3D printing python

3d-printing · GitHub Topics · GitHub

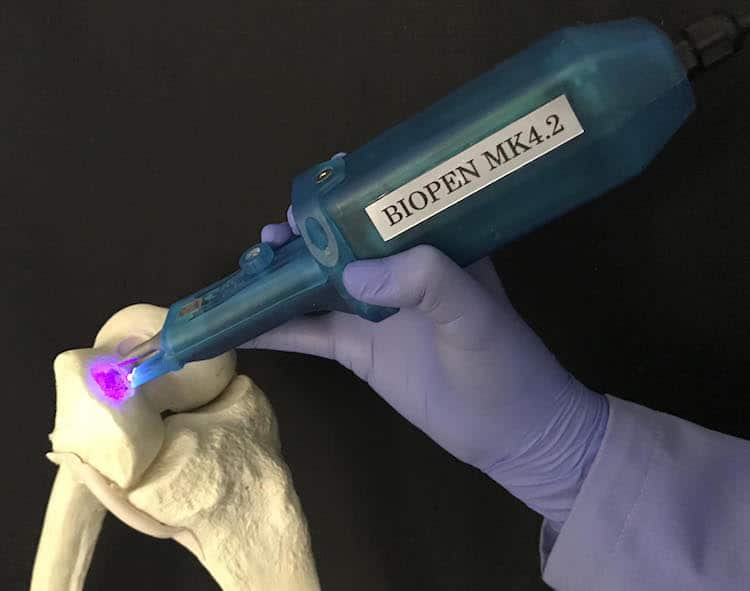

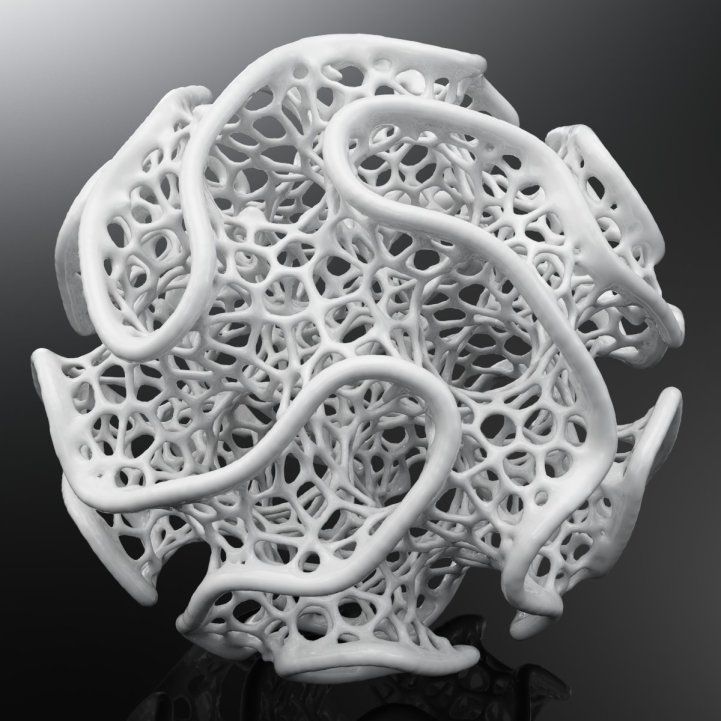

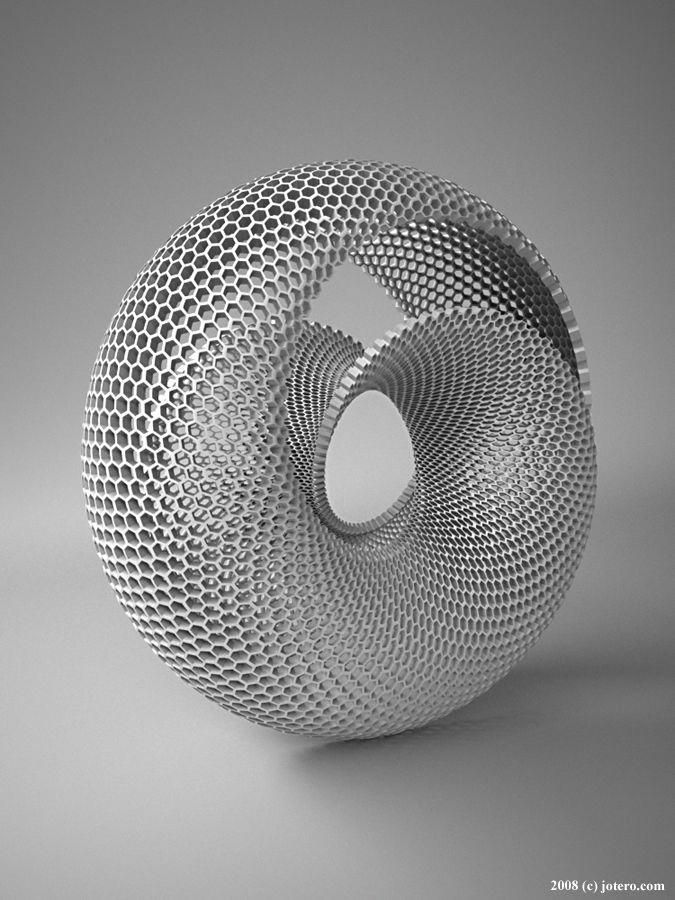

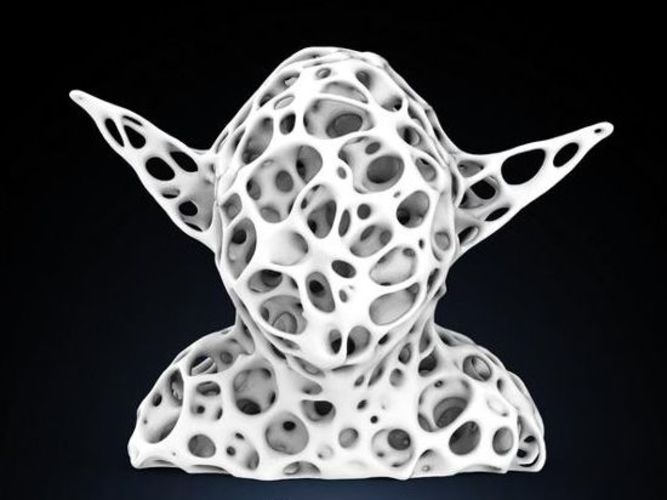

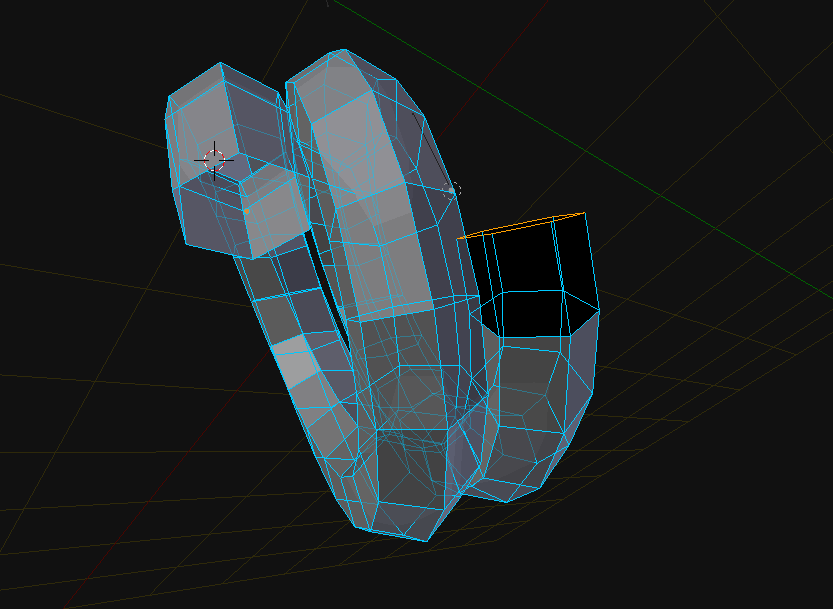

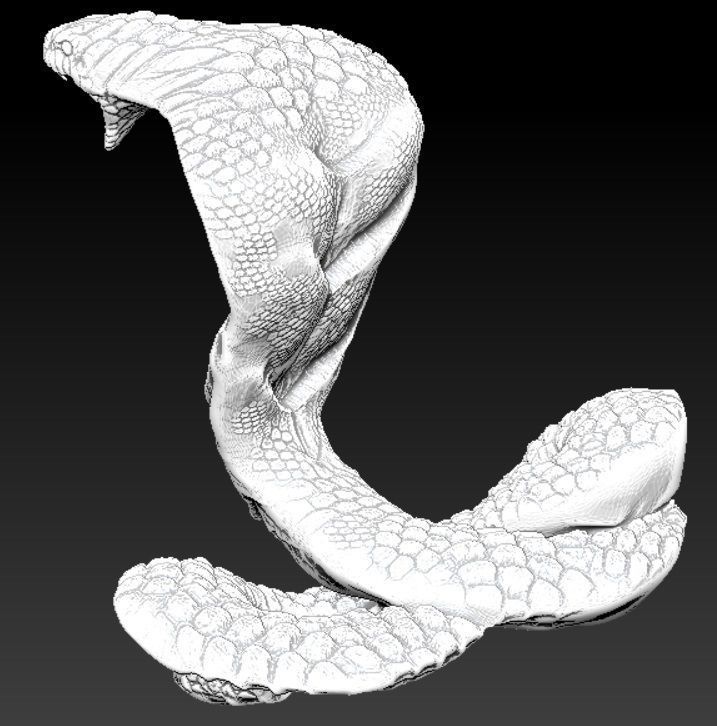

3D modeling uses specialized software to create a digital model of a physical object. It is an aspect of 3D computer graphics, used for video games, 3D printing, and VR, among other applications.

MarlinFirmware / Marlin

Sponsor Star 13.9kFreeCAD / FreeCAD

Sponsor Star 12.5kopenscad / openscad

Sponsor Star 5.1kUltimaker / Cura

Star 4.2kcnr-isti-vclab / meshlab

Star 3.3kslic3r / Slic3r

Star 3khuxingyi / dust3d

Sponsor Star 2.bencbartlett / 3D-printed-mirror-array

Star 2.3kBenRoe / awesome-mechanical-keyboard

Sponsor Star 2.3kshunsukesaito / PIFu

Star 1.5kMarlinFirmware / Configurations

Sponsor Star 1.5kth43xitus / kiauh

Star 1.3kHaskell-Things / ImplicitCAD

Star 1.2kfogleman / sdf

Star 1. 1k

1k feelfreelinux / octo4a

Sponsor Star 946mainsail-crew / mainsail

Star 944UnchartedBull / OctoDash

Star 892Slicer / SlicerGitSVNArchive

Star 891gregsaun / prusa_i3_bear_upgrade

Star 846nophead / NopSCADlib

Star 831- Wikipedia

- Wikipedia

9781696881944: Python for 3D Printing: Using Python to enhance the power of OpenSCAD for 3D modeling (Computer-aided 3D Design, Modeling and Printing - using Python and OpenSCAD) - Craig, John Clark: 1696881943

Python is quickly becoming the world's most popular programming language, for everything from quick-and-easy hobbyist calculations to running some of the biggest online websites such as Google, YouTube, Dropbox, Reddit, and many others.

OpenSCAD is a powerful 3D modeling language for creating 3D printed plastic parts for hobbyists and engineers.

Python for 3D Printing enables the reader to leverage the power, versatility, & simplicity of Python to enhance & super-charge the already powerful capabilities of OpenSCAD for Makers, Engineers, & anyone who wants to create 3D shapes for 3D printing or manufacturing.

Both Python and OpenSCAD are free software tools that run on Windows, Macs, and Linux machines. The symbiotic use of these two tools enables a MUCH SHORTER LEARNING CURVE than when using the expensive software packages, and it puts you in control of your designs instead of your designs controlling you!

The complete source code Python listing for driving OpenSCAD using easier-to-remember and easier-to-use commands IS INCLUDED WITH THIS BOOK, along with creative examples of the use of all new commands. You'll see how easy it is to integrate these two tools such that you'll see results instantly on your screen when your Python code runs.

Table of Contents of Python for OpenSCADIntroduction...About Python...About OpenSCAD...OpenSCAD Limitations...Python to the Rescue...How Python was added to OpenSCAD...How to Get Started...Where to Get Python...Where to Get OpenSCAD...How to Learn from this Book1 - Spheres2 - Color3 - Boxes4 - Cylinders5 - Tubes6 - Cones7 - Triangles8 - Animation9 - Polygons10 - Polyhedrons11 - Regular polygons12 - Text13 - Translate and Rotate14 - Scale15 - Resize16 - Rotate extrude17 - Spiral18 - Hull19 - Minkowski20 - Mirror21 - Projection22 - Slice23 - Offsets24 - Difference, Union, & Intersection25 - Assemblies26 - Gears27 - Mason bees28 - Surface29 - Platonic solids

OpenSCAD is an amazing program for designing 3D parametric models for 3D printing, most often by creating industry standard STL files to command 3D printers. OpenSCAD is unlike most of the expensive software packages you perhaps have heard about or used. First, it’s an open source, free program, instead of costing up to thousands of dollars. Another important feature is the way it works. Instead of interacting visually with a myriad of menus, sub-menus, buttons, complex settings, and parametrically driven object trees, OpenSCAD lets you drive the 3D modeling using a programming language all its own. It’s a different way of thinking and creating, and once the few commands are understood, many people prefer it greatly over other programs. Even though OpenSCAD is driven by text commands, the results are shown in an interactive 3D window, complete with panning, zooming, and rotating. This instant visual feedback makes creating your 3D objects a breeze.

Another important feature is the way it works. Instead of interacting visually with a myriad of menus, sub-menus, buttons, complex settings, and parametrically driven object trees, OpenSCAD lets you drive the 3D modeling using a programming language all its own. It’s a different way of thinking and creating, and once the few commands are understood, many people prefer it greatly over other programs. Even though OpenSCAD is driven by text commands, the results are shown in an interactive 3D window, complete with panning, zooming, and rotating. This instant visual feedback makes creating your 3D objects a breeze.

By creating an interpretive Python syntax layer that translates to OpenSCAD, these and several other unique issues are eliminated or minimized. You are required to learn and use only a simplified subset of standard Python syntax, which you possibly already know. (If you’re new to Python, just know it’s great for many other programming tasks as well.) Python enables more complex OpenSCAD models to be created in a shorter time because of its shorter learning curve, extendibility, flexibility, and the overriding of some limitations and quirks of the OpenSCAD language. In short, the combination of Python and OpenSCAD provides a very powerful and flexible system for creating 3D models in ways neither programming language alone can provide. All while having you learn a simple subset of the syntax of only one programming language, one of the most popular & powerful programming language in the world.

In short, the combination of Python and OpenSCAD provides a very powerful and flexible system for creating 3D models in ways neither programming language alone can provide. All while having you learn a simple subset of the syntax of only one programming language, one of the most popular & powerful programming language in the world.

"synopsis" may belong to another edition of this title.

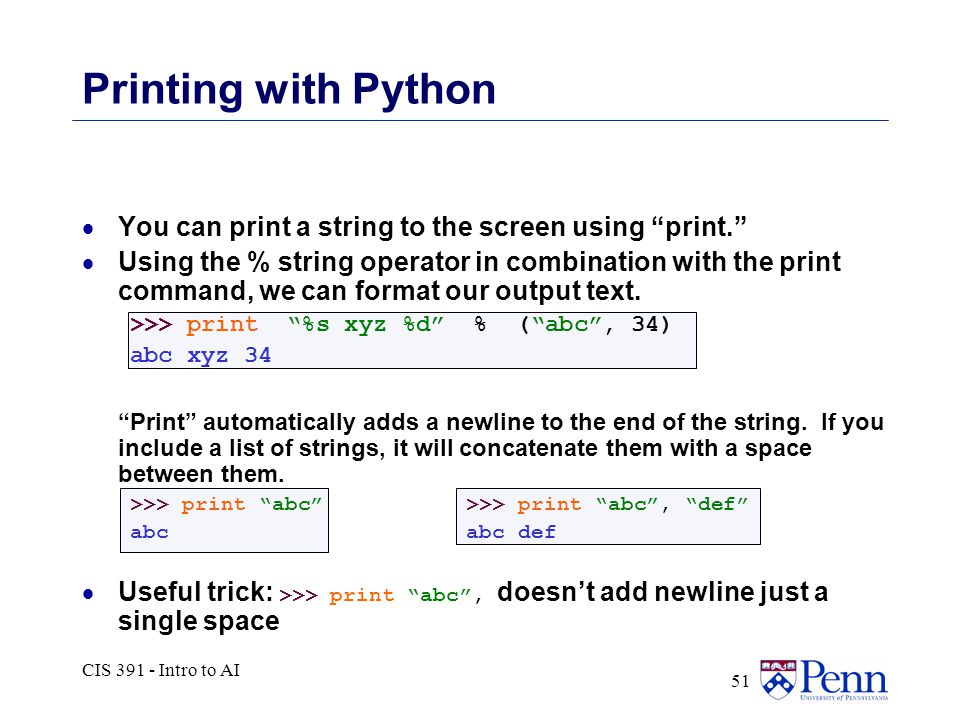

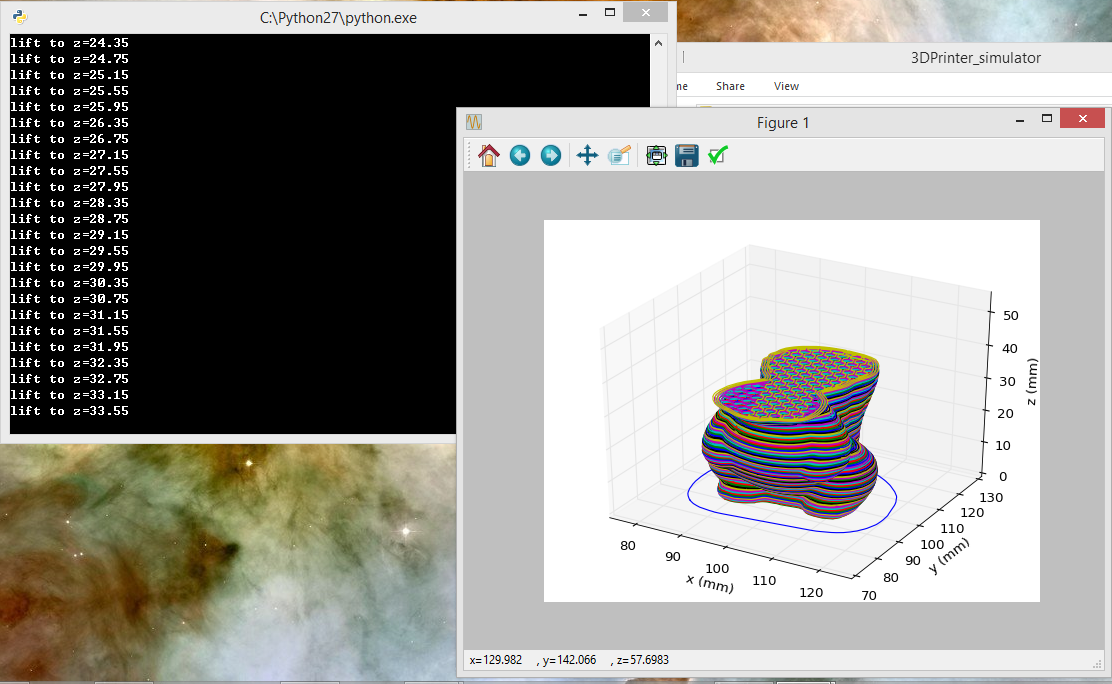

Answers to python questions

This question is related to the Python programming language

- Why is this central area filled with STL? We have done some work to automatically generate STL files with Python. We made a ring of cubes like this: Importing it into Cura still makes it valid, but with...

- Flip file x-axis G-code I have some sliced models that represent the robot's right-handed arms and legs. I'm really happy with how they are printed, so now I would like to print the arms and legs...

- Convert 3D NumPy array of voxels to STL file Given a 3D boolean array representing voxels, how can it be converted to a 3D printer-ready file? The end goal I would like to achieve is to print…

- Get the M114 command while printing with Printrun I am working on a project for which I am using the Printrun package to serialize my G-code to my 3D -printer (Creality Ender 3, Marlin firmware).

The idea is that I have…

The idea is that I have… - How do you send a G-code from a USB port using Python? I am working on a project for my wizards where I am trying to detect printing errors using object detection and I want to be able to pause the printer when a potential error is detected… For the last 3 months I've been working on a CNC drawing machine, but still can't get the line detection algorithm, that's why I came here. I can't understand only one part and that is CAM the (image…

- Sending G-code commands to Hyrel 30M using python I am using python 3.6 with pySerial library to connect to Hyrel System 30M 3D printer. I can read data from the device, but I can't write commands to it Here is the code: ser =…

- Can a Las/Laz file be converted to an STL or OBJ file? I would like to know if there is any tool/library (preferably based on python) that can be used in parsing a Laz file to extract information that…

- How do I create my own Cura GUI? I am trying to create my own Cura GUI.

I keep getting the error: UM module not found. Do I need to see the UI file? I think I...

I keep getting the error: UM module not found. Do I need to see the UI file? I think I... - How to build Cura on Windows? I'm interested in Cura development. Initially, I want to start with the user interface, not the Engine. I found the repository and cloned it on my computer. I also looked at the wiki and…

- How do I display DLP images using HDMI for 3D printing? I am working on a DLP based 3D printer. I have already cut my STL file into several layers. Each layer is saved as an SVG file. Because it's an SVG file, I can always convert each layer to...

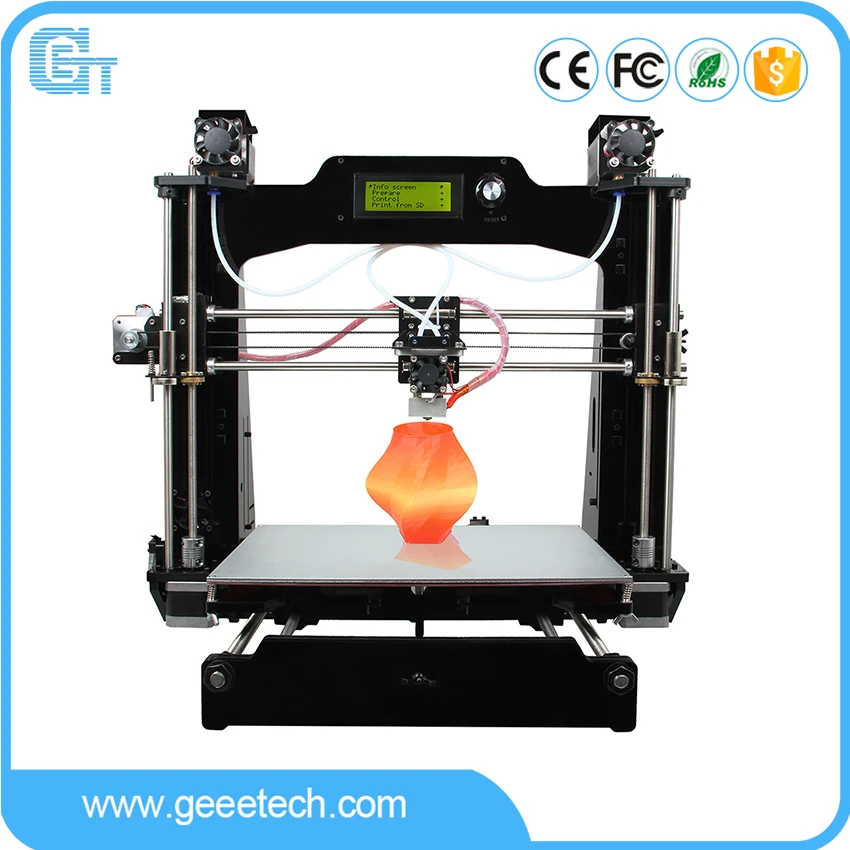

3D printing software

Basically, there are 4 steps on the way from concept to printed physical object:

- 1. The idea itself,

- 2. Its digital model,

- 3. A set of print head paths,

- 4. And finally, printing.

Turning an idea into a physical object is carried out using three levels of software:

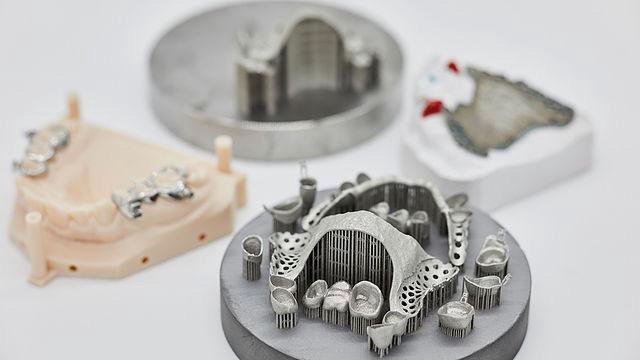

In 3D printing, CAD and CAM (Computer Aided Design/Manufacturing) programs are used to create digital models and their translation into physical instructions for the printer; while the “client” program manages the printer hardware.

Modeling / CAD

Even if you are scanning a real object with a scanner, you will most likely want to refine it with CAD programs. There are many file formats for models, but most 3D printers use the STL format. Unfortunately, not all STL files can be printed. A model suitable for printing should have a "sealed" form with a closed monolithic surface, without any breaks, that clearly separates the inside and outside of the model. Computer graphics programs (such as Blender) usually model the surface without caring about the "tightness" of the model. Therefore, beginners are advised to use software that is more specialized in creating monolithic models, for example, 123 Design, at first.

Sketchup

TRIMBLE

20000

0/$ 590 (Pro)

Good Balance of simplicity of use and functionality. The built-in 3D model sharing feature has a large user community. No native STL support

The built-in 3D model sharing feature has a large user community. No native STL support

FreeCAD

Juergen Riegel, Werner Mayer

123D Sculpt

Autodesk

2011

0

Expands the ability to model the interface for the touch screen IPAD.

123d Creature 9

Autodesk

0 9000

in their intuitively understood tetrilates, the0002 Sculpting software designed specifically for 3D printing. Supports import and export of STL format files. Supported OS: Windows

C AM/ Slicing Software.

"Slicing" (separation of the model into layers for 3D printing). A slicing program translates 3D models into physical instructions for a 3D printer. They are a sequence of paths that the printer's print head will take to fill (print) the shape of an object. The most common format for such files in 3D printing is G-code.

| SKEINFORGE | Enrigue Perez | 2009 9000 9000 9000 2 Free | The same ways for a large number of functions due tangled | |

| Slic3r | Alessandro Ranelucc | 2011 | Free | Is one of the most popular slicing programs, replacing Skeinforge in this place. It has open code, supports various operating systems, fast and easy to use |

| CURA | David Braam/Ultimaker | 9000 9000 9000 9000 9000 Free 9000 Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free Free is Ultimaker 3D printers and some others. One of the fastest slicer programs to date. Carries out "slicing" layers in the background, and automatically corrects the result in case of making any changes. Exports G-code format files. One of the fastest slicer programs to date. Carries out "slicing" layers in the background, and automatically corrects the result in case of making any changes. Exports G-code format files. |

Printer management (“ Client” program)

The “Client” program is basically a kind of printer control panel. It sends instructions to the CAM printer and provides an interface for controlling printer functions. Currently, there is a tendency to combine CAM and client programs into a single printer management interface.

| Replicator G | MakerBot | 2008 | Free | Original Replicator printer client, later replaced by MakerWare. |

| Printerface | Kliment Yanev | 9000 9000 9000 9000 Free | The most famous of the 3rd dwell of the popular PRINTRUNTRUN set. |