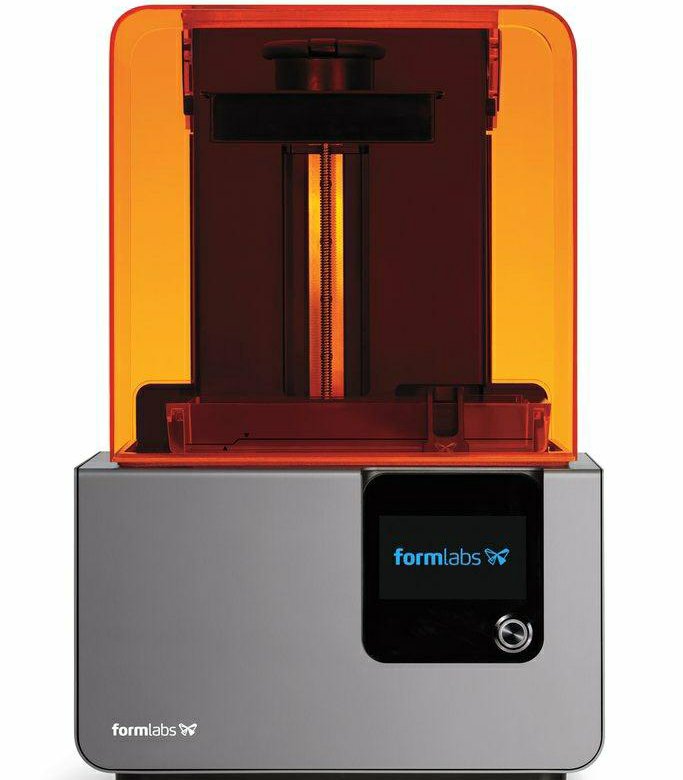

Form 1 high resolution 3d printer

Formlabs 3D Printing Materials Library

Advanced 3D printing materials designed to deliver beautiful results.

Need help selecting the right material from our catalog? Try our interactive material wizard.

Recommend Me a Material

Explore Libraries

General Purpose

Outstanding performance. Excellent detail.

Custom-formulated to deliver the highest-quality output, our Standard Resins capture astonishing detail without sacrificing strength.

Learn More

Engineering Resins

Functional prototyping materials.

Our library of versatile, reliable Engineering Resins is formulated to help you reduce costs, iterate faster, and bring better experiences to market.

Learn More

Dental Resins

Professional materials for digital dentistry.

Formlabs Dental Resins enable high precision, low-cost digital production of a range of dental products in-house, including surgical guides, orthodontic models, retainers, and aligners.

Learn More

Jewelry Resins

High-detail materials for jewelry design and clean investment casting.

Prototype impressive concept models and manufacture distinctive pieces with sharp resolution and the best surface finish on the market, from idea to fitting to casting.

Learn More

Medical Resins

3D Printing Materials for Healthcare.

Access a library of over 20 materials available on one powerful desktop 3D printer, the Form 3B+. Our technology has been validated in FDA-cleared workflows and we develop and manufacture our own biocompatible materials in an ISO 13485 certified facility.

Learn More

Production-Ready Materials for the Fuse 1 generation printers.

Balancing strength and detail, our powders for selective laser sintering (SLS) are highly capable materials for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

Learn More

SAMPLE REQUEST

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Material Selector

Our interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of materials.

Recommend Me a Material

Data Sheets

Download safety and technical data sheets for all Formlabs materials.

Handling & Safety

Handling & Safety

Resin should be handled with care. Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

The Safety Data Sheets (SDS) are up to date for every resin product and follow the latest government guidelines. Always consult the SDS as the primary source of information to understand safety and handling of Formlabs materials. For more information about handling resin, learn more tips for resin maintenance in our Help Center.

Technical Data

Technical Data

Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Material

– Select –BioMed AmberBioMed BlackBioMed ClearBioMed WhiteBlackCastableCastable WaxCastable Wax 40CeramicClearColor BaseColor PigmentsCustom TrayDental LT ClearDental LT Clear V2Dental SGDigital DenturesDraftDurableESDElasticElastic 50AFlexibleFlexible 80AFull Materials LibraryGreyGrey ProHigh TempIBTModelModel V3Nylon 11Nylon 11 CFNylon 12Nylon 12 GFPU Rigid 1000PU Rigid 650Permanent CrownReboundRigid 10KRigid 4000Soft TissueSurgical GuideTemporary CBToughTough 1500Tough 2000White

Language

– Select –BulgarianChineseCroatianCzechDanishDutchEnglishEstonianFinnishFrenchGermanGreekHungarianIrishItalianJapaneseKoreanLatvianLithuanianMalteseNorwegianPolishPortugueseRomanianRussianSlovakSlovenianSpanishSwedishTurkish

Technical Data Sheets

There is no technical data sheet available for the chosen material.

Safety Data Sheets

There is no safety data sheet available for the chosen material.

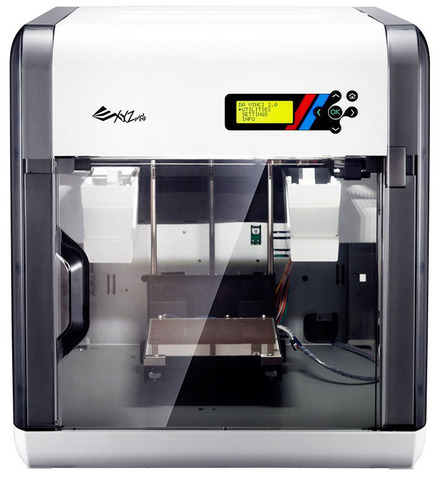

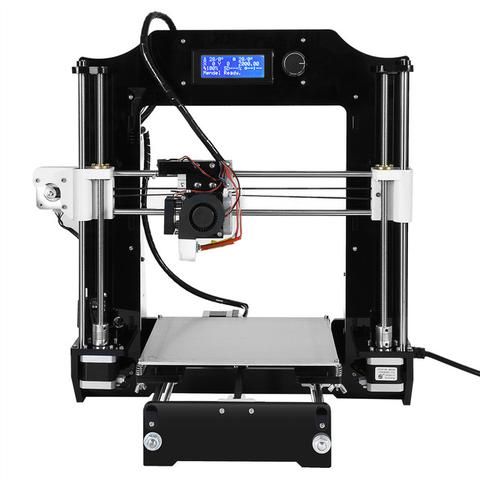

Form 1+ High-Resolution 3D Printer

3D printing, also known as additive manufacturing, is a method for fabricating a physical object from a digital model. Whereas traditional “subtractive manufacturing” cuts material away from a solid piece of material (i.e. wood carving or metal machining) to create an object, 3D printing adds layer upon layer of material to gradually build an object. For a simple visualization, imagine placing successive circular sheets of paper on top of one another until the stack becomes a three dimensional cylinder.

WHY IS THE FORM 1+ BETTER THAN OTHER 3D PRINTERS?

The Form 1+ is a high-resolution desktop machine that matches the print quality of large, industrial printers at a far lower cost. The Form 1+ uses stereolithography (SLA) technology to achieve a professional print quality that plastic extrusion printers just can’t match. Stereolithography is the gold standard for accuracy and resolution in 3D printing. Our custom PreForm software and single button interface make the entire print experience simple, intuitive, and enjoyable. Learn more about the Form 1+ printer.

Stereolithography is the gold standard for accuracy and resolution in 3D printing. Our custom PreForm software and single button interface make the entire print experience simple, intuitive, and enjoyable. Learn more about the Form 1+ printer.

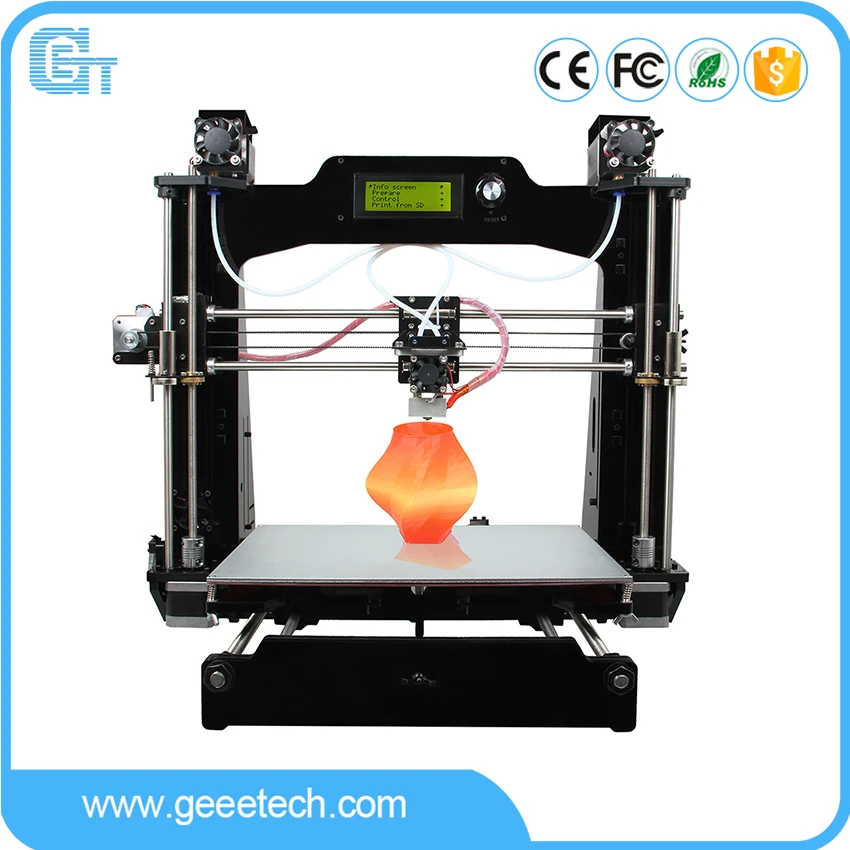

WHAT IS THE DIFFERENCE BETWEEN STEREOLITHOGRAPHY/SL AND PLASTIC EXTRUSION/FDM?

Plastic extrusion, or fused deposition modeling (FDM), is the most common desktop 3d printer technology; FDM printers melt plastic and use an extruder to print each layer with molten plastic. The vast majority of desktop plastic extrusion machines lack the finish and resolution for professional-grade output. SL can outperform the print quality of even high-end FDM machines. In our photopolymer-based process, a high precision system directs a laser across a tray of liquid resin and causes a thin layer to solidify. Until now, a professional SL printer has been far out of reach for the individual designer.

WHAT IS THE RESOLUTION OF THE PRINTER?

Different 3D printer manufacturers use different metrics to define “resolution”, but layer thickness is one commonly cited standard. The Form 1+ can create layers as thin as 25 microns, which is much finer than other desktop machines. Minimum feature size, on the other hand, refers to the thinnest wall or finest point, which can be as small as 300 microns on the Form 1+. The Form 1+’s laser beam can move in steps of fewer than 10 microns, creating extremely precise movements and an impressively smooth surface finish that FDM machines can’t match.

The Form 1+ can create layers as thin as 25 microns, which is much finer than other desktop machines. Minimum feature size, on the other hand, refers to the thinnest wall or finest point, which can be as small as 300 microns on the Form 1+. The Form 1+’s laser beam can move in steps of fewer than 10 microns, creating extremely precise movements and an impressively smooth surface finish that FDM machines can’t match.

WHAT ARE THE DIMENSIONS OF THE FORM 1+’S BUILD VOLUME?

The build envelope dimensions are 125 x 125 x 165 mm (4.9 x 4.9 x 6.5 in). For larger models, you may be able to print multiple segments.

HOW FAST DOES THE FORM 1+ PRINT?

The build speed is comparable to FDM machines when comparing layer thickness and density. As a general rule, the build speed is 1-3 cm/hour along the Z axis when printing at 100 microns. Our rook, as an example, takes around 2 hours to print at 100 micron layer-height. Recently, we added a 200 micron layer-height setting that works with our Clear resin to reduce print times. The same rook at 200 microns takes 45 minutes to print. To calculate the print speed of any specific part, please download our PreForm application, load the model, and calculate the print time.

The same rook at 200 microns takes 45 minutes to print. To calculate the print speed of any specific part, please download our PreForm application, load the model, and calculate the print time.

Best High-Resolution 3D Printers of 2022: A Complete Buying Guide

Resolution is a little-understood aspect of precision 3D printing, and there are many important factors that affect print quality beyond layer height. This article recommends the best high resolution 3D printers, explains the factors that make up a high resolution 3D printer, and the advantages and disadvantages.

Usually, when choosing a resolution for 3D printing, the Z-axis resolution, or Z-resolution, is the most discussed. This is the vertical resolution, which refers to the minimum height or layer thickness possible for a 3D printer.

Smaller layers mean better resolution and better surface finish on parts with smoother surfaces and sharper edges.

So having a high quality 3D printer that can print at low layer heights can be a big advantage. However, this is not the only factor that affects print quality, there are many others that affect whether a high resolution 3D printer actually prints accurate and smooth details.

However, this is not the only factor that affects print quality, there are many others that affect whether a high resolution 3D printer actually prints accurate and smooth details.

Contents

- Resolution in 3D printing: X, Y and Z resolution

- Other factors affecting print quality

- When do high quality 3D printers matter most?

- Best High Resolution 3D Printers

- Ender 3 V2 - Precision 3D Printer Under $0

- Elegoo Mars 2 Pro

- Anycubic Photon Mono 4K

- Elegoo Mars 3 - Best Inexpensive Resin Choice + 3903S

- Formlabs Form 3

- Ultimaker S3

- Advantages of a high resolution 3D printer

- Disadvantages of a precision 3D printer

- High resolution 3D printing technologies

- High resolution 3D printer FAQ

Resolution in 3D printing: X, Y and Z resolution

The Z resolution corresponds to the layer height of the printed part. However, the X and Y planes are also very important in a high resolution 3D printer.

The X and Y axes control the 2D print details: the ones that are inside each 2D layer. Then the Z-axis adds several layers, representing the height - the third dimension. Although these are all axes, the XY and Z axes are controlled by two different systems, with some FDM printers having a much finer resolution in Z than in XY.

low and high resolution in 3d printing layers

X and Y resolution is the smallest movement of the printer's print head (projector, extruder or laser, depending on the technology) within the layer - horizontally.

Various 3D printing technologies are able to provide better resolution than others. For example, SLA 3D printers are more accurate than FDM 3D printers, although their Z-resolutions may look the same on paper. This is mainly due to the better XY resolution resin 3D printers can print at, resulting in smoother surfaces, and better resin printers are able to print parts with barely visible layer lines.

However, other factors can significantly affect print quality.

Other factors affecting print quality

- Nozzle size: Smaller nozzles on FDM 3D printer extruders allow more complex and precise parts to be printed. Standard nozzles are typically 0.4mm, although much smaller 0.1mm or 0.2mm nozzles are available for printing small and precise parts. They are also better suited for printing supports and ledges.

- Frame and Vibration Stability: The strong, heavy metal frame that secures the printer and print bed to the ground is less susceptible to vibrations and other external factors that can affect print quality.

- Material: different materials are more accurate and precise than others, or are easier to print successfully than others.

- Technology: for example, SLA printers are more accurate than FDM and PolyJet offers some of the best accuracy in 3D printing.

- Slicer and Printer Settings: Your 3D slicer settings will be critical to print quality, and even the highest resolution 3D printers will print poor quality models if not optimized.

When do high quality 3D printers matter the most?

If you are planning to 3D print a very simple structure, like a cube, then using a high quality 3D printer, using large or small layers will make no difference. In fact, using low layer heights will cause the exact same print to take much longer.

For these very simple models with few complex parts, a regular cheap 3D printer will work almost as well as a high resolution industrial 3D printer that costs 20 times more.

However, high-quality precision 3D printers greatly improve the quality of more complex parts that have diagonal or arcuate lines or sides, as well as embossing and engraving.

Particularly for curved or diagonal parts, the lower the layer height and the more precise the printer, the less stepped these elements will look and the smoother they will look even up close.

Very high resolution 3D printers such as resin printers are commonly used to 3D print jewelry molds such as this 3D printed ring.

Source: Shapeways.

What's more, if you're printing a small part, such as 3D printing a miniature or desktop model, using an accurate printer with a very low layer height can be worth it, because even if it takes several times longer, it still won't take more than an hour.

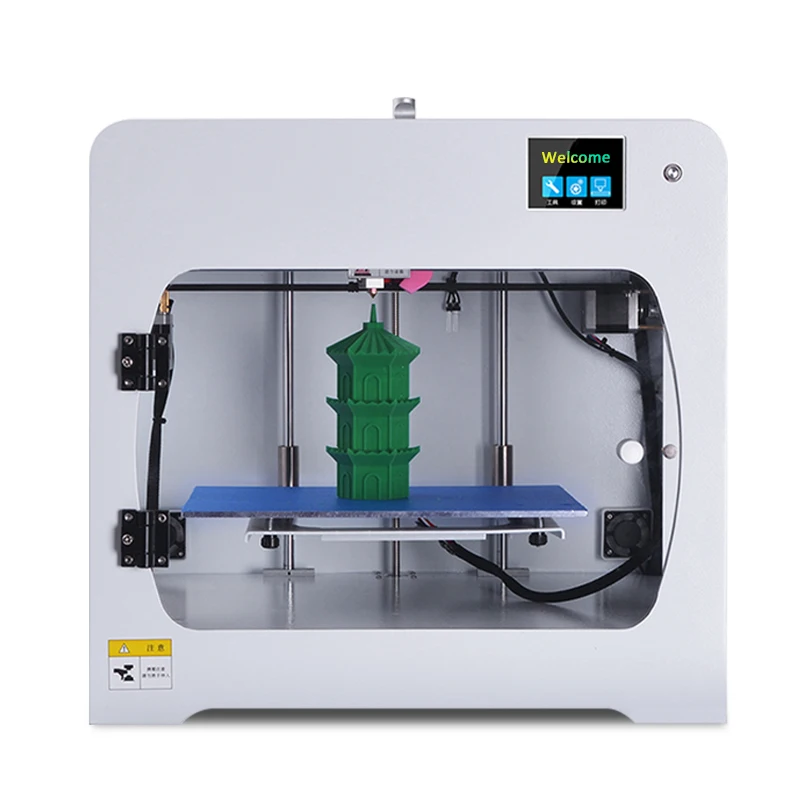

Best High Resolution 3D Printers

Now we have illustrated the components that make up a high quality 3D printer, here are some guidelines.

High resolution and quality are relative here, meaning we have chosen printers in each price range that outperform others - a $200 3D printer can't compete with a $20,000 industrial 3D printer, but it can be the best in its class. price range.

Ender 3 V2 - Under $300 Precision 3D Printer

- Price: $279

- Assembly volume: 220 x 220 x 250 mm

- 3D printer type: FDM 3D printer and DIY 3D printer

- Minimum layer height: 0.

1 mm

1 mm

The Ender 3 is an inexpensive and relatively high quality 3D printer.

Just as the original Ender 3 began to age, Creality released the Ender 3 V2. A well-designed printer, the Ender 3 V2 eliminates many of the shortcomings of its predecessor while maintaining an affordable price for even the most budget-conscious manufacturers.

Belt tensioners, a 4.2.2 32-bit motherboard, and silent stepper drivers do a lot to present a printer that feels much more modern than the Ender 3. 3 V2 is not amazing: the layer resolution is only 100 microns. But don't be fooled: high resolution printing is only defined by high resolution.

In action, the Ender 3 V2 is built to a level of precision that seems unusually high for an inexpensive FDM printer. With few visible, warping or layering issues, with excellent overall quality for large parts and decent results for small, detailed parts. Added to this is a fairly large build volume - 220 x 220 x 250 mm to be precise - for large projects and even for small-scale printing.

For the price, you also get to work with a decent range of materials - PLA, ABS, PETG, TPU. The only caveat is that you'll have to stick with simpler prints that are relatively free of complex embossing, small details, narrow arches, and the like.

In our experience, the Ender 3 V2 works best when creating household items such as plant pots or, say, vases, figurines, toys, accessories, and the like. We are sure that his printing abilities will be enough for a modest business selling non-geometrically complex products.

Keep in mind that the Ender 3 V2 is largely a hobby printer that needs a fair amount of tweaking to get the best results. Curious beginners and seasoned makers should find this an enjoyable part of the printing process, but "green" beginners may prefer an option with fewer "practical" aspects.

Elegoo Mars 2 Pro

- Price: $299

- Assembly volume: 129 x 80 x 160 mm

- 3D printer type: LCD 3D printer

- Z-axis accuracy: 0.

00125 mm, XY-axis resolution: 0.05 mm

00125 mm, XY-axis resolution: 0.05 mm

The Elegoo Mars and Anycubic Photon ranges have revolutionized low-cost, high-resolution 3D printing for hobbyists and businesses around the world. The Elegoo Mars 2 is able to create resin models so accurate that it is increasingly being used to 3D print jewelry molds before they are molded into gold or other metal rings, bracelets and chains.

As an MSLA printer, Elegoo Mars prints resin models that outperform FDM counterparts in high resolution 3D prints with almost no visible layers. The 6-inch 2K LCD screen enables fast 3D printing by allowing a layer to be cured every 2 seconds.

In addition, Mars 2 Pro's CNC-machined aluminum construction improves stability by eliminating external vibrations that can affect 3D print detail. In addition, the new and improved build plate is designed for better adhesion and a higher quality result.

The printer is available in 12 languages, so those who do not speak English need not worry, and if you have any problems with the Elegoo Mars 2 Pro, the company will replace it under a 1-year warranty. Overall, this is a great, high quality 3D printer for producing resin parts cheaply and accurately.

Overall, this is a great, high quality 3D printer for producing resin parts cheaply and accurately.

3D print of a dinosaur head we made while reviewing the Elegoo Mars 2 Pro.

Anycubic Photon Mono 4K

- Price: $299

- Assembly volume: 132 x 80 x 165 mm

- 3D printer type: LCD 3D printer

- Z-axis accuracy: 0.00125 mm, XY resolution: 0.035 mm

The Anycubic Photon Mono 4K is another iterative upgrade of the venerable family of resin printers, an impressive option for those into high-resolution 3D printers. The Anycubic Photon Mono 4K is without a doubt one of the best cheap high resolution 3D printers out there.

Under the hood of the Anycubic Photon Mono 4K is, you guessed it, a 4K LCD panel capable of delivering 35 micron pixel resolution, 15 microns better than its predecessor. In simple terms, this means a smooth surface and the finest detail in every print, which is immediately visible to the naked eye.

Imperfections are almost indistinguishable and, dare we say, the results are overwhelmingly close to perfection, as we have seen in this price range. Anycubic Photon Mono 4K also penetrates prints with a more than respectable layer cure time of less than 2 seconds.

For us, this printer has great hobby potential. We could hardly find an application where it would not impress. However, the Anycubic Photon Mono 4K comes into its own when working with 3D models and the like, thanks to its penchant for carving out detailed details.

Like other resin printers, the Anycubic Photon Mono 4K has its fair share of clutter and requires a strict regular cleaning routine. The lack of a resume feature and the sometimes unstable native slicer seem like annoying oversights. But these are minor shortcomings for a great inexpensive small form factor resin printer.

Elegoo Mars 3 - Best inexpensive resin choice

- Price: $349 - Available on Amazon here

- Assembly volume: 143 x 90 x 165 mm

- 3D printer type: LCD 3D printer

- Z-axis accuracy: 0.

00125 mm, XY-axis resolution: 0.035 mm

00125 mm, XY-axis resolution: 0.035 mm

The Elegoo Mars is back and perhaps even better than ever, plus a new number. Fast, superbly detailed, compact and economical, the Elegoo Mars 3 also has the features we prefer to see in high-resolution resin printers, namely a 6.6-inch 4K ultra-monochrome LCD display and razor-slim 35-micron resolution.

Marketing and technical chatter aside, the Elegoo Mars 3 delivers impressively detailed results with clean edges and precise precision suitable for even the most demanding resin projects. The larger case volume of 143 x 90 x 165mm compared to the Mars 2 Pro also allows for larger prints while retaining the finest features and fine details.

We're particularly impressed with how well the printer handles figurines, toys and models, even those we think are big for a resin printer. Most importantly, the Elegoo Mars 3 sticks to the Mars tradition of flawless printers that perform at the same high level day in and day out. In other words, it's a workhorse.

In other words, it's a workhorse.

Despite some concerns about the flimsy lid and the lack of features such as air filtering and Wi-Fi connectivity, we highly recommend the Elegoo Mars 3 to manufacturers, hobbyists and businesses looking for an affordable high resolution 3D printer. Please note that Elegoo Mars 3 is tied to the ChiTuBox slicer and will not work with third party alternatives.

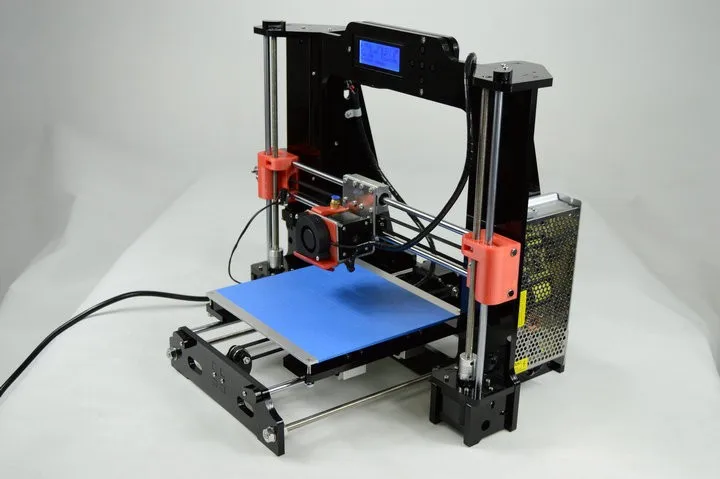

Prusa i3 MK3S+

- Price: $749 set / $999 complete

- Assembly volume: 250 x 210 x 200 mm

- 3D printer type: FDM 3D printer and DIY 3D printer

- Minimum layer height: 50 microns

The Prusa i3 MK3S+ combines high resolution with workhorse reliability and is known as one of the best 3D printers in the world. This FDM printer can print accurate 50 micron layers and do it again and again without fail.

For better XY resolution and detail quality, resin printers like Elegoo Mars are better, but Prusa still has great quality, wider material compatibility - from ABS to PLA, polycarbonate to nylon! - and can even be converted into a color 3D printer that can print 5 colors at once if you purchase the Multi Material Upgrade Kit.

It's fast, constantly improving, and combines superior resolution with tenacity and reliability.

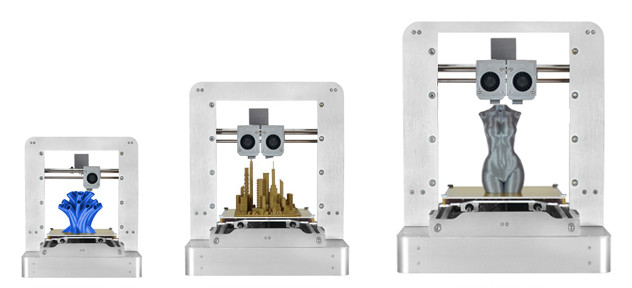

Formlabs Form 3

- Price: $3,499

- Assembly volume: 145 x 145 x 185 mm

- 3D printer type: SLA 3D printer

- XY resolution: 25 microns

Printers from Formlabs, a leading company in consumer 3D resin printing, are currently widely used in the jewelry, dental, medical and hearing aid industries.

If you look at the numbers behind the Formlabs Form 3 - which is, first of all, the build volume of 145 x 145 x 185 mm and a resolution of 25 microns - it does not attract too much attention. However, Formlabs' innovative LFS technology is the type of innovation we love to see. The real sophistication lies in how easy the printer is to use. With Formlabs Form 3, it's all about the machine doing its job, no fiddling or babysitting.

And the results will not keep you waiting. Equipped with high quality resin, the Formlabs Form 3 works exceptionally well, producing gorgeous and detailed prints suitable for commercial purposes. Print failures are virtually non-existent; in order for any errors to occur, it is necessary to physically shake the machine while printing.

Print failures are virtually non-existent; in order for any errors to occur, it is necessary to physically shake the machine while printing.

For the pleasure of owning a Formlabs Form 3, you pay a lot of money. However, these costs are quickly repaid in time savings due to the printer's set-and-forget nature, which can be invaluable in a rapidly changing business environment. For SMBs that require low-volume, trouble-free, accurate models along with prototyping, there is little that can compete with the Formlabs Form 3.

Overall, for precision 3D printing, the Form 3 is one of the best quality high-resolution 3D printers out there.

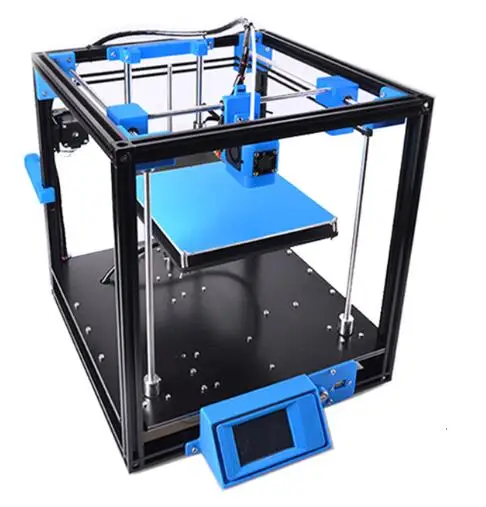

Ultimaker S3

- Price: $3,850

- Assembly volume: 230 x 190 x 200 mm

- 3D printer type: FDM 3D printer and dual extruder 3D printer

- Minimum layer height: 20 microns

The Ultimaker S3 is smaller but has the same performance as the S5. It is capable of creating incredible 20 micron layers that are so small they are hard to see. While this slows down print times by increasing the number of layers per part, the resulting model will be of unsurpassed quality compared to almost any other FDM printer.

While this slows down print times by increasing the number of layers per part, the resulting model will be of unsurpassed quality compared to almost any other FDM printer.

In addition to being fantastically accurate, the Ultimaker S3 is also a dual-extruder 3D printer that produces accurate, multi-color or multi-material 3D prints and is therefore widely used for prototyping architectural models of buildings prior to construction work.

For those interested in creating architectural models, check out our ranking of the best architectural software.

The printer is easy to use, easy to print with - Ultimaker also owns Cura, the most popular 3D slicer - and delivers fantastic 20 micron precision with a wide range of compatible materials, including carbon fiber. Overall, the printer speaks for itself and proves to be one of the best high resolution 3D printers in FDM.

Benefits of High Resolution 3D Printer

Best Quality: High resolution results in a smoother surface, with excellent detail and detail aesthetics.

The only way to get fine details: models that have arches and sharp diagonal details can look very jagged at high layer heights, and low resolution 3D printers can't adequately print those details.

Ideal settings required: improved accuracy requires perfect calibration, perfect temperature settings to avoid filament or resin defects, and proper bed temperature and adhesion on the platen. Any errors here may result in defects in the print.

Significantly slower: prints with a 25 micron layer height four times longer than with a 100 micron layer because four 25 micron layers equals one 100 micron layer height. Large and complex models may take several days to print.

Higher chance of print failure: The more layers a model has, the more chances for errors to occur that can render a part useless.

High-Resolution 3D Printing Technologies

High-Resolution 3D Printing Technologies include:

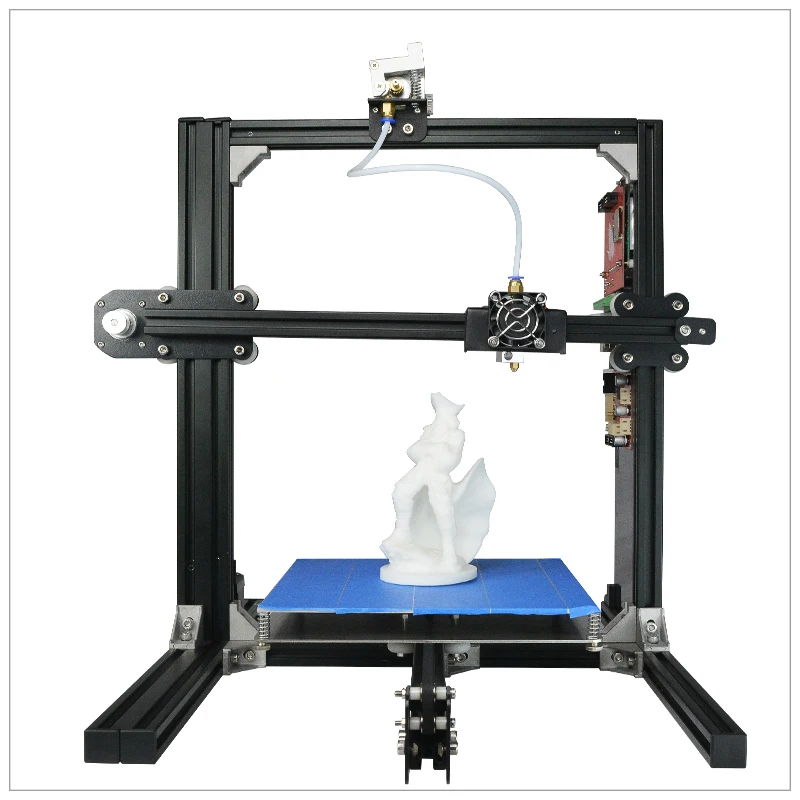

FDM - Fused Deposition Modeling

resolution. The process involves layering molten filament onto a fixed build platform using a heated extruder to create patterns. FDM is at the lower end of the high resolution spectrum and is commonly used as a low cost alternative to more expensive technologies. FDM printers typically provide resolutions in the 50 to 200 micron range.

The process involves layering molten filament onto a fixed build platform using a heated extruder to create patterns. FDM is at the lower end of the high resolution spectrum and is commonly used as a low cost alternative to more expensive technologies. FDM printers typically provide resolutions in the 50 to 200 micron range. Resin (SLA, DLP, LCD)

Photopolymerization, commonly known as resin 3D printing, involves projecting a laser or light source to cure a liquid photosensitive resin into layers. Specific technologies include stereolithography (SLA), low power stereolithography (LFS), masked stereolithography (MSLA), and digital light processing (DLP). Resin printers typically achieve a layer resolution of 25-35 microns.

MJF - multi-jet simulation

Multi-jet modeling, or material inkjet, uses inkjet printheads to layer-by-layer melted materials to create a 3D part or model. Expensive and high-precision MJF printers are a reserve of large companies with a large treasury.

PolyJet - Resin Inkjet

PolyJet, or photopolymer inkjet, printers use layers of photosensitive liquid photopolymer resin to create prints, which is fed through the printheads and cured by exposure to ultraviolet light. Like the MJF, the PolyJet is expensive, although the printers are usually smaller.

High Definition 3D Printer FAQ

Are high definition 3D prints more durable?

No, on the contrary. Generally, thicker layers (or lower resolution) produce harsher results. This is because they minimize the number of contact points between layers. Fewer layers in contact with each other means less chance of bond strength problems.

However, print strength depends on many factors, including adhesion and layer height, extruder and bed temperatures, media quality and type, and the printing technology used. The definitive answer depends more on the specific printer than the resolution. A capable device, such as any of the best high resolution 3D printers, produces reliable parts at higher resolution.

What is high resolution 3D printing?

The answer to this question varies greatly depending on who you ask. To keep things simple, high-resolution 3D printing is best described as the process of printing parts with a higher overall quality—whether it be smoothness, quality of finish, detail, or model fidelity—than is typically found in the realm of 3D printing.

What can be done with a high resolution 3D printer?

High resolution 3D printing suitable for a wide range of applications. In the commercial realm, companies prefer high-resolution printing in areas such as dentistry, jewelry, biomedicine, and all kinds of functional prototyping where accuracy is critical. In the hobby realm, creators are turning to high-resolution printing for projects that require fine detail, such as figurines, modeling, and other decorative items.

How does 3D printing resolution affect speed?

Higher resolution reduces speed.

Print speed refers to how quickly the printer applies each layer. Because high resolution printing is synonymous with thinner layers, print speeds are typically slower than low resolution printing. With high-resolution 3D printing, printing speed is sacrificed in favor of accuracy. The exact time depends on the desired resolution, the underlying technologies of the printer being used such as resin or MJF, and the complexity of the model.

Because high resolution printing is synonymous with thinner layers, print speeds are typically slower than low resolution printing. With high-resolution 3D printing, printing speed is sacrificed in favor of accuracy. The exact time depends on the desired resolution, the underlying technologies of the printer being used such as resin or MJF, and the complexity of the model.

Formlabs Form 1+ 3D Printer Review

Formlabs Form 1+ 3D Printer is elegant in design, easy to use and more accurate and faster than any other printer in this form factor with SLA printing technology .

Model 1+ received one of the highest ratings on the popular site 3DHubs, specializing in comparisons, reviews and collecting statistics from users around the world. The highest rating for this model was given after collecting opinions from more than 2000 users.

Unlike more popular FDM 3D printers that produce models using melted plastic filament layering, the Form 1+ uses laser stereolithography (SLA) technology. The Form 1+ 3D printer uses a high-precision violet laser, with a wavelength of 405nm, to bake a special liquid photopolymer in a special printer tank. The laser beam falls into the photopolymer tank, which causes the liquid to solidify, so layer by layer, the finished model rises upside down from the tank.

The Form 1+ 3D printer uses a high-precision violet laser, with a wavelength of 405nm, to bake a special liquid photopolymer in a special printer tank. The laser beam falls into the photopolymer tank, which causes the liquid to solidify, so layer by layer, the finished model rises upside down from the tank.

Laser and photopolymer work result in amazingly precise and smooth surfaces of the finished model. Such results cannot be achieved on a conventional, household 3D printer with FDM printing technology.

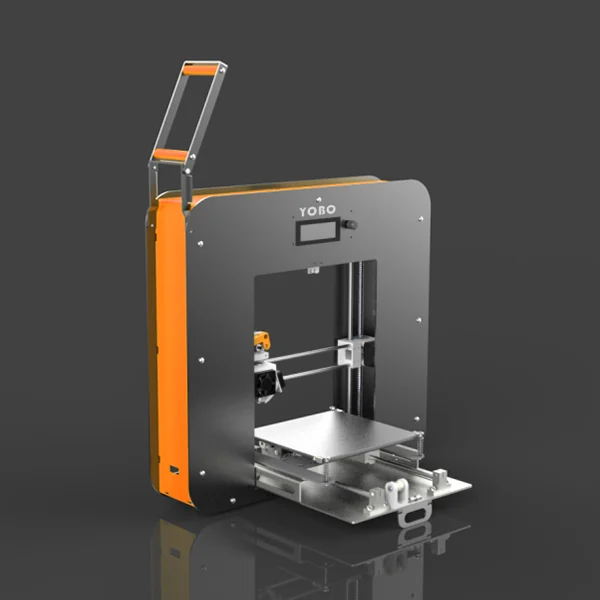

Appearance

Form 1+ 3D printer is surprisingly small and light, measuring 20 x 28 x 45 cm and weighing only 8 kg.

Form 1+ 3D printer print area size - 125 x 125 x 165 mm, when compared with the dimensions of FDM printers, it may seem that this is extremely small, but the printer is intended for other tasks where it is not necessary to create large models, but high requirements for quality, accuracy and speed.

The appearance of the printer is a cube in a minimalist style. In the lower part there are software and control boards, all optics and mechanics, in the upper part, there is a transparent orange hood / cover that protects the printing process from mechanical external influences and the influence of sunlight on the photopolymer during printing.

In the lower part there are software and control boards, all optics and mechanics, in the upper part, there is a transparent orange hood / cover that protects the printing process from mechanical external influences and the influence of sunlight on the photopolymer during printing.

On the front of the printer there is a power button, combined with an LED that displays blue, yellow and green, different printing processes. The button can also be controlled, Press once - pause in printing, press again - start. Holding down the button for three seconds cancels the print job.

Form 1+ is very quiet. Unlike plastic printers, where 2-3 motors move a massive print head in 3 axes, the FORM 1+ printer only moves the platform along the vertical axis, and the movement of the laser unit is so quiet that you can talk in a whisper in the room. An intermittent beep may be a little disturbing, but this is a signal for the start or end of the printing process.

One of the advantages of this printer is the built-in memory. You don't need to constantly use a cable, or download models to an SD card. After starting the printing process, you can safely disconnect the printer from the computer. The STL file is loaded into the printer's internal memory. Printing is completely offline.

You don't need to constantly use a cable, or download models to an SD card. After starting the printing process, you can safely disconnect the printer from the computer. The STL file is loaded into the printer's internal memory. Printing is completely offline.

Printer setup is very easy. At the first start, you need to remove all the foam and shipping stickers, then fill the acrylic transparent container with photopolymer resin, connect the printer to the computer using the USB cable that comes with the kit. Download the original software and start printing.

Proprietary printer setup program is a friendly, intuitive program with a lot of settings, manipulation and editing of virtual 3D models. In addition to manual control of all settings, the program has preset values. You just have to choose the print quality, which varies from the highest - 25 microns (0.025 mm.) to the lowest - 200 microns (0.2 mm)

The printing process

You must understand that any 3D printing, of any technology, is not a fast process. Although the Form 1+ is faster than its competitors, it will take a long time to build a full-size model. Depending on the complexity of the virtual model, the set resolution and the need to build additional supports, the printing time will take you from 1 to 8 hours.

Although the Form 1+ is faster than its competitors, it will take a long time to build a full-size model. Depending on the complexity of the virtual model, the set resolution and the need to build additional supports, the printing time will take you from 1 to 8 hours.

Every 3D printer requires a complex procedure for removing finished models. Due to the fact that the FDM technology is based on heating to high temperatures, it is quite difficult to remove the figure from the platform, because. it is literally welded to the surface of the platform. With SLS and Form 1+, everything is much simpler, thanks to the stainless steel surface and relatively low temperatures, the finished model is removed very simply, without special tools and without fear of mechanical damage, both to the model and the printer itself.

In order for post-printing work to be easy, the printer comes with a set of special tools and accessories for cleaning the surface of the printer platform from photopolymer residues, removing support elements on the model itself, special washing containers, absorbent swabs, scraper and of course gloves to protect your hands.

After printing, the finished figurine is covered with sticky resin residue from photopolymer. In order to get rid of the unpleasant sticky layer and give the figure a marketable appearance, it is necessary to lower the figure into a special bath (included) with isopropyl alcohol, which is commercially available. You can learn more about the washing process in the instruction manual for the Form 1+ 3D printer.

Why choose Formlabs Form 1+

Of course, the relative high price of a printer, the speed of printing 3D technology in general, and the complexity of processing the model after printing may scare you away, but what you get in the end will frankly surprise you. Printing results can be described in one word - accuracy.

The most rigorous and difficult test for a printer, we found on the site Thingiverse.com we downloaded a model of the Eiffel Tower and launched it into print. The results exceeded all our expectations. In 3 hours and without additional support for the model, the tower was printed without flaws, or marriage of textures.