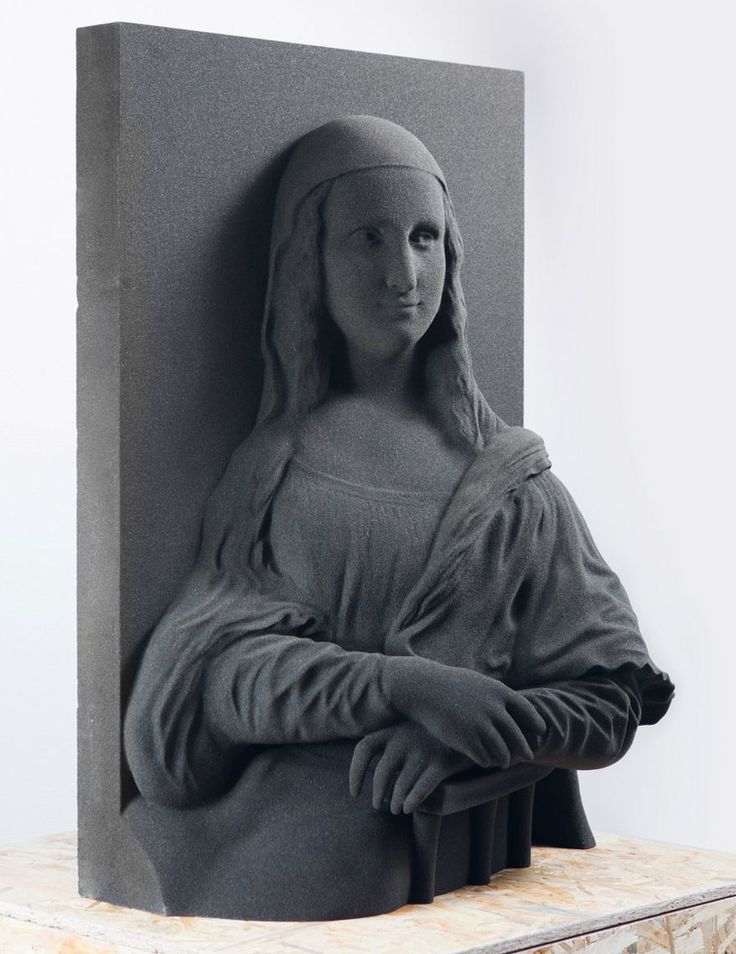

Reduced copies of the Tsar Cannon, the Tsar Bell and other iconic objects made using 3D printing will appear on the territory of the Moscow Kremlin. The project aims to provide sightseeing opportunities for the blind and visually impaired.

Miniature copies will be located on separate pedestals near real monuments and will be provided with tactile signs with inscriptions in Braille. The height of the copies will be 25-40 centimeters. It is indicated that the models will be made of bronze alloy according to the forms made using 3D printing. In addition to a cannon and a bell, copies of the Archangel, Assumption and Annunciation Cathedrals, as well as the bell tower of Ivan the Great, will be presented.

It is indicated that the models will be made of bronze alloy according to the forms made using 3D printing. In addition to a cannon and a bell, copies of the Archangel, Assumption and Annunciation Cathedrals, as well as the bell tower of Ivan the Great, will be presented.

“Such a size is enough for the visually impaired to be able to “examine” the building with all its elements in detail. All safety requirements will be met. Buildings, for example, should not have sharp corners so that a blind visitor does not get injured while touching a cathedral or a cannon,” representatives of the Kremlin museums specify. nine0003

Of course, the new versions of the monuments will be available to everyone, and the tactile signs will be duplicated with the usual inscriptions made in Russian and English. The first exhibits of the new collection were demonstrated in May at the Intermuseum festival as part of the Museum to the Touch program.

The needs of people with disabilities have received increased attention in recent years. Thus, tactile terminals have recently appeared at the cash desks of Kremlin museums, allowing blind visitors to get acquainted with the description of objects, and audio-tactile mnemonic maps, with which you can find buildings by touch. For people with hearing impairments, induction loops are installed that convert sound waves into radio signals transmitted to hearing aids. nine0003

According to the head of the 3Dtoday portal, Sergey Pushkin, additive technologies have a high social potential: “Helping the visually impaired is a noble cause, and 3D printing demonstrates its ability to help people with disabilities. Braille books, tactile exhibits - all this helps people with disabilities feel like full-fledged members of our society.”

Two weeks ago, the first trial tour for the visually impaired was held with a specially trained guide. Visitors were provided with a reference audiobook that tells about the Kremlin museums and reinforces the descriptions with relief images. Such excursions should become publicly available by the end of the year. So far, ten consultants are working on the territory of the Kremlin, who can be called from the box office to help with the purchase of a ticket and escort during a walk around the territory. Perhaps the most unusual example of new amenities can be considered a relief icon for the blind, installed in the Cathedral of Christ the Savior with a description in Braille. nine0003

Visitors were provided with a reference audiobook that tells about the Kremlin museums and reinforces the descriptions with relief images. Such excursions should become publicly available by the end of the year. So far, ten consultants are working on the territory of the Kremlin, who can be called from the box office to help with the purchase of a ticket and escort during a walk around the territory. Perhaps the most unusual example of new amenities can be considered a relief icon for the blind, installed in the Cathedral of Christ the Savior with a description in Braille. nine0003

Subscribe to the author

Subscribe

Your username is

Your password is

Have you forgotten your password?

Password recovery

Recover your password

Your email address

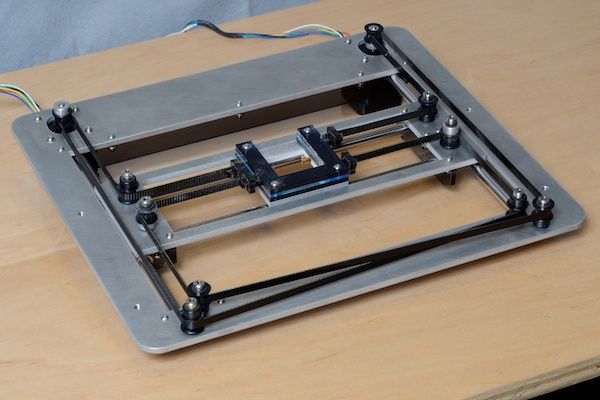

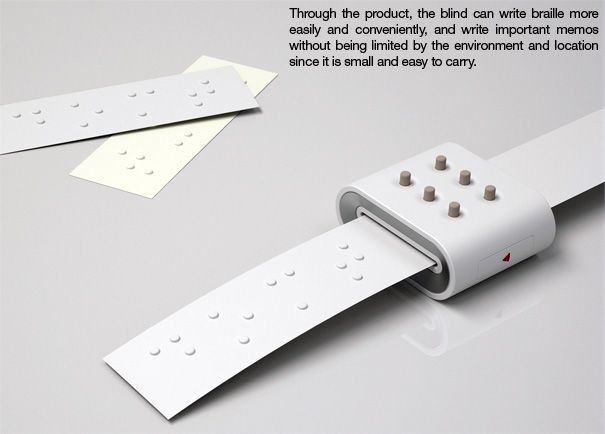

Computer engineering specialists from Stanford University in the USA today presented their new unique development in the form of tactile display technology for 3D printers. The development represents a new phase in a long-term study dedicated to enabling blind or visually impaired people to create their own designs on a 3D printer and CAD devices. It is worth noting that the presented stage is also characterized by many interesting features, among which the ability of the technology to flexibly adapt to any shape stands out. nine0003

The development represents a new phase in a long-term study dedicated to enabling blind or visually impaired people to create their own designs on a 3D printer and CAD devices. It is worth noting that the presented stage is also characterized by many interesting features, among which the ability of the technology to flexibly adapt to any shape stands out. nine0003

Thus, the project is made in the format of a special platform device with many long vertical sticks made of a special alloy of plastic and soft metals - which gives the material a really high level of tactile feedback. By placing an object under the contact pad, the user thereby starts the process of replicating the shape of this object, which is accepted by the sticks themselves, either rising up or falling down.

The presented tactile display allows people with limited or completely absent vision to control objects and reproduce their shape on a 3D printer, and do it with such precision that no other similar development can boast of the past.