3D printing for engineers

Making it work: 3D printing and engineering

Adam Kohut12 December 2019

Applications

Engineering is about creating designs that work as efficiently as possible. Wasted time is wasted money, and to have a project stall because of an unforeseen design flaw or a delay in the supply chain can be as frustrating as it is costly. That’s why control is so valuable – control of your time, control of your costs, control of your entire process. And 3D printing is all about control.

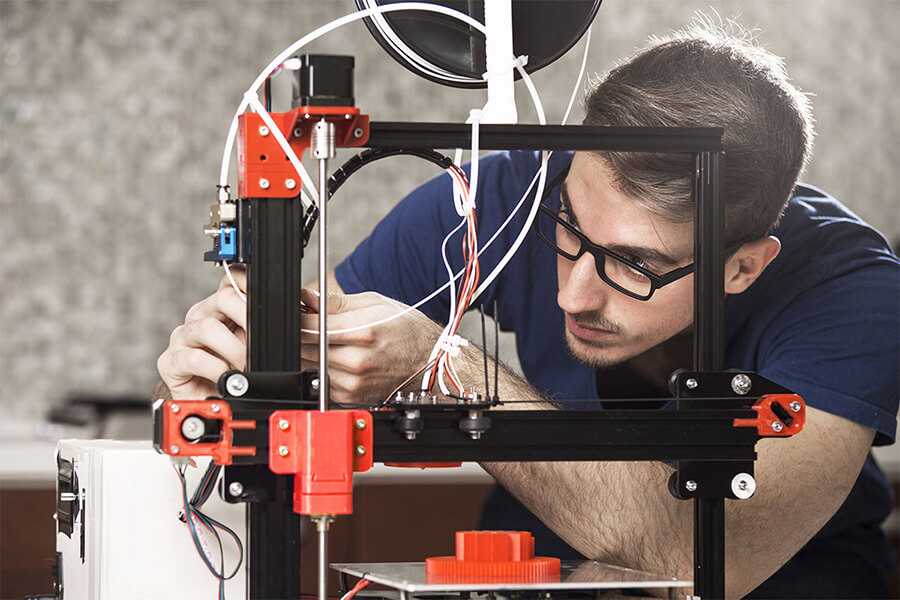

Using 3D printing, engineers can create new prototypes – even those with complex internal structures and geometries – address problems, and find solutions, without ever leaving their working environments. The right 3D printer holds the potential to shrink development time from months to days, encourages collaboration between peers, and enables the creation of rapid prototypes and end-use parts – ensuring that projects are finished on deadline, within budget, and bring about desired results.

Design flexibility

When creating custom parts for small bore motorcycles, engineers at MNNTHBX (Man in the Box) know that the design and testing phases both have the capacity to be time-consuming and expensive, especially when using materials such as aluminum.

Using Ultimaker 3D printers, MNNTHBX is able to increase the flexibility of its designs and improve product test phases. It has also seen a marked increase in its return on investment, saving upwards of $1,000 per printed part.

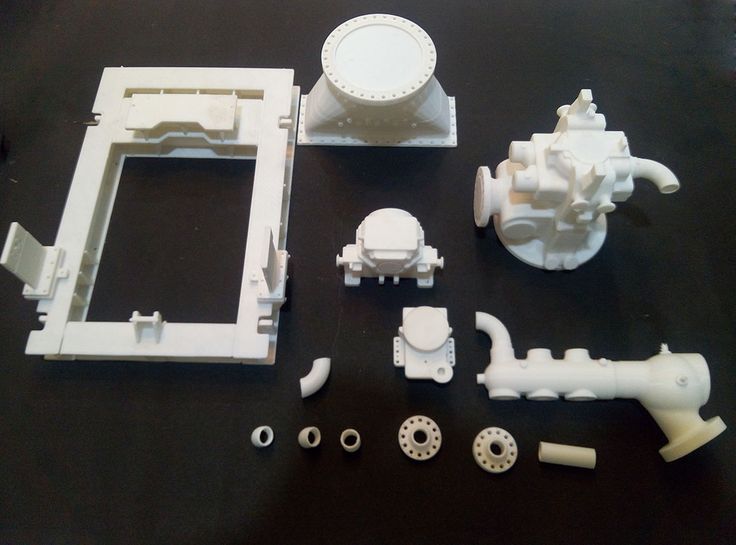

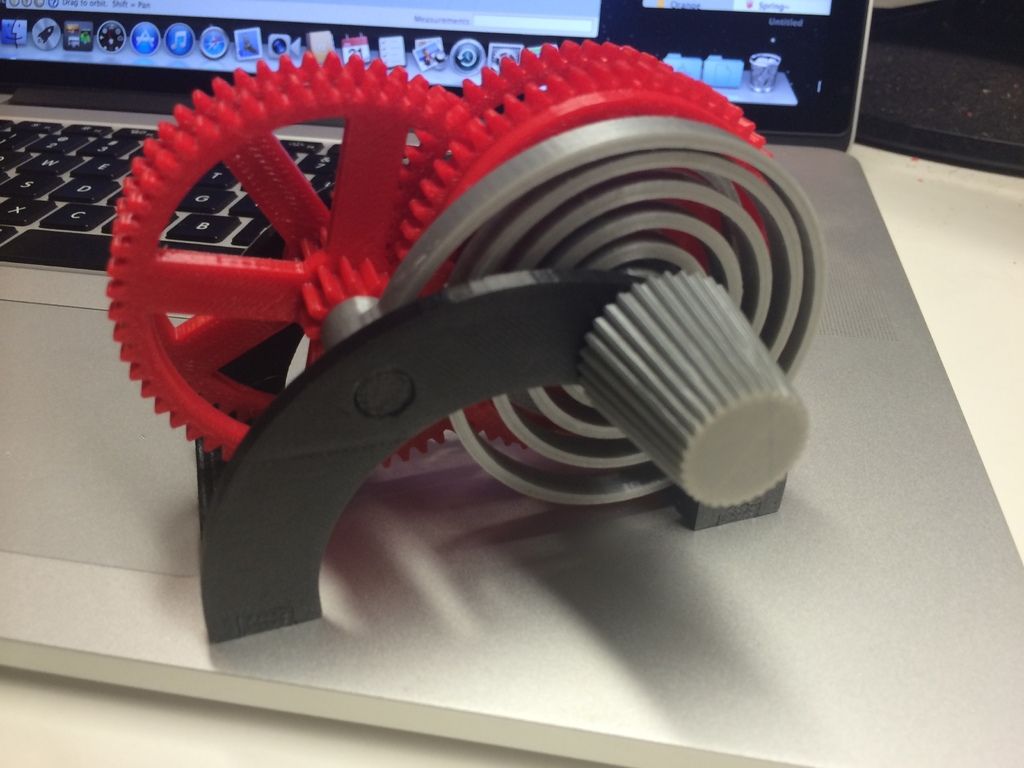

A 3D print mounted on a part created by small-bore motorcycle parts manufacturer MNNTHBX

“Our printer basically paid for itself the first time we saw a product through prototyping. Being that we prototype roughly 15 products annually, the cost savings become apparent,” Greg Hatcher, Owner of MNNTHBX, said. “3D printing on Ultimaker mitigates risk and opens the door to creating working concepts on extremely low investment. Long gone are the days of spending thousands of dollars running multiple prototypes through traditional CNC machining methods. When we take a design to the machine shop, we know before we start that it’s a fully functional design meeting our standards.”

Proof of concept

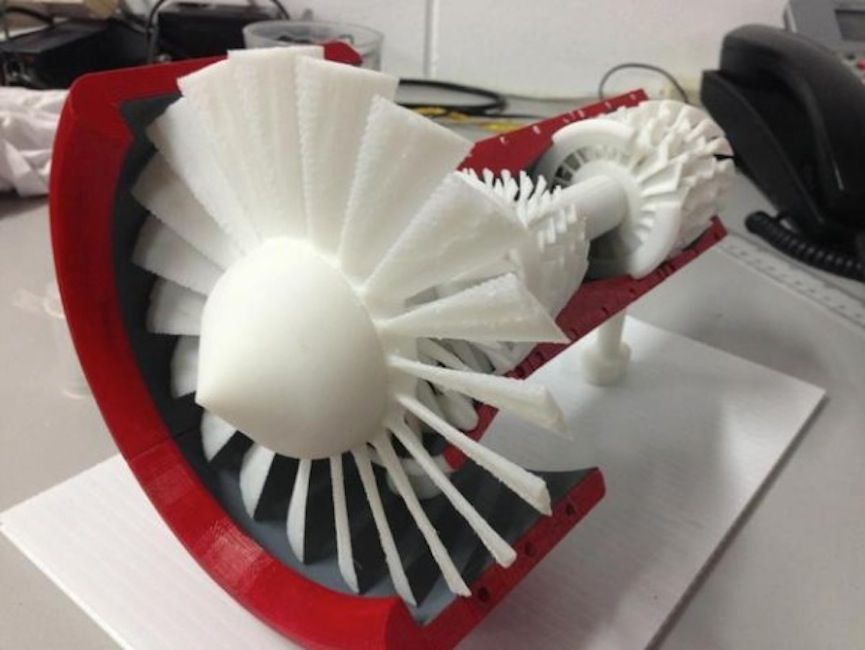

It’s one thing to create a bold new design – it’s another entirely for that design to work as intended. Sending those designs into space adds an additional level of complexity. Honeybee Robotics has contributed critical planetary analysis technology incorporated into three of NASA’s Mars mission, including planetary drills and sampling systems on the Curiosity rover.

Sending those designs into space adds an additional level of complexity. Honeybee Robotics has contributed critical planetary analysis technology incorporated into three of NASA’s Mars mission, including planetary drills and sampling systems on the Curiosity rover.

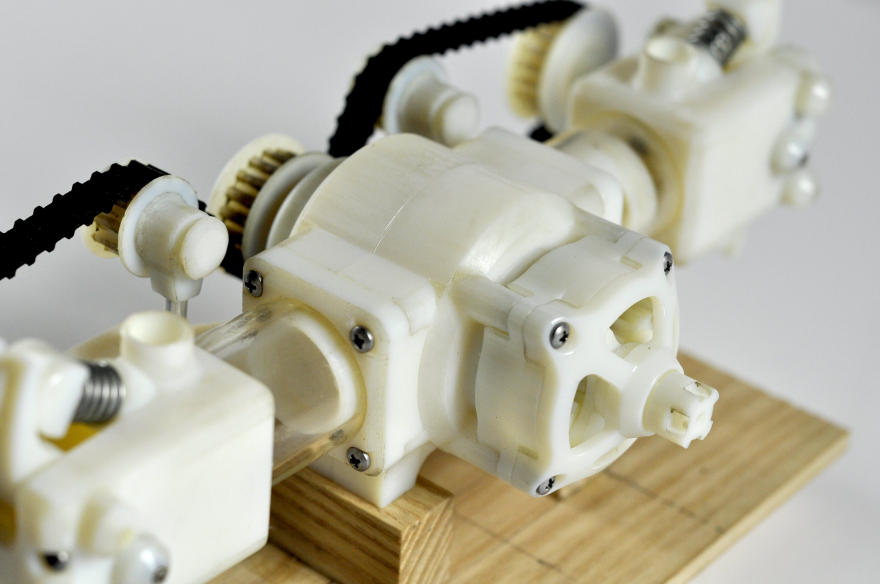

Honeybee Robotics’ projects demand complex, load-bearing metal parts that can survive harsh environments. Using 3D printing, engineers were able to quickly and cheaply test concepts and establish project parameters, rather than relying fully on methods of outsourced fabrication, which were slower and more costly.

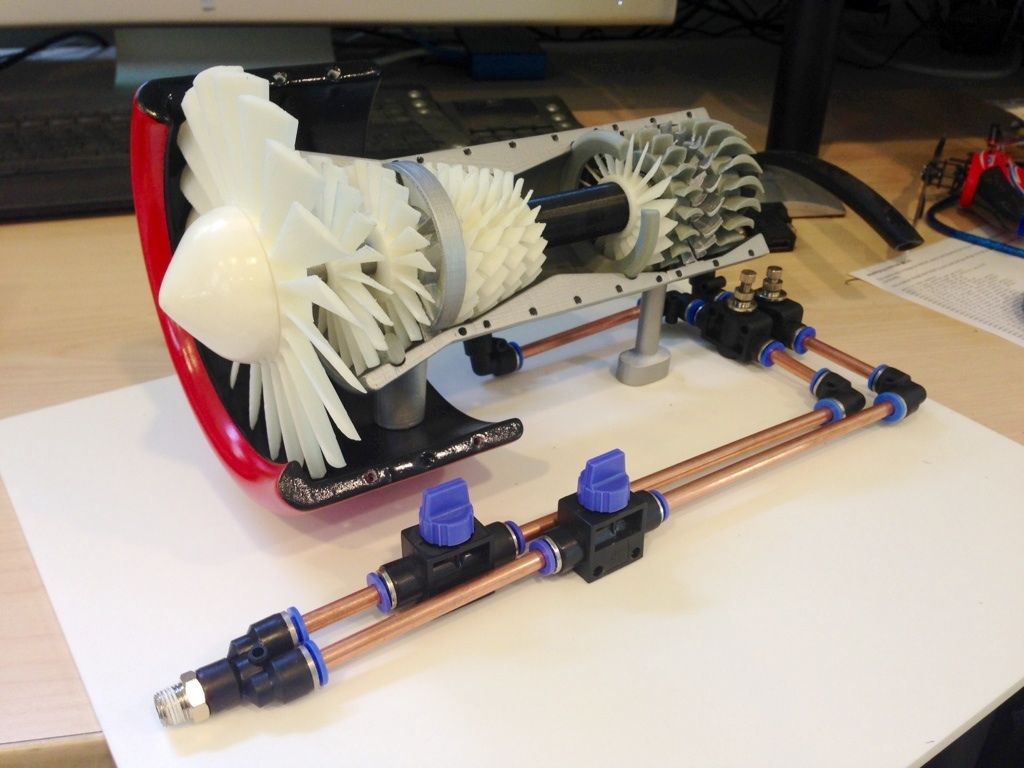

A soil scooper partially created with 3D printing by Honeybee Robotics

“A lot of what we do is to build subsystems and then test their performance,” says Yoni Saltzman, Project Engineer, said. “How fast they are, things like that. So physically building key elements of the robot is what the printer allows us to do cheaply and quickly.”

End-use parts

At a Heineken brewery in Seville, Spain, Ultimaker printers are used to create parts in-house, which are then implemented on its bottling line, replacing metal parts that are heavy, and tend to knock bottles over. The redesigned 3D printed parts are lighter and cheaper alternatives, and now play active roles in Heineken’s manufacturing environment.

The redesigned 3D printed parts are lighter and cheaper alternatives, and now play active roles in Heineken’s manufacturing environment.

“3D printing has proven to be a technology that helps us, brings value to us, and enables our people to work more efficiently,” Juan Padilla, Packaging Manager at the plant, said.

Watch the videoLow-volume production

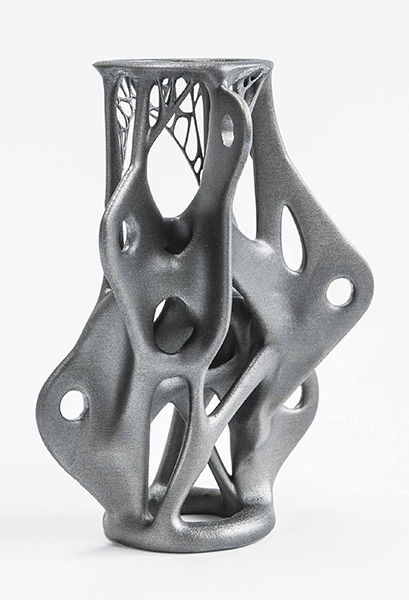

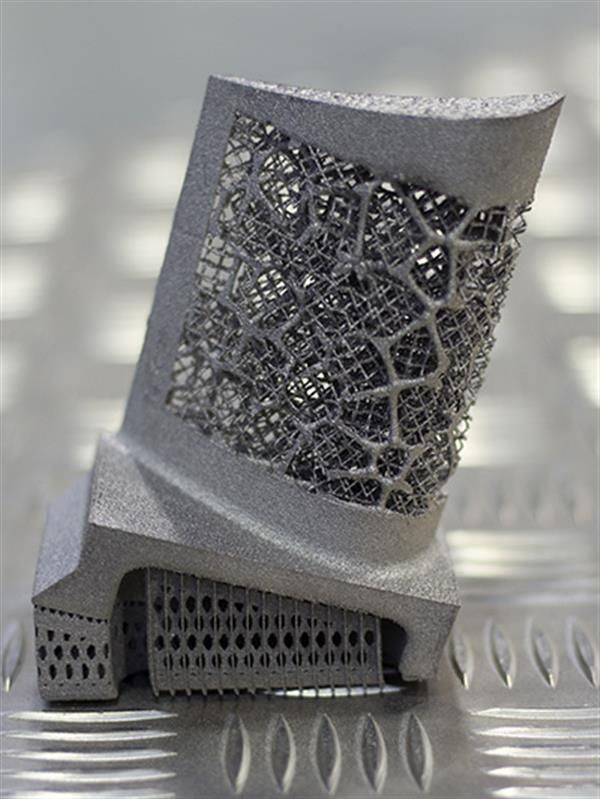

3D printing can also play a part in low-volume production of complex parts. IMI Precision Engineering is a world leader in motion and fluid control technologies. It needed a new additive manufacturing technique that would allow the creation of geometrically complex parts. By turning to 3D printing and the Ultimaker S5, the firm saved thousands of dollars in part creation – and nearly 2,000 hours per year in labor.

A finished complex print created by IMI Precision Engineering

“The Ultimaker S5 offered the best value, with the size and materials we needed to print all the parts,” Kathryn Jones, an IMI Graduate Engineer, said. “It added new capability to another 3D printer that we had purchased last year, with lower costs for low volume parts and improved manufacturing efficiency.”

“It added new capability to another 3D printer that we had purchased last year, with lower costs for low volume parts and improved manufacturing efficiency.”

Ready to introduce 3D printing into your workflow?

Discover Ultimaker 3D printers

7 Best 3D Printers for Engineers & Mechanical Engineers Students – 3D Printerly

3D printing is slowly becoming an essential part of our everyday lives. Various professions are incorporating the use of 3D printers in their workplaces.

No profession benefits from the application of 3D printing as much as engineering, whether it is electrical, mechanical, civil, structural, or mechanical.

3D printing plays a crucial role in the designing and production phases of any engineering project. With a 3D printer, engineers are able to create visual prototypes to bring out their design ideas.

Mechanical engineering students can easily create various mechanical components of their products e.g. gears through 3D printing. Structural engineers can easily create scale models of buildings to get a clearer view of how the various parts of the structure would interlink and look.

Structural engineers can easily create scale models of buildings to get a clearer view of how the various parts of the structure would interlink and look.

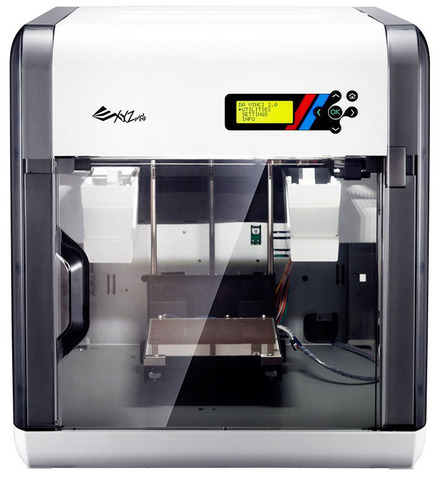

The applications of 3D printing by engineers are limitless. However, to create accurate models for your designs, you will need a solid printer. Let’s have a look at some of the best printers for engineers and mechanical engineering students.

We’ll start our list with the Qidi Tech X-Max. This machine is solely designed to handle more advanced materials like nylon, carbon fiber and PC, without compromising on the speed and quality of production.

This makes it one of the favorites among mechanical engineering students. Let’s take a closer look at some of its features.

Features of the Qidi Tech X-Max

- Solid Structure and Wide Touchscreen

- Different Types of Printing for You

- Double Z-axis

- Newly Developed Extruder

- Two Different Ways for Placing the Filament

- QIDI Print Slicer

- QIDI TECH One-to-One Service & Free Warranty

- Wi-Fi Connectivity

- Ventilated & Enclosed 3D Printer System

- Large Build Size

- Removable Metal Plate

Specifications of the Qidi Tech X-Max

- Build Volume: 300 x 250 x 300mm

- Filament Compatibility: PLA, ABS, TPU, PETG, Nylon, PC, Carbon Fiber, etc

- Platform Support: Double Z-axis

- Build Plate: Heated, removable plate

- Support: 1-Year with infinite customer support

- Filament Diameter: 1.

75mm

75mm - Printing Extruder: Single extruder

- Layer Resolution: 0.05mm – 0.4mm

- Extruder Configuration: 1 set of a specialized extruder for PLA, ABS, TPU & 1 set of a high performance extruder for printing PC, Nylon, Carbon Fiber

Giving this printer an edge over its competitors is a set of Qidi Tech third-generation extruder assembly. The first extruder prints general material like PLA, TPU, and ABS, while the second one prints materials that are more advanced e.g. Carbon fiber, Nylon, and PC.

This makes it possible for mechanical engineering students to print out mechanical components for the machine they are trying to develop, be it shafts, gears, or any other parts.

The Qidi Tech X-Max (Amazon) has a double Z-axis, which stabilizes the printer when it prints large models.

What impressed me the most is the flexible metal plate which makes it easier to extract a printed model. Both sides of the plates are usable. On the front side, you can print general material and on the backside, you can print advanced material.

It also has a 5-inch touchscreen with a more practical user interface, making it simpler to operate than its competitors.

User Experience of the Qidi Tech X-Max

One user liked how well-packaged the printer came. He said that he was able to unpack it and assemble it for use in less than half an hour.

Another user said that the Qidi Tech X-Max was one of the most reliable printers for producing prototypes because of its large print area. She said that she had already printed over 70 hours of prints without any complications.

When it comes to safety, the Qidi Tech X-Max doesn’t compromise at all. A customer could not hold his excitement when he saw an air filter on the back of the print chamber’s wall. This feature is noticeably absent from most 3D printers.

One user liked that they didn’t have to use any adhesives since the coating on the build plate was able to hold his prints firmly in place.

Pros of the Qidi Tech X-Max

- Amazing and consistent 3D print quality that will impress many

- Durable parts can be created with ease

- Pause and resume function so you can change over the filament anytime

- This printer is set up with high-quality thermostats with more stability and potentiality

- Excellent UI interface that makes your printing operation easier

- Quiet printing

- Great customer service and helpful community

Cons of the Qidi Tech X-Max

- Doesn’t have filament run-out detection

- The instructional manual isn’t too clear, but you can get good video tutorials to follow

- The internal light can’t be turned off

- Touchscreen interface can take a little getting used to

Final Thoughts

The Qidi Tech X-Max does not come cheap, but if you got a few bucks to spare, then this massive machine will definitely give you a return on your investment.

Check out the Qidi Tech X-Max for a 3D printer able to help handle your mechanical engineering projects.

The Dremel brand is known for producing products that help people to get acquainted with 3D printing technology. The Dremel 3D45 is one of their ultra-modern 3rd generation 3D printers designed for heavy usage.

Let’s see some of the features that make the Dremel 3D45 a good fit for engineers.

Features of the Dremel Digilab 3D45

- Automated 9-Point Levelling System

- Includes Heated Print Bed

- Built-In HD 720p Camera

- Cloud-Based Slicer

- Connectivity Through USB and Wi-Fi Remotely

- Fully Enclosed With Plastic Door

- 5″ Full-Color Touch Screen

- Award-Winning 3D Printer

- World-Class Lifetime Dremel Customer Support

- Heated Build Plate

- Direct Drive All-Metal Extruder

- Filament Run-Out Detection

Specifications of the Dremel Digilab 3D45

- Print Technology: FDM

- Extruder Type: Single

- Build Volume: 255 x 155 x 170mm

- Layer Resolution: 0.

05 – 0.3mm

05 – 0.3mm - Compatible Materials: PLA, Nylon, ABS, TPU

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Bed Levelling: Semi-Automatic

- Max. Extruder Temperature: 280°C

- Max. Print Bed Temperature: 100°C

- Connectivity: USB, Ethernet, Wi-Fi

- Weight: 21.5 kg (47.5 lbs)

- Internal Storage: 8GB

Unlike many other 3D printers, The Dremel 3D45 doesn’t need any assembling. It is ready for usage straight out of the package. The manufacturer even provides 30 lesson plans, which could be useful for mechanical engineering students who are using it for the first time.

It has an all-metal direct drive extruder that can heat up to 280 degrees Celsius. This extruder is also resistant to clogging ensuring that you can print a designed product freely e.g. a car engine model.

Another standout feature is the filament run-out detection system. It ensures that you can continue printing from the last position anytime the filament finishes, and you feed in a new one.

With the Dremel 3D45 (Amazon), you don’t have to worry about adjusting knobs to do your leveling as it comes with a built-in automatic leveling sensor. The sensor will detect any variation in the bed level and adjust it accordingly.

To interact with the printer, you have a 4.5” colored touch screen that you can operate effortlessly.

User Experience for the Dremel 3D45

What the majority of the users seem to concur with is that setting up the Dremel 3D45, after purchasing it, is a straightforward task. You can start with its pre-loaded print in less than 30 minutes.

One user who owns two Dremel 3D45 printers said that they never cease to amaze him. He has printed in virtually all colors of Dremel’s filaments, and they were still simple to use.

He added that the nozzle works perfectly. However, you will need to upgrade to a hardened nozzle if you want to print carbon fiber, which is preferred by mechanical and automotive engineers due to its good weight to strength ratio.

Using the 4.5” touch screen was a pleasant experience for one user who could read and operate everything easily.

A satisfied customer said that this printer was very silent even with its door open. The enclosed design definitely plays a big role in that

Pros of the Dremel Digilab 3D45

- Print quality is very good and it’s easy to use as well

- Has powerful software along with being user-friendly

- Prints through a USB thumb drive via Ethernet, Wi-Fi, and USB

- Has a safely secured design and body

- Compared to other printers, it is relatively quiet and less noisy

- Easier to set up and use as well

- Provides a 3D comprehensive ecosystem for education

- The removable glass plate allows you to remove prints easily

Cons of the Dremel Digilab 3D45

- Limited filament colors compared with competitors

- The touch screen is not particularly responsive

- There is no nozzle cleaning mechanism

Final Thoughts

Knowing that they had an almost 80-year reputation to maintain, Dremel did not compromise when it came to the 3D45. This robust printer is the epitome of reliability and quality printing.

This robust printer is the epitome of reliability and quality printing.

You can always count on the Dremel 3D45 to create perfectly molded prototypes.

Find the Dremel Digilab 3D45 on Amazon today.

The Bibo 2 Touch laser which is popularly known as the Bibo 2 was first released in 2016. Since then, it has slowly gained popularity among 3D printing fanatics in the engineering fraternity.

Additionally, it has a lot of good reviews on Amazon and has been appearing in many bestseller lists.

Let’s find out why this machine is an engineer’s favorite.

Features of the Bibo 2 Touch

- Full-Color Touch Display

- Wi-Fi control

- Removable Heated Bed

- Copy Printing

- Two-Color Printing

- Sturdy Frame

- Removable Enclosed Cover

- Filament Detection

- Power Resume Function

- Double Extruder

- Bibo 2 Touch Laser

- Removable Glass

- Enclosed Print Chamber

- Laser Engraving System

- Powerful Cooling Fans

- Power Detection

- Open Build Space

Specifications of the Bibo 2 Touch

- Build Volume: 214 x 186 x 160mm

- Nozzle Size: 0.

4 mm

4 mm - Hot End Temperature: 270℃

- Temperature of Heated Bed: 100℃

- of Extruders: 2 (Dual Extruder)

- Frame: Aluminum

- Bed Leveling: Manual

- Connectivity: Wi-Fi, USB

- Filament Materials: PLA, ABS, PETG, flexible etc.

- File Types: STL, OBJ, AMF

At first glance, you might mistake the Bibo 2 Touch for a 3D printer from a different era due to its outdated look. But, don’t judge a book by its cover. The Bibo 2 is a beast in its own right.

This printer has a 6mm thick composite panel made of aluminum. So, its frame is stronger than more the conventional plastic ones.

The Bibo 2 Touch (Amazon) has dual extruders that will enable you to print a model with two different colors without having to change the filament.

Impressive, right? Well, it can do more than that. With dual extruders, you can print two different models at the same time. This will be very important for engineering projects with time constraints.

You can control all aspects of the printing from your phone or computer thanks to its Wi-Fi control feature. This is suitable for mechanical engineering students who love using their PC for more than just design.

As the name suggests, the Bibo 2 Touch has a color touch screen with a friendlier user interface.

User Experience of the Bibo 2 Touch

According to one user, setting up the Bibo 2 Touch is an amusing experience. The user said that she only had to do minimal work as the printer was already 95% assembled.

She also said that the printer came with, and SD card with a tonne of information that helps her carry out her first test print with ease. It also helped her learn the basics of operating the machine.

In one review, a user stated how they have been able to print with PLA, TPU, ABS, PVA, and nylon without any issues. She added that the laser engraver worked perfectly.

One user loved how the Filament Sensor enabled printing to continue from where it left off immediately after a blackout. Therefore, he didn’t have to worry about wasted filament, time or crooked prints.

Therefore, he didn’t have to worry about wasted filament, time or crooked prints.

This can be important for engineers when printing out more intricate designs such as car models.

Bibo’s tech support has been lauded by many consumers for its fast and direct way of addressing problems.

The only downside is that they are in a different time zone, so you will have to find out the best times for sending inquiries, or else you’ll wait for a long time for a response. The screen is also a bit buggy, and the user interface can be improved.

Pros of the Bibo 2 Touch

- Dual extruder improves 3D printing capabilities and creativity

- Very stable frame which translates to better print quality

- Easy to operate with the full-color touchscreen

- Known for having great customer support based in the US & China

- Great 3D printer for high volume printing

- Has Wi-Fi controls for more convenience

- Great packaging to ensure a safe and sound delivery

- Easy to use for beginners, giving out high performance and much enjoyment

Cons of the Bibo 2 Touch

- Relatively small build volume compared to some 3D printers

- The hood is quite flimsy

- The location to put the filament is at the back

- Leveling the bed can be a little difficult

- Has quite a learning curve because there are so many features

Final Thoughts

The Bibo 2 Touch doesn’t have many positive reviews for no good reason. If you ignore the small issues here and there, you’ll get a highly efficient printer that will serve you for quite some time.

If you ignore the small issues here and there, you’ll get a highly efficient printer that will serve you for quite some time.

If you want a good printer for handling your undergraduate engineering degree projects, check out the Bibo 2 Touch on Amazon.

The Ender 3 V2 is the third iteration of the Ender 3 line by Creality.

By tweaking certain of its predecessors (the Ender 3 and Ender 3 Pro), Creality was able to come up with a machine that is not only a good size, but also has excellent print quality at a good price.

In this section, we’ll dive into the specifics of this printer.

Features of the Ender 3 V2

- Open Build Space

- Carborundum Glass Platform

- High-Quality Meanwell Power Supply

- 3-Inch LCD Color Screen

- XY-Axis Tensioners

- Built-In Storage Compartment

- New Silent Motherboard

- Fully Upgraded Hotend & Fan Duct

- Smart Filament Run Out Detection

- Effortless Filament Feeding

- Print Resume Capabilities

- Quick-Heating Hot Bed

Specifications of the Ender 3 V2

- Build Volume: 220 x 220 x 250mm

- Maximum Printing Speed: 180mm/s

- Layer Height/Print Resolution: 0.

1mm

1mm - Maximum Extruder Temperature: 255°C

- Maximum Bed Temperature: 100°C

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Extruder: Single

- Connectivity: MicroSD Card, USB.

- Bed Levelling: Manual

- Build Area: Open

- Compatible Printing Materials: PLA, TPU, PETG

The most noticeable upgrade is the silent 32-bit motherboard which is the spine of the Creality Ender 3 V2 and reduces the noise produced when printing to below 50 dBs.

If you set up the Ender 3 V2, you will not fail to notice the V-guide rail pulley system which stabilizes movement while increasing the wear resistance. This will enable you to use your printer to produce 3D prints for prototypes for longer.

When it comes to printing 3D models, you need a good filament feed-in system. Creality 3D has added a rotary knob to make it simpler for you to load the filament.

On the XY-axis you have a new injection tensioner that you can use to conveniently adjust the tension in the belt.

On the software side, you have a new user interface that has been designed to improve the user’s experience. All this is projected on a 4.3” color screen which you can detach easily for repair.

For engineers, who are more hands-on, there is a toolbox on the machine where you can store your tools and retrieve them easily at any time.

User Experience of the Ender 3 V2

One user liked how clear the instructions for helping to set up the printer were. By following them and watching a few videos on YouTube, she was able to set up the printer in a relatively shorter time.

Another user states that he has been able to print PLA models with no complications using the test filament the company provides. He was able to do the test print successfully, and after that has been printing without problems.

This means that mechanical engineering students can print out things like brushless motors without any challenges.

In one five-star review, the customer states that the Ender 3 V2 was his second printer and he was impressed with how easy it was to use the print bed.

The bed adhesion was a bit off at first but he was able to fix this issue by increasing the rate of extrusion and slightly sanding the Carborundum glass bed.

He also appreciated that the Ender 2 came with a little drawer under the print bed which allowed him to keep his micro USB cards, nozzles, Bowden tubes, and card readers.

Pros of the Ender 3 V2

- Easy to use for beginners, giving out high performance and much enjoyment

- Relatively cheap and great value for money

- Great support community.

- Design and structure look very aesthetically pleasing

- High precision printing

- 5 minutes to heat up

- All-metal body gives stability and durability

- Easy to assemble and maintain

- Power supply is integrated underneath the build-plate unlike the Ender 3

- It is modular and easy to customize

Cons of the Ender 3 V2

- A bit difficult to assemble

- Open build space is not ideal for minors

- Only 1 motor on the Z-axis

- Glass beds do tend to be heavier so it may lead to ringing in prints

- No touchscreen interface like some other modern printers

Final Thoughts

If you’re looking for a low-budget printer with pretty standard capabilities, the Ender 3 V2 will do the trick. However, if you want to print more advanced materials, you should consider looking for a different printer.

However, if you want to print more advanced materials, you should consider looking for a different printer.

The Ender 3 V2 can be found on Amazon.

The Dremel Digilab 3D20 is every hobbyist or engineering student’s first choice printer. Its relatively low cost and high performance make it a better choice to purchase as compared to other 3D printers in the market.

It’s similar to the Dremel Digilab 3D45, but with a few less features and at a much cheaper price.

Let’s take a look under the hood.

Features of the Dremel Digilab 3D20

- Enclosed Build Volume

- Good Print Resolution

- Simple & Easy to Maintain Extruder

- 4-Inch Full-Color LCD Touch Screen

- Great Online Support

- Premium Durable Build

- Established Brand With 85 Years of Reliable Quality

- Simple to Use Interface

Specifications of the Dremel Digilab 3D20

- Build Volume: 230 x 150 x 140mm

- Printing Speed: 120mm/s

- Layer Height/Print Resolution: 0.

01mm

01mm - Maximum Extruder Temperature: 230°C

- Maximum Bed Temperature: N/A

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Extruder: Single

- Connectivity: USB A, MicroSD card

- Bed Levelling: Manual

- Build Area: Closed

- Compatible Printing Materials: PLA

The Dremel Digilab 3D20 (Amazon) has a fully enclosed design that is essential for extra safety. This design also maintains the stability of temperature inside the machine to ensure that every print is successful.

Children cannot poke their fingers into the print area, which can come in handy for engineers working on projects on a part-time basis at home.

This printer comes with a non-toxic plant-based PLA filament, which has been designed to produce strong and precisely finished prints and is less harmful.

The only downside is that the Dremel Digilab doesn’t come with a heated bed, which means that you can mostly print with just PLA.

On the software, you have a full-colored LCD touch screen with a more modern interface. You can perform functions such as modifying the printer setting, obtaining files from the micro SD card, and printing easily.

You can perform functions such as modifying the printer setting, obtaining files from the micro SD card, and printing easily.

User Experience of the Dremel Digilab 3D20

This printer comes fully pre-assembled. You can just unbox it and immediately start using it. This, from reviews, has been helpful to many people who were beginners.

One user who wanted to undertake a project he called “Dabbing Thanos” with his son said that using the Dremel Digilab 3D20 was his best decision yet.

The Dremel software which he put on an SD card was simple to use. It sliced the file and added supports where necessary. This will help when printing prototypes with complex designs.

The final result was a nicely printed “Dabbing Thanos” which his son took to school to show his friends. He only had to clean up the final print with sandpaper.

Another user mentioned how precise the printer was thanks to its precise nozzle. Although it needed regular cleaning, he was more than happy to do it.

Pros of the Dremel Digilab 3D20

- Enclosed build space means better filament compatibility

- Premium and durable build

- Easy to use – bed leveling, operation

- Has its own Dremel Slicer software

- Durable and long-lasting 3D printer

- Great community support

Cons of the Dremel Digilab 3D20

- Relatively expensive

- Can be hard to remove prints from build plate

- Limited software support

- Only supports SD card connection

- Restricted filament options – listed as just PLA

Final Thoughts

The Dremel Digilab 3D20 is an easy-to-use printer with the ability to print out high-quality models. Since it comes fully assembled, you can use the time you would have used to set it up to come up with more innovative designs to print out.

You can check out the Dremel Digilab 3D20 on Amazon if you need a 3D printer to serve your engineering prototyping needs.

The Anycubic Photon Mono X is a resin 3D printer larger than most that you will get on the market today. While it may not have been the first resin 3D printer to be manufactured, it is slowly overtaking its competitors.

While it may not have been the first resin 3D printer to be manufactured, it is slowly overtaking its competitors.

Let look at some of its features to see how it fares.

Features of the Anycubic Photon Mono X

- 8.9″ 4K Monochrome LCD

- New Upgraded LED Array

- UV Cooling System

- Dual Linear Z-Axis

- Wi-Fi Functionality – App Remote Control

- Large Build Size

- High Quality Power Supply

- Sanded Aluminum Build Plate

- Fast Printing Speed

- 8x Anti-Aliasing

- 3.5″ HD Full Color Touch Screen

- Sturdy Resin Vat

Specifications of the Anycubic Photon Mono X

- Build Volume: 192 x 120 x 245mm

- Layer Resolution: 0.01-0.15mm

- Operation: 3.5″ Touch Screen

- Software: Anycubic Photon Workshop

- Connectivity: USB, Wi-Fi

- Technology: LCD-Based SLA

- Light Source: 405nm Wavelength

- XY Resolution: 0.05mm, 3840 x 2400 (4K)

- Z Axis Resolution: 0.

01mm

01mm - Maximum Printing Speed: 60mm/h

- Rated Power: 120W

- Printer Size: 270 x 290 x 475mm

- Net Weight: 10.75kg

This is pretty large even by 3D printer’s standards. The Anycubic Photon Mono X (Amazon) has a respectable size, measuring 192mm x 120mm x 245mm, easily double the size of many resin 3D printers out there.

Its upgraded LED array is unique to only a few printers. The UV matrix of LEDs distributes light evenly across the entire print.

The Anycubic Photon Mono X is 3 times faster than the average 3D printer. It has a short exposure time of between 1.5 to 2 seconds and a top print speed of 60mm/h. This is important when you’re trying to shorten the design-test-revise cycle time in challenging mechanical engineering projects.

With a Dual Z-Axis, you won’t have to worry about the Z-Axis track becoming loose. This makes the Photon Mono X very stable and improves the quality of printing.

On the operating side, you have an 8. 9” 4K monochrome LCD with a resolution of 3840 by 2400 pixels. Its clarity is really good as a result.

9” 4K monochrome LCD with a resolution of 3840 by 2400 pixels. Its clarity is really good as a result.

Your machine can often overheat especially when you use it continually to complete a fairly long engineering project. For that, the Anycubic Photon Mono X has a UV cooling system for efficient cooling and longer run times.

This printer’s bed is purely made out of anodized Aluminum to improve its adhesive properties so your 3D prints stick down to the build plate well.

User Experience for the Anycubic Photon Mono X

A satisfied customer from Amazon states how well the Anycubic resin works with the machine especially when you follow the recommended exposure settings that it usually comes with.

Another user says that his prints stuck to the print bed quite well because of the material used to make it (anodized aluminum).

He added that the Z-axis had never wobbled in the short duration that he had been printing. Overall, the mechanics were pretty solid.

One user who was printing at 0.05mm was thrilled that the Photon Mono X was able to capture the most intricate patterns for her prints.

A frequent user of the Anycubic Mono X said that its slicer software could use some improvements. However, he liked its auto-support function which enables every print to come out great despite its complexity.

A great thing about the software complaint though is how other slicers have stepped up to the plate to deliver amazing features that Anycubic missed out on. One such software is the LycheeSlicer, a personal favorite of mine.

You can export the specific .pwmx files needed for this 3D printer, as well as do plenty of functions that automate most of the slicing process.

Pros of the Anycubic Photon Mono X

- You can get printing really quickly, all within 5 minutes since it’s mostly pre-assembled

- It’s really easy to operate, with simple touchscreen settings to get through

- The Wi-Fi monitoring app is great for checking on the progress and even changing settings if desired

- Has a very large build volume for a resin 3D printer

- Cures full layers at once, resulting in quicker printing

- Professional looking and has a sleak design

- Simple leveling system which stays sturdy

- Amazing stability and precise movements that lead to almost invisible layer lines in 3D prints

- Ergonomic vat design has a dented edge for easier pouring

- Build plate adhesion works well

- Produces amazing resin 3D prints consistently

- Growing Facebook Community with plenty of helpful tips, advice, and troubleshooting

Cons of the Anycubic Photon Mono X

- Only recognizes .

pwmx files so you may be limited in your slicer choice

pwmx files so you may be limited in your slicer choice - The acrylic cover doesn’t sit in place too well and can move easily

- Touchscreen is a little flimsy

- Fairly pricey compared to other resin 3D printers

- Anycubic doesn’t have the best customer service track record

Final Thoughts

For a budget-friendly printer, the Anycubic Photon Mono X offers high accuracy during printing. Its big build volume and high resolution make it possible to print large models. I definitely recommend it to any engineer or mechanical engineering student.

You can get yourself the Anycubic Photon Mono X directly from Amazon today.

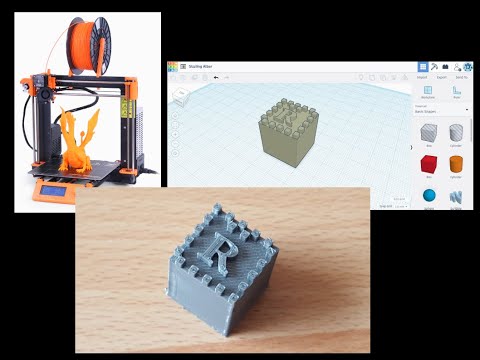

The Prusa i3MK3S is the crème de la crème when it comes to mid-range 3D printers. After successfully upgrading the Original Prusa i3 MK2, Prusa was able to come up with a newly designed 3D printing machine that is popular among engineering students.

Let’s have a look at some of its features.

Features of the Prusa i3 MK3S+

- Fully Automated Bed Leveling – SuperPINDA Probe

- MISUMI Bearings

- Bondtech Drive Gears

- IR Filament Sensor

- Removable Textured Print Sheets

- E3D V6 Hotend

- Power Loss Recovery

- Trinamic 2130 Drivers & Silent Fans

- Open Source Hardware & Firmware

- Extruder Adjustments to Print More Reliably

Specifications of the Prusa i3 MK3S+

- Build Volume: 250 x 210 x 210mm

- Layer Height: 0.

05 – 0.35mm

05 – 0.35mm - Nozzle: 0.4mm

- Max. Nozzle Temperature: 300 °C / 572 °F

- Max. Heatbed Temperature: 120 °C / 248 °F

- Filament Diameter: 1.75 mm

- Supported Materials: PLA, PETG, ASA, ABS, PC (Polycarbonate), PVA, HIPS, PP (Polypropylene), TPU, Nylon, Carbon filled, Woodfill etc.

- Max Travel Speed: 200+ mm/s

- Extruder: Direct Drive, BondTech gears, E3D V6 hotend

- Print Surface: Removable magnetic steel sheets with different surface finishes

- LCD Screen: Monochromatic LCD

The Prusa i3 has an MK25 heatbed. This heatbed is magnetic and can be switched any time you like, you can decide to go with a smooth PEI sheet, or a textured powder coated PEI.

To enhance stability, Prusa remodeled the Y-axis with aluminum. This not only provides the i3 MK3S+ with a sturdy frame but also makes it look sleeker. It also increases the total Z height by about 10mm. You can print a prosthetic arm without struggling.

This model has an improved filament sensor that doesn’t wear off mechanically. A simple mechanical lever is used to trigger it. It can function well with almost all filaments.

A simple mechanical lever is used to trigger it. It can function well with almost all filaments.

Prusa i3 MK3S+ has Trinamic 2130 Drivers and a Noctua fan. This combination makes this machine one of the quietest 3D printers available.

You can choose from either two modes, the normal mode, or the stealth mode. In the normal mode, you can achieve incredible speeds of approximately 200mm/s! This speed slightly reduces in slight mode, thus decreasing the noise levels.

For the extruder, there is an up-to-date BondTech drive extruder. It holds the filament firmly in place, increasing the reliability of the printer. It also has an E3D V6 hot end capable of handling very high temperatures.

User Experience for the Prusa i3 MK3S

One user said that he had fun assembling the Prusa i3 MK3S+, and it helped her learn the basic principles that applied when constructing 3D printers. He added that he could now repair his broken machine by himself.

Another user said that they had never seen a 3D printer operate for more than one year with 4-5 different transitions without being calibrated again.

According to a review from a satisfied user on their site, the user was able to get the print quality he desired with the i3 MK3S+ after being disappointed by many other printers before. The user added that he could switch between different materials effortlessly.

One customer said that he had printed out about 15 objects using different filaments like PLA, ASA, and PETG.

All of them worked alright although he needed to change the temperature and flow rates for quality results.

You can purchase this 3D printer as a kit, or the fully assembled version to save you the building, but you’ll have to pay a fairly hefty amount extra for the benefit (over $200).

Pros of the Prusa i3 MK3S+

- Easy to assemble with basic instructions to follow

- Top level customer support

- One of the largest 3D printing communities (forum & Facebook groups)

- Great compatibility and upgradability

- Quality guarantee with every purchase

- 60-day hassle-free returns

- Produces reliable 3D prints consistently

- Ideal for either beginners and experts

- Has won many awards for best 3D printer in several categories.

Cons of the Prusa i3 MK3S+

- No touchscreen

- Doesn’t have Wi-Fi inbuilt but it’s upgradable

- Fairly pricey – great value as stated by its many users

Final Thoughts

The Prusa MK3S is more than capable of competing with other top 3D printers when it comes to print quality. For its price tag, it performs above expectation.

It is great for civil engineers, electrical engineers, mechatronics engineers, and mechanical engineers alike.

You can get the Prusa i3 MK3S+ directly from the official Prusa website.

where to study, where to work, salary

Updated

3D printing engineer is engaged in technical support, work with equipment, software, creation of 3D models. A specialist needs to have deep knowledge of engineering, programming, and mathematics. The profession is referred to the specialties of the future. By the way, the ProfGid career guidance center has recently developed an accurate career guidance test that will tell you which professions suit you, give an opinion about your personality type and intelligence. The profession is suitable for those who are interested in physics and mathematics (see. choosing a profession based on interest in school subjects).

The profession is suitable for those who are interested in physics and mathematics (see. choosing a profession based on interest in school subjects).

Content:

- Short description

- Features of the profession

- Pros and minuses

- Plus

- Minuses

- Important personal qualities

- PROMICATION

- Universities

- Salary

- 3d printing engineer salary as of October 2022

- Professional knowledge

- Examples of companies with 3d printing engineer vacancies

Brief description

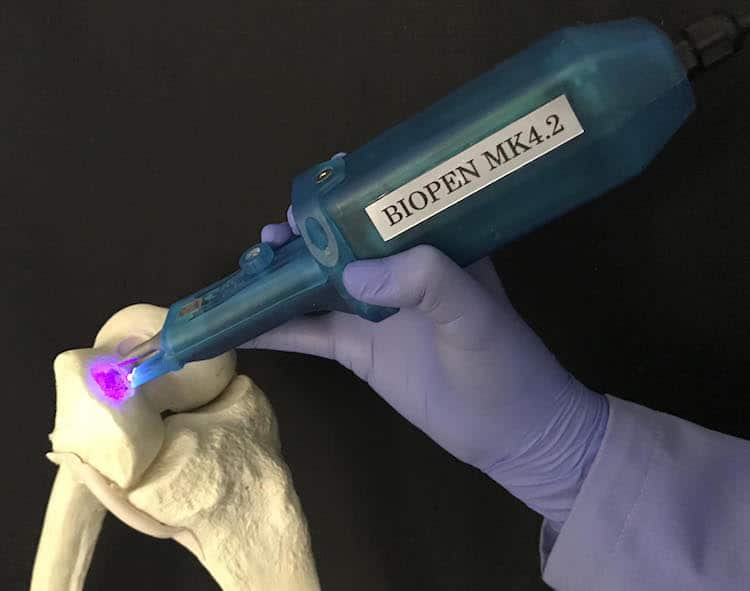

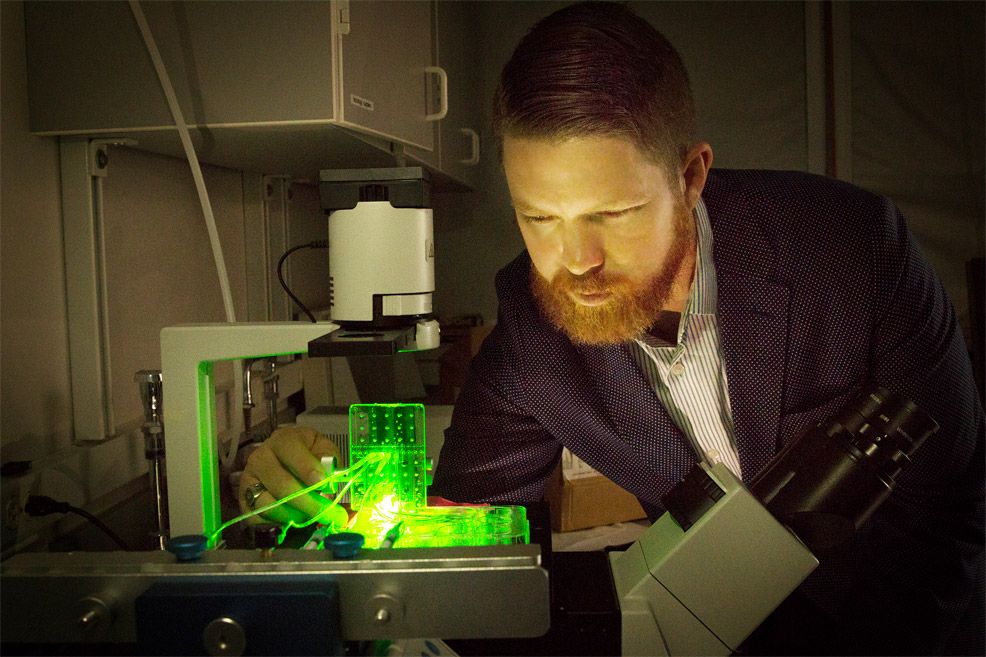

The profession of a 3D printing engineer has appeared quite recently, but its value and social significance cannot be underestimated. With the help of 3D printing, unique products used in medicine and industry are already being created today. Mathematicians and engineers are constantly developing more advanced technologies that make it possible to create blanks, anatomical models, souvenirs, houses, prostheses using this type of printing. And printers used for printing with biomaterials make it possible to create human skin, which has become a breakthrough in the treatment of wounds, injuries, and acceleration of the rehabilitation period.

And printers used for printing with biomaterials make it possible to create human skin, which has become a breakthrough in the treatment of wounds, injuries, and acceleration of the rehabilitation period.

Read also :

Complete control over 3D printing is carried out by an engineer who is an excellent programmer, technologist, biologist and even a chemist, because the profession forces him to know the composition and properties of different materials well. To work in this area, you must have a technical education, attending IT courses, lectures on modeling will be a plus. A specialist must be able to independently design a 3D model, select the necessary materials, calculate all the risks, and then print, creating products for the field of medicine, aviation, industry, etc.

Occupation specifics

3D printing engineers use different materials for their work, computer programs and industrial 3D printers. Today, medical centers, industrial, aerospace, engineering and other industries need these specialists. There are few specialists, their work cannot be called simple, because the duties of a 3D printing engineer include:

There are few specialists, their work cannot be called simple, because the duties of a 3D printing engineer include:

- selection of new materials, testing;

- using modern software to improve and adjust 3D printer settings;

- preparation of layouts, development of raster images for subsequent printing;

- full print control;

- study of new technologies;

- knowledge of certification rules, requirements that are put forward for 3D models and finished products;

- documentation development, software debugging;

- selection of new equipment, training of other employees;

- equipment maintenance.

Responsibilities vary by location, but a 3D Printing Engineer must be a multi-skilled professional who is ready to quickly learn new technologies at any time and then successfully apply them in practice. Employers put forward strict requirements for engineers, because the wages of such specialists are solid. They must have at least 3 years of practical work experience, the obligatory knowledge of a technical foreign language is important. A 3D printing engineer must know the basics of economics and marketing, because his duties include optimizing workflows aimed at reducing the cost and speed of printing.

They must have at least 3 years of practical work experience, the obligatory knowledge of a technical foreign language is important. A 3D printing engineer must know the basics of economics and marketing, because his duties include optimizing workflows aimed at reducing the cost and speed of printing.

Read also:

Pluses and minuses

Pluses

- An important profession that will help save millions of lives in the future, improve the environment, and allow the rational use of natural resources.

- 3D printing engineers are unique specialists today.

- Demand in various fields.

- A specialist will have no problems finding a job in megacities.

- The salary is stable and high.

- An experienced engineer will be able to open his own production for the manufacture of souvenirs or other products.

- You can study in Russia by enrolling in a technical university.

- Lack of physical activity.

Cons

- Working sedentary, but not monotonous.

- Irregular working hours, because the creation of a large product can last for more than 5 hours.

- The cost of industrial 3D printers is high, so in order to organize your own production, you need to think about starting capital or finding an investor.

- Any mistakes made by a 3D printing engineer are associated with huge financial losses.

- Difficulties with finding work in small towns and villages.

- Work at the computer leads to a decrease in vision.

Important Personal Qualities

A 3D Printing Engineer has a lot of professional knowledge, so he must be an erudite person with an excellent memory. The character of this rare specialist should contain responsibility, curiosity, and creativity. An engineer is obliged to constantly study, a craving for both the exact sciences and linguistics is welcomed, because most of the instructions, books and technical documentation are still being created mainly in foreign languages.

See also:

3D printing engineer training

Universities

-

4 years

220,000 ₽/year

15 budget places

-

4 years

48,500 ₽/year

12 budget places

-

36 200 ₽/year

25 budget places

-

4 years

200,000 ₽/year

25 budget places

See also:

Place of work

3D printing engineers will be able to work in agencies engaged in the production of consumer goods. They are in demand in architectural companies, factories, medical centers and nanolaboratories, clothing design and manufacturing agencies. 3D printing is used in all spheres of our life, so a young university graduate will be able to choose an interesting and useful direction.

3D printing is used in all spheres of our life, so a young university graduate will be able to choose an interesting and useful direction.

Salary

3d printing engineer salary for October 2022

Salary information provided by hh.ru portal.

Russia 30000–100000 RUB

Moscow 40000–180000 RUB

Professional knowledge

- 3D printing technologies (SLA, FDM and others).

- 3D modeling.

- 3D printing materials (PLA, ABS and others).

- Slicers for preparing for 3D printing, working with software (Autodesk 3ds Max, SolidWorks, Autodesk 123D Design and others).

- Knowledge of the specifics of different models of equipment.

- Features of processing printed 3D models.

- English.

Read also:

Examples of companies with engineer vacancies 3D-print

Description, where to receive in Russia, prospects

Higher education in Synergy: leading university, all forms of education, star teachers

Apply

Category: Physical and technical sciences and technologies

Promising

The profession of 3D printing engineer is relatively new in the labor market. Such specialists are engaged in maintenance of equipment designed for 3D printing of physical objects, software development, installation and adjustment of 3D printers. Also, a 3D printing engineer can be engaged in research activities in his field.

Such specialists are engaged in maintenance of equipment designed for 3D printing of physical objects, software development, installation and adjustment of 3D printers. Also, a 3D printing engineer can be engaged in research activities in his field.

Close

On the profession

universities 15

What USE submit

courses Link 5

salaries: how much does an engineer 3D printing

* 9000 9000 9000 Experienced: 50000 per monthProfessional: 70000 per month

* - information on salaries is given approximately based on vacancies on profiling sites. Salary in a particular region or company may differ from those given. Your income is greatly influenced by how you can apply yourself in the chosen field of activity. Income is not always limited only by the fact that you are offered vacancies in the labor market.

Demand for the profession

The market for 3D printing services is developing unevenly. There are certain areas where such specialists are in high demand. However, as a rule, very strict requirements are imposed on applicants in terms of qualifications and professionalism. It seems that over time the need for 3D printing engineers will increase significantly. Many areas of activity, from medicine to industrial production, will attract such specialists. Prospects for the profession are wide.

Who is the profession for?

A 3D printing engineer is focused on working with complex computer equipment. Such a profession makes special demands on the personal qualities of a specialist.

The profession can be recommended to those who:

- Interested in technology, computers, programming;

- Purposeful and organized;

- Can formulate problems and build algorithms for solving them;

- Comprehensively developed, erudite, has a large vocabulary;

- Interested in innovation, easily adapts to new technologies;

- Able to work in a team.

Career

Career growth is not obvious, this profession is not yet widespread in the labor market. Such specialists work in rather specific organizations that provide narrow-profile services. However, a qualified 3D printing engineer is a highly qualified specialist in the field of programming and the use of computer systems. Such engineers will be able to achieve good positions in related professions, in large industrial and commercial structures. Most often, a young engineer is expected to occupy the position of a specialist in a scientific or industrial organization.

Responsibilities

Being a highly specialized specialist, a 3D printing engineer performs the entire range of maintenance and operation of 3D printers.

His duties include:

- Installation and adjustment of equipment for 3D printing;

- Development, installation, maintenance of 3D printer software;

- Perform routine maintenance, minor repairs of equipment;

- Adaptation of the terms of reference to the specific conditions for the manufacture of 3D printing products;

- Control of geometric and physical parameters at all stages of product manufacturing;

- Procurement of additional equipment and consumables.

Learn more